Abstract

Considering that in the E.U. public procurement in the construction sector is highly represented, the Directive 2014/24/EU is implemented for harmonizing procurement processes across European countries. The Directive is transposed in Italy, through the Sustainable Public Procurement (SPP) national action plan, for supporting public procurement and public–private partnership (PPP) interventions. SPP is founded on two pillars: according to an economic viewpoint, the financial efficiency is the key aspect to verify, and, according to a sustainability viewpoint, externalities are a key element in the environmental evaluation, despite the fact that their monetary quantification into the global cost calculation is quite complex. Thus, this work aims to explore a methodology for the joint evaluation of economic–environmental sustainability of project options, in the tender evaluation phase of the SPP. The methodology is based on the life cycle costing (LCC) and CO2 emissions joint assessment, including criteria weighting and uncertainty components. Two alternative technologies—a timber and an aluminum window frame—are assumed as a case for a simulation, implemented with the software “Smart SPP LCC-CO2 Tool” (developed through the research “Smart SPP—Innovation through sustainable procurement”, supported by Intelligent Energy Europe). The simulation demonstrates that the methodology is a fast and effective modality for selecting alternative options, introducing sustainability in the decision-making process. The work is a contribution to the growing literature on the topic, and for giving support to subjects (public authorities and private operators) involved in public procurement processes/PPP interventions.

1. Introduction

In the European Union, public procurement is highly represented, covering about 14% of the Gross Domestic Product (GDP), including interventions in the construction sector. In Italy, public procurement confirms this relevant amount, covering about 10% of the GDP, of which 6% is related to public works in the construction sector [1]. This reveals a strong capacity to influence the market by encompassing a considerable availability of green options, but in the meantime, a high environmental impact.

In relation to the construction sector, the European regulatory system, in the wider framework of energy and environmental policies, developed the Green Public Procurement (GPP) approach. GPP assumes the objectives of climate change impacts reductions, the restraint of energy/resources consumptions, and, in general, the public sector spending in European countries. The growing sensitivity to the effects of climate change due to the use and production of goods and services further influenced procurement processes in every phase. By introducing environmental and social criteria in the decisions and tendering, the term Green Public Procurement has turned into Sustainable Public Procurement (SPP), opening the way for developing green products into the construction market segment. Contextually, a set of E.U. procurement Directives has been published in the last decades (see Section 2). Among these, the Directive 2014/24/EU of the European Parliament and of the Council of 26 February 2014 on public procurement and repealing Directive 2004/18/EC [2], which transposes the Directive of the European Parliament and of the Council of 31 March 2004 on the coordination of procedures for the award of public works contracts, public supply contracts, and public service contracts [3], is implemented for harmonizing public sector procurement processes. Sectorial legislation is strictly linked, such as the energy efficiency Directives for new-build constructions and existing assets retrofitting [4,5,6]. The Directive on public procurement is transposed also in Italy through the GPP/SPP national action plan, edited by the Ministry of the Environment and the Protection of Natural Resources [7].

In the official documents, centrality is posed in the introduction, through GPP/SPP revised processes, of the life cycle perspective in the evaluation practices, and in quantifying the environmental costs (negative externalities, such as CO2 emissions, water consumption, energy consumption, etc.) due to the works under analysis (e.g., low energy buildings). Externalities, as known, are crucial elements in the environmental sustainability evaluation, despite the difficulties in quantifying their weight in monetary terms. Specifically, in defining the costs crucial at the award stage, Directive 2014 requires the inclusion of life cycle costs related to the entire building life cycle, including costs during the acquisition and construction stage, the use–maintenance–adaptation stage, and end-of-life costs, besides the negative environmental externalities [8].

Thus, the LCC approach—integrated with the externalities—demonstrates compliance with the requirements of public procurement processes, given that the value for money and financial efficiency are the key aspects to verify (Directive 2014/24/EU, Article 67-2; Directive 2014/25/EU, Article 82-2), and the externalities, as said, are the key elements in the evaluation of environmental sustainability. According to an “ex-post” perspective, it allows for the verification of the goodness of the decision taken, by evaluating the environmental and social value of the selected option. Furthermore, it can be used in different stages during the procurement process, as will be underlined in the present article [9,10,11].

From a theoretical viewpoint, the inclusion of externalities in modeling the LCC opens the way to the “Environmental LCC”, which is implemented by including into the “Conventional LCC” all the costs in the life cycle stages (calculated in terms of whole life costs), the environmental costs (calculated with LCA), and externalities quantifiable in monetary terms (through willingness-to-pay and/or eco-costs) [12,13,14]. In the literature, the application of Conventional LCC is the subject of great attention in recent years. Concerning the Environmental LCC, instead, the studies have mostly focused on the integration between LCC and LCA, which, from an operational viewpoint, is quite demanding in terms of analysis. In practical applications, the monetization of environmental impacts measured with LCA is not always faced. Furthermore, in the face of numerous works related to the evaluation of private projects, public interventions under contract are poorly explored; thus, demonstrating a gap in the existing knowledge.

Thus, the purpose of this work is to present the application of a methodology for the joint economic and environmental sustainability evaluation of options at the component scale, highlighting the potentialities of the modality for supporting the tender evaluation phase in an SPP process. The work assumes the hypothesis that the proposed methodology could guarantee a faster and simpler modality for selecting and prioritizing alternative solutions, in comparison to methodologies based on the LCC and LCA integrated calculation, or on LCC and monetized externalities, or a full monetized global cost calculation (as proposed by the authors in a previous work) [15].

Considering that public procurement implies a set of relationships among different stakeholders involved in the process, the present research is directed, on one hand, to the public authorities (procurers) for supporting the tender evaluation activities, and, on the other, to private operators (suppliers) for calibrating their product designs, production, and supply.

Operatively, the simulation avails of the software “Smart SPP LCC-CO2 Tool” (www.smart-spp.eu (accessed on 1 June 2022)), implemented through the research “Smart SPP—Innovation through sustainable procurement”, supported by Intelligent Energy Europe. The core of the methodology proposed by the project consists of the life cycle costing and the CO2 emissions joint assessment. In order to achieve the research aim, an application of the methodology is proposed by selecting, as a case study, two alternative technological components (a timber frame and an aluminum window frame) of a hypothetical multi-story office building with a glass façade located in Northern Italy. This case is particularly suitable for three main reasons: (1) it allows a comparison with the results of previous works, in which the same components were analyzed with a more complex approach under the formal viewpoint [15,16]; (2) it is representative of a frequent case in procurement processes, given that the selection among alternative components is relevant for specific typologies; and (3) it allows the application of the procedure at a detailed scale, as discussed in Section 3.1.1.

The results show that the methodology offers a modality of simple and rather fast use for selecting alternative technological options without resorting to the application of complex and expensive calculations (namely, a full LCA or the calculation of a composite indicator, such as the “synthetic economic-environmental indicator” for calculating the global cost). Notice that the results obtained are fully coherent with the results obtained with the methodology applied in previous works. Thus, the contribution given by the work is double: on one hand, it could simplify the analysis and practical applications developed by public operators; on the other, it could incentivize the development of innovative technologies capable, for example by recycling waste materials, of reaching higher environmental standards. In Europe, this was done for decades, for example, by the cement industry where blended cements are produced by the addition of several by-products (blast furnace slags (BFS), fly ashes (FA), and silica fume) from different industries to ordinary Portland cement [17,18]. The added by-products will probably be different in the future (biomass ashes, diatomite, recycled concrete, and biochar) to further reduce the embodied carbon of cement, but some of these by-products will be more difficult to source in Europe, due to blast furnace dismantling and the closing of coal plants (specifically, BFS and FA) [19,20,21,22,23].

Starting from these premises, the paper is structured as follows: Section 2 presents the literature and regulatory background on the topic. Section 3 illustrates the methodology. In Section 4, the case study is presented. Section 5 illustrates the results of the application. Section 6 presents the discussion, and Section 7 concludes the work.

2. Regulatory and Literature Background

The research presented in this contribution is founded on a twofold scientific background, at least in relation to the most relevant references for the purpose of this study. Firstly, the European and international regulatory framework related to economic–environmental sustainability within the wider framework of energy policies is considered, with particular attention towards the life cycle evaluative approaches. Secondly, the international literature on the topic is assumed to focus on the recent contributions to GPP/SPP processes in public projects and PPP interventions in the construction sector (with special attention to building projects). Both the regulatory and literature background are summarized in the following sub-sections.

2.1. The Regulatory Framework

The regulatory background consists of international standards and European Directives formulated to concretize the energy–environmental policies and their economic correlated aspects (notice that the below-mentioned standards and directives are transposed into local laws by every single State), and European Directives implemented for harmonizing public sector procurement processes. The main documents considered in the study are listed in the following bullet points, focusing on the construction sector and emphasizing the link with the research sections.

The first group includes the most relevant international standards for introducing a life cycle perspective in economic and environmental policies and evaluation tools, assuming the principles of sustainability in energy and buildings. These documents are the main reference for the operative framework presented in the methodological section of this work. Specifically:

- Standard ISO 15686-5:2008, Buildings and Constructed Assets—Service-Life Planning—Part 5: Life Cycle Costing (revised July 2017—ISO 15686-5:2017) [24]. This standard represents the methodological foundation for life cycle cost analysis, presented in Section 3.1;

- Standard ISO 14040:2006, Environmental Management—Life Cycle Assessment—Principles and Framework [25]. This standard represents the methodological foundation for life cycle assessment analysis, mentioned in Section 3.2;

- Standard EN 15459-1:2007, Energy Performance of Buildings—Economic Evaluation Procedure for Energy Systems in Buildings (revised by EN 15459-1:2017, and repealed by UNI EN 15459-1:2018) [26]. This standard represents the methodological foundation for the global cost calculation, illustrated in Section 3.1;

- Standard EN ISO 15643-2:2011, Sustainability of Construction Works—Assessment of Buildings—Part 2: Framework for the Assessment of Environmental Performance [27]. This standard represents the methodological foundation for the assessment of a building’s environmental performance, as described in Section 3.2;

- Guidelines Accompanying Commission Delegated Regulation (EU) No 244/2012 [28]. This document is an integral part of the previous EU standard, specifically for the assessment of economic performances of buildings, deepened in Section 3.1. The guidelines establish a comparative methodology for calculating cost-optimal levels of minimum energy performance requirements for buildings and building elements.

- The second group includes the most relevant European directives oriented to the achievement of sustainability and energy efficiency in buildings. Furthermore, on these documents the methodology illustrated in Section 3 is founded:

- Directive 2002 [4]. This Directive is also known as the Energy Performance of Buildings Directive—EPBD. For European countries, it represents the reference framework for developing norms directed to achieve the energy efficiency of buildings;

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings—recast [5]. This Directive is known as the Energy Performance of Buildings Directive recast—EPBD recast. It updates the above-mentioned one, and it introduces the Energy Performance Certificate—EPC as a mandatory certificate for all E.U. buildings. The EPCs represent a tool for introducing transparency in the calculation of the energy performance of buildings, and a tool for informing potential buyers/renters about the energy performance of buildings/dwellings [29];

- Directive 2018/844/EU—EPBD recast recast [6]. This Directive is oriented at supporting the cost-effective retrofit of existing buildings, with the aim to achieve a decarbonized building stock by 2050, and to mobilize investments;

- European Commission, A Renovation Wave for Europe—greening our buildings, creating jobs, improving lives. Communication from the European Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Brussels, 14 October 2020 [30]. In 2020 the European Commission published this new strategy to boost renovation, aiming to pursue energy gains and economic growth. This strategy tries to double annual energy renovation rates within ten years, reduce emissions, enhance the quality of life of building occupants, and improve green jobs in the construction sector;

- European Commission, A European Green Deal. Striving to be the first climate-neutral continent, 2021 [31]. This represents a set of policies aiming at making Europe the first net-zero climate impact continent, in the framework of the Next Generation E.U. Recovery Plan and the E.U.’s seven-year budget. Specifically, Italy introduced the “Superbonus” (law n. 77, July 2020), to favor economic recovery after the COVID-19 crisis and the achievement of green objectives [32].

The third group of documents is related to the procedures for the award of public works contracts, with a focus on the most recent directives oriented toward the introduction of sustainability principles in public procurement processes. More precisely, the 2014 Procurement Directives enable public authorities to include environmental principles in the processes. All of these directives are assumed as the foundation for the reasoning presented in this work:

- Directive 2004/18/EC of the European Parliament and of the Council of 31 March 2004 on the coordination of procedures for the award of public works contracts, public supply contracts, and public service contracts [3];

- Directive 2014/23/EU of the European Parliament and of the Council of 26 February 2014 on the award of concession contracts [33];

- Directive 2014/24/EU of the European Parliament and of the Council of 26 February 2014 on public procurement and repealing Directive 2004/18/EC [2];

- Directive 2014/25/EU of the European Parliament and of the Council of 26 February 2014 on procurement by entities operating in the water, energy, transport, and postal services sectors and repealing Directive 2004/17/EC [34].

2.2. The Literature Background

The contents of this work are based on a review of the literature and on the results of previous research experiences. The most relevant research upon which the work is contextualized is addressed toward the GPP/SPP and the related environmental building requirements [35]. Nowadays, this topic is under great attention by scholars, for different reasons, such as: (1) the growing sensibility towards the environmental effects of building production activities and the opportunities given by the renovated norms about public works; (2) the closed correlation between sustainability in energy and buildings and the real estate market dynamics; and (3) the introduction of life cycle evaluation tools due to the recent regulations for promoting the transition to the circular economy and waste management even in the public construction sector.

Regarding the first point, the research is in line with the efforts made by scholars for enhancing the holistic conception of sustainability, including social and environmental dimensions as well as the economic ones, for example, by means of multi-criteria approaches [36], transposing the reasoning to the procurement context. Notice that the growing attention for the GPP potentialities are accompanied by a certain degree of difficulty and limits. The drawbacks and opportunities of GPP in a sustainable perspective emerge, for example, in a deep analysis presented in [37]. Given the importance of GPP in improving the development of green products and services, the authors underline the necessity to analyze the relationship between environmental criteria and public tenders, for supporting the development of GPP, particularly among local authorities. In another study, Shen et al. [38] analyze the barriers which limit the adoption of green procurement by real estate developers in countries such as China. The purpose of the study is to support the mitigation of these barriers and to enhance the knowledge about green procurement, specifically through the use of green building materials as a driver to improve the environmental performance of real estate assets.

The reasoning highlighted in this last contribution is strictly correlated to the second point—the relation between sustainability principles and real estate market dynamics. The extensive literature about the influence of green attributes of buildings on the real estate market dynamics, and specifically, about the detection of the effects of green features on listing/selling prices and time-on-market, confirms the growing sensibility of the market towards building energy–environmental performance and towards the tools for certifying the energy performance requisites of real estate properties [39,40,41,42,43,44,45,46].

