Mathematical Model for the Generalized VRP Model

Abstract

:1. Introduction

2. The Mathematical Model of the Generalization of the Vehicle Routing Problem

- : level index

- : position index (positions within the level)

- : time in a period

- : vehicle index (vehicles within the level)

- : product index

- : stochastic value index

- : forecasted value index

- : time window index

- : positive large constant

- : start time of node service

- : arrival time at the node

- : time window penalty point

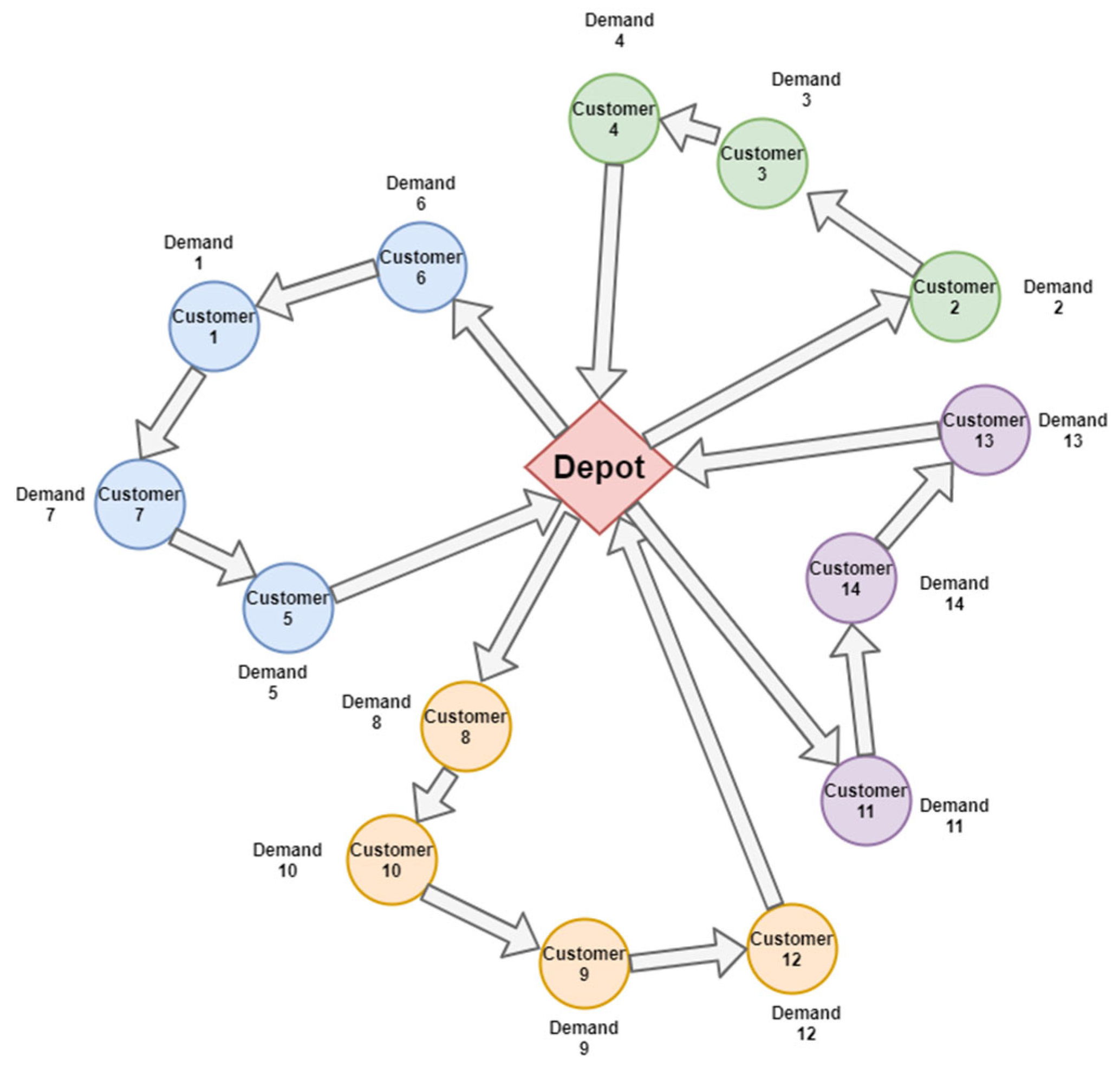

2.1. Topology Graph Description

2.2. Vehicles

2.3. Products, Services

2.4. Time

2.5. Values

2.6. The Attributes of the Node Main Group

2.7. The Attributes of the Vehicle Group

2.8. The Attributes of the Time Group

2.9. The Attributes of the Product Group

2.10. The Attributes of the Cost Group

2.11. The Attributes of the Functional Parameter Group

2.12. Decision Variable and Constraints of Our Model

- (1)

- Decision variable

- (2)

- Constraints

- Constraint 1:

- Constraint 2:

- Constraint 3:

- Constraint 5:

- Constraint 6:

- Constraint 7:

- Constraint 8:

- Constraint 9:

- Constraint 10:

- Constraint 11:

2.13. Objective Function

3. Case Studies of the Generalization of the Vehicle Routing Problem

3.1. Treatment of Waste

Test Runs for Treatment of Waste

3.2. Transport of a Newspaper

Test Runs

3.3. Case Studies in the Literature

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dantzig, G.B.; Ramser, J.H. The Truck Dispatching Problem. Manag. Sci. 1959, 6, 1–140. [Google Scholar] [CrossRef]

- Lin, S. Computer Solutions of the Traveling Salesman Problem. Bell Syst. Tech. J. 1965, 44, 2245–2269. [Google Scholar] [CrossRef]

- Ralphs, T.K.; Kopman, L.; Pulleyblank, W.R.; Trotter, L.E. On the Capacitated Vehicle Routing Problem. Math. Program. 2003, 94, 343–359. [Google Scholar] [CrossRef]

