3D Printing as a Disruptive Technology for the Circular Economy of Plastic Components of End-of-Life Vehicles: A Systematic Review

Abstract

1. Introduction

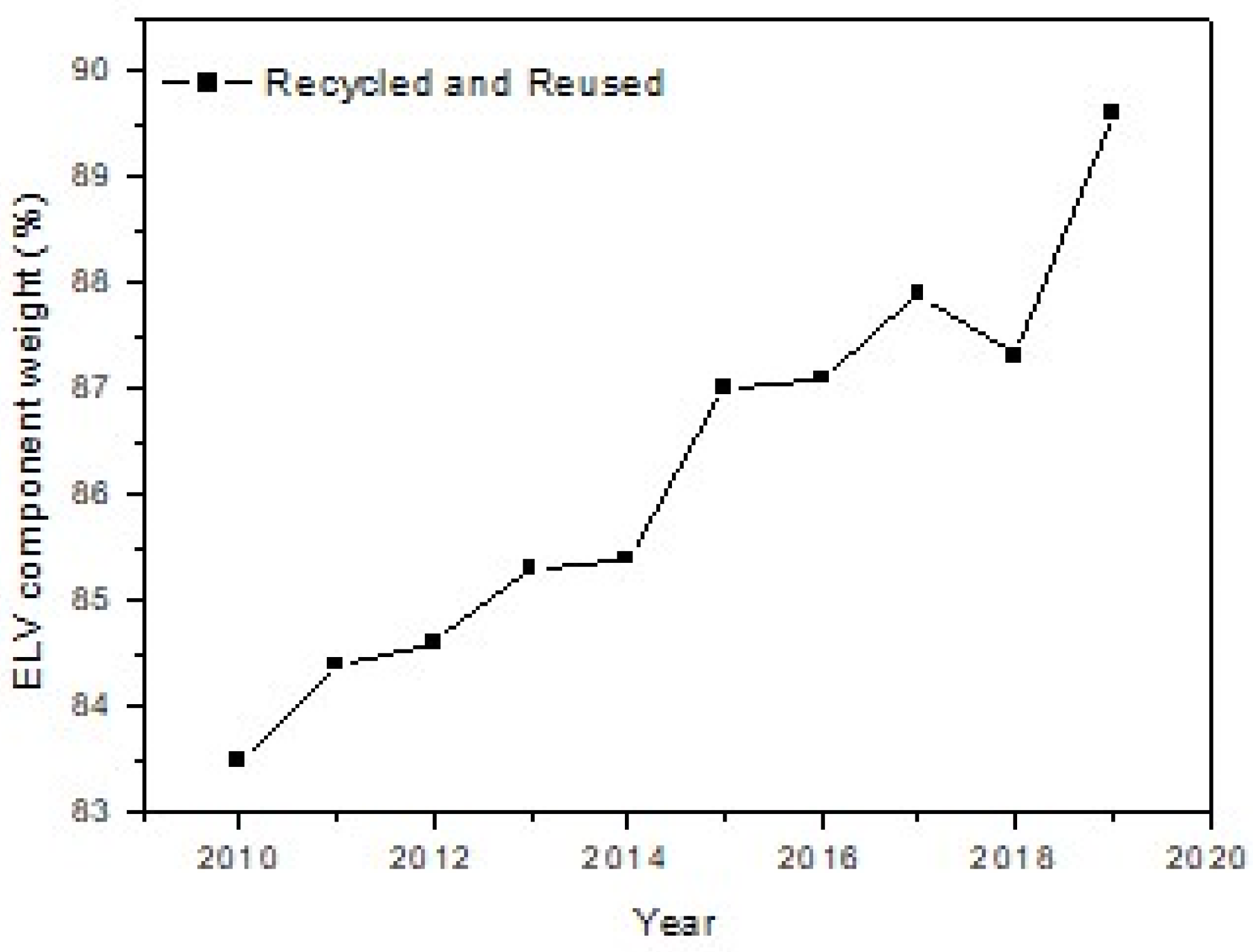

1.1. Circular Economy in the Automotive Industry

1.2. Three-Dimensional Printing

- -

- Question 1: Is the growth of scientific production in the field of 3D printing for application in the vehicle industry comparable to the growth of 3D printing research between 2000 and 2021?

- -

- Question 2: Is the application of 3D printing for circular economy and recovery of plastic materials from ELVs feasible?

