Study on Anti-Uplift Effect of Micro-Steel-Pipe Pile on Red-Bedded Soft Rock Subgrade

Abstract

:1. Introduction

2. Field Test on Uplift Behavior of Micro-Piles

2.1. Geological Setting and Sample Description

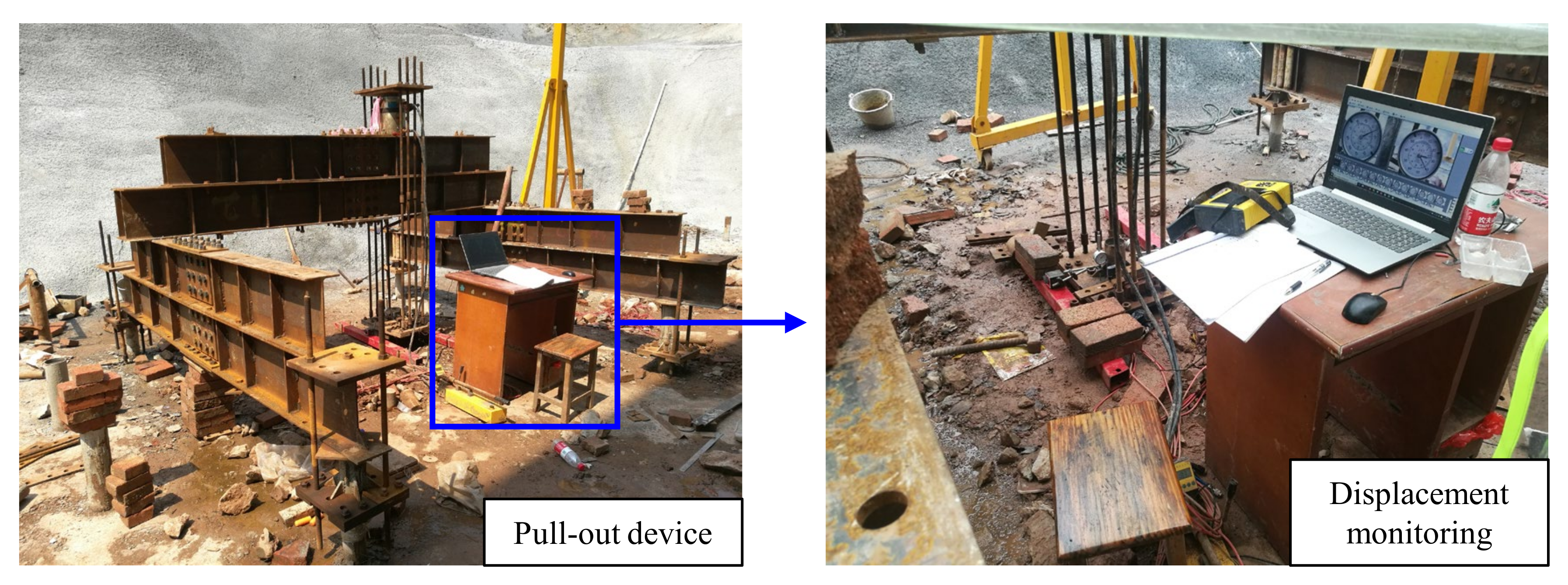

2.2. Test Scheme and Preparation

2.3. Testing Process

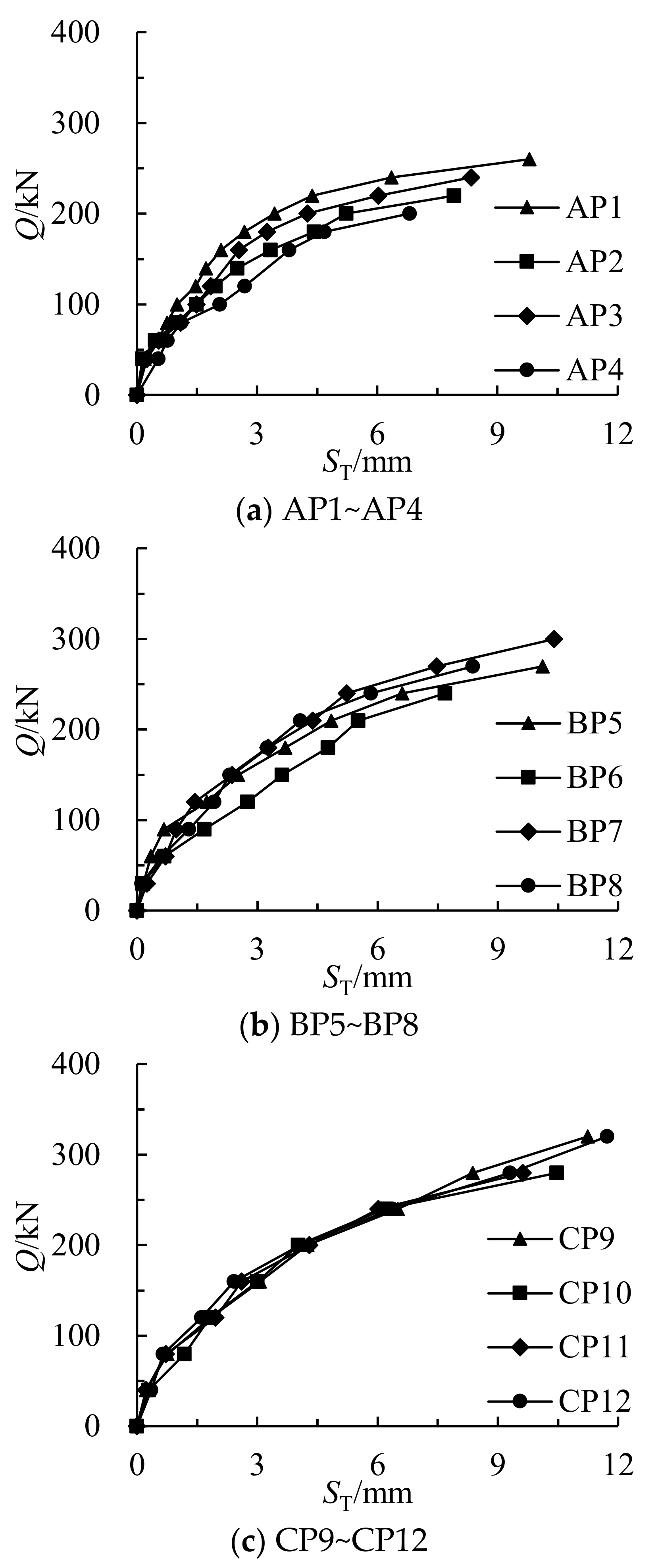

2.4. Testing Results Presentation

2.4.1. Vertical Uplift Bearing Capacity and Uplift Displacement

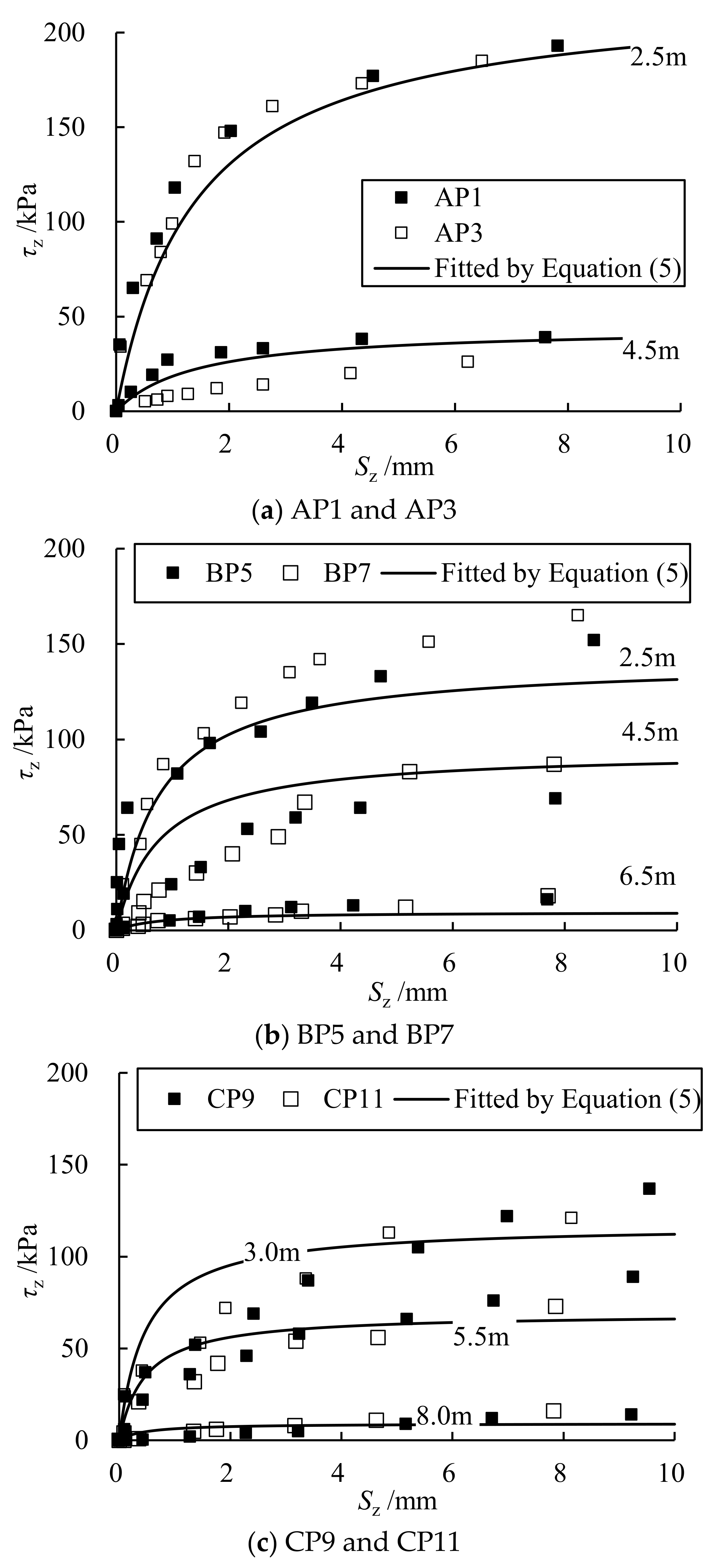

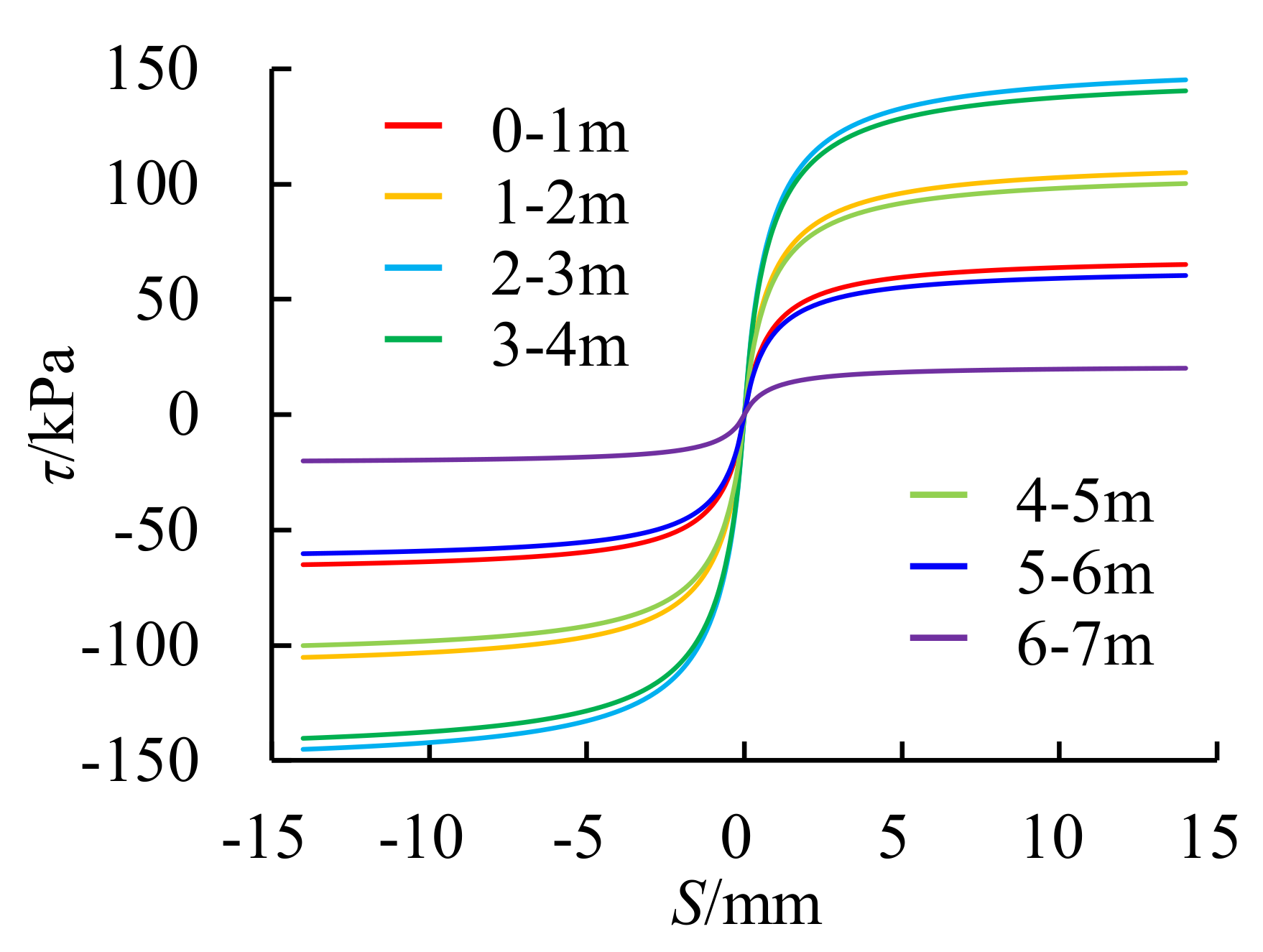

2.4.2. Lateral Friction and Relative Displacement between Soil and Pile

3. Numerical Simulation and Parameter Inversion

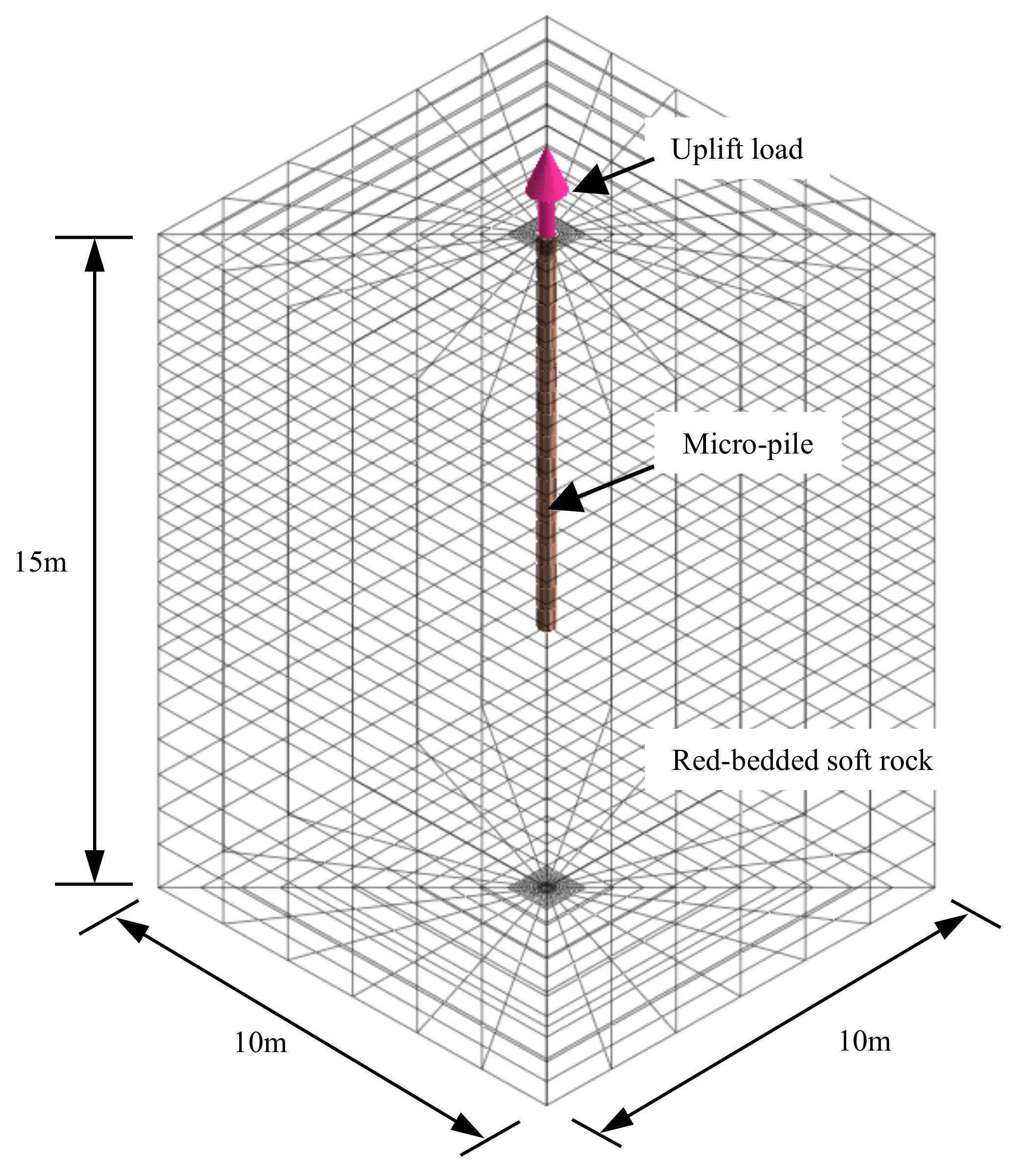

3.1. Numerical Model

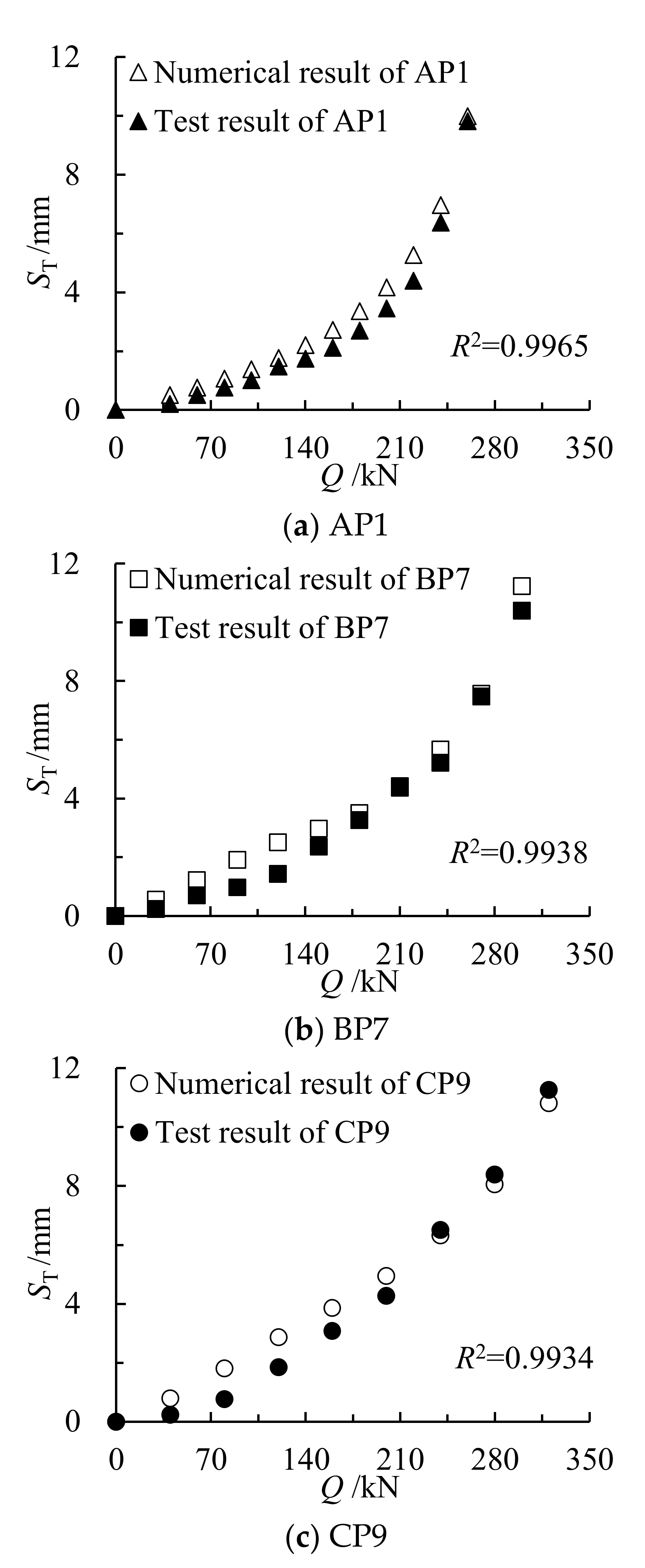

3.2. Numerical Results

