Red Ceramics Produced with Primary Processing Fine Waste of Ornamental Stones According to the Circular Economy Model

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Characterization of Raw Materials

2.2.2. Mass Preparation for Extrusion

Ceramics Manufacture by Extrusion

2.2.3. Physical and Mechanical Tests on Fired Ceramics

- ASTM C 373-72 [20] was used to determine the density of ceramic pieces;

- A Mitutoyo caliper (resolution ± 0.01 mm) was used to determine the linear shrinkage of the ceramic pieces;

- ABNT 15270-2 [21] was used to determine the water absorption of ceramic pieces;

- ASTM C373-88 [22] was used to determine the porosity of ceramic pieces;

- ASTM C674-77 [23] was used to assess the flexural strength (σ), which was determined by three points bending.

3. Results

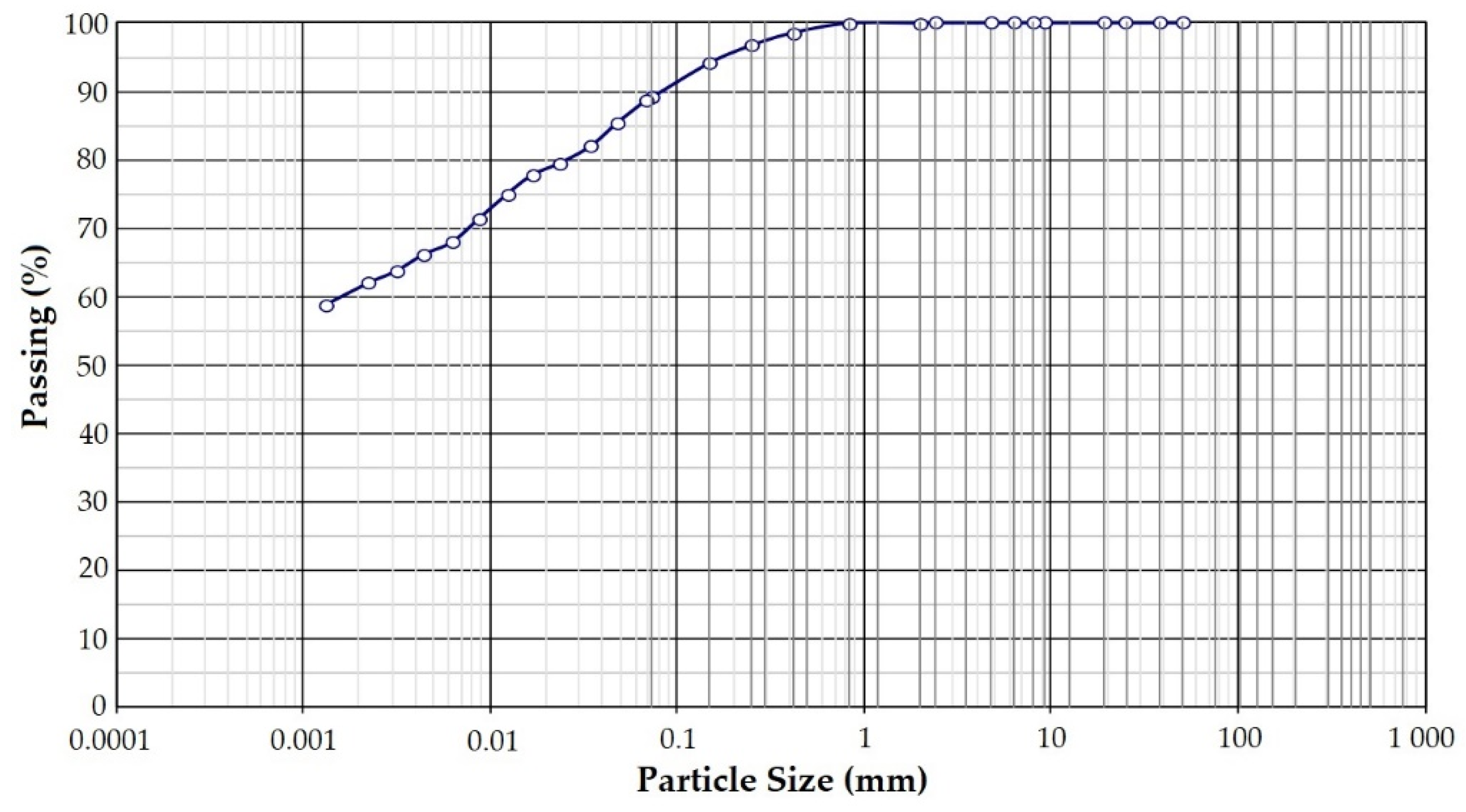

3.1. Granulometry

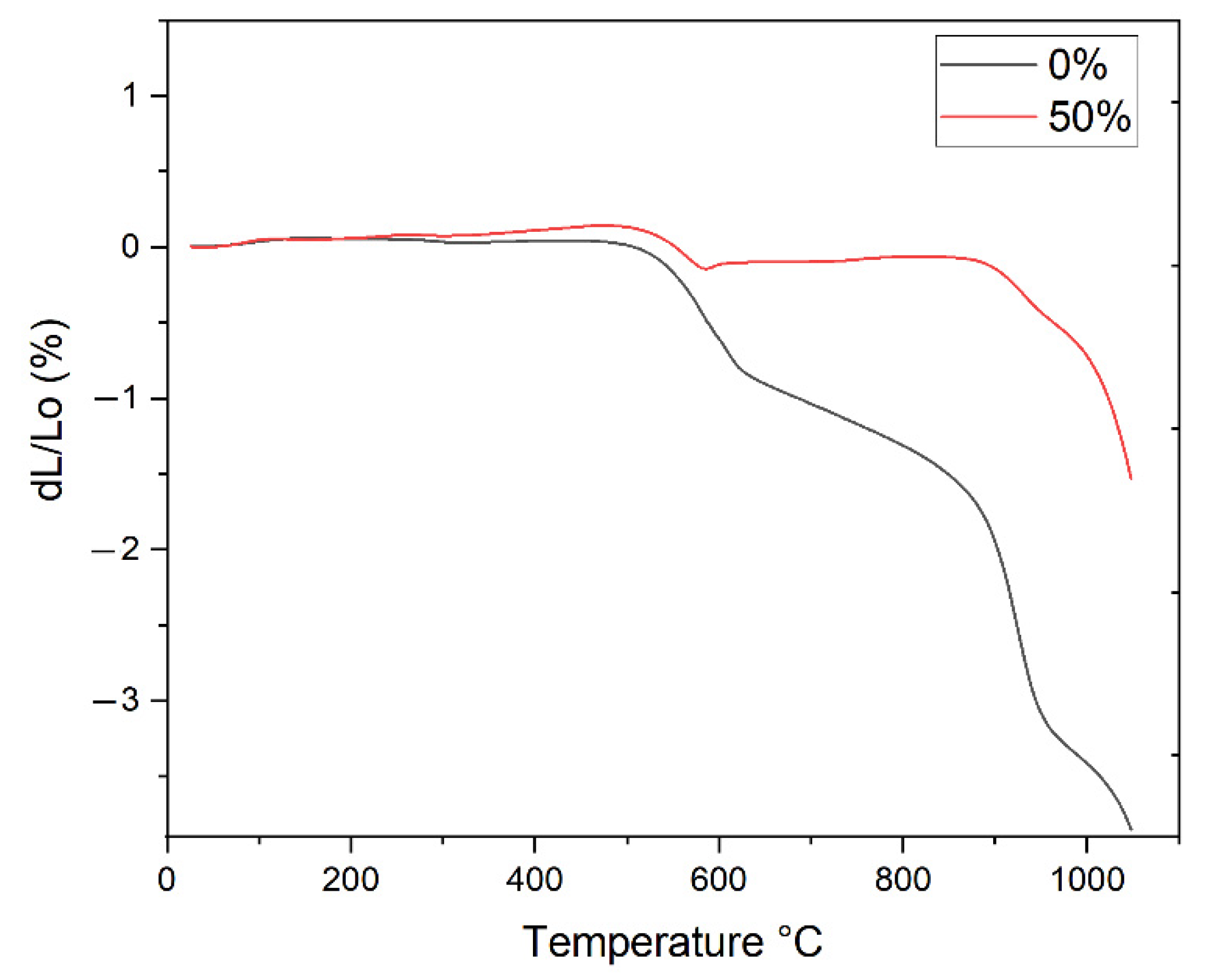

3.2. Dilatometry

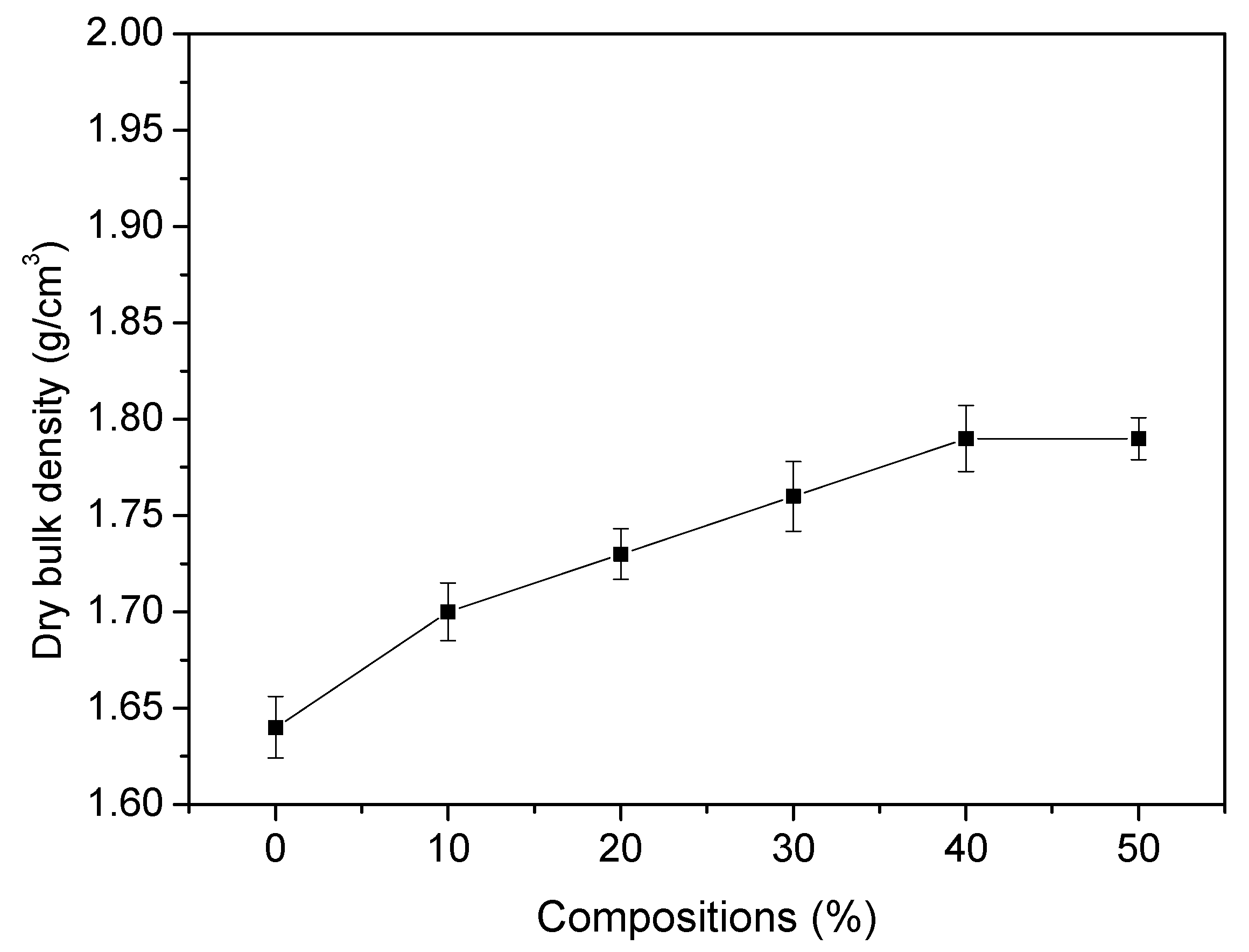

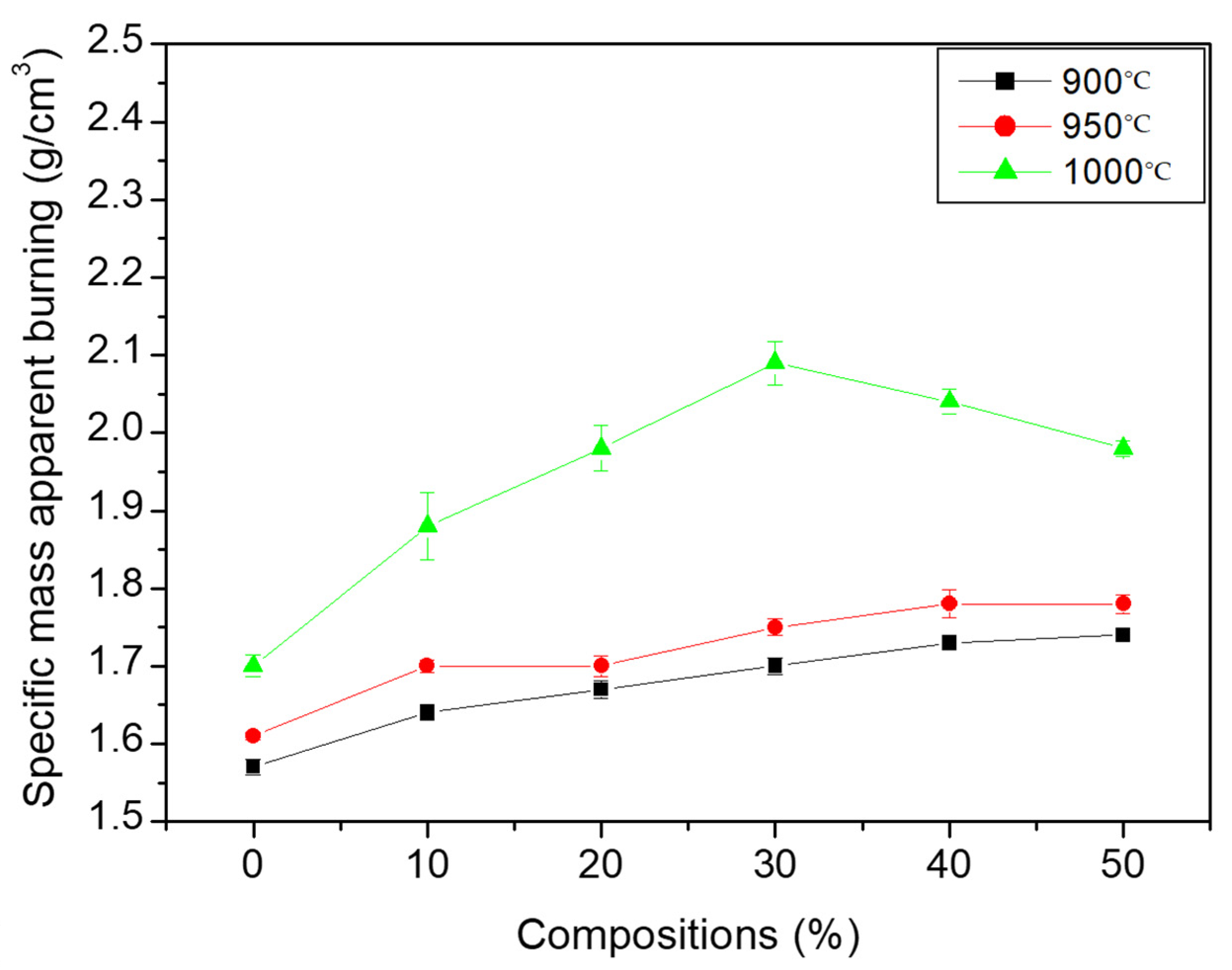

3.3. Density

