1. Introduction

The global warming caused by CO2 emissions from anthropogenic activities is threatening life on earth. Intermittent renewables, such as wind and solar energy, are foreseen to provide the largest increase in renewable power generation as the most important contributors to sustainable development. The paradigm change, from today’s energy system to the future’s carbon-free version based on intermittent renewables, can be formulated as the power will be generated when possible, not when needed. However, the intermittent nature of these energy sources is already causing grid instability, which will become even more severe when their share in the power mix will further increase in the near future. Therefore, fuel-flexible, dispatchable energy conversion technologies and energy storage will be needed to bridge the gap caused by the intermittency of the renewables, such as wind and solar.

Distributed energy generation (DEG) facilitates the use of different energy sources. Since distributed power is generated at or near the point of use, transfer losses can be reduced, and small heat sinks close to end-users can be utilized resulting in considerable efficiency improvements and reduction in emissions. The characteristics of micro gas turbines, i.e., reliability and low maintenance, along with their fuel flexibility and load-following capability have made them an interesting option for combined heat and power generation and a prime mover for competitive, secure and sustainable micro-scale poly-generation [

1]. In fact, MGTs can operate on a range of fuels, from high heating values such as methane to low heating value fuels such as biogas [

2]. The combustion systems of micro gas turbines can also be designed so that they can burn fuels with lower octane numbers and heavier hydrocarbon components [

3,

4]. This applies also to fuels containing hydrogen [

5].

Fuel flexible, distributed generation units that can utilize locally available resources to provide heat and power on demand, will be of paramount importance for the realization of sustainable energy solutions. Therefore, experimental studies for technology verification and the provision of data for model validation are needed to support this development. Utilizing hydrogen or hydrogen blends has become an important issue for carbon-free power generation. Various challenges are associated with developing and/or modifying the engine components to manage the variable volume flow of the fuel and the changing flame structure and kinetics due to hydrogen combustion [

6,

7]. However, evaluating the system operation with a large portion of the hydrogen in the fuel blend is a concern for which just a limited number of publications are available in the open literature.

The journey of driving gas turbines with hydrogen-enriched fuels began decades ago. In 1939, Hans von Ohain tested a prototype of a gas turbine that was supplied with hydrogen from an externally pressurized source. The smooth and fast combustion of hydrogen was observed while metal burnout was reported as an obstacle [

7]. A combustor prototype for a micro gas turbine was developed by Minakawa et al. [

8] to run with pure hydrogen. The combustor was a lean premixed swirling type, and it was tested in atmospheric pressure conditions, resulting in efficient combustion and low NOx emissions. The prototype was later assembled on an MGT which resulted in flashbacks during the startup. This issue, which was unforeseen during the component test, was addressed by modifying the air inlet to the combustor [

8]. One of the first publications reporting the measurements of hydrogen injection into a heavy-duty gas turbine was provided by Morris et al. [

9] in 1998. An immediate reduction in CO emissions and a slight increase in NOx production were observed by hydrogen injection up to 10% in the fuel.

With the development of computers over the years, researchers pursued modeling and simulation of combustion with hydrogen to reduce experimental costs and attain a deep understanding of the phenomena. Combustion of hydrogen/methane-blended fuels in a micro gas turbine was studied by Shih et al. utilizing computational fluid dynamic (CFD) methods [

10]. In their research, the effect of hydrogen on flame structure and emissions were investigated by adding hydrogen from 0 to 90% on volume bases. The authors concluded that although simulation results indicate a stable combustion performance, modifications to the original combustor will be required to address the emissions of the combustor with a high hydrogen content [

10]. Experiments, as well as numerical investigations, were conducted by Rajpara et al. [

11] to assess the effect of hydrogen injection on a gas turbine burning methane, upstream of the swirl combustor. Increasing hydrogen content resulted in smaller flame dimensions with an increase in NOx emissions due to higher flame temperature but a decrease in CO emissions. Cappelletti et al. [

12] investigated the combustion of pure hydrogen in a lean premix burner with experimental and numerical simulations. The experimental setup was built based on an existing burner from a heavy-duty gas turbine, which was modified to enable variable premixing levels. With hydrogen combustion, high flow velocity was required to avoid the flame positioning inside the pre-mixer duct. The results of their work confirmed the possibilities of developing combustion technology with pure hydrogen fuel while keeping the emissions below the regulated limits. Binesh et al. [

13] performed a series of experiments to investigate the combustion behavior of hydrogen-enriched methane fuel in a swirl-stabilized model gas-turbine combustor. The amount of hydrogen in the blended fuel was increased up to 80% in volume and during their test, the upper and lower limits of air to maintain stable combustion were derived.

