Quality of Forecasts as the Factor Determining the Coordination of Logistics Processes by Logistic Operator

Abstract

:1. Introduction

- Question 1: What features must a logistic operator have to create forecasts that will be useful for other links in the distribution network?

- Question 2: How does the characteristics of the products within the distribution network affect the quality of the forecasts made by a logistics operator?

- Question 3: How do the elements of the distribution network configuration affect the quality of forecasts made by a logistics operator?

2. Theoretical Background

2.1. The Distribution Network as a Particularly Complex System

2.2. Factors Influencing the Quality of Forecasts for Inventory Management in Distribution Networks

2.3. Logistics Operator in the Distribution Network

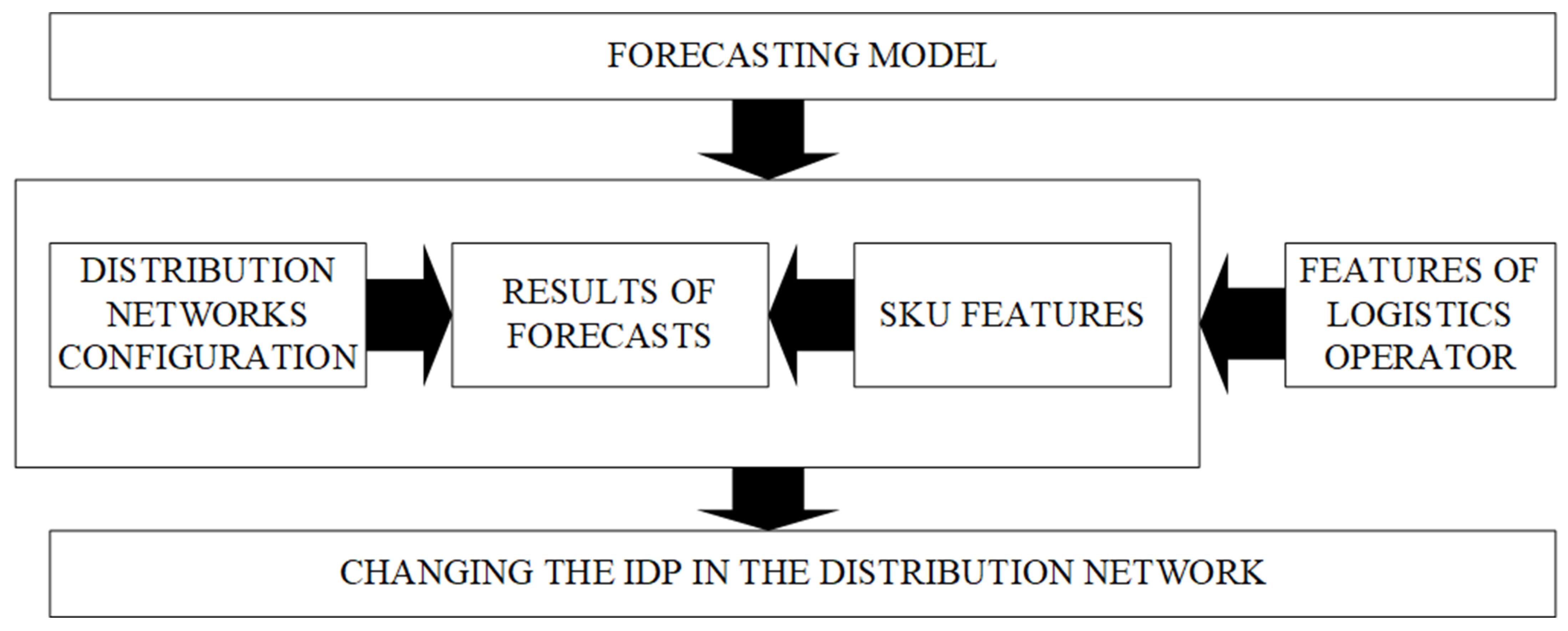

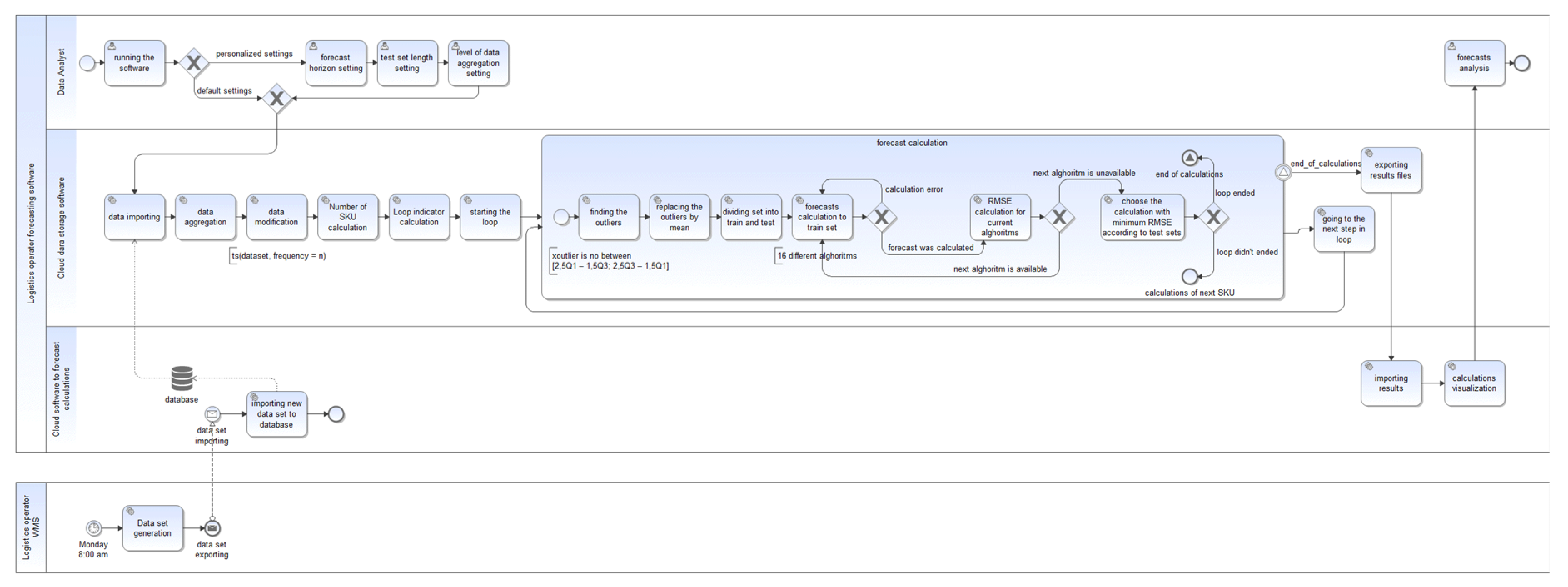

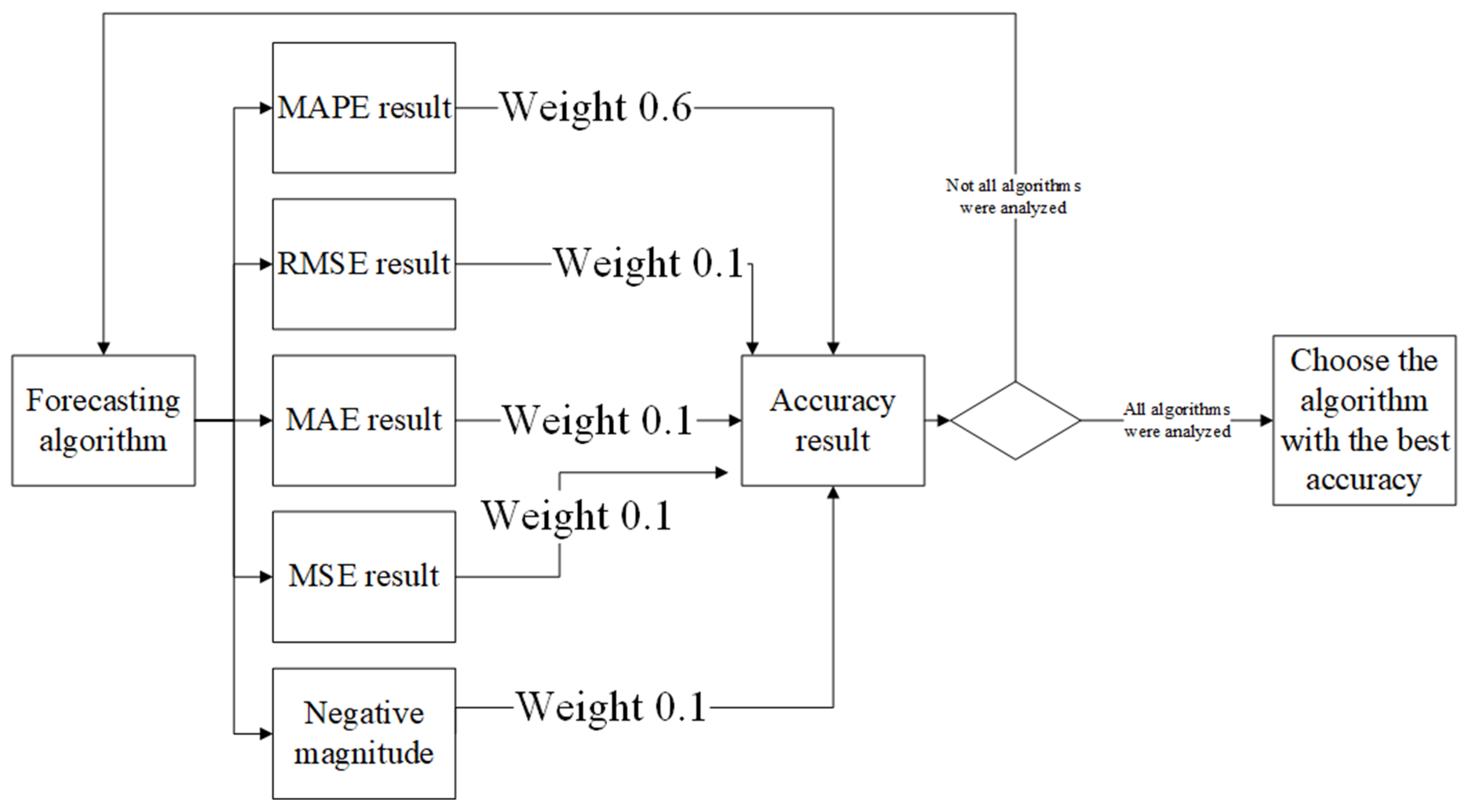

3. Research Methodology

- Distribution network configuration

- Characteristics of products within the network

- Central link features

| Algorithm 1: Tool script running in the example of part with ETS calculation |

| 1: try({ 2: dd.ETS <- ets(learn[,k]) #using ets() to learn set for the chosen SKU 3: dd.ETS.f <- forecast(dd.ETS, h=horizon_length) #forecast calculation based on training set in the chosen horizon 4: acc_ETS <- accuracy(dd.ETS.f[,k]) #accuracy calculation 5: MAPE_train.ETS <- acc_ETS[1,4] #checking the MAPE value for training set 6: MAPE_test.ETS <- acc_ETS[2,4] #checking the MAPE value for test set 7: col.n.ETS <- colnames(learn)[k] 8: model.ETS <- “ETS” 9: cbindETS <- cbind(print(col.n.ETS),print(dd.ETS.f),print(MAPE_train.ETS), print(MAPE_test.ETS), model.ETS) 10: c(“SKU”,“Forecast”,“Lo80”,“Hi80”,“Lo95”,“Hi95”,“MAPE.Train”,“MAPE.Test”,“Model”) }, silent = T) |