Concerning the third point, i.e., the adoption of life cycle evaluation tools in coherence with the European Directives and related government laws, insight in the literature has been produced in the last decades. Nevertheless, the potentialities of the employment of LCC in GPP have still to be enhanced, as evidenced, for example, by the study in [47]. Methodologically, the use of LCC in GPP is well explored in the work “Life cycle costing (LCC) as a contribution to sustainable construction. Guidance on the use of the LCC Methodology and its application in public procurement” [48], under a more extensive research report focused on the LCC methodology as downstream introduced by ISO 15686-5:2008. The work, also through a selection of case studies of common uses of LCC, provides evidence of the interrelationships between sustainability analysis and LCC, and the ways for integrating these. A focus is presented on the employment of the common methodology in public procurement and in PPP projects, in relation to the role of the different subject involved. Special attention is devoted to the potentialities of the methodology to support economic and environmental sustainability, besides methodological aspects. A specific focus is also devoted to LCC and LCA integrated application.

Despite the growing literature that has been produced in the last decade about the joint application of life cycle approaches, as emerged from the literature itself [49,50,51,52,53,54,55], the research concerning joint LCC and LCA in GPP is rather poor. An alternative to the full LCC and LCA application is given by the employment of operative modalities capable of managing model outputs expressed in monetary or non-monetary units of measurement. This is the case of practical contributions, such as the work by Adell et al. [56]. The authors present the before-mentioned software package “Smart SPP LCC-CO2 Tool” (www.smart-spp.eu, accessed on 1 June 2022), implemented through the research “Smart SPP—Innovation through sustainable procurement”, supported by Intelligent Energy Europe, implied for the present work simulations. As will be illustrated in Section 4, the approach develops LCC and CO2 emissions analyses as a practical way to operate the analysis in a sustainable public procurement perspective. To contextualize the work, and the advancements in GPP toward sustainability, the EC handbook [57] highlights the principles, norms, and case studies across European countries.

Finally, a contribution is made by the previous authors’ research, whose results are illustrated in [15]. In that work, the conjoint environmental and economic analysis is explored, by proposing a “synthetic economic-environmental indicator” for supporting the selection between two alternative technologies in new building construction. The indicator avails of the global cost method, and thus, is expressed in monetary terms. It incorporates the environmental and economic impacts previously calculated with LCC and LCA. The analysis, developed in three steps, includes (1) the definition of an environmental indicator by means of LCA analysis, with the calculation of parameters, such as embodied energy (EE), embodied carbon (EC), level of disassembly (LD), recycled materials index (RM), and waste production (notice that the paper focused on the end-of-life stage in the building’s life cycle); (2) the calculation of economic indicators by means of LCC analysis; and (3) the calculation of a synthetic economic–environmental indicator by monetizing the environmental indicators into economic parameters. The main environmental impacts are quantified in monetary terms, and thus, the results are expressed in economic terms. The application is concluded by a deterministic sensitivity analysis.

Despite the potentialities of this last work, a great effort in terms of data and analysis is required, so that it seems particularly suitable for testing new components/technologies during the design/development stages, rather than to be employed for selection among existing ones, even more in the case of procurement processes in the presence of a relevant number of options.

3. Methodology

The results of the research “Smart SPP—Innovation through sustainable procurement”, mentioned in the Introduction, are assumed to support the theoretical and operative approach. More precisely, the “Smart SPP” consists of “a three-year project which promotes the introduction of new, innovative low carbon emission technologies and integrated solutions onto the European market. This is being done through encouraging early market engagement between public authority procurers and suppliers and developers of new innovative products and services in the pre-procurement phase of public tendering” [56]. The aim of the methodology is to support the procurement decision-making activities, specifically during the tendering processes, oriented towards energy efficiency and sustainability, as expressed in [57].

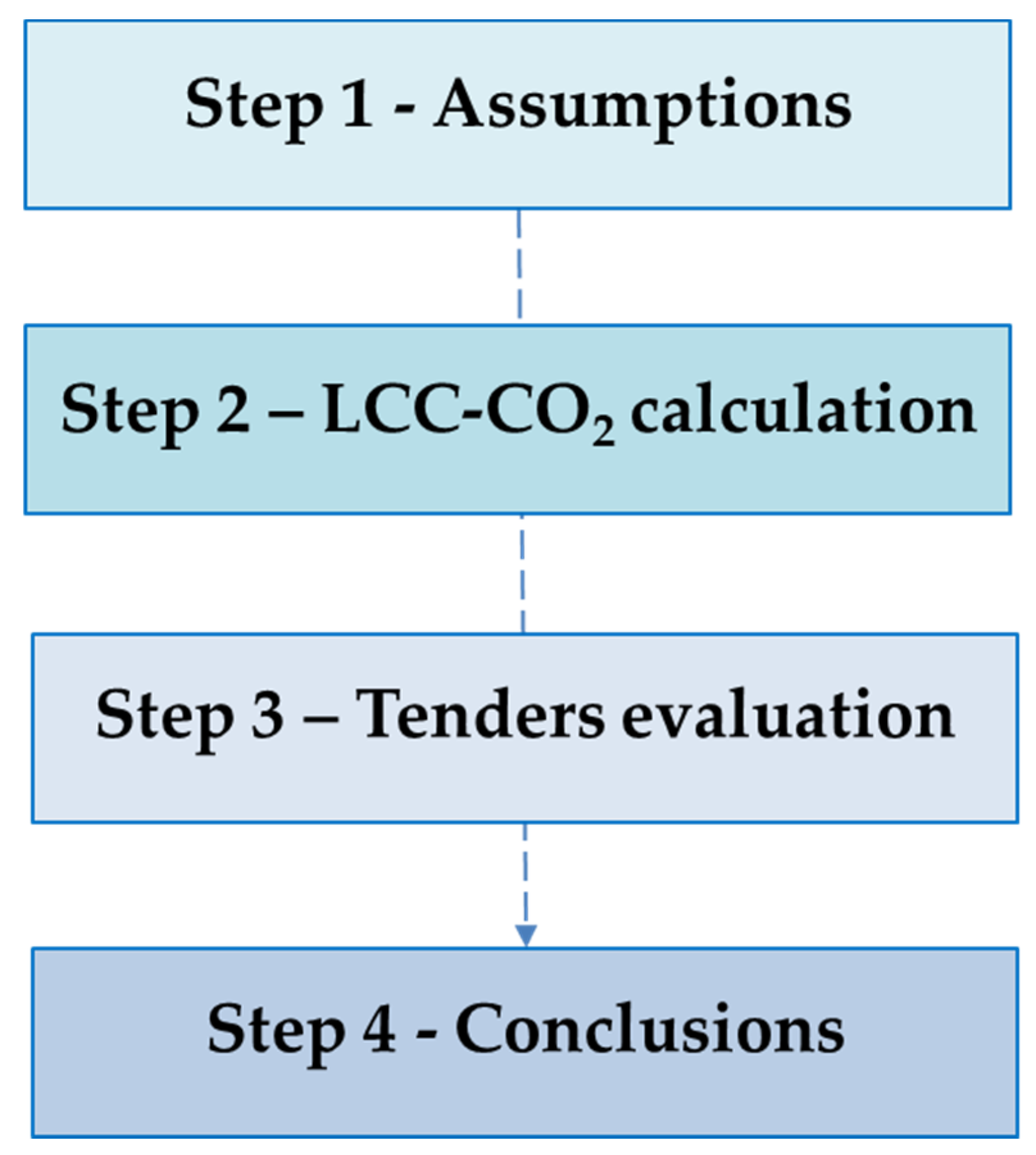

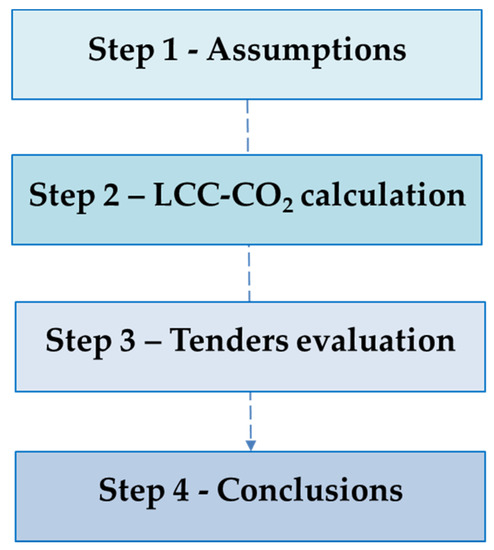

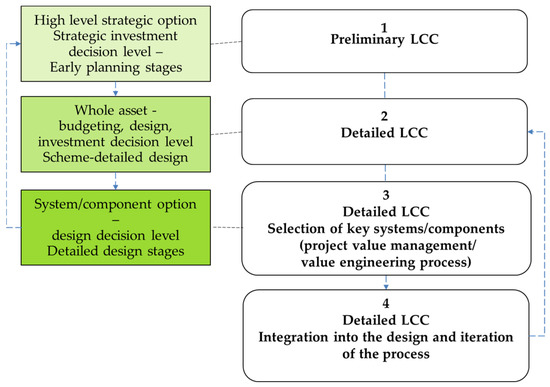

The steps of the public procurement process, in a sustainable perspective as assumed by the “Smart SPP” project, are summarized in the following work-flow, Figure 1:

Figure 1.

The main steps in the SPP process. Authors’ elaboration.

Operatively, the application is supported by the software “SMART SPP LCC-CO2 Tool” (www.smart-spp.eu, accessed on 1 June 2022), illustrated in the tool users’ guide [56]. The core of the methodology consists of the life cycle costing and the assessment of the CO2 emissions. These results are harmonized through an Excel spreadsheet. The object of the analysis can be alternative products or services, particularly innovative products in the development phase and in the market introduction phase. The products/technologies can effectively be compared with a base-case solution, in financial and environmental terms, through the before-mentioned analysis:

- Life cycle costing (or life cycle cost analysis);

- CO2 emissions calculation.

Notice that this modality is oriented to guarantee value for money by considering jointly the financial and environmental effects, overcoming the purely financial perspective. In other terms, value for money is the result of the procedure itself.

Furthermore, notice that in this methodology the externalities are considered separately, in order to guarantee a less complex procedure. In fact, the proposed modality does not set itself the goal of monetizing the externalities, as with the (more complex) LCA approach, and is different from the approach proposed in the before-mentioned work (through a composite indicator), and verifying if the results are coherent.

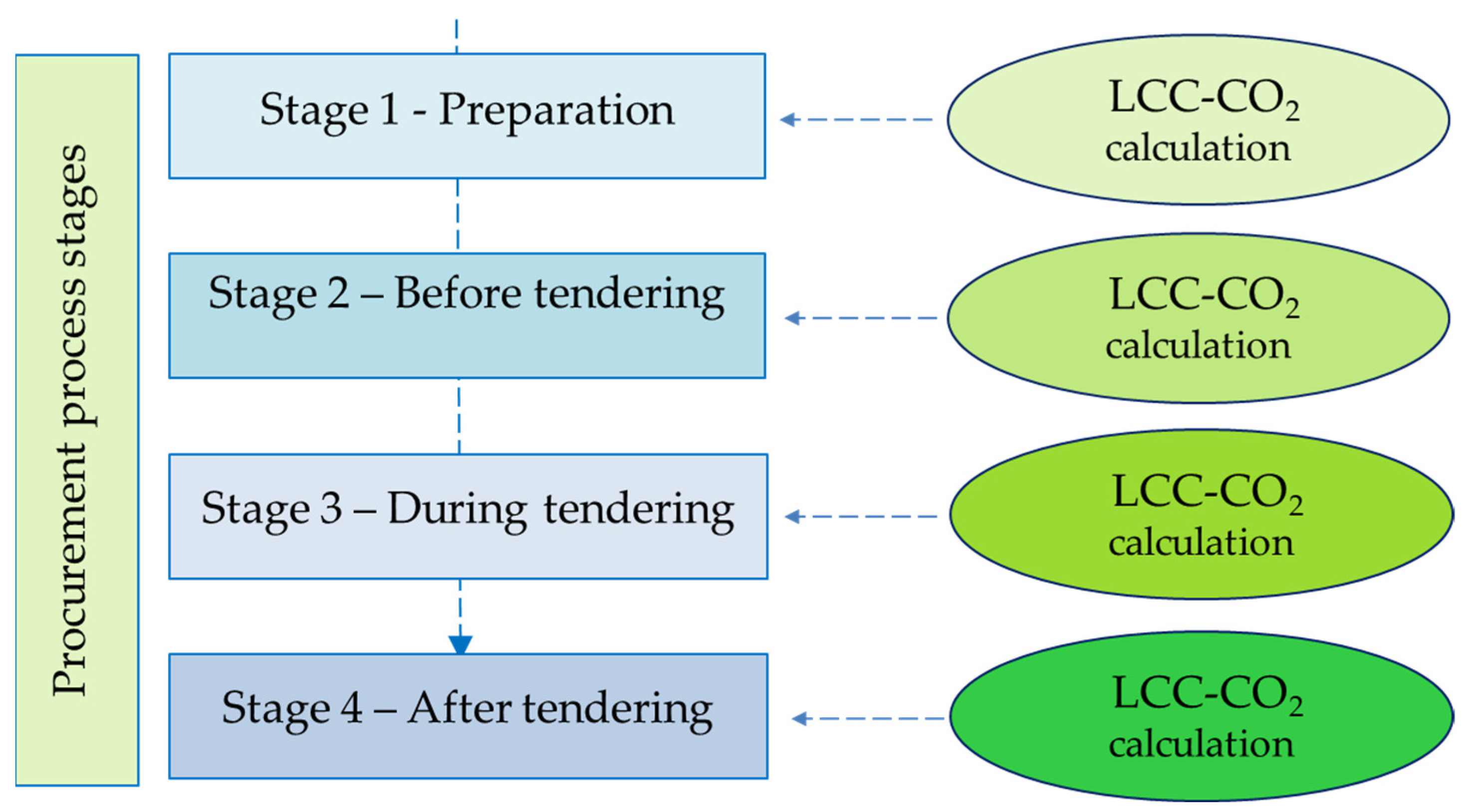

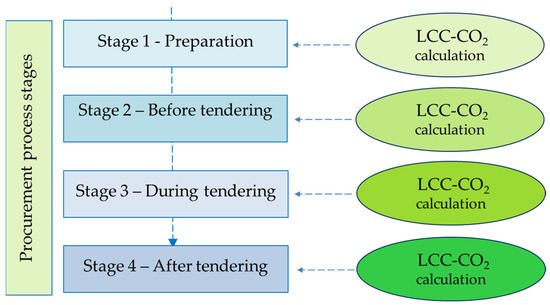

As specified in the tool users’ guide, the methodology and the related tool can be applied at different stages in the “procurement process”, as summarized in the following Figure 2. More precisely, in the first stage, during which a baseline is prepared with related LCC and CO2 emissions, in the second stage, before the tendering process, for selecting the technological solutions in the market to be analyzed, in the third stage, during the tendering process for comparing the LCC and CO2 emissions related to the different options, supporting the supply evaluation phase, and, finally, in the fourth stage, after the tendering, for comparing and highlighting the differences between the current solution and the alternative one/s.

Figure 2.

