Brittleness Evolution Model of the Supply Chain Network Based on Adaptive Agent Graph Theory under the COVID-19 Pandemic

Abstract

1. Introduction

- The evolution law of the vertex state of the uncertain supply chain under COVID-19 attack will be analyzed.

- The evolution law of brittleness entropy of the vertex in the supply chain will be solved.

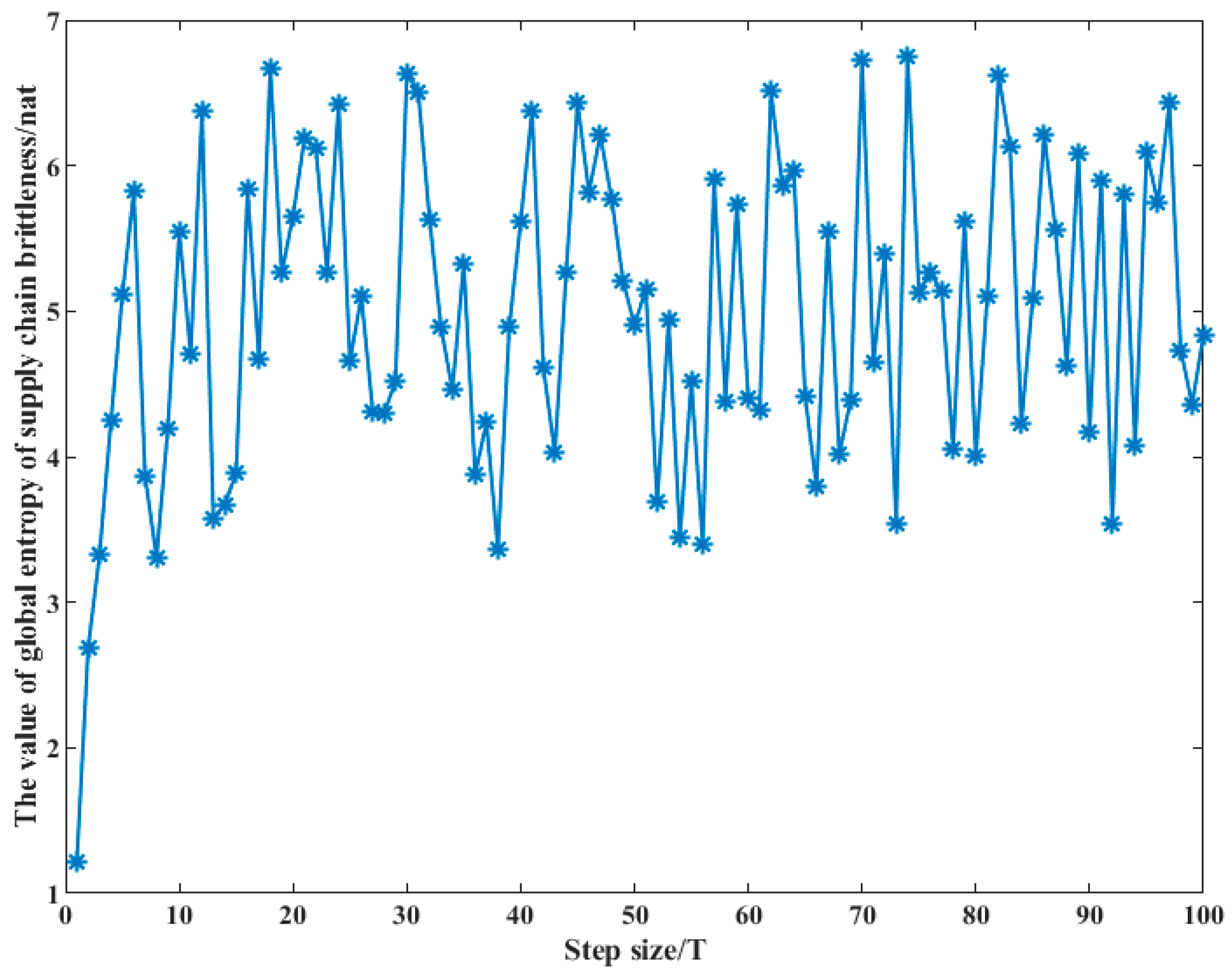

- The evolution law of the global brittleness entropy of the uncertain supply chain will be demonstrated.

- The seasonal evolution law of the uncertain supply chain brittleness will be illustrated.

- The evolution law of the brittleness behavior of the uncertain supply chain will be solved.

- The model and algorithm of the vertex state and brittleness entropy of the vertex of the uncertain supply chain are established.

- The brittleness evolution model of the supply chain based on the adaptive agent graph is constructed.

- The simulation algorithm of the brittleness evolution of the uncertain supply chain based on the adaptive agent graph is designed.

2. Literature Review

2.1. Supply Chain Vulnerability

- The identification of vulnerability factors of the supply chain

- 2.

- Evaluation of supply chain vulnerability

- 3.

- Mechanism of correlation influence of supply chain vulnerability

- 4.

- Conceptual differences between supply chain vulnerability and supply chain brittleness

2.2. Brittleness Theory of Complex Systems

- Brittleness of complex systems based on catastrophe theory

- 2.

- Brittleness entropy of complex systems

- 3.

- Brittleness of complex systems based on the theory of self-organized criticality

- 4.

- Brittleness of complex systems based on graph theory

2.3. Research Summary

3. Study Description and Problem Definition

3.1. Study Description

3.2. The Adaptive Agent Graph of the Supply Chain Brittleness Network

- Vertexes: the suppliers, manufacturers, distributors, and end retailers of the supply chain are defined as the vertexes of the adaptive agent graph of the brittleness network.