- The main limitations of the proposed model are:

- High dependency on input data—which can be solved by implementing the correct information exchange system.

- Relying only on quantitative data—which can be solved by training 3PL staff in the area of forecasting and using the results of the XYZ analysis to find better forecasting methods for the Z group.

- A prediction model embedded locally which can cause problems with computing power—this can be solved by moving the computing infrastructure to the cloud.

- The fact that forecasts are now based on distorted data related to poor perception and description of certain time series—which can be solved by improving cooperation in the distribution network and developing better information exchange systems.

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3PL | Third-party logistics |

| ABC/XYZ | Inventory classification method by ABC/XYZ |

| ATO | Assembly-to-order |

| BPMN 2.0 | Business Process Modeling and Notation 2.0 |

| CDP | Customers orders decoupling point |

| CPFR | Collaborative Planning Forecasting and Replenishment |

| DN | Distribution network |

| ETO | Engineering-to-order |

| IDP | Information decoupling point |

| IT | Information technology |

| MAE | Mean Absolute Error |

| MAPE | Mean Absolute Percentage Error |

| MSE | Mean Square Error |

| MTO | Make-to-order |

| MTS | Make-to-stock |

| POS | Point of sales |

| R | R programming language |

| RMSE | Root Mean Square Error |

| SKU | Stock keeping unit |

| TSL | Transport-forwarding-logistics |

| WMS | Warehouse management system |

References