In May 2020, Kawasaki announced a successful test of an industrial gas turbine with hydrogen fuel, through their dry low emission combustion technology. The combustor applies micro-mix combustion technology, which features ultra-small hydrogen-fueled flames and achieves low NOx combustion without using water or steam, which is beneficial in terms of cycle efficiency [

14,

15].

This paper presents the experimental setup of a test rig in Stavanger, Norway, utilizing a T100 micro gas turbine in combined heat and power (CHP) mode. As the reviewed literature shows, the goal of operating micro gas turbines has been pursued for decades, however, the successful operation of a micro gas turbine with high (up to 100%) content of hydrogen was not achieved before. In fact, burning high hydrogen content fuels was investigated in two ways, either numerical or experiments with combustor test rigs to focus on combustion phenomena. The stable combustion was achieved in most of the combustor test rigs at the atmospheric condition which fails to imitate the real pressure conditions in an engine. Furthermore, a test rig that is specified for a combustor, fails to simulate the interaction between the combustor and other components, different operating conditions of the engine, the transitions, and how they all affect the combustion of the hydrogen-enriched fuel.

This paper provides insights into the application of hydrogen-enriched fuel on a commercial micro gas turbine. The complications of running the engine in part-loads and base-load operations have been addressed. The transitions between loads are crucial situations in the engine, where the varying fuel flow rate and rotational speed in the engine will impact the air/fuel ratio in the combustor and the main flow rate through the engine as well. The complications of hydrogen combustion have a destructive effect on the performance of the engine, which has been encountered during the current endeavor and undertaken via design modifications and controller optimization.

The structure of the paper is as follows: first, an overview of the main challenges with hydrogen combustion is provided. Secondly, the engine setup is presented, with a focus on technology modifications, overcoming the issues of hydrogen combustion. The preliminary results from engine operation with various mixtures of methane and hydrogen are also presented which verifies the presented technology.

3. Test Rig Description

The test rig was based on a commercial Turbec T100 unit (T100PH) Series 2 micro gas turbine. T100PH is a single shaft micro gas turbine designed to work both in power generation mode and in cogeneration mode for combined heat and power generation. The T100 is equipped with a recuperator that preheats the air before the combustion chamber by transferring heat from the turbine exhaust gas. There is also a heat exchanger, exploiting the remaining heat in the exhaust gas to warm up the circulating water.

The power generating unit consists of a single-stage centrifugal compressor, a single-stage radial turbine, a tubular combustor, and a high-speed permanent magnet generator. The compressor and the turbine work with a pressure ratio of about 4.3 and a turbine inlet temperature of around 950 degrees Celsius. At nominal operating conditions (with ISO ambient conditions), the unit can produce 100 kW of electrical power at a rotational speed of 70,000 rpm and electrical efficiency of 30%, thanks to the recuperator which is compensating for the low-pressure ratio and low turbine-inlet temperature. In cogeneration mode, the total efficiency (fuel utilization factor) increases to 80%. The test rig, modified for fuel flexible operation is presented in

Figure 2.

During the past few years, numerous modifications have been made to the engine to enable research and development activities, exploring the fuel flexibility of the unit. Recently, the original engine was modified to enable running with hydrogen-enriched fuels, by replacing the original combustor with a new design. The fuel train was also modified to enable different fuel blends in terms of hydrogen content. Over 50 sensors have been installed in different locations of the engine for a comprehensive overview of the engine condition during a test run. In this section, an overview of the main modifications implemented on the engine is provided.

Hydrogen and methane fuel is provided by bundles, each comprising high-pressure interconnected bottles. The bundles are connected to the fuel train via a pressure regulator, to reduce the pressure from over 200 bars to below 20 bars. There are also flashback arrestors and disconnecting valves in the circuit which protect the line. The disconnecting valves are controlled by a leakage sensor inside the building. The bundles and regulator are shown in

Figure 3.

