“Zero-Waste” Food Production System Supporting the Synergic Interaction between Aquaculture and Horticulture

Abstract

1. Introduction

1.1. Increasing Concerns Related to Conventional Aquaculture Waste Management Practices

1.2. Evaluation of Existing Options for Managing Aquaculture Waste

1.3. Growing Vegetables in Straw Bales, as a Regenerative Technology for Establishing Soilless Cultures

1.4. Circular Production Models in Aquaculture and Horticulture

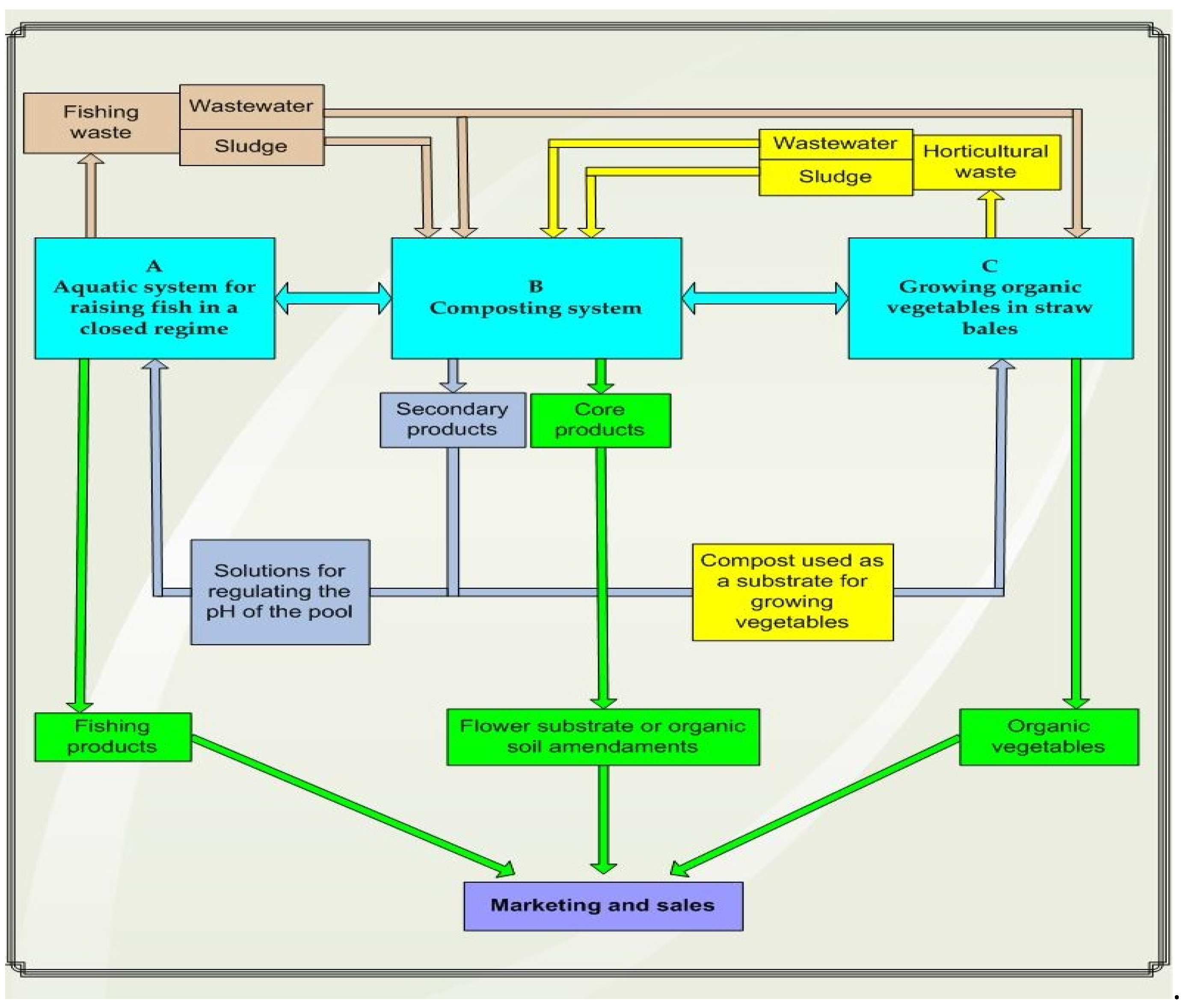

1.5. Research Approach and Key Considerations for the Zero-Waste Food Production System

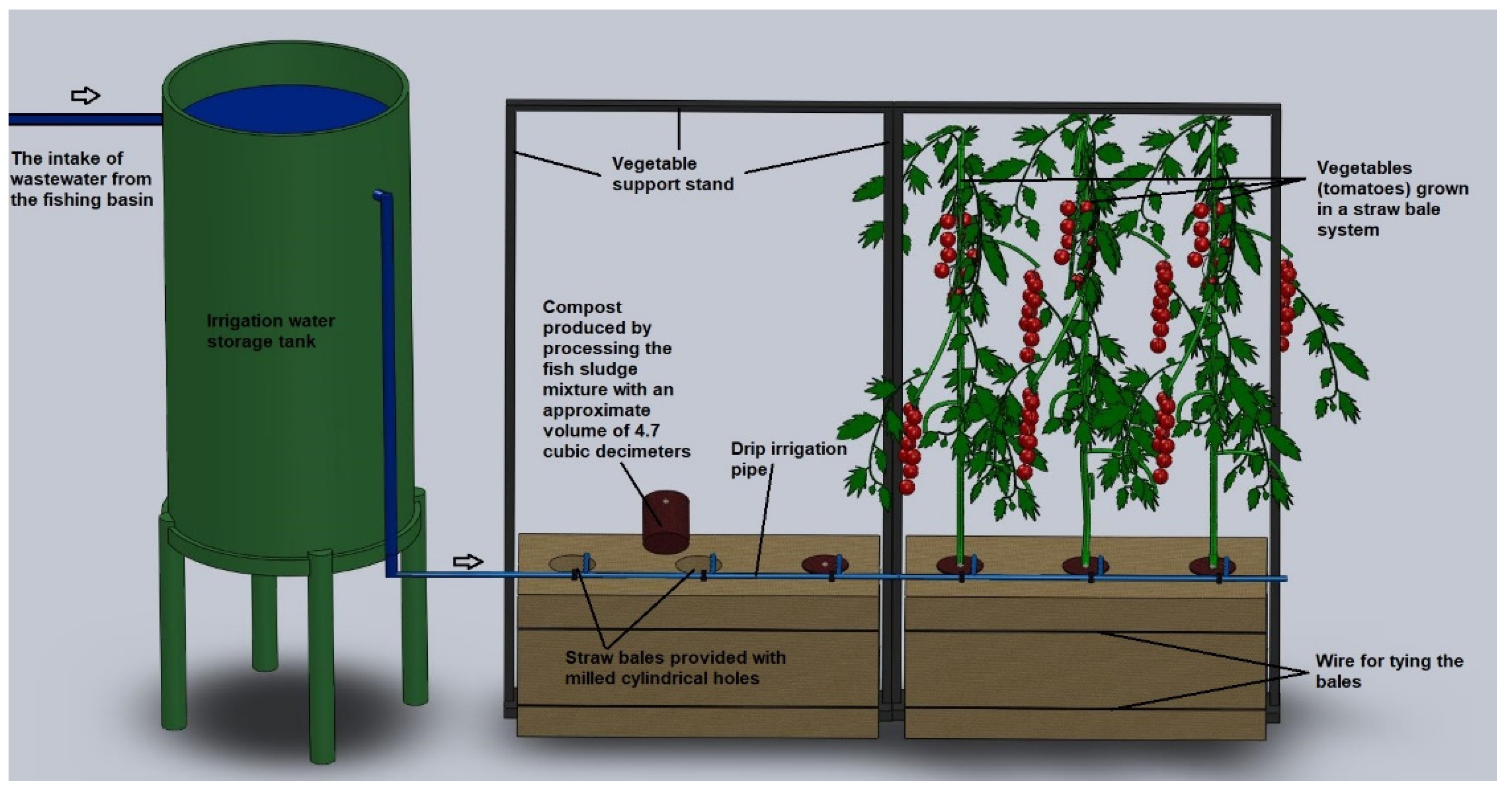

2. Materials and Methods

2.1. Development of Fish-Sludge Composting Processes

2.2. Characterization of Raw Material and Compost

2.3. Establishment of Vegetable Crops on Bales Using Compost Produced from Fishing Sludge as Nutrient Material

3. Results

3.1. Compost Characteristics

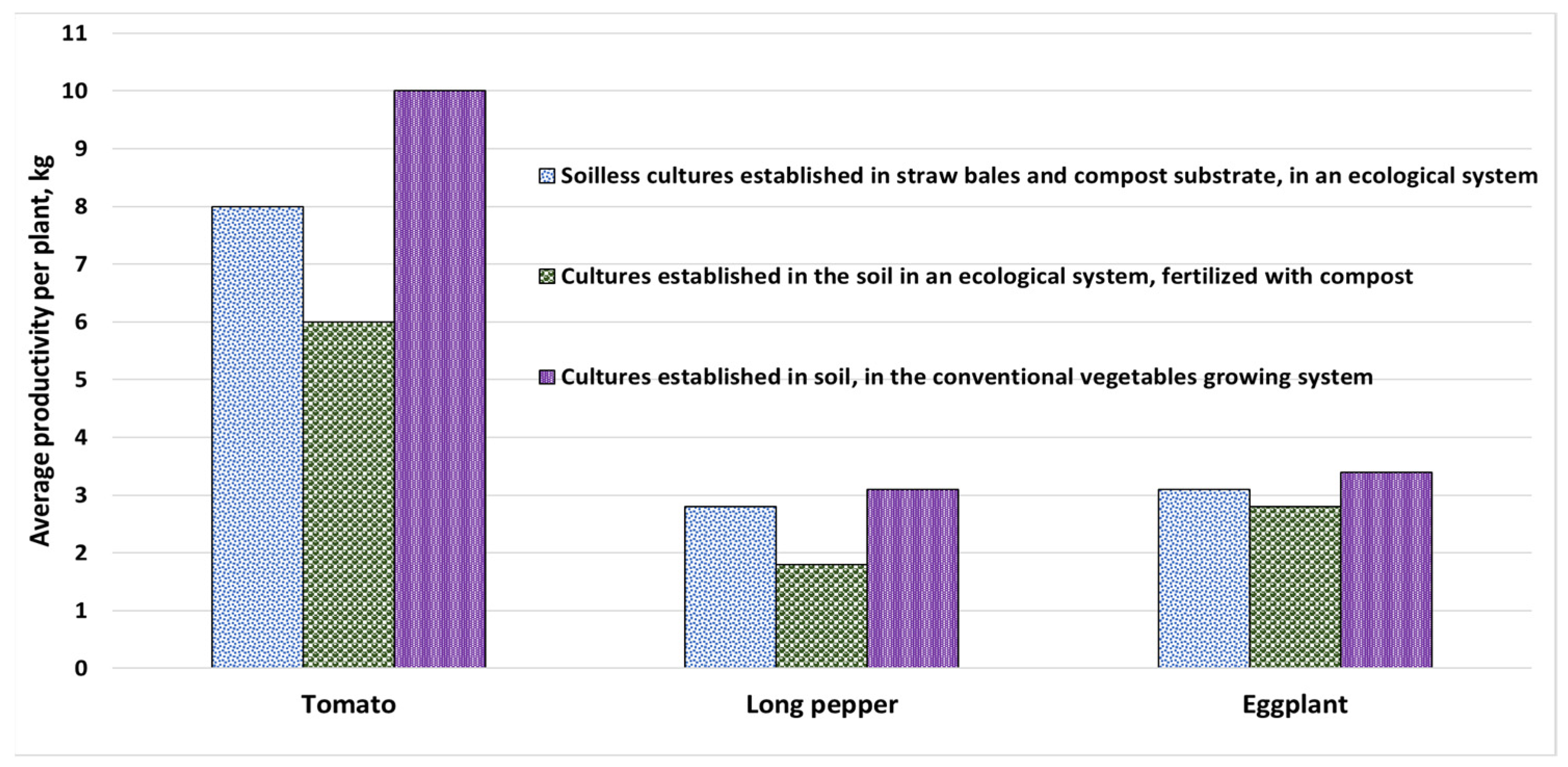

3.2. Vegetable Growth Yield

4. Discussion

5. Conclusions

- -