- Kim, Y.; Chen, Y.-S.; Linderman, K. Supply network disruption and resilience: A network structural perspective. J. Oper. Manag. 2014, 33–34, 43–59. [Google Scholar] [CrossRef] [Green Version]

- Levalle, R.R.; Nof, S.Y. Resilience by teaming in supply network formation and re-configuration. Int. J. Prod. Econ. 2015, 160, 80–93. [Google Scholar] [CrossRef]

- Kawa, A. Konfigurowanie Łańcucha Dostaw. Teoria, Instrumenty i Technologie; Wyższa Szkoła Logistyki: Poznań, Poland, 2011. [Google Scholar]

- Vazquez, R.; Iglesias, V.; Álvarez-gonzález, L.I. Distirbution channel relationships: The conditions and strategic outcomes of cooperation between manufaturer and distributor. Int. Rev. Retail. Consum. Res. 2005, 15, 125–150. [Google Scholar]

- Kim, S.; Kim, N.; Pae, J.H.; Yip, L. Cooperate and compete: Coopetition strategy in retailer supplier relationships. J. Bus. Ind. Mark. 2013, 28, 263–275. [Google Scholar] [CrossRef]

- Chopra, S. Designing the distibution network in supply chain. Logist. Transp. Rev. 2003, 39, 123–140. [Google Scholar] [CrossRef]

- Kramarz, W.; Kramarz, M. Zakłócenia w przepływach wyrobów hutniczych w modelu z centrum logistycznym. Zesz. Nauk. Politech. Śląskiej 2018, 121, 221–235. [Google Scholar]

- Olgaher, J. The role of decoupling points in value chain management. In Modelling Value; Jodlbauer, H., Olhager, J., Schonberher, R., Eds.; Physica-Verlag: Heidelberg, Germany, 2012; pp. 37–47. [Google Scholar]

- Wikner, J.; Johansson, E. Inventory classification based on decoupling points. Prod. Manuf. Res. 2015, 3, 218–235. [Google Scholar] [CrossRef] [Green Version]

- Mishra, R.; Singh, R.K.; Koles, B. Consumer decision-making in omnichannel retailing: Literature review and future research agenda. Int. J. Consum. Stud. 2020, 45, 147–174. [Google Scholar] [CrossRef]