4. Investigation on the Effect of Micro-Piles against Uplift

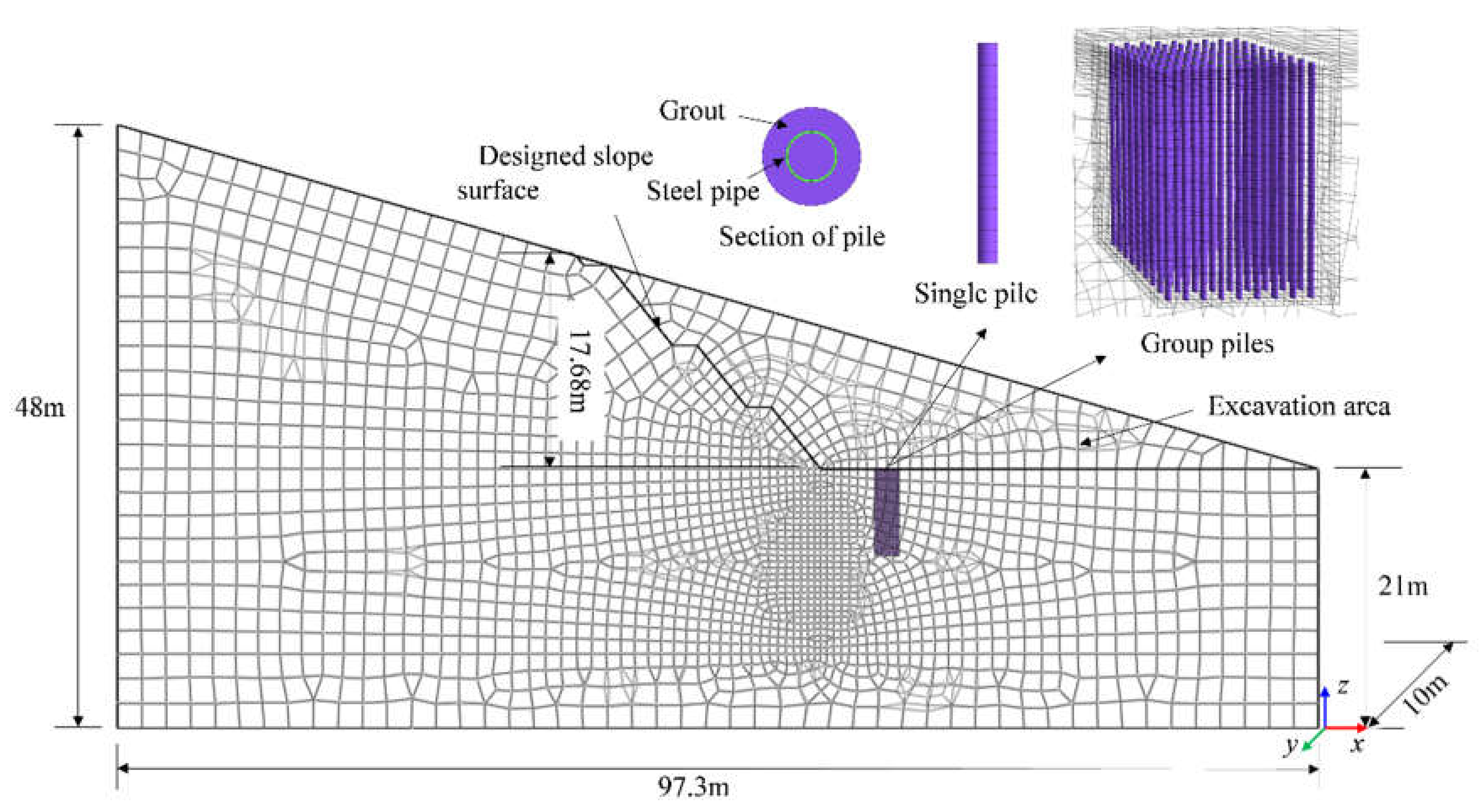

4.1. Numerical Model

4.2. Effect of Single Micro-Pile against Uplift

4.3. Effect of Group Micro-Piles against Uplift

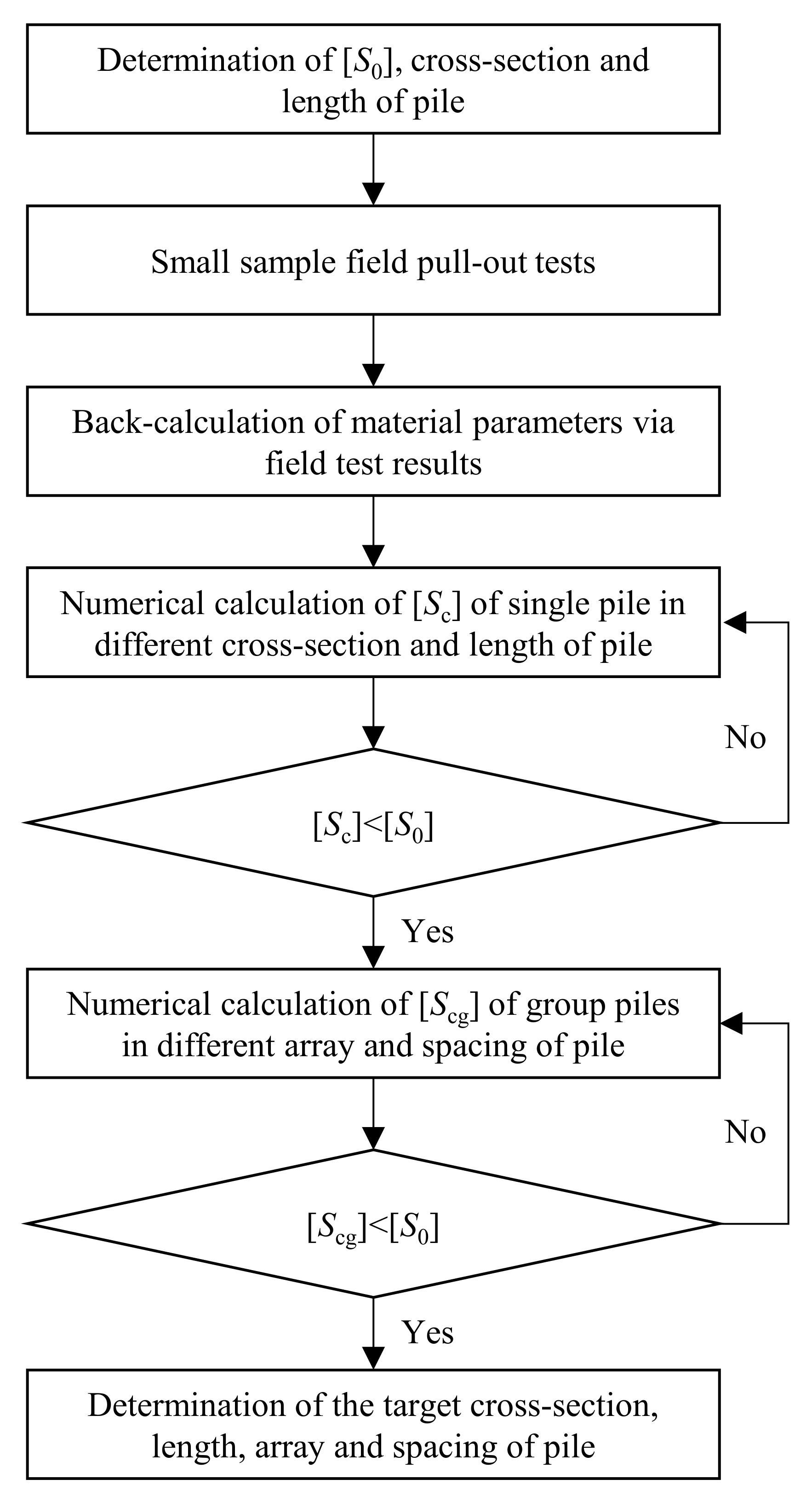

5. Design Method of Micro-Piles in Red-Bedded Soft Rock against Uplift

5.1. Neutral Point of Micro-Pile

5.2. Anti-Uplift Design Method of Micro-Piles in Red-Bedded Soft Rock

- Determine the allowable uplift displacement of subgrade [S0] based on working condition, and pre-set the micro-pile cross-section and length.

- Conduct the small sample field pull-out tests on micro-piles in the area to be treated to obtain site-related test data.

- Conduct numerical simulations to invert the relevant material parameters based on the field test results.

