Disaster-Causing Mechanism of Hidden Disaster-Causing Factors of Major and Extraordinarily Serious Gas Explosion Accidents in Coal Mine Goafs

Abstract

:1. Introduction

2. Identification of HDCFs of MESGEAs in Coal Mine Goafs

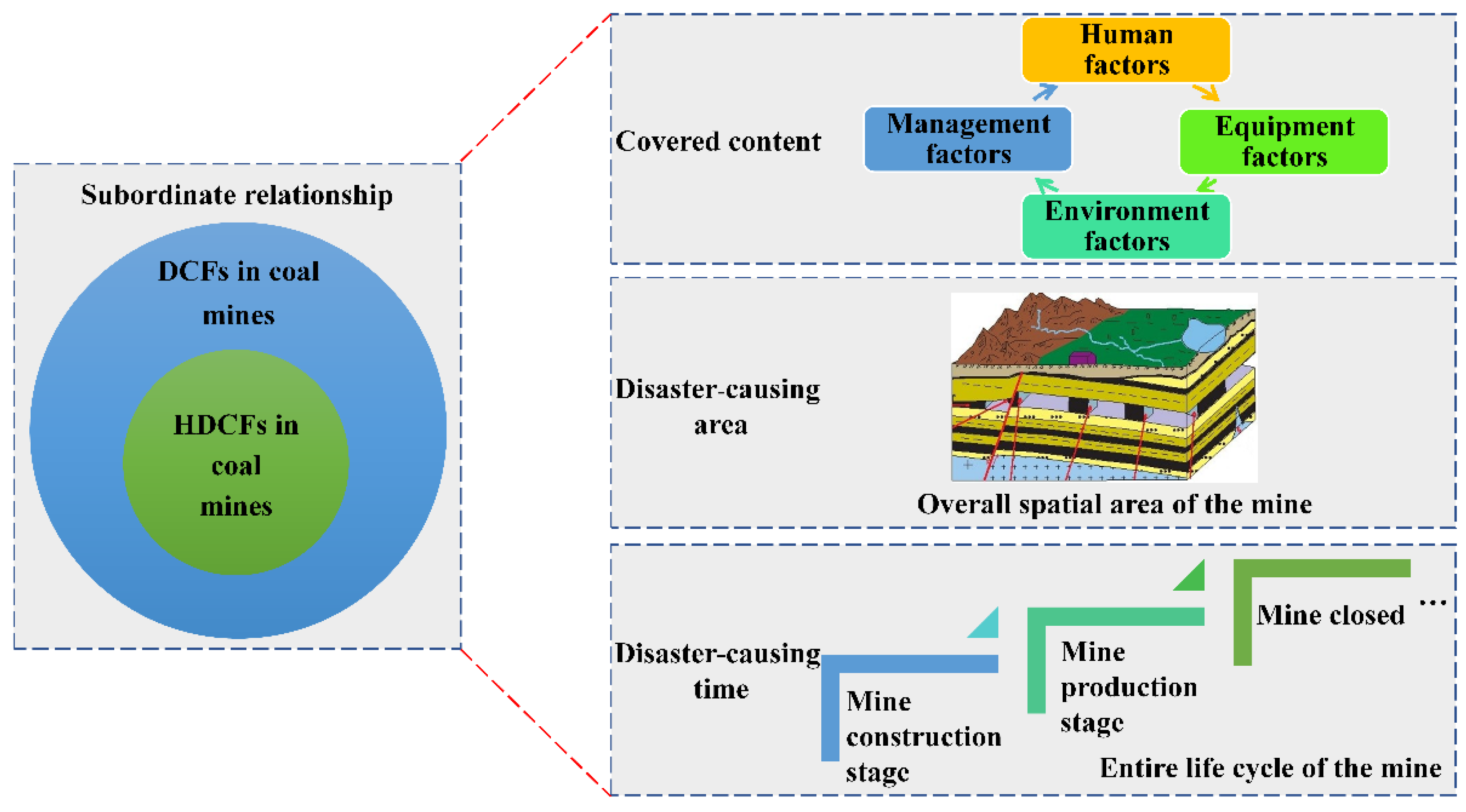

2.1. Definition of HDCFs in Coal Mines

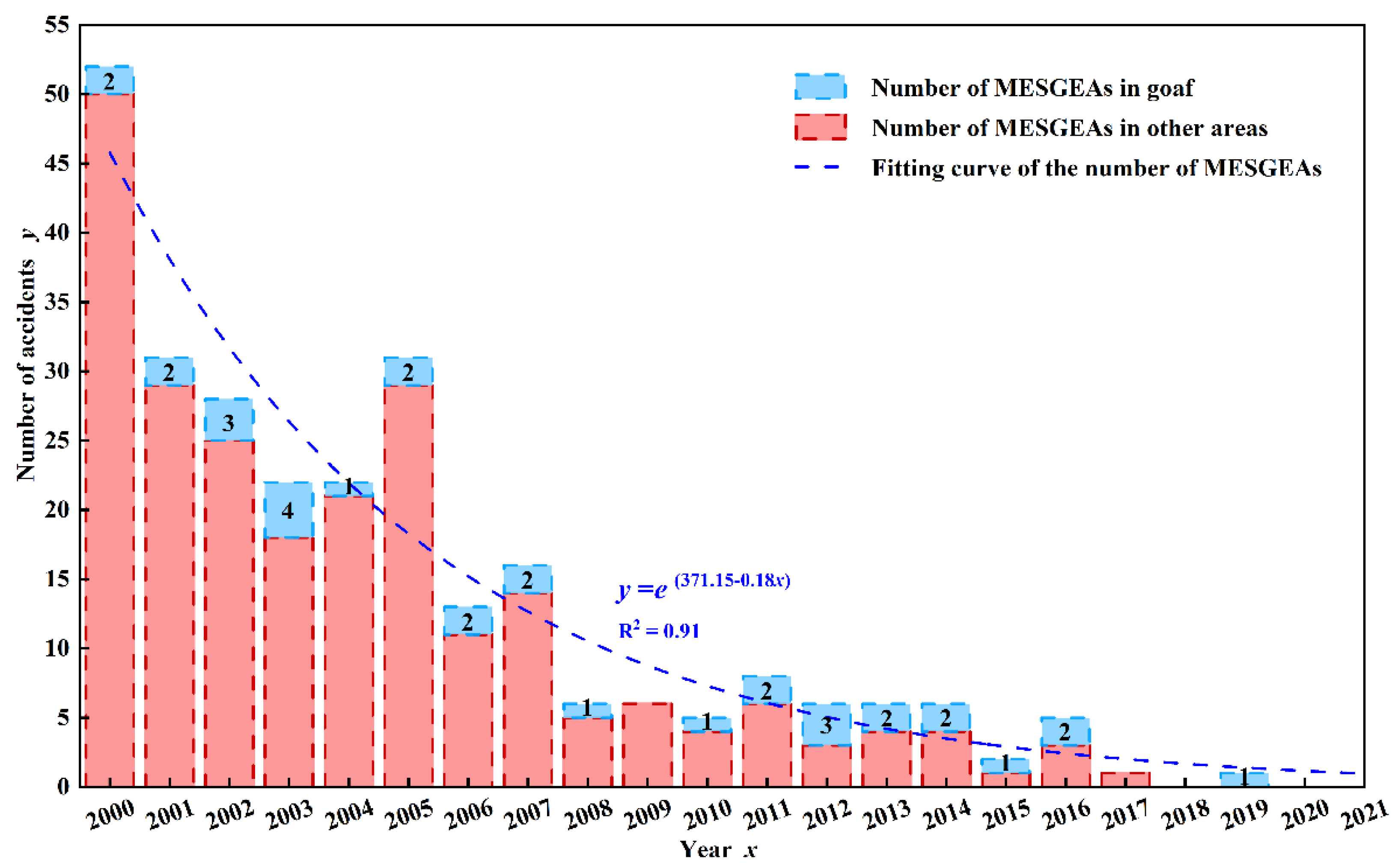

2.2. Identification of HDCFs of MESGEAs in the Goaf

2.2.1. Determination of DCFs of MESGEA in the Goaf

2.2.2. Identification of HDCFs of MESGEAs in the Goaf

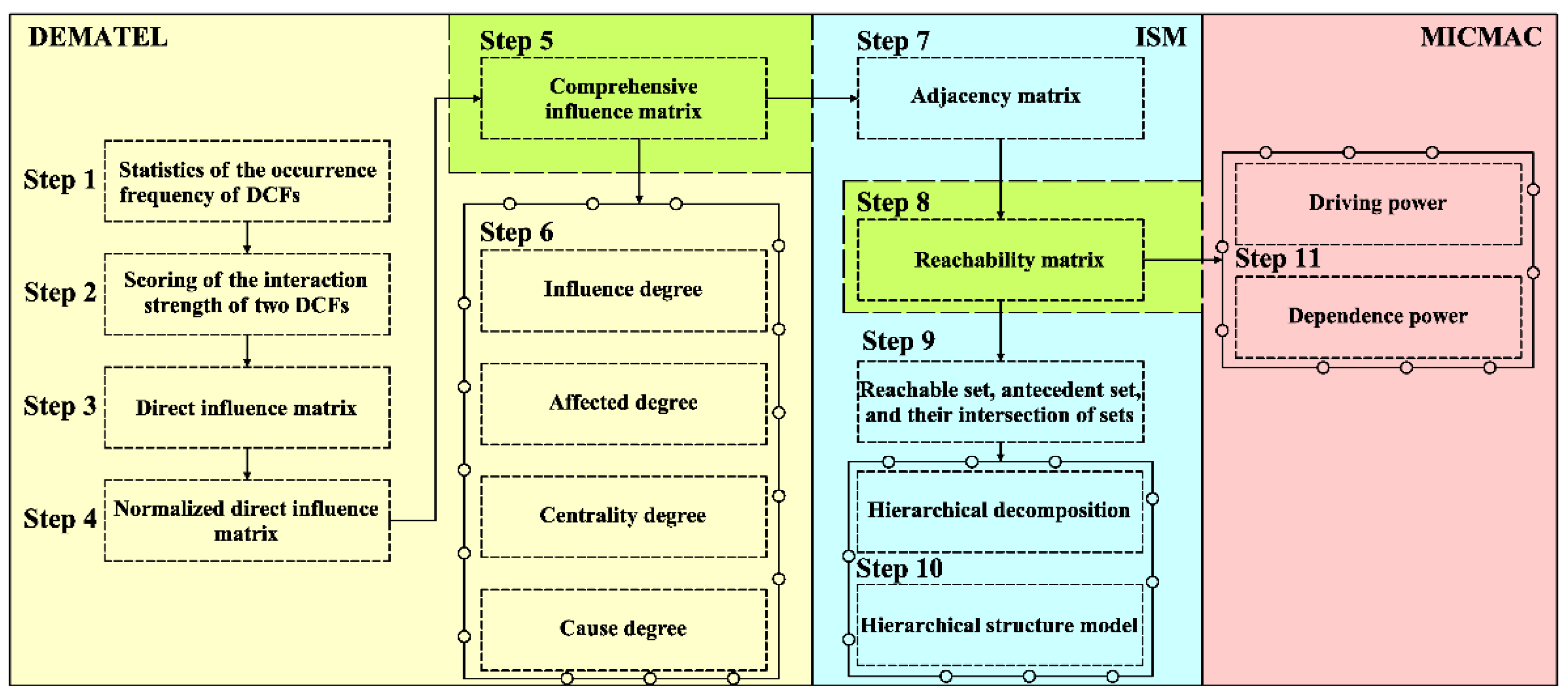