- -

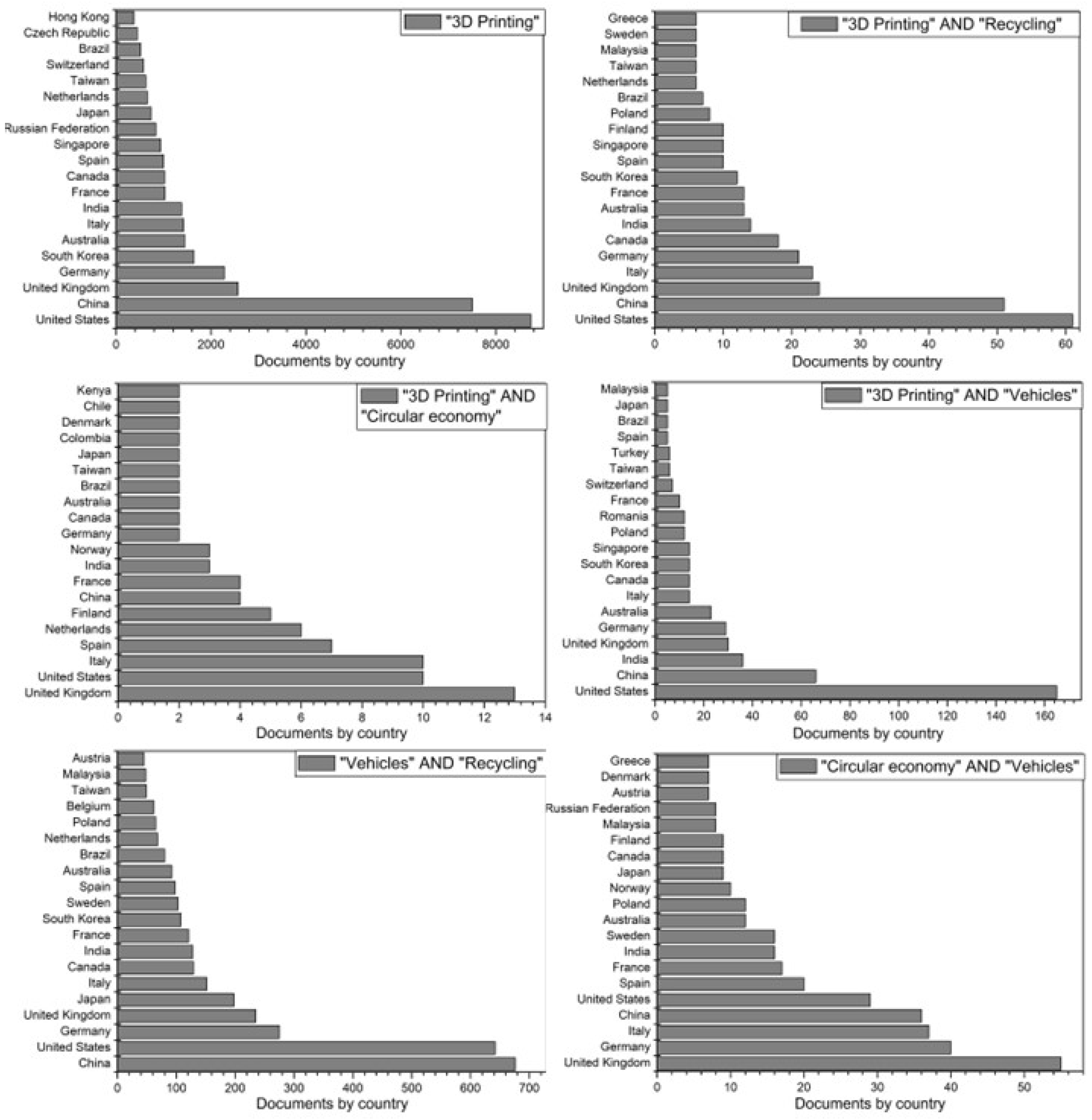

- Question 3: Is the term “circular economy” more used by European researchers?

