An Iterative Design Method from Products to Product Service Systems—Combining Acceptability and Sustainability for Manufacturing SMEs

Abstract

:1. Introduction

2. Related Work

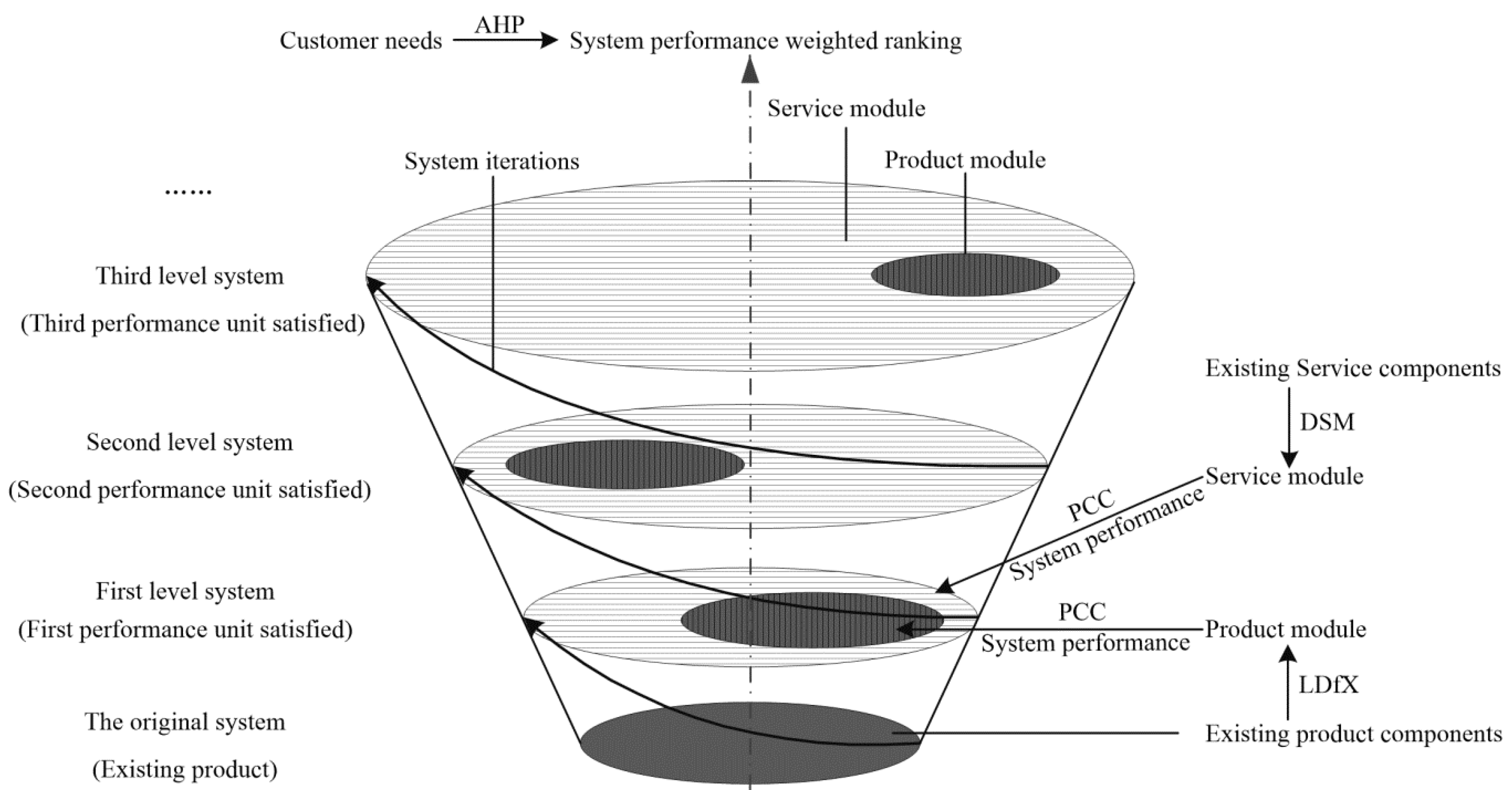

3. Method

3.1. System Performance Weighted Ranking

3.2. Modular Approach to Existing Product and Service Components

3.3. Correlation Analysis of System Performance and Modules

4. Case Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Budhwar, P.S.; Varma, A.; Patel, C. Convergence-divergence of HRM in the Asia-Pacific: Context-specific analysis and future research agenda. Hum. Resour. Manag. Rev. 2016, 26, 311–326. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L.; Ndubisi, N.O.; Seles, B.M.R.P. Sustainable development in Asian manufacturing SMEs: Progress and directions. Int. J. Prod. Econ. 2020, 225, 107567. [Google Scholar] [CrossRef]