To enable seamless fuel mixing and to accommodate for the changing volume flow of the fuel blend, the fuel train and the gas mixing station have been modified. The system consists of two separate flow controllers for methane and hydrogen, a mixing station, two main valves, and a pilot valve to supply fuel to the MGT. The mixing station is a wide and long pipe that provides enough space so that methane and hydrogen mix well together, preventing hydrogen pockets and local high temperatures inside the combustor which could result in thermal damage and NOx production. The mixed fuel rate is determined by the MGT controller, which has a PID system that finds the adequate fuel flow rate that provides enough heat input to the system at each power set point. The amount of each fuel type is however defined and regulated by the additional controller provided for the fuel train, working based on the ratio of the fuel types defined by the operator.

In

Figure 4, the fuel train temporarily installed on top of the MGT encloser is shown with a schematic diagram of the system. Originally, two main valves were installed to increase the flexibility during the operation, however, one of them remained closed since it was not required. A three-way valve that provides discharge to the atmosphere is also included in the system for safety reasons.

The combustion chamber and fuel system of the MGT test rig have been replaced with a new design to accommodate various fuel mixtures of hydrogen and hydrocarbon-based fuels. The original combustor has been replaced by a fuel-flexible combustor designed and manufactured by the German Aerospace Centre (DLR) to investigate the performance of the engine in different load conditions. To evaluate the unit’s performance and cyclic behavior, additional pressure and temperature sensors have been installed.

The test rig is equipped with an F400s FLOX

® combustor (see

Figure 5). It is a low NOx, flameless combustor with proven fuel flexibility, capable of running on hydrogen [

3,

5]. The combustor was tested on an atmospheric test rig with up to 100% hydrogen, but its hydrogen capability in real conditions inside a gas turbine was verified during the current experiments. An overview of the original combustor’s geometry could be found in [

34].

The baseline engine is equipped with sensors, that measure the flow properties, rotational speed, power output, and a few other parameters mainly for controlling the engine operation. The test rig has been equipped with over 50 additional sensors to enable detailed condition monitoring and performance analysis.

Figure 6 shows the position of the sensors at different locations. These sensors can be divided into four different categories:

Cycle measurements: Pressure and temperature sensors are placed in different locations to provide operational data;

Fuel measurement: Pressure, temperature, and mass flow sensors are providing comprehensive information about the fuel at every operational condition;

Metal temperature measurement: The metal temperature is measured inside the combustor for lifetime assessments;

Emissions measurement: Measuring the concentration of the exhaust gas components.

Among the 32 sensors listed in the table of

Figure 6 are 6 Turbec built-in sensors and 26 are additionally installed. It is worth mentioning that two thermocouples have been installed in position 5, where the working flow has the highest temperature in the cycle. These sensors are located inside the combustor, measuring the temperature of the flow close to the combustion and dilution zone. The temperature of the inlet air to the combustor is also measured (see

Figure 7).

The measurements related to the fuel system are presented in

Table 2, providing detailed information about fuel conditions, before and after mixing. The sensors listed in rows 1 to 3 are installed in the fuel train (

Figure 3 and

Figure 4) and the fuel temperature in the combustor is measured by a thermocouple close to the combustion point.

4. Results

To investigate the transient performance of the engine running with high hydrogen content, a maneuver of the engine with increasing hydrogen content, from 85% to 90% was conducted without changing the controller’s settings. The run was executed in 13 °C ambient temperature and 1.01 bar ambient pressure for which the logged data are presented in

Figure 8. Snapshot data are extracted and presented in

Table 3, where the performance parameters at each power step in steady-state conditions are presented. The hydrogen content in the fuel is calculated based on the volume flow rate. Power step-up was run with 88% hydrogen and at the maximum load it was increased to 90% and then a step-down was conducted. These data provide the bases for comparison as it was collected from less than an hour’s run, however, the ambient temperature during the run gradually increased by one degree.