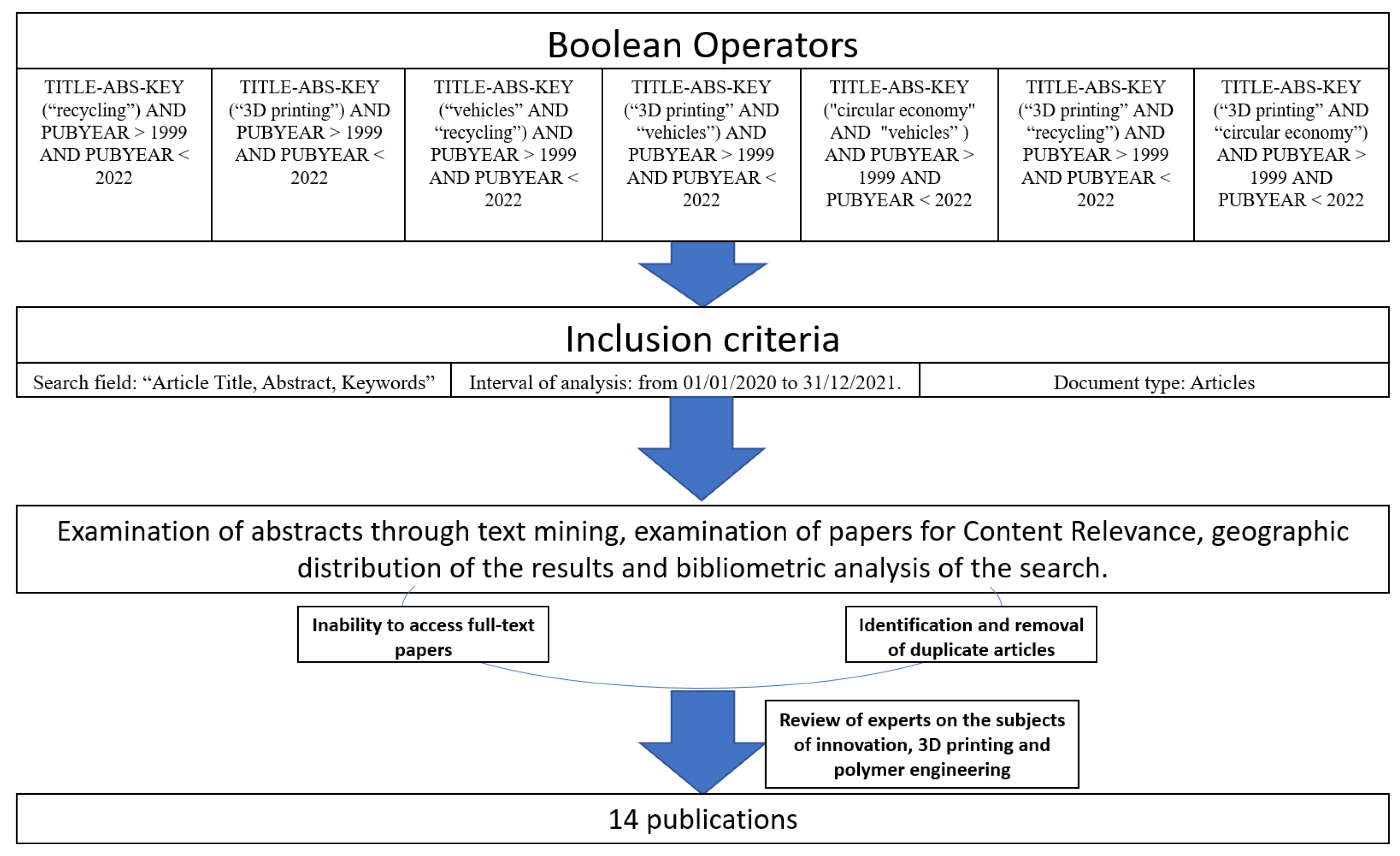

2. Materials and Methods

2.1. Eligibility Criteria

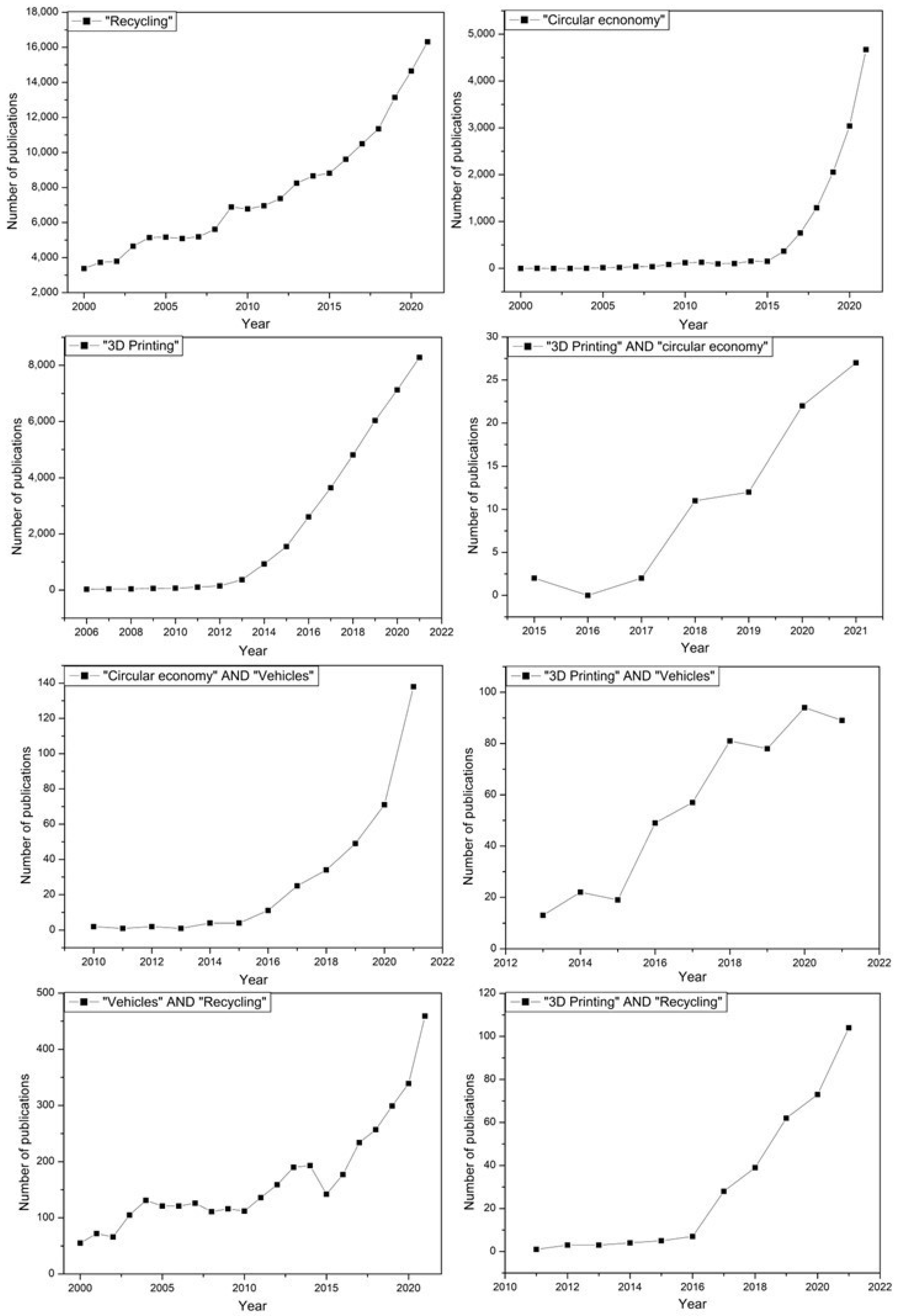

2.2. Search Strategy and Information Resources

2.3. Selection and Data Collection Process

3. Results

3.1. Temporal Distribution of the Studies

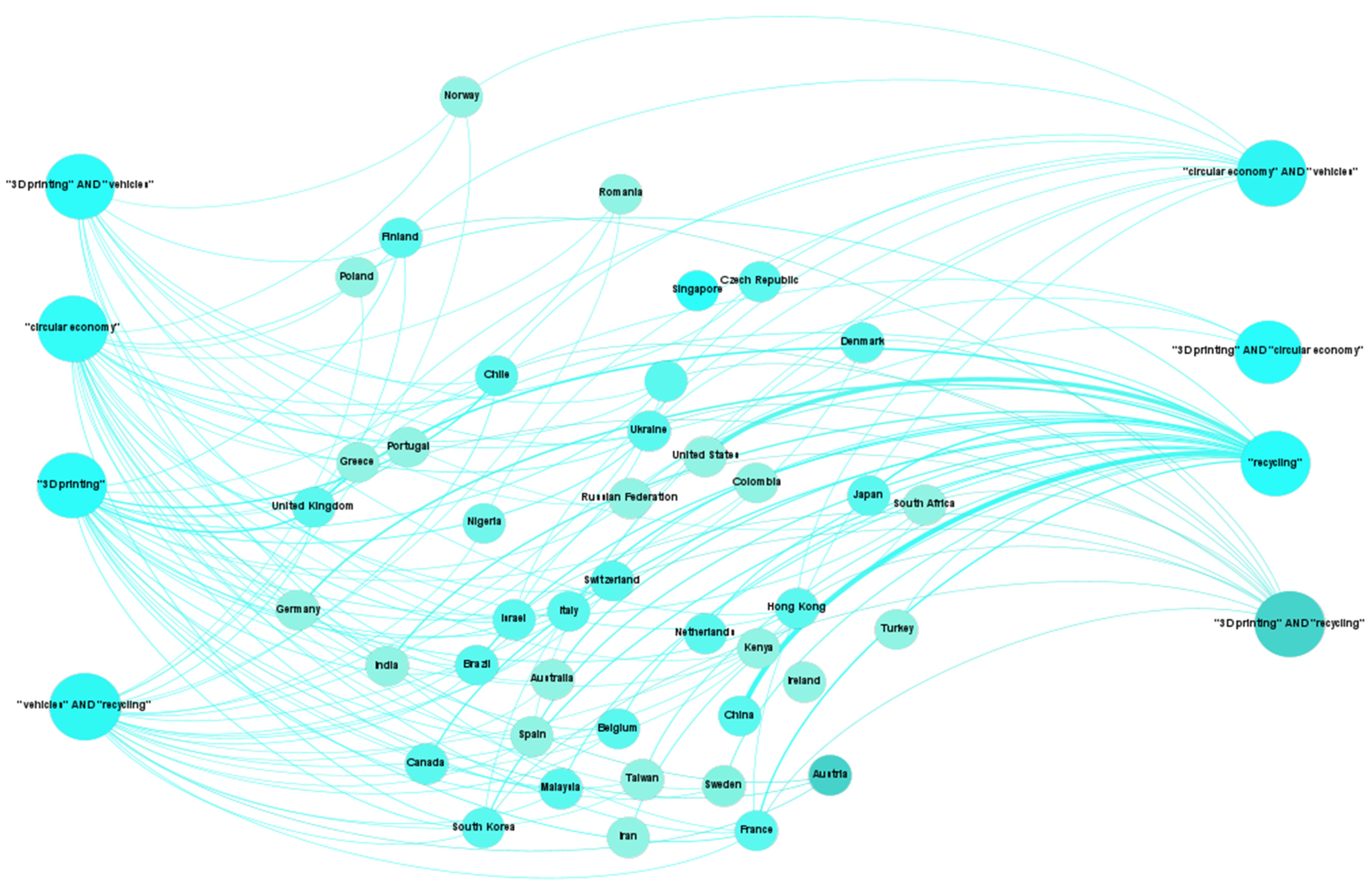

3.2. Geographic Distribution of the Results

3.3. Review Collection Process

3.4. Text Corpora Analysis

“The sustainable aspects of 3D Printing such as less material wastage, less post processing and very less cost even for manufacturing complex parts makes 3D Printing a technology of the future. The other sustainable aspects include the potential of 3D printing to reuse plastics, recycle and reduce emissions”(Jandyal et al. [31], p. 33)

“The use of 3D Printing helps to produce designs which are sustainable”(Jandyal et al. [31], p. 34)

“3D printing being a sustainable technology has a potential to replace conventional technologies”(Jandyal et al. [31], p. 41)

“3D Printing apart from being cost effective is also environment friendly, hence can help to mitigate the adverse effects of industrialization on the environment”(Jandyal et al. [31], p. 41)