- Stock, G.N.; Greis, N.P.; Kasarda, J.D. Enterprise logistics and supply chain structure: The role of fit. J. Oper. Manag. 2000, 18, 531–547. [Google Scholar] [CrossRef]

- Briel, F. The future of omnichannel retail: A four-stage Delphi study. Technol. Forecast. Soc. Change 2018, 132, 217–229. [Google Scholar] [CrossRef]

- Ali, M.M.; Babai, M.Z.; Boylan, J.E.; Syntetos, A. Supply chain forecasting when information is not shared. Eur. J. Oper. Res. 2017, 260, 984–994. [Google Scholar] [CrossRef]

- Fildes, R.; Bretschneider, S.; Collopy, F.L. Researching sales forecasting practice. Int. J. Forecast. 2003, 19, 27–42. [Google Scholar] [CrossRef]

- van Steenbergen, R.; Mes, M. Forecasting demand profiles of new products. Decis. Support Syst. 2020, 139, 113401. [Google Scholar] [CrossRef]

- Iannaccone, G.; Marcucci, E.; Gatta, V. What Young E-Consumers Want? Forecasting Parcel Lockers Choice in Rome. Logistics 2021, 5, 57. [Google Scholar] [CrossRef]

- Corsaro, D.; Ramos, C.; Henneberg, S.C.; Naudé, P. The impact of network configurations on value constellations in business markets—The case of an innovation network. Ind. Mark. Manag. 2012, 41, 54–67. [Google Scholar] [CrossRef]

- Alinezhad, A.; Kazemi, A.; Khorasani, M. Presenting a model for decoupling points in supply chain networks. Int. J. Logist. Syst. Manag. 2019, 33, 383–403. [Google Scholar] [CrossRef]

- Kramarz, W. Modelowanie Przepływów Materiałówych w Sieciowych Łańcuchach Dostaw. Odporność Sieciowego Łańcucha Dostaw Wyrobów Hutniczych; Difin: Warszawa, Poland, 2013. [Google Scholar]

- Aktan, H.; Akyuz, G. Positioning the decoupling point along a supply chain: A case study. Int. J. Product. Qual. Manag. 2017, 22, 309–339. [Google Scholar] [CrossRef]

- Giesberts, P.M.J.; van der Tang, J. Dynamics of the customer order decoupling point: Impact on information system for production control. Prod. Plan. Control. 1992, 3, 300–313. [Google Scholar] [CrossRef] [Green Version]

- Beck, N.; Rygl, D. Categorization of multiple channels retailing in multi-, cross-, and omni-channel retailing for retailers and retailer. J. Retail. Consum. Serv. 2015, 27, 170–178. [Google Scholar] [CrossRef]

- Lu, X.; Hu, Z. Research on Russian cross-border e-commerce logistics platform based on block chain technology. In Proceedings of the International Confer-ence on Humanities and Advanced Education Technology, Guangzhou, China, 19–20 August 2018; pp. 435–438. [Google Scholar]

- Dalgic, Y.; Lazakis, I.; Dinwoodie, I.; McMillan, D.; Revie, M. Advanced logistics planning for offshore wind farm operation and maintenance activities. Ocean Eng. 2015, 101, 211–226. [Google Scholar] [CrossRef] [Green Version]

- Mikesell, J.L. Often Wrong, Never Uncertain: Lessons from 40 Years of State Revenue Forecasting. Public Adm. Rev. 2018, 78, 795–802. [Google Scholar] [CrossRef]

- Cadavid, J.P.U.; Lamouri, S.; Grabot, B. Trends in machine learning applied to demand & sales forecasting: A review. In Proceedings of the International Conference on Information Systems, Logistics and Supply Chain, Lyon, France, 8–11 July 2018. [Google Scholar]

- Hentschel, B.; Cyplik, P.; Hadaś, Ł.; Domański, R.; Adamczak, M.; Kupczyk, M.; Pruska, Ż. Wieloaspektowe Uwarunkowania Integracji Łańcucha Dostaw Typu Forward i Backward; Wyższa Szkoła Logistyki: Poznań, Poland, 2015. [Google Scholar]

- Chandra, C.; Grabis, J. Supply Chain Configuration: Concepts, Solutions, and Applications; Springer: New York, NY, USA, 2007. [Google Scholar]

- Truong, T.H.; Azadivar, F. Simulation based optimization for supply chain configuration design. In Proceedings of the 2003 Winter Simulation Conference, New Orleans, LA, USA, 7–10 December 2003. [Google Scholar]

- Tsiakis, P.; Papageorgiou, L.G. Optimal production allocation and distribution supply chain networks. Int. J. Prod. Econ. 2008, 111, 468–483. [Google Scholar] [CrossRef]

- Yao, X.; Askin, R. Review of supply chain configuration and design decision-making for new product. Int. J. Prod. Res. 2019, 57, 2226–2246. [Google Scholar] [CrossRef]

- Croxton, K.L.; Lambert, D.M.; Garcia-Dastugue, J.G. The demand management process. Int. J. Logist. Manag. 2002, 13, 51–66. [Google Scholar] [CrossRef] [Green Version]