The procurement process stages and the LCC-CO2 calculation in a sustainable perspective. Authors’ elaboration.

In this work, with reference to Figure 1 and Figure 2, attention is paid to Stage 2—LCC-CO2 calculation, by proposing an interpretation of the operative modality developed according to the following steps:

- 1.

- Life cycle cost analysis application

- 2.

- CO2 emissions calculation

- 3.

- Criteria weighting application

- 4.

- Sensitivity analysis application.

Summing up, the results of the methodology consist of prioritizing alternative options through a multi-criteria approach, which avails the model of an output expressed, in part, in monetary terms, and, in part, by means of an appropriate unit of measurement for the hierarchization of environmental effects in relation to their acceptability.

Thus, in practice, the methodology can be applied to decision-making contexts in which both public authorities can be involved, specifically in the management of the procurement process, and private subjects, specifically for orienting the definition of their products offered.

In the following sub-sections, an insight into these four methodological steps is illustrated.

3.1. The Life Cycle Cost Analysis

The life cycle costing (LCC) approach, defined by the before-mentioned standard ISO 15686-5:2008, is applied for quantifying short- or long-term costs and benefits of alternative design solutions, from a life cycle perspective. Assuming the economic sustainability aim, LCC can be applied—as in this study—to alternative products, both in the case of new building projects or in the retrofit of existing ones. The core of the approach is the assessment of the difference among life cycle costs of each option. These are quantified in terms of global cost as defined in the before-mentioned Standard EN 15459:2007 and in the guidelines provided in the Commission Delegated Regulation (E.U.) No. 244/2012, solved by means of the global cost method or by means of the annuity method, capable to monetize the energy need of alternative solutions, for selecting the preferable option in terms of energy-saving, and thus, of economic sustainability. Alternatively, it can be used for quantifying the economic performance of a building as a whole. As a main result of the global cost method, the net present value (NPV) is calculated (usually with other synthetic indicators, such as net savings, savings to investment ratio, simple/discounted pay-back period, and adjusted internal rate of revenues).

The global cost represents the amount of discounted cash flows of a project option, considering the investment costs, the periodic maintenance, and replacement costs in relation to the lifespan of the components, the energy costs, the end-of-life (dismantling) and disposal costs, and, if present, the eventual residual value of an asset/component. The well-known Equation (1) expresses the formalization of the method:

where: CG(τ) = global cost (referred to starting year τ0) [€]; CI = initial investment costs; Ca,i(j) = annual cost during the year i of component j, which includes annual running costs (energy costs, operational costs, maintenance costs) and periodic replacement costs; dismantling and disposal costs; Rd(i) = discount factor during the year i; Vf,τ(j) = residual value of the component j at the end of the calculation period, referred to the starting year. The discount factor Rd is implied for discounting:

where: p represents the number of years starting from the initial time, r represents the real discount rate; the initial investment costs are not discounted.

3.1.1. LCC in Public Procurement Processes

As highlighted in the Introduction, the LCC approach is highly employed in recent research dealing with the evaluation of project economic sustainability in the private sector. Poorly explored are the cases of LCC application as a tool for supporting the evaluation of economic sustainability of projects in the public context, or in PPP interventions, as illustrated in Section 2.2. Thus, this sub-section is devoted to remembering the methodological aspects related to the use of LCC in public procurement processes, with a focus on Green Public Procurement. As a general assumption, notice that the principles of the LCC methodology related to private interventions are equally applicable to public construction procurement [48]. In this second context, the value for money and financial efficiency are key aspects. Furthermore, in public procurement cases, LCC applications observe some of the public project evaluation fundamental assumptions, such as the use of low/zero real discount rates, long project lifespans in a life cycle perspective, and low/zero incomes (except for the PPP projects, in which the private subject perspective must be considered); employment of components/systems selected according to their durability and with special attention to their environmental and social sustainability.

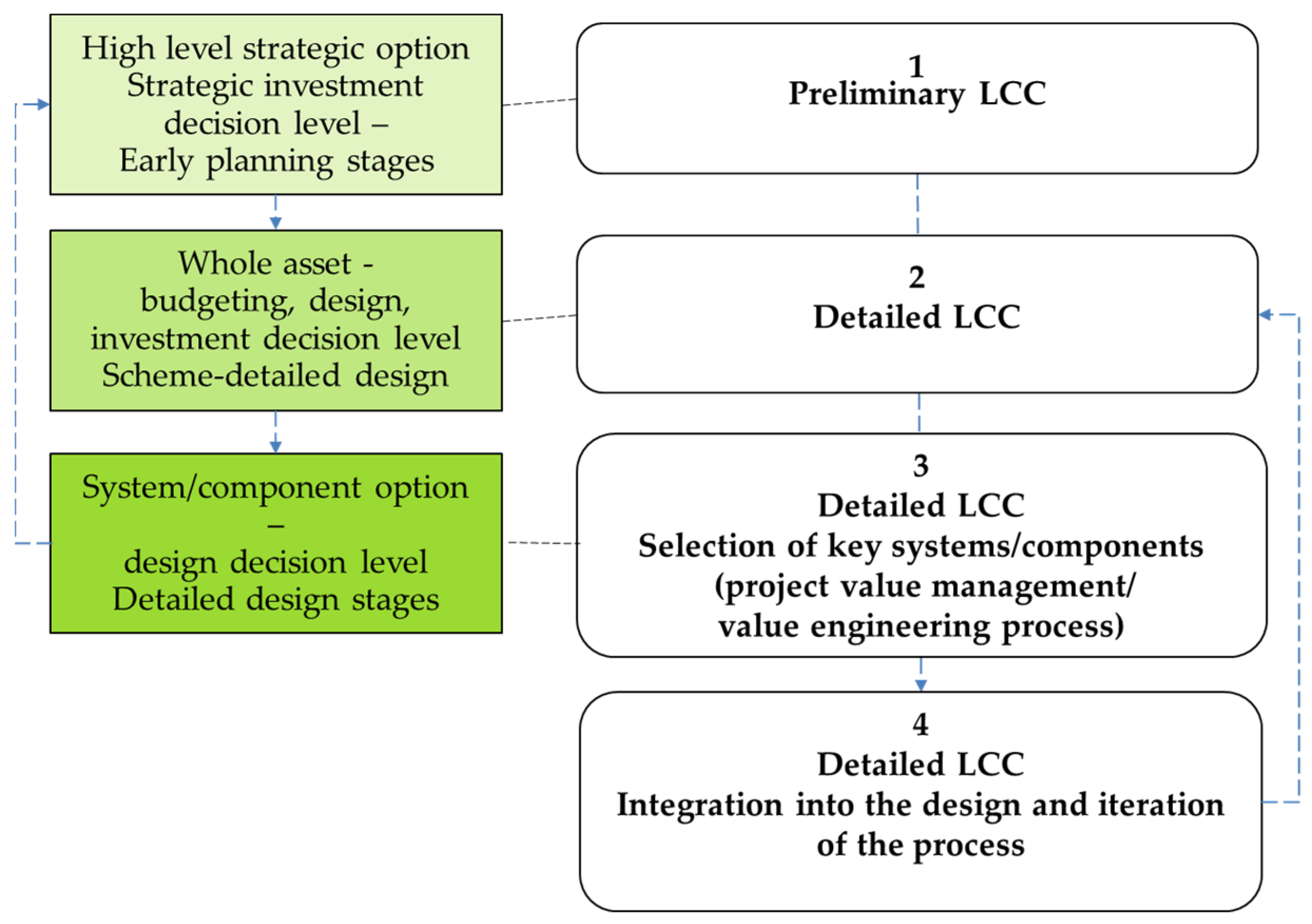

The LCC methodology can be declined in three main levels [48], which, in turn, correspond to three decision levels and design stages, as illustrated in Figure 3.

Figure 3.

The LCC integrated process in relation to the design stages/decision levels. Elaboration from ref. [48].

The preliminary LCC deals with high-level strategic decisions, usually faced during the early pre-project (planning) stages. In sum, the aim of this preliminary analysis is to decide about the opportunity to proceed with the intervention, or not. The detailed LCC can be firstly applied by considering the whole asset (building, construction), with the aim to evaluate the life cycle costs upon which the investment or design decisions will be oriented. In this case, a detailed design scale is necessary. Thirdly, the detailed LCC analysis can be applied for supporting design decision-making at the system/component level, and for selecting the options to be adopted into the design. This third level, which implies a detailed project, can support project value management activities or value engineering processes. Notice that the process is iterative in nature, and thus, the detailed LCC at the whole asset level can be replicated after the integration of the selected components/systems into the design.

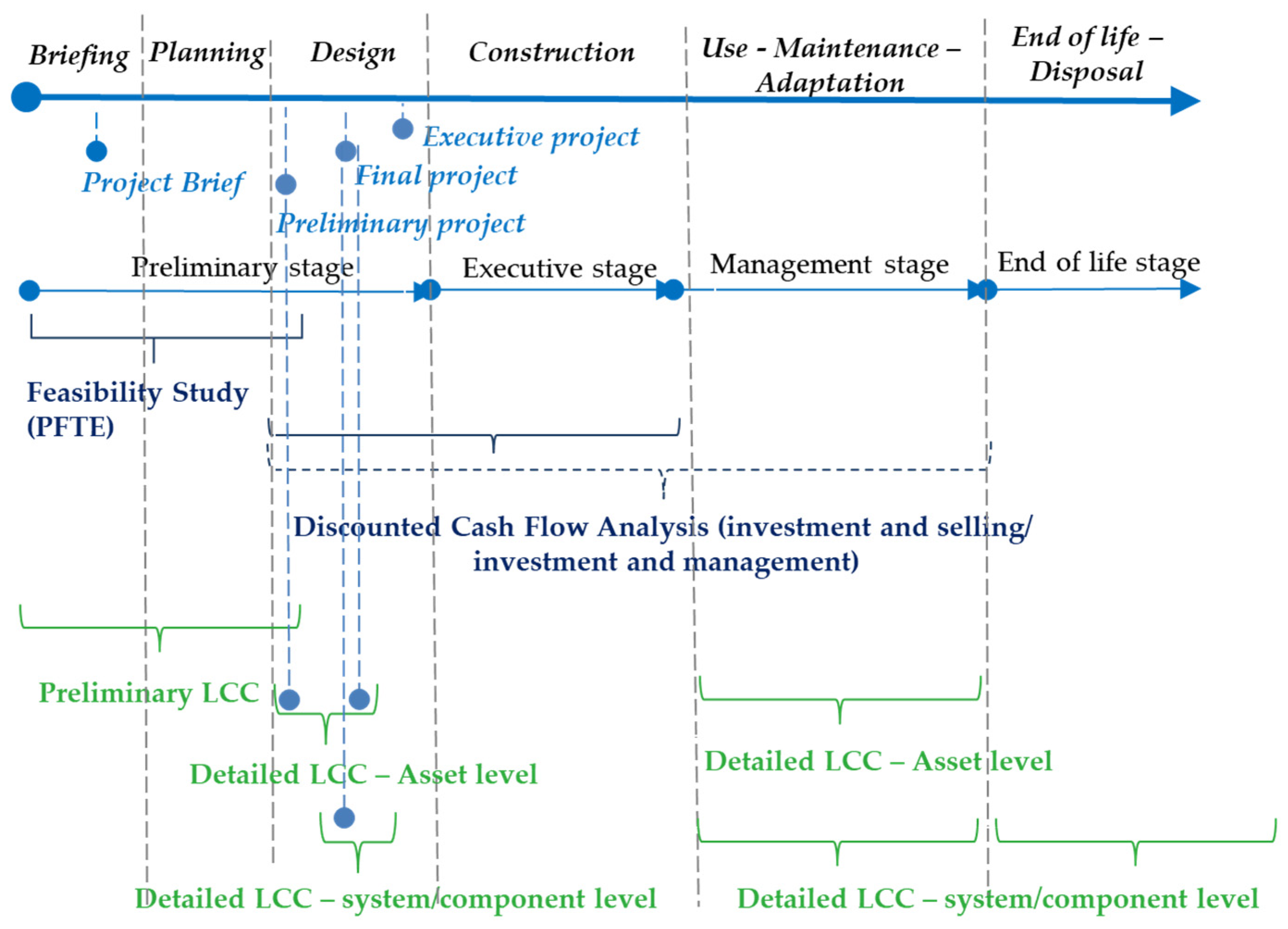

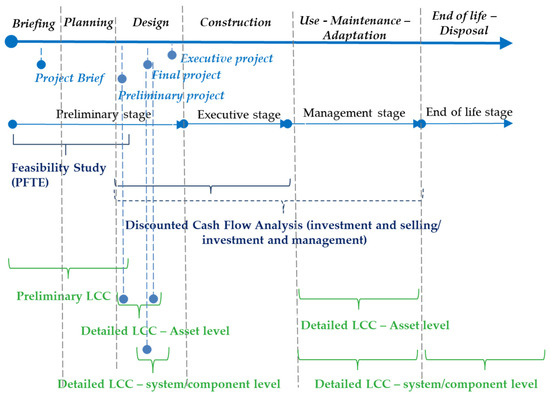

Finally, considering the project’s whole life cycle, as described in the literature [8], it is possible to spread the LCC preliminary/detailed versions according to the correspondent stages in a time perspective, as synthesized in Figure 4.

Figure 4.

LCC application in relation to the life cycle stages in building and construction projects. Elaboration from ref. [8].

For the reasons explained before, preliminary LCC can be applied during the briefing/planning stages in parallel with the feasibility study production (this, in Italy, has recently been replaced by the Technical Economic Feasibility Project). At the whole asset level, detailed LCC can be applied for supporting the preliminary and the final project production, during the design stage, or for supporting management activities during the use–maintenance–adaptation stage. At the system/component level, it can be adopted during the design stage for supporting the final project production, during the use–maintenance–adaptation stage for supporting planning/monitoring/management activities; or, furthermore, in the end-of-life stage for assessing the residual value of systems/components and the related waste management and recycling activity.

3.2. The CO2 Emissions Calculation

The CO2 emission calculation is oriented to quantify, on one hand, the emissions deriving from the usage/operation activities, for example, energy consumption, and, on the other hand, the embodied emissions released during production activities.

The tool foresees the possibility to internalize the results of an LCA approach previously produced. LCA is normed by the before-mentioned ISO 14040/44:2006 standard and recommended within the standard EN 15643-2:2011 [57], which provides the principles for the assessment of a building’s environmental performance. The approach quantifies both energy and environmental loads and potential effects of a product, over its whole life cycle, in terms of environmental impacts. According to the LCA standard, the embodied energy (EE) corresponds to the primary energy (MJ) contents obtained by summing up different contributions over the entire product’s life cycle, specifically: raw materials extraction and delivery to the place of transformation, energy consumption for their transformation and successive shaping, eventual maintenance, and dismantling/recycling/landfilling operations, as well as the feedstock energy. The embodied carbon (EC) is a measure of CO2 equivalent emissions (i.e., the global emissions of all greenhouse gases) related to the entire life cycle (kg CO2eq) over a time horizon of usually 100 years. The EC assessment, illustrated in the Standard UNI 8290-1, is formalized according to the following equation:

where: ECj stands for the EC for the j-th building system analyzed, expressed in kg CO2eq; ECi stands for the EC for the i-th material or component used in the j-th building system, expressed in kg CO2eq/kg.