“AM gives a high degree of freedom to the design and production process”(Sauerwein et al. [40], p. 1137)

“The analysis of the design projects showed that AM creates opportunities to enable circular design strategies like upgrades and repair which extend a product’s lifespan, even if these were not considered in the original product design”(Sauerwein et al. [40], p. 1138)

“Based on the recycling and remanufacturing process of 3D printed CFRTPCs, a cleaner production pattern of composites for the future can be conceived”(Tian et al. [44], p. 1617)

“3D printing process itself is a clean manufacturing method without any waste of raw material”(Tian et al. [44], p. 1617)

“3D printing may offer a simple way of instant robotic fabrication and ready-to-use functional systems”(Ugur et al. [38], p. 548)

“AM may play a significant role in diminishing waste resources and reducing energy consumption by employing just-in-time production”(Ugur et al. [38], p. 552)

“In recent years, there has been an increasing amount of interest in the scientific community and entrepreneurial initiatives to propose solutions to tackle the issue, including the use of plastic recycling for 3D printing purposes”(Santander et al. [45], p. 10)

“The mode of manufacturing is gradually shifting from traditional to non-conventional processes. It requires intensive knowledge of materials and their respective properties. With the current knowledge of materials and processes, some modifications have been done in the traditional techniques using 3D printing”(Jandyal et al. [31], p. 38)

“Recent advances in 3D-printing have enabled more accurate control of material placement than ever before, making multi-material 3D-printing a new tool for manufacturing bioinspired composites”(Gu et al. [16], p. 318)

“Cyber-physical integration facilitates smart factories with high efficiency that are capable of fabricating high-quality customized products”(Ugur et al. [38], p. 553)

“The current barrier of mass production on location will be overcome with personal- and customized fabrication”(Ugur et al. [38], p. 553)

“As the global shift because of the superior economics of distributed recycling and manufacturing, the prosumer community will benefit from regulations that stipulate that manufacturers identify the materials in their products”(Reich et al. [43], pp. 12–13)

“The economic and environmental feasibility of the local plastic recycling network will be possible at decreasing prices of virgin plastic filament. From a market perspective, this implies that as the 3D printing market grows and the price of virgin plastic filament decrease”(Santander et al. [45], p. 10)

“Efforts need to be taken in the pre-treatment of the recycled material, including efficient models to collect waste material, technology, and methodologies to develop quality indicators of the waste material. Then, based on these indicators, strategies of local cleaning and sorting process could be potential opportunities to promote”(Cruz et al. [39], p. 14)

“However, the research on the creation of minimal standards and legal framework are major elements to validate”(Cruz et al. [39], p. 14)

“It is easy to see that recycling the ELVs depends on establishment of an efficient ELV recycling network, which not only can reduce the impact on the environment during the recycling process, but also can facilitate the effective reuse of recycled resource”(Zhang et al. [22], p. 2)

“This study clearly shows that a combination of 3D-printing, droptower impact testing, and finite element simulation is vital to gain a fundamental understanding of the key material attributes critical for the design of next-generation impact resistant materials”(Gu et al. [16], p. 322)

“The tests confirm the possibility of secondary processing of used electronic equipment housings into an extrudate used as a filament in the FFF additive manufacturing technology. The mechanical properties of testing structural elements depend on manufacturing technology and process parameters, mainly temperature and pressure”(Czyzewski et al. [42], p. 1452)

“In the industry, [3D printed components] will have a positive impact on the possible applications of re-using ABS waste like a structural secondary material to apply in additive manufacturing”(Czyzewski et al. [42], p. 1453)

“The results of this study found that sifted recycled PC shards could be effectively used as feedstock for PME/FPF additive manufacturing”(Reich et al. [43], p. 13)

“The viability of recycled PC particles offers a wide range of uses that can replace more expensive solutions for prosumers and industry alike”(Reich et al. [43], p. 13)

“In the present research, a recycling and remanufacturing process for 3D printed CFRTPCs has been put forward, which provided a fully recyclable composite materials with mechanical properties even higher than the original ones”(Tian et al. [44], p. 1615)

“A better interface and mechanical performance have been obtained due to the [3D printing] recycling process”(Tian et al. [44], p. 1617)

“The developed PLA filaments are very practical and provide the greatest application potential in the AM industry since the PLA filaments can be employed to print physical models with high tensile strength economically”(Kuo et al. [35], p. 16)

“It is interesting to note that the barrel temperature is the most significant control factor affecting the diameter of PLA filament followed by recycling material addition ratio, extrusion speed, and cooling distance”(Kuo et al. [35], p. 10)

“According to the above findings, the developed PLA filaments are very practical and provide the greatest application potential in the industry because the PLA filaments can be used to fabricate three-dimensional models with high tensile strength under the condition of low manufacturing cost.”(Kuo et al. [35], p. 15)

“A wide range of materials…can also be recycled to manufacturing new filament”(Kuo et al. [35], p. 16)

“This work has demonstrated the economic and environmental feasibility of a distributed closed loop supply chain network for plastic recycling using OS 3D printing technologies”(Santander et al. [45], p. 11)

“The proposed model and the developed algorithm in this paper have provided an efficient quantitative method to find a compromising (optimal) policy for the practical ELV recovery management problem in an uncertain environment”(Zhang et al. [22], p. 22)