- Arcs: The directed link a which connects the ordered vertex pairs i and j is defined as the arc of the adaptive agent graph of the supply chain brittleness network, denoted as a = <i, j>. Link a has both the meaning of directionality (vertex i and vertex j, respectively, represent the starting point and the ending point) and weight value.

- Adjacency relation: Whether there is a brittleness link between vertex i and vertex j is defined as the adjacency relation of the adaptive agent graph in this paper. If there is a brittleness link, rij = 1, rij ∈ R; otherwise, rij = 0. The mathematical expression is as follows:

- Topological structure: The weighted and directed graph D = <V,A,R> is defined as the topological structure of the adaptive agent graph, which is the graphic representation of the brittleness relationship of supply chain complex systems.Thereinto, V(i, j ∈ V) represents the vertex set of a supply chain brittleness network. A(a ∈ A) represents the directed link set of a brittleness network, and R(rij∈ R) represents the set of adjacency relations between vertex i and vertex j.

- The Flow of vertex: The entropy flow of supply chain nodes is defined as the flow of a vertex of an adaptive agent graph of a supply chain brittleness network. And the adjacency relationship would be obtained through the distribution results of the flow of vertex.

- The weight of adaptive agent graph: The proportion of the quantity of material flow supplied from vertex i to vertex j to total material flow of vertex i is defined as the weight ωij of the adaptive agent graph of the supply chain brittleness network.

- The interaction between vertexes: the transferring and exchanging of entropy flow between vertexes are defined as the interaction between vertexes in the adaptive agent graph of the supply chain brittleness network.

- The memory function of the vertex: the memory function is composed of the vertex state function and the entropy flow function of the vertex, which is used to store the state, the entropy flow, and brittleness evolution rules of each vertex.

- The global energy function: The global energy function reflects the disorder degree of the supply chain brittleness network and also reflects the superposition effect of the brittleness behavior of vertexes. In this study, the weighted sum of all brittleness entropy (the global brittleness entropy) of the supply chain brittleness network is defined as the global energy function of the adaptive agent graph.

3.3. The Problem Definition of Brittleness Evolution of the Supply Chain

4. Problem Formulation

4.1. The Brittleness Evolution Model of Adaptive Agent Graph of the Supply Chain

- AssumptionsAccording to Holland’s CAS (complex adaptive systems) theory [46], the evolutionary steps of vertexes of the adaptive agent graph of the supply chain are set as follows:

- (1)

- Each vertex senses the entropy flow from other agents and the increase of entropy caused by external environmental interference through the detector. And then, the entropy flow of the vertex is determined according to its own state value.

- (2)

- The memory function of the vertex is established to store its own state, the entropy flow, and other information into the memory, and the knowledge base is preliminarily constructed.

- (3)

- The vertex constantly learns from the knowledge base and establishes the control strategies. A series of IF/THEN rules are established to continuously learn memory functions, and the vertex state and vertex entropy flow are updated to update the knowledge base in the memory.

- (4)

- According to the interaction process of entropy flow, the vertex entropy flow is output through the reactor, and the vertex state is output through the flow function φ. The relationship between the vertex state value and the entropy flow value is determined by the IF/THEN rules in the actuator.

- (5)

- The updated flow of the vertex agent would be used as input to the actuator in times of t + 1.

- The brittleness evolution model of the vertex of the adaptive agent graph of the supply chain

- (1)

- When the adaptive behavior of the vertex is not considered, the entropy flow evolution model of the vertex is

- (2)

- When the adaptive behavior of the vertex is considered, the brittleness connection between vertexes is built through the distribution of entropy flow, and the evolution model of entropy flow of the vertex is

4.2. Model of Maximum/Minimum Brittleness Collapse Path of the Supply Chain

4.3. Calculation Model of Brittleness Evolution Parameters

- The collapse probability of vertex i under normal scenarios is

- 2.

- The probability of the brittleness event s of a supply chain is

- 3.

- The scheduling model of the brittleness network of the supply chain is [44]

- 4.

- When the brittleness event s occurs, the collapse probability of vertex i is

- 5.

- The state value of vertex i of the supply chain is

- 6.

- The entropy flow of vertex i of the supply chain is

- 7.

- The global brittleness entropy of each OD pair of the adaptive agent graph of the supply chain is as follows:

- 8.

- The global brittleness entropy of the adaptive agent graph of the supply chain is as follows:

4.4. Evolution Index Model of the Brittleness Behavior of the Supply Chain

5. Algorithm Design

| Algorithm 1: Pseudocode of simulation algorithm of brittleness evolution of supply chain. |

| Input: Parameters of integration scheduling of uncertainty supply chain |

| Output: State value xi, entropy flow fi, the global brittleness entropy H(D,n) |

| //Step 1. Compute the load value Ci and collapse probability Pi |

| 1: Compute scheduling results← Call scheduling model F = min [γf1 + (1 − γ)f2] |

| 2: Compute collapse probability Pi according to Pi = C(i)/Ck(i) |

| //Step 2. Compute the state value and entropy flow fi |

| 3: Compute the state value xi according to |

| 4: Compute the entropy flow fi according to fi = −logxi |

| //Step 3. Compute the weights ωmax, ωmin of brittleness collapse path |

| 5: Compute ωmax, ωmin according to Equations (15)–(18) via Lagrange relaxation algorithm |

| //Step 4. Compute the brittleness entropy H(D) |

| 6: Compute H(D) of each OD pair according to |

| //Step 5. Compute the global brittleness entropy H(D,n). |

| 7: Compute H(D,n) according to H(D,n) = ΣnH(D) |

| //Step 6–7. Compute the results of brittleness evolution |

| 8: Update the value of xi and according to Equations (7)–(14) 9: If Then 10: Remove the vertex i 11: Call the scheduling model to compute the scheduling results 12: Compute Pi, xi, , ωmax, ωmin , H(D) and H(D,n) 13: End if 14: Else 15: Update the value of xi and fi according to Equations (10), (13) and (14) 16: Update H(D) and H(D,n) according to Equations (31) and (34) 17: While xi = 1 for all vertexs 18: End while 19: End |

6. Numerical Results and Discussion of Simulation Example

6.1. Case Description and Parameter Values

- Case description

- 2.