- Set up the numerical model of micro single-pile in red-bedded soft rock subgrade after excavation, perform trial calculations by changing the pile cross-section as well as the length, and calculate the corresponding subgrade uplift displacement [Sc] until [Sc] < [S0], to obtain the target pile cross-section and pile length.

- According to the target pile cross-section and length, perform trial calculations by changing the array of piles as well as the pile spacing, and calculate the corresponding subgrade uplift displacement [Scg] until [Scg] < [S0], to obtain the target pile array and pile spacing.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Gao, W. Effect of different test methods on the disintegration behaviour of soft rock and the evolution model of disintegration breakage under cyclic wetting and drying. Eng. Geol. 2020, 279, 105888. [Google Scholar] [CrossRef]

- Zhou, M.; Li, J.; Luo, Z.; Sun, J.; Xu, F.; Jiang, Q.; Deng, H. Impact of water-rock interaction on the pore structures of red-bed soft rock. Sci. Rep. 2021, 11, 73–98. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Kang, B.; Zha, F.; Li, Y.; Zhang, Q.; Chu, C. Disintegration characteristics and mechanism of red-bed argillaceous siltstone under drying-wetting cycle. Environ. Earth Sci. 2022, 81, 336. [Google Scholar] [CrossRef]

- Liu, Z.; He, X.; Zhou, C. Influence mechanism of different flow patterns on the softening of red-bed soft rock. J. Mar. Sci. Eng. 2019, 7, 155. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, S.; Wang, Y.; Dai, Z. Crack evolution characteristics and cracking mechanism of red beds in central Sichuan during seepage and swelling. Geofluids 2021, 2021, 9981046. [Google Scholar] [CrossRef]