- Asian Development Bank Institute. Available online: http://indiaenvironmentportal.org.in/content/441081/asia-pacific-sustainable-development-goals-outlook (accessed on 29 March 2017).

- McAloone, T.C.; Pigosso, D.C.A. From Ecodesign to Sustainable Product/Service-Systems: A Journey through Research Contributions over Recent Decades. Sustain. Manuf. 2017, 3, 99–111. [Google Scholar] [CrossRef] [Green Version]

- Park, H.; Yoon, J. A chance discovery-based approach for new product–service system (PSS) concepts. Serv. Bus. 2015, 9, 115–135. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Benedettini, O.; Kay, J.M. The servitization of manufacturing: A review of literature and reflection on future challenges. J. Manuf. Technol. Manag. 2013, 20, 547–567. [Google Scholar] [CrossRef] [Green Version]

- Li, J.H.; Lin, L.; Chen, D.P.; Ma, L.Y. An empirical study of servitization paradox in China. J. High Technol. Manag. Res. 2015, 26, 66–76. [Google Scholar] [CrossRef]

- Beuren, F.H.; Ferreira, M.G.G.; Miguel, P.A.C. Product-service systems: A literature review on integrated products and services. J. Clean. Prod. 2013, 47, 222–231. [Google Scholar] [CrossRef]

- Eun, S.S. Product Service System Availability Improvement through Field Repair Kit Optimization: A Case Study. Appl. Sci. 2019, 9, 4272. [Google Scholar] [CrossRef] [Green Version]

- Mont, O.K. Clarifying the concept of product–service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Haase, R.P.; Pigosso, D.C.A.; McAloone, T.C. Product/Service-System Origins and Trajectories: A Systematic Literature Review of PSS Definitions and their Characteristics. Procedia CIRP 2017, 64, 157–162. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Jia, G.; Kong, J. Requirement-Oriented Engineering Characteristic Identification for a Sustainable Product–Service System: A Multi-Method Approach. Sustainability 2020, 12, 8880. [Google Scholar] [CrossRef]

- Haber, N.; Fargnoli, M. Sustainable Product-Service Systems Customization: A Case Study Research in the Medical Equipment Sector. Sustainability 2021, 13, 6624. [Google Scholar] [CrossRef]

- Agher, J.-R.; Dubois, P.; Aoussat, A. A Bibliometric Analysis of Product-Service Systems’ Design Methodologies: Potential Root-Cause Identification of PSS’ Failures. Sustainability 2021, 13, 6237. [Google Scholar] [CrossRef]

- Xu, Z.; Ming, X.; Song, W.; Li, M.; He, L.; Li, X. Towards a new framework: Understanding and managing the supply chain for product-service systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1642–1652. [Google Scholar] [CrossRef]

- Geng, X.; Chu, X.; Xue, D.; Zhang, Z. A systematic decision-making approach for the optimal product–service system planning. Expert Syst. Appl. 2011, 38, 11849–11858. [Google Scholar] [CrossRef]

- Maccioni, L.; Borgianni, Y.; Pigosso, D.C. Creativity in successful eco-design supported by ten original guidelines. Int. J. Des. Creat. Innov. 2021, 9, 193–216. [Google Scholar] [CrossRef]

- Michalik, A.; Besenfelder, C.; Henke, M. Servitization of Small- and Medium-Sized Manufacturing Enterprises: Facing Barriers through the Dortmund Management Model. IFAC-PapersOnLine 2019, 52, 2326–2331. [Google Scholar] [CrossRef]