3.3. The Criteria Weighting

A particularly important step of the methodology is represented by tenders’ evaluation. During the comparison of different options, the scores for economic and environmental criteria, LCC and CO2 emissions, respectively, are assigned by the tool through the following formula (see LCC-CO2 tool user guide, p. 23):

[Lower costs (CO2 emissions) of all products/costs (CO2 emissions of the specific product)] multiplied by 100.

According to a multi-criteria perspective, as experimented with in previous works [58,59], it is possible to consider the total costs and environmental impacts as two separate criteria, measured through their own units of measurement, and eventually, to assign them a different weight, in percentage. The weighting, operatively solved by assigning a specific percentage for financial and environmental criteria, reflects the specific priority given during the decision-making process (for example, the preference for “greener alternatives”, in compliance with the norms about the environmental award criteria).

3.4. The Sensitivity Analysis

Uncertainty/risk due to market variability can be considered as a generalized condition in project economic and environmental evaluation. LCC and CO2 assessment can be influenced by the presence of uncertainty in discount rates, inflation rates, in service lives, in “critical” cost items (these are usually preliminarily selected among the set of input variables, for their potential perturbation on the model output). In the literature, deterministic/probabilistic approaches are available for detecting and possibly reducing the uncertainty in model applications, recently, in life cycle approaches [60,61,62,63,64].

Among the tools, the sensitivity analysis is an approach that can be applied both in a deterministic and in a probabilistic version, according to the quantity of available data. In this study, a deterministic sensitivity analysis is implied, resolved through the iteration of the model with multiple estimates obtained by varying systematically some selected input variables. The systematic variation is obtainable by assigning different values, both in percentage and in absolute values, with negative/positive steps (increment/decrement in values). A graphical output (spider graph) can support the interpretation of the results in terms of identification of the most influencing input variables.

Thus, input variables, and more precisely, the critical ones, must be intended as expected values when in the presence of probabilistic sensitivity analysis, or initial value in the deterministic version of the analysis. In conclusion, the aim of the sensitivity analysis application is the detection of the impact produced by uncertain input data on the output, in order to obtain a more robust results calculation.

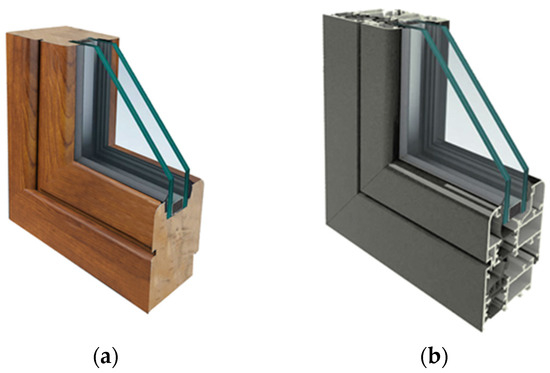

4. Case Study

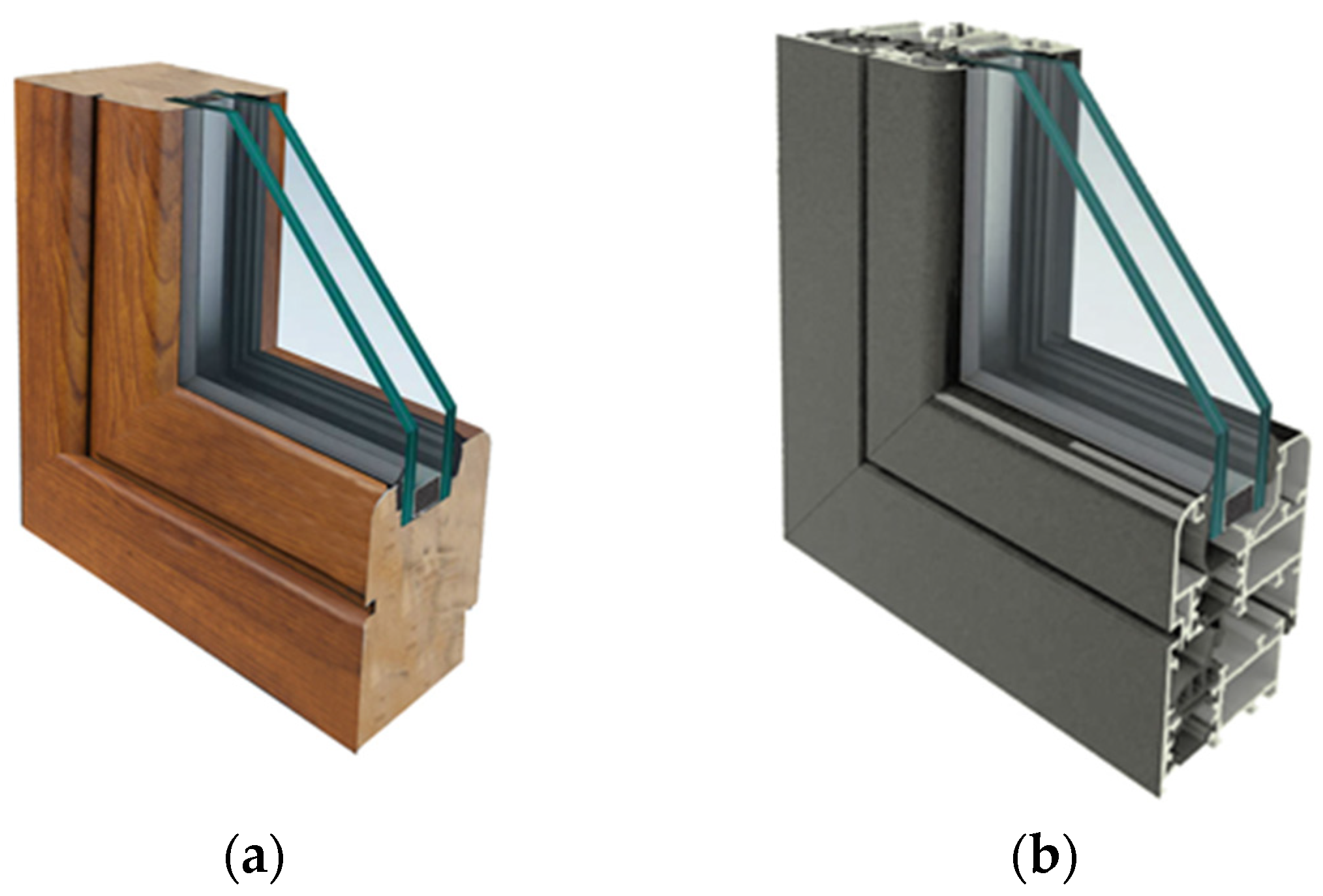

As a basis for the application of the proposed methodology, a case study—illustrated and adopted in previous studies—is considered in this work [15]. More precisely, a timber frame window, and an aluminum frame window (see Figure 5), are assumed as alternative components to be adopted in a hypothetical multifunctional building project.

Figure 5.

Alternative components: (a) timber window frame; (b) aluminum window frame. Reprinted from ref. [64] p. 8.

As indicated in the previous studies, the initial investment cost, the total running and replacement costs, and the disposal costs, as well as the EE and EC for both options are calculated; among these, the fundamental data for the application of the tool are summarized in the following subsection.

4.1. Assumptions: Input Data

As a preliminary step of the analysis, a set of input data is assumed. Particularly, the relevant costs (Cost Drivers in Table 1) are selected with their unit of measure, both for the aluminum and for the timber frame. Considering the specificity of the component, maintenance costs, and CO2-related costs (calculated in terms of embodied carbon, or embedded emissions) are selected as relevant for the global cost (or total cost) calculation. Furthermore, relevant items are the initial investment costs (which includes the installation costs), the annual running and replacement costs including inspection, the breakdown of the before-mentioned maintenance items, and replacement; then, the eventual residual value, and the discount rate, lifespan, and period of analysis.

Table 1.

Input data: cost drivers for aluminum/timber frames. Elaboration from ref. [15].

The input data assumed for the LCC and CO2 emissions calculation are summarized in the Table below.

A planning horizon equal to 25 years is adopted for the application: it corresponds to the maximum time horizon admitted by the tool. The lifespans related to aluminum and the timber frame are 20 years and 15 years, respectively, given that these year amounts are not representative of the effective mean life cycle of the products, but a useful lifespan for testing the tool with likely input values.

5. Simulation and Results

By means of the SMART SPP LCC-CO2 Tool, a simulation of the methodology illustrated in Section 3 is applied, on the basis of the case study presented in the previous section. The results are illustrated in the following subsections.

5.1. LCC and CO2 Calculation Results

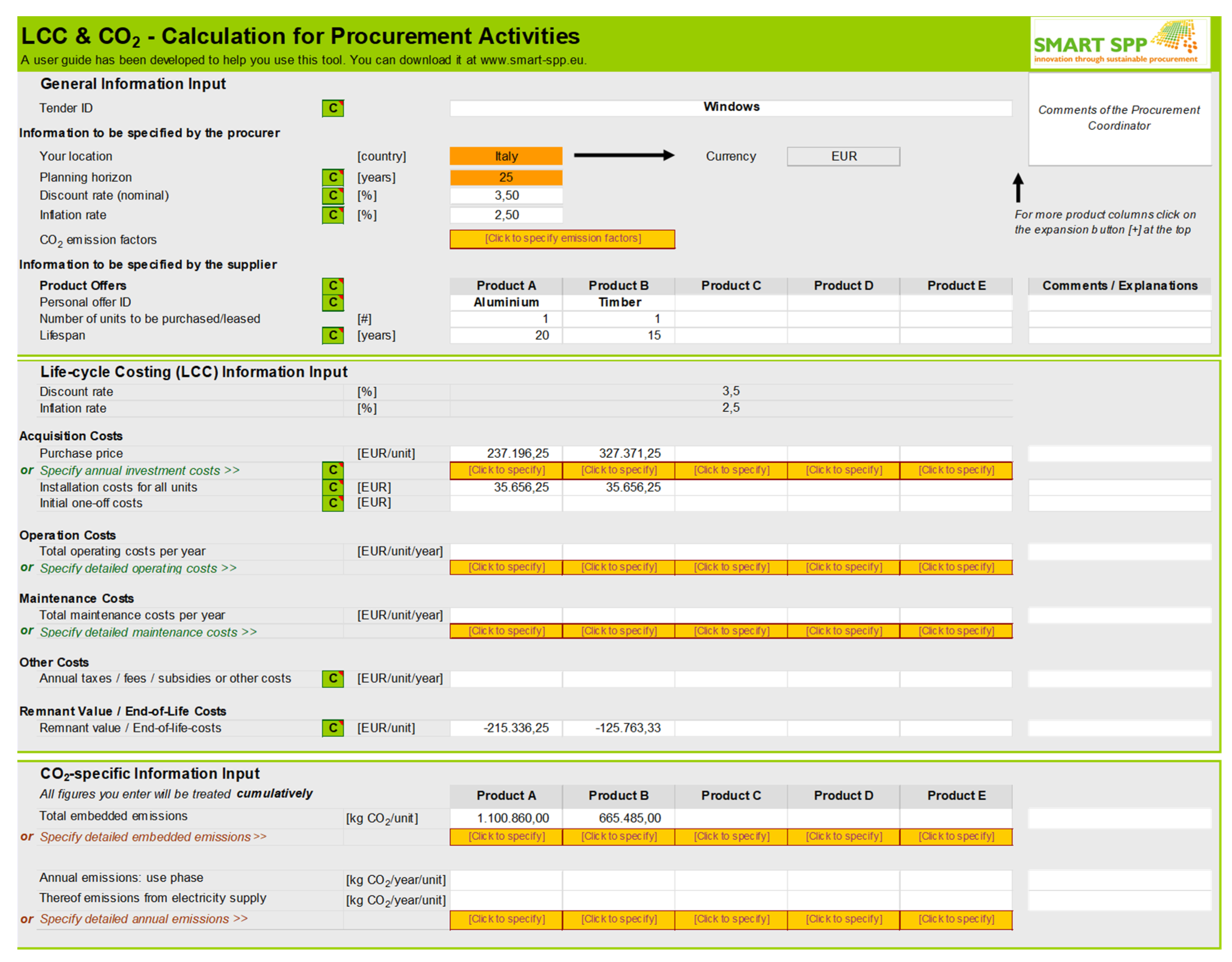

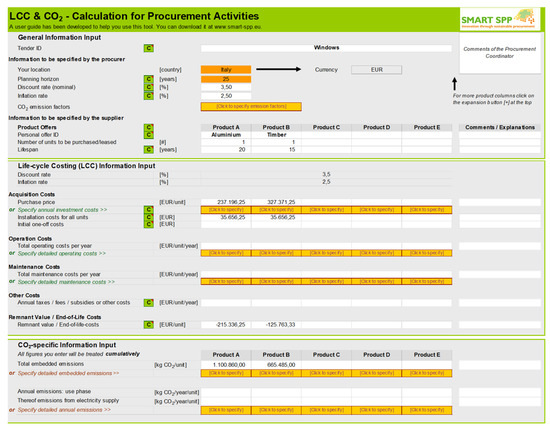

The first step of the methodology consists in setting all the required input data for the LCC and CO2 emissions calculation. The data entry result is illustrated in Figure 6, by distinguishing among:

Figure 6.

LCC and CO2 emissions calculation: data assumptions. Authors’ elaboration by SMART SPP LCC-CO2 Tool.

- the “general information input”, which includes the assumptions specified both by the procurer (Country in which the process is developed, in this case, Italy, and the related currency, Euro; lifespan in years; nominal discount rate, in this case, 3.50%; inflation rate, in this case, 2.50%) and by the supplier (list of the specific products offered, in this case, equal to two, the aluminum and the timber frames; the number of units offered for the selling/rental market, in this case, one by considering the entire external transparent envelop as a single unit; and lifespan in years, in this case, 20 for the aluminum frame and 15 for the timber frame);

- the “Life Cycle Costing—LCC information input”, which includes all the assumptions necessary for the LCC application, specifically: the discount rate, in this case, 3.5%; inflation rate, in this case, 2.50%; acquisition/operational/maintenance costs (with a breakdown of the specific items); other costs; and residual value/end-of-life costs;

- the “CO2 specific information input”, with assumptions related to the total embodied emissions, eventually detailed with a specification of the annual emissions during the usage stage (without enucleating the emissions due to electricity supply, having considered components with equal energy performances). For the calculation of the embedded emissions, the following operative steps are implemented by the tool:

- 1.

- the calculation of the embedded emissions per unit is obtained by summing all of the absolute amounts of embodied emission due to production, transport, installation, and disposal, calculated per unit;

- 2.

- the calculation of the embodied emissions over usage time is obtained by embedded emissions per unit * number of units to be purchased/leased (including necessary replacements, if planning horizon > lifespan) per offer;

- 3.