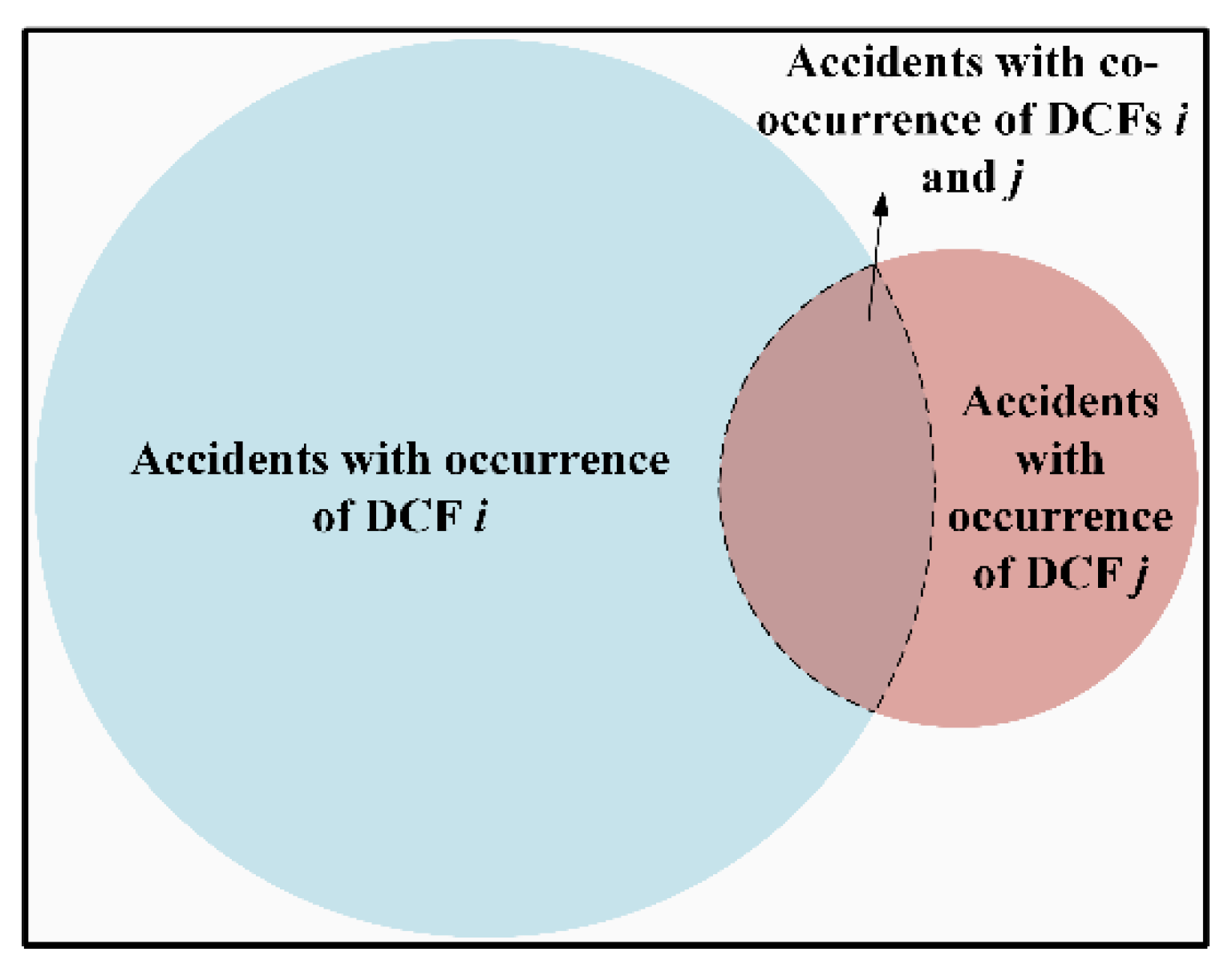

3. Computational Model Construction

3.1. Overview of the DEMATEL, ISM and MICMAC Methods

3.2. Calculation Steps of the Improved DEMATEL-ISM-MICMAC Model

4. Disaster-Causing Mechanism of HDCFs

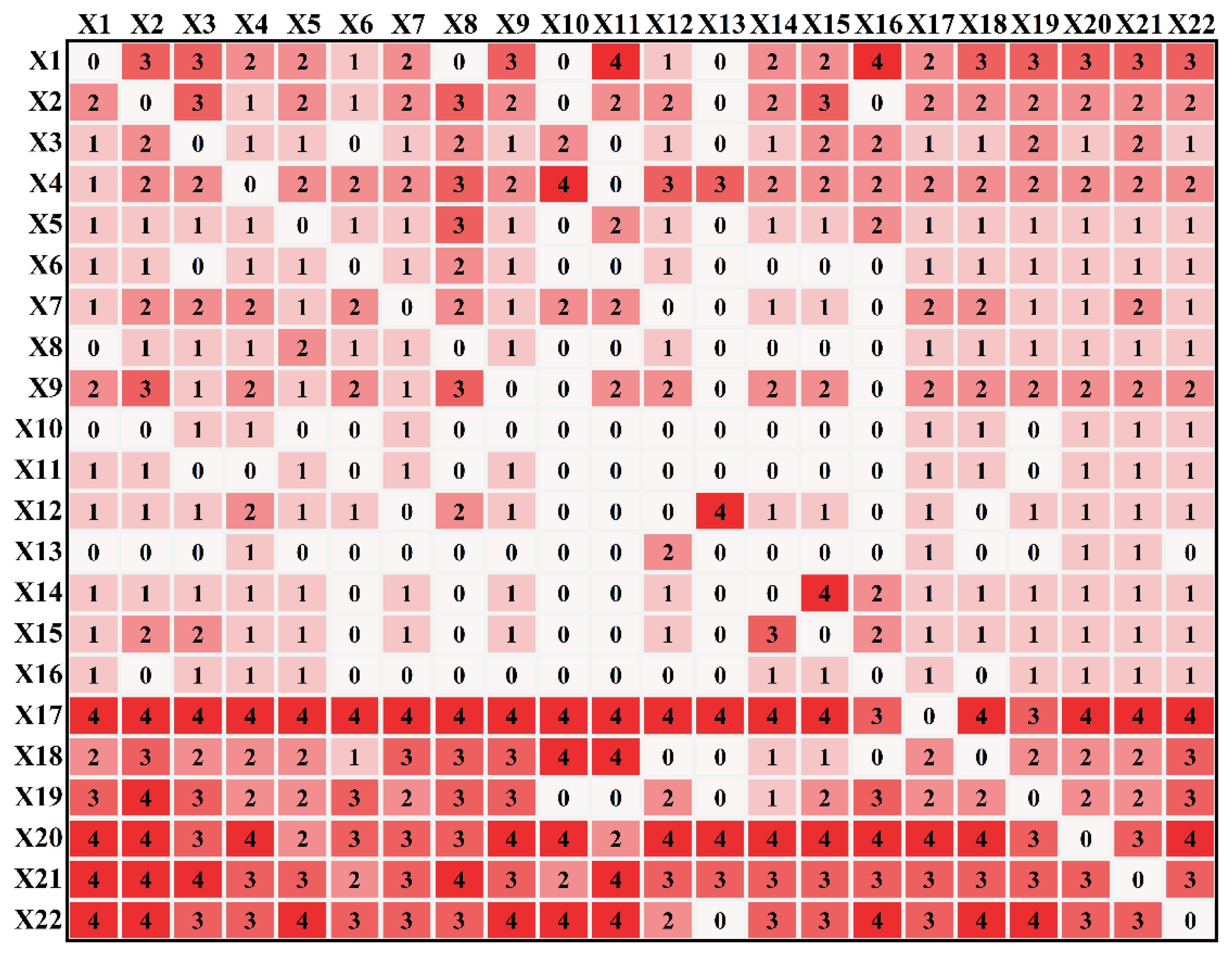

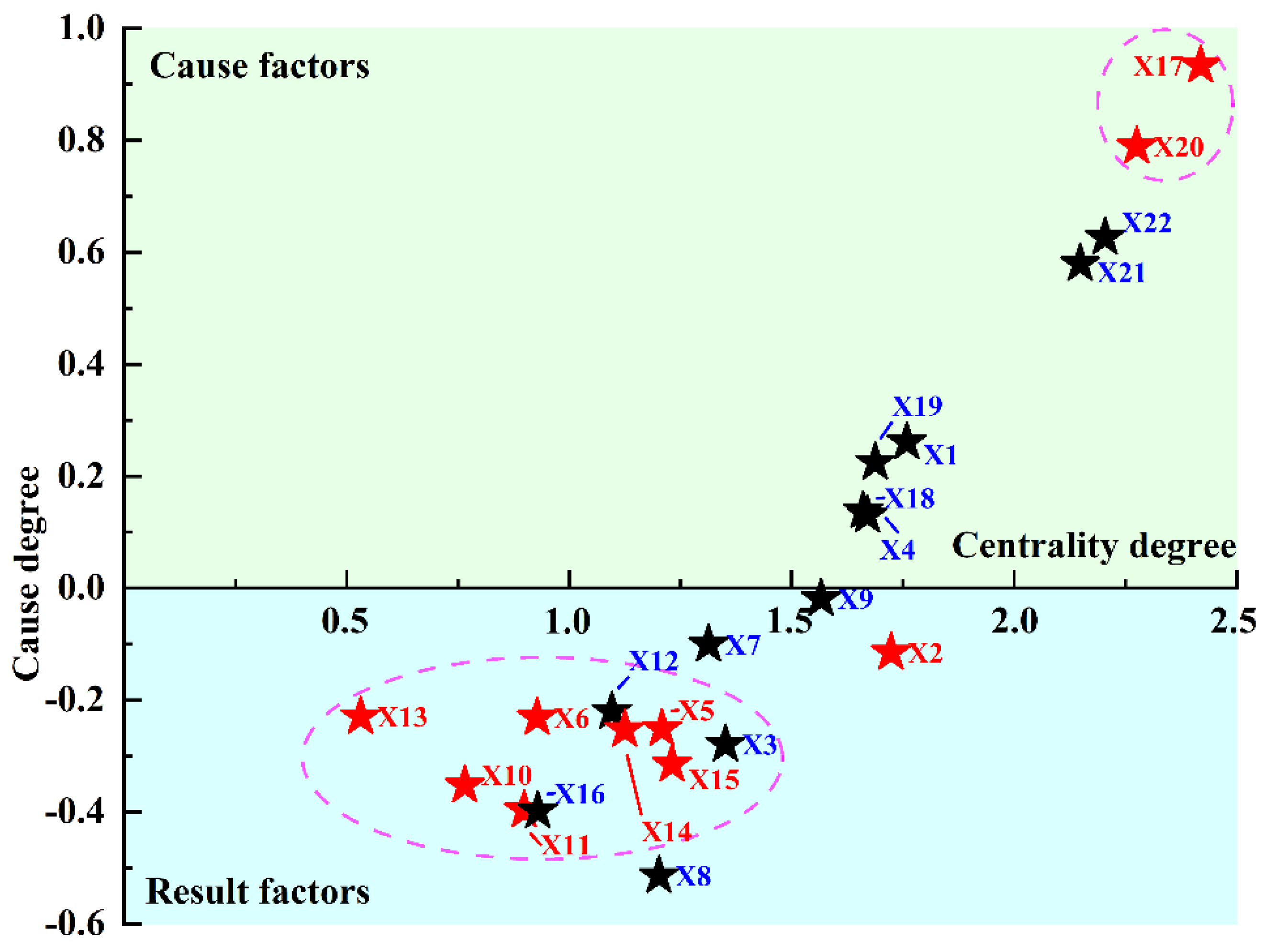

4.1. Analysis of the DEMATEL Calculation Results

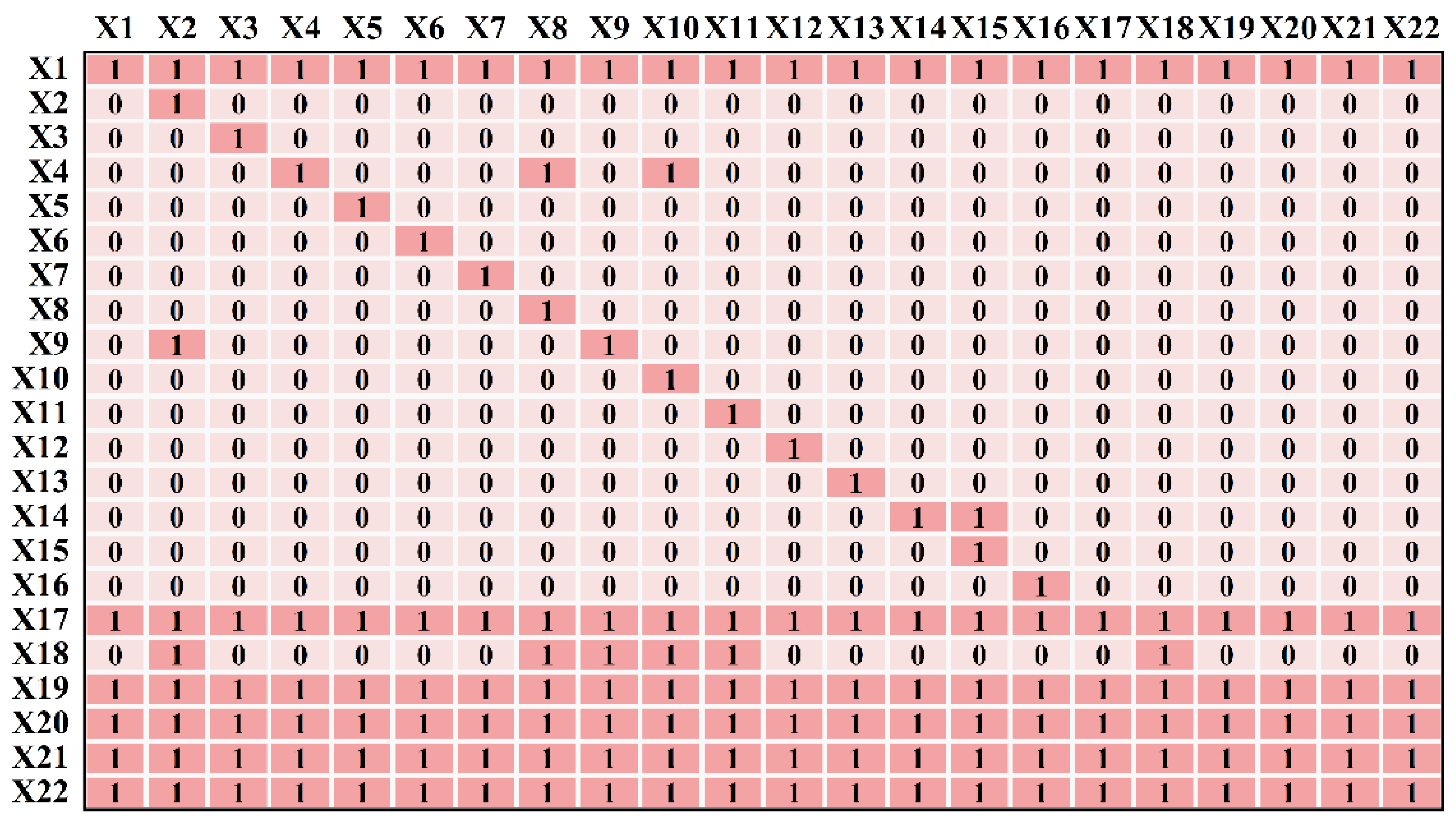

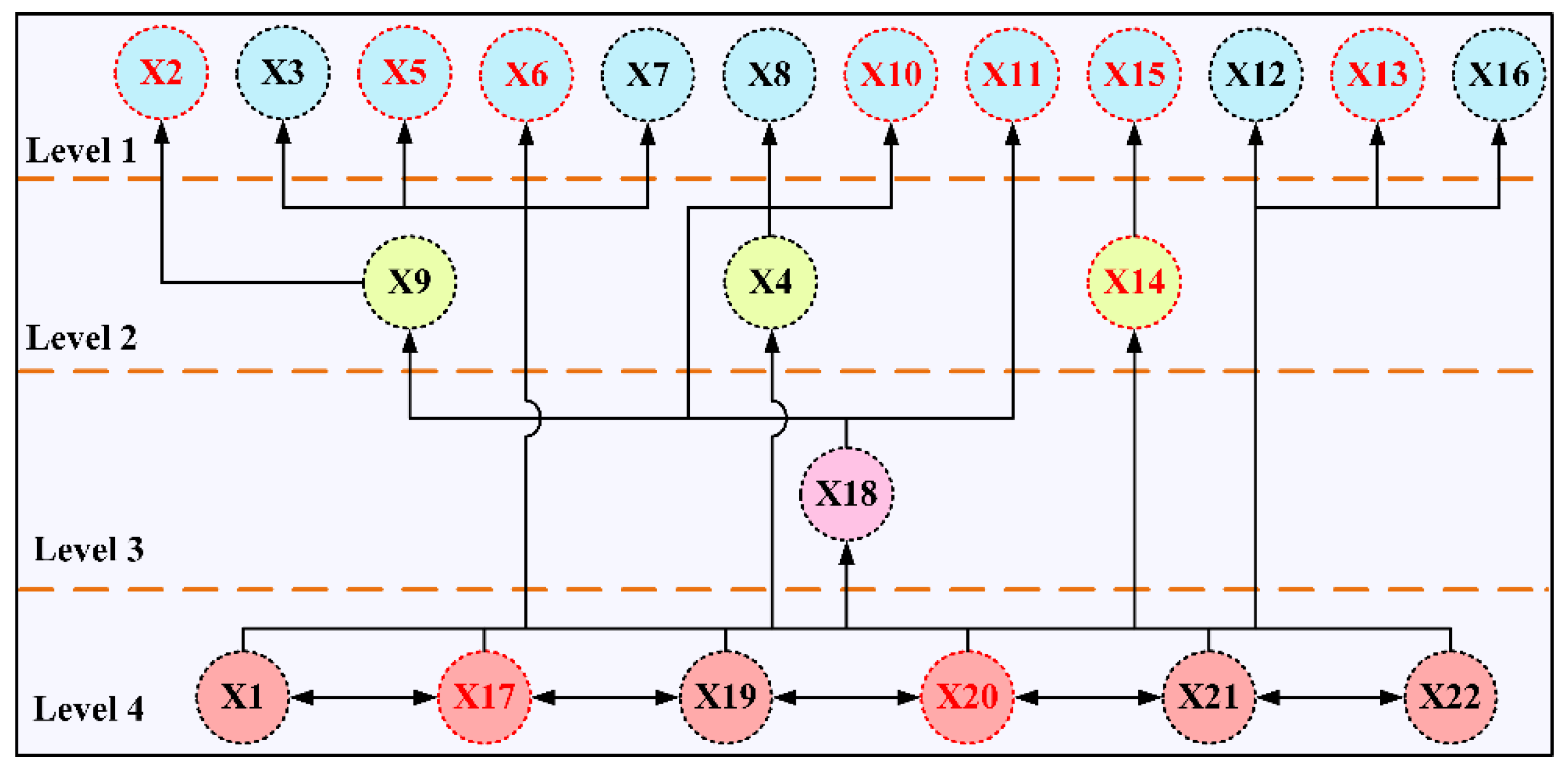

4.2. Analysis of the ISM Calculation Results

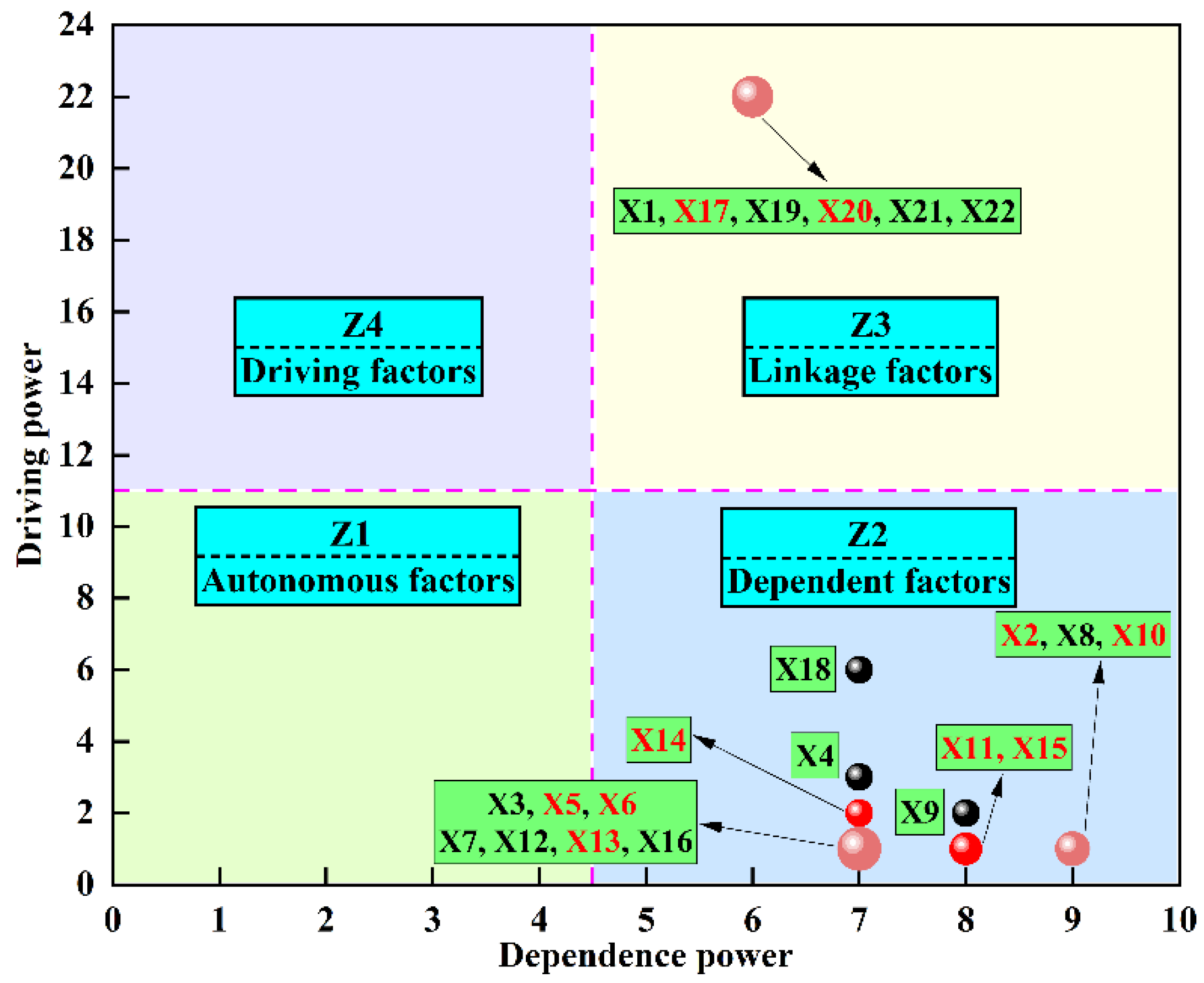

4.3. Analysis of the MICMAC Calculation Results