- The study successfully proved the system functionality and usefulness, especially in terms of managing to create a circular management of resources and wastes, even though the research is in its early stages.

- -

- The main management issue reported by the aquaculture sector, related to the evacuation of the sludge without going through the expensive and time-consuming processes of dehydration, was addressed by composting in a mix with other vegetable waste. In this way, expenses and time allocated with labor force and energy consumption were reduced.

- -

- The zero-waste approach brings significant benefits to environmental sustainability, allowing the reintegration of sludge and water into the production circuit (which would otherwise have ended up in rivers and landfills), as well as the maximum efficiency of using agricultural waste (straw and shredded branches). In addition, the excess of compost being produced has high quality and can be used outside the production cluster for soil reconditioning or can be sold to local farmers.

- -

- Ecological agriculture involves a series of risks; therefore, the establishment in protected space has proven very important in order to protect against pests. However, the quantities achieved using straw bales as substrate were lower than those obtained with conventional farming. In order to assess if the greenhouse’s space is adequately utilized and which plants are more appropriate for the technology, a feasibility study would be required.

- -

- The designed zero-waste food production system supported the symbiotic connection among the three subsystems (aquaculture, horticulture and composting), and showed effective functioning, while reducing operating costs and increasing productivity. However, the improvements were not constant; therefore, the production quantities and the mode of operation must be optimized. In the conducted study, too large amounts of compost resulted (correlated to the amount of waste generated), while the production of vegetables was constrained by the limited space of the greenhouse.

- -

- The quantitative influence on the productivity produced by the synergistic action of the new system has to be further tested in association with several small-sized farms, considering that production may involve some management challenges.