- Neely, A. Exploring the financial consequences of the servitization of manufacturing. Oper. Manag. Res. 2008, 1, 103–118. [Google Scholar] [CrossRef] [Green Version]

- Jiang, S.; Feng, D.; Lu, C. A Sustainable Innovation—Additional Services for Products Based on Personalised Customer Value. Sustainability 2019, 11, 1763. [Google Scholar] [CrossRef] [Green Version]

- Gebauer, H.; Fleisch, E.; Friedli, T. Overcoming the Service Paradox in Manufacturing Companies. Eur. Manag. J. 2005, 23, 14–26. [Google Scholar] [CrossRef]

- Clegg, B.; Little, P.; Govette, S.; Logue, J. Transformation of a small-to-medium-sized enterprise to a multi-organisation product-service solution provider. Int. J. Prod. Econ. 2017, 192, 81–91. [Google Scholar] [CrossRef] [Green Version]

- Rondini, A.; Matschewsky, J.; Pezzotta, G.; Bertoni, M. A simplified approach towards customer and provider value in PSS for small and medium-sized enterprises. Procedia CIRP 2018, 73, 61–66. [Google Scholar] [CrossRef]

- Gartzen, T.; Brambring, F.; Basse, F. Target-oriented Prototyping in Highly Iterative Product Development. Procedia CIRP 2016, 51, 19–23. [Google Scholar] [CrossRef] [Green Version]

- Adrodegari, F.; Saccani, N.; Kowalkowski, C.; Vilo, J. PSS business model conceptualization and application. Prod. Plan. Control 2017, 28, 1251–1263. [Google Scholar] [CrossRef]

- Rey, J.; Apelt, S.; Trauth, D.; Mattfeld, P.; Bergs, T.; Klocke, F. Highly iterative technology planning: Processing of information uncertainties in the planning of manufacturing technologies. Prod. Eng. 2019, 13, 361–371. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Evans, S.; Neely, A.; Greenough, R.; Peppard, J.; Roy, R.; Shehab, E.; Braganza, A.; Tiwari, A.; et al. State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 1543–1552. [Google Scholar] [CrossRef] [Green Version]

- Tran, T.; Park, J.Y. Development of a Novel Co-Creative Framework for Redesigning Product Service Systems. Sustainability 2016, 8, 434. [Google Scholar] [CrossRef] [Green Version]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Song, W.; Ming, X.; Han, Y.; Wu, Z. A rough set approach for evaluating vague customer requirement of industrial product-service system. Int. J. Prod. Res. 2013, 51, 6681–6701. [Google Scholar] [CrossRef]

- Carreira, R.; Patricío, L.; Jorge, R.N.; Magee, C.L. Development of an extended Kansei engineering method to incorporate experience requirements in product–service system design. J. Eng. Des. 2013, 24, 738–764. [Google Scholar] [CrossRef]

- Schuh, G.; Riesener, M.; Breunig, S.; Koch, J.; Kuntz, J. Evaluation of Variety-induced Costs in Product-Service Systems (PSS). Procedia CIRP 2017, 61, 673–678. [Google Scholar] [CrossRef]

- Trevisan, L.; Brissaud, D. Engineering models to support product–service system integrated design. CIRP J. Manuf. Sci. Technol. 2016, 15, 3–18. [Google Scholar] [CrossRef]

- Durugbo, C. Strategic framework for industrial product-service co-design: Findings from the microsystems industry. Int. J. Prod. Res. 2013, 52, 2881–2900. [Google Scholar] [CrossRef]

- Zhou, K.; Zhao, P.; Hu, F. Research on Product Service System Design Based on Activity and Function—Take the Household Water Purifier as an Example. Procedia CIRP 2019, 83, 495–500. [Google Scholar] [CrossRef]

- Vezzoli, C.; Ceschin, F.; Diehl, J.C.; Kohtala, C. New design challenges to widely implement ‘Sustainable Product–Service Systems’. J. Clean. Prod. 2015, 97, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Pieroni, M.; Marques, C.A.N.; Moraes, R.N.; Rozenfeld, H.; Ometto, A.R. PSS Design Process Models: Are They Sustainability-oriented? Procedia CIRP 2017, 64, 67–72. [Google Scholar] [CrossRef]