- Dittmann, P. Metody Prognozowania Sprzedaży w Przedsiębiorstwie; Wydawnictwo Akademii Ekonomicznej: Wroclaw, Poland, 2000. [Google Scholar]

- Taghiyeh, S.; Lengacher, D.C.; Handfield, R.B. A Multi-phase approach for product hierarchy forecasting in supply chain management: Application to MonarchFx Inc. arXiv 2020, arXiv:2006.08931. [Google Scholar]

- Motwani, J.; Kumar, A.; Youssef, M.A.; Mahmoud, E. Forecasting quality of Indian manufacturing organizations: An exploratory analysis. Total. Qual. Manag. 1997, 8, 361–374. [Google Scholar] [CrossRef]

- Kim, K.; Pandit, S.; Wasley, C.E. Macroeconomic Uncertainty and Management Earnings Forecasts. Account. Horiz. 2016, 30, 157–172. [Google Scholar] [CrossRef]

- Hofman, E.; Rutschmann, E. Big data analytics and demand forecasting in supply chains: A conceptual analysis. Int. J. Logist. Manag. 2018, 29, 739–766. [Google Scholar] [CrossRef]

- Kmiecik, M. Utility of forecasting algorithms in the case of selected distribution networks. Zesz. Nauk. Politech. Częstochowskiej 2020, 38, 60–66. [Google Scholar] [CrossRef]

- Wacker, J.G.; Sprague, L.G. Forecasting accuracy: Comparing the relative effectiveness of practices between seven developed countries. J. Oper. Manag. 1998, 16, 271–290. [Google Scholar] [CrossRef]

- Min, H.; Yu, W. Collaborative planning, forecasting and replenishemnt: Demand planning in supply chain management. In Proceedings of the Fourth International Conference on Electronic Business, Beijing, China, 5–9 December 2004. [Google Scholar]

- Lieb, R.; Kendrick, S. The Use of Third-Party Logistics Services by Large American Manufacturers, the 2002 Survey. Supply Chain Forum Int. J. 2002, 3, 2–10. [Google Scholar] [CrossRef]

- Lin, F.R.; Shaw, M.J. Reengineering the order fulfillment process in suppy chain networks. Int. J. Flex. Manuf. Syst. 1998, 10, 197–229. [Google Scholar] [CrossRef]

- Coyle, J.J.; Bardi, E.J.; Langley, J.C. The Management of Business Logistics: A Supply Chain Perspective; Thomsom South-Western: Mason, OH, USA, 2003. [Google Scholar]

- Bask, A.H. Relationships among TPL providers and members of supply chains—A strategic perspective. J. Bus. Ind. Mark. 2001, 16, 470–486. [Google Scholar] [CrossRef]

- Ji, G.; Zhang, T. Supply chain innovation behavior on perspective view of modular organization network. In Proceedings of the 9th International Conference on Service Systems and Service Management (ICSSSM 2012), Shanghai, China, 2–4 July 2012; pp. 804–809. [Google Scholar]

- Kramarz, M. Strategie Adaptacyjne Przedsiębiorstw Flagowych Sieci Dystrybucji z Odroczoną Produkcją. Dystrybucja Wyrobów Hutniczych; Wyd. Politechniki Śląskiej: Gliwice, Poland, 2012. [Google Scholar]

- Kramarz, M.; Kramarz, W. Struktura sieci dostaw—Sieciowe łańcuchy dostaw wyrobów hutniczych. Nowocz. Przemysłu Usług-Nowe Wyzwania 2012, 1, 300–310. [Google Scholar]

- Zhang, J.; Nault, B.R.; Tu, Y. A dynamic pricing strategy for a 3PL provider with heterogeneous customers. Int. J. Prod. Econ. 2015, 169, 31–43. [Google Scholar] [CrossRef]

- Czakon, W. Sieci międzyorganizacyjne w naukach o zarządzaniu-w kierunku sieciowych modeli biznesu. Studia Ekon. 2015, 217, 9–18. [Google Scholar]

- Jonsson, P.; Gustavsson, M. The impact of supply chain relationships and automatic data communication and registration on forecast information quality. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 280–295. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Fu, X. Research on centrality of urban transport network nodes. AIP Conf. Proc. 2017, 1839, 020181. [Google Scholar]

- Toldbod, T.; van der Kolk, B. Changing fast and slow: A longitudinal case study on the calibration of management control elments in a global manufacturing company. In Proceedings of the 9th Conference on Performance Measurement and Management Control, Nice, France, 13–15 September 2017. [Google Scholar]

- Andersen, L. How Options Analysis Can Enhance Managerial Performance. Eur. Manag. J. 2002, 20, 505–511. [Google Scholar] [CrossRef]

- Heikkilä, J. From supply to demand chain management: Efficiency and customer satisfaction. J. Oper. Manag. 2002, 20, 747–767. [Google Scholar] [CrossRef]

- Martynenko, D. Demand at the marketing planning of the enterprise. Sci. J. Pol. Univ. 2018, 29, 19–26. [Google Scholar] [CrossRef]

- Mark, D.; Rau, D.P. Splitting demand from supply in IT. McKinsey Q. 2018, 30, 1–5. [Google Scholar]