“To maximise the potential of distributing recycling, attention should be focused on the willingness to use recycled 3D objects”(Cruz et al. [39], p. 14)

“It is essential that sustainable opportunities offered by AM support multiple product life cycles when designing for a circular economy”(Sauerwein et al. [40], p. 1138)

“Reduction of the costs such as the processing costs and the transportation costs generate more significant impacts on the optimal recycling policy than the change of the component selling prices in the secondary markets”(Zhang et al. [22], p. 23)

“It is suggested that adopting advanced processing technology and machinery equipment is the most important measure to improve the ELV recovery efficiency in this case”(Zhang et al. [22], p. 23)

4. Three-Dimensional Printing as a Path to Improve the Circular Economy of ELV Polymers

5. Conclusions

6. Recommendations and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rezai, M. 2022 Raw Materials and Chemicals Overview. Available online: https://www.adhesivesmag.com/ (accessed on 1 October 2022).

- Yu, Z.; Khan, S.A.R.; Umar, M. Circular Economy Practices and Industry 4.0 Technologies: A Strategic Move of Automobile Industry. Bus. Strategy Environ. 2022, 31, 796–809. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Umar, M.; Asadov, A.; Tanveer, M.; Yu, Z. Technological Revolution and Circular Economy Practices: A Mechanism of Green Economy. Sustainability 2022, 14, 4524. [Google Scholar] [CrossRef]

- Setaki, F.; van Timmeren, A. Disruptive Technologies for a Circular Building Industry. Build. Environ. 2022, 223, 109394. [Google Scholar] [CrossRef]

- Ford Europe Sustainability Report Summary 2018/19. Available online: www.sustainability.ford.com (accessed on 1 October 2022).

- Sadeghi, M.; Mahmoudi, A.; Deng, X.; Luo, X. Prioritizing Requirements for Implementing Blockchain Technology in Construction Supply Chain Based on Circular Economy: Fuzzy Ordinal Priority Approach. Int. J. Environ. Sci. Technol. 2022. Available online: https//link.springer.com/article/10.1007/s13762-022-04298-2 (accessed on 1 October 2022). [CrossRef]

- Kumar, N.M.; Chopra, S.S. Leveraging Blockchain and Smart Contract Technologies to Overcome Circular Economy Implementation Challenges. Sustainability 2022, 14, 9492. [Google Scholar] [CrossRef]

- Bhubalan, K.; Tamothran, A.M.; Kee, S.H.; Foong, S.Y.; Lam, S.S.; Ganeson, K.; Vigneswari, S.; Amirul, A.-A.; Ramakrishna, S. Leveraging Blockchain Concepts as Watermarkers of Plastics for Sustainable Waste Management in Progressing Circular Economy. Environ. Res. 2022, 213, 113631. [Google Scholar] [CrossRef] [PubMed]

- Elghaish, F.; Matarneh, S.T.; Edwards, D.J.; Pour Rahimian, F.; El-Gohary, H.; Ejohwomu, O. Applications of Industry 4.0 Digital Technologies towards a Construction Circular Economy: Gap Analysis and Conceptual Framework. Constr. Innov. 2022, 22, 647–670. [Google Scholar] [CrossRef]

- Chauhan, C.; Parida, V.; Dhir, A. Linking Circular Economy and Digitalisation Technologies: A Systematic Literature Review of Past Achievements and Future Promises. Technol. Forecast. Soc. Chang. 2022, 177, 121508. [Google Scholar] [CrossRef]

- Stahel, W.R. The Circular Economy. Nat. News 2016, 531, 435. [Google Scholar] [CrossRef]

- Pinho, A.C.; Amaro, A.M.; Piedade, A.P. 3D Printing Goes Greener: Study of the Properties of Post-Consumer Recycled Polymers for the Manufacturing of Engineering Components. Waste Manag. 2020, 118, 426–434. [Google Scholar] [CrossRef] [PubMed]

- British Standards Institution. Framework for Implementing the Principles of the Circular Economy in Organizations-Guide; BSI: London, UK, 2017; ISBN 0580926443. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Cohen, B. Urbanization in Developing Countries: Current Trends, Future Projections, and Key Challenges for Sustainability. Technol. Soc. 2006, 28, 63–80. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards Circular Economy Implementation: A Comprehensive Review in Context of Manufacturing Industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Eurostat. End-of-Life Vehicles—Reuse, Recycling and Recovery, Totals; Eurostat: Luxembourg, 2020. [Google Scholar]

- Kanari, N.; Pineau, J.-L.; Shallari, S. End-of-Life Vehicle Recycling in the European Union. JOM 2003, 55, 15–19. [Google Scholar] [CrossRef]

- European Parliament and of the Council. Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on End-of Life Vehicles; European Parliament and of the Council: Brussels, Belgium, 2000. [Google Scholar]

- D’Adamo, I.; Gastaldi, M.; Rosa, P. Recycling of End-of-Life Vehicles: Assessing Trends and Performances in Europe. Technol. Forecast. Soc. Chang. 2020, 152, 119887. [Google Scholar] [CrossRef]

- Wilberforce, T.; El-Hassan, Z.; Khatib, F.N.; Al Makky, A.; Baroutaji, A.; Carton, J.G.; Olabi, A.G. Developments of Electric Cars and Fuel Cell Hydrogen Electric Cars. Int. J. Hydrogen Energy 2017, 42, 25695–25734. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, J.; Wan, Z. Optimizing Transportation Network of Recovering End-of-Life Vehicles by Compromising Program in Polymorphic Uncertain Environment. J. Adv. Transp. 2019, 2019, 3894064. [Google Scholar] [CrossRef]

- Renault Group on the Road to Carbon Neutrality. Available online: https://cdn.group.renault.com (accessed on 3 October 2022).