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Paone, E.; Fazzino, F.; Pizzone, D.M.; Scurria, A.; Pagliaro, M.; Ciriminna, R.; Calabrò, P.S. Towards the Anchovy Biorefinery: Biogas Production from Anchovy Processing Waste after Fish Oil Extraction with Biobased Limonene. Sustainability 2021, 13, 2428. [Google Scholar] [CrossRef]

- Lucarini, M.; Zuorro, A.; Di Lena, G.; Lavecchia, R.; Durazzo, A.; Benedetti, B.; Lombardi-Boccia, G. Sustainable Management of Secondary Raw Materials from the Marine Food-Chain: A Case-Study Perspective. Sustainability 2020, 12, 8997. [Google Scholar] [CrossRef]

- Nenciu, F.; Oprescu, M.R.; Biris, S.-S. Improve the Constructive Design of a Furrow Diking Rotor Aimed at Increasing Water Consumption Efficiency in Sunflower Farming Systems. Agriculture 2022, 12, 846. [Google Scholar] [CrossRef]

- Cuevas, J.; Daliakopoulos, I.N.; del Moral, F.; Hueso, J.J.; Tsanis, I.K. A Review of Soil-Improving Cropping Systems for Soil Salinization. Agronomy 2019, 9, 295. [Google Scholar] [CrossRef]