At 100 kW the increase in hydrogen resulted in less than 2 °C increase in flue gas temperature and more than 1 ppm increase in NOx emissions. The same difference in the temperature and emissions could be observed for other power rates as well. The difference in NOx emission rate is due to the higher temperature in the combustor, previously discussed in the section "flame temperature." The variation in combustion temperature is illustrated in

Figure 8 and according to the data reported in

Table 3, less than 2 °C could be observed in flue gas temperature. This change is measured by the thermocouple shown in

Figure 7 which is installed inside the combustor and closed to the dilution holes. Therefore, the measured temperature could only be an indicator of the increase in combustion temperature, since it is a local measurement after cooling and the actual value of the increase in combustion temperature is not clear. Other than the 100 kW case, the comparison for other power rates shows that NOx production is 1 ppm higher due to a 3% increase in hydrogen content.

The rotational speed of the engine for the same power outputs is slightly (less than 1% relative to the nominal speed) higher with increased hydrogen content, however, the ambient temperature is higher during the second half of the operation and that has a direct impact on the rotational speed. In general, when weather is warmer, the engine rotates at higher speeds.

The position of the pilot and main valves is also presented in

Figure 8, where the pilot valve position is almost constant throughout the operation. The main valve provides variations in fuel flow rate for the maneuver. The pilot opening for the steady-state operation was originally set to 14%, which is a value appropriate for methane and blended methane/hydrogen fuel with small share of hydrogen. With increasing the amount of hydrogen, the pilot valve is recalibrated to a lower value which keeps the NOx emissions below the regulated amount and also stabilizes the combustion.

Other than the discussed maneuvers, several runs with different hydrogen content have been conducted. Using the data post-processing tool, the steady-state period data are extracted which can provide insights into the influence of hydrogen injection on the MGT performance parameters. In

Figure 9, the NOx emissions in different power outputs with various hydrogen content are presented. The general trend taken from the figure suggests that the production of NOx increases as the share of hydrogen in the fuel increases. There are a few points in

Figure 9 that are from the runs with a hydrogen content of around 55% (white circles) which do not follow the general behavior. The reason is that, during that test, the original valve setting was used which led to high NOx emissions. The high temperatures in the combustor encouraged modifying the valves’ settings which led to the lower opening of the pilot valve. All other points are from the maneuvers after recalibration of the valves.

The impact of hydrogen injection on the efficiency of the engine cycle is investigated in

Figure 10. The performance of the engine in terms of electrical efficiency for a range of hydrogen contents is similar to each other and increases with the power output. There is a slight difference in the efficiency of the cycle at a constant power output, but the main reason is the effect of ambient conditions; as the engine inlet temperature increases, the efficiency of the engine reduces [

35].