- the remaining share of embodied emissions (which are equally allocated over the lifetime of units) at the end of the planning horizon = total embedded emissions per offer—(number of units to be purchased/leased * embedded emissions per unit * (planning horizon [years]/lifespan [years])).

All of the other input data are described in Section 4.1. Notice that the empty columns indicate the potentiality of the tool to include more than two products in the evaluation process (as specified in the tool user guide, up to 15 products), allowing a wider comparison among suppliers’ products.

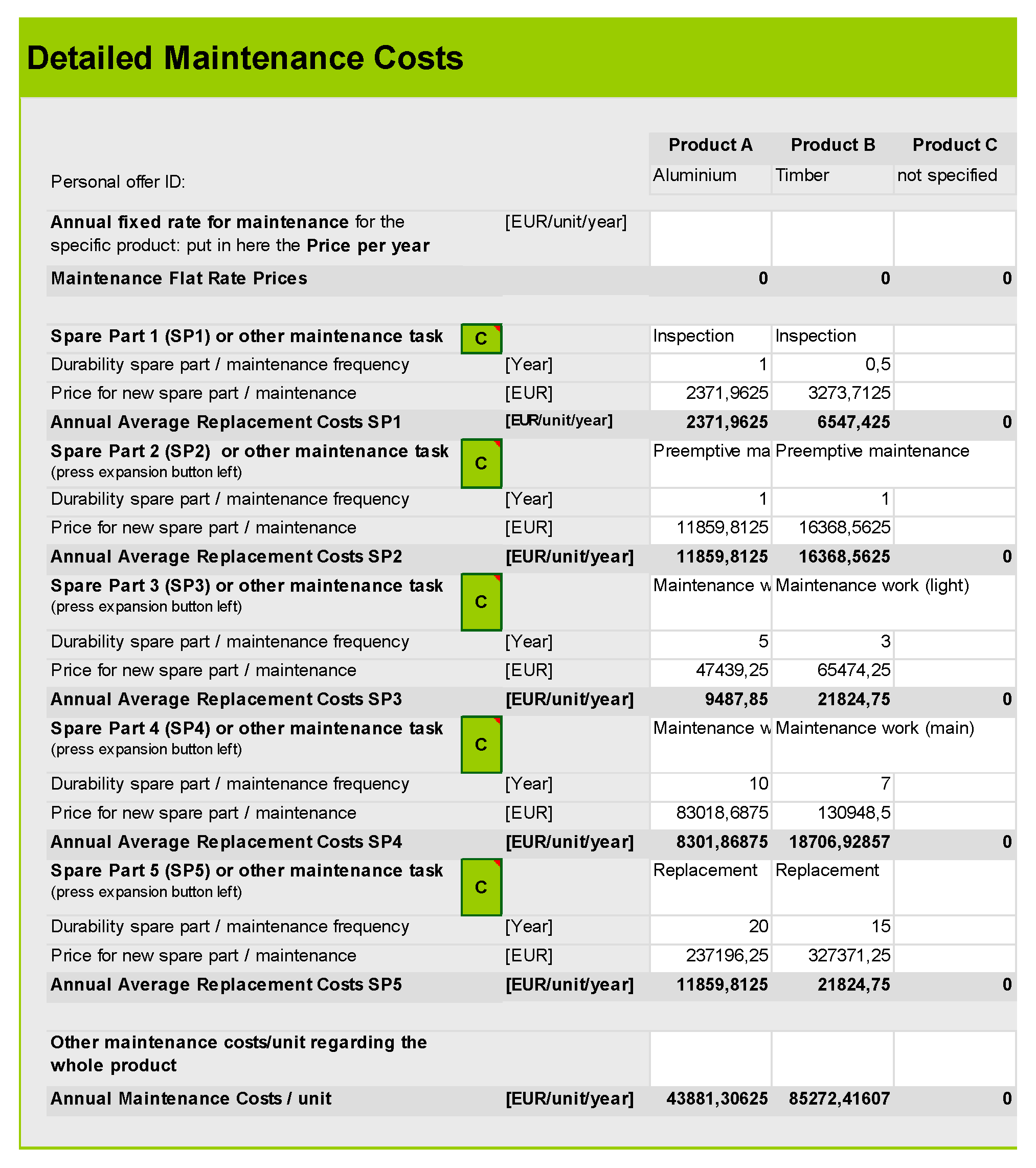

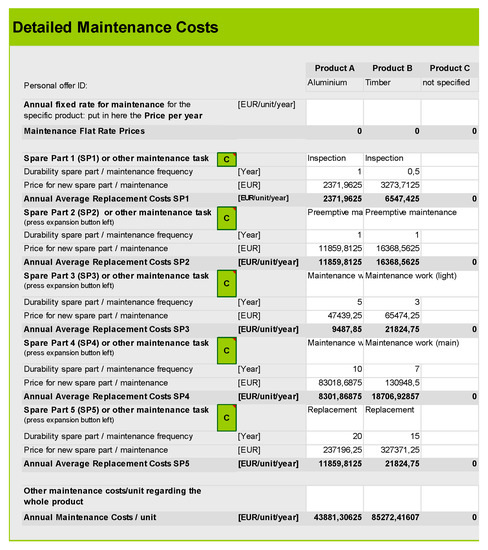

Then, a detailed breakdown of maintenance costs (see Section 4.1) is assumed, as illustrated in Figure 7 below.

Figure 7.

Maintenance costs breakdown. Authors’ elaboration by SMART SPP LCC-CO2 Tool.

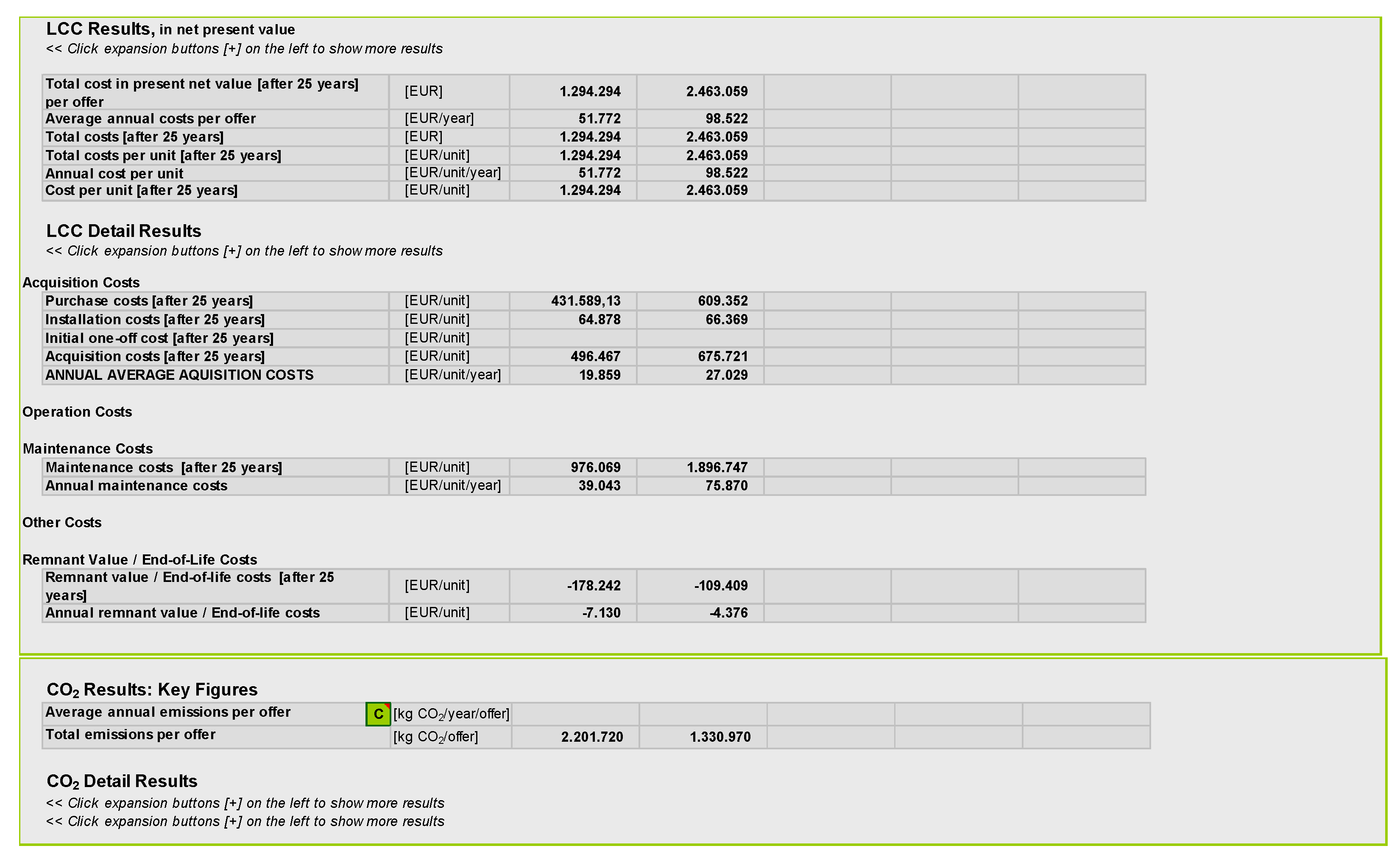

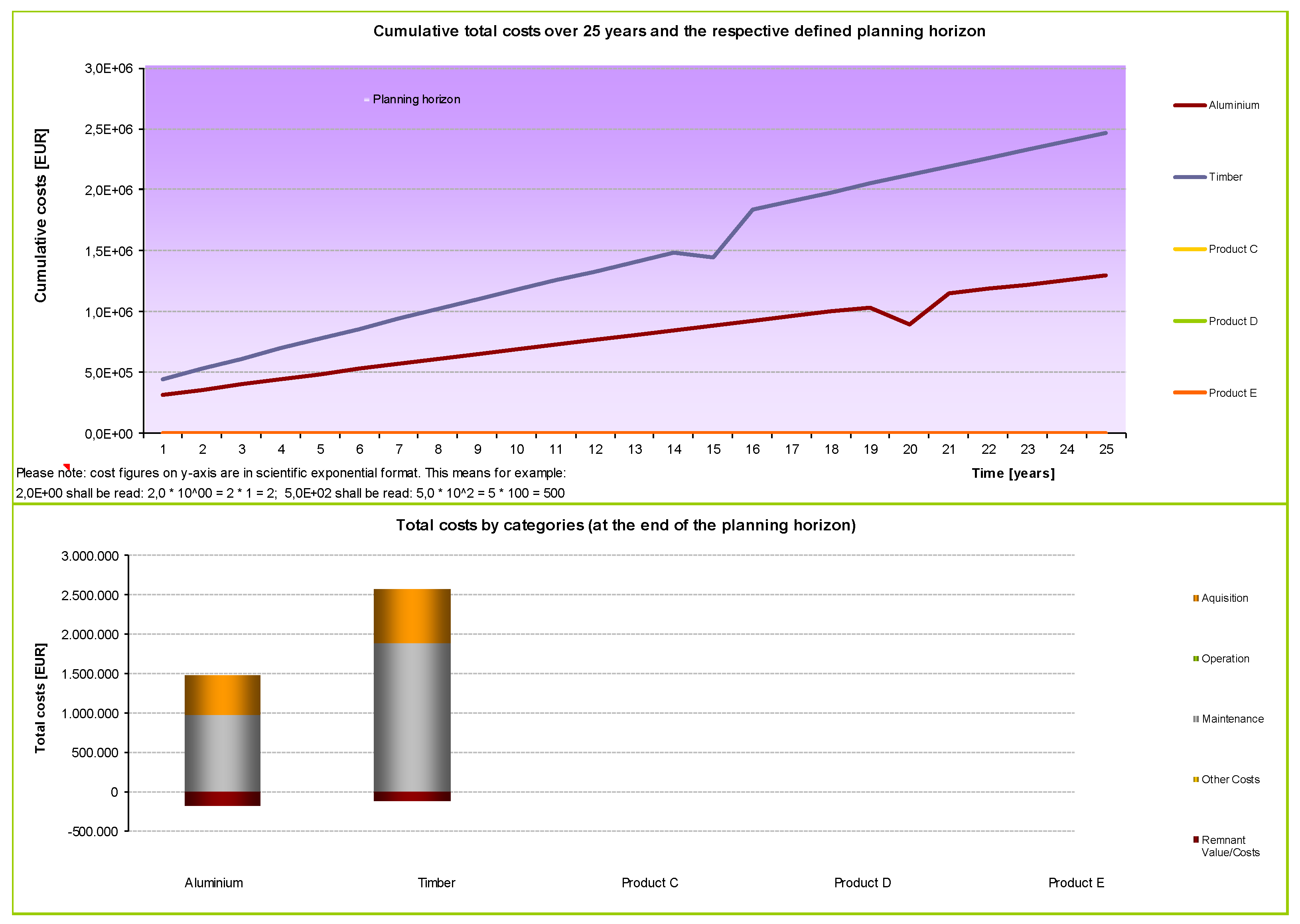

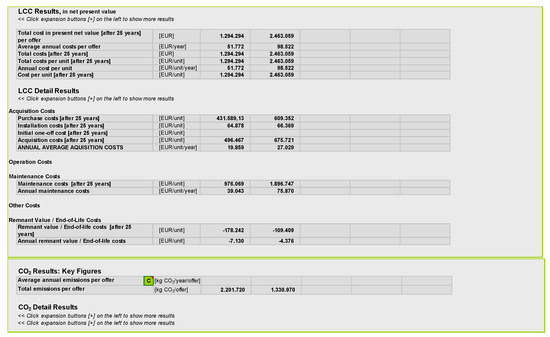

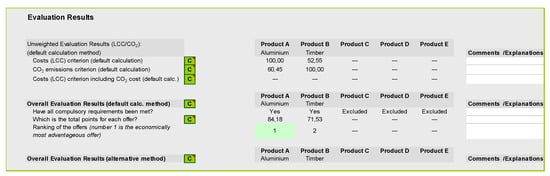

The second step consists of the calculation of the results. In Figure 8, the obtained output is illustrated; notice that the term total cost is adopted in place of the term global cost. The first group encompasses the LCC results calculated in terms of net present value (NPV), per each offer, both in total and in annual average terms. Then, a second group includes LCC detailed results, by considering the main cost items mentioned before (acquisition costs, operation costs, maintenance costs, other costs, and residual value/end-of-life costs). Finally, the third group includes the CO2 calculation results, in terms of average annual emissions per offer and total emissions per offer, with the possibility to calculate more detailed results.

Figure 8.

LCC and CO2 emissions calculation results. Authors’ elaboration by SMART SPP LCC-CO2 Tool.

Notice that, in this simulation, as indicated in the Figure above, the CO2 emissions are not monetized: these are calculated in kg CO2/offer, which represents the physical quantity of emissions produced. Given the importance of this step, the monetary quantification of the CO2 will be developed in a future step of research, as highlighted in the conclusions.