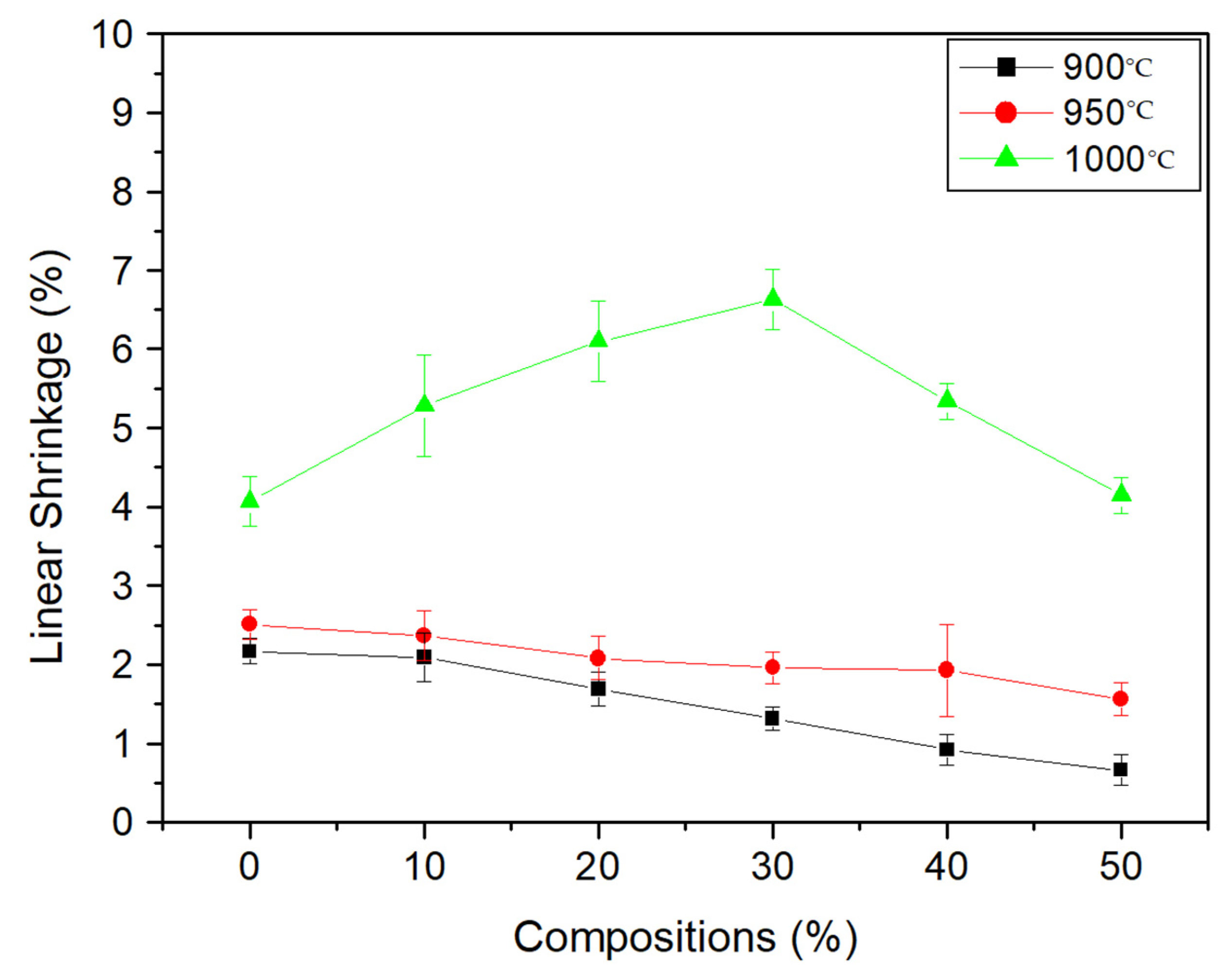

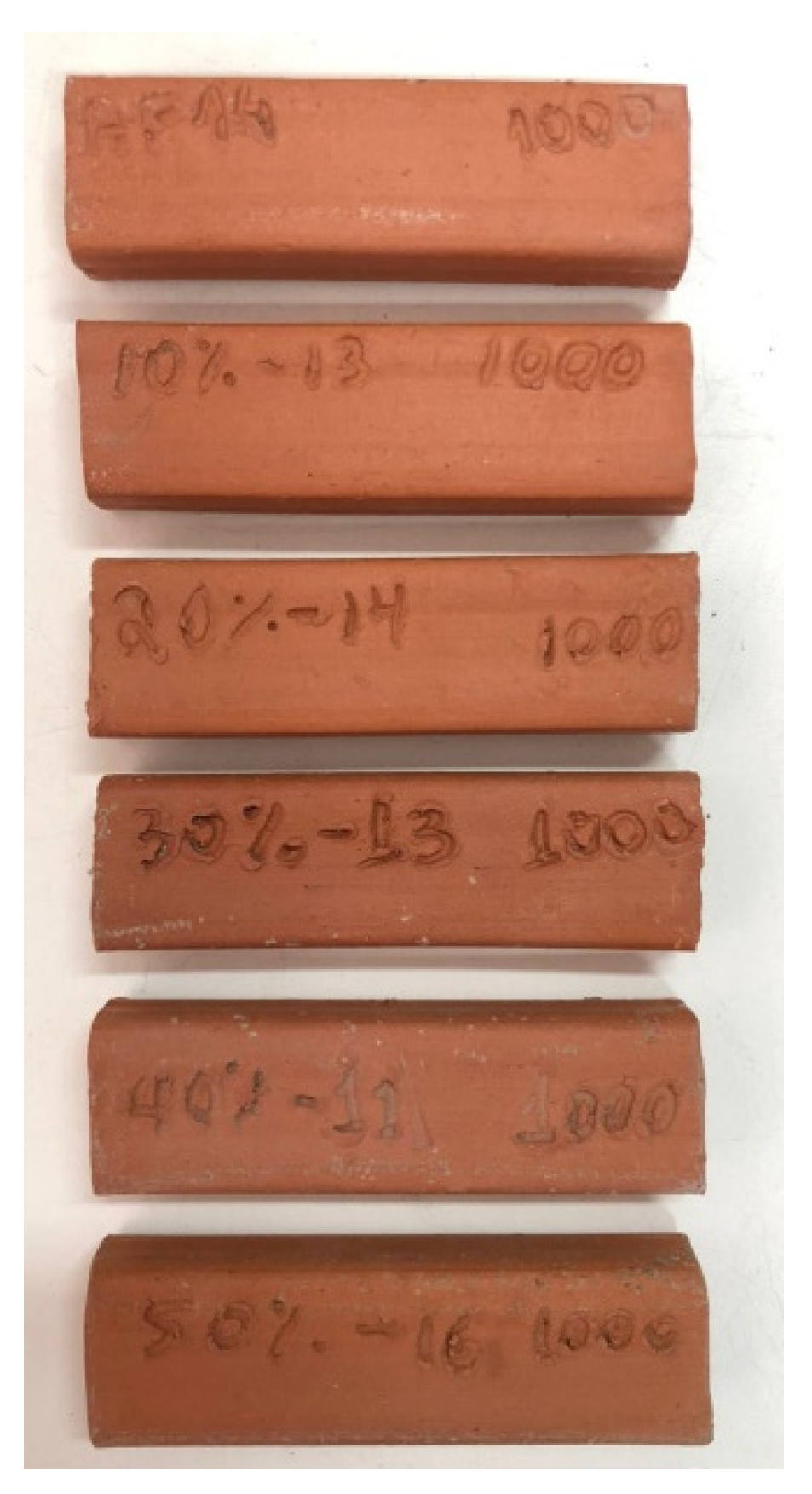

3.4. Linear Shrinkage

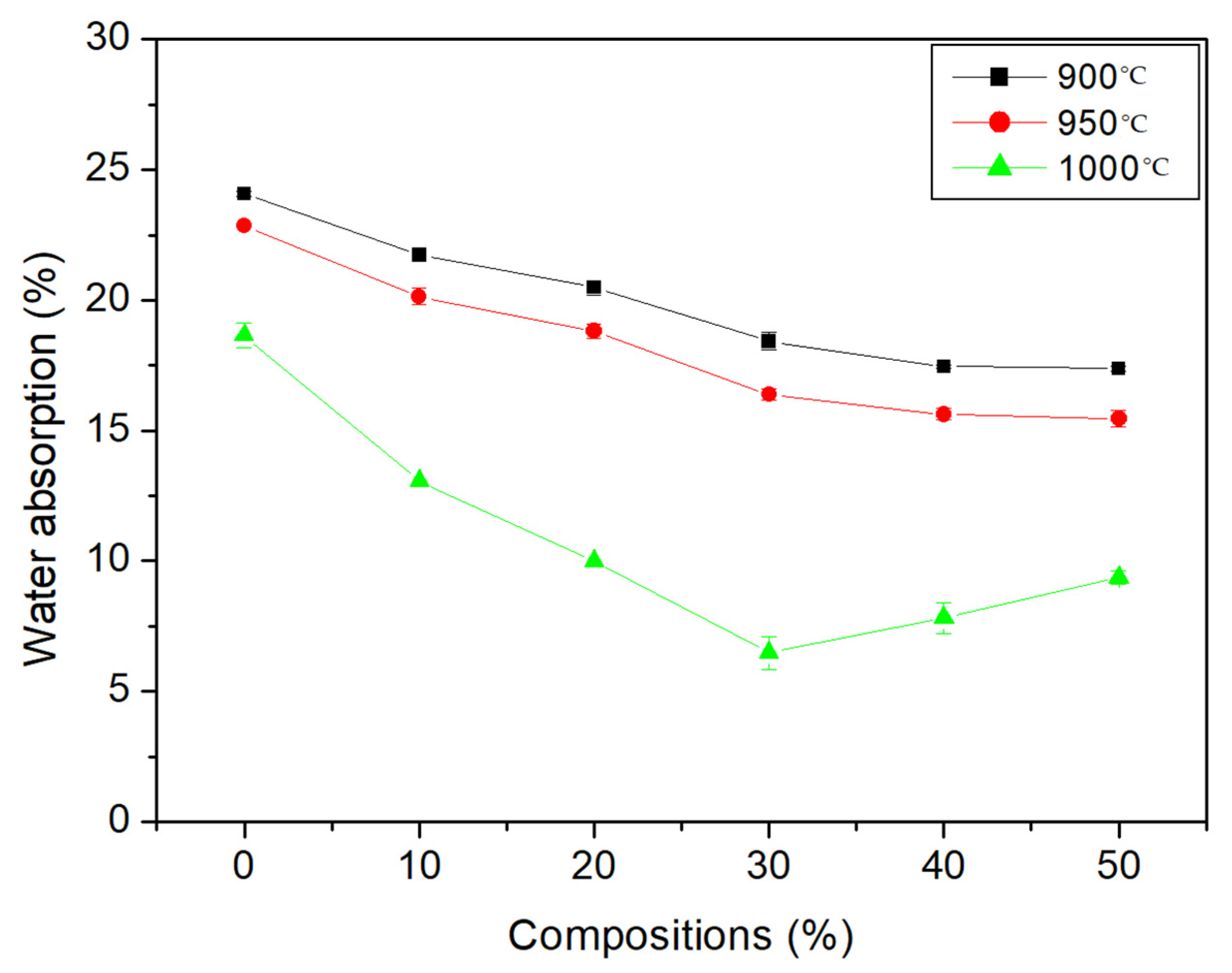

3.5. Absorption

3.6. Porosity

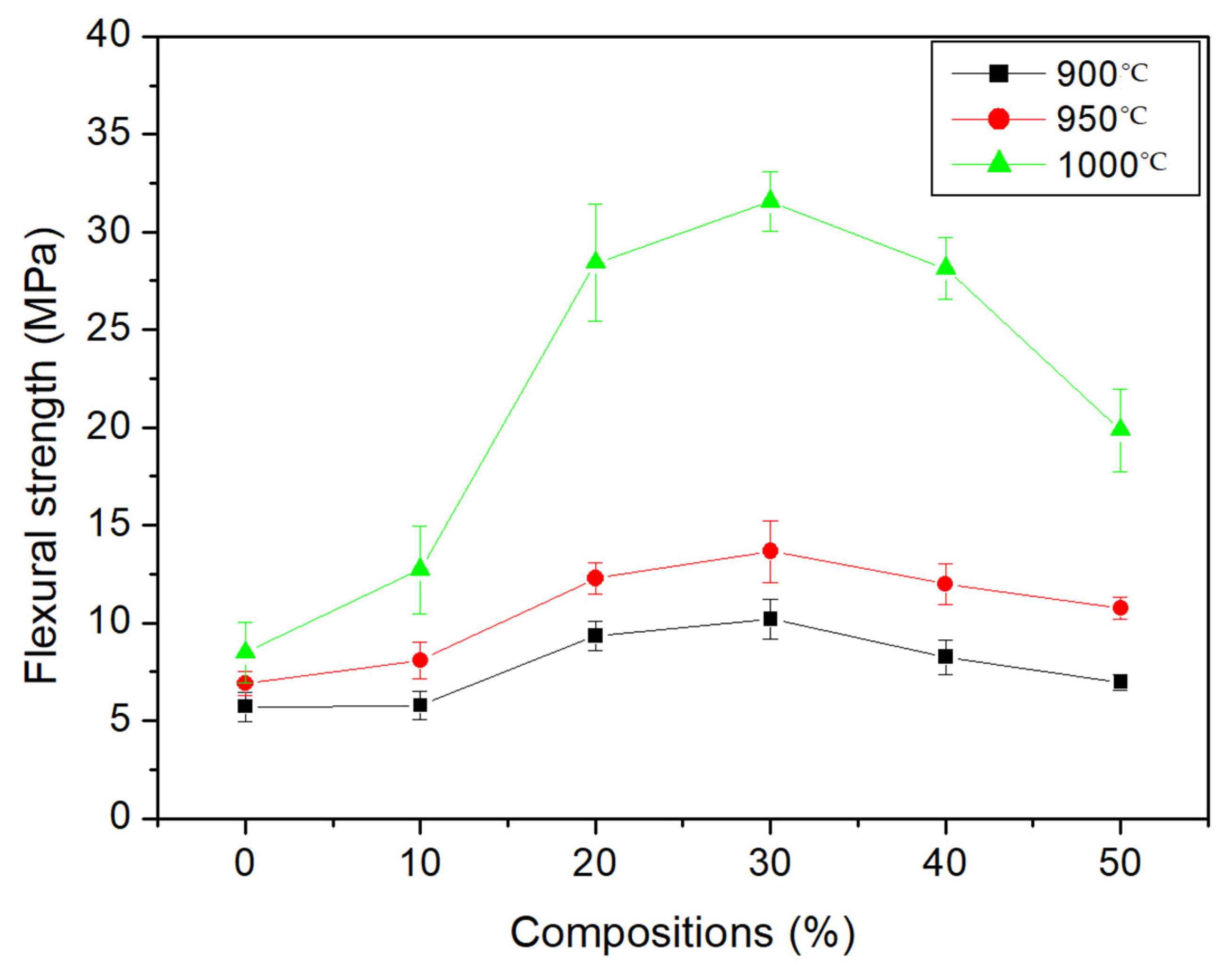

3.7. Flexural Strength

4. Discussion

5. Conclusions

- From the characterization of the clay, it has a typically kaolinitic composition and is constituted, above all, by kaolinite, quartz, gibbsite, microclimate, sepiolite, and vermiculite. The large amount of grains in the “clay” fraction is associated with the presence of clay minerals. The FIBRO is constituted by quartz, albite, anorthite, hornblende, microcline, muscovite, and orthoclase;

- In the dry density, there was an increase in the replacement masses with FIBRO, improving the packing of the particles. However, the compositions with the replacement of granite waste did not increase significantly with increasing replacement. However, this increase is beneficial so that the shrinkage is reduced and so the particles are more consolidated during burning;