- Parameter values

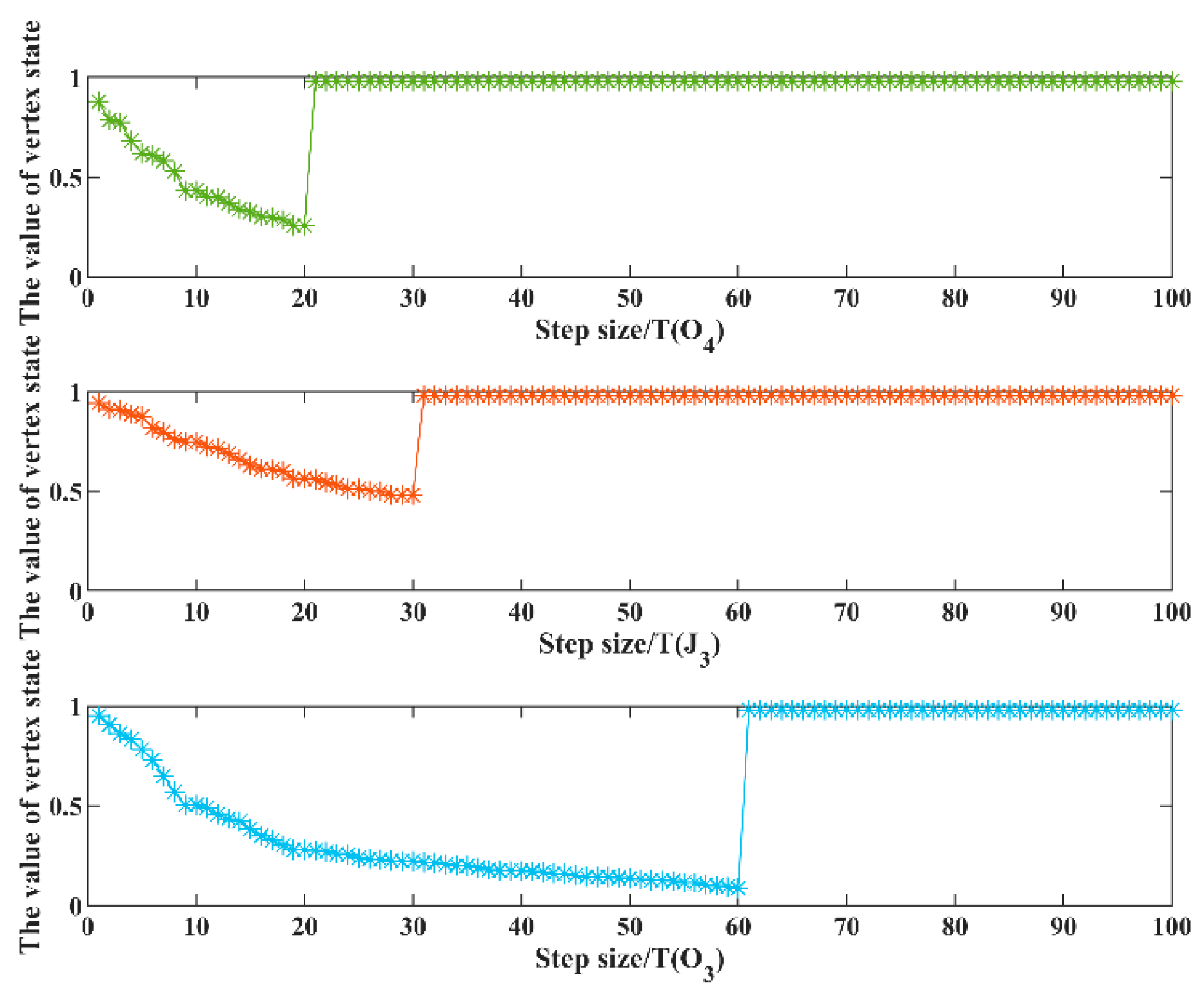

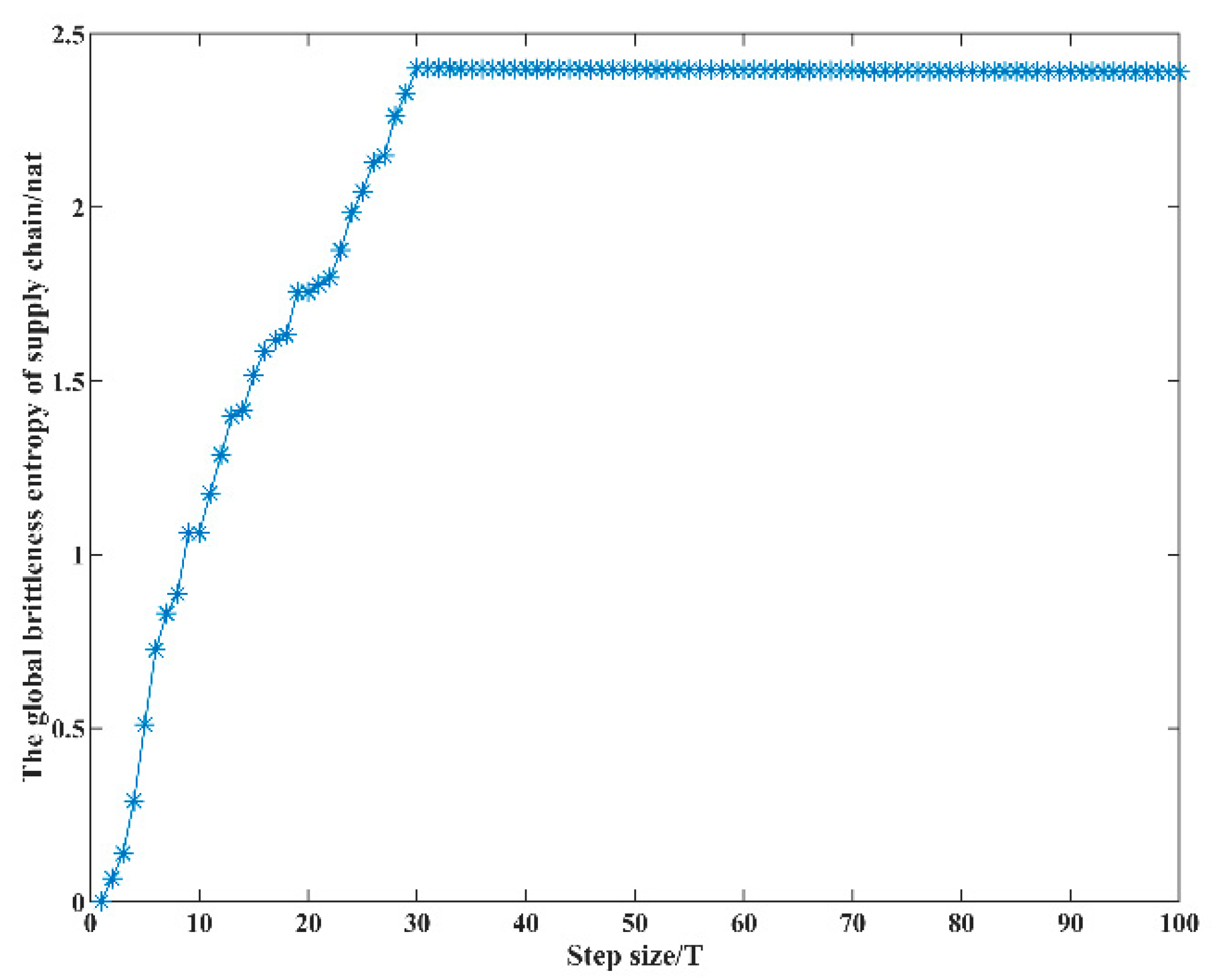

6.2. Brittleness Evolution Simulation When Vertex Adaptability Is Not Considered

6.3. Brittleness Evolution Simulation When Vertex Adaptability Is Considered

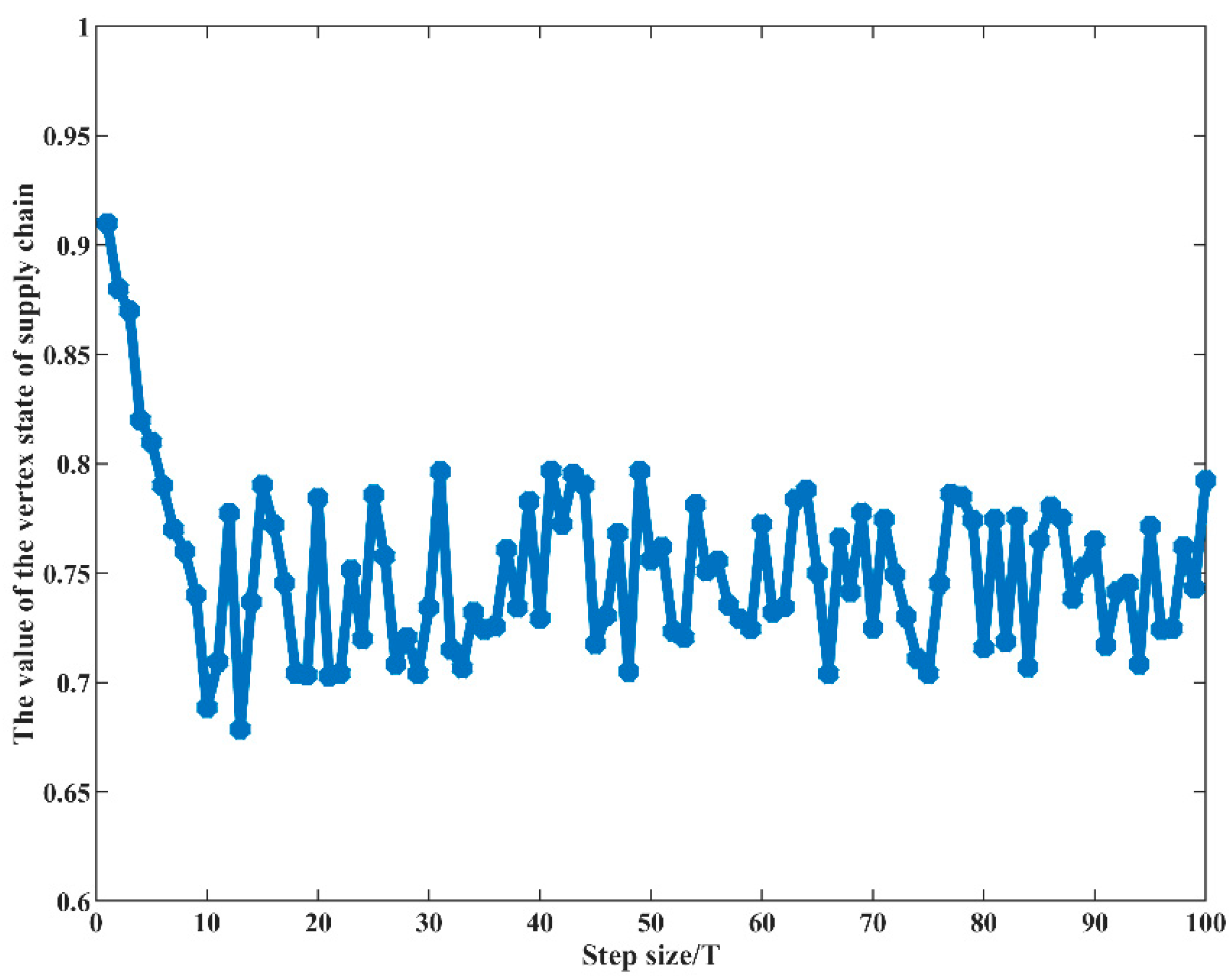

6.4. Evolution Simulation Considered Characteristics of Seasonal Demand of the Supply Chain