- Lopez-Mosquera, M.E.; Fernández-Lemaa, E.; Villaresa, R.; Corralb, R.; Alonsob, B.; Blancob, C. Composting fish waste and seaweed to produce a fertilizer for use in organic agriculture. Procedia Environ. Sci. 2011, 9, 113–117. [Google Scholar] [CrossRef]

- Stanescu, M.D. State of the art of post-consumer textile waste upcycling to reach the zero waste milestone. Environ. Sci. Pollut. Res. 2021, 28, 14253–14270. [Google Scholar] [CrossRef] [PubMed]

- Morales-Polo, C.; Cledera-Castro, M.D.M. An optimized water reuse and waste valorization method for a sustainable development of poultry slaughtering plants. Desalination Water Treat. 2016, 57, 2702–2711. [Google Scholar] [CrossRef]

- Zaman, A.U.; Lehmann, S. Urban growth and waste management optimization towards ‘zero waste city’. City Cult. Soc. 2011, 2, 177–187. [Google Scholar] [CrossRef]

- Zaman, A.U.; Lehmann, S. The zero-waste index: A performance measurement tool for waste management systems in a ‘zero waste city’. J. Clean. Prod. 2013, 50, 123–132. [Google Scholar] [CrossRef]

- Cole, D.W.; Cole, R.; Gaydos, S.J.; Gray, J.; Hyland, G.; Jacques, M.L.; Powell-Dunford, N.; Sawhney, C.; Au, W.W. Aquaculture: Environmental, toxicological, and health issues. Int. J. Hyg. Environ. Health 2009, 212, 369–377. [Google Scholar] [CrossRef]

- Summerfelt, S.T.; Adler, P.R.; Glenn, D.M.; Kretschmann, R.N. Aquaculture sludge removal and stabilization within created wetlands. Aquac. Eng. 1999, 19, 81–92. [Google Scholar] [CrossRef]

- Ewart, J.W.; Hankins, J.A.; Bullock, D. State Policies for Aquaculture Effluents and Solid Wastes in the Northeast Region Bulletin No. 300; Northeastern Regional Aquaculture Center, University of Massachusetts, Dartmouth: North Dartmouth, MA, USA, 1995; Volume 1, pp. 1–24. [Google Scholar]

- Westers, H. Operational waste management in aquacultural effluents. Nutritional Strategies and Aquaculture Waste. In Proceedings of the First International Symposium on Nutritional Strategies in Management of Aquaculture Waste, Guelph, ON, Canada, 1991; pp. 231–238. [Google Scholar]

- Radziemska, M.; Vaverková, M.D.; Adamcová, D.; Brtnicky, M.; Mazur, Z. Valorization of Fish Waste Compost as a Fertilizer for Agricultural Use. Waste Biomass Valor. 2019, 10, 2537–2545. [Google Scholar] [CrossRef]

- Belyaeva, O.N.; Haynes, R.J.; Sturm, E.C. Chemical, physical and microbial properties and microbial diversity in manufactured soils produced from co-composting green waste and biosolids. Waste Manag. 2012, 32, 2248–2257. [Google Scholar] [CrossRef]

- Zeng, G.M.; Yu, M.; Chen, Y.N.; Huang, D.L.; Zhang, J.C.; Huang, H.L.; Jiang, R.Q.; Yu, Z. Effects of inoculation with Phanerochaete chrysosporium at various time points on enzyme activities during agricultural waste composting. Bioresour. Technol. 2010, 101, 222–227. [Google Scholar] [CrossRef]

- Möller, K. Effects of anaerobic digestion on soil carbon and nitrogen turnover, N emissions, and soil biological activity. A review. Agron. Sustain. Dev. 2015, 35, 1021–1041. [Google Scholar] [CrossRef]