- Kjaer, L.L.; Pigosso, D.C.; McAloone, T.C.; Birkved, M. Guidelines for evaluating the environmental performance of Product/Service-Systems through life cycle assessment. J. Clean. Prod. 2018, 190, 666–678. [Google Scholar] [CrossRef] [Green Version]

- Pigosso, D.C.; McAloone, T.C. Maturity-based approach for the development of environmentally sustainable product/service-systems. CIRP J. Manuf. Sci. Technol. 2016, 15, 33–41. [Google Scholar] [CrossRef] [Green Version]

- Maccioni, L.; Borgianni, Y.; Pigosso, D.C.A. Can the choice of eco-design principles affect products’ success? Des. Sci. 2019, 5, 5. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Jiao, R.; Tseng, M. Evolutionary product line design balancing customer needs and product commonality. CIRP Ann. 2009, 58, 123–126. [Google Scholar] [CrossRef]

- Riesener, M.; Doelle, C.; Perau, S.; Lossie, P.; Schuh, G. Methodology for iterative system modeling in agile product development. Procedia CIRP 2021, 100, 439–444. [Google Scholar] [CrossRef]

- Bergs, T.; Apelt, S.; Beckers, A.; Barth, S. Agile ramp-up production as an advantage of highly iterative product development. Manuf. Lett. 2021, 27, 4–7. [Google Scholar] [CrossRef]

- Saaty, T.L. The Seven Pillars of the Analytic Hierarchy Process Multiple Criteria Decision Making in the New Millennium; Springer: Berlin/Heidelberg, Germany, 2001; pp. 15–37. [Google Scholar]

- Mardani, A.; Jusoh, A.; Nor, K.M.; Khalifah, Z.; Zakwan, N.; Valipour, A. Multiple criteria decision-making techniques and their applications—A review of the literature from 2000 to 2014. Economic Research-Ekonomska Istraživanja 2015, 28, 516–571. [Google Scholar] [CrossRef]

- Asadabadi, M.R.; Zwikael, O. The ambiguous proposal evaluation problem. Decis. Support Syst. 2020, 136, 113359. [Google Scholar] [CrossRef]

- Liang, D.; Dai, Z.; Wang, M. Assessing customer satisfaction of O2O takeaway based on online reviews by integrating fuzzy comprehensive evaluation with AHP and probabilistic linguistic term sets. Appl. Soft Comput. 2021, 98, 106847. [Google Scholar] [CrossRef]

- Lu, M.H.; Madu, C.N.; Kuei, C.; Winokur, D. Integrating QFD, AHP and Benchmarking in Strategic Marketing. J. Bus. Ind. Mark. 1994, 9, 41–50. [Google Scholar] [CrossRef]

- Parasuraman, A.; Zeithaml, V.A.; Berry, L.L. A Conceptual Model of Service Quality and Its Implications for Future Research. J. Mark. 1985, 49, 41. [Google Scholar] [CrossRef]

- Wen, B.C.; Han, Q.K. The importance of product design and the integrated design approach to product overall quality. Technol. Ind. 2003, 3, 12–23. [Google Scholar] [CrossRef]

- Atilano, L.; Martinho, A.; Silva, M.; Baptista, A. Lean Design-for-X: Case study of a new design framework applied to an adaptive robot gripper development process. Procedia CIRP 2019, 84, 667–672. [Google Scholar] [CrossRef]

- Baptista, A.; Peixoto, D.; Ferreira, A.; Pereira, J. Lean Design-for-X Methodology: Integrating Modular Design, Structural Optimization and Ecodesign in a Machine Tool Case Study. Procedia CIRP 2018, 69, 722–727. [Google Scholar] [CrossRef]

- Kuo, T.C.; Huang, S.H.; Zhang, H.-C. Design for manufacture and design for ‘X’: Concepts, applications, and perspectives. Comput. Ind. Eng. 2001, 41, 241–260. [Google Scholar] [CrossRef]

- Ijomah, W.; McMahon, C.A.; Hammond, G.; Newman, S. Development of design for remanufacturing guidelines to support sustainable manufacturing. Robot. Comput. Manuf. 2007, 23, 712–719. [Google Scholar] [CrossRef]

