Abstract

Vinasse is a toxic pollutant if it is poured into the ecosystem indiscriminately; despite this, it integrates components that make it valuable in nutrients and water. However, its use has been questioned due to the costs involved in its purification. This systematic review focuses on the valorization of vinasse from the studies performed for its post-industrial use. Trends in vinasse management and bioproduct development were analyzed. The PRISMA statement was used as a formal guide for collecting and analyzing 131 studies from 2018 to 2022. We determined that biological processes are the most used to obtain the benefits of vinasse, obtaining up to three post-industrial bioproducts. While it is true that there is a predominant trend of studies focused on the generation of biofuels, it must be noted that the beginning of the sucro-alcohol chain was the agricultural field. In this sense, we determine that 14% of the studies treat vinasse for agricultural reuse purposes, so, under Circular Economy principles, the reincorporation of vinasse into the agricultural field to take advantage of its goodness in nutrients and minerals as a sustainable and eco-efficient alternative should be a research trend that accelerates the consumption of vinasse generated in alcohol distilleries.

1. Introduction

In Mexico and the world, the sugar industry is one of several industries with high energy consumption, discharges of effluents at high temperature with a high content of organic matter, and generation of co-products with value for agro-industries, such as agricultural crop residue, bagasse, molasses, cachaça, and vinasse.

The cultivation of sugarcane in Mexico as a perennial crop occupies the first place with 84.51% of tons cultivated with a cultivation area of at least 34.30% ha higher than all perennial crops in Mexico [1]. Globally, as of 2020, Mexico ranks seventh as a producer of cane sugar with 53,952,698 tons; this is 2.73% of world sugar production [2].

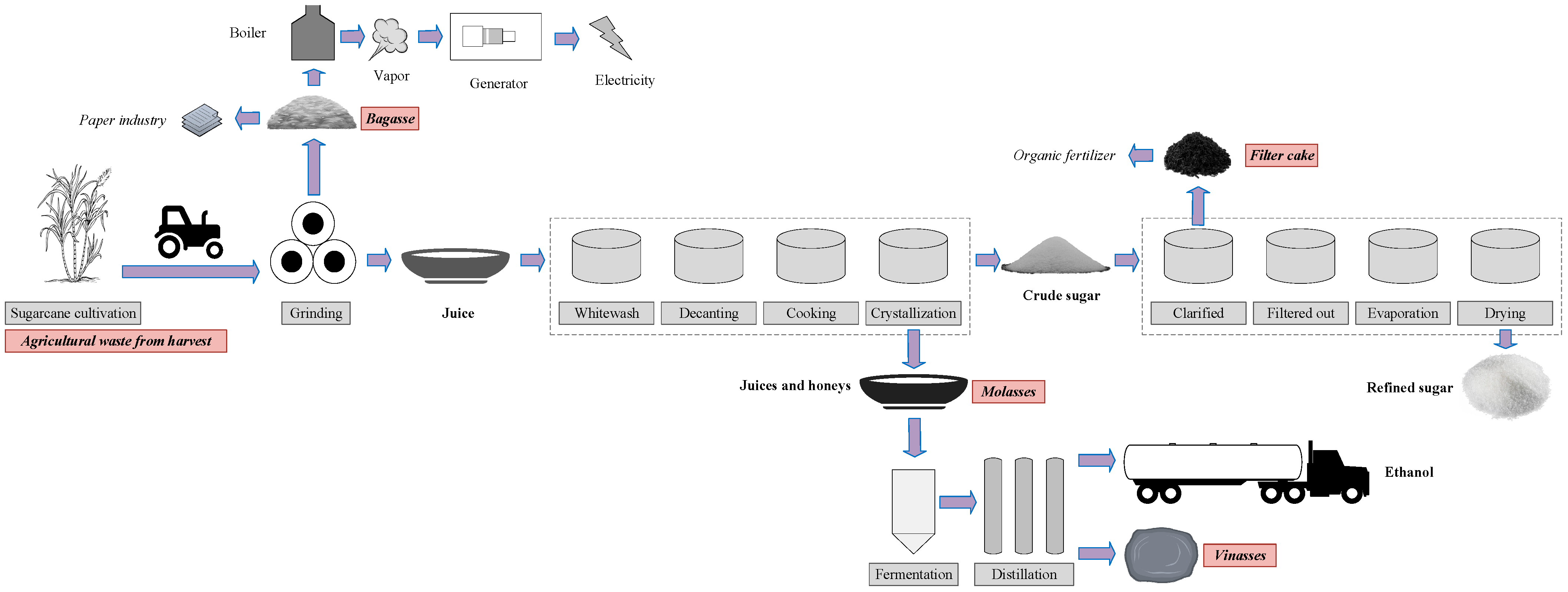

The basic process of making sugar begins with the cultivation of sugar cane, which is harvested and transported to the sugar mill to extract the juice. The juice of the cane is treated and conducted to a process of concentration by evaporation. The sugar cane juice converted into molasses with a high sucrose content leads to a crystallization process in which the crystallized sugar is obtained. Conversely, what fails to crystallize continues as crystallizable honey, known as molasses. Crystallized sugar follows the drying process until it is packaged, while molasses is stored for disposal by a food chain. Here, a vertical industry associated with the sugar industry is the alcohol industry, in which it is customary to observe that alcohol facilities are installed near the sugar mill to consume molasses in large volumes and obtain ethanol from it.

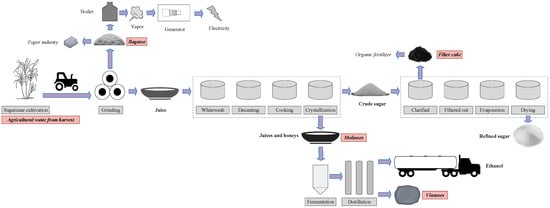

In Mexico, the sucro-alcohol industry produces 96° GL alcohol [3]. The process to obtain this product uses sugar molasses, fermented and conducted to a distillation process from which the alcohols are obtained in the distillation column, while, in the last distiller, vinasse is obtained as a distillation residue (see Figure 1).

Figure 1.

Value chain of the sucro-alcohol industry.

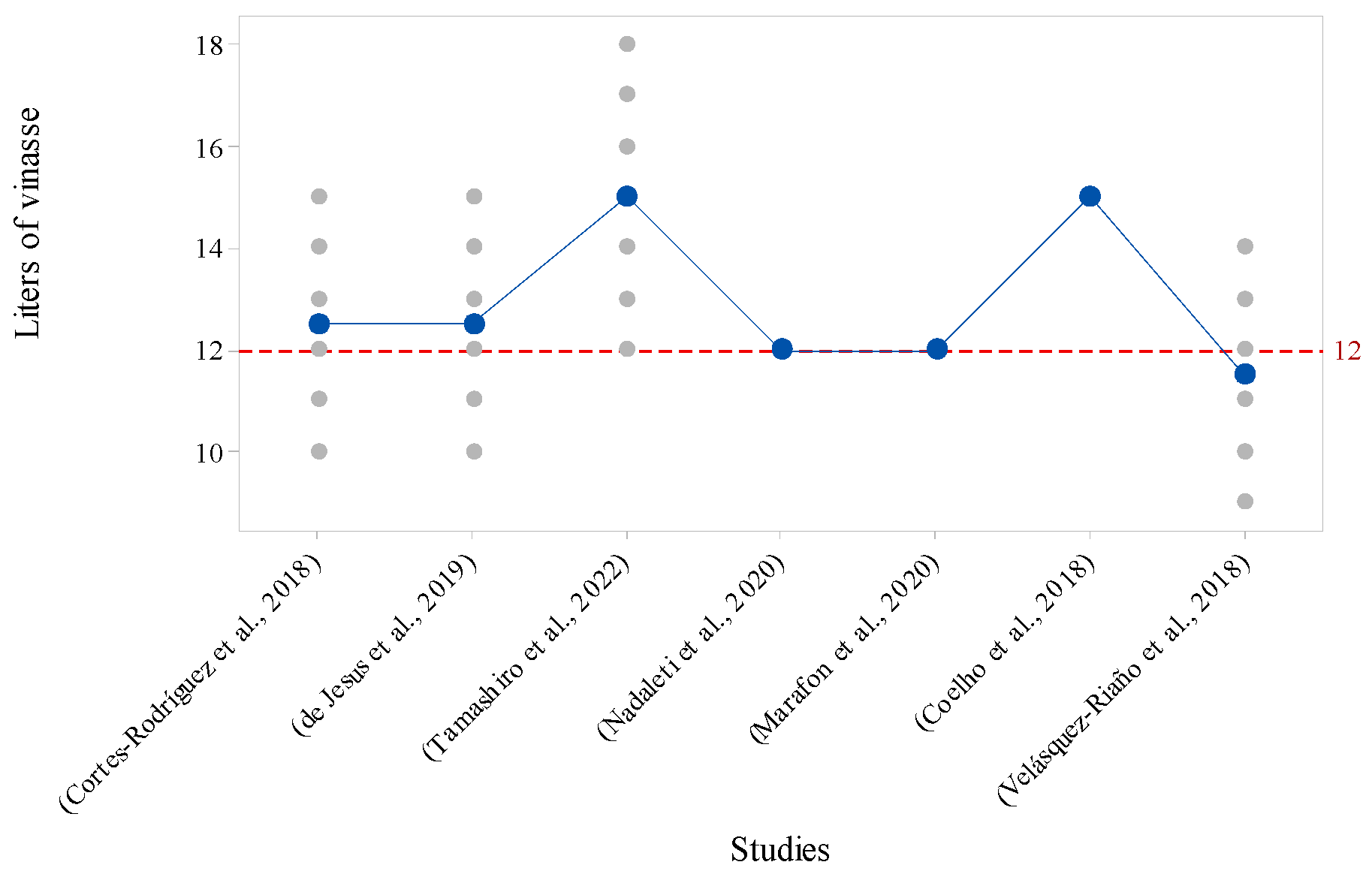

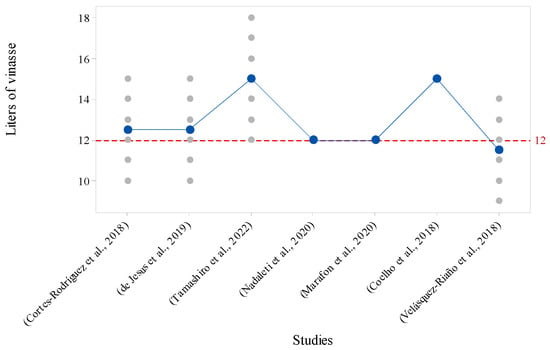

Ethanol vinasse from sugar cane is the organic liquid residue generated as a co-product of production at the end of distillation [4,5,6,7], having a dark brown and unpleasant odor [8] with high organic matter content. Where the chemical oxygen demand (COD) is >100,000 mg/L and the biological oxygen demand (BOD5) is 31,250 mg/L [9], it can cause negative environmental impacts if it is improperly disposed of [10]. Vinasse is a valuable organic residue in nutrients and water [7], containing macronutrients (N, P, K) [5]. However, the incorporation of vinasse excessively into the soil modifies the pH and conductivity, causing toxicity to the environment where it is poured [11], approximately 100 times more than domestic wastewater [8]. It is estimated that for each liter of ethanol, 10 to 15 L of vinasse are produced [5,12], from 12 to 18 L [13], about 12 L [14,15]; 15 L [16], or from 9 to 14 L [17], depending on the use or not of a recirculation process in the distillery, the richness of sugars in molasses, the quality of the fermented must, and the operating conditions in the distillation columns, among other factors. Of these studies, 85.71% consider within their estimate that 12 L are generated from vinasse for each liter of ethanol (see Figure 2).

Figure 2.

Liters of co-produced vinasse for each liter of distilled ethanol [5,12,13,14,15,16,17].

Worldwide, a production of 22.4 gigaliters of vinasse is estimated [18]; while, in Mexico, during the 2020–2021 harvest, 15,530,667 L of alcohol were produced from sugar cane from the 49 mills included in the 7 regions considering the milling of 49,144,354 tons arranged in 789,996 ha [3]. From these figures, the generation of vinasses can be estimated to be at least from 139,776,003 to 279,552,006 L during the 2020–2021 harvest. This volume of vinasse only in Mexico is an environmental problem in the absence of environmentally friendly integral management.

From their properties, the valorization of the waste of agricultural residue of the harvest, bagasse, molasses, and cachaça has allowed them to be easily used as raw material. However, this does not happen with vinasse, of which the management is complex given its characteristics; being the frequent practice used in Mexico, its indiscriminate discharge into the environment contributes to pollution [19,20]. The literature reports studies that have focused on enhancing the components of vinasse for the development of value-added products that can be beneficial within the same sucro-alcohol logistics chain from raw vinasse through physical, chemical, biological, or combined processes. However, relatively little is known about the contributions to the development of these products, the technologies used, and the application of vinasse as a strengthener of agricultural soils.

This article synthesizes the literature from 2018 to 2022, seeking to fill this information gap. It is not the scope of this review to discuss the results reported by the authors, and only the applications, technologies, and sectors interested in the benefits of vinasse from this study period are reported. Finally, this article contributes to synthesizing the research of the development of high-impact products that have incorporated vinasse as a waste management strategy and its revaluation for the development of high added-value products that seek to establish simple and friendly technology capable of processing the vinasse that is generated from the production of ethanol. This review’s findings will guide research for developing high-impact projects incorporating vinasse.

The document is structured as follows: Section 2: Describes the approach used for the search, selection, and analysis of the contributions of vinasse; Section 3: Presents the findings found in the studies according to their characteristics; Section 4: Discusses the findings based on the generation of high-value-added products according to the technologies used in the sectors interested in the components of vinasse while minimizing the negative impact on the ecosystem; finally, Section 5: Conclusions and lines of research are presented that must be addressed for adequate management of vinasse.