- Nagy, G.; Salhi, S. Heuristic Algorithms for Single and Multiple Depot Vehicle Routing Problems with Pickups and Deliveries. Eur. J. Oper. Res. 2005, 162, 126–141. [Google Scholar] [CrossRef]

- Crainic, T.G.; Perboli, G.; Mancini, S.; Tadei, R. Two-Echelon Vehicle Routing Problem: A Satellite Location Analysis. Procedia Soc. Behav. Sci. 2010, 2, 5944–5955. [Google Scholar] [CrossRef]

- Sabar, N.R.; Bhaskar, A.; Chung, E.; Turky, A.; Song, A. A Self-Adaptive Evolutionary Algorithm for Dynamic Vehicle Routing Problems with Traffic Congestion. Swarm Evol. Comput. 2019, 44, 1018–1027. [Google Scholar] [CrossRef]

- Oosthuizen, N.-M. A Decision Support Framework towards a Simulation Model for the Risk-Constrained Vehicle Routing Problem. Ph.D. Thesis, Stellenbosch University, Stellenbosch, South Africa, 2019. [Google Scholar]

- Talarico, L.; Sörensen, K.; Springael, J. Metaheuristics for the Risk-Constrained Cash-in-Transit Vehicle Routing Problem. Eur. J. Oper. Res. 2015. [Google Scholar] [CrossRef]

- Dondo, R.; Cerdá, J. A Cluster-Based Optimization Approach for the Multi-Depot Heterogeneous Fleet Vehicle Routing Problem with Time Windows. Eur. J. Oper. Res. 2007, 176, 1478–1507. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; Bektaş, T. The Time-Dependent Two-Echelon Capacitated Vehicle Routing Problem with Environmental Considerations. Int. J. Prod. Econ. 2015, 164, 366–378. [Google Scholar] [CrossRef]

- Lin, J.; Zhou, W.; Wolfson, O. Electric Vehicle Routing Problem. In Transportation Research Procedia; 2016. [Google Scholar] [CrossRef] [Green Version]

- Poonthalir, G.; Nadarajan, R. A Fuel Efficient Green Vehicle Routing Problem with Varying Speed Constraint (F-GVRP). Expert Syst. Appl. 2018, 100, 131–144. [Google Scholar] [CrossRef]