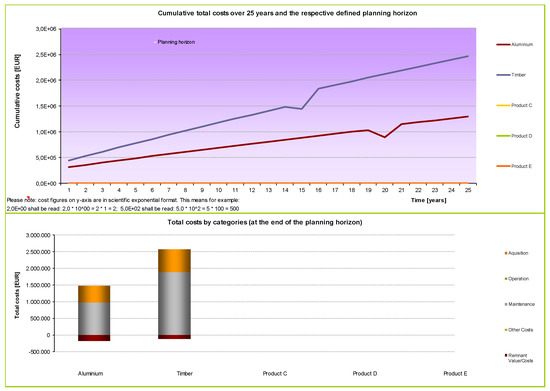

The results of the LCC calculation are graphically represented in Figure 9, through a cumulative total cost curve over the whole planning horizon (graph above), and by means of a bar diagram in which the cost categories for both frames are represented (graph below). The cost curves present a similar trend, with a cost amount increasing over time, and with a negative peak in correspondence to the replacement of the component. In the meantime, the graph demonstrates that the timber frame implies a higher cost amount for the entire time horizon (25 years) and a shorter number of years required before the first replacement of the component. The bars confirm the sensibly higher costs implied for timber frames, both for acquisition and, particularly, for maintenance, and a lower residual value/end-of-life cost for the same timber frame.

Figure 9.

LCC calculation results: graphical representation. Authors’ elaboration by SMART SPP LCC-CO2 Tool.

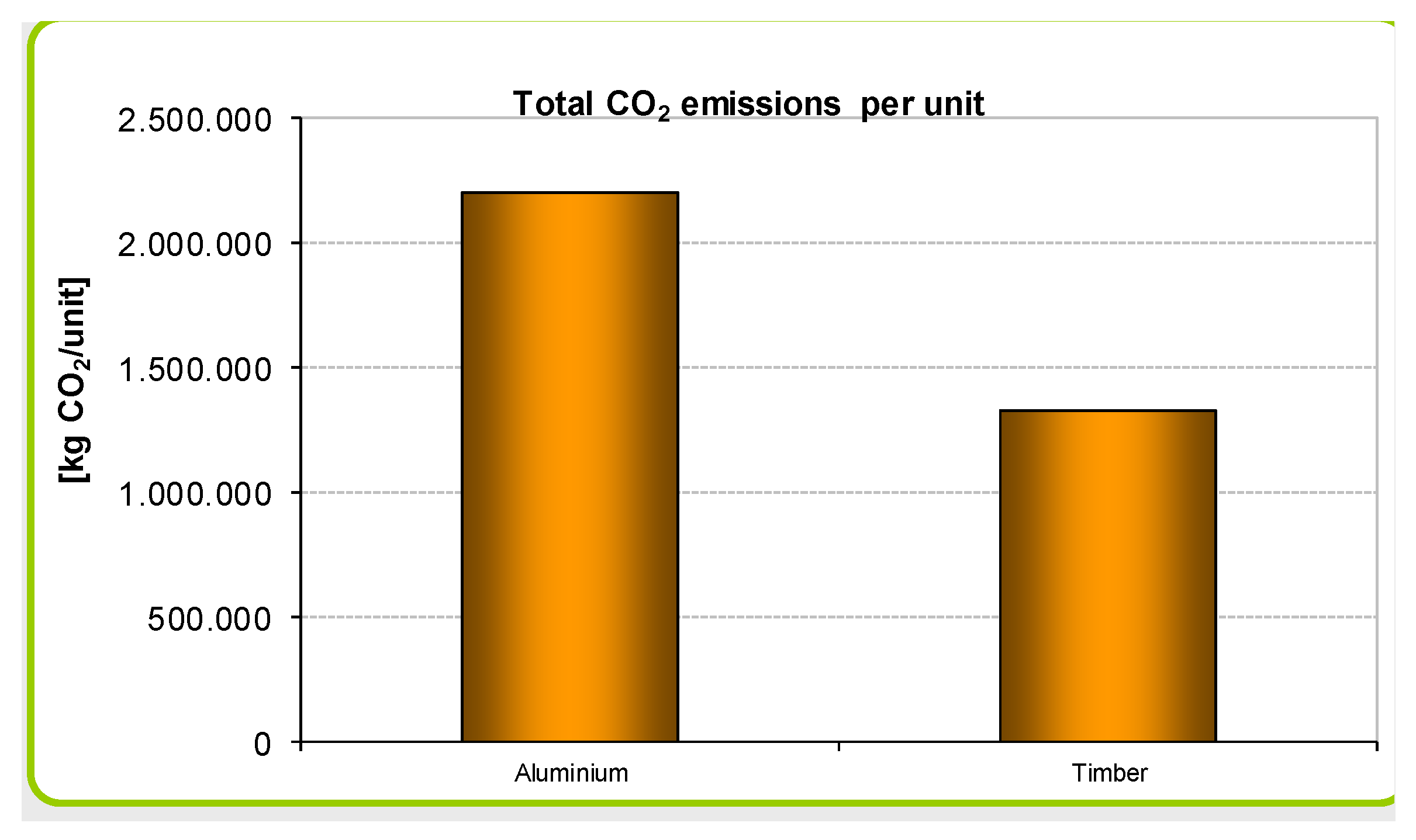

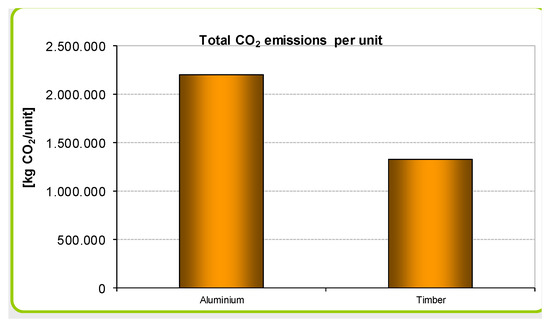

The results for CO2 emissions are very different. These are calculated through the embodied carbon produced, as illustrated in Section 3.2 (see Figure 10): the EC produced during the production stage for aluminum is sensibly higher than the EC produced during the production activity for timber frames.

Figure 10.

CO2 emissions calculation results: graphical representation. Authors’ elaboration by SMART SPP LCC-CO2 Tool.

As illustrated, the results under the economic and the environmental viewpoint are opposite, and the final decision (tenders’ evaluation) could be reached through the support of the criteria weighting step, as mentioned in Section 3.3 of the methodology and as illustrated in the following subsection.

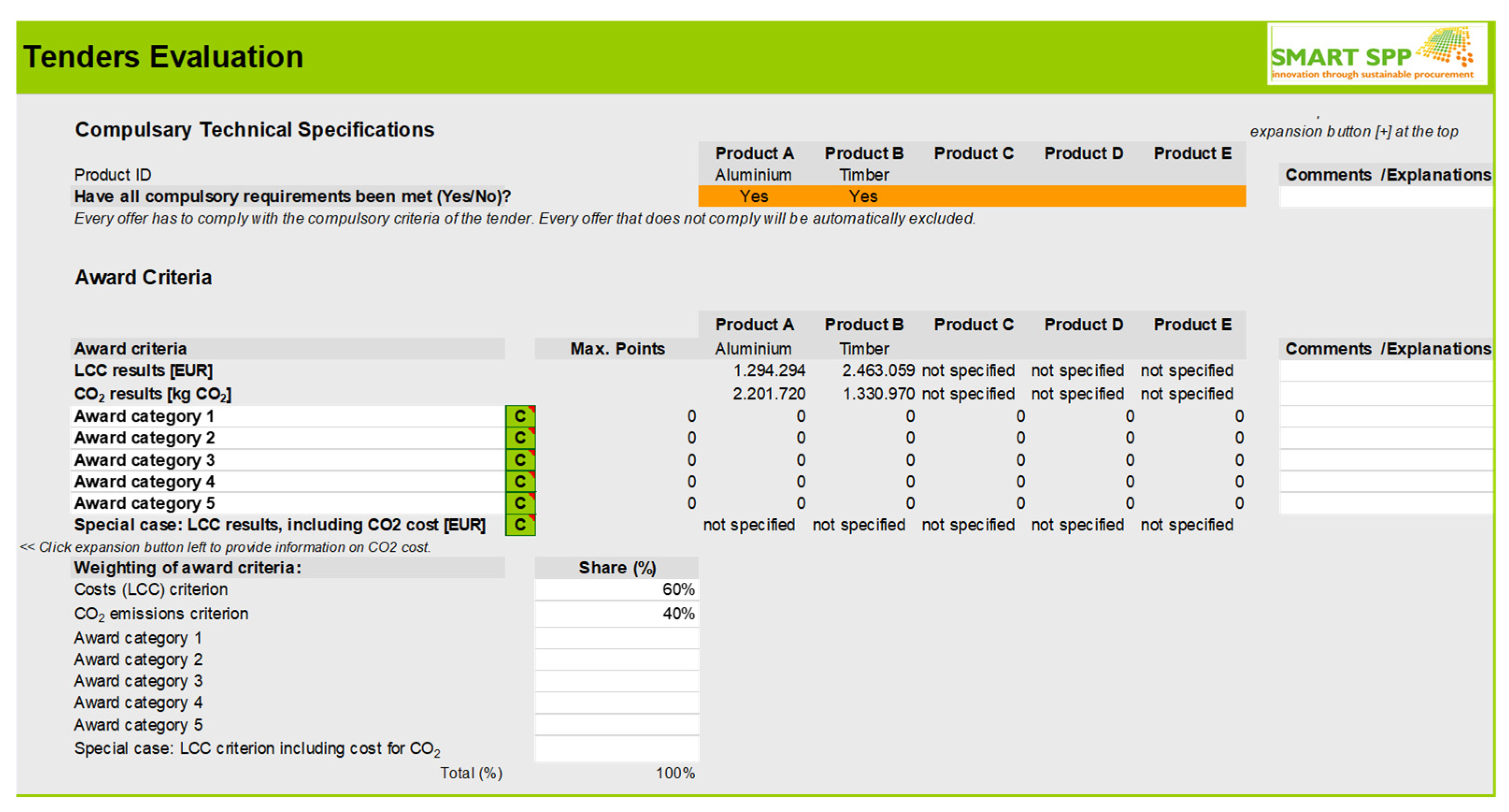

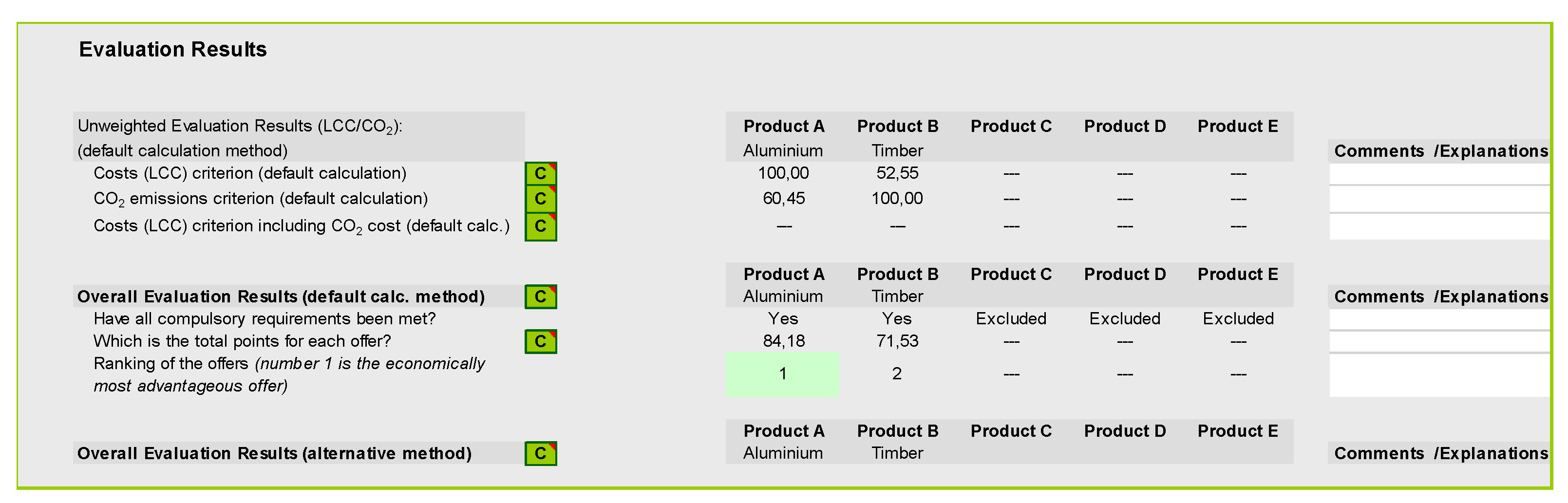

5.2. Criteria Weighting Results

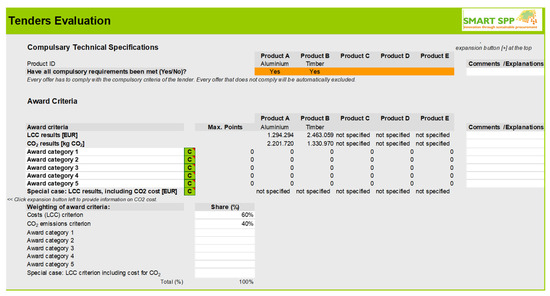

The third step of the application consists of the tenders’ evaluation. Fundamental to the evaluation is the weighting of the award criteria assigning a different weight to the economic and environmental indicators, according to the specific procurer’s viewpoint. Assuming the sustainability perspective, including both economic and environmental aspects, in this case—as an example—60% and 40% of the weights are assigned to economic and environmental criteria, respectively (see Figure 11).

Figure 11.

Tenders’ evaluation with the specification for the criteria weighting. Authors’ elaboration by SMART SPP LCC-CO2 Tool.

Thus, in the following Figure 12, the weighted results, calculated by means of the formula presented in Section 3.3, are reported. A slightly preferable result emerges for the aluminum frame (highlighted in the green cell) in comparison to the timber frame (84.18 points against 71.53 points).

Figure 12.

Tenders’ evaluation results with criteria weighting. Authors’ elaboration by SMART SPP LCC-CO2 Tool.