2. Materials and Methods

The literature review was supported by the Systematic Review of the Literature [21], which was recorded in osf.io/znuwt (accessed on 20 June 2022) [22]. Study eligibility was supported by the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) statement [23]. The PICO framework (population, intervention, comparator, outcome) [24] was used to evaluate the effects of the interventions and thus establish the comparisons that were made; simultaneously, it was used to structure the report of the eligibility criteria. The search boolean operators were “vinasse” AND “ethanol” OR “alcohol” AND “sugarcane”. This literature review was conducted in the Elsevier, SpringerLink, and Google Scholar databases for the feasibility of search and easy access, by allowing for tracking enriching studies from various sources for the last 5 years (January 2018 to February 2022) to collect studies of trends that involve the use of vinasse. This period of the analysis is considered since it is intended in the scope of the study: to identify in a clear and precise manner the current behavior in the implementation of contemporary technologies in the development of bioproducts from the vinasse. Papers were reviewed individually and discriminated against those studies that did not originate from peer reviews. The databases were consulted during March 2022, as follows: On 18 March, we searched Elsevier [25] by A.M.-R., and G.F.-L.; On 23 March, we searched SpringerLink [26] for A.M.-R., and N.M.-R.; On 28 March, Google Scholar was searched [27] by A.M.-R., and L.E.G.-S.

The literature review included works where vinasse is (a) treated for incorporation into the ecosystem and (b) when vinasse is used as an input to add value to processes and-or products in addition to those articles with the objective of the co-generation of products, without being limited to a single product or process. However, the analysis of technical or economic scenarios was excluded from this review. This literature review included studies that report results on the treatment of vinasse by physical, chemical, biological, or combined processes as an alternative to make processes or products more efficient, in addition to studies that seek to minimize the negative environmental impact of vinasse when incorporated into the environment without treatment. Studies in which the results indicated the harmful effects of vinasse on flora and fauna were excluded from the review. We did not consider revision studies and papers not written in the English language. All papers were considered without discriminating between discipline and subdiscipline.

A selection of articles was made considering the relevance of the results to the purpose of this research. For this, three researchers (A.M.-R., N.M.-R., and L.E.G.-S) performed an independent review and screening, reviewing titles and abstracts and eliminating those that did not meet the inclusion criteria; meanwhile, those which met the inclusion criteria were considered for the review. In addition, two researchers resolved the discrepancies for documents wherein ambiguity was presented for inclusion and exclusion, depending on the title and abstract (H.B.-S., and L.C.S.-H.). The articles were organized in the Mendeley Reference Manager 2.72.0, while a knowledge management matrix was developed in Microsoft® Excel® for Microsoft 365 MSO (16.0.12827.20236) 64-bit with license ID: EWW_484c267c-a191-4910-b9ca-47fc8b8ebf17_9be68bd11ffa2e4add, and session ID: 72DEB1D3-512F-4125-B423-BA3D9C055B60. Finally, the selected documents were concentrated according to the following data: author, title, country, year, bioproduct 1, bioproduct 2, bioproduct 3, technology, process, and industry. The extraction of the information was performed independently by four researchers (A.M.-R., N.M.-R., G.F.-L., and L.E.G.-S.) with a double verification, and the supervision was performed by two researchers (H.B.-S., and L.C.S.-H.).

3. Results

This section describes the main findings of the studies reviewed. The first instance demonstrates the process of searching and selecting the studies. Subsequently, the characteristics of each study are synthesized. The challenges of the revised works are defined.

3.1. Search

Table 1 summarizes the parameters of the search strategy used for screening the studies that are part of the review.

Table 1.

Search strategies.

The parameters considered involve: search period, databases and repositories, search terms, document type, discipline, subdiscipline, language, country, type of review, and selection process. These parameters were defined in common agreement by the authors.

3.2. Eligibility

The works’ inclusion or exclusion was determined per the PICO strategy (see Table 2). The adequate definition of the criteria strengthened the screening process of the works considered within the review.

Table 2.

Eligibility criteria.

3.3. Selection of Studies

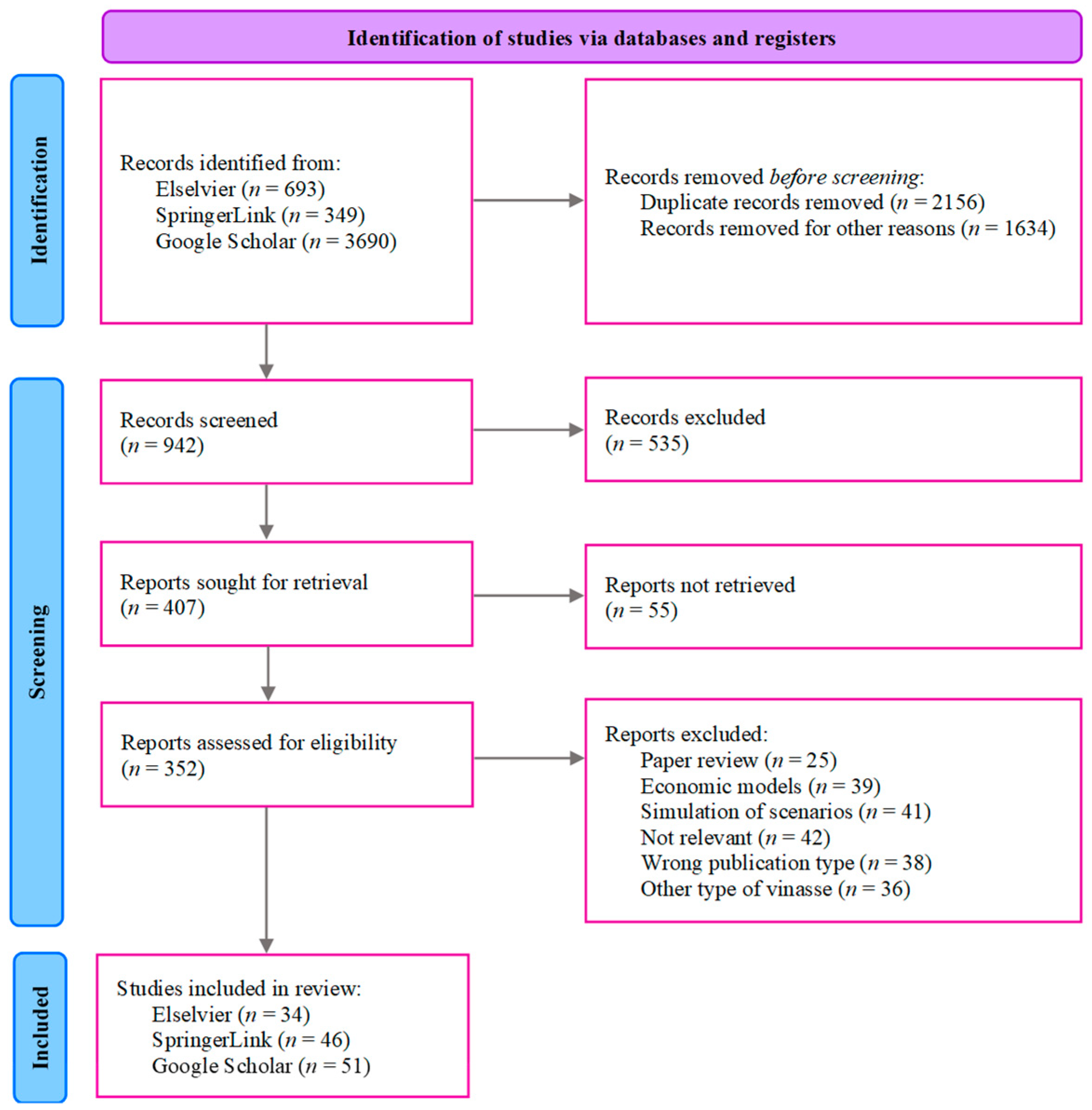

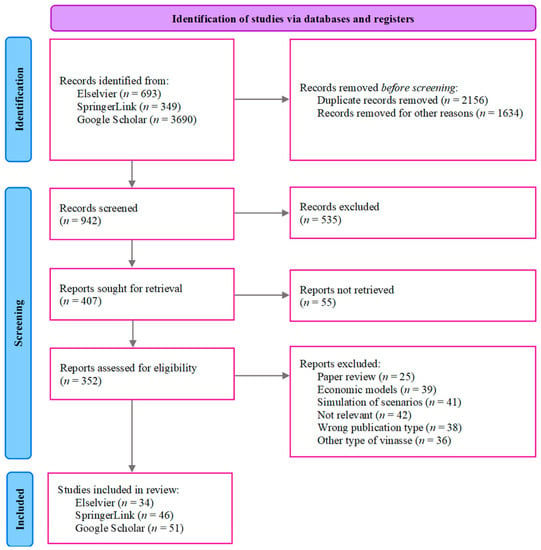

Once the search strategies and eligibility criteria are defined and following the PRISMA methodology, Figure 3 presents the flowchart of the studies reviewed.

Figure 3.

PRISMA flowchart of the screening process.

We identified 4732 articles: Elsevier 693, SpringerLink 349, and Google Scholar 3690. Of these articles, 131 presented relevance for systematic review and meta-analysis: Elsevier 34, SpringerLink 46, and Google Scholar 51. We excluded 2156 for duplicity and 1634 studies for lack of relevance. While 535 records were excluded as they were not related to the object of study, in addition to 55 articles could not be retrieved from their web links. Finally, we excluded review articles, papers that addressed economic models based on evaluating possible cases, and simulation studies of scenarios to establish production policies. We also excluded non-relevant works, publications that did not clearly define the origin of the type of vinasse used in the study, and studies that considered other types of vinasse—e.g., corn, agave, beets, straw—; in this sense, 221 works were not considered.

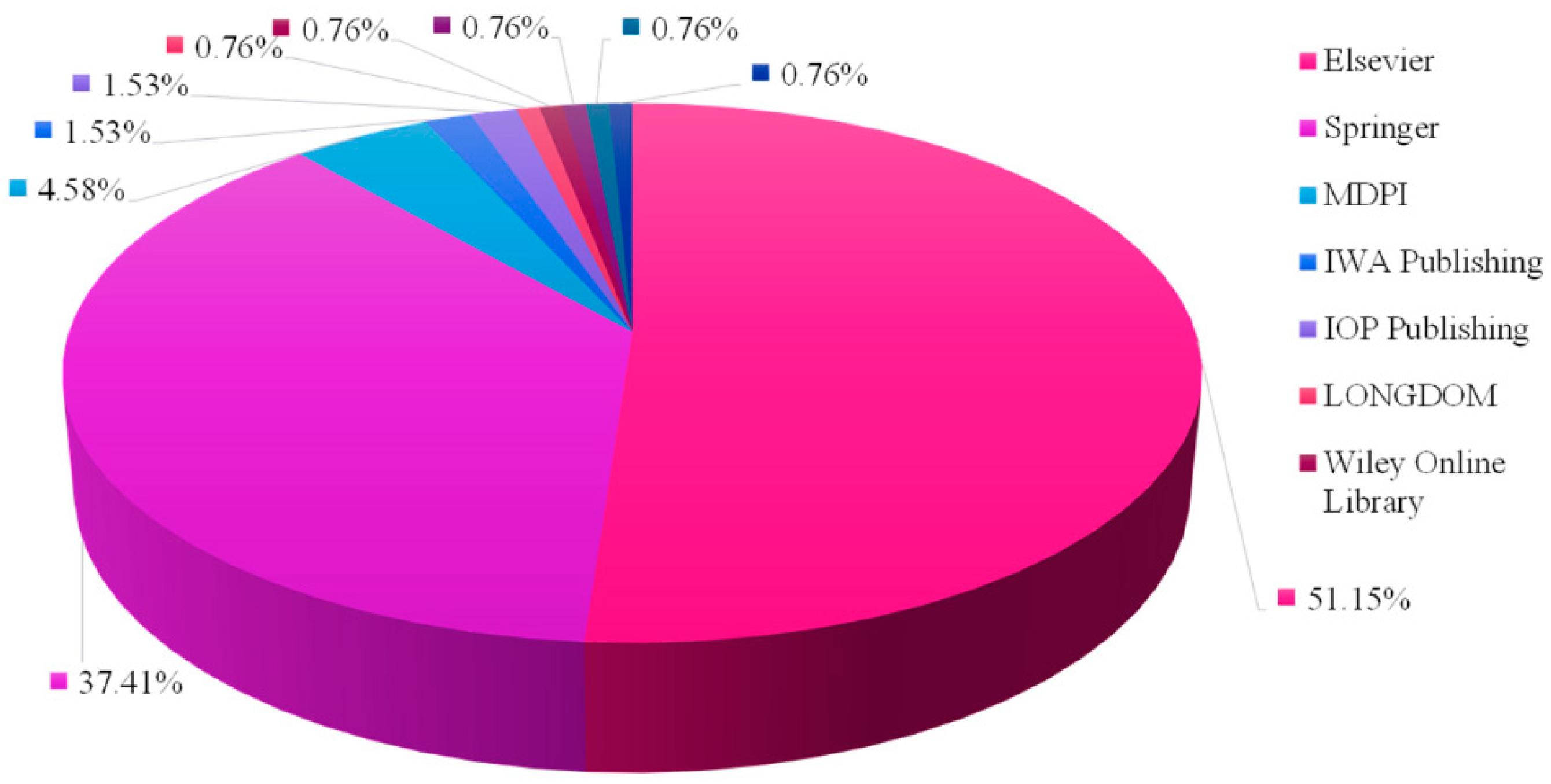

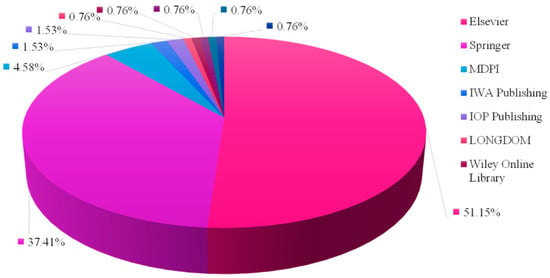

Of the 131 studies, we identified the publishers in which the most significant number of contributions are grouped, Elsevier being predominant, followed by Springer and MDPI (see Figure 4).

Figure 4.

Contributions by publisher.