4.4. Discussion

4.4.1. Comprehensive Analysis

4.4.2. Suggested Measures for Accident Prevention and Control

4.4.3. Limitations of the Study

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qian, M.; Xu, J. Behaviors of strata movement in coal mining. J. China Coal Soc. 2019, 44, 973–984. [Google Scholar]

- Tian, S.; Yang, P.; Tang, K.; Shen, X.; Shi, F. Safety performance of coal mine survey technology using nano-fiber material in coal mining process. Arab. J. Geosci. 2020, 13, 841. [Google Scholar] [CrossRef]

- Qu, Q.; Xu, J.; Wu, R.; Qin, W.; Hu, G. Three-zone characterisation of coupled strata and gas behaviour in multi-seam mining. Int. J. Rock Mech. Min. 2015, 78, 91–98. [Google Scholar] [CrossRef]

- Tian, S.; Mao, J.; Li, H. Porosity Distribution Law of Overlying Strata in the Goaf of the Adjacent Working Face: From the Perspective of Section Coal Pillar Types. Minerals 2022, 12, 782. [Google Scholar] [CrossRef]

- Zhang, Y.; Niu, K.; Du, W.; Zhang, J.; Wang, H.; Zhang, J. A method to identify coal spontaneous combustion-prone regions based on goaf flow field under dynamic porosity. Fuel 2021, 288, 119690. [Google Scholar] [CrossRef]