- Archetti, C.; Savelsbergh, M.; Speranza, M.G. The Vehicle Routing Problem with Occasional Drivers. Eur. J. Oper. Res. 2016, 254, 472–480. [Google Scholar] [CrossRef]

- Schulze, J.; Fahle, T. A Parallel Algorithm for the Vehicle Routing Problem with Time Window Constraints. Ann. Oper. Res. 1999, 86, 585–607. [Google Scholar] [CrossRef]

- Belhaiza, S.; Hansen, P.; Laporte, G. A Hybrid Variable Neighborhood Tabu Search Heuristic for the Vehicle Routing Problem with Multiple Time Windows. Comput. Oper. Res. 2014, 52, 269–281. [Google Scholar] [CrossRef]

- Figliozzi, M.A. An Iterative Route Construction and Improvement Algorithm for the Vehicle Routing Problem with Soft Time Windows. Transp. Res. Part C Emerg. Technol. 2010, 18, 668–679. [Google Scholar] [CrossRef]

- Gaudioso, M.; Paletta, G. Heuristic for the Periodic Vehicle Routing Problem. Transp. Sci. 1992, 26, 86–92. [Google Scholar] [CrossRef]

- Mattos Ribeiro, G.; Laporte, G. An Adaptive Large Neighborhood Search Heuristic for the Cumulative Capacitated Vehicle Routing Problem. Comput. Oper. Res. 2012, 39, 728–735. [Google Scholar] [CrossRef]

- Hsu, C.I.; Hung, S.F.; Li, H.C. Vehicle Routing Problem with Time-Windows for Perishable Food Delivery. J. Food Eng. 2007, 80, 465–475. [Google Scholar] [CrossRef]

- Kabcome, P.; Mouktonglang, T. Vehicle Routing Problem for Multiple Product Types, Compartments, and Trips with Soft Time Windows. Int. J. Math. Math. Sci. 2015, 2015, 126754. [Google Scholar] [CrossRef]

- Allahviranloo, M.; Chow, J.Y.J.; Recker, W.W. Selective Vehicle Routing Problems under Uncertainty without Recourse. Transp. Res. Part E Logist. Transp. Rev. 2014, 62, 68–88. [Google Scholar] [CrossRef]

- Li, F.; Golden, B.; Wasil, E. The Open Vehicle Routing Problem: Algorithms, Large-Scale Test Problems, and Computational Results. Comput. Oper. Res. 2007, 34, 2918–2930. [Google Scholar] [CrossRef]

- Crevier, B.; Cordeau, J.F.; Laporte, G. The Multi-Depot Vehicle Routing Problem with Inter-Depot Routes. Eur. J. Oper. Res. 2007, 176, 756–773. [Google Scholar] [CrossRef]

- Lin, C.K.Y. A Vehicle Routing Problem with Pickup and Delivery Time Windows, and Coordination of Transportable Resources. Comput. Oper. Res. 2011, 38, 1596–1609. [Google Scholar] [CrossRef]

- Yu, V.F.; Jewpanya, P.; Redi, A.A.N.P. Open Vehicle Routing Problem with Cross-Docking. Comput. Ind. Eng. 2016, 94, 6–17. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, B. Fuzzy Vehicle Routing Model with Credibility Measure and Its Hybrid Intelligent Algorithm. Appl. Math. Comput. 2006, 176, 673–683. [Google Scholar] [CrossRef]

- Stewart, W.R.; Golden, B.L. Stochastic Vehicle Routing: A Comprehensive Approach. Eur. J. Oper. Res. 1983, 14, 371–385. [Google Scholar] [CrossRef]

- Keskin, M.; Çatay, B.; Laporte, G. A Simulation-Based Heuristic for the Electric Vehicle Routing Problem with Time Windows and Stochastic Waiting Times at Recharging Stations. Comput. Oper. Res. 2021, 125, 105060. [Google Scholar] [CrossRef]

- Molina, J.C.; Salmeron, J.L.; Eguia, I.; Racero, J. The Heterogeneous Vehicle Routing Problem with Time Windows and a Limited Number of Resources. Eng. Appl. Artif. Intell. 2020, 94, 103745. [Google Scholar] [CrossRef]