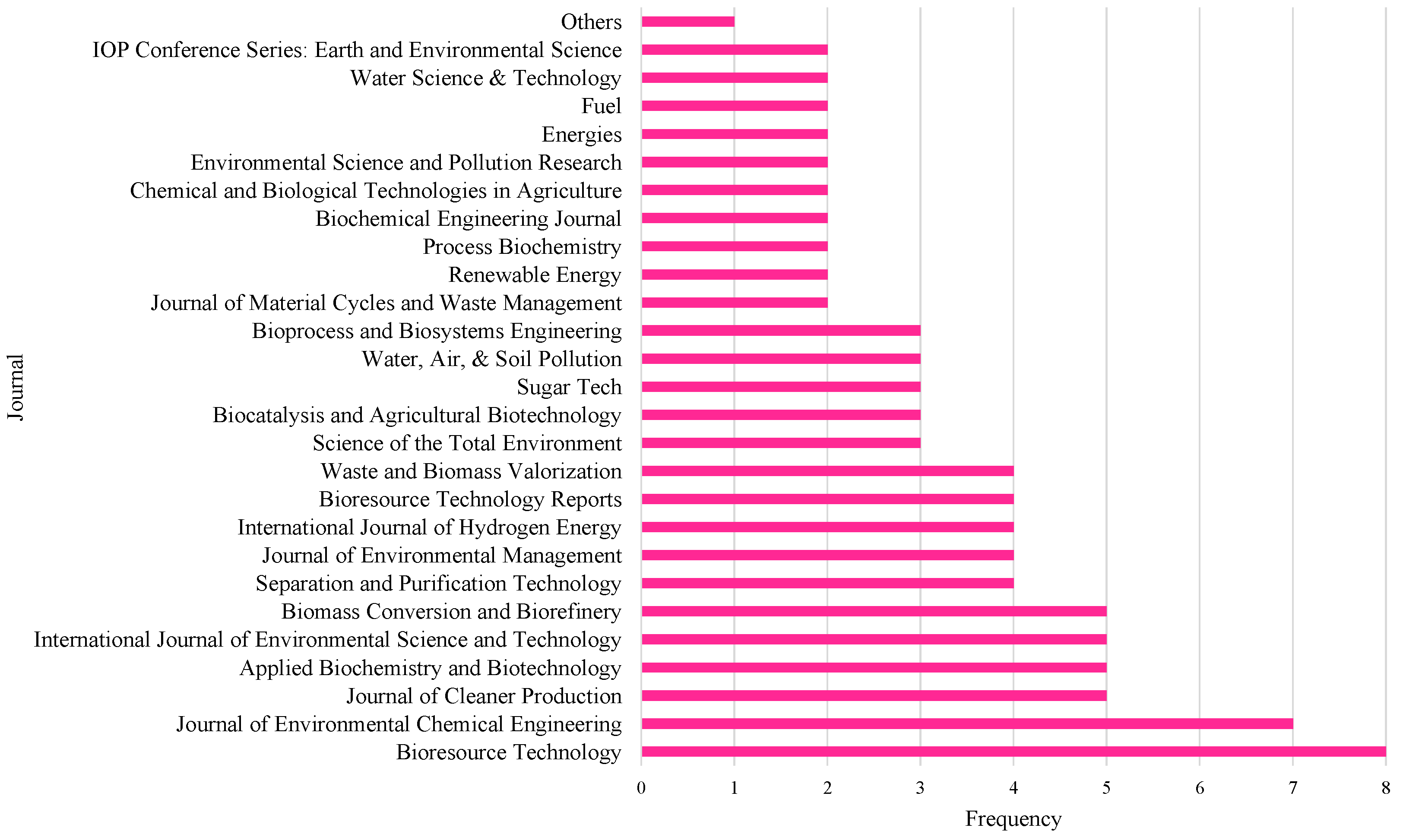

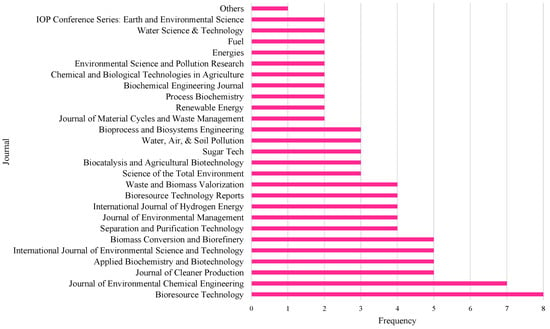

Figure 5 presents the frequency of contributions per journal, with the journal Bioresource Technology of the Elsevier publishing house being the journal with the highest identified contributions. With this, it is possible to cover the search heterogeneously in the different journals available.

Figure 5.

Contributions by journal.

3.4. Study Characteristics

This section describes and analyzes the features of the studies that allow for identifying the applications, the technologies used, and the sectors interested in the benefits of sugarcane ethanol vinasse. The knowledge management base consisted of author, title, country, year, bioproduct 1, bioproduct 2, bioproduct 3, technology, process, and industry.

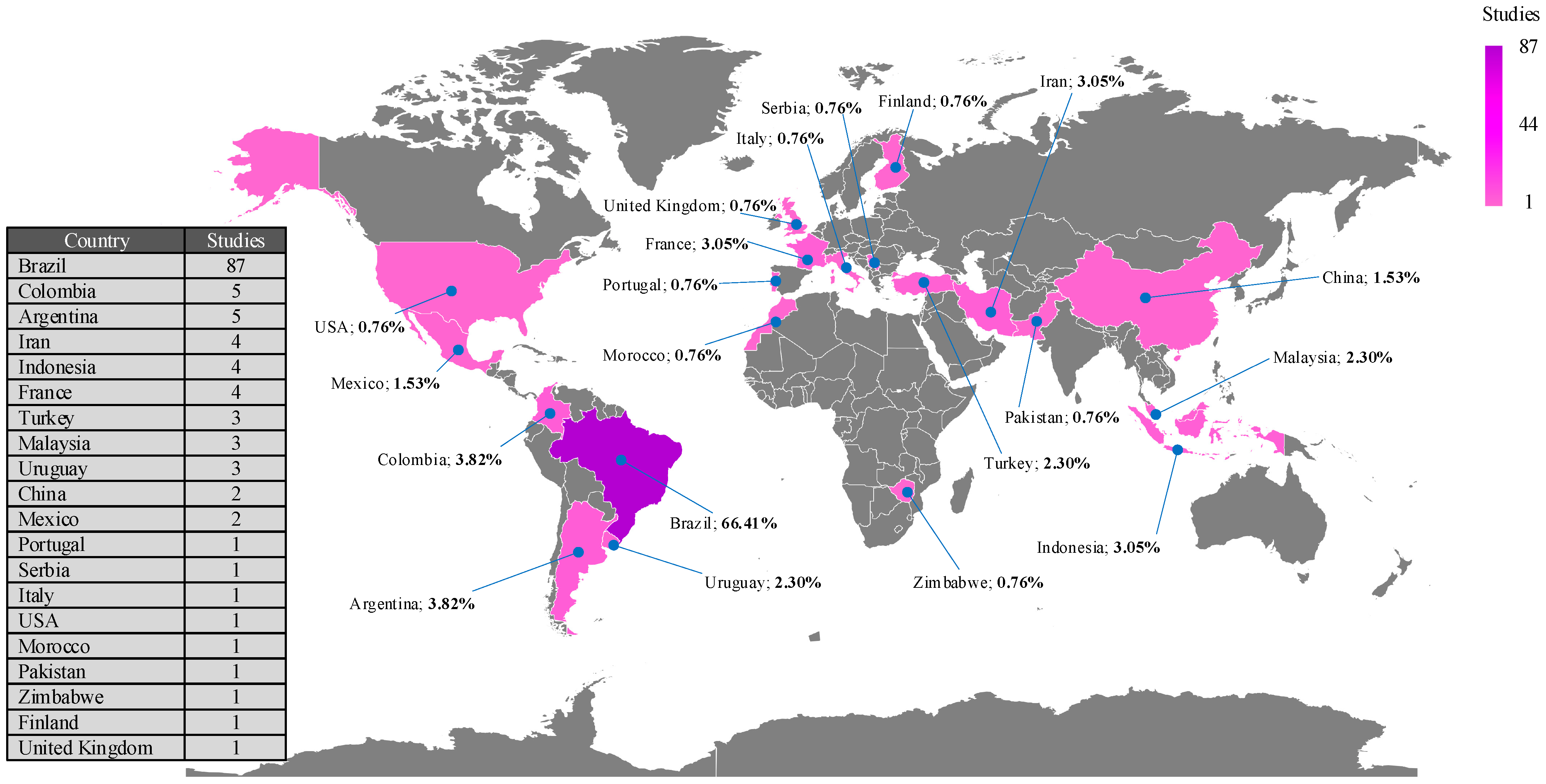

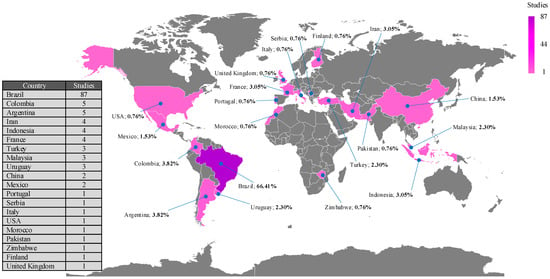

3.4.1. Geographical Distribution of Studies

Figure 6 portrays the 131 studies around the world where vinasse has been valued and their distribution. 78.63% corresponds to America, Asia with 12.98% of studies, Europe contributes 6.87%, and 1.52% corresponds to Africa. The leadership of studies related to vinasse is Brazil with 66.41%; followed by Colombia and Argentina with 3.82%; Iran, Indonesia, and France contribute 3.05%; while Turkey, Malaysia, and Uruguay each contribute 2.30%; with China and Mexico contributing 1.53% independently; finally, Portugal, Serbia, Italy, USA, Morocco, Pakistan, Zimbabwe, Finland and the United Kingdom each contribute 0.76%.

Figure 6.

Distribution of studies around the world.

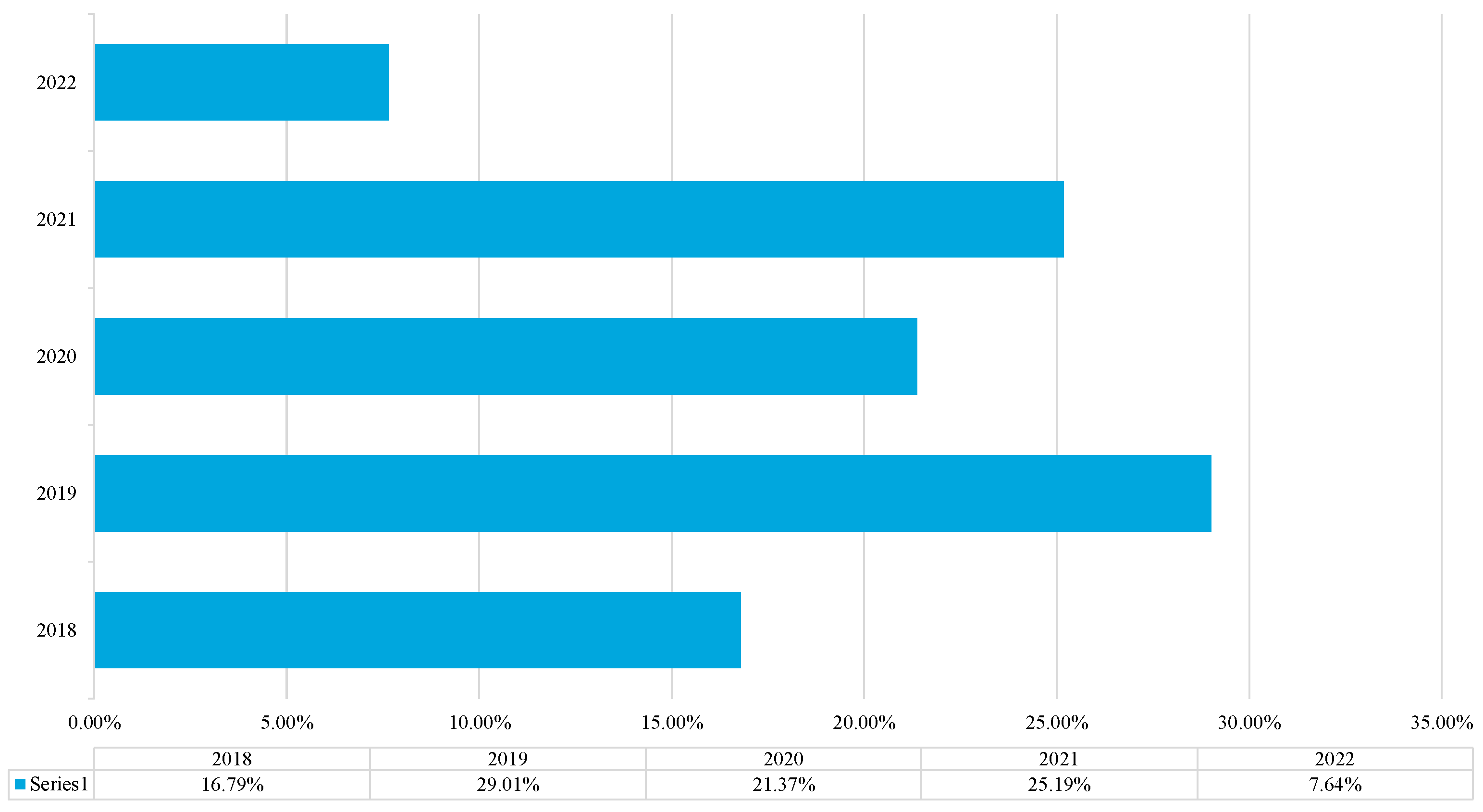

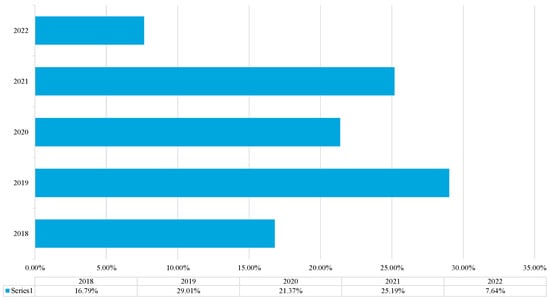

3.4.2. Distribution of Studies over the Search Period

The 131 studies retrieved during the review period are distributed as follows: 22 during 2018, 38 in 2019, 28 for 2020, 33 during 2021, and finally, 10 studies in 2022 (Figure 7).

Figure 7.

Distribution of studies during the analysis period.

3.4.3. Scope of Studies

In 2018 we collected 22 studies: Queiroga et al. [28] used asymmetric tubular membranes —prepared through the joint use of barbotine casting and immersion coating techniques— for the treatment of sugarcane vinasse. This treatment allowed us to decrease color, turbidity, and COD after permeation. In Velásquez-Riaño et al. [17], the researchers performed a mixed treatment with Komagataeibacter kakiaceti GM5 and Trametes Versicolor DSM 3086 to degrade and reduce the toxicity of vinasse; the results proved to be an innovative biological alternative. In [29], the treatment and application of vinasse in the food industry as a waste management approach to biotechnological production and the production of single-celled proteins (SCP) is analyzed.