- Strauch, S.M.; Wenzel, L.C.; Bischoff, A.; Dellwig, O.; Klein, J.; Schüch, A.; Wasenitz, B.; Palm, H.W. Commercial African Catfish (Clarias gariepinus) Recirculating Aquaculture Systems: Assessment of Element and Energy Pathways with Special Focus on the Phosphorus Cycle. Sustainability 2018, 10, 1805. [Google Scholar] [CrossRef]

- Fu, C.; Liu, H.; Yang, Z. Analysis of pollution and treatment status of residual bait feces in the development of domestic recirculating aquaculture. J. Anhui Agric. Sci. 2018, 46, 76–79. [Google Scholar]

- Goddek, S.; Joyce, A.; Kotzen, B.; Burnell, G.M. Aquaponics Food Production Systems; Springer Nature Switzerland AG: Cham, Switzerland, 2019; pp. 333–352. [Google Scholar] [CrossRef]

- Laidlaw, J.; Magee, L. Towards urban food sovereignty: The trials and tribulations of community-based aquaponics enterprises in Milwaukee and Mand Melbourne. Local Environ. 2016, 21, 573–590. [Google Scholar] [CrossRef]

- Monsees, H.; Keitel, J.; Paul, M.; Kloas, W.; Wuertz, S. Potential of aquacultural sludge treatment for aquaponics: Evaluation of nutrient mobilization under aerobic and anaerobic conditions. Aquac. Environ. Interact. 2017, 9, 9–18. [Google Scholar] [CrossRef]

- Delaide, B.; Goddek, S.; Keesman, K.; Jijakli, H. A methodology to quantify aerobic and anaerobic sludge digestion performances for nutrient recycling in aquaponics. Biotechnol. Agron. Société Et Environ. 2018, 22, 106–112. [Google Scholar] [CrossRef]

- Nenciu, F.; Stanciulescu, I.; Vlad, H.; Gabur, A.; Turcu, O.L.; Apostol, T.; Vladut, V.N.; Cocarta, D.M.; Stan, C. Decentralized Processing Performance of Fruit and Vegetable Waste Discarded from Retail, Using an Automated Thermophilic Composting Technology. Sustainability 2022, 14, 2835. [Google Scholar] [CrossRef]

- Bocken, N.; Strupeit, L.; Whalen, K.; Nußholz, J. A Review and Evaluation of Circular Business Model Innovation Tools. Sustainability 2019, 11, 2210. [Google Scholar] [CrossRef]

- Abdet-Sattar, M.A.; El-Marzoky, H.A.; Mohamed, A.I. Occurrence of Soilborne Diseases and Root Knot Nematodes in Strawberry Plants Grown on Compacted Rice Straw Bales Compared with Naturally Infested Soils. J. Plant Prot. Res. 2008, 48, 223–235. [Google Scholar] [CrossRef]

- El-Marzoky, H.A.; Abdel-Sattar, M.A. Influence of Growing Sweet Pepper in Compacted Rice Straw BalesCompared with Natural Soil, on Infection with Pathogenic Fungiand Nematodes under Greenhouse Conditions. J. Agric. Sci. 2008, 16, 481–492. [Google Scholar]

- Cardei, P.; Nenciu, F.; Ungureanu, N.; Pruteanu, M.A.; Vlăduț, V.; Cujbescu, D.; Găgeanu, I.; Cristea, O.D. Using Statistical Modeling for Assessing Lettuce Crops Contaminated with Zn, Correlating Plants Growth Characteristics with the Soil Contamination Levels. Appl. Sci. 2021, 11, 8261. [Google Scholar] [CrossRef]

- Riad, G.S.; Ghoname, A.A.; Hegazi, A.M.; Fawzy, Z.F.; El-Nemr, M.A. Cultivation in Rice Straw and Other Natural Treatments as an Eco-Friendly Methyl Bromide Alternative in Head Lettuce Production. Gesunde Pflanz. 2017, 69, 21–28. [Google Scholar] [CrossRef]