- Li, Y.; Soleimani, H.; Zohal, M. An Improved Ant Colony Optimization Algorithm for the Multi-Depot Green Vehicle Routing Problem with Multiple Objectives. J. Clean. Prod. 2019, 227, 1161–1172. [Google Scholar] [CrossRef]

- Xu, Z.; Elomri, A.; Pokharel, S.; Mutlu, F. A Model for Capacitated Green Vehicle Routing Problem with the Time-Varying Vehicle Speed and Soft Time Windows. Comput. Ind. Eng. 2019, 137, 106011. [Google Scholar] [CrossRef]

- Babagolzadeh, M.; Shrestha, A.; Abbasi, B.; Zhang, S.; Atefi, R.; Woodhead, A. Sustainable Open Vehicle Routing with Release-Time and Time-Window: A Two-Echelon Distribution System. IFAC-Pap. 2019, 52, 571–576. [Google Scholar] [CrossRef]

- Simeonova, L.; Wassan, N.; Salhi, S.; Nagy, G. The Heterogeneous Fleet Vehicle Routing Problem with Light Loads and Overtime: Formulation and Population Variable Neighbourhood Search with Adaptive Memory. Expert Syst. Appl. 2018, 114, 183–195. [Google Scholar] [CrossRef]

- Mutar, M.; Burhanuddin, M.; Hameed, A.; Yusof, N.; Mutashar, H. An efficient improvement of ant colony system algorithm for handling capacity vehicle routing problem. Int. J. Ind. Eng. Comput. 2020, 11, 549–564. [Google Scholar] [CrossRef]

- Abbasi, M.; Rafiee, M.; Khosravi, M.R.; Jolfaei, A.; Menon, V.G.; Koushyar, J.M. An efficient parallel genetic algorithm solution for vehicle routing problem in cloud implementation of the intelligent transportation systems. J. Cloud Comput. 2020, 9, 1–14. [Google Scholar] [CrossRef]

- İlhan, İlhan An improved simulated annealing algorithm with crossover operator for capacitated vehicle routing problem. Swarm Evol. Comput. 2021, 64, 100911. [CrossRef]

- Gmira, M.; Gendreau, M.; Lodi, A.; Potvin, J.Y. Tabu search for the time-dependent vehicle routing problem with time windows on a road network. Eur. J. Oper. Res. 2021, 288, 129–140. [Google Scholar] [CrossRef]

- Moustafa, A.; Abdelhalim, A.A.; Eltawil, A.B.; Fors, N. Waste collection vehicle routing problem: Case study in Alexandria, Egypt. In The 19th International Conference on Industrial Engineering and Engineering Management; Springer: Berlin/Heidelberg, Germany, 2013; pp. 935–944. [Google Scholar] [CrossRef]

- Boonkleaw, A.; Suthikarnnarunai, N.; Srinon, R. Strategic planning and vehicle routing algorithm for newspaper delivery problem: Case study of morning newspaper, bangkok, thailand. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 20–22 October 2009; Volume 2, pp. 1067–1071. [Google Scholar]

- Campelo, P.; Neves-Moreira, F.; Amorim, P.; Almada-Lobo, B. Consistent vehicle routing problem with service level agreements: A case study in the pharmaceutical distribution sector. Eur. J. Oper. Res. 2019, 273, 131–145. [Google Scholar] [CrossRef]

- Ramadhani, D.S.; Masruroh, N.A.; Waluyo, J. Model Of Vehicle Routing Problem With Split Delivery, Multi Trips, Multi Products And Compartments For Determining Fuel Distribution Routes. ASEAN J. Syst. Eng. 2021, 5, 51–55. [Google Scholar]

| Name | Description |

|---|---|

| Node Component | |

| Traveling Salesman Problem [2] | A single agent (vehicle) visits the cities (customers). The vehicle makes a trip. The objective is to minimize the distance the vehicle travels. Cities (customers) have no product demand |

| Vehicle Routing Problem with Single Depot [3] | The vehicles leave a common depot, visit the customers (deliver products to the customers) and then return to the depot (after the customers have visited). |