In da Silva et al. [30], the authors propose the evaluation of the kinetic parameters of the first step of mass loss by thermal decomposition of organic matter present in bagasse, cachaça, and vinasse samples from two sugarcane mills by thermogravimetric pyrolysis under combustion conditions.

Whereas in [31], the authors perform a mixed culture from substrates such as glucose and derivatives from the processing of sugar cane (sucrose, molasses, and vinasse) combined with landfill leachate to produce hydrogen. In del Gobbo & Colin [32], the fungal technology applied for vinasse treatment is presented; likewise, the first advances on the potential of an autochthonous fungal strain (strain IV) to degrade sugarcane vinasse are discussed.

In Chuppa-Tostain et al. [33], the authors demonstrate that the fungus Aspergillus niger can grow in sugarcane distillery wastewater to degrade this complex and hostile medium while producing interesting metabolites. In [34], the strategy of biotechnologically important fungi such as yeasts, molds, and white-rot fungi in wastewater mycoremediation is presented.

In Fuess et al. [35], the researchers characterize sugarcane vinasse from a biorefinery to assess the environmental effects of fertigation and estimate biogas’s energy potential. In [36], the treatment of vinasse effluent was investigated in terms of COD reduction and acidity removal using sugarcane bagasse fly ash. An up-flow anaerobic sludge blanket (UASB) reactor was operated on a pilot scale (120 L) to produce biogas by vinasse degradation [37]. In [38], two fungi, Pycnoporus sp. P6 and Trametes sp. T3, discolor vinasse and synthesize lignocellulolytic enzymes in an agar medium. In [39], the technical, economic, and environmental aspects of implementing anaerobic digestion (AD) in two phases―i.e., acidogenic + methanogenic systems―were evaluated in biorefineries based on different strategies for the use of hydrogen-rich biogas (biogas-H2) generated through acidogenesis.

In [40], AD in an expanded granular sludge bed (EGSB) bioreactor is evaluated as a sustainable alternative for the treatment of sugarcane vinasse. In López et al. [41], it was reported that COD was inhibited in high potassium (K) concentrations. In [42], the authors use mesophilic anaerobic co-digestion (AcD) of food residues and vinasse to produce biogas efficiently; for this purpose, they design a pilot plant of two reactors to work them sequentially and semi-continuously.

In Pinto et al. [43], the authors use coffee residues with sugarcane vinasse, co-digested under anaerobic conditions in a pilot plant using mesophilic sludge seeds to produce biohydrogen and biohythane. In Fuess, Ferraz, et al. [44], researchers characterize the microbial structure and dark fermentation (DF) dynamics of vinasse to demonstrate that at higher levels of bioH2 production, they were associated with Thermoanaerobacterium, while lactate-producing bacteria comprised Lactobacillus and Leuconostoc. Within the reactor are stable and unstable bioH2 production periods.

In Ramos & Silva [45], the authors evaluated the co-fermentation of vinasse and cheese whey using two thermophilic Anaerobic Fluidized Bed Reactors (AFBRs) at 55 °C. In Vilar et al. [46], the authors employed Pleurotus Sajor-caju followed by electrochemical oxidation for the degradation of sugarcane vinasse. In Kazak et al. [47], the authors prepare chemically activated carbon from waste from the vinasse process. In [48], three mesophilic microbial consortia―LPBAH1 and LPBAH2, predominant by Oxalobacteraceae and Lactobacillaceae, and LPBAH3 rich in Sporolactobacillaceae―were identified to produce hydrogen and volatile, vinasse-based fatty acids.

In 2019 we identified 38 studies; in [49], it is mentioned that sugarcane vinasse thermophilic AD is a viable option for recovering energy in the form of methane. However, the authors of Prazeres et al. [50] report that vinasse can be decontaminated with precipitation treatment, coagulation-flocculation, and atmospheric carbonation. In Campanhol et al. [51], the researchers produce citric acid by a microbial consortium of Aspergillus niger and Trichoderma reesei in sugarcane bagasse with vinasse, while ethanol serves as an inducer of the metabolic production of this organic acid. Under mesophilic conditions (37 °C), from a kinetic perspective of different sugarcane vinasses, methane production and removal of organic matter is possible [52].

In Santos et al. [53], the authors use vinasse as a substrate and as a culture medium for the growth of Candida utilis CCT 3469 to produce yeast cell biomass. Conversely, Desmodesmus subspicatus immobilized in alginate allows the removal of nutrients—carbon, nitrogen (N), and K—from sugarcane vinasse [12]. Conversely, in Dalsasso et al. [54], the authors use vinasse and sugarcane molasses as a substrate for producing polyhydroxybutyrate.

In Sousa et al. [55], the authors produce methane in an anaerobic sequencing batch biofilm reactor (AnSBBR) sequencing by co-digestion of sugarcane vinasse and cheese whey. In G. A. Silva et al. [56], the authors dehydrate sugarcane vinasse using reverse osmosis (RO), thus generating potassium vinasse. In Vaz et al. [57], the authors used hydrolyzed sugarcane bagasse supplemented with different proportions of industrial sugar and vinasse residues to optimize fermentative ethanol production using two Spathaspora passalidarum yeast strains isolated from decaying wood in the amazon biome.

Vinasse is concentrated and enriched with N, thus used to supply N in sugarcane fields [58]. In Lovato et al. [59], the authors demonstrate the feasibility of using glycerin as a co-substrate in anaerobic vinasse digestion to increase process efficiency and biogas productivity. Whereas in Morais & Bastos [60], the researchers demonstrate that mixotrophic production of phycocyanin by Aphanothece microscopica Nägeli in BG11 medium supplemented with vinasse is possible.

In Ventorino et al. [61], the authors demonstrated that the Azotobacter chroococcum 76A strain could synthesize biopolymers from vinasse. In Lovato, Albanez, et al. [62], the researchers co-digest vinasse and cheese whey at 30 °C in an AnSBBR operated in batch mode and fed by batches to remove organic matter while improving methane production. In Ottoni et al. [63], it is reported that technology based on two-chamber microbial fuel cells operated with variable distance between electrodes and Nafion membrane and specific inoculum concentration is highly promising for treating vinasse.

In dos Reis et al. [64], researchers use vinasse in the production of SCP at the same time as an aerobic biological treatment of vinasse is performed, which allows for reducing COD and BOD. In [65], acidified sugarcane vinasse is a raw material for producing polyhydroxyalkanoates by mixed microbial cultures. In D. R. Santos et al. [66], they use hydrothermal carbonization to transform biomass into hydrocarbon to apply to the soil from a mixture of bagasse and vinasse.

In [67], the coupling of ozone treatment, AD, and aerobic growth of fungi is used as a treatment of vinasse that promotes the reduction of COD levels, phenolic compounds, and their mineral content. In Hakika et al. [9], the authors demonstrate that the Fenton treatment—an advanced degradation process method—can mitigate the environmental impacts of sugarcane vinasse by reducing organic matter. In Montalvo et al. [68], authors report that it is possible to produce Arthrospira maxima biomass from sugarcane vinasse; in this research, peptide fractions with high potential for application in the pharmaceutical, cosmetic, and food industries were obtained from enzymatically hydrolyzed biomass. Considering the high temperatures in which vinasse is generated (90 °C–100 °C), using an extreme thermophilic condition (70 °C) with the genera Clostridium, Pectinatus, Megasphaera, and Lactobacillus, Niz et al. [69], they produced biohydrogen through the lactic acid/acetic acid pathway.

In de Souza Moraes et al. [70], they produced short-chain organic acids and value-added alcohols in acidogenic systems using sugarcane vinasse. In Fuess et al. [71], the authors use the dark thermophilic fermentation of sugarcane vinasse as a substrate to produce biohydrogen from vinasse in an anaerobic bed reactor structured in lactate. In Rodrigues Reis et al. [72], the authors use raw vinasse as a substrate by Mucor circinelloides to produce lipids that can be used to synthesize biodiesel. In del Gobbo et al. [73], the authors demonstrate that degradation of 50% (v/v) vinasse is possible by a bioprocess involving the autochthonous fungus identified as Aspergillus sp. V1. In Dirbeba et al. [74], the authors report rapid pyrolysis of dehydrated vinasse at 400 and 500 °C, as an alternative for producing biochar with high K content for fertilizers.

In Marcato et al. [75], the authors present a hybrid biogeochemical treatment system (stabilization, filtration, and phytoremediation) to optimize the physical and chemical characteristics of the vinasse; then, it can be used as a fertilizer in crops with a lower polluting impact. In [76], using pyrolysis, vinasse is converted into the matter for bio-oil and biochar production. In Bettani et al. [77], the researchers produce soil fertilizer from slow-release with sugarcane vinasse and lipid-extracted microalgae (Desmodesmus subspicatus). Vinasse is a promising and sustainable medium for the growth of Chlorella Vulgaris and the production of valuable metabolites [78].

Electrodialysis is a vinasse treatment method that generates a concentrated solution to use as fertilizer and a diluted effluent that can be used for biogas production or fertigation [79]. In Karchiyappan et al. [80], the researchers report that electrocoagulation followed by ultrafiltration (UF) is a combined technique that reduces vinasse’s color, turbidity, and COD. In Albuquerque et al. [81], the authors demonstrate that it is feasible to produce methane from the co-digestion of sugarcane vinasse and cheese whey in a thermophilic anaerobic reactor (55 °C) with immobilized biomass mechanically stirred and operated in an AnSBBR.

In [82], hydrogen production is performed from the electrolysis of vinasse. In [83], sugarcane and cognac vinasse are treated by catalytic oxidation processing by humid air using platinum (Pt) and rhodium (Ru) catalysts in discontinuous mode and a trickle-bed reactor under a temperature of 190 °C, and a pressure condition of 70 bar of air. In [84], reducing toxicity and increasing biogas production from hydrolyzing hemicelluloses, vinasse, yeast extract, and sugarcane bagasse fly ash were viable.

In 2020, 28 studies were published; the authors of Madaleno et al. [85] demonstrated that biofuel and biogas production is possible through the bio-digestion of sugarcane vinasse in two-stage up-flow UASB reactors (R1 and R2 connected in series). However, in Magalhães et al. [86], the authors demonstrated that the reduction of organic matter and the production of methane for energy purposes is feasible from the integration of nanofiltration (NF), RO, UF, and treatment with a two-stage anaerobic membrane bio-reactor (2S-AnMBR) to recover energy, nutrients (NF/RO concentrate), and water (NF/RO permeate). In [87], the production of konjac glucomannan (KGM)/alginate (ALG) films enriched with vinasse (VIN) is presented, so KGM/SA/VIN films are a new bio-based material enriched with nutrients for potential agricultural applications.

In Romanholo Ferreira et al. [88], the authors report that the fungus Pleurotus Sajor-caju can be grown in vinasse, making it viable for the treatment of sugarcane wastewater. In Junior et al. [89], the authors demonstrated that biphasic aqueous systems could achieve vinasse degradation and laccase production by Pleurotus Sajor-caju. The production of hydrogen and volatile fatty acids from different concentrations of vinasse from Bacillus cereus, Enterobacter aerogenes, and Enterococcus faecalis individually, as co-cultures, in bioaugmentation, and by the microbial consortium is presented in [90].

In Reis et al. [91], the authors studied sugarcane molasses and vinasse in combination as a culture medium of Mucor circinelloides URM 4182 to obtain purified ethyl esters complying with the values to produce biodiesel. In [92], the development of fertilizer based on pectin, chitosan, and sugarcane vinasse―the physicochemical properties of pectin particles improved with the addition of vinasse―is presented. In Silva et al. [93], they demonstrate that it is possible to treat vinasse in a 2S-AnMBR.

In [94], DF obtains butyrate as a soluble metabolite product from vinasse. Hydrothermal carbonization of sugarcane bagasse and vinasse, 4-methyl-3-pentenoic acid, and 4-hydroxy-butanoic acid are of industrial interest [95]. The microfiltration (MF) and NF pathways prove to be technically and economically viable for the treatment of vinasse [96]. Electrodialysis is presented as a potential alternative method for fertilizer production from vinasse treatment [97]. Biogas and biofertilizer are obtained by AD in a UASB reactor [98].

In [99], two AFBRs under mesophilic (AFBR-M, 30 °C) and thermophilic (AFBR-T, 55 °C) conditions were operated to improve the performance of the acidogenic stage of AD of sugarcane vinasse, and thus increase hydrogen production. In Sacchi et al. [100], the authors used cross-flow coagulation and MF to clarify vinasse for organic fertilizer and microalgae cultivation. In [101], vinasse is converted into organic fertilizer by anaerobic fermentation in the presence of promoter microbes and formulation of fermented vinasse with filtration cake, lead tree leaves, and banana peel to produce liquid organic fertilizer. In [102], methane is produced using sludge from an effluent treatment from the vegetable oil industry as an inoculum in vinasse-containing media. In [103], a P-laden vinasse–dolomite nanocomposite can significantly improve a plant’s growth, so it demonstrated its potency as a substitute for phosphorus-based fertilizers. Removing polyphenols from sugarcane vinasses is feasible from three UASB operating isothermally at temperatures of 45, 55, and 65 °C [104].

In Behravan et al. [105], the researchers demonstrate that humic acid extraction from potassium hydroxide (KOH) made from vinasse solution is possible. Laccases, as biocatalysts, are produced by Trametes Versicolor―white-rot fungus―induced by a combination of cotton gin residues (1%), a lignocellulosic residue, and vinasse (15%) [106]. In Rulli et al. [107], the authors demonstrated that treatment with Aspergillus sp. V2 reduces vinasse’s organic load and acidity, thus improving its fertilizing properties, after testing it in two species: Triticum aestivum L. and Raphanus sativus.

Hydrothermal treatment successfully converted sugarcane vinasse into carbon [108]. Hydrodynamic cavitation pretreatment based on vinasse vortices significantly improves biogas yields [109]. The degradation of vinasse and the production of enzymes and biomass is possible from the culture of Pleurotus Sajor-caju CCB020 [110]. In [111], bio-digested vinasse was used to produce biomass by growing Chlorella Vulgaris. In Chuppa-Tostain et al. [112], the authors report that the use of filamentous fungi and yeasts for the treatment of sugarcane vinasse is very promising and viable.