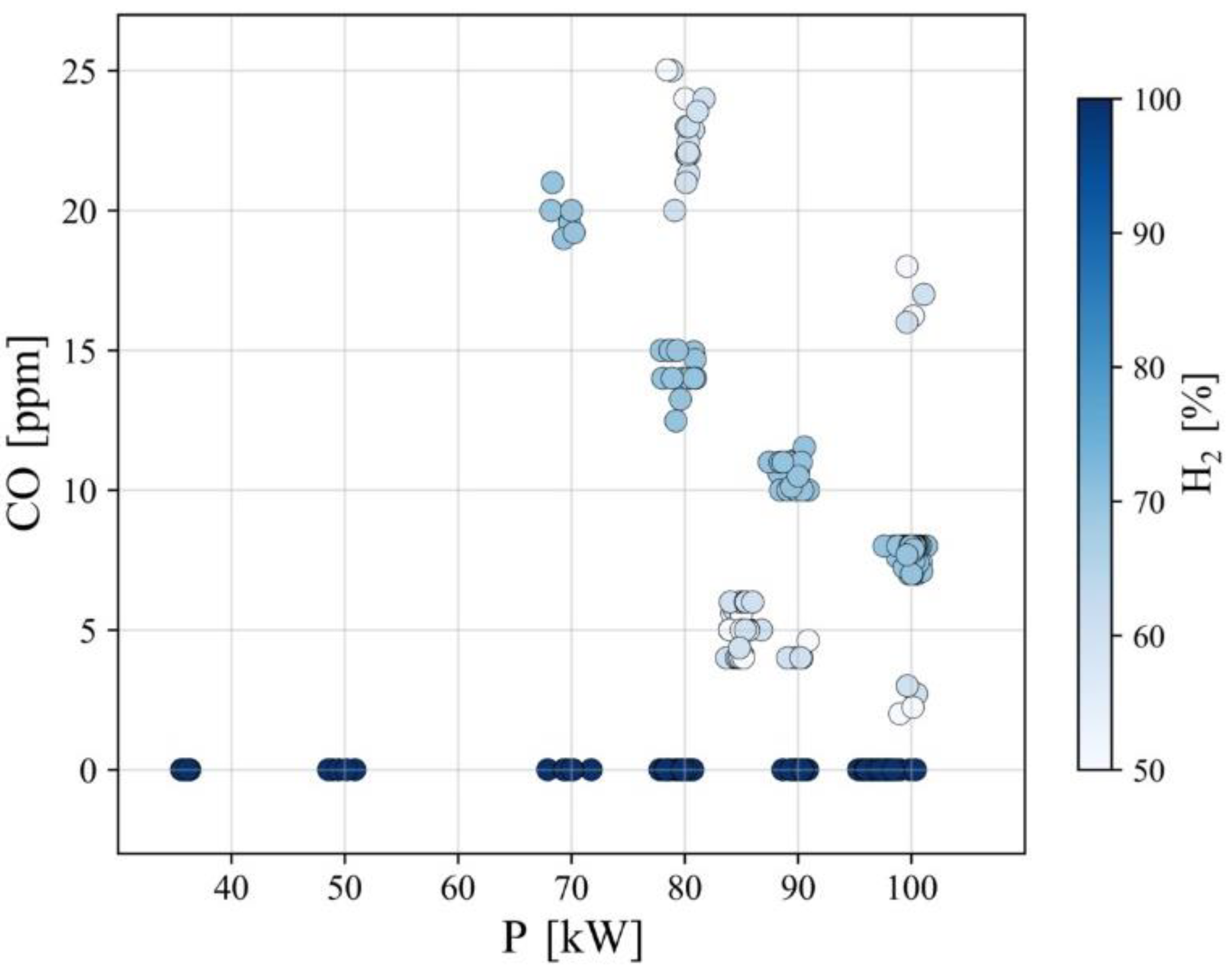

The main reason for replacing carbon-based fuels with hydrogen is to reduce the production of carbon oxides. As discussed, adding hydrogen fuel will contribute to the reduction in the greenhouse gasses that result in global warming, both by replacement of carbon atoms with hydrogen and by promoting combustion efficiency and complete combustion. This effect is illustrated in

Figure 11, where a higher content of hydrogen has resulted in lower CO emissions and zero CO emissions are evident for pure hydrogen. The only points that are not compliant with the trends are, once again, the experiment with 55% hydrogen. The run of that case included trials and errors to ensure a stable operation with NOx emissions below the regulated values, so different arrangements for pilot valves were tried. The results of these tests led to different combustion efficiencies and therefore CO emission rates.

5. Conclusions

In this paper, the process of redeveloping a commercial micro gas turbine to operate with blended methane/hydrogen fuel is presented. Previous studies have shown that a small amount of hydrogen injection into gas turbines is tolerated, however, as the share of hydrogen increases, combustion temperatures and therefore NOx emissions increase. Moreover, using the same combustion system will result in unstable combustion and the risk of flashbacks, because of the difference between the combustion characteristics between hydrogen and methane (or natural gas).

During a collaboration between the university of Stavanger and the German Aerospace Centre (DLR), a modified version of the T100 PH micro gas turbine is provided, with minimum modifications required. A new combustor with an innovative design based on FLOX technology developed by DLR is used to accommodate combustion with high hydrogen content. The engine is also equipped with a new fuel train with an additional controller, so a range of fuel blends could be provided for the engine. The modifications to the main controller of the engine are kept to a minimum and confined only to the controller parameters in the software. With a smaller opening in the pilot valve, stable combustion with regulated NOx is realized.

Several maneuvers with different hydrogen contents are conducted for a range of power outputs. The maximum NOx emission is 25 ppm for running the engine at maximum load with pure hydrogen. The corrected NOx emission based on the case with 15% O2 is 64 ppm, which is lower than the regulated value. The electrical efficiency of the engine is not impaired by hydrogen injection into the system. The greenhouse gas emission is reduced by increasing the share of hydrogen in the fuel, by replacement of the carbon element with hydrogen, also by the improvement of combustion efficiency. Close to zero CO emissions are realized when the engine is derived with pure hydrogen.