5.3. Sensitivity Analysis Results

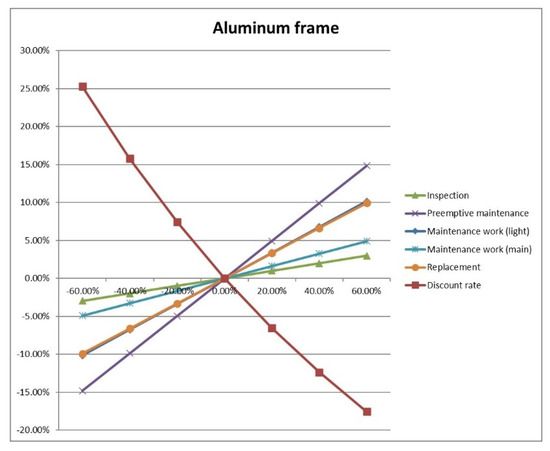

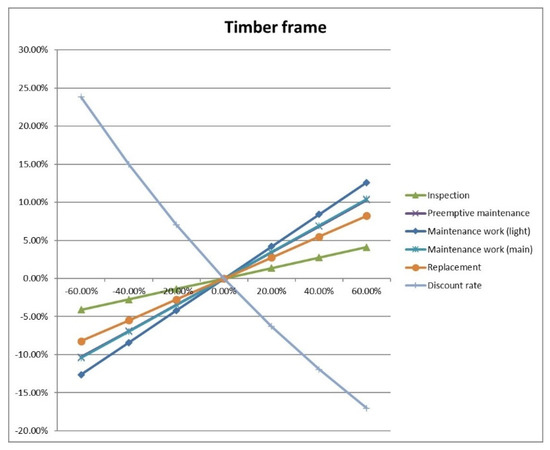

In order to complete the simulation, for the reasons explained in Section 3.4, a deterministic sensitivity analysis is produced by assuming a variability in critical input parameters. Precisely, critical inputs are related to costs for inspection activities, costs for preemptive maintenance, costs for maintenance work (by distinguishing between light interventions and main interventions), costs for replacement, and, finally, discount rate value.

As Table 2 and Table 3 show, in relation to the aluminum frame and timber frame, respectively, the variations in the global cost (total cost) are reported in percentage terms. These variations are related to the values calculated for the base-case scenario, by applying a decrease (−60%, −40%, −20%) and an increase (+60%, +40%, +20%) in the values of the critical inputs listed before.

Table 2.

Sensitivity analysis with a decrease/increase in critical input costs—aluminum frame. Authors’ elaboration.

Table 3.

Sensitivity analysis with a decrease/increase in critical input costs—timber frame. Authors’ elaboration.

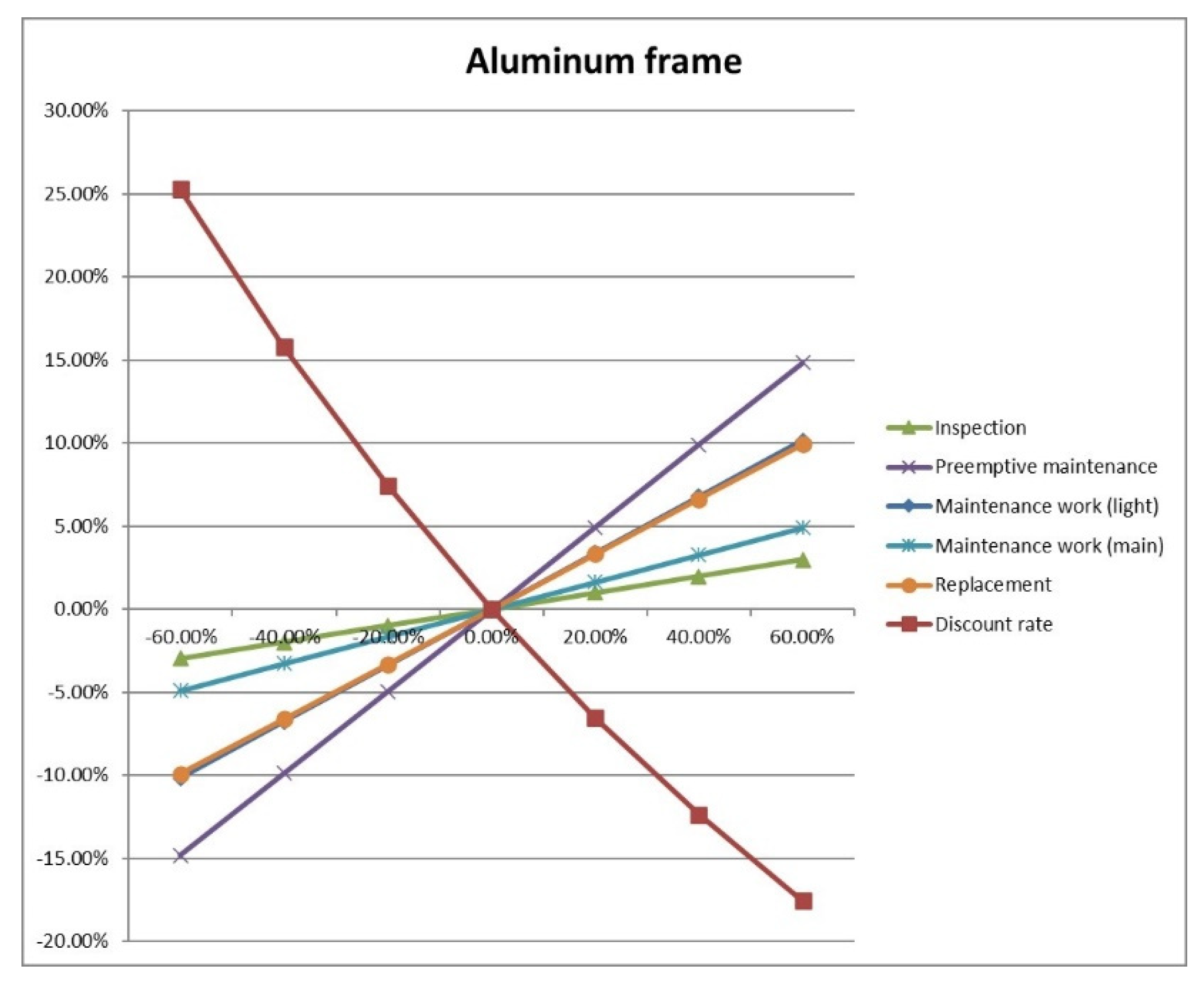

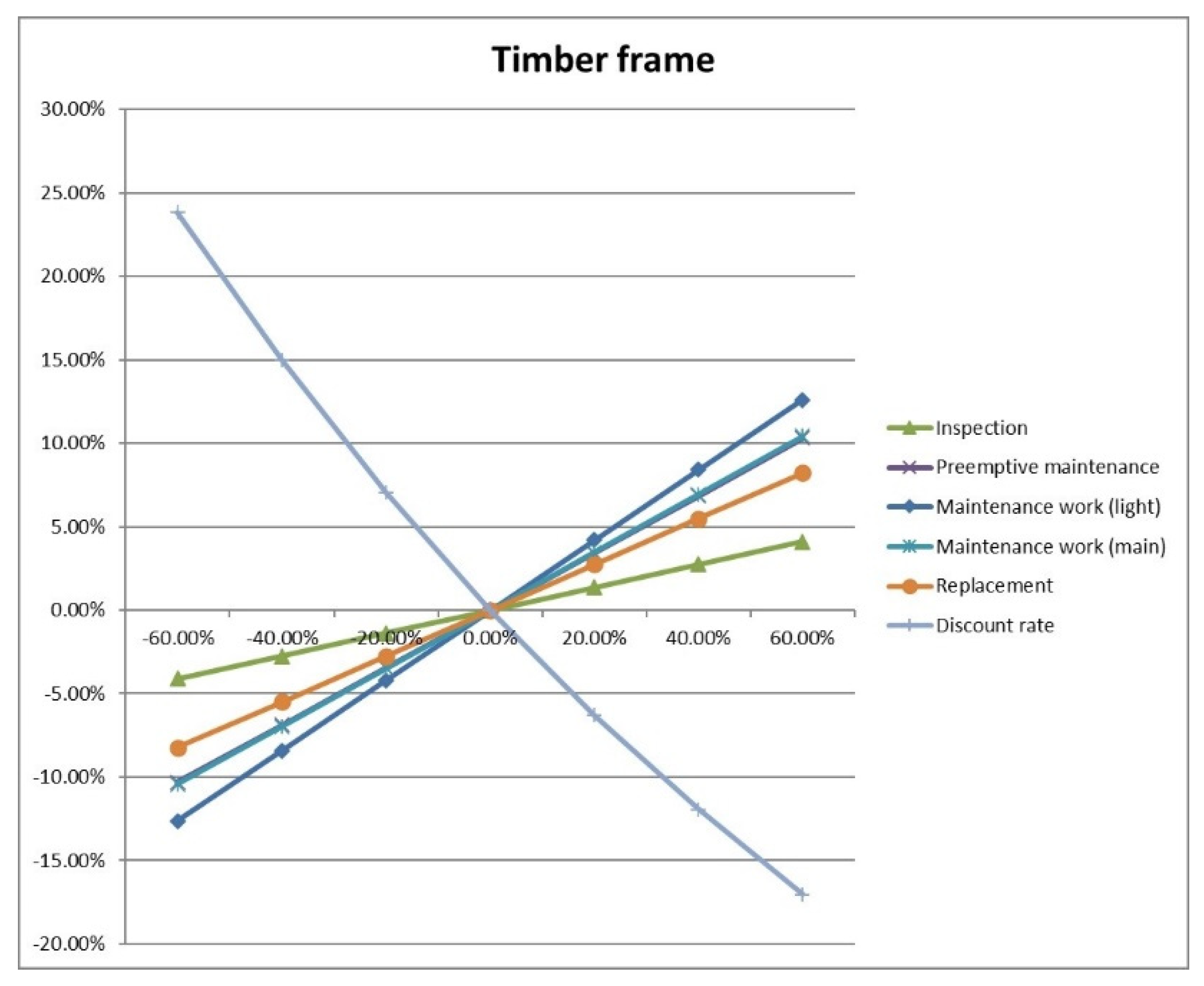

For completing the analysis, in Figure 13 and Figure 14, a graphical representation of the sensitivity analysis is reported through the spider graph for the aluminum frame and the timber frame.

Figure 13.

Sensitivity analysis: spider graph for the aluminum frame. Authors’ elaboration.

Figure 14.

Sensitivity analysis: spider graph for the timber frame. Authors’ elaboration.

As emerges from the spider graphs, given that the steeper curves in spider graphs represent the more critical variables, the discount rate is the most impacting (financial) variable in both products, with a steep negative curve (with a non-linear trend, as expected). Differences, with respect to the two products, emerge for the other variables: for the aluminum frame, preemptive maintenance, maintenance work (light), and replacement are the most impacting variables, followed by maintenance work (main) and inspection. On the contrary, for the timber frame the maintenance work (light), maintenance work (main), and preemptive maintenance are most impactful, followed by replacement and inspection costs.

No variable is able to present opposite behavior in relation to the two alternative frames. The maintenance work (main) is significant for the timber frame and much less significant for the aluminum frame; maintenance work (main) is a way of differentiating between the behaviors of the two technological products. To a lesser extent, preemptive maintenance is a way of differentiating between the behavior of the two products, being quite highly significant for aluminum and, even less for the timber frame.

Summing up, the choice between the two technologies will also depend on the procurers’ propensity to balance the environmental performances with the economic performances.

6. Discussion

Despite the potentialities of the methodology, some limits emerge from the study. Notice that these are due, on one hand, to the availability of data and assumptions, and, on the other, to the specific context and aim of the analysis: the simplified operative modality applied for the calculation of environmental impacts. The main limits are summarized in the following bullet points:

- Firstly, the use of embodied carbon as a quantitative indicator for the calculation of CO2 emissions as done in this work should be transposed in monetary terms, as with the sustainability impact metrics (see: https://www.ecocostsvalue.com/eco-costs/, accessed on 29 June 2022), in order to complete the evaluation of the economic sustainability of the project options by internalizing the externalities into the global cost calculation;

- Secondly, the robustness of the method could be improved by introducing the results of a detailed life cycle assessment (LCA), produced contextually or before the LCC calculation: as mentioned, the LCA can be calculated by including not only the embodied carbon but also the embodied energy, due to the different stages in the product life cycle;

- Thirdly, strictly linked to the previous point, the methodology should be tested on a case suitable for the assessment of the energy consumptions assessment during the operative/use/management stage, whilst in this case, the energy analysis was not applicable to the two alternative products considered;

- Finally, the methodology is applied to a technological component, and it should be tested on a wider range of options covering different object scales (component/system/asset), different decision-making contexts, and different design levels.

As underlined in the Conclusions, these points could address future research developments.

7. Conclusions

The aim of this paper was to explore the application of an operative methodology for the joint evaluation of economic and environmental sustainability of different project solutions, capable of supporting public procurement processes in a sustainable perspective and to reduce the efforts for the analyses.

The methodology, with the support of the software “Smart SPP LCC-CO2 Tool”, was applied to a simulated case study, aimed at selecting the preferable solution between two different products for a hypothetic building project with a glass façade, located in Northern Italy. This same case was already assumed in previous works for exploring other methodologies and operative modalities, focusing on the evaluation of economic–energy–environmental sustainability from the life cycle perspective, and focusing on the definition of a synthetic economic–environmental indicator for the global cost calculation. In this work, the methodology was applied through a three-step procedure: in the first step, all the input data required (general information and specific LCC and CO2 information) were entered; in the second step, the results were calculated in terms of total cost (global cost) for the LCC and in terms of total emissions (kg) for embodied CO2; in the third step, the simulated tenders were evaluated assigning different weights to the economic and environmental indicators, taking into account the procurer’s viewpoint. To deepen the analysis, a deterministic sensitivity analysis was applied to specific critical input parameters, such as maintenance/replacement costs and discount rate. The results indicated that, according to an economic viewpoint, the aluminum frame is preferable, but, according to an environmental viewpoint, the timber frame is the preferable option. Finally, weighing the results by adopting 60%/40% in favor of the economic criterion, indicated a slight preference for the aluminum frame.

In conclusion, the results obtained are in line with those obtained by the authors applying, in previous work, a methodology based on the composite economic–environmental indicator for the global cost calculation. In this regard, given the aim posed in the present work, the proposed simplified methodology seems to be capable of producing reliable results for selecting alternative solutions in a SPP tender evaluation process.

Starting from the results of this work, and considering the limitations evidenced in Section 6, future research developments can be addressed. Firstly, a future research step will develop the application of the methodology to a more extended list of technological options. Secondly, a wider project scale will be considered, shifting from the single component scale up to the entire building/infrastructure one, at different design stages and different decision-making contexts. Thirdly, specific steps, such as the monetization of the CO2 emissions, or the inclusion of LCA results into the analysis, could be deepened by involving sectoral competencies in a multidisciplinary perspective. Thus, the present work can be considered as a first step for growing the literature on the application of LCC in the presence of externalities as key elements in the environmental–economic sustainability evaluation, and, in the meantime, for giving support to the subjects involved in public procurement processes or in PPP interventions. It represents a potential advancement in public decision-making procurement processes: the joint application of economic and environmental criteria in public interventions is a fundamental advancement in the “modernization” and innovation in procurement processes, and a step forward in the ecological transition from a circular economy perspective.