- Savvas, D.; Gianquinto, G.; Tuzel, Y.; Gruda, N. Soilless Culture. Plant Production and Protection Paper No. 217. In Good Agricultural Practices for Greenhouse Vegetable Crops; FAO, Food and Agriculture Organization of the United Nations: Rome, Italy, 2013; ISBN 978-92-5-107649-1. [Google Scholar]

- Zhang, H.; Gao, Y.; Liu, J.; Lin, Z.; Lee, C.T.; Hashim, H.; Wu, W.-M.; Li, C. Recovery of Nutrients from Fish Sludge as Liquid Fertilizer to Enhance Sustainability of Aquaponics: A Review. Chem. Eng. Trans. 2021, 83, 55–60. [Google Scholar] [CrossRef]

- Scheel, C. Beyond sustainability. Transforming industrial zero-valued residues into increasing economic returns. J. Clean. Prod. 2016, 131, 376–386. [Google Scholar] [CrossRef]

- Gichana, Z.M.; Liti, D.; Waidbacher, H.; Zollitsch, W.; Drexler, S.; Waikibia, J. Waste management in recirculating aquaculture system through bacteria dissimilation and plant assimilation. Aquac. Int. 2018, 26, 1541–1572. [Google Scholar] [CrossRef]

- Rakocy, J.E.; Bailey, D.S.; Shultz, R.C.; Danaher, J.J. Preliminary evaluation of organic waste from two aquaculture systems as a source of inorganic nutrients for hydroponics. Acta Hortic. 2007, 742, 201208. [Google Scholar] [CrossRef]

- Mircea, C.; Nenciu, F.; Vlǎduț, V.; Voicu, G.; Cujbescu, D.; Gageanu, I.; Voicea, I. Increasing the performance of cylindrical separators for cereal cleaning, by using an inner helical coil. INMATEH Agric. Eng. 2020, 62, 249–258. [Google Scholar] [CrossRef]

- Nenciu, F.; Vladut, V. Studies on the perspectives of replacing the classic energy plants with Jerusalem artichoke and Sweet Sorghum, analyzing the impact on the conservation of ecosystems. IOP Conf. Ser. Earth Environ. Sci. 2020, 635, 012002. [Google Scholar] [CrossRef]

- Ciobotaru, I.E.; Nenciu, F.; Vaireanu, D.I. The Electrochemical Generation of Ozone using an Autonomous Photovoltaic System. Rev. Chim. 2013, 64, 1339–1342. [Google Scholar]

- Nenciu, F.; Voicea, I.; Stefan, V.; Nae, G.; Matache, M.; Milian, G.; Arsenoaia, V.N. Experimental research on a feed pelletizing equipment designed for small and medium-sized fish farms. INMATEH-Agric. Eng. 2022, 67, 374–383. [Google Scholar] [CrossRef]

- Cojocaru, C.; Cocârţă, D.M.; Istrate, I.A.; Creţescu, I. Graphical Methodology of Global Pollution Index for the Environmental Impact Assessment Using Two Environmental Components. Sustainability 2017, 9, 593. [Google Scholar] [CrossRef]

- Nenciu, F.; Paraschiv, M.; Kuncser, R.; Stan, C.; Cocarta, D.; Vladut, V.N. High-Grade Chemicals and Biofuels Produced from Marginal Lands Using an Integrated Approach of Alcoholic Fermentation and Pyrolysis of Sweet Sorghum Biomass Residues. Sustainability 2022, 14, 402. [Google Scholar] [CrossRef]

- Pardossi, A.; Carmassi, G.; Diara, C.; Incrocci, L.; Maggini, R.; Massa, D. Efficient Use of Inputs in Protected Horticulture; Department of Biologicial Agriculture, University of Pisa: Pisa, Italy, 2011; Volume 7, pp. 67–85. [Google Scholar] [CrossRef]

- Putra, P.A.; Yuliando, H. Soilless culture system to support water use efficiency and product quality: A review. Agric. Sci. Procedia 2015, 3, 283–288. [Google Scholar] [CrossRef]