- GAIA. Available online: https://www.gaiaautorecycling.com (accessed on 3 October 2022).

- Boone Comenor Metalimpex about US. Available online: https://www.metalimpexgroup.com (accessed on 3 October 2022).

- Balaji, A.B.; Rudd, C.; Liu, X. Recycled Carbon Fibers (RCF) in Automobiles: Towards Circular Economy. Mater. Circ. Econ. 2020, 2, 4. [Google Scholar] [CrossRef]

- Tesla Inc. Tesla Impact Report 2020. Available online: https://www.tesla.com/impact-report/2020 (accessed on 3 October 2022).

- Keoleian, G.A.; Sullivan, J.L. Materials Challenges and Opportunities for Enhancing the Sustainability of Automobiles. MRS Bull. 2012, 37, 365–372. [Google Scholar] [CrossRef]

- Aguilar Esteva, L.C.; Kasliwal, A.; Kinzler, M.S.; Kim, H.C.; Keoleian, G.A. Circular Economy Framework for Automobiles: Closing Energy and Material Loops. J. Ind. Ecol. 2021, 25, 877–889. [Google Scholar] [CrossRef]

- Hallack, E.; Peris, N.M.; Lindahl, M.; Sundin, E. Systematic Design for Recycling Approach—Automotive Exterior Plastics. In Proceedings of the Procedia CIRP, Leuven, Belgium, 4–6 April 2022; Volume 105, pp. 204–209. [Google Scholar]

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Ul Haq, M.I. 3D Printing—A Review of Processes, Materials and Applications in Industry 4.0. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Bechtold, S. 3D Printing, Intellectual Property and Innovation Policy. IIC—Int. Rev. Intellect. Prop. Compet. Law 2016, 47, 517–536. [Google Scholar] [CrossRef]

- Unruh, G. Circular Economy, 3D Printing, and the Biosphere Rules. Calif. Manag. Rev. 2018, 60, 95–111. [Google Scholar] [CrossRef]

- Garmulewicz, A.; Holweg, M.; Veldhuis, H.; Yang, A. Disruptive Technology as an Enabler of the Circular Economy: What Potential Does 3D Printing Hold? Calif. Manag. Rev. 2018, 60, 112–132. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Chen, J.-Y.; Chang, Y.-H. Optimization of Process Parameters for Fabricating Polylactic Acid Filaments Using Design of Experiments Approach. Polymers 2021, 13, 1222. [Google Scholar] [CrossRef] [PubMed]

- Madhu, N.R.; Erfani, H.; Jadoun, S.; Amir, M.; Thiagarajan, Y.; Chauhan, N.P.S. Fused Deposition Modelling Approach Using 3D Printing and Recycled Industrial Materials for a Sustainable Environment: A Review. Int. J. Adv. Manuf. Technol. 2022, 122, 2125–2138. [Google Scholar] [CrossRef] [PubMed]

- Ponis, S.; Aretoulaki, E.; Maroutas, T.N.; Plakas, G.; Dimogiorgi, K. A Systematic Literature Review on Additive Manufacturing in the Context of Circular Economy. Sustainability 2021, 13, 6007. [Google Scholar] [CrossRef]

- Santander, P.; Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M. Closed Loop Supply Chain Network for Local and Distributed Plastic Recycling for 3D Printing: A MILP-Based Optimization Approach. Resour. Conserv. Recycl. 2020, 154, 104531. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Sauerwein, M.; Doubrovski, E.; Balkenende, R.; Bakker, C. Exploring the Potential of Additive Manufacturing for Product Design in a Circular Economy. J. Clean. Prod. 2019, 226, 1138–1149. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia. Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Czyżewski, P.; Bieliński, M.; Sykutera, D.; Jurek, M.; Gronowski, M.; Ryl, Ł.; Hoppe, H. Secondary Use of ABS Co-Polymer Recyclates for the Manufacture of Structural Elements Using the FFF Technology. Rapid Prototyp. 2018, 24, 1447–1454. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and Remanufacturing of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Gu, G.X.; Takaffoli, M.; Hsieh, A.J.; Buehler, M.J. Biomimetic Additive Manufactured Polymer Composites for Improved Impact Resistance. Extrem. Mech. Lett. 2016, 9, 317–323. [Google Scholar] [CrossRef]

- Grabowski, L.; Gliniak, M.; Polek, D.; Gruca, M. Cost-Assessment Analysis of Local Vehicle Scrapping Facility. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Semarang, Indonesia, 9–10 August 2017; Volume 95. [Google Scholar]

- Simon, C.J.; Schnieders, F. Business Data and Charts 2020 by PlasticsEurope Market Research Group (PEMRG). 2021. Available online: https://plasticseurope.org/ (accessed on 1 October 2022).