- Ahrne, G.; Brunsson, N. Organization outside organizations: The significance of partial organization. Organization 2010, 18, 83–104. [Google Scholar] [CrossRef]

- Aertsen, F.; Blanc, I.I.; Rongen, J.; Wouwe, L. Building a competitive demand planning organization. Eyeon White Pap. 2016, 1, 4–15. [Google Scholar]

- Brito, B. Centralization of Supply Chain Management Operations: The Case of Unilever Ultralogistik. Master’s Thesis, University of Porto, Porto, Portugal, 2016. [Google Scholar]

- Qi, Y.; Tang, M.; Zhang, M. Mass customization in flat organization: The mediating role of supply chain planning and corporation coordination. J. Appl. Res. Technol. 2014, 12, 171–181. [Google Scholar]

- Ballou, R.H. The evolution and future of logistics and supply chain management. Produção 2008, 18, 375–388. [Google Scholar]

- Loukarakis, E.; Dent, C.; Bialek, J.W. Decentralized Multi-Period Economic Dispatch for Real-Time Flexible Demand Management. IEEE Trans. Power Syst. 2015, 31, 672–684. [Google Scholar] [CrossRef] [Green Version]

- Kucharska, W.; Drozd, R. E-logistyka dystrybucji a czynnik ludzki w procesie kształtowania wartości marki—Ujęcie praktyczne. Zesz. Nauk. Uniw. Szczecińskiego 2015, 875, 497–507. [Google Scholar]

- Szozda, N.; Świerczek, A. Zarządzanie Popytem na Produkty w Łańcuchu Dostaw; PWE: Warszawa, Poland, 2016. [Google Scholar]

- Hüseyin, B.; Selin Soner, K.; Pelin, A.; Betül, Ö.; Gözde, Ç. A distribution network optimization problem for third party logistics service providers. Expert Syst. Appl. 2011, 38, 12730–12738. [Google Scholar]

- Singh, R.K. Developing the framework for coordination in supply chain of SMEs. Bus. Process Manag. J. 2011, 17, 619–638. [Google Scholar] [CrossRef]

- Tsanos, C.S.; Zografos, K.G.; Harrison, A. Developing a conceptual model for examining the relationship between behavioral antecedents of supply chain collaboration, integration and performance. Int. J. Logist. Manag. 2014, 25, 418–462. [Google Scholar] [CrossRef] [Green Version]

- Verdouw, C.; Beulens, A.; Trienekens, J.; Wolfert, J. Process modelling in demand-driven supply chains: A reference model for the fruit industry. Comput. Electron. Agric. 2010, 73, 174–187. [Google Scholar] [CrossRef]

- Alnaggar, A.; Gzara, F.; Bookbinder, J.H. Distribution planning with random demand and recourse in a transshipment network. EURO J. Transp. Logist. 2020, 9, 100007. [Google Scholar] [CrossRef]

- Burnham, K.P.; Anderson, D.R. Multimodel inference—Understanding AIC and BIC in model selection. Sociol. Methods Res. 2001, 33, 261–304. [Google Scholar] [CrossRef]

- Chernoff, H. Estimation of the mode. Ann. Inst. Stat. Math. 1964, 16, 31–41. [Google Scholar] [CrossRef]

- Ding, N.; Benoit, C.; Foggia, G.; Besanger, Y.; Wurtz, F. Neural Network-Based Model Design for Short-Term Load Forecast in Distribution Systems. IEEE Trans. Power Syst. 2015, 31, 72–81. [Google Scholar] [CrossRef]

- Haslett, J.; Raftery, A.E. Space-time modelling with long-memory dependence: Assessing Ireland’s Wind Power Resource. Appl. Stat. 1989, 38, 1–21. [Google Scholar] [CrossRef]

- Hyndman, R.J.; Akram, M.; Archibald, B.C. The admissible parameter space for exponential smoothing models. Ann. Inst. Stat. Math. 2007, 60, 407–426. [Google Scholar] [CrossRef]

- Hyndman, R.J.; Khandakar, Y. Automatic Time Series Forecasting: The forecast Package for R. J. Stat. Softw. 2008, 27, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Rogalska, M. Wieloczynnikowe Modele w Prognozowaniu Czasu Procesów Budowlanych; Politechnika Lubelska: Lublin, Poland, 2016. [Google Scholar]

- Zagdański, A.; Suchwałko, A. Analiza i Prognozowanie Szeregów Czaoswych. Praktyczne Wprowadzenie na Podstawie Środowiska; PWN: Warszawa, Poland, 2016. [Google Scholar]

- Grzelak, M.; Borucka, A.; Buczyński, Z. Forecasting the demand for transport services on the example of a selected logistic operator. Arch. Transp. 2019, 52, 81–93. [Google Scholar] [CrossRef]

- Ren, S.; Choi, T.-M.; Lee, K.-M.; Lin, L. Intelligent service capacity allocation for cross-border-E-commerce related third-party-forwarding logistics operations: A deep learning approach. Transp. Res. Part E Logist. Transp. Rev. 2020, 134, 101834. [Google Scholar] [CrossRef]