- Feng, G.; Li, Z.; Hu, S.; Zhang, Y.; Zhang, A.; Gao, Q.; Jiang, H.; Guo, X.; Li, C.; Cui, J. Distribution of gob empty space for methane drainage during the longwall mining: A case study. J. Nat. Gas Sci. Eng. 2018, 60, 112–124. [Google Scholar] [CrossRef]

- Lin, B.; Li, Q.; Zhou, Y. Research advances about multi-field evolution of coupled thermodynamic disasters in coal mine goaf. J. China Coal Soc. 2021, 46, 1715–1726. [Google Scholar]

- Qin, C.; Huang, Q.; Wang, S.; Li, J.; Ju, S.; Wang, G. Prevention and Control of Spontaneous Combustion of Residual Coals in Acid-Soaked Goaf in Gas Drainage Condition. Adv. Civ. Eng. 2022, 2022, 1668952. [Google Scholar] [CrossRef]

- Feng, G.; Zhang, Y.; Qi, T.; Kang, L. Status and research progress for residual coal mining in China. J. China Coal Soc. 2020, 45, 151–159. [Google Scholar]

- Su, H.; Zhou, F.; Song, X.; Qiang, Z. Risk analysis of spontaneous coal combustion in steeply inclined longwall gobs using a scaled-down experimental set-up. Process Saf. Environ. Prot. 2017, 111, 1–12. [Google Scholar] [CrossRef]