| Vehicle Routing Problem with Multiple Depot [4] | The system includes several depots, each vehicle starts their route from one of the depots and then returns there at the end of their route. |

| Two-Echelon Vehicle Routing Problem [5] | The products are first transported from the depot to intermediate locations (satellites) and then onwards to customers. Movements of products between a depot-satellite and a satellite-customer can be made by different types of (capacity-constrained) vehicles. Thus, depot-satellite vehicles have a higher capacity limit and satellite-customer vehicles have a lower capacity limit. |

| Vehicle Routing Problems with Traffic Congestion [6] | The time between each node (depots, satellites, customers) also depends on the traffic. The objective is for vehicles to make their route as soon as possible. |

| Risk Constrained Vehicle Routing Problem [7] | The road safety between the individual nodes (depots, satellites, customers) was also given. The objective is for vehicles to travel as safely as possible. |

| Risk-constrained Cash-in-Transit Vehicle Routing Problem [8] | This problem is similar to the Risk Constrained Vehicle Routing Problem, but here cash-in-transit vehicles travel |

| Vehicle component | |

| Homogeneous Fleet Vehicle Routing Problem [9] | The system includes vehicles of the same type. |

| Heterogeneous Fleet Vehicle Routing Problem [9] | The system includes different types of vehicles. |

| Capacitated Vehicle Routing Problem [3] | The vehicles have a capacity constraint on the products. |

| Environmentally Friendly Vehicle Routing Problem [10] | The vehicles are of an environmentally friendly type. |

| Electric Vehicle Routing Problem [11] | Electric vehicles travel, the vehicles visit recharger stations after a certain distance. |

| Fuel Efficient Green Vehicle Routing Problem [12] | The objective is to minimize fuel emissions from vehicles. |

| Vehicle Routing Problem with Occasional Drivers [13] | If the company is unable to deliver the products with its fleet of vehicles, it can also use rented vehicles to meet the goods needs of the customers. |

| Time component | |

| Vehicle Routing Problem with Time Window [14] | Customers may have different time windows. The product demands of the customers must be served within the time window. The customer can have single or multiple time window. |

| Vehicle Routing Problem with Multiple Time Windows [15] | Multiple time windows have been added to customers. The product demands of the customers must be satisfied within a time window. |

| Vehicle Routing Problem with Soft Time Window [16] | The demands of the customers can be met outside the time window, but then there is a penalty point. |

| Periodic Vehicle Routing Problem [17] | Customers do not have to be visited once, but periodically, even several times within a (predefined) period. |

| Cumulative Capacitated Vehicle Routing Problem [18] | The objective is to minimize latency at the nodes. |

| Vehicle Routing Problem with Perishable Food Products Delivery [19] | Perishable products are delivered, so the expiration date of the products must also be taken into account. |

| Product component | |

| Vehicle Routing Problem with Multiple Product [20] | There are several types of products in the system. This means that each customer may have multiple product demands. |

| Cost component | |

| Selective Vehicle Routing Problem [21] | Not all demands of the customers are satisfied, only those that are profitable. |

| Functional parameter component | |

| Open Vehicle Routing Problem [22] | One or more depots are in the system from which vehicles departed to visit customers. However, the vehicles after visit the customers do not return to the depot. |

| Multi-Depot Vehicle Routing Problem with Inter-Depot Routes [23] | One or more depots are in the system from which vehicles departed to visit customers. Once the customers are visited, vehicles can return to any depot. |

| Vehicle Routing Problem with Pickup and Delivery [24] | Not only the delivery but also the collection (pickup) of products is important. |

| Vehicle Routing Problem with Cross-Docking [25] | The collected products are not stored for a long time, almost immediately after the pick-up, delivery phase begins. |

| Value parameter component | |

| Static value | The value is given by a real number. |

| Fuzzy Vehicle Routing Problem [26] | Some factors, e.g., time window, demand for products, the distance between nodes, etc. given with fuzzy numbers. |

| Stochastic Vehicle Routing Problem [27] | Some factors, e.g., time window, demand for products, the distance between nodes, etc. given with a probability distribution. |