- Sohrabpour, V.; Oghazi, P.; Toorajipour, R.; Nazarpour, A. Export sales forecasting using artificial intelligence. Technol. Forecast. Soc. Chang. 2020, 163, 120480. [Google Scholar] [CrossRef]

- Barrow, D.K.; Kourentzes, N. Distributions of forecasting errors of forecast combinations: Implications for inventory management. Int. J. Prod. Econ. 2016, 177, 24–33. [Google Scholar] [CrossRef] [Green Version]

- Bayraktar, E.; Koh, S.L.; Gunasekaran, A.; Sari, K.; Tatoglu, E. The role of forecasting on bullwhip effect for E-SCM applications. Int. J. Prod. Econ. 2007, 113, 193–204. [Google Scholar] [CrossRef]

- Omar, H.; Hoang, V.H.; Liu, D.-R. A hybrid neural network model for sales forecasting based on ARIMA and search popularity of article tiles. Hindawi 2016, 2016, 9656453. [Google Scholar]

- Moon, M.A.; Mentzer, J.T.; Smith, C.D. Conducting a sales forecasting audit. Int. J. Forecast. 2003, 19, 5–25. [Google Scholar] [CrossRef]

- Chu, C.-W.; Zhang, G.P. A comperative study of linear and nonlinear models for aggregate retail sales forecasting. Int. J. Prod. Econ. 2003, 86, 217–231. [Google Scholar] [CrossRef]

| Basic Roles in the Distribution Network Taking into Account the Degree of Their Implementation | |||

|---|---|---|---|

| Low Degree | Medium Degree | High Degree | |

| Logistic operator | Distribution network integration, Selection of business partners in the distribution network, the ability to direct the activities of other network participants | Network monitoring, network creation (the ability to freely shape the network structure), selection of logistic partners, maintaining the consistency of the network structure, network reconfiguration, assigning tasks to network partners according to competences, creating identity and organizational culture, a significant number of processes implemented in the stream of added value | Coordination of logistics processes in the distribution network, a significant position in the network in terms of leadership and intermediation, the ability to cooperate with production companies, a significant share in the logistics services market, a significant number of market segments served, geographic coverage, width of service areas, access to logistics infrastructure |

| Function | Brief Function Description |

|---|---|

| ses() | Forecasting stationary time series connected with simple exponential smoothing methods. |

| holt() | Forecasting time series with trend using Holt Method |

| holtWinters() | Forecasting time series with trend and seasonality using Holt-Winters Method. In default version function HoltWinters() is using two additive seasonality versions. To use multiplicative version of the method it is necessary to modify the function as follows: HoltWinters(x, seasonal = c(“multiplicative”), where x is the time series. |

| ets() | Forecasting based on three dimensions: error (E), trend (T) and seasonality (S). Function gives a chance to determine mentioned parameters. In all cases: N—none, A—additive, M—multiplicative and Z—automatically selected. In default function configuration, all parameters are automatically selected and default function is equivalent to ets(x, model = “ZZZ”), where x is the time series. |

| ar() | Forecasting based on fitting the time series autoregression model to the input data. |

| arima() | Forecasting based on fitting ARIMA(p,q,d) model to time series. Focus on connection between autoregression process (AR(p)) to moving average process (MA(q)). |

| auto.arima() | Forecasting based on ARIMA(p,q,d) model, but additionally taking into account information criteria as AIC (Akaike Information Criterion), AICc(Corrected Akaike Information Criterion) and BIC(Bayesian Information Criterion). |

| arfima() | Forecasting based on autoregressive fractionally integrated moving average model (ARFIMA(p,d,q)) with two-steps procedure where parameters p, d and q are determined separately. Parameters of autoregression (p) and moving average (q) are determined by Hyndman-Khandakara algorithm. Integration level (d) is determined by Haslett and Raftery algorithm. |

| tbats() | Forecasting based on exponential smoothing with Box-Cox transformation (tb), ARMA errors (a) and components of: trend (t) and seasonal (s). |

| splinef() | Forecasting based on cubic smoothing splines equivalent of ARIMA(0,2,2) model but with some parameters restriction. |

| stlf() | Forecasting based on time series decomposition using local regression. Function uses Seasonal Decomposition of Time Series by LOESS (developed by Helsel and Hirsch in 1997). |

| meanf() | Forecasting based on assumption that random component is independent and identically distributed to whole time series. |

| rwf() | Forecasting based on random walk with drift model. |

| snaive() | Forecasting based on the middle of the range which contains most observations. It references to one of the direct modal estimator called Chernoff’s estimator. |

| nnetar() | Forecasting based on neural network (neural network time series forecasting). In default settings function forecasting demand based on simple, feedforwarded neural network with one hidden layer. |

| Selected Attributes | Attribute Type * | Whether the Logistic Operator has an Equal Attribute? |

|---|---|---|

| Ability to configure a distribution network | Necessary. | yes |

| Good specificity of relationships with enterprises in the network and experience in developing cooperation. | Additional. | partially |

| Good relationships with links in the network. | Necessary. | yes |

| Cooperation establishing skills. | Additional. | yes |

| The ability to manage the marketing and sales facilities. | Additional. | no |

| The ability to select a demand management strategy for a given distribution network. | Necessary. | yes |