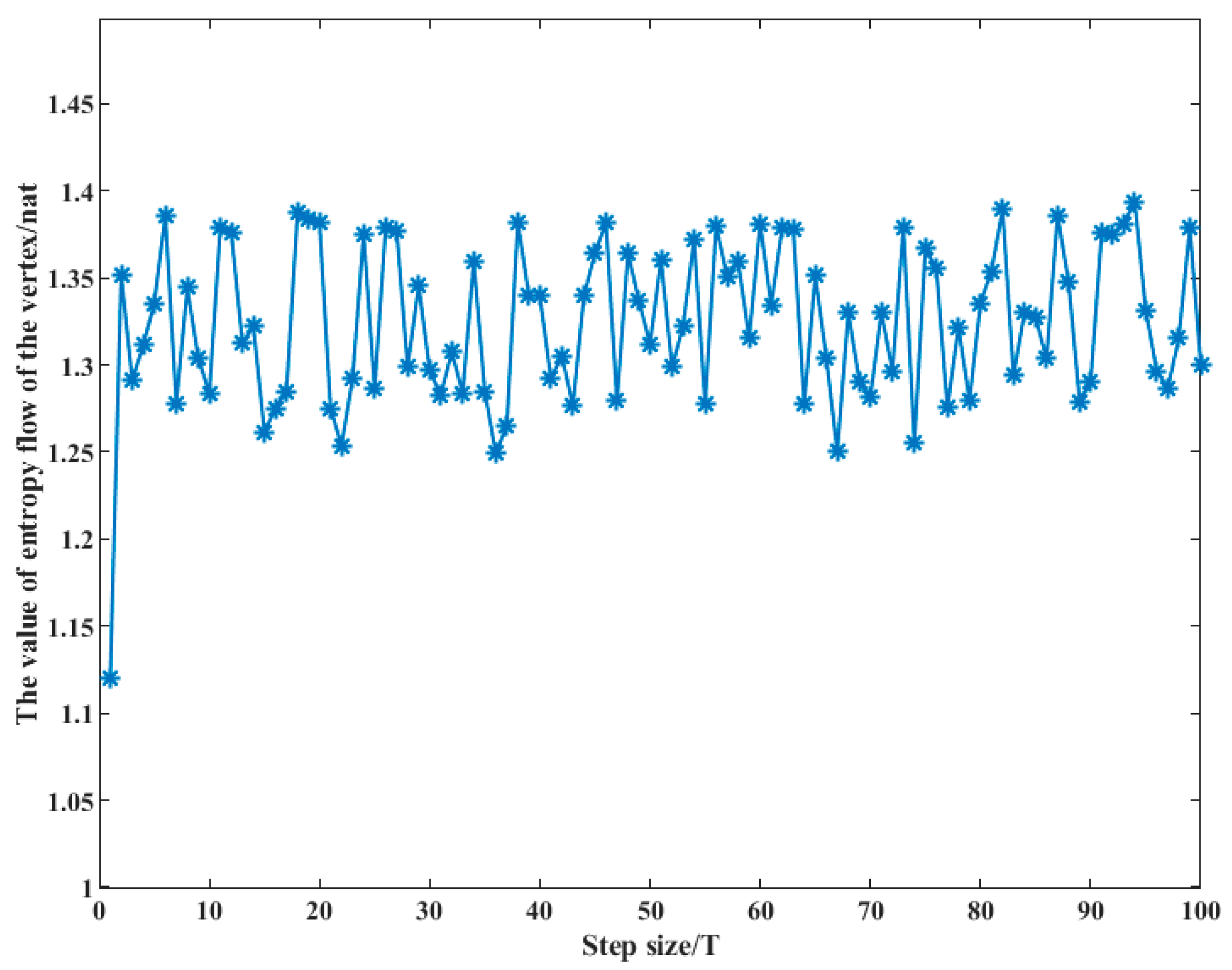

6.5. The Evolution Simulation of Brittleness Behavior

7. Conclusions and Future Research

- Brittleness evolution law based on the vertex adaptability of the supply chain

- (1)

- When the vertex adaptability is not considered, the supply chain system does not collapse immediately when the vertex of the brittleness source is failed but takes a certain period of time, which reflects the feature of delay of the supply chain’s brittleness.

- (2)

- When the vertex adaptability is considered, the vertex which has a close brittleness link with the brittleness source does not immediately collapse. This is because the adaptive behavior of the vertex agent resists the brittleness evolution of the supply chain to collapse.