In the year 2021, we found 33 studies. In [113], the growth of the Chlorella Vulgaris crop using vinasses in strict heterotrophic conditions and the use of microalgae biomass to reduce the pollutant load is presented. From a kinetic perspective, the mesophilic co-digestion (30 °C) of sugarcane vinasse and distilled glycerol allows the production of methane and biogas [114]. The DF of sugarcane vinasse allows for the production of soluble metabolites through the biorefinery approach [115].

In Piffer et al. [116], the authors generate energy from SO42− free vinasse by sulfidogenesis in the dark thermophilic fermentation of sugarcane vinasse. In Arslanoğlu & Tümen [117], the authors use pyrolysis to produce K and activated charcoal from vinasse and pomace. The development of a multi-product biorefinery scheme for the valorization of vinasse involving the extraction of trans-aconitic acid, its transformation into biopolymers by microwave irradiation, and the use of refined vinasse for the production of biogas are presented in [118].

In Chai et al. [119], the authors demonstrate that anaerobic degradation of vinasse through an anaerobic suspended growth closed bioreactor at thermophilic temperature with various hydraulic retention times provides a low degree of substrate inhibition and high biogas production.

In Buller et al. [120], the researchers report that bio-digested vinasse is a suitable strategy for N fertilization in sugarcane crops, while burning biogas can also provide a surplus of electrical energy. DF of sugarcane vinasse in three mesophilic EGSB reactors exhibited increased carboxylate productivity [121].

In Nogueira et al. [122], the authors use a down-flow structured bed bioreactor to treat synthetic acid mine drainage using vinasse. In Li et al. [123], the authors report that vinasse is converted into activated carbon by thermal action. In Ramos et al. [124], the authors report that the operation of a second-stage reactor at mesophilic temperature is best suited for AD of vinasse due to its flexibility, robustness, and stability of methane production and digestate for ferti-irrigation.

In Volpi et al. [125], the researchers report methane production by AcD from vinasse, cachaça, and deacetylation liquor using a semi-continuous stirred tank reactor. AD of sugarcane vinasse in two stages (acidogenic/methanogenic) and one stage (methanogenic) was used under extreme temperature conditions in structured-bed reactors to produce methane and acetic acid [126]. In Magrini, de Almeida, da Maia Soares, Fuentes, et al. [127], the authors used vinasse as a substrate in microbiological processes to obtain hydrogen and volatile fatty acids through DF.

In [128], the researchers used a UASB methanogenic reactor to treat vinasse. In Magrini, de Almeida, da Maia Soares, dos Anjos Borges, et al. [129], the authors produce hydrogen from sugarcane vinasse by high-throughput sequencing of the 16S and 18S rRNA genes. In [130], a microbial community is operated in an anaerobic chamber reactor to treat ethanol distillery vinasse. In Brito Codato et al. [131], the researchers ferment ethanol from hydrolyzed sugarcane bagasse after being grown in solid-state with vinasse as an impregnation solution by a consortium of A. niger and T. reesei for ethanol production. In [132], vinasse, cachaça, and straw deacetylation pretreatment liquor were used to generate methane by co-digestion.

In Tasic et al. [133], the authors produce Chlamydomonas reinhardtii biomass and ethanol from a biofuel process that integrates vinasse treatment by removing nutrients with algae in bioethanol. Bioremediation by culture and fermentation were performed in a single step, turning the light air on and off, respectively.

In Karouach et al. [134], the authors demonstrated that AcD of cellulose recycled with vinasse improved methane production and biodegradability. The cultivation of corn benefited from N obtained from organomineral ammonium sulfate, in combination with the highest doses of K from vinasse, which is presented in [135].

In Raza et al. [136], the authors demonstrate that the integrated use of various amendments, including vinasse, with chemical fertilization, improves soil properties and rice yield. The hydrothermal carbonization process using vinasse and sugarcane bagasse allows producing hydrocarbon [137].

Direct contact membrane distillation allows for the treatment of sugarcane vinasse [138]. Methanobacterium and Methanosaeta drive the treatment of vinasse and methane production, so the metabolic pathways used are hydrogenotrophic and acetoclastic [139]. In Kiani Deh Kiani et al. [140], the authors report that biogas production from vinasse is possible using a static granular bed reactor.

In Caillet & Adelard [141], the authors employ semi-continuous AD of sugarcane vinasse to produce biogas. In Rulli et al. [142], the researchers generate biomass from Aspergillus sp. V2 from vinasse with N, and phosphorus supplements meet nutritional requirements in the fish diet.

In Widyastuti et al. [143], the researchers use electro-Fenton as a pretreatment method in the AD of vinasse as an advanced oxidation process to produce biogas while decreasing the organic matter of sugarcane vinasse. In Ferreira et al. [144], the authors produce Chlorella Vulgaris and Desmodesmus sp. grown in bagasse and sugarcane vinasse using a biofertilizer from bagasse biochar and pretreatment by filtration to the vinasse. In Heredia Falconí et al. [145], the authors demonstrate that the cultivation of the Scenedesmus bajacalifornicus BR024 strain yields good performance when pre-treated with ozone in sugarcane ethanol vinasse and ethanol biorefinery wastewater.

As of May 2022, we have collected 10 studies. In Tamashiro et al. [13], it was concluded that sugarcane vinasse’s wastewater as an additive in the manufacture of concrete in replacement of water creates more excellent resistance to compression. In Hashemi et al. [146], the authors cultivated a first-stage Neurospora intermedia in wastewater from sugarcane vinasse and cheese whey; in a second stage, the effluent from the mushroom culture was digested anaerobically to produce biomethane, thus having treated vinasse. As an advanced oxidation process, vinasse can be effectively treated by photocatalytic degradation [147].

Finally, in Silva et al. [148], the authors use the cultivation and enrichment of Thermoanaerobacterium calidifontis (VCS1) to degrade xylose-containing vinasse to produce hydrogen and ethanol. In [149], the authors demonstrated that different species of the genus Pleurotus (Pleurotus Sajor-caju CCB 020, Pleurotus florida, Pleurotus ostreatoroseus, Pleurotus flabellatus, Pleurotus sp. CCB 068 and Pleurotus spleurotus) produced exopolysaccharides and fungal biomass in culture submerged in vinasse.

In Candido et al. [150], they use vinasse as a culture medium for microalgae by bioprospecting the species Chlamydomonas sp., Chlorella sorokiniana, Chlorella Vulgaris, Desmodesmus spinosus, Haematococcus Pluvialis, Monoraphidium sp., Scenedesmus quadricauda, and Tetraselmis gracilis. Whereas in Yabuki et al. [151], the authors demonstrate that anaerobic treatment allows for the removal of metals from vinasse.

In Martinez-Silveira et al. [152], the authors produce intracellular lipids by the oilseed yeast strain R. graminis S1/2R, previously selected in a medium composed solely of sugarcane vinasse and crude glycerol. In Kee et al. [153], the researchers developed a recirculated sequencing batch reactor to treat anaerobically digested vinasse. In ref. Hakika et al. [154], they report that Fenton pretreatment improves vinasse biodegradability and biogas production.

The studies reviewed in this section demonstrate the efforts developed by the scientific community, to take advantage of the benefits of the components of vinasse for post-industrial purposes, and to do so while being paid to mitigate the negative impact of this waste on the environment if it were deposited indiscriminately to the soil. In this review, it is possible to observe that the various investigations address alternatives that have contributed to recovering the benefits of vinasse; however, there is a gap in the analysis of processes that require higher volumes of vinasse as a raw material to balance the generation of vinasse in alcohol factories.

3.4.4. Technological Processes Used in the Treatment of Vinasse

Table 3 portrays the bioproducts generated from vinasse reported in the literature review.

Table 3.

Technologies used to generate bioproducts.

Obtained through the implementation of technologies based on physical processes (9.92%), chemical (12.21%), biological (66.42%), and others (11.45%).

3.4.5. Recovered Bioproducts

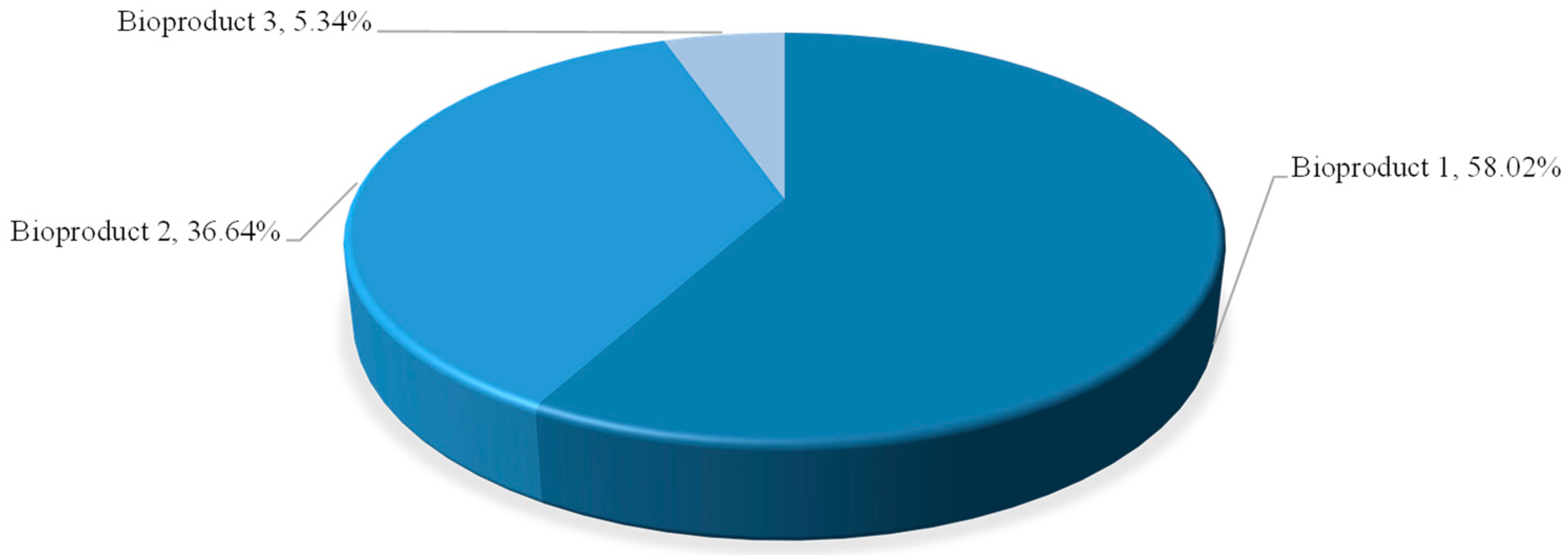

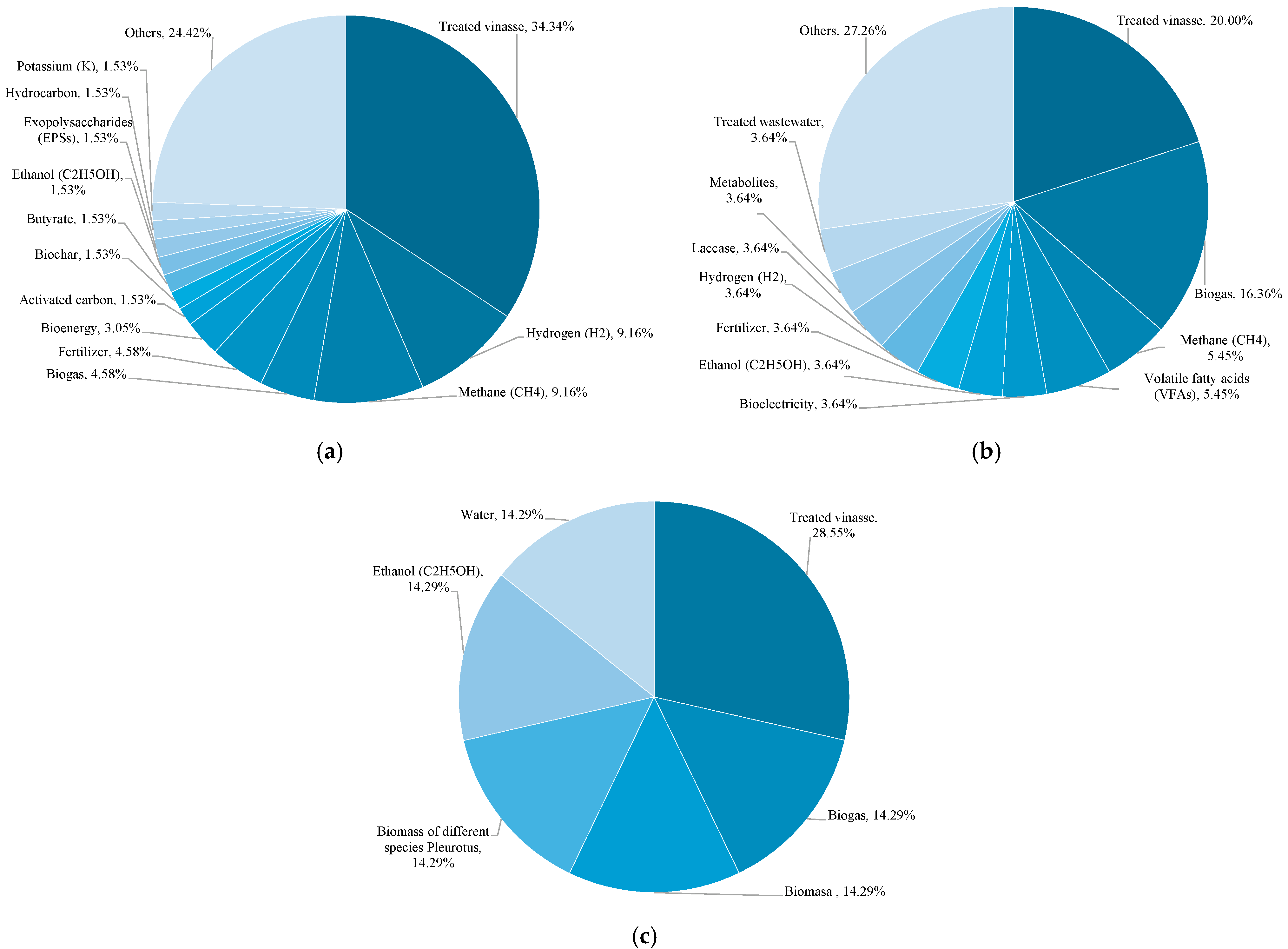

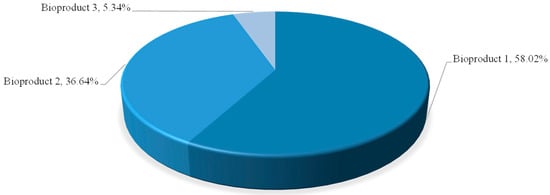

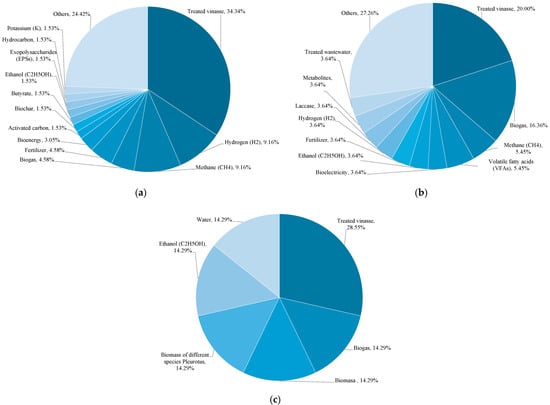

This literature review reports that the processes used to treat vinasse are physical, chemical, biological, or combined, through which it is reported to obtain one to three bioproducts derived from sugarcane ethanol vinasse (see Figure 8).