- Huang, W.; Feng, R.; Fu, H.; Chen, J.; Feng, Z. Mechanical properties of soft rocks subjected to water-rock reaction and cyclic pressure. Adv. Civ. Eng. 2022, 2022, 1533464. [Google Scholar] [CrossRef]

- Yang, Y.C.; Zhou, J.W.; Xu, F.G.; Xing, H.-G. An experimental study on the water-induced strength reduction in Zigong argillaceous siltstone with different degree of weathering. Adv. Mater. Sci. Eng. 2016, 2016, 4956986. [Google Scholar] [CrossRef]

- Mana, D.; Gourvenec, S.; Randolph, M.F. Numerical modelling of seepage beneath skirted foundations subjected to vertical uplift. Comput. Geotech. 2014, 55, 150–157. [Google Scholar] [CrossRef]

- Kim, N.; Park, D.; Jung, H.; Kim, M.I. Deformation characteristics of tunnel bottom after construction under geological conditions of long-term deformation. Geomech. Eng. 2020, 21, 171–178. [Google Scholar] [CrossRef]

- Tao, X.; Su, Y.; Zhu, Q.; Wang, W.-L. Pasternak model-based tunnel segment uplift model of subway shield tunnel during construction. Adv. Civ. Eng. 2021, 2021, 8587602. [Google Scholar] [CrossRef]

- Zhong, Z.; Li, A.; Deng, R.; Wu, P.P.; Xu, J. Experimental study on the time-dependent swelling characteristics of red-bed mudstone in Central Sichuan. Chin. J. Rock Mech. Eng. 2019, 38, 76–86. (In Chinese) [Google Scholar]

- Dai, Z.; Guo, J.; Zhou, Z.; Chen, S.X.; Li, J.; Yu, F. Inversion and prediction of long-term uplift deformation of high-speed railway subgrade in Central Sichuan red-bed. Chin. J. Rock Mech. Eng. 2020, 39, 3538–3548. (In Chinese) [Google Scholar]