- Seasonal evolution law of supply chain brittleness based on demand characteristics

- 3.

- The evolution law of brittleness behavior of the supply chain

- The model constructed in this paper is only considered the characteristics of the vertex within the supply chain system, based on which the brittleness evolution of the supply chain is compared and analyzed. The COVID-19 pandemic outside the supply chain system has attacked and disrupted the supply chain to varying degrees; therefore, the attack of the COVID-19 pandemic can be modeled and quantified to study its impact on the brittleness evolution of the supply chain in the future.

- The characteristics of the seasonal demand of brittleness evolution of the supply chain are compared and analyzed in this paper. In the future, more cluster analysis of demand characteristics can be conducted to study the relationship between brittleness evolution and more demand characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, N.R.; Liu, J.B.; Li, D.X.; Wang, J. Research on Evolutionary Mechanism of Agile Supply Chain Network via Complex Network Theory. Math. Probl. Eng. 2016, 2016, 4346580. [Google Scholar] [CrossRef]

- Yamin, M.A. Investigating the Drivers of Supply Chain Resilience in the Wake of the COVID-19 Pandemic: Empirical Evidence from an Emerging Economy. Sustainability 2021, 13, 11939. [Google Scholar] [CrossRef]

- Sombultawee, K.; Lenuwat, P.; Aleenajitpong, N.; Boon-itt, S. COVID-19 and Supply Chain Management: A Review with Bibliometric. Sustainability 2022, 14, 3538. [Google Scholar] [CrossRef]

- Moyano-Fuentes, J.; Bruque-Camara, S.; Maqueira-Marin, J.M. Development and validation of a lean supply chain management measurement instrument. Prod. Plan. Control 2019, 30, 20–32. [Google Scholar] [CrossRef]

- Rivera-Gomez, H.; Medina-Marin, J.; Santana-Robles, F.; Montano-Arango, O.; Barragan-Vite, I.; Cisneros-Flores, G. Impact of Unreliable Subcontracting on Production and Maintenance Planning Considering Quality Decline. Appl. Sci. 2022, 12, 3379. [Google Scholar] [CrossRef]

- Golan, M.S.; Mahoney, E.; Trump, B.; Linkov, I. Resilience and efficiency for the nanotechnology supply chains underpinning COVID-19 vaccine development. Curr. Opin. Chem. Eng. 2021, 34, 100759. [Google Scholar] [CrossRef]

- Elwood, A. Supply chain resilience. J. Bus. Contin. Emerg. Plan. 2021, 15, 65–77. [Google Scholar]

- Nakatani, J.; Tahara, K.; Nakajima, K.; Daigo, I.; Kurishima, H.; Kudoh, Y.; Matsubae, K.; Fukushima, Y.; Ihara, T.; Kikuchi, Y.; et al. A graph theory-based methodology for vulnerability assessment of supply chains using the life cycle inventory database. Omega-Int. J. Manag. Sci. 2018, 75, 165–181. [Google Scholar] [CrossRef]

- Sharma, S.K.; Routroy, S.; Singh, R.K.; Nag, U. Analysis of supply chain vulnerability factors in manufacturing enterprises: A fuzzy DEMATEL approach. Int. J. Logist.-Res. Appl. 2022, 20, 83590. [Google Scholar] [CrossRef]

- Blackhurst, J.; Rungtusanatham, M.J.; Scheibe, K.; Ambulkar, S. Supply chain vulnerability assessment: A network based visualization and clustering analysis approach. J. Purch. Supply Manag. 2018, 24, 21–30. [Google Scholar] [CrossRef]

- Wagner, S.M.; Neshat, N. Assessing the vulnerability of supply chains using graph theory. Int. J. Prod. Econ. 2010, 126, 121–129. [Google Scholar] [CrossRef]

- Karwasra, K.; Soni, G.; Mangla, S.K.; Kazancoglu, Y. Assessing dairy supply chain vulnerability during the COVID-19 pandemic. Int. J. Logist.-Res. Appl. 2021. [Google Scholar] [CrossRef]

- Ekanayake, E.; Shen, G.Q.; Kumaraswamy, M.; Owusu, E.K. Critical supply chain vulnerabilities affecting supply chain resilience of industrialized construction in Hong Kong. Eng. Constr. Archit. Manag. 2021, 28, 3041–3059. [Google Scholar] [CrossRef]

- Sharma, S.K.; Srivastava, P.R.; Kumar, A.; Jindal, A.; Gupta, S. Supply chain vulnerability assessment for manufacturing industry. Ann. Oper. Res. 2021. [Google Scholar] [CrossRef]

- Majumdar, A.; Sinha, S.K.; Shaw, M.; Mathiyazhagan, K. Analysing the vulnerability of green clothing supply chains in South and Southeast Asia using fuzzy analytic hierarchy process. Int. J. Prod. Res. 2021, 59, 752–771. [Google Scholar] [CrossRef]

- Liu, J.G.; Liu, F.; Zhou, H.; Kong, Y.D. An Integrated Method of Supply Chains Vulnerability Assessment. Sci. Program. 2016, 2016, 2819238. [Google Scholar] [CrossRef]

- Naghshineh, B.; Carvalho, H. The implications of additive manufacturing technology adoption for supply chain resilience: A systematic search and review. Int. J. Prod. Econ. 2022, 247, 108387. [Google Scholar] [CrossRef]

- Ruel, S.; Shaaban, S.; Ducros, M. Supply chain vulnerability: Contributions from an edifying case study. J. Enterp. Inf. Manag. 2019, 32, 214–232. [Google Scholar] [CrossRef]