| Supply chain coordination skills. | Additional. | no |

| The ability to improve processes in the distribution network. | Additional. | yes |

| Having an IT system to exchange information across the entire network. | Additional. | no |

| Ability to make improvements in information flows and to implement EDI. | Necessary. | yes |

| Appropriate location in the distribution network. | Additional. | yes |

| Significant position in the market compared to other operators. | Additional. | no |

| Ability to influence the actions of other nodes. | Necessary. | yes |

| A wide spectrum of services offered in various fields. Operational knowledge of all company-specific processes. | Additional. | no |

| Comprehensive services (offering additional services related to logistic flows) | Necessary. | yes |

| Analytical knowledge and the ability to manage large data sets. | Necessary. | yes |

| Having a well-constructed and selected forecasting algorithm. | Additional. | currently being created |

| Distribution Network | Number of SKU * | Number of Assortment Groups | Number of SKU ** | Direct Distribution from Logistic Operator | POS Number in Total | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Intermediaries | POS *** | Wholesalers | ||||||||||

| A | B | C | Q | % | Q | % | Q | % | ||||

| DN.1 | 1362 | 19 | 282 | 302 | 778 | 322 | 78.39 | 185 | 21.61 | 0 | 0 | 14,870 |

| DN.2 | 1152 | 15 | 171 | 219 | 762 | 132 | 25.15 | 1152 | 55.78 | 231 | 19 | 18,495 |

| DN.3 | 415 | 12 | 72 | 95 | 248 | 111 | 2.68 | 2110 | 97.18 | 8 | 0.14 | 2660 |

| DN.4 | 60 | 5 | 13 | 15 | 32 | 25 | 98.95 | 15 | 1.65 | 0 | 0 | 3247 |

| DN.5 | 272 | 8 | 11 | 30 | 231 | 168 | 100 | 0 | 0 | 0 | 0 | 8180 |

| Evaluated Element | Weight | Distribution Network | |||||

|---|---|---|---|---|---|---|---|

| DN.1 | DN.2 | DN.3 | DN.4 | DN.5 | |||

| Relationship of manufacturer with logistic operator | Information exchange on the changes in production and stock references identification | 0.2 | 1 | 2 | 1 | 2 | 2 |

| Information exchange on sales peaks | 0.2 | 1 | 1 | 1 | 2 | 2 | |

| Sending cumulative forecasts | 0.1 | 3 | 2 | 0 | 2 | 3 | |

| Often direct contact | 0.1 | 2 | 3 | 1 | 3 | 3 | |

| Seldom assortment changes | 0.15 | 1 | 1 | 2 | 3 | 3 | |

| Inclusion of the operator into information exchange | 0.25 | 1 | 1 | 0 | 2 | 3 | |

| final result—relationship of operator with manufacturer | 1.3 | 1.5 | 0.8 | 2.25 | 2.6 | ||

| Results of distribution network configuration | Information distribution | 0.2 | 3 | 2 | 1 | 2 | 3 |

| Low safety buffers | 0.1 | 2 | 2 | 2 | 2 | 2 | |

| Low dependence of manufacturer on clients | 0.15 | 0 | 3 | 1 | 2 | 3 | |

| Information exchange on sales peaks within the whole network | 0.25 | 1 | 2 | 0 | 1 | 3 | |

| Satisfactory productiveness | 0.15 | 3 | 2 | 1 | 2 | 3 | |

| Frequency of orders update | 0.15 | 1 | 3 | 1 | 3 | 2 | |

| final result—network configuration | 1.65 | 2.3 | 0.85 | 1.9 | 2.75 | ||

| Characteristics of products within the network | High warehouse susceptibility | 0.2 | 2 | 2 | 3 | 2 | 2 |

| High transport susceptibility | 0.2 | 2 | 2 | 0 | 3 | 3 | |

| AX share—result | 0.3 | 0 | 2 | 1 | 1 | 3 | |

| Release variability level | 0.3 | 1 | 2 | 0 | 1 | 3 | |

| final result—characteristics of products within networks | 1.3 | 2 | 0.9 | 1.6 | 2.8 | ||

| Total result | 4.25 | 5.8 | 2.55 | 5.75 | 8.15 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kramarz, M.; Kmiecik, M. Quality of Forecasts as the Factor Determining the Coordination of Logistics Processes by Logistic Operator. Sustainability 2022, 14, 1013. https://doi.org/10.3390/su14021013

Kramarz M, Kmiecik M. Quality of Forecasts as the Factor Determining the Coordination of Logistics Processes by Logistic Operator. Sustainability. 2022; 14(2):1013. https://doi.org/10.3390/su14021013

Chicago/Turabian StyleKramarz, Marzena, and Mariusz Kmiecik. 2022. "Quality of Forecasts as the Factor Determining the Coordination of Logistics Processes by Logistic Operator" Sustainability 14, no. 2: 1013. https://doi.org/10.3390/su14021013

APA StyleKramarz, M., & Kmiecik, M. (2022). Quality of Forecasts as the Factor Determining the Coordination of Logistics Processes by Logistic Operator. Sustainability, 14(2), 1013. https://doi.org/10.3390/su14021013