- Veludo, J.; Julio EN, B.S.; Dias-da-Costa, D. Compressive strength of micropile-to-grout connections. Constr. Build. Mater. 2012, 26, 172–179. [Google Scholar] [CrossRef]

- Malik, B.A.; Shah, M.Y.; Sawant, V.A. Influence of micropile parameters on bearing capacity of footings. Environ. Sci. Pollut. Res. 2021, 28, 48274–48283. [Google Scholar] [CrossRef]

- Jeng, C.; Lin, C. Performance analysis of slopes reinforced using micropiles. J. Perform. Constr. Facil. 2018, 32, 04018008. [Google Scholar] [CrossRef]

- Seo, H.; Prezzi, M.; Salgado, R. Instrumented static load test on rock-socketed micropile. J. Geotech. Geoenviron. Eng. 2013, 139, 2037–2047. [Google Scholar] [CrossRef]

- Lee, T.; Chul, I.J.; Kim, C. A method for reinforcing the ground adjacent to the footing using micropiles. Mar. Georesour. Geotechnol. 2016, 34, 341–355. [Google Scholar] [CrossRef]

- Zeng, Z.; Ye, M.; Wang, W.; Liu, J.; Shen, S.; Qahtan, A.A.S. Analysis on mechanical characteristics of CRTSII slab ballastless track structures in rectification considering material brittleness. Constr. Build. Mater. 2022, 319, 126058. [Google Scholar] [CrossRef]

- Cai, X.; Zhang, Q.; Wang, Q.; Cui, X.; Dong, B. Effects of the subgrade differential arch on damage characteristics of CRTS III slab track and vehicle dynamic response. Constr. Build. Mater. 2022, 327, 126982. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, J.; Wang, W.; Bai, S.; Lin, P. Study on slope stability due to the influence of excavation of the high-speed rail tunnel. Geomat. Nat. Hazards Risk 2019, 10, 1193–1208. [Google Scholar] [CrossRef]

- Wang, G.; Chen, W.; Cao, L.; Li, Y.; Liu, S.; Yu, J.; Wang, B. Retaining technology for deep foundation pit excavation adjacent to high-speed railways based on deformation control. Front. Earth Sci. 2021, 9, 735315. [Google Scholar] [CrossRef]

- Duan, J.; Yang, G.; Hu, M.; Wang, G.; Lin, Y. Heave performance of a ballastless track subgrade of double line high-speed railway filled with micro-expansive andesite under water immersion. Constr. Build. Mater. 2020, 252, 119087. [Google Scholar] [CrossRef]

- Dai, Z.; Guo, J.; Yu, F.; Zhou, Z.; Li, J.; Chen, S. Long-term uplift of high-speed railway subgrade caused by swelling effect of red-bed mudstone: Case study in Southwest China. Bull. Eng. Geol. Environ. 2021, 80, 4855–4869. [Google Scholar] [CrossRef]

- Wang, P.; Ye, Y.; Zhang, Q.; Liu, J.; Yao, J. Investigation on the sulfate attack-induced heave of a ballastless track railway subgrade. Transp. Geotech. 2020, 23, 100316. [Google Scholar] [CrossRef]

- Yu, F.; Tong, K.; Dai, Z.; Feng, G.-S.; Zhou, Z.; Chen, S.-X. Macro and micro research on swelling characteristics and deformation mechanism of red-bed mudstone in Central Sichuan, China. Geofluids 2022, 2022, 6431590. [Google Scholar] [CrossRef]

- Shan, Y.; Xiao, W.; Xiang, K.; Wang, B.; Zhou, S. Semi-automatic construction of pile-supported subgrade adjacent to existing railway. Autom. Constr. 2022, 134, 104085. [Google Scholar] [CrossRef]

- Shan, Y.; Zhou, X.; Zhou, S. One-dimensional semi-analytical model on longitudinal thermal loads of a tram track pile-plank structure buried beneath the pavement. Arch. Civ. Mech. Eng. 2021, 21, 36. [Google Scholar] [CrossRef]

- Wei, L.; Li, S.; Lin, Y.; He, Q.; Zhang, C. Dynamic performance of a deep buried pile-plank structure transition section for a high-speed railway-field tests and numerical analyses. Transp. Geotech. 2020, 25, 100408. [Google Scholar] [CrossRef]

- Li, S.; Wei, L.; Chen, X.; He, Q. Numerical investigation on dynamic performance of a bridge-tunnel transition section with a deep buried pile-plank structure. Adv. Civ. Eng. 2020, 2020, 8885535. [Google Scholar] [CrossRef]

- Lee, T.; Im, J.; Kim, C.; Seo, M. An experimental study for reinforcing the ground underneath a footing using micropiles. Geotech. Test. J. 2018, 41, 648–663. [Google Scholar] [CrossRef]

- Kyung, D.; Lee, J. Uplift load-carrying capacity of single and group micropiles installed with inclined conditions. J. Geotech. Geoenviron. Eng. 2017, 143, 04017031. [Google Scholar] [CrossRef]

- Kyung, D.; Kim, G.-R.; Park, D.-S.; Kim, D.-H.; Lee, J.-H. Uplift behavior of group micropile according to embedded pile condition in sand. J. Korean Geotech. Soc. 2015, 31, 27–37. [Google Scholar] [CrossRef] [Green Version]

- Ying, C.; Hu, X.; Siddiqua, S.; Makeen, G.M.H.; Xia, P.; Xu, C.; Wang, Q. Model tests for observing the deformation characteristics of micropile boreholes during drilling in a soil-limestone mixture. Bull. Eng. Geol. Environ. 2021, 80, 6373–6393. [Google Scholar] [CrossRef]

- Gupta, R.K.; Chawla, S. Performance evaluation of micropiles as a ground improvement technique for existing railway tracks: Finite-element and genetic programming approach. Int. J. Geomech. 2022, 22, 04021287. [Google Scholar] [CrossRef]

- Zekavati, A.; Khodaverdian, A.; Jafari, M.; Hosseini, A. Investigating performance of micropiled raft in foundation of power transmission line towers in cohesive soil: Experimental and numerical study. Can. Geotech. J. 2018, 55, 312–328. [Google Scholar] [CrossRef]

- JGJ 94-2008; Technical Code for Building Pile Foundations. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2008.