- Bassett, H.R.; Sharan, S.; Suri, S.K.; Advani, S.; Giordano, C. A comparative study of small-scale fishery supply chains’ vulnerability and resilience to COVID-19. Marit. Stud. MAST 2022, 21, 173–192. [Google Scholar] [CrossRef]

- Viljoen, N.M.; Joubert, J.W. The Road most Travelled: The Impact of Urban Road Infrastructure on Supply Chain Network Vulnerability. Netw. Spat. Econ. 2018, 18, 85–113. [Google Scholar] [CrossRef]

- Saengchai, S.; Jermsittiparsert, K. The mediating role of supplier network, the moderating role of flexible resources in the relationship between lean manufacturing practices and the organizational performance. Humanit. Soc. Sci. Rev. 2019, 7, 720–727. [Google Scholar] [CrossRef][Green Version]

- Ma, F.; Xue, H.F.; Yuen, K.F.; Sun, Q.P.; Zhao, S.M.; Zhang, Y.X.; Huang, K. Assessing the Vulnerability of Logistics Service Supply Chain Based on Complex Network. Sustainability 2020, 12, 1991. [Google Scholar] [CrossRef]

- Wagner, S.M.; Neshat, N. A comparison of supply chain vulnerability indices for different categories of firms. Int. J. Prod. Res. 2012, 50, 2877–2891. [Google Scholar] [CrossRef]

- Shughrue, C.; Seto, K.C. Systemic vulnerabilities of the global urban-industrial network to hazards. Clim. Change 2018, 151, 173–187. [Google Scholar] [CrossRef]

- Kurniawan, R.; Zailani, S.H.; Iranmanesh, M.; Rajagopal, P. The effects of vulnerability mitigation strategies on supply chain effectiveness: Risk culture as moderator. Supply Chain Manag.-Int. J. 2017, 22, 1–15. [Google Scholar] [CrossRef]

- Bai, H.X.; Ran, W.X. Analysis of the Vulnerability and Resilience of the Tourism Supply Chain under the Uncertain Environment of COVID-19: Case Study Based on Lijiang. Sustainability 2022, 14, 2571. [Google Scholar] [CrossRef]

- Zhang, H.; Jia, F.; You, J.X. Striking a balance between supply chain resilience and supply chain vulnerability in the cross-border e-commerce supply chain. Int. J. Logist.-Res. Appl. 2021. [Google Scholar] [CrossRef]

- Guo, J.; Wu, D.J. Qualitative Analyzing Brittleness of Complex System Based on Catastrophe Theory. In Proceedings of the 20th Chinese Control and Decision Conference, Yantai, China, 2–4 July 2008. [Google Scholar]

- Guo, J.; Wu, D.J. Researching the Brittleness of Traffic System Based on Cusp Catastrophe Model. In Proceedings of the IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2008. [Google Scholar]

- Guo, J.; Chen, X.L.; Jin, H.Z.; Wu, D.J. Analyzing brittleness of complex system based on the catastrophe theory. In Proceedings of the 2007 International Conference on Intelligent Systems and Knowledge Engineering, Chengdu, China, 15–16 October 2007. [Google Scholar]

- Guo, J.; Wu, D.J. Based on the relation of evolution among systems to analyze brittleness of complex system. In Proceedings of the 6th World Congress on Intelligent Control and Automation, Dalian, China, 21–23 June 2006. [Google Scholar]

- Guo, J.; Wu, D.J. Based on cusp catastrophe potential function to analyze brittleness of complex system. In Proceedings of the Chinese Control Decision Conference, Guangzhou, China, 3–6 July 2007. [Google Scholar]

- Wei, Q.; Jin, H.Z.; Ji, M. The research on brittle catastrophe of complex giant system. In Proceedings of the IEEE Region 10 Technical Conference on Computers, Communications, Control and Power Engineering, Beijing, China, 28–31 October 2002. [Google Scholar]

- Guo, J.; Li, W.C.; Wu, D.J. Research on the brittleness of complex system based on brittleness potential function. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics, The Hague, The Netherlands, 10–13 October 2004. [Google Scholar]

- Wei, Q.; Jin, H.Z.; Guo, J.; Ji, M. Research on the complex system based on the brittle characteristic. In Proceedings of the SICE 2003 Annual Conference, Fukui, Japan, 4–6 August 2003. [Google Scholar]

- Cao, R.; Jin, H.Z. Brittleness Analysis of Complex Systems Subject to Cascading Failure. In Proceedings of the 10th IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 4–6 August 2013. [Google Scholar]

- Wei, Q.; Wei, X.L.; Jin, H.Z. Brittleness theory and its application on the analysis of SARS. In Proceedings of the 6th World Congress on Intelligent Control and Automation, Dalian, China, 21–23 June 2006. [Google Scholar]

- Wei, Q.; Jin, H.Z.; Guo, J.; Ji, M. Study on complex system based on the brittleness. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics (SMC 03), Washington, DC, USA, 5–8 October 2003. [Google Scholar]

- Yan, L.M.; Jin, H.Z.; Xu, J.J.; Wang, Q.; Rong, P.X. Analysis of brittleness in complex electric power systems. In Proceedings of the 17th Chinese Control and Decision Conference, Harbin, China, 25–27 June 2005. [Google Scholar]

- Jin, H.Z.; Yan, L.M.; Rong, P.X.; Liu, X.B.; Li, M.D. Brittleness analysis of electric network. Dyn. Contin. Discret. Impulsive Syst. -Ser. B-Appl. Algorithms 2005, 1, 32–36. [Google Scholar]