- Regarding the firing behavior, in general, the higher temperature had a lower water absorption and greater flexural strength and the ceramics fabricated with FIBRO had lower absorption and greater flexural strength. For linear shrinkage, it can be concluded that the ceramic mass with the replacement of FIBRO in the highest percentages showed lower shrinkage values, due to its lower mass loss and better packaging;

- It is observed that the flexural strength increased with the use of FIBRO. This increase in resistance was due to the influence of clay and the fluxing action of the waste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ABIROCHAS—Associação Brasileira da Indústria de Rochas Ornamentais. Balanço das Exportações e Importações Brasileiras de Rochas Ornamentais em 2021; Informe 01/2022; ABIROCHAS: Brasília, Brazil, 2022. [Google Scholar]

- COMEX STAT. Ministério da Indústria, Comércio Exterior e Serviços. Exportação e Importação Geral. Base de Dados 2021. 2022. Available online: http://comexstat.mdic.gov.br/pt/home (accessed on 16 September 2022).

- SINDIROCHAS—Sindicato da Indústria de Rochas Ornamentais, Cal e Calcários do Espírito Santo. Relatório de Exportação de Rochas Ornamentais 2021. Available online: https://www.sindirochas.com/ (accessed on 16 September 2022).

- Vidal, F.W.H.; Pinheiro, J.R.; Castro, N.F.; Caranassios, A. Lavra de rochas ornamentais. In Tecnologia de Rochas Ornamentais: Pesquisa, Lavra e Beneficiamento; CETEM/MCTI: Rio de Janeiro, Brazil, 2014; Chapter 4; pp. 155–257. [Google Scholar]

- Silveira LL, L.; Vidal FW, H.; Souza, J.C. Beneficiamento de rochas ornamentais. In Tecnologia de Rochas Ornamentais: Pesquisa, Lavra e Beneficiamento; CETEM/MCTI: Rio de Janeiro, Brazil, 2014; Chapter 7; pp. 329–398. [Google Scholar]

- BRASIL. Lei n. 12.305, de 02 de Agosto de 2010. Institui a Política Nacional de Resíduos Sólidos. Diário Oficial [da] República Federativa do Brasil, Brasília, 02 Ago. 2010. Available online: http://www.planalto.gov.br/ccivil_03/_ato20072010/2010/lei/l12305.htm (accessed on 24 June 2022).

- ANICER—Associação Nacional da Indústria Cerâmica. ANICER. Dados do Setor. Santa Gertrudes, Brazil, 19 September 2019. Available online: https://www.anicer.com.br/anicer/setor/ (accessed on 25 July 2021).

- SEBRAE—Serviço Brasileiro de Apoio às Micro e Pequenas Empresas. Construção Civil. Cerâmica Vermelha. Panorama do Mercado no Brasil. 2015. Available online: http://www.bibliotecas.sebrae.com.br/chronus/arquivos_chronus/bds/bds.nsf/b877f9b38e787b32594c8b6e5c39b244/$file/5846.pdf (accessed on 14 September 2019).

- Almeida, G.S. Simulação e Experimentação da Secagem de Cerâmica Vermelha em Sistemas Térmicos Industriais. Ph.D. Thesis, Portal da Universidade Federal de Campina Grande (UFCG), Campina Grande, Brazil, 2009; 209p. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Ciência e Engenharia de Materiais: Uma Introdução, 8th ed.; Springer: New York, NY, USA, 2012; 716p. [Google Scholar]

- Batista, V.R.; Nascimento, J.J.S.; Lima, A.G.B. Secagem e queima de tijolos cerâmicos maciços e vazados incluindo variações dimensionais e danos estruturais. Rev. Eletrônica Mater. Process. 2008, 3, 46–61. [Google Scholar]

- Freire, A.S.; Motta, J.F.M. Potencialidades para o aproveitamento econômico do rejeito da serragem do granito. Rochas Qual. 1995, 16, 98–108. [Google Scholar]

- Rodrigues, D.V.; Xavier, G.C.; Saboya, F.; Maia, P.C.; Alexandre, J. Durabilidade de peças cerâmicas vermelhas com adição de rejeito de rocha ornamental isenta de granalha. Cerâmica 2012, 58, 286–293. [Google Scholar] [CrossRef][Green Version]

- Aguiar, M.C. Utilização de Resíduo de Serragem de Rocha Ornamental com Tecnologia de Fio Diamantado em Cerâmica Vermelha. Master’s Thesis, Centro de Ciência e Tecnologia, Departamento de Ciências dos Materiais, UENF, Campos dos Goytacazes, Brazil, 2012; 100p. [Google Scholar]

- Moraes, M.S.; Xavier, G.C.; Alexandre, J.; Azevedo, A.R.G. Análise do comportamento de peças cerâmicas com e sem a incorporação de resíduo de rocha ornamental após ciclos de umedecimento e secagem. In Proceedings of the 64th Congresso Brasileiro de Cerâmica, Águas de Lindóia, Brazil, 7–10 December 2020. [Google Scholar]

- Azevedo, A.C.; Marvila, M.T.; Delaqua GC, G.; Amaral, L.F.; Colorado, H.; Vieira, C.M.F. Economy analysis of the implementation of extruded tiles fabrication in a ceramic industry containing ornamental rock waste. Int. J. Appl. Ceram. Technol. 2021, 18, 1876–1890. [Google Scholar] [CrossRef]

- Sant’ana, M.A.K.; Gadioli, M.C.B. Estudo da Viabilidade Técnica da Utilização de Resíduos de Rochas em Massas Cerâmicas; Série Tecnologia Ambiental; Centro de Tecnologia Mineral: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Gadioli, M.C.B.; Aguiar, M.C.; Vidal, F.W.H.; Sant’ana, M.A.K.; Almeida, K.M.; Giori, A.J.N. Incorporation of Ornamental Stone Waste in the Manufacturing of Red Ceramics. Materials 2022, 15, 5635. [Google Scholar] [CrossRef] [PubMed]

- NBR 7181; Análise Granulométrica. ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 1984.