Author Contributions

This paper is to be attributed in equal parts to the authors. Conceptualization, E.F. and J.-M.T.; data curation, D.G.F.; formal analysis, E.F., D.G.F. and J.-M.T.; investigation, Fregonara, D.G.F. and J.-M.T.; methodology, E.F.; supervision, E.F. and J.-M.T.; writing—original draft, E.F.; writing—review and editing, E.F., D.G.F. and J.-M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

Acknowledgement goes to the anonymous reviewers who have contributed their suggestions to improve the quality of the paper, to the academic editor, and to all MDPI staff for their valuable work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission, Directorate-General for Regional and Urban Policy. Stock-Taking of Administrative Capacity, Systems and Practices across the EU to Ensure the Compliance and Quality of Public Procurement Involving European Structural and Investment (ESI) Funds: Final Report; Publications Office: Luxembourg, 2016. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. Directive 2014/24/EU of the European Parliament and of the Council of 26 February 2014 on Public Procurement and Repealing Directive 2004/18/EC; L 94/65; Official Journal of the European Union: Brussels, Belgium, 2014. [Google Scholar]

- Official Journal of the European Union. Directive 2004/18/EC of the European Parliament and of the Council of 31 March 2004 on the Coordination of Procedures for the Award of Public Works Contracts, Public Supply Contracts and Public Service Contracts; L 134/114; Official Journal of the European Union: Brussels, Belgium, 2004. [Google Scholar]

- European Parliament. Directive 2002/91/EC of the European Parliament and of the Council of 6 December 2002 on the Energy Performance of Buildings. Off. J. Eur. Union 2003, 1, 65–70. [Google Scholar]

- European Parliament. Directive 2010/31/EU of the European Parliament and of Council of 19 May 2010 on the Energy Performance of Buildings (Recast); Official Journal of the European Union: Brussels, Belgium, 2010. [Google Scholar]

- European Parliament. Directive (EU) 2018/844 of the European Parliament and of the Council. Off. J. Eur. Union 2018, 6, 75–91. [Google Scholar]

- European Commission. National Action Plans-GPP-Environment; European Parliament: Brussels, Belgium, 2022. [Google Scholar]

- Fregonara, E. Methodologies for supporting sustainability in energy and buildings. The contribution of Project Economic Evaluation. Energy Procedia 2017, 111, 2–11. [Google Scholar] [CrossRef]

- König, H.; Kohler, N.; Kreissig, J.; Lützkendorf, T. A Life Cycle Approach to Buildings. Principles, Calculations, Design Tools; Detail Green Books: Regensburg, Germany, 2010. [Google Scholar]

- Flanagan, R.; Norman, G. Life Cycle Costing for Construction; Royal Institution of Chartered Surveyors: London, UK, 1983. [Google Scholar]

- Department of Energy (DOE). Life Cycle Cost Handbook Guidance for Life Cycle Cost Estimate and Life Cycle Cost Analysis; Department of Energy (DOE): Washington, DC, USA, 2014. [Google Scholar]

- Rebitzer, G.; Hunkeler, D. Life cycle costing in LCM: Ambitions, opportunities, and limitations. Int. J. Life Cycle Assess. 2003, 8, 253–256. [Google Scholar] [CrossRef]

- Swarr, T.E.; Hunkeler, D.; Klöpffer, W.; Pesonen, H.L.; Ciroth, A.; Brent, A.C.; Pagan, R. Environmental life-cycle costing: A code of practice. Int. J. Life Cycle Assess. 2011, 16, 389–391. [Google Scholar] [CrossRef]

- Thiebat, F. Life Cycle Design; PoliTo Springer Series; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Fregonara, E.; Giordano, R.; Ferrando, D.G.; Pattono, S. Economic-Environmental Indicators to Support Investment Decisions: A Focus on the Buildings’ End-of-Life Stage. Buildings 2017, 7, 65. [Google Scholar] [CrossRef]

- Fregonara, E.; Pattono, S. A sustainability indicator for building projects in presence of risk/uncertainty over time: A research experience. Aestimum 2018, 73, 173–205. [Google Scholar]

- Huntziger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 7. [Google Scholar]

- Nguyen, L.; Moseson, A.J.; Farnam, Y.; Spatari, S. Effects of composition and transportation logistics on environmental, energy and cost metrics for the production of alternative cementitious binders. J. Clean. Prod. 2018, 185, 628–645. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Damgaard, A.; Comans, R.N.J. Life cycle assessment of the reuse of fly ash from biomass combustion as secondary cementitious material in cement products. J. Clean. Prod. 2020, 245, 118937. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Rizwan, S.A.R.; Memon, S.A.; Tulliani, J.-M.; Ferro, G.A. Experimental Investigation on Use of Wheat Straw Ash and Bentonite in Self-Compacting Cementitious System. Adv. Mater. Sci. Eng. 2014, 2014, 832508. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Li, C.; Monteiro, P.J.M. Eco-friendly mortar with high-volume diatomite and fly ash: Performance and life-cycle assessment with regional variability. J. Clean. Prod. 2020, 261, 121224. [Google Scholar] [CrossRef]

- Caneda-Martínez, L.; Monasterio, M.; Moreno-Juez, J.; Martínez-Ramírez, S.; García, R.; Frías, M. Behaviour and properties of eco-cement pastes elaborated with recycled concrete powder from construction and demolition wastes. Materials 2021, 14, 1299. [Google Scholar] [CrossRef]

- Gupta, S.; Tulliani, J.-M.; Kua, H.W. Carbonaceous admixtures in cementitious building materials: Effect of particle size blending on rheology, packing, early age properties and processing energy demand. Sci. Total Environ. 2022, 807, 17. [Google Scholar] [CrossRef] [PubMed]

- ISO 15686:2008; Buildings and Constructed Assets—Service-Life Planning—Part 5: Life Cycle Costing; ISO/TC 59/CS 14. International Organization for Standardization: Geneva, Switzerland, 2008.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework; ISO/TC 207. International Organization for Standardization: Geneva, Switzerland, 2006.

- Standard EN ISO 15459-1:2017; Energy Performance of Buildings—Economic Evaluation Procedure for Energy Systems in Buildings. European Committee for Standardization: Brussels, Belgium, 2017.

- Standard EN ISO 15643-2:2011; Sustainability of Construction Works—Assessment of Buildings—Part 2: Framework for the Assessment of Environmental Performance. European Committee for Standardization: Brussels, Belgium, 2011.

- European Parliament. Guidelines Accompanying Commission Delegated Regulation (EU) No 244/2012 of 16 January 2012 Supplementing Directive 2010/31/EU; European Parliament: Brussels, Belgium, 2012. [Google Scholar]

- Barreca, A.; Fregonara, E.; Rolando, D. EPC Labels and Building Features: Spatial Implications over Housing Prices. Sustainability 2021, 13, 5. [Google Scholar] [CrossRef]

- European Commission. A Renovation Wave for Europe—Greening our Buildings, Creating Jobs, Improving Lives; Communication from the European Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, Eds.; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. A European Green Deal. Striving to be the First Climate-Neutral Continent; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Fregonara, E.; Rubino, I. Buildings’ energy performance, green attributes and real estate prices: Methodological perspectives from the European literature. Aestimum 2021, 79, 43–73. [Google Scholar] [CrossRef]

- Official Journal of the European Union. Directive 2014/23/EU of the European Parliament and of the Council of 26 February 2014 on the Award of Concession Contracts; Official Journal of the European Union: Brussels, Belgium, 2014. [Google Scholar]

- Official Journal of the European Union. Directive 2014/25/EU of the European Parliament and of the Council of 26 February 2014 on Procurement by Entities Operating in the Water, Energy, Transport and Postal Services Sectors and Repealing Directive 2004/17/EC; Official Journal of the European Union: Brussels, Belgium, 2014. [Google Scholar]

- Rebaudengo, M.; Manzone, F.; Prizzon, F.; Caldera, C. Environmental quantity survey for buildings GPP requirements. In Proceedings of the 17th International Multidisciplinary Scientific GeoConference SGEM, Vienna, Austria, 27–29 November 2017. [Google Scholar]

- Curto, R.; Brigato, M.V.; Coscia, C.; Fregonara, E. Assessing strategies for developing sustainable tourism in the Iglesias area, Sardinia. Territorio 2014, 69, 123–133. [Google Scholar]

- Testa, F.; Annuziata, E.; Iraldo, F.; Frey, M. Drawbacks and opportunities of green public procurement: An effective tool for sustainable production. J. Clean. Prod. 2014, 112, 1893–1900. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, Z.; Long, Z. Significant barriers to green procurement in real estate development. Resour. Conserv. Recycl. 2017, 116, 160–168. [Google Scholar] [CrossRef]

- Fuerst, F.; Oikarinen, E.; Harjunen, O. Green signalling effects in the market for energy-efficient residential buildings. Appl. Energy 2016, 180, 560–571. [Google Scholar] [CrossRef]

- Aydin, E.; Correa, S.B.; Brounen, D. Energy performance certification and time on the market. J. Environ. Econ. Manag. 2019, 98, 102270. [Google Scholar] [CrossRef]

- Kamal, A.; Al-Ghamdi, S.G.; Koc, M. Revaluing the costs and benefits of energy efficiency: A systematic review. Energy Res. Soc. Sci. 2019, 54, 68–84. [Google Scholar] [CrossRef]

- Taltavull de La Paz, P.; Perez-Sanchez, V.; Mora-Garcia, R.-T.; Perez-Sanchez, J.-C. Green Premium Evidence from Climatic Areas: A Case in Southern Europe, Alicante (Spain). Sustainability 2019, 11, 686. [Google Scholar] [CrossRef]

- Brounen, D.; Groh, A.M.; Haran, M. The value effects of green retrofits. J. Eur. Real Estate Res. 2020, 13, 301–319. [Google Scholar] [CrossRef]

- Marmolejo-Duarte, C.; García-Hooghuis, A.; Masià, A.G. How much and why are we willing to pay for energy-efficient homes? A stated preferences analysis in Barcelona. Archit. City Environ. 2020, 14, 9215. [Google Scholar] [CrossRef]

- Wilkinson, S.J.; Sayce, S. Decarbonising real estate: The evolving relationship between energy efficiency and housing in Europe. J. Eur. Real Estate Res. 2020, 13, 387–408. [Google Scholar] [CrossRef]

- Pommeranz, C.; Steininger, B.I. What Drives the Premium for Energy-Efficient Apartments—Green Awareness or Purchasing Power? J. Real Estate Financ. Econ. 2021, 62, 220–241. [Google Scholar] [CrossRef]

- De Giacomo, M.R.; Testa, F.; Iraldo, F.; Formentini, M. Does Green Public Procurement lead to Life Cycle Costing (LCC) adoption? J. Purch. Supply Manag. 2019, 25, 100500. [Google Scholar] [CrossRef]

- Life Cycle Costing (LCC) as a Contribution to Sustainable Construction. Guidance on the Use of the LCC Methodology and Its Application in Public Procurement. Davis Langdon Management Consulting, Final Guidance. 2007. Available online: https://www.google.it/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwi9y7b395X6AhWnLEQIHfpVBWwQFnoECAYQAQ&url=http%3A%2F%2Fwww.brita-in-pubs.eu%2Ftoolbox%2FLCC_files%2FLCC-methodology%2520Rev1%25205-3-07%2520(2).pdf&usg=AOvVaw2FhUDrHbPoouoOlAA1HEmU (accessed on 29 June 2022).

- Gustafsson, M.; Di Pasquale, C.; Pioppi, S.; Bellini, A.; Fedrizzi, R.; Bales, C.; Ochs, F.; Siè, M.; Holmberg, S. Economic and environmental analysis of energy renovation packages for European office buildings. Energy Build. 2017, 148, 155–165. [Google Scholar] [CrossRef]

- Rodrigues, C.; Freire, F. Building retrofit addressing occupancy: An integrated cost and environmental life-cycle analysis. Energy Build. 2017, 140, 388–398. [Google Scholar] [CrossRef]

- Rodrigues, C.; Freire, F. Adaptive reuse of buildings: Eco-efficiency assessment of retrofit strategies for alternative uses of an historic building. J. Clean. Prod. 2017, 157, 94–105. [Google Scholar] [CrossRef]

- Moschetti, R.; Brattebø, H. Combining Life Cycle Environmental and Economic Assessments in Building Energy Renovation Projects. Energies 2017, 10, 1851. [Google Scholar] [CrossRef]

- Silvestre, J.D.; Castelo, A.; Silva, J.; De Brito, J.L.; Pinheiro, M.D. Energy Retrofitting of a Buildings’ Envelope: Assessment of the Environmental, Economic and Energy (3E) Performance of a Cork-Based Thermal Insulating Rendering Mortar. Energies 2019, 13, 143. [Google Scholar] [CrossRef]

- Colli, C.; Bataille, A.; Antczak, E. Investigating eco-efficiency procedure to compare refurbishment scenarios with different insulating materials. Procedia CIRP 2020, 90, 322–327. [Google Scholar] [CrossRef]

- Galimshina, A.; Moustapha, M.; Hollberg, A.; Padey, P.; Lasvaux, S.; Sudret, B.; Habert, G. Statistical method to identify robust building renovation choices for environmental and economic performance. Build. Environ. 2020, 183, 107143. [Google Scholar] [CrossRef]

- Adell, A.; Seebach, D.; Moller, M. Smart SPP. Innovation through sustainable procurement. LCC-CO2 tool user guide. Visual guide to using the life cycle costing and CO2 assessment tool (LCC-CO2 tool). The Smart SPP Consortium. 2011. Available online: https://www.smart-spp.eu/fileadmin/template/projects/smart_spp/files/Guidance/Final_versions/EN_SMART_SPP_Tool_User_Guide_2011_FINAL.pdf (accessed on 29 June 2022).

- European Commission. Buying Green! A Handbook on Green Public Procurement; Publication Office of the European Union: Luxembourg, 2016. [Google Scholar]

- Fregonara, E.; Curto, R.; Grosso, M.; Mellano, P.; Rolando, D.; Tulliani, J.M. Environmental Technology, Materials Science, Architectural Design, and Real Estate Market Evaluation: A Multidisciplinary Approach for Energy-Efficient Buildings. J. Urban Technol. 2013, 20, 57–80. [Google Scholar] [CrossRef]

- Fregonara, E.; Giordano, R.; Rolando, D.; Tulliani, J.M. Integrating Environmental and Economic Sustainability in New Building Construction and Retrofits. J. Urban Technol. 2016, 23, 3–28. [Google Scholar] [CrossRef]

- Flanagan, R.; Kendell, A.; Norman, G.; Robinson, G.D. Life cycle costing and risk management. Constr. Manag. Econ. 1987, 5, 53–71. [Google Scholar] [CrossRef]

- Boussabaine, A.; Kirkham, R. Whole Life-Cycle Costing: Risk and Risk Responses; Blackwell Publising: Oxford, UK, 2004; pp. 56–83, 142–162. [Google Scholar]

- Oduyemi, O.; Okoroh, M.; Fajana, O.S. Risk assessment methods for life cycle costing in buildings. Sustain. Build. 2016, 1, 9–18. [Google Scholar] [CrossRef]

- Bourke, K.; Davies, H. Factors Affecting Service Life Predictions of Buildings: A Discussion Paper; Laboratory Report—Building Research Establishment; Garston: Watford, UK, 1997. [Google Scholar]

- Fregonara, E.; Ferrando, D.G. How to Model Uncertain Service Life and Durability of Components in Life Cycle Cost Analysis Applications? Stoch. Approach Factor Method Sustain. 2018, 10, 3642. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).