| Attribute Name | Notation | Short Notation | Dependency | Value Type |

|---|---|---|---|---|

| Travel time between the nodes | : the starting node : the ending node : the vehicle type : the time | static, stochastic, fuzzy, forecasted | ||

| Travel distance between the nodes | ||||

| Reliability between the nodes | ||||

| Route status between the nodes | ||||

| Type of the node | : the node | CUSTOMER, DEPOT, SATELLITE, RECHARGERSTATION |

| Attribute Name | Notation | Short Notation | Dependency | Value Type |

|---|---|---|---|---|

| The capacity constraint | : vehicle : product | static, stochastic, fuzzy, forecasted | ||

| Fuel consumption | : vehicle | |||

| Recharger time | ||||

| Own vehicle or borrowed vehicle | ||||

| Rental fee per vehicle types | ||||

| Maximum distance with a full tank |

| Attribute Name | Notation | Short Notation | Dependency | Value Type |

| Service handling time | : the starting node : the ending node the product : the vehicle type : the time | static, stochastic, fuzzy, forecasted | ||

| Packing time | ||||

| Unpacking time | ||||

| Loading time | ||||

| Unloading time | ||||

| Fixed capital time | ||||

| Administration time | ||||

| Quality control time | ||||

| Time window | : the starting node : the ending node the product : the time | (latest time) can be static, stochastic, fuzzy, forecasted |

| Attribute Name | Notation | Short Notation | Dependency | Value Type |

|---|---|---|---|---|

| The capacity constraint of the node | : the starting node : the ending node the product : the time | static, stochastic, fuzzy, forecasted | ||

| Product demand of the node | ||||

| Prices of product | ||||

| Given order of products | . | |||

| Given products handling together | one product another product | true, false | ||

| Storage level of the locations | : the starting node : the ending node the product : the time | static, stochastic, fuzzy, forecasted |

| Attribute Name | Notation | Short Notation | Dependency | Value Type |

|---|---|---|---|---|

| Packaging costs | : the starting node the product : the vehicle : the time | static, stochastic, fuzzy, forecasted | ||