- Wu, H.M.; Jin, H.Z. Analysis of brittle tree of complex system based on chart theory. In Proceedings of the 21st Chinese Control and Decision Conference, Guilin, China, 17–19 June 2009. [Google Scholar]

- Wang, J.; Zhu, X.Y.; Hu, X.W. Research on the Evaluation Methods of Highway Traffic System Brittle Source. In Proceedings of the 5th International Conference on Intelligent Systems Design and Engineering Applications (ISDEA), Zhangjiajie, China, 15–16 June 2014. [Google Scholar]

- Lin, D.M.; Jin, H.Z.; Xue, P.; Wu, H.M.; Wang, H. Research on brittleness of traffic system based on adaptive agent digraph. J. Syst. Simul. 2008, 20, 733–737. [Google Scholar]

- Yan, W. Study of supply chain’s brittleness based on the complex system brittle theory. In Proceedings of the IEEE International Conference on Grey Systems and Intelligent Services, Nanjing, China, 18–20 November 2007. [Google Scholar]

- Cao, W.; Wang, X.F. A Multiobjective Multiperiod Mixed-Integer Programming Optimization Model for Integrated Scheduling of Supply Chain Under Demand Uncertainty. IEEE Access 2022, 10, 63958–63970. [Google Scholar] [CrossRef]

- Holland, J.H. Complex Adaptive Systems. Daedalus 1992, 121, 17–30. [Google Scholar]

- Lin, D.M.; Jin, H.Z.; Wu, H.M.; Xue, P.; Wang, H. Research on brittleness of complex systems based on ant colony algorithm. Syst. Eng. Electron. 2008, 30, 743–747. [Google Scholar]

- Wang, A.J.; Lin, G.L.; Wang, X.Q. Research on the Model of Hazardous Material Transport System’s Brittle Risk. In Proceedings of the International Conference of Management Engineering and Information Technology, Zhengzhou, China, 17–18 October 2009. [Google Scholar]

- Jiang, Z.; Pan, X.; Lin, Y. Risk analysis of equipment system-of-systems architecture based on entropy and brittleness. In Proceedings of the 26th Conference on European Safety and Reliability (ESREL), Glasgow, Scotland, 25–29 September 2016. [Google Scholar]

- Zhou, J.B.; Dong, S.; Yan, B.; Zhang, M.J.; Yang, R.F. An adaptive agent digraph simulation for road traffic safety statue in bridge-tunnel groups. Adv. Mech. Eng. 2017, 9, 1687814017715979. [Google Scholar] [CrossRef]

- Yang, J.X.; Zhou, J.T.; Han, F.Q. Study on State Recognition of ASCE Benchmark FEM based on Lyapunov Exponent Spectrum Entropy. In Proceedings of the International Conference on Applied Mechanics, Materials and Manufacturing (ICAMMM 2011), Shenzhen, China, 18–21 November 2011. [Google Scholar]

- Gao, X.Y.; Zhao, Y.; Wang, Y.H.; Zuo, X.; Chen, T. A Lagrange Relaxation Based Decomposition Algorithm for Large-Scale Offshore Oil Production Planning Optimization. Processes 2021, 9, 1257. [Google Scholar] [CrossRef]

| Cpit 1 | 1 | 21 | 25 | 28 | 24 | 23 | 19 | 30 | 15 | 17 |

| 2 | 20 | 26 | 28 | 25 | 22 | 19 | 28 | 15 | 16 | |

| 3 | 21 | 25 | 27 | 23 | 23 | 18 | 29 | 14 | 16 | |

| 4 | 21 | 25 | 27 | 24 | 22 | 18 | 30 | 13 | 17 | |

| fli 2 | 0.6 | 0.40 | 0.30 | 0.45 | 0.55 | 0.63 | 0.20 | 0.7 | 0.65 |

| t | J1 | J2 | J3 | |

|---|---|---|---|---|

| cdjt 1 | 1 | 5 | 12 | 7 |

| 2 | 6 | 11 | 8 | |

| 3 | 4 | 12 | 7 | |

| 4 | 5 | 13 | 6 |

| K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 | K11 | K12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| dk 1 | 6 | 8 | 6 | 7 | 7 | 6 | 7 | 9 | 6 | 7 | 6 | 6 |

| gk 2 | 2.4 | 1.7 | 2.2 | 2.1 | 1.7 | 2.4 | 2.1 | 1.7 | 1.8 | 1.7 | 2.4 | 1.9 |

| hk 3 | 5.1 | 3.8 | 4.0 | 4.6 | 3.9 | 4.8 | 4.0 | 4.9 | 4.2 | 3.8 | 3.6 | 3.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, W.; Wang, X. Brittleness Evolution Model of the Supply Chain Network Based on Adaptive Agent Graph Theory under the COVID-19 Pandemic. Sustainability 2022, 14, 12211. https://doi.org/10.3390/su141912211

Cao W, Wang X. Brittleness Evolution Model of the Supply Chain Network Based on Adaptive Agent Graph Theory under the COVID-19 Pandemic. Sustainability. 2022; 14(19):12211. https://doi.org/10.3390/su141912211

Chicago/Turabian StyleCao, Wei, and Xifu Wang. 2022. "Brittleness Evolution Model of the Supply Chain Network Based on Adaptive Agent Graph Theory under the COVID-19 Pandemic" Sustainability 14, no. 19: 12211. https://doi.org/10.3390/su141912211

APA StyleCao, W., & Wang, X. (2022). Brittleness Evolution Model of the Supply Chain Network Based on Adaptive Agent Graph Theory under the COVID-19 Pandemic. Sustainability, 14(19), 12211. https://doi.org/10.3390/su141912211