- Ma, D.; Qin, B.; Gao, Y.; Jiang, J.; Feng, B. An experimental study on the methane migration induced by spontaneous combustion of coal in longwall gobs. Process Saf. Environ. Prot. 2021, 147, 292–299. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. Applying computational fluid dynamics in research on ventilation safety during underground hard coal mining: A systematic literature review. Process Saf. Environ. Prot. 2021, 151, 373–400. [Google Scholar] [CrossRef]

- Feng, G.; Zhang, A.; Hu, S.; Cheng, J.; Miu, X.; Hao, G.; Han, D.; Guan, S.; Zhao, G. A methodology for determining the methane flow space in abandoned mine gobs and its application in methane drainage. Fuel 2018, 227, 208–217. [Google Scholar] [CrossRef]

- Liu, Q.; Lin, B.; Zhou, Y.; Li, Y.; Ting, L. Experimental verification of permeability and inertial resistance coefficient model in the goaf. Energy Sources Part A 2022. accepted. [Google Scholar] [CrossRef]

- Liu, J.; Qin, G.; Cao, J.; Zhai, M.; Pei, Y. Theoretical and Experimental Study on the Mechanism of Instability and Firing Gas in Hard Quartz Sandstone. Adv. Civ. Eng. 2021, 2021, 6665387. [Google Scholar] [CrossRef]

- Liang, Y.; Dai, J.; Zou, Q.; Li, L.; Luo, Y. Ignition mechanism of gas in goaf induced by the caving and friction of sandstone roof containing pyrite. Process Saf. Environ. Prot. 2019, 124, 84–96. [Google Scholar] [CrossRef]

- Zhang, P.; Jiang, J.; Qin, G.; Wu, Q.; Xu, L. Methane burning and explosion mechanism induced by hard roof collapse and its prevention. J. Min. Saf. Eng. 2014, 31, 814–818+823. [Google Scholar]

- Fan, L. Hidden Disaster-Causing Factors and Exploration in Coal Mines, 1st ed.; China Coal Industry Publishing House: Beijing, China, 2014; pp. 1–3. [Google Scholar]

- Xu, D.; Shao, D. Identification method for covert causal factors of water disasters in local small coal mines. J. Liaoning Technol. Univ. Nat. Sci. 2014, 33, 1599–1602. [Google Scholar]

- Liu, S.; Chen, S.; Xu, K. Detection technology of Ground-Roadway DC resistivity method. J. China Coal Soc. 2017, 42, 360–366. [Google Scholar]

- Zhao, Y.; Tian, S. Identification of hidden disaster causing factors in coal mine based on Naive Bayes algorithm. J. Intell. Fuzzy Syst. 2021, 41, 2823–2831. [Google Scholar] [CrossRef]

- Li, L.; Qin, B.; Liu, J.; Leong, Y.-K. Integrated experimentation and modeling of the formation processes underlying coal combustion-triggered methane explosions in a mined-out area. Energy 2020, 203, 117855. [Google Scholar] [CrossRef]

- Li, Y.; Su, H.; Ji, H.; Cheng, W. Numerical simulation to determine the gas explosion risk in longwall goaf areas: A case study of Xutuan Colliery. Int. J. Min. Sci. Technol. 2020, 30, 875–882. [Google Scholar] [CrossRef]

- Li, J.; Qin, Y.; Wang, Z.; Xin, Y. How to Analyse the Injury Based on 24Model: A Case Study of Coal Mine Gas Explosion Injury. Inj. Prev. 2021, 27, 542–553. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Liu, Q.; Luo, X.; Zhou, X. Risk Assessment of the Unsafe Behaviours of Humans in Fatal Gas Explosion Accidents in China’s Underground Coal Mines. J. Clean. Prod. 2019, 210, 970–976. [Google Scholar] [CrossRef]

- Li, L.; Fang, Z. Cause Analysis of Coal Mine Gas Explosion Based on Bayesian Network. Shock Vib. 2022, 2022, 1923734. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, K.; You, G.; Wang, B.; Zhao, L. Causation Analysis of Risk Coupling of Gas Explosion Accident in Chinese Underground Coal Mines. Risk Anal. 2019, 39, 1634–1646. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Fu, G.; Nieto, A. A comparative study of gas explosion occurrences and causes in China and the United States. Int. J. Min. Reclam. Environ. 2016, 30, 269–278. [Google Scholar] [CrossRef]

- Tong, R.; Yang, Y.; Ma, X.; Zhang, Y.; Li, S.; Yang, H. Risk Assessment of Miners’ Unsafe Behaviors: A Case Study of Gas Explosion Accidents in Coal Mine, China. Int. J. Environ. Res. Public Health 2019, 16, 1765. [Google Scholar] [CrossRef]

- He, S.; Lu, Y.; Li, M. Probabilistic risk analysis for coal mine gas overrun based on FAHP and BN: A case study. Environ. Sci. Pollut. Res. 2022, 29, 28458–28468. [Google Scholar] [CrossRef]

- Wang, S. Research on Test of MWD System Used for Exploration of the Hidden Geological Factors Causing Disasters in Coal Mine. Drill. Eng. 2016, 43, 68–71. [Google Scholar]

- Yang, C.; An, A.; Cao, S. Influences analysis of geological factors about hidden hazard affecting coal mine in Zhengzhou Area. China Energy Environ. Prot. 2018, 40, 42–46. [Google Scholar]

- Duan, J.; Xu, C. Application of Surface Geophysical Prospecting in Coal Mine Hidden Hazard Factor Detection. Coal Geol. China 2015, 27, 53–57. [Google Scholar]

- Peleckis, K. Application of the DEMATEL Model for Assessing IT Sector’s Sustainability. Sustainability 2021, 13, 13866. [Google Scholar] [CrossRef]

- Li, Y.; Diabat, A.; Lu, C.-C. Leagile Supplier Selection in Chinese Textile Industries: A DEMATEL Approach. Ann. Oper. Res. 2020, 287, 303–322. [Google Scholar] [CrossRef]

- Yazdi, M.; Khan, F.; Abbassi, R.; Rusli, R. Improved DEMATEL Methodology for Effective Safety Management Decision-Making. Saf. Sci. 2020, 127, 104705. [Google Scholar] [CrossRef]

- Fontela, E.; Gabus, A. DEMATEL: Progress achieved. Futures 1974, 6, 361–363. [Google Scholar] [CrossRef]