- JGJ/T 72-2017; Standard for Geotechnical Investigation of Tall Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2017.

- JGJ 106-2014; Technical Code for Testing of Building Foundation Piles. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2014.

- Zhou, J.; Zhou, C.; Feng, Q.; Gao, T. Analytical model for load-transfer mechanism of rock-socketed drilled piles: Considering bond strength of the concrete-rock interface. Int. J. Geomech. 2020, 20, 04020059. [Google Scholar] [CrossRef]

- Xu, Y.; Kong, F.; Gao, K.; Hu, Z.; Han, L. The mechanism of mudstone skin friction of large-diameter and long piles based on the pile test of the Longhua Songhua River Bridge in Jilin Province, China. Arab. J. Geosci. 2021, 14, 2401. [Google Scholar] [CrossRef]

| Natural Unit Weight | Saturated Uniaxial Compressive Strength | Standard Value of End Resistance | Standard Value of Lateral Friction | Cohesion | Internal Friction Angle | Elastic Modulus | Poisson’s Ratio |

|---|---|---|---|---|---|---|---|

| /(kN·m−3) | /MPa | /kPa | /kPa | /kPa | /(°) | /MPa | |

| 23.0 | 4.2~12.9 | 1500 | 120 | 90 | 30 | 1000 | 0.25 |

| Test Series | Ultimate Uplift Bearing Capacity/kN | Ultimate Uplift Displacement/mm | ||

|---|---|---|---|---|

| Value | Average Value | Value | Average Value | |

| AP1 | 240 | 215 | 6.35 | 6.11 |

| AP2 | 200 | 5.23 | ||

| AP3 | 220 | 6.03 | ||

| AP4 | 200 | 6.81 | ||

| BP5 | 240 | 255 | 6.61 | 7.54 |

| BP6 | 240 | 7.69 | ||

| BP7 | 270 | 7.48 | ||

| BP8 | 270 | 8.38 | ||

| CP9 | 320 | 300 | 11.25 | 10.77 |

| CP10 | 280 | 10.47 | ||

| CP11 | 280 | 9.62 | ||

| CP12 | 320 | 11.74 | ||

| Pile Length/m | Depth/m | Fitting Parameters | R2 | ||||

|---|---|---|---|---|---|---|---|

| λ1 | λ2 | λ3 | k/(MN·m−3) | τmax/kPa | |||

| 5 | 2.5 | 1.000 | 2.00 | 0.50 | 157.8 | 221.8 | 0.9899 |

| 4.5 | 0.8132 | ||||||

| 7 | 2.5 | 1.073 | 1.85 | 0.42 | 210.5 | 160.0 | 0.9638 |

| 4.5 | 0.9113 | ||||||

| 6.5 | 0.9231 | ||||||

| 9 | 3.0 | 1.120 | 1.75 | 0.36 | 266.7 | 123.1 | 0.9114 |

| 5.5 | 0.9304 | ||||||

| 8.0 | 0.8078 | ||||||

| Item | Natural Unit Weight | Elastic Modulus | Poisson’s Ratio | Cohesion | Internal Friction Angle |

|---|---|---|---|---|---|

| γ/(kN·m−3) | E/GPa | v | c/kPa | φ/(°) | |

| Steel pipe | 78.5 | 208.0 | 0.25 | / | / |

| Slurry injection body | 24.0 | 8.0 | 0.20 | / | / |

| Red-bedded soft rock | 23.0 | 0.6 | 0.30 | 90 | 30 |

| Pile Length | Uplift Deformation | Reduction in Uplift Deformation | Maximum Soil-Pile Relative Displacement | Maximum Axial Force | Maximum Lateral Friction Resistance |

|---|---|---|---|---|---|

| /m | /mm | /mm | /mm | /kN | /kPa |

| 5 | 4.58 | 0.54 | 0.25 | 11.25 | 9.54 |

| 7 | 3.69 | 1.43 | 0.40 | 19.16 | 17.29 |

| 9 | 3.18 | 1.94 | 0.39 | 29.66 | 17.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Luo, H.; Liu, Z.; Nie, R. Study on Anti-Uplift Effect of Micro-Steel-Pipe Pile on Red-Bedded Soft Rock Subgrade. Sustainability 2022, 14, 11923. https://doi.org/10.3390/su141911923

Zhang R, Luo H, Liu Z, Nie R. Study on Anti-Uplift Effect of Micro-Steel-Pipe Pile on Red-Bedded Soft Rock Subgrade. Sustainability. 2022; 14(19):11923. https://doi.org/10.3390/su141911923

Chicago/Turabian StyleZhang, Rui, Hui Luo, Zhengnan Liu, and Rusong Nie. 2022. "Study on Anti-Uplift Effect of Micro-Steel-Pipe Pile on Red-Bedded Soft Rock Subgrade" Sustainability 14, no. 19: 11923. https://doi.org/10.3390/su141911923

APA StyleZhang, R., Luo, H., Liu, Z., & Nie, R. (2022). Study on Anti-Uplift Effect of Micro-Steel-Pipe Pile on Red-Bedded Soft Rock Subgrade. Sustainability, 14(19), 11923. https://doi.org/10.3390/su141911923