| Unpacking cost | ||||

| Loading costs | ||||

| Unloading costs | ||||

| Administrative costs | ||||

| Quality control cost |

| Attribute Name | Notation | Short Notation | Dependency | Value Type |

| Inter-depot route | : the vehicle | true, false | ||

| Delivery | : the starting node the product | |||

| Pickup | ||||

| Soft time window | ||||

| Open route | : the vehicle |

| Parameter | Value |

| Ant Colony System | |

| Number of ants | 70 |

| 0.8 | |

| 1 | |

| 2 | |

| 0.8 | |

| Genetic algorithm | |

| Population size | 6 |

| Elitism rate | 16% |

| Order crossover rate | 18% |

| Partially matched crossover rate | 18% |

| Cycle crossover rate | 18% |

| Mutation rate | 30% |

| Simulated annealing | |

| 0.85 | |

| Temperature | 1000 |

| Length | 2 |

| Tabu list | |

| Tabu List Size | 5 |

| Parameter | Value |

| Base parameters | |

| Number of levels | 2 |

| Number of nodes belonging to the first level | 1 |

| Location of first level nodes | [0, 100] |

| Number of second-level nodes | 50 |

| Location of second level nodes | [200, 300] |

| Number of charging stations | 2 |

| Location of charging stations | [100, 110] |

| Number of periods | 1 |

| Number of product types | 1 |

| Number of vehicles | 3 |

| Node parameters | |

| Travel Distance Between Nodes | uniform |

| Product parameters | |

| Product Demand of The Node | uniform, [0, 50] |

| Vehicle parameters | |

| Capacity Constraint of The Vehicle | uniform, [1000, 5000] |

| Metrics | |

| Length of the route | |

| Unvisited customers | |

| Instance + Algorithm | Average Fitness | Average Running Time (sec) |

| Number of Nodes: 1st Level: 1, 2nd Level:50, Recharger station:2 | ||

| I-1-50-2 + ACS | 4139.87 | 96.86 |

| I-1-50-2 + GA | 4534.91 | 100.75 |

| I-1-50-2 + SA | 4608.17 | 106.84 |

| I-1-50-2 + TS | 4804.29 | 137.80 |

| Parameter | Value | ||

| Base Parameters | |||

| Number of levels | 4 | ||

| Number of nodes belonging to the first level | 1 | ||

| Location of first level nodes | [0, 100] | ||

| Number of second-level nodes | 2 | ||

| Location of second level nodes | [200, 300] | ||

| Number of third level nodes | 2 | ||

| Location of third level nodes | [400, 500] | ||

| Number of nodes belonging to the fourth level | 15 | 20 | 30 |

| Location of fourth level nodes | [600, 700] | ||

| Number of charging stations | 2 | ||

| Location of charging stations | [100, 110] | ||

| Number of periods | 1 | ||

| Number of product types | 1 | ||

| Number of vehicles (per level) | 2 | ||

| Number of vehicles rented | 0 | ||

| Cost-related parameters | |||

| Administration Cost | uniform, [10, 50] | ||

| Loading Cost | uniform, [10, 50] | ||

| Quality Control Cost | uniform, [10, 50] | ||

| Unloading Cost | uniform, [10, 50] | ||

| Node parameters | |||

| Route Status Between Nodes | uniform, [100, 500] | ||

| Travel Distance Between Nodes | uniform | ||

| Travel Time Between Nodes | uniform, [10, 100] | ||

| Product parameters | |||

| Product Demand of The Node | uniform, [10, 100] | ||

| Admininstration Time | uniform, [30, 50] | ||

| Loading Time | uniform, [30, 50] | ||

| Unloading Time | uniform, [30, 50] | ||

| Vehicle parameters | |||

| Capacity Constraint of The Vehicle | uniform, [10,000, 50,000] | ||

| Fuel Consumption of The Vehicle | uniform, [10, 100] | ||

| Metrics | |||

| Length of the route | |||

| Fuel consumption | |||

| Route status | |||

| Route time | |||

| Unvisited customers | |||

| Instance+Algorithm | Average Fitness | Average Running Time (s) |

| Number of Nodesnodes: 1st Level: 1, 2nd Level: 2, 3rd Level: 2, 4th Level:15, Recharger station:2 | ||

| I-1-2-2-15-2 + ACS | 5613.22 | 220.20 |

| I-1-2-2-15-2 + GA | 5747.99 | 225.51 |

| I-1-2-2-15-2 + SA | 5459.81 | 250.19 |

| I-1-2-2-15-2 + TS | 5780.00 | 249.83 |

| Number of nodes: 1st level: 1, 2nd level: 2, 3rd level: 2, 4th level:20, recharger station:2 | ||

| I-1-2-2-20-2 + ACS | 6089.87 | 452.53 |

| I-1-2-2-20-2 + GA | 7685.11 | 410.73 |

| I-1-2-2-20-2 + SA | 6394.58 | 430.10 |

| I-1-2-2-20-2 + TS | 7590.70 | 421.03 |

| Number of nodes: 1st level: 1, 2nd level: 2, 3rd level: 2, 4th level:30, recharger station:4 | ||

| I-1-2-2-30-4 + ACS | 6144.91 | 1190.27 |

| I-1-2-2-30-4 + GA | 7072.18 | 1132.62 |

| I-1-2-2-30-4 + SA | 6512.46 | 1132.15 |

| I-1-2-2-30-4 + TS | 6928.09 | 1198.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agárdi, A.; Kovács, L.; Bányai, T. Mathematical Model for the Generalized VRP Model. Sustainability 2022, 14, 11639. https://doi.org/10.3390/su141811639

Agárdi A, Kovács L, Bányai T. Mathematical Model for the Generalized VRP Model. Sustainability. 2022; 14(18):11639. https://doi.org/10.3390/su141811639

Chicago/Turabian StyleAgárdi, Anita, László Kovács, and Tamás Bányai. 2022. "Mathematical Model for the Generalized VRP Model" Sustainability 14, no. 18: 11639. https://doi.org/10.3390/su141811639