- Warfield, J. Developing Interconnection Matrices in Structural Modeling. IEEE Trans. Syst. Man, Cybern. 1974, SMC-4, 81–87. [Google Scholar] [CrossRef]

- Dekker, S.; Cilliers, P.; Hofmeyr, J.-H. The Complexity of Failure: Implications of Complexity Theory for Safety Investigations. Saf. Sci. 2011, 49, 939–945. [Google Scholar] [CrossRef]

- Leveson, N.G. Applying Systems Thinking to Analyze and Learn from Events. Saf. Sci. 2011, 49, 55–64. [Google Scholar] [CrossRef]

- Leveson, N.G. Engineering a Safer World: Systems Thinking Applied to Safety, 1st ed.; The MIT Press: Cambridge, MA, USA, 2012; pp. 31–33. [Google Scholar]

- Looking beyond the Operator. Available online: https://www.neimagazine.com/features/featurelooking-beyond-the-operator-4447549 (accessed on 19 September 2022).

- Komljenovic, D.; Loiselle, G.; Kumral, M. Organization: A New Focus on Mine Safety Improvement in a Complex Operational and Business Environment. Int. J. Min. Sci. Technol. 2017, 27, 617–625. [Google Scholar] [CrossRef]

- Kahneman, D. Thinking, Fast and Slow, 1st ed.; Farrar, Straus and Giroux: New York, NY, USA, 2011; pp. 61–71. [Google Scholar]

- Putting People in the Mix: Part I. Available online: https://www.neimagazine.com/features/featureputting-people-in-the-mix-4321534 (accessed on 19 September 2022).

- Putting People in the Mix: Part 2. Available online: https://www.neimagazine.com/features/featureputting-people-in-the-mix-part-2-4322674 (accessed on 19 September 2022).

- Montibeller, G.; von Winterfeldt, D. Cognitive and Motivational Biases in Decision and Risk Analysis. Risk Anal. 2015, 35, 1230–1251. [Google Scholar] [CrossRef] [PubMed]

| DCF Serial Number | Frequency | DCF Serial Number | Frequency | DCF Serial Number | Frequency |

|---|---|---|---|---|---|

| X1 | 17 | X9 | 10 | X17 | 27 |

| X2 | 9 | X10 | 2 | X18 | 13 |

| X3 | 7 | X11 | 2 | X19 | 15 |

| X4 | 13 | X12 | 6 | X20 | 25 |

| X5 | 6 | X13 | 3 | X21 | 22 |

| X6 | 4 | X14 | 7 | X22 | 23 |

| X7 | 8 | X15 | 5 | — | — |

| X8 | 3 | X16 | 3 | — | — |

| DCF (Serial Number) | Contents Covered | Characteristics |

|---|---|---|

| Illegal operation (X1) | Illegal blasting, illegal entry into the goaf to operation, … | — |

| Poor safety awareness (X2) | Insufficient understanding of hazards, poor awareness of regulations and measures, … | Hidden |

| Lack of skills or experience (X3) | Low technical quality, lack of timely adjustment of the ventilation system, … | — |

| Lack of timely resolution of potential safety hazards (X4) | Hazard investigation goes through the motions, long-term unresolved hazards, … | — |

| Weak sense of professional responsibility of employees (X5) | Gas monitoring probes were not installed in place, unattended gas monitoring system, … | Hidden |

| Cable breakage and short circuit (X6) | Short circuit caused by the impact of a falling object, short circuit caused by miners’ pulling and damage at will, … | Time-varying |

| Unreliable ventilation system (X7) | Poor quality of ventilation facilities, air ducts are disconnected, … | — |

| Equipment explosion-proof failure (X8) | Explosion-proof failure of various types of electrical equipment | — |

| Monitoring and control systems are not operating properly (X9) | There are various problems in system operation, imperfect system equipment, … | — |

| Metal material friction or impact (X10) | Sparks generated by friction or impact of metal materials | Time-varying |

| Blocked ventilation route (X11) | Roadway blockage due to falling objects | Time-varying |

| Large areas of the overhanging roof in the goaf (X12) | The main roof is hard and does not easily fall, and caving the roof is not in time | — |

| Rock friction or impact (X13) | Sparks generated by friction or impact of rocks | Time-varying |

| Coal spontaneous combustion (X14) | Spontaneous combustion of residual coal in the goaf | Sudden |

| Poor sealing conditions (X15) | Poorly sealed goaf, poorly sealed abandoned coal mines, … | Sudden |

| Unreasonable setting of the coal pillar width (X16) | The coal pillar width is smaller than the minimum blast resistance line width, section coal pillars fail to provide a supporting effect, … | — |

| Inadequate enforcement of safety regulations (X17) | Laws, regulations and rules have not been implemented, inadequate safety assurance measures, … | Hidden |

| Ventilation management confusion (X18) | Auxiliary fans are activated and stopped at will, the mine ventilation mode is randomly adjusted, … | — |

| Inadequate safety education and training (X19) | Lax safety education and training, no custom safety education and training, … | — |

| Inadequate safety supervision (X20) | Government and group company supervision is a mere formality, insufficient supervision, investigation and treatment, … | Hidden |

| Insufficient safety investment and safety technology (X21) | Inadequate equipment and facilities, irrational technical scheme, … | — |

| Confusion in organizational management (X22) | Confusion in labor organization and management, deliberate concealment and supervision evasion, … | — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, S.; Mao, J.; Li, H. Disaster-Causing Mechanism of Hidden Disaster-Causing Factors of Major and Extraordinarily Serious Gas Explosion Accidents in Coal Mine Goafs. Sustainability 2022, 14, 12018. https://doi.org/10.3390/su141912018

Tian S, Mao J, Li H. Disaster-Causing Mechanism of Hidden Disaster-Causing Factors of Major and Extraordinarily Serious Gas Explosion Accidents in Coal Mine Goafs. Sustainability. 2022; 14(19):12018. https://doi.org/10.3390/su141912018

Chicago/Turabian StyleTian, Shuicheng, Junrui Mao, and Hongxia Li. 2022. "Disaster-Causing Mechanism of Hidden Disaster-Causing Factors of Major and Extraordinarily Serious Gas Explosion Accidents in Coal Mine Goafs" Sustainability 14, no. 19: 12018. https://doi.org/10.3390/su141912018