- ASTM C373-72; Test Method for Water Absorption, Bulk Density, Apparent Porosity and Apparent Specific Gravity of Fired Whiteware Products. American Society for Testing and Materials: West Conshohocken, PA, USA, 1977.

- ASTM C373-88; Test Method for Water Absorption, Bulk Density and Apparent Porosity. American Society for Testing and Materials: West Conshohocken, PA, USA, 1994.

- NBR 15270-2; Componentes Cerâmicos—Blocos e Tijolos para Alvenaria. Parte 2: Métodos de Ensaio. ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- ASTM C674-77; Flexural Properties of Ceramic Whiteware Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 1977.

- Callister, W.D. Ciência e Engenharia dos Materiais, uma Introdução, 7th ed.; LTC: Rio de Janeiro, Brazil, 2008. [Google Scholar]

- German, R.M. Liquid Phase Sintering; Rensselaer Polytechnic Institute Troy: New York, NY, USA, 1985. [Google Scholar]

- NBR 15270-1; Componentes Cerâmicos–Blocos e Tijolos para Alvenaria. Parte 1: Requisitos. ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- NBR 15310; Componentes Cerâmicos–Telhas–Terminologia, Requisitos e Métodos de Ensaio. ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2009.

- Cerqueira, N.A.; Souza, V.; Alexandre, J.; Xavier, G.C.; Fediuk, R.; Monteiro, S.N.; Barreto, M.N.; Azevedo, A.R.G. Mechanical Feasibility Study of Pressed and Burned Red Ceramic Blocks as Structural and Sealing Masonry. Materials 2022, 15, 5004. [Google Scholar] [CrossRef] [PubMed]

- Vieira, M.T.; Catarino, L.; Oliveira, M.; Sousa, J.; Torralba, J.M.; Cambronero, L.E.G.; Victoria, A. Optimization of the sintering process of raw material wastes. J. Mater. Process. Technol. 1999, 92, 97–101. [Google Scholar] [CrossRef]

- Menezes, R.R.; Neves, G.D.A.; Ferreira, H.C. O estado da arte sobre o uso de resíduos como matérias-primas cerâmicas alternativas. Rev. Bras. Eng. Agrícola Ambient. 2002, 6, 303–313. [Google Scholar] [CrossRef]

- Ribeiro, W.S.; Babisk, M.P. Estudo da influência de adição de resíduos de quartzitos na resistência de cerâmica vermelha. In Jornada de Iniciação Científica; CETEM: Rio de Janeiro, Brazil, 2012. [Google Scholar]

| SiO2 | Al2O3 | Fe2O3 | Na2O | MgO | K2O | P2O5 | CaO | Ti2O | SO3 | BaO | LOI * | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ceramic Mass | 41.6 | 30.8 | 9.0 | 0.13 | 1.2 | 0.92 | 0.17 | 0.16 | 1.3 | - | - | 14.6 |

| Waste | 56.0 | 19.9 | 5.8 | 5.4 | 1.6 | 4.3 | 0.48 | 3.6 | 1.1 | 0.19 | 0.59 | 0.74 |

| Clay | Waste | |

|---|---|---|

| M0 | 100 | 0 |

| M1 | 90 | 10 |

| M2 | 80 | 20 |

| M3 | 70 | 30 |

| M4 | 60 | 40 |

| M5 | 50 | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguiar, M.C.d.; Gadioli, M.C.B.; Sant’Ana, M.A.K.; Almeida, K.M.d.; Vidal, F.W.H.; Vieira, C.M.F. Red Ceramics Produced with Primary Processing Fine Waste of Ornamental Stones According to the Circular Economy Model. Sustainability 2022, 14, 12887. https://doi.org/10.3390/su141912887

Aguiar MCd, Gadioli MCB, Sant’Ana MAK, Almeida KMd, Vidal FWH, Vieira CMF. Red Ceramics Produced with Primary Processing Fine Waste of Ornamental Stones According to the Circular Economy Model. Sustainability. 2022; 14(19):12887. https://doi.org/10.3390/su141912887

Chicago/Turabian StyleAguiar, Mariane Costalonga de, Mônica Castoldi Borlini Gadioli, Maria Angelica Kramer Sant’Ana, Kayrone Marvila de Almeida, Francisco Wilson Hollanda Vidal, and Carlos Maurício Fontes Vieira. 2022. "Red Ceramics Produced with Primary Processing Fine Waste of Ornamental Stones According to the Circular Economy Model" Sustainability 14, no. 19: 12887. https://doi.org/10.3390/su141912887

APA StyleAguiar, M. C. d., Gadioli, M. C. B., Sant’Ana, M. A. K., Almeida, K. M. d., Vidal, F. W. H., & Vieira, C. M. F. (2022). Red Ceramics Produced with Primary Processing Fine Waste of Ornamental Stones According to the Circular Economy Model. Sustainability, 14(19), 12887. https://doi.org/10.3390/su141912887