- Jeswani, H.; Krüger, C.; Russ, M.; Horlacher, M.; Antony, F.; Hann, S.; Azapagic, A. Life Cycle Environmental Impacts of Chemical Recycling via Pyrolysis of Mixed Plastic Waste in Comparison with Mechanical Recycling and Energy Recovery. Sci. Total Environ. 2021, 769, 144483. [Google Scholar] [CrossRef] [PubMed]

- Lim, L.-T.; Auras, R.; Rubino, M. Processing Technologies for Poly(Lactic Acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life Cycle Analysis of Distributed Recycling of Post-Consumer High Density Polyethylene for 3-D Printing Filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

| Search Term |

|---|

| TITLE-ABS-KEY (“recycling”) AND PUBYEAR > 1999 AND PUBYEAR < 2022 |

| TITLE-ABS-KEY (“3D printing”) AND PUBYEAR > 1999 AND PUBYEAR < 2022 |

| TITLE-ABS-KEY (“vehicles” AND “recycling”) AND PUBYEAR > 1999 AND PUBYEAR < 2022 |

| TITLE-ABS-KEY (“3D printing” AND “vehicles”) AND PUBYEAR > 1999 AND PUBYEAR < 2022 |

| TITLE-ABS-KEY (“circular economy” AND “vehicles”) AND PUBYEAR > 1999 AND PUBYEAR < 2022 |

| TITLE-ABS-KEY (“3D printing” AND “recycling”) AND PUBYEAR > 1999 AND PUBYEAR < 2022 |

| TITLE-ABS-KEY (“3D printing” AND “circular economy”) AND PUBYEAR > 1999 AND PUBYEAR < 2022 |

| Search Term | Number of Articles Found in Scopus |

|---|---|

| “recycling” | 171.005 |

| “3D printing” | 47.385 |

| “vehicles” AND “recycling” | 3.719 |

| “3D printing” AND “vehicles | 509 |

| “circular economy” AND “vehicles” | 340 |

| “3D printing” AND “recycling” | 342 |

| “3D printing” AND “circular economy” | 79 |

| Ref | The Study Deals with | Topics of the Article | Accept? (Yes/No) | |||

|---|---|---|---|---|---|---|

| Business Strategy | Innovation | Material Science | Policy and Planning | |||

| [16] | Circular economy and business strategies for the implementation of CE in the manufacturing industry. | X | X | X | Yes | |

| [14] | Study the interrelation of circular economy with academia, industry, and policymakers, pointing out the gaps between them. | X | X | X | Yes | |

| [38] | This study highlights the potential uses of AM in a sustainable industry. | X | X | X | Yes | |

| [18] | An overview of recycling in the European Union since the implementation of the European directives for waste management of ELVs. | X | X | X | Yes | |

| [31] | Three-dimensional printing process development for the future of the industry and the strategic framework of this technology for materials. | X | X | X | X | Yes |

| [39] | The framework of additive manufacturing to perform a closed recycling global chain. | X | X | X | Yes | |

| [40] | A qualitative study to explore the opportunities of 3D printing for sustainable design and circular economy of polymers. | X | X | X | Yes | |

| [41] | Analyzes the opportunity of design using 3D printing technology for next-generation low-weight components. | X | X | X | Yes | |

| [42] | Compares mechanical properties between 3D printed and injection molding samples from recycled ABS. | X | X | X | Yes | |

| [43] | This paper is a comparative mechanical performance analysis between particle material extrusion and filament printing using recycled polycarbonate and virgin polycarbonate. | X | X | X | Yes | |

| [44] | Performs the reprocessing of carbon fiber composites, characterizes the mechanical properties of the recycled pieces, and analyzes the energetic consumption of reprocessing. | X | X | X | Yes | |

| [35] | Conducts a mechanical performance analysis of PLA after successive recycling. | X | X | X | Yes | |

| [45] | Explores the economic feasibility of a distributed closed-loop supply chain network using OS 3D printing technologies. | X | X | X | Yes | |

| [22] | Develop an interactive algorithm to investigate an effective strategy for recycling ELVs. | X | X | X | Yes | |

| [46] | Analyses the financial situation of the vehicle scraping and recycling industry in Poland. | X | X | No | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz, L.E.; Pinho, A.C.; Resende, D.N. 3D Printing as a Disruptive Technology for the Circular Economy of Plastic Components of End-of-Life Vehicles: A Systematic Review. Sustainability 2022, 14, 13256. https://doi.org/10.3390/su142013256

Ruiz LE, Pinho AC, Resende DN. 3D Printing as a Disruptive Technology for the Circular Economy of Plastic Components of End-of-Life Vehicles: A Systematic Review. Sustainability. 2022; 14(20):13256. https://doi.org/10.3390/su142013256

Chicago/Turabian StyleRuiz, Luis E., Ana C. Pinho, and David N. Resende. 2022. "3D Printing as a Disruptive Technology for the Circular Economy of Plastic Components of End-of-Life Vehicles: A Systematic Review" Sustainability 14, no. 20: 13256. https://doi.org/10.3390/su142013256

APA StyleRuiz, L. E., Pinho, A. C., & Resende, D. N. (2022). 3D Printing as a Disruptive Technology for the Circular Economy of Plastic Components of End-of-Life Vehicles: A Systematic Review. Sustainability, 14(20), 13256. https://doi.org/10.3390/su142013256