- Liu, Q.; Li, H.; Zuo, X.; Zhang, F.; Wang, L. A survey and analysis on public awareness and performance for promoting circular economy in China: A case study from Tianjin. J. Clean. Prod. 2009, 17, 265–270. [Google Scholar] [CrossRef]

| Parameter | Tests Performed | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | N | P | K | Ca | Mg | Cd | Cu | Cr | Ni | Mn | Pb | Zn | |

| % | % | % | % | % | % | % | mg/kg | mg/kg | mg/kg | mg/kg | mg/kg | mg/kg | |

| Fish sludge | 12.11 | 2.84 | 2.95 | 0.12 | 3.8 | 0.5 | 0.7 | 19 | 3.2 | 2.6 | 125 | 0.11 | 286 |

| Vegetable wastes and wheat straw | 43.45 | 1.15 | 0.22 | 1.44 | 1.18 | 0.08 | N.A. | 5.5 | 11.5 | 7.8 | 17.2 | 3.78 | 17.4 |

| Chopped wood material (garden waste) | 39.99 | 0.45 | 0.08 | 0.37 | 0.61 | 0.08 | N.A. | 9.4 | 91.6 | 31.9 | 48.4 | 2.26 | 106 |

| Compost (average value) | 37 | 1.5 | 0.3 | 0.2 | 1.1 | 0.2 | 0.7 | 70 | 22 | 6 | 315 | 28.3 | 166 |

|  |  |

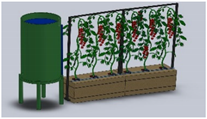

| A. Aquatic system for raising fish in a closed system | B. Composting system | C. Growing organic vegetables in straw bales |

| Most important benefits identified for each of the three subsystems operating in the synergistic production model | ||

|

|

|

| The influence on the productivity of each production system caused by the synergistic action | ||

| Since both sludge and wastewater are fully utilized in the other two systems, without harming the environment, the pond water is replaced with fresh water from deep wells. The better quality of this water, as well as the lower temperature during the summer compared to surface water, improves the health of the fish and can increase productivity by up to 18%. | The sludge from fish farming has constant characteristics; it contains microorganisms that improve the process, shortening the composting time and improving the amount of nutrients such as phosphorus. | Providing, at any time and free of charge, qualitative fertilizers (compost), irrigation water (wastewater from the basin), and an efficient management scheme for waste has been addressed as the most frequent challenges encountered by farmers. By optimizing the cultivation practices and the hybrids employed, a significant increase in production can be achieved for ecological and regenerative agriculture. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nenciu, F.; Voicea, I.; Cocarta, D.M.; Vladut, V.N.; Matache, M.G.; Arsenoaia, V.-N. “Zero-Waste” Food Production System Supporting the Synergic Interaction between Aquaculture and Horticulture. Sustainability 2022, 14, 13396. https://doi.org/10.3390/su142013396

Nenciu F, Voicea I, Cocarta DM, Vladut VN, Matache MG, Arsenoaia V-N. “Zero-Waste” Food Production System Supporting the Synergic Interaction between Aquaculture and Horticulture. Sustainability. 2022; 14(20):13396. https://doi.org/10.3390/su142013396

Chicago/Turabian StyleNenciu, Florin, Iulian Voicea, Diana Mariana Cocarta, Valentin Nicolae Vladut, Mihai Gabriel Matache, and Vlad-Nicolae Arsenoaia. 2022. "“Zero-Waste” Food Production System Supporting the Synergic Interaction between Aquaculture and Horticulture" Sustainability 14, no. 20: 13396. https://doi.org/10.3390/su142013396

APA StyleNenciu, F., Voicea, I., Cocarta, D. M., Vladut, V. N., Matache, M. G., & Arsenoaia, V.-N. (2022). “Zero-Waste” Food Production System Supporting the Synergic Interaction between Aquaculture and Horticulture. Sustainability, 14(20), 13396. https://doi.org/10.3390/su142013396