- Schermann, M.; Prilla, M.; Böhmann, T.; Krcmar, H.; Herrmann, T. Designing Services as Adaptable Reference Models. Implement. Int. Serv. 2011, 275–292. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, S.; Chen, S. Healthcare process modularization using design structure matrix. Adv. Eng. Inform. 2019, 39, 320–330. [Google Scholar] [CrossRef]

- Avnet, M.S.; Weigel, A.L. An application of the Design Structure Matrix to Integrated Concurrent Engineering. Acta Astronaut. 2010, 66, 937–949. [Google Scholar] [CrossRef]

- Sakao, T.; Song, W.; Matschewsky, J. Creating service modules for customising product/service systems by extending DSM. CIRP Ann. 2017, 66, 21–24. [Google Scholar] [CrossRef] [Green Version]

- Yassine, A.; Braha, D. Complex Concurrent Engineering and the Design Structure Matrix Method. Concurr. Eng. 2003, 11, 165–176. [Google Scholar] [CrossRef]

- Steward, D.V. The design structure system: A method for managing the design of complex systems. IEEE Trans. Eng. Manag. 1981, EM-28, 71–74. [Google Scholar] [CrossRef]

- Xu, J.; Tang, B.; He, H.; Man, H. Semisupervised Feature Selection Based on Relevance and Redundancy Criteria. IEEE Trans. Neural Netw. Learn. Syst. 2016, 28, 1974–1984. [Google Scholar] [CrossRef]

- Edelmann, D.; Móri, T.F.; Székely, G.J. On relationships between the Pearson and the distance correlation coefficients. Stat. Probab. Lett. 2021, 169, 108960. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Song, J.; Chen, X.; Lu, Y.; Wang, W. Pearson correlation coefficient of current derivatives based pilot protection scheme for long-distance LCC-HVDC transmission lines. Int. J. Electr. Power Energy Syst. 2020, 116, 116. [Google Scholar] [CrossRef]

- Liedtke, C.; Buhl, J.; Ameli, N. Microfoundations for Sustainable Growth with Eco-Intelligent Product Service-Arrangements. Sustainability 2013, 5, 1141–1160. [Google Scholar] [CrossRef] [Green Version]

| X | Characteristic Index |

|---|---|

| Assembly | Size, geometry, weight, material, assembly process, etc. |

| Manufacturing | Structure, geometry, material, manufacturing technology, manufacturing equipment, etc. |

| Disassembly | Structure, assembly method, disassembly process, disassembly tools, etc. |

| Disassembly | Ease of disassembly, ease of reassembly, reliability, repair cost, maintenance tools, etc. |

| Recycling | Ease of disassembly, material, etc. |

| Quality | Dimensional tolerance limits, ease of testing, standard type, standardization, etc. |

| Reliability | Material, durability, etc. |

| Environmental | Recyclability, maintainability, reliability, eco-safety |

| Cost | Purchase cost, manufacturing cost, assembly cost, etc. |

| Matrix | ||||

|---|---|---|---|---|

| 6.1542 | 0.0308 | 1.24 | 0.0249 | |

| 4.0313 | 0.0104 | 0.90 | 0.0116 | |

| 2 | 0 | 0.00 | 0 | |

| 3.0184 | 0.0092 | 0.58 | 0.0159 | |

| 2 | 0 | 0.00 | 0 | |

| 3.0038 | 0.0019 | 0.58 | 0.0033 | |

| 3.0093 | 0.0047 | 0.58 | 0.008 |

| System Performance | C1 0.3821 | C2 0.224 | C3 0.0574 | C4 0.1056 | C5 0.0703 | C6 0.1606 | Weight |