Figure 8.

Bioproducts generated are derived from the treatment of vinasse.

That is, given the resources available in a first recovery effort—first phase—76 studies describe the development of a bioproduct and, in the same context, are limited to a single bioproduct, which can be, e.g., hydrocarbon, or hydrogen (H2). Meanwhile, 48 studies under a context with greater availability of resources report obtaining up to two bioproducts from the same vinasse, either sequentially or jointly—second phase—e.g., hydrogen (H2)-biohetane, potassium (K)-treated vinasse. Finally, seven studies reported that, given various resources, it is possible to obtain up to three bioproducts—third phase—e.g., Treated vinasse-biogas-biomass, bioenergy-nutrients-water. For each study, the bioproducts reported in this literature review were identified from the treatment or use of vinasse. Figure 9 presents the bioproducts identified by phase and reported by the authors in each case.

Figure 9.

Bioproducts developed in each of the phases: (a) Developed bioproducts identified in the first phase; (b) Developed bioproducts identified in the second phase; (c) Developed bioproducts identified in the third phase.

In the first phase, it was identified that treated vinasse predominates as a bioproduct (45 studies), followed by obtaining hydrogen (12 studies), obtaining methane (12 studies), the generation of biogas (6 studies), fertilizer (6 studies), bioenergy (4 studies), activated carbon, biochar, butyrate, ethanol, exopolysaccharides, hydrocarbon, and potassium (2 studies each), in addition to others (32 studies) (Figure 9a). In the second stage of recovery, treated vinasse predominates (11 studies), followed by biogas (9 studies), methane (3 studies), volatile fatty acids (3 studies), bioelectricity, ethanol, fertilizer, hydrogen, metabolites, treated wastewater (2 studies each), and others (15 studies) (Figure 9b). Finally, in a third phase, the bioproducts obtained focus on generating treated vinasse (2 studies), biogas, biomass, the biomass of different species of Pleurotus, ethanol, and water (1 study each) (Figure 9c).

These bioproducts were generated primarily by biological processes (66.41%). The predominant technologies in these studies were AD with 23.66%; cultivation with 16.03%, AcD with 8.40%, DF (7.63%), and fermentation (4.58%).

3.4.6. Industrial Sectors

The bioproducts generated from vinasse have been valued in various studies to develop products with high added value. In this review, 10 industrial sectors were identified that have taken advantage of the benefits of processed vinasse as a process and-or product improver (see Table 4).

Table 4.

Industrial sectors using vinasse.

3.4.7. Applications of Vinasse in the Agricultural Sector

The sucro-alcohol industry begins its productive cycle in the cultivation of sugar cane; then, under an environmental responsibility supported by the principles of the Circular Economy, the vinasse should be reincorporated into the soil or the crop in the conditions that allow it to improve the properties or increase the yield. Efforts like this approach have been developed and identified in this review. Vinasse has been used as a soil improver [66,73], as a fertilizer for various crops [74,75,79,97,107,117] and sugarcane [56,77]; it has also been proven in a combined way to be used as a fertilizer and soil improver [92]; influencing the growth of the plant Setaria viridis [103], likewise, vinasse as a fertilizer has demonstrated benefit in the cultivation of Chlorella Vulgaris and Desmodesmus sp. and in the growth of cultivation Desmodesmus sp. [144]. While it has been used as an integral fertilizer and soil improver, for tomato crop growth [101], in addition to rice [136] and maize [137]. Finally, vinasse has been used as an improver in the yield of corn [135] and sugarcane [58]. The scope of these applications was achieved by pre-treatment of vinasse through physical, chemical, biological, physicochemical, and biogeochemical processes.

4. Discussion

Sugarcane is one of the leading crops in Mexico and the world [1,2]. The sucro-alcohol industry is responsible for producing sugar as food and ethyl alcohol for various purposes. However, this industry is also responsible for the waste co-generated along its value chain, positioning it in an industry with significant waste management challenges.

In this field of study, an average annual increase of 2.8% is observed in research focused on the use of vinasse components to obtain up to three bioproducts from the same processing system, i.e., 58.02, 36.64, and 5.34% of the studies reported obtaining one bioproduct, two bioproducts, and up to three bioproducts, respectively, mainly treated vinasse, methane, hydrogen, biogas, and to a lesser extent, for use as fertilizer. The bioproducts generated from vinasse have been directed to the bioenergy industry (43.51%), waste and wastewater management (22.14%), agriculture (13.74%), and biotechnology (13.74%). Using biological-electrochemical processes; physical and chemical; electrochemical; electrochemical oxidation; various technologies such as membranes, hydrolysis, inverse osmosis, coagulation/cross-flow microfiltration. This demonstrates that there is no single technology primed for taking advantage of the components of vinasse, which makes it clear that in the last five years, the importance of taking advantage of the richness of nutrients in alcohol vinasse for the development of bioproducts in the value chains of the pharmaceutical industries has been accentuated, especially in cosmetic, construction, and food and agricultural industries. The studies reviewed identified that the main limitations and difficulties in managing vinasse are based on environmental regulations and available resources—e.g., infrastructure, technology, and budget—.

In addition to the scientific contributions—which have been exposed and reviewed in this document—there are contributions on an industrial scale made from the technological development of processes/products that they consider innovative inventions suitable for application in the management of vinasse as an agro-industrial waste. In this sense, the use of vinasse in the process of saccharification/fermentation of biomass as a means of enrichment of lignocellulosic residues [155,156,157] is proposed; in the production of solid fertilizer and biofuel [158,159,160]; in [161,162,163], it is used for the production of organo-mineral fertilizer. Vinasse in isolation or conjunction with other organic waste is reported to produce organic fertilizer in [164,165,166]; in [167], it is used as a component in the treatment by atomization or nebulization in the leaves, or by spraying in the seeds of the plants to form a coating on the seeds by granulation, or by fertigation in the soil; in [168], vinasse is used by a method to prepare a concrete mixture.

Vinasse has also been employed in the technical field of food processing at an industrial level. In [169], the invention describes a method for producing a stock solution of vinegar; in [170], the process of making a novel fish sauce with saccharification-fermentation flavor is described; the method of production of polyphenols is detailed in [171]; an innovative process for producing food through high-protein fermentation is demonstrated in [172]. In [173], the method for obtaining molasses from the reconstruction of vinasse is described.

Finally, ref. Reginato [174] reports an industrial procedure to purify and filter vinasses. In [175], there is a method to process vinasse and reduce its turbidity for use as a culture medium for the growth of microorganisms—particularly, microalgae and cyanobacteria—.

Although these works have indeed presented contributions from the development of innovative technologies that manage vinasse to mitigate its negative impact on the environment; these technologies have practical implications associated with technological investment to make them a reality. Conversely, the technologies developed on an industrial scale result to be of high complexity for their scaling, associated with the high cost of installation and operation, which is reflected in the fact that these technologies have not been adopted in the companies that generate this agro-waste. In this sense, the practical implications for adopting these technologies are related to the technological processes from the perspective of not only cost-benefit but also the infrastructure for their adoption. This situation makes evident the need for developing simple and environmentally friendly technologies capable of processing the large volume of vinasse that is generated and its reincorporation into the fields that create it without limiting itself to other cultivation systems.

In this context, the principles of the Circular Economy in the value chain of the sucro-alcohol industry have approached the reincorporation of vinasse to its origin. The treated vinasse has been reincorporated into the sugarcane fields as a strengthener of the soil and the crop. In this sense, in Silva et al. [56], the authors have entirely replaced the mineral K with potassium vinasse; similarly, in Gallucci et al. [58], the researchers have to supply N using concentrated vinasse enriched with N, whereas in Bettani et al. [77], through biomass particles, the researchers have provided macro and micronutrients to the soil.

Vinasse is rich in nutrients, with K being the primary macronutrient of interest recovered. The desalination and recovery of nutrients such as K employing electrodialysis is reported by [79,97], being promising in the form of struvite [97,117]. The researchers in Silva et al. [56] obtained it by RO; the authors of Dirbeba et al. [74] obtained it by thermal degradation at 400 and 500 °C. However, the authors of Santos et al., Fregolente et al. [66,137] agree that vinasse treated in the form of hydrocarbon as a soil conditioner improves its nutrient characteristics. Therefore, vinasse possesses valuable nutrients for crops’ fertilization and is attractive for soil fertility.

In [73], it is mentioned that by reducing the harmful effects of vinasse on the quality of agricultural practices, it is improved, coinciding with [75], since the polluting impact on crops is reduced. Therefore, the adequate generation of bioproducts from vinasse is of utmost importance for natural resources, as mentioned [117], these bioproducts being a source of nutrients capable of improving the physicochemical conditions of the soil without generating health conditions [136].

As the author cites [176], the research results “aligned with the principles of the Circular Economy” have presented developments of bioproducts of high added value, which warn of being unaffordable in industrial practice. The contribution of these studies has demonstrated alternatives to guide the use of vinasse alcohol, converting this agro-industrial waste as “potential organo-mineral fertilizer”, coinciding with [101], and emphasizing that this is the most advanced process of valorization of vinasse; since, as he mentions [135], this duct can increase the recovery of N, in addition to being able to change the electrical conductivity of the soil. In this sense, studies related to the development of biofertilizers are trending, which can find a rich source of minerals in the components of vinasse, especially to return to the agricultural soil the benefit of the nutrients of vinasse to strengthen crop soils [56,74,75,77,79,92,97,101,107,117,136,137]. However, studies of methods for applying vinasse to agricultural soil are also necessary, especially, as reported [176], in a controlled manner to avoid soil salinization and contamination of groundwater.

5. Conclusions

Today, vinasse as a post-industrial waste of alcohol distillation indicates a trend of use in biological processes to obtain high-value-added bioproducts. Various production chains have valued the beneficial components of vinasse, e.g., pharmaceutical, cosmetic, construction, food, and agricultural. However, the need for strategies supported by the Circular Economy principles is evident as a promising alternative to deplete with more incredible speed the volume generated of vinasse in distilleries.

While it is true that there are efforts in the agricultural sector to reincorporate vinasse as a soil improver, it is also true that the physicochemical processes currently reported taking advantage of the benefits of vinasse as a biofertilizer. However, they are expensive and unfriendly to the environment, not biological processes.

There is no denying that significant eco-technological challenges must be addressed for the treatment or handling of vinasse as a fertilizer alternative. Therefore, given the trends in developing products/processes that value the benefits of the components of vinasse, it is necessary to raise several questions: What manners of treatment of vinasse should develop the sucro-alcohol agro-industry to manage the large volume that is generated? How can vinasse be treated so that it is easy to handle and treat, from the distillery to the fields, and at the lowest cost? So, what are the possibilities of revaluing the vinasse to treat it as an input for the canes under a simple and environmentally friendly technology?

Despite the advances and knowledge reported for the use of alcohol vinasse, there is no single treatment that efficiently treats the effluent from the distillery. The technologies proposed today for the treatment of vinasse are not able to process the large volume that is generated in alcohol distilleries, which, in some cases, proves to be expensive and unaffordable, becomes a slow process, and do not prove to be friendly to the environment. In this context, the research trend in this field must also seek industrial scale-ups to channel work capable of processing the large volume of vinasse generated in distilleries. In this sense, a couple of investigations of the year 2022 open a path of treating vinasses as agro-industrial effluent directly and massively to reincorporate the effluent under Circular Economy principles.

Author Contributions

Conceptualization, A.M.-R., N.M.-R., and G.F.-L.; data curation, A.M.-R., N.M.-R., G.F.-L., H.B.-S., L.E.G.-S., and L.C.S.-H.; formal analysis, A.M.-R., N.M.-R., and G.F.-L.; investigation, A.M.-R., N.M.-R., G.F.-L., H.B.-S., L.E.G.-S., and L.C.S.-H.; methodology, A.M.-R. and N.M.-R.; project administration, A.M.-R. and N.M.-R.; resources, A.M.-R., N.M.-R., G.F.-L., H.B.-S., L.E.G.-S., and L.C.S.-H.; supervision, A.M.-R. and G.F.-L.; validation, H.B.-S. and L.C.S.-H.; visualization, A.M.-R., N.M.-R., and L.E.G.-S.; writing—original draft preparation, A.M.-R., N.M.-R., G.F.-L., H.B.-S., L.E.G.-S., and L.C.S.-H.; writing—review and editing, A.M.-R., N.M.-R., and G.F.-L. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the National Council of Science and Technology of Mexico (CONACyT). With the scholarship 805151, for postgraduate studies.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data analyzed are available in the protocol registry at (osf.io, accessed on 20 June 2022), available to the public.

Conflicts of Interest

The authors declare no conflict of interest.

References

- INEGI. Agriculture. Available online: https://www.inegi.org.mx/temas/agricultura/#Informacion_general (accessed on 11 May 2022).

- FAO. FAOSTAT. Available online: https://www.fao.org/faostat/es/#data/QCL (accessed on 11 May 2022).

- SADER. CONADESUCA 8th Statistical Report of the Agro-Industrial Sector of Sugar Cane in Mexico, Harvests 2011–2012/2020–2021. Available online: https://siiba.conadesuca.gob.mx/infocana/informe/informe.html (accessed on 13 May 2022).