|---|---|---|---|---|---|---|---|

| SP1 | 0.4658 | 0.178 | |||||

| SP2 | 0.2771 | 0.1059 | |||||

| SP3 | 0.096 | 0.0367 | |||||

| SP4 | 0.1611 | 0.0615 | |||||

| SP5 | 0.75 | 0.168 | |||||

| SP6 | 0.25 | 0.056 | |||||

| SP7 | 0.6232 | 0.0358 | |||||

| SP8 | 0.1373 | 0.0079 | |||||

| SP9 | 0.2395 | 0.0137 | |||||

| SP10 | 0.3333 | 0.0352 | |||||

| SP11 | 0.6667 | 0.0704 | |||||

| SP12 | 0.2299 | 0.0161 | |||||

| SP13 | 0.648 | 0.0456 | |||||

| SP14 | 0.1221 | 0.0086 | |||||

| SP15 | 0.2972 | 0.0477 | |||||

| SP16 | 0.539 | 0.0866 | |||||

| SP17 | 0.1638 | 0.0263 |

| PM1P5-1 | PM2P5-2 | PM3P5-1 | PM5P5-1 | SM1P5-1 | SM5P5-1 | |

|---|---|---|---|---|---|---|

| Degree of satisfaction with SP5 | 0.987 ** | −0.630 * | 0.776 ** | 0.784 ** | 0.755 ** | 0.666 * |

| Significance (two-tailed) | 0.000 | 0.016 | 0.001 | 0.001 | 0.001 | 0.009 |

| Factors | Weight | Sub Factors | Sub Weight |

|---|---|---|---|

| Customer satisfaction | 0.38 | Satisfaction of customer value needs | 0.58 |

| Acceptable expenditure | 0.42 | ||

| Resource utilization | 0.25 | Product utilization rate | 0.61 |

| Service utilization rate | 0.39 | ||

| Solution iteration | 0.22 | Stage implementation | 0.6 |

| Stage optimization | 0.4 | ||

| Design efficiency | 0.15 | Design difficulty | 0.57 |

| Design duration | 0.43 |

| PSS Design Methods | Customer Satisfaction | Resource Utilization | Design Iteration | Design Efficiency | Acceptability |

|---|---|---|---|---|---|

| A method for evaluating customer needs [19] | 0.90 | 0.45 | 0.24 | 0.61 | 0.52 |

| Study of customer experiences [20] | 0.85 | 0.78 | 0.35 | 0.25 | 0.63 |

| A mode of PSS cost quantification [21] | 0.52 | 0.51 | 0.57 | 0.72 | 0.56 |

| A PSS design framework for an integrated PSS design [22] | 0.72 | 0.64 | 0.34 | 0.45 | 0.58 |

| A collaborative PSS design system [23] | 0.75 | 0.56 | 0.65 | 0.55 | 0.65 |

| A new approach for PSS design through functional activity mapping [24] | 0.62 | 0.52 | 0.78 | 0.78 | 0.64 |

| An iterative design method to build modular PSS based on existing resources | 0.82 | 0.93 | 0.83 | 0.8 | 0.85 |

| PSS design methods | Acceptability | Reuse of Resources | Resource Saving | Flexible Iteration |

|---|---|---|---|---|

| A method for evaluating customer needs [19] | ||||

| Study of customer experiences [20] | √ | |||

| A mode of PSS cost quantification [21] | √ | √ | ||

| A PSS design framework for an integrated PSS design [22] | √ | |||

| A collaborative PSS design system [23] | √ | |||

| A new approach for PSS design through functional activity mapping [24] | √ | |||

| An iterative design method to build modular PSS based on existing resources | √ | √ | √ | √ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, D.; Lu, C.; Jiang, S. An Iterative Design Method from Products to Product Service Systems—Combining Acceptability and Sustainability for Manufacturing SMEs. Sustainability 2022, 14, 722. https://doi.org/10.3390/su14020722

Feng D, Lu C, Jiang S. An Iterative Design Method from Products to Product Service Systems—Combining Acceptability and Sustainability for Manufacturing SMEs. Sustainability. 2022; 14(2):722. https://doi.org/10.3390/su14020722

Chicago/Turabian StyleFeng, Di, Chunfu Lu, and Shaofei Jiang. 2022. "An Iterative Design Method from Products to Product Service Systems—Combining Acceptability and Sustainability for Manufacturing SMEs" Sustainability 14, no. 2: 722. https://doi.org/10.3390/su14020722

APA StyleFeng, D., Lu, C., & Jiang, S. (2022). An Iterative Design Method from Products to Product Service Systems—Combining Acceptability and Sustainability for Manufacturing SMEs. Sustainability, 14(2), 722. https://doi.org/10.3390/su14020722