- Moran-Salazar, R.G.; Sanchez-Lizarraga, A.L.; Rodriguez-Campos, J.; Davila-Vazquez, G.; Marino-Marmolejo, E.N.; Dendooven, L.; Contreras-Ramos, S.M. Utilization of Vinasses as Soil Amendment: Consequences and Perspectives. Springerplus 2016, 5, 1007. [Google Scholar] [CrossRef] [PubMed]

- Cortes-Rodríguez, E.F.; Fukushima, N.A.; Palacios-Bereche, R.; Ensinas, A.V.; Nebra, S.A. Vinasse Concentration and Juice Evaporation System Integrated to the Conventional Ethanol Production Process from Sugarcane—Heat Integration and Impacts in Cogeneration System. Renew. Energy 2018, 115, 474–488. [Google Scholar] [CrossRef]

- Rabelo, S.C.; da Costa, A.C.; Vaz Rossel, C.E. Industrial Waste Recovery. In Sugarcane: Agricultural Production, Bioenergy and Ethanol; Academic Press: Cambridge, MA, USA, 2015; pp. 365–381. [Google Scholar] [CrossRef]

- da Silva, J.J.; da Silva, B.F.; Zanoni, M.V.B.; Stradiotto, N.R. Sample Preparation and Antibiotic Quantification in Vinasse Generated from Sugarcane Ethanol Fuel Production. J. Chromatogr. A 2022, 1666, 462833. [Google Scholar] [CrossRef] [PubMed]

- Bergmann, J.C.; Trichez, D.; Sallet, L.P.; de Paula e Silva, F.C.; Almeida, J.R.M. Technological Advancements in 1G Ethanol Production and Recovery of By-Products Based on the Biorefinery Concept. In Advances in Sugarcane Biorefinery: Technologies, Commercialization, Policy Issues and Paradigm Shift for Bioethanol and By-Products; Elsevier: Amsterdam, The Netherlands, 2018; pp. 73–95. [Google Scholar] [CrossRef]

- Hakika, D.C.; Sarto, S.; Mindaryani, A.; Hidayat, M. Decreasing COD in Sugarcane Vinasse Using the Fenton Reaction: The Effect of Processing Parameters. Catalysts 2019, 9, 881. [Google Scholar] [CrossRef]

- Nakashima, R.N.; de Oliveira Junior, S. Comparative Exergy Assessment of Vinasse Disposal Alternatives: Concentration, Anaerobic Digestion and Fertirrigation. Renew. Energy 2020, 147, 1969–1978. [Google Scholar] [CrossRef]

- Silva, L.C.M.; Moreira, R.A.; Pinto, T.J.S.; Vanderlei, M.R.; Athayde, D.B.; Lopes, L.F.P.; Ogura, A.P.; Yoshii, M.P.C.; Freitas, J.S.; Montagner, C.C.; et al. Lethal and Sublethal Toxicity of Pesticides and Vinasse Used in Sugarcane Cultivation to Ceriodaphnia Silvestrii (Crustacea: Cladocera). Aquat. Toxicol. 2021, 241, 106017. [Google Scholar] [CrossRef]

- de Jesus, G.C.; Gaspar Bastos, R.; Altenhofen da Silva, M. Production and Characterization of Alginate Beads for Growth of Immobilized Desmodesmus Subspicatus and Its Potential to Remove Potassium, Carbon and Nitrogen from Sugarcane Vinasse. Biocatal. Agric. Biotechnol. 2019, 22, 101438. [Google Scholar] [CrossRef]

- Tamashiro, J.R.; Kinoshita, A.; Pereira Silva, L.H.; Friol Guedes de Paiva, F.; Antunes, P.A.; Simões, R.D. Compressive Resistance of Concrete Produced with Recycled Concrete Aggregate and Sugarcane Vinasse Waste-Water. Clean. Eng. Technol. 2022, 6, 100362. [Google Scholar] [CrossRef]

- Nadaleti, W.C.; Lourenço, V.A.; Filho, P.B.; dos Santos, G.B.; Przybyla, G. National Potential Production of Methane and Electrical Energy from Sugarcane Vinasse in Brazil: A Thermo-Economic Analysis. J. Environ. Chem. Eng. 2020, 8, 103422. [Google Scholar] [CrossRef]

- Marafon, A.C.; Salomon, K.R.; Amorim, E.L.C.; Peiter, F.S. Use of Sugarcane Vinasse to Biogas, Bioenergy, and Biofertilizer Production. In Sugarcane Biorefinery, Technology and Perspectives; Academic Press: Cambridge, MA, USA, 2020; pp. 179–194. [Google Scholar] [CrossRef]

- Coelho, M.P.M.; Correia, J.E.; Vasques, L.I.; de Castro Marcato, A.C.; de Andrade Guedes, T.; Soto, M.A.; Basso, J.B.; Kiang, C.; Fontanetti, C.S. Toxicity Evaluation of Leached of Sugarcane Vinasse: Histopathology and Immunostaining of Cellular Stress Protein. Ecotoxicol. Environ. Saf. 2018, 165, 367–375. [Google Scholar] [CrossRef]

- Velásquez-Riaño, M.; Carvajal-Arias, C.E.; Rojas-Prieto, N.L.; Ausecha-García, S.A.; Vera-Díaz, M.Á.; Meneses-Sánchez, J.S.; Villa-Restrepo, A.F. Evaluation of a Mixed Simultaneous Vinasse Degradation Treatment Using Komagataeibacter Kakiaceti GM5 and Trametes Versicolor DSM 3086. Ecotoxicol. Environ. Saf. 2018, 164, 425–433. [Google Scholar] [CrossRef] [PubMed]

- Parsaee, M.; Kiani Deh Kiani, M.; Karimi, K. A Review of Biogas Production from Sugarcane Vinasse. Biomass Bioenergy 2019, 122, 117–125. [Google Scholar] [CrossRef]

- Melchor, G.I.; Salgado-García, S.; Palma, D.; Lagunes-Espinoza, L.; Castelán-Estrada, M.; Ruiz Rosado, O. Vinasse and Filter Cake Compost as Nutrient Source for Sugarcane in a Molic Gleysol of Chiapas, México. Interciencia 2008, 33, 855–860. [Google Scholar]

- FIRA. FIRA Boletín Informativo: Producción Sostenible de Caña de Azúcar en México; 2010. Available online: www.fira.gob.mx (accessed on 22 May 2022).

- Pati, D.; Lorusso, L.N. How to Write a Systematic Review of the Literature. HERD Health Environ. Res. Des. J. 2017, 11, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Montiel, A.; Montalvo, N.; Fernández, G.; García, L.E.; Bautista, H.; Sandoval, L.C. Post-Industrial Use of Sugarcane Ethanol Vinasse: A Systematic Review; OSF: Misantla, Mexico, 2022. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Morton, S.; Berg, A.; Levit, L.; Eden, J. Finding What Works in Health Care: Standards for Systematic Reviews; National Academies Press: Washington, DC, USA, 2011. [Google Scholar]

- Elsevier. Available online: https://www.elsevier.com/es-mx (accessed on 18 March 2022).

- Springer. Nature Springer. Available online: https://link.springer.com/ (accessed on 23 March 2022).

- Google. Google Scholar. Available online: https://scholar.google.com/ (accessed on 28 March 2022).

- Queiroga, J.A.; Souza, D.F.; Nunes, E.H.M.; Silva, A.F.R.; Amaral, M.C.S.; Ciminelli, V.S.T.; Vasconcelos, W.L. Preparation of Alumina Tubular Membranes for Treating Sugarcane Vinasse Obtained in Ethanol Production. Sep. Purif. Technol. 2018, 190, 195–201. [Google Scholar] [CrossRef]

- Martínez, E.A.; dos Santos, J.F.; Araujo, G.S.; de Souza, S.M.A.; de Cássia Lacerda Brambilla Rodrigues, R.; Canettieri, E.V. Production of Single Cell Protein (SCP) from Vinasse. In Fungal Biorefineries; Kumar, S., Dheeran, P., Taherzadeh, M., Khanal, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 215–238. ISBN 978-3-319-90379-8. [Google Scholar]

- da Silva, D.R.; Crespi, M.S.; Ribeiro, C.A.; Capela, J.M.V. Thermal Decomposition Kinetics of Sugarcane Mills Wastes. J. Therm. Anal. Calorim. 2018, 131, 811–822. [Google Scholar] [CrossRef]

- da Silva, I.A.; de Lima, S.T.; Siqueira, M.R.; da Veiga, M.A.M.S.; Reginatto, V. Landfill Leachate Enhances Fermentative Hydrogen Production from Glucose and Sugarcane Processing Derivatives. J. Mater. Cycles Waste Manag. 2018, 20, 777–786. [Google Scholar] [CrossRef]

- del Gobbo, L.M.; Colin, V.L. Fungal Technology Applied to Distillery Effluent Treatment. In Approaches in Bioremediation: The New Era of Environmental Microbiology and Nanobiotechnology; Prasad, R., Aranda, E., Eds.; Springer: Cham, Switzerland, 2018; pp. 185–197. ISBN 978-3-030-02369-0. [Google Scholar]

- Chuppa-Tostain, G.; Hoarau, J.; Watson, M.; Adelard, L.; Shum Cheong Sing, A.; Caro, Y.; Grondin, I.; Bourven, I.; Francois, J.-M.; Girbal-Neuhauser, E.; et al. Production of Aspergillus Niger Biomass on Sugarcane Distillery Wastewater: Physiological Aspects and Potential for Biodiesel Production. Fungal Biol. Biotechnol. 2018, 5, 1. [Google Scholar] [CrossRef]

- Saglam, N.; Yesilada, O.; Saglam, S.; Apohan, E.; Sam, M.; Ilk, S.; Emul, E.; Gurel, E. Bioremediation Applications with Fungi. In Mycoremediation and Environmental Sustainability: Volume 2; Prasad, R., Ed.; Springer: Cham, Switzerland, 2018; pp. 1–37. ISBN 978-3-319-77386-5. [Google Scholar]

- Fuess, L.T.; Garcia, M.L.; Zaiat, M. Seasonal Characterization of Sugarcane Vinasse: Assessing Environmental Impacts from Fertirrigation and the Bioenergy Recovery Potential through Biodigestion. Sci. Total Environ. 2018, 634, 29–40. [Google Scholar] [CrossRef]

- Chingono, K.E.; Sanganyado, E.; Bere, E.; Yalala, B. Adsorption of Sugarcane Vinasse Effluent on Bagasse Fly Ash: A Parametric and Kinetic Study. J. Environ. Manag. 2018, 224, 182–190. [Google Scholar] [CrossRef]

- del Nery, V.; Alves, I.; Zamariolli Damianovic, M.H.R.; Pires, E.C. Hydraulic and Organic Rates Applied to Pilot Scale UASB Reactor for Sugar Cane Vinasse Degradation and Biogas Generation. Biomass Bioenergy 2018, 119, 411–417. [Google Scholar] [CrossRef]

- Ahmed, P.M.; Pajot, H.F.; de Figueroa, L.I.C.; Gusils, C.H. Sustainable Bioremediation of Sugarcane Vinasse Using Autochthonous Macrofungi. J. Environ. Chem. Eng. 2018, 6, 5177–5185. [Google Scholar] [CrossRef]

- Fuess, L.T.; Klein, B.C.; Chagas, M.F.; Alves Ferreira Rezende, M.C.; Garcia, M.L.; Bonomi, A.; Zaiat, M. Diversifying the Technological Strategies for Recovering Bioenergy from the Two-Phase Anaerobic Digestion of Sugarcane Vinasse: An Integrated Techno-Economic and Environmental Approach. Renew. Energy 2018, 122, 674–687. [Google Scholar] [CrossRef]

- Vaquerizo, F.R.; Cruz-Salomon, A.; Valdovinos, E.R.; Pola- Albores, F.; Lagunas-Rivera, S.; Meza- Gordillo, R.; Ruiz Valdiviezo, V.M.; Simuta Champo, R.; Moreira- Acosta, J. Anaerobic Treatment of Vinasse from Sugarcane Ethanol Production in Expanded Granular Sludge Bed Bioreactor. J. Chem. Eng. Process Technol. 2018, 9, 375. [Google Scholar] [CrossRef]

- López, I.; Borzacconi, L.; Passeggi, M. Anaerobic Treatment of Sugar Cane Vinasse: Treatability and Real-Scale Operation. J. Chem. Technol. Biotechnol. 2018, 93, 1320–1327. [Google Scholar] [CrossRef]

- Náthia-Neves, G.; de Alencar Neves, T.; Berni, M.; Dragone, G.; Mussatto, S.I.; Forster-Carneiro, T. Start-up Phase of a Two-Stage Anaerobic Co-Digestion Process: Hydrogen and Methane Production from Food Waste and Vinasse from Ethanol Industry. Biofuel Res. J. 2018, 5, 813–820. [Google Scholar] [CrossRef]

- Pinto, M.P.M.; Mudhoo, A.; de Alencar Neves, T.; Berni, M.D.; Forster-Carneiro, T. Co–Digestion of Coffee Residues and Sugarcane Vinasse for Biohythane Generation. J. Environ. Chem. Eng. 2018, 6, 146–155. [Google Scholar] [CrossRef]

- Fuess, L.T.; Ferraz, A.D.N.; Machado, C.B.; Zaiat, M. Temporal Dynamics and Metabolic Correlation between Lactate-Producing and Hydrogen-Producing Bacteria in Sugarcane Vinasse Dark Fermentation: The Key Role of Lactate. Bioresour. Technol. 2018, 247, 426–433. [Google Scholar] [CrossRef] [PubMed]

- Ramos, L.R.; Silva, E.L. Continuous Hydrogen Production from Cofermentation of Sugarcane Vinasse and Cheese Whey in a Thermophilic Anaerobic Fluidized Bed Reactor. Int. J. Hydrog. Energy 2018, 43, 13081–13089. [Google Scholar] [CrossRef]

- Vilar, D.S.; Carvalho, G.O.; Pupo, M.M.S.; Aguiar, M.M.; Torres, N.H.; Américo, J.H.P.; Cavalcanti, E.B.; Eguiluz, K.I.B.; Salazar-Banda, G.R.; Leite, M.S.; et al. Vinasse Degradation Using Pleurotus Sajor-Caju in a Combined Biological—Electrochemical Oxidation Treatment. Sep. Purif. Technol. 2018, 192, 287–296. [Google Scholar] [CrossRef]

- Kazak, O.; Eker, Y.R.; Bingol, H.; Tor, A. Preparation of Chemically-Activated High Surface Area Carbon from Waste Vinasse and Its Efficiency as Adsorbent Material. J. Mol. Liq. 2018, 272, 189–197. [Google Scholar] [CrossRef]

- Sydney, E.B.; Novak, A.C.; Rosa, D.; Pedroni Medeiros, A.B.; Brar, S.K.; Larroche, C.; Soccol, C.R. Screening and Bioprospecting of Anaerobic Consortia for Biohydrogen and Volatile Fatty Acid Production in a Vinasse Based Medium through Dark Fermentation. Process Biochem. 2018, 67, 1–7. [Google Scholar] [CrossRef]

- Santana Junior, A.E.; Duda, R.M.; de Oliveira, R.A. Improving the Energy Balance of Ethanol Industry with Methane Production from Vinasse and Molasses in Two-Stage Anaerobic Reactors. J. Clean. Prod. 2019, 238, 117577. [Google Scholar] [CrossRef]

- Prazeres, A.R.; Lelis, J.; Alves-Ferreira, J.; Carvalho, F. Treatment of Vinasse from Sugarcane Ethanol Industry: H2SO4, NaOH and Ca(OH)2 Precipitations, FeCl3 Coagulation-Flocculation and Atmospheric CO2 Carbonation. J. Environ. Chem. Eng. 2019, 7, 103203. [Google Scholar] [CrossRef]

- Campanhol, B.S.; Silveira, G.C.; Castro, M.C.; Ceccato-Antonini, S.R.; Bastos, R.G. Effect of the Nutrient Solution in the Microbial Production of Citric Acid from Sugarcane Bagasse and Vinasse. Biocatal. Agric. Biotechnol. 2019, 19, 101147. [Google Scholar] [CrossRef]

- Santos, P.S.; Zaiat, M.; Oller do Nascimento, C.A.; Fuess, L.T. Does Sugarcane Vinasse Composition Variability Affect the Bioenergy Yield in Anaerobic Systems? A Dual Kinetic-Energetic Assessment. J. Clean. Prod. 2019, 240, 118005. [Google Scholar] [CrossRef]

- dos Santos, J.F.; Canettieri, E.V.; Souza, S.M.A.; Rodrigues, R.C.L.B.; Martínez, E.A. Treatment of Sugarcane Vinasse from Cachaça Production for the Obtainment of Candida Utilis CCT 3469 Biomass. Biochem. Eng. J. 2019, 148, 131–137. [Google Scholar] [CrossRef]

- Dalsasso, R.R.; Pavan, F.A.; Bordignon, S.E.; de Aragão, G.M.F.; Poletto, P. Polyhydroxybutyrate (PHB) Production by Cupriavidus Necator from Sugarcane Vinasse and Molasses as Mixed Substrate. Process Biochem. 2019, 85, 12–18. [Google Scholar] [CrossRef]

- Sousa, S.P.; Lovato, G.; Albanez, R.; Ratusznei, S.M.; Rodrigues, J.A.D. Improvement of Sugarcane Stillage (Vinasse) Anaerobic Digestion with Cheese Whey as Its Co-Substrate: Achieving High Methane Productivity and Yield. Appl. Biochem. Biotechnol. 2019, 189, 987–1006. [Google Scholar] [CrossRef]

- Silva, G.A.; Ferreira, S.L.; de Souza, G.R.; da Silva, J.A.; Pagliuso, J.D. Utilization of a New Approach for the Potassium Concentration of Sugarcane Vinasse by Reverse Osmosis: Case Study. Int. J. Environ. Sci. Technol. 2019, 16, 6441–6446. [Google Scholar] [CrossRef]

- Vaz, F.L.; de Souza, R.d.F.R.; Dutra, E.D.; Alencar, B.R.A.; Vidal, E.E. Valorization of Sugar-Ethanol Industry Waste Vinasse for Increased Second-Generation Ethanol Production Using Spathaspora Passalidarum Yeast Strains. Sugar Tech 2019, 21, 312–319. [Google Scholar] [CrossRef]

- Gallucci, A.D.; Natera, M.; Moreira, L.A.; Nardi, K.T.; Altarugio, L.M.; de Mira, A.B.; de Almeida, R.F.; Otto, R. Nitrogen-Enriched Vinasse as a Means of Supplying Nitrogen to Sugarcane Fields: Testing the Effectiveness of N Source and Application Rate. Sugar Tech 2019, 21, 20–28. [Google Scholar] [CrossRef]

- Lovato, G.; Batista, L.P.P.; Preite, M.B.; Yamashiro, J.N.; Becker, A.L.S.; Vidal, M.F.G.; Pezini, N.; Albanez, R.; Ratusznei, S.M.; Rodrigues, J.A.D. Viability of Using Glycerin as a Co-Substrate in Anaerobic Digestion of Sugarcane Stillage (Vinasse): Effect of Diversified Operational Strategies. Appl. Biochem. Biotechnol. 2019, 188, 720–740. [Google Scholar] [CrossRef]

- Morais, D.V.; Bastos, R.G. Phycocyanin Production by Aphanothece Microscopica Nägeli in Synthetic Medium Supplemented with Sugarcane Vinasse. Appl. Biochem. Biotechnol. 2019, 187, 129–139. [Google Scholar] [CrossRef] [PubMed]

- Ventorino, V.; Nicolaus, B.; di Donato, P.; Pagliano, G.; Poli, A.; Robertiello, A.; Iavarone, V.; Pepe, O. Bioprospecting of Exopolysaccharide-Producing Bacteria from Different Natural Ecosystems for Biopolymer Synthesis from Vinasse. Chem. Biol. Technol. Agric. 2019, 6, 18. [Google Scholar] [CrossRef]

- Lovato, G.; Albanez, R.; Triveloni, M.; Ratusznei, S.M.; Rodrigues, J.A.D. Methane Production by Co-Digesting Vinasse and Whey in an AnSBBR: Effect of Mixture Ratio and Feed Strategy. Appl. Biochem. Biotechnol. 2019, 187, 28–46. [Google Scholar] [CrossRef]

- Ottoni, C.A.; Simões, M.F.; Santos, J.G.; Peixoto, L.; Martins, C.R.; Silva, B.P.; Neto, A.O.; Brito, A.G.; Maiorano, A.E. Application of Microbial Fuel Cell Technology for Vinasse Treatment and Bioelectricity Generation. Biotechnol. Lett. 2019, 41, 107–114. [Google Scholar] [CrossRef]

- dos Reis, K.C.; Coimbra, J.M.; Duarte, W.F.; Schwan, R.F.; Silva, C.F. Biological Treatment of Vinasse with Yeast and Simultaneous Production of Single-Cell Protein for Feed Supplementation. Int. J. Environ. Sci. Technol. 2019, 16, 763–774. [Google Scholar] [CrossRef]

- de Oliveira, G.H.D.; Niz, M.Y.K.; Zaiat, M.; Rodrigues, J.A.D. Effects of the Organic Loading Rate on Polyhydroxyalkanoate Production from Sugarcane Stillage by Mixed Microbial Cultures. Appl. Biochem. Biotechnol. 2019, 189, 1039–1055. [Google Scholar] [CrossRef]

- Santos, D.R.; Cunha, O.d.M.; Bisinoti, M.C.; Ferreira, O.P.; Moreira, A.B.; Melo, C.A. Hydrochars Produced with By-Products from the Sucroenergetic Industry: A Study of Extractor Solutions on Nutrient and Organic Carbon Release. Environ. Sci. Pollut. Res. 2019, 26, 9137–9145. [Google Scholar] [CrossRef] [PubMed]

- Reis, C.E.R.; Bento, H.B.S.; Alves, T.M.; Carvalho, A.K.F.; de Castro, H.F. Vinasse Treatment within the Sugarcane-Ethanol Industry Using Ozone Combined with Anaerobic and Aerobic Microbial Processes. Environments 2019, 6, 5. [Google Scholar] [CrossRef]

- Montalvo, G.E.B.; Thomaz-Soccol, V.; Vandenberghe, L.P.S.; Carvalho, J.C.; Faulds, C.B.; Bertrand, E.; Prado, M.R.M.; Bonatto, S.J.R.; Soccol, C.R. Arthrospira Maxima OF15 Biomass Cultivation at Laboratory and Pilot Scale from Sugarcane Vinasse for Potential Biological New Peptides Production. Bioresour. Technol. 2019, 273, 103–113. [Google Scholar] [CrossRef] [PubMed]

- Niz, M.Y.K.; Etchelet, I.; Fuentes, L.; Etchebehere, C.; Zaiat, M. Extreme Thermophilic Condition: An Alternative for Long-Term Biohydrogen Production from Sugarcane Vinasse. Int. J. Hydrog. Energy 2019, 44, 22876–22887. [Google Scholar] [CrossRef]

- de Souza Moraes, B.; Mary dos Santos, G.; Palladino Delforno, T.; Tadeu Fuess, L.; José da Silva, A. Enriched Microbial Consortia for Dark Fermentation of Sugarcane Vinasse towards Value-Added Short-Chain Organic Acids and Alcohol Production. J. Biosci. Bioeng. 2019, 127, 594–601. [Google Scholar] [CrossRef]

- Fuess, L.T.; Zaiat, M.; do Nascimento, C.A.O. Novel Insights on the Versatility of Biohydrogen Production from Sugarcane Vinasse via Thermophilic Dark Fermentation: Impacts of PH-Driven Operating Strategies on Acidogenesis Metabolite Profiles. Bioresour. Technol. 2019, 286, 121379. [Google Scholar] [CrossRef]

- Rodrigues Reis, C.E.; Furtado Carvalho, A.K.; Bento, H.B.S.; de Castro, H.F. Integration of Microbial Biodiesel and Bioethanol Industries through Utilization of Vinasse as Substrate for Oleaginous Fungi. Bioresour. Technol. Rep. 2019, 6, 46–53. [Google Scholar] [CrossRef]

- del Gobbo, L.M.; Villegas, L.B.; Colin, V.L. The Potential Application of an Autochthonous Fungus from the Northwest of Argentina for Treatment of Sugarcane Vinasse. J. Hazard. Mater. 2019, 365, 820–826. [Google Scholar] [CrossRef]

- Dirbeba, M.J.; Aho, A.; DeMartini, N.; Brink, A.; Mattsson, I.; Hupa, L.; Hupa, M. Fast Pyrolysis of Dried Sugar Cane Vinasse at 400 and 500 °C: Product Distribution and Yield. Energy Fuels 2019, 33, 1236–1247. [Google Scholar] [CrossRef]

- de Castro Marcato, A.C.; de Souza, C.P.; de Paiva, A.B.; Eismann, C.E.; Navarro, F.F.; Camargo, A.F.M.; Menegário, A.A.; Fontanetti, C.S. Hybrid Treatment System for Remediation of Sugarcane Vinasse. Sci. Total Environ. 2019, 659, 115–121. [Google Scholar] [CrossRef]

- Devia-Orjuela, J.S.; Alvarez-Pugliese, C.E.; Donneys-Victoria, D.; Marriaga Cabrales, N.; Barba Ho, L.E.; Brém, B.; Sauciuc, A.; Gál, E.; Espin, D.; Schichtel, M.; et al. Evaluation of Press Mud, Vinasse Powder and Extraction Sludge with Ethanol in a Pyrolysis Process. Energies 2019, 12, 4145. [Google Scholar] [CrossRef]

- Bettani, S.R.; de Oliveira Ragazzo, G.; Leal Santos, N.; Kieckbusch, T.G.; Gaspar Bastos, R.; Soares, M.R.; Altenhofen da Silva, M. Sugarcane Vinasse and Microalgal Biomass in the Production of Pectin Particles as an Alternative Soil Fertilizer. Carbohydr. Polym. 2019, 203, 322–330. [Google Scholar] [CrossRef] [PubMed]

- Quintero-Dallos, V.; García-Martínez, J.B.; Contreras-Ropero, J.E.; Barajas-Solano, A.F.; Barajas-Ferrerira, C.; Lavecchia, R.; Zuorro, A. Vinasse as a Sustainable Medium for the Production of Chlorella Vulgaris UTEX 1803. Water 2019, 11, 1526. [Google Scholar] [CrossRef]

- Barros, L.B.M.; Andrade, L.H.; Drewes, J.E.; Amaral, M.C.S. Investigation of Electrodialysis Configurations for Vinasse Desalting and Potassium Recovery. Sep. Purif. Technol. 2019, 229, 115797. [Google Scholar] [CrossRef]

- Karchiyappan, T.; Delcolle, R.D.; Goncalves, G.L.; Vareschini, D.T.; Gimenes, M.L. Treatment of Vinasse Liquid from Sugarcane Industry Using Electro-Coagulation/Flocculation Followed by Ultra Filtration. Pol. J. Chem. Technol. 2019, 21, 40–47. [Google Scholar] [CrossRef]

- Albuquerque, J.N.; Ratusznei, S.M.; Rodrigues, J.A.D. Biomethane Production by Thermophilic Co-Digestion of Sugarcane Vinasse and Whey in an AnSBBR: Effects of Composition, Organic Load, Feed Strategy and Temperature. J. Environ. Manag. 2019, 251, 109606. [Google Scholar] [CrossRef]

- Crisafulli, R.; de Lino Amorim, F.M.; de Oliveira Marcionilio, S.M.L.; Mendes Cunha, W.; Brenda, B.R.; Dias, J.A.; Linares, J.J. Electrochemistry for Biofuels Waste Valorization: Vinasse as a Reducing Agent for Pt/C and Its Application to the Electrolysis of Glycerin and Vinasse. Electrochem. Commun. 2019, 102, 25–30. [Google Scholar] [CrossRef]

- le Phuong, T.; Besson, M. Catalytic Wet Air Oxidation Using Supported Pt and Ru Catalysts for Treatment of Distillery Wastewater (Cognac and Sugarcane Vinasses). Energies 2019, 12, 3974. [Google Scholar] [CrossRef]

- Adarme, O.F.H.; Baêta, B.E.L.; Filho, J.B.G.; Gurgel, L.V.A.; de Aquino, S.F. Use of Anaerobic Co-Digestion as an Alternative to Add Value to Sugarcane Biorefinery Wastes. Bioresour. Technol. 2019, 287, 121443. [Google Scholar] [CrossRef]