Corporate Social Responsibility Index for Mine Sites

Abstract

:1. Introduction

2. Methods

2.1. Indicators Obtaining

- -

- The initiative called ISEAL alliance defines some standards applicable to any economic activity, considering social, environmental and economic impacts.

- -

- The global reporting initiative (GRI) gives very detailed information about the general elements to consider in any type of economic activity and also some specific considerations for certain sectors such as coal, oil and gas or agriculture. However, the mining sector is still under development. Moreover, it is not focused on quantitative analysis for mine sites.

- -

- The ISO 26000 gives a good approach of the main elements to consider, but it does not give any value nor any technical or specific approach.

- -

- The mining local procurement reporting mechanism (LPRM) is focused on local procurement of goods and services of the mining industry, without giving any rating.

- -

- The extractive industries transparency initiative (EITI) promotes the correct management of natural resources, strengthening public and corporate governance and accountability by means of defining procedures.

- -

- Some mining firms have developed similar qualitative tools. For instance, the Anglo-American socio-economic assessment toolbox (SEAT) helps to approach the needs of the communities where the mining operations are planned to be placed, with the idea to improve the socio-economic impact understanding to local and regional communities.

2.2. Rating Definition

- Definition of the relevant elements, including all the stakeholders in the process. New elements can be added if necessary.

- Establish a scale, preferably transformed to a 100-point scale. Figure 2 shows a tentative scale based on five categories. This scale should be used only for an overall analysis or a dimension analysis.

- Analyze each element included, giving a score for each of them based on the definition completed in Section 3. Each element is defined as a Likert 1–5 scale, evaluating the specific CSR performance.

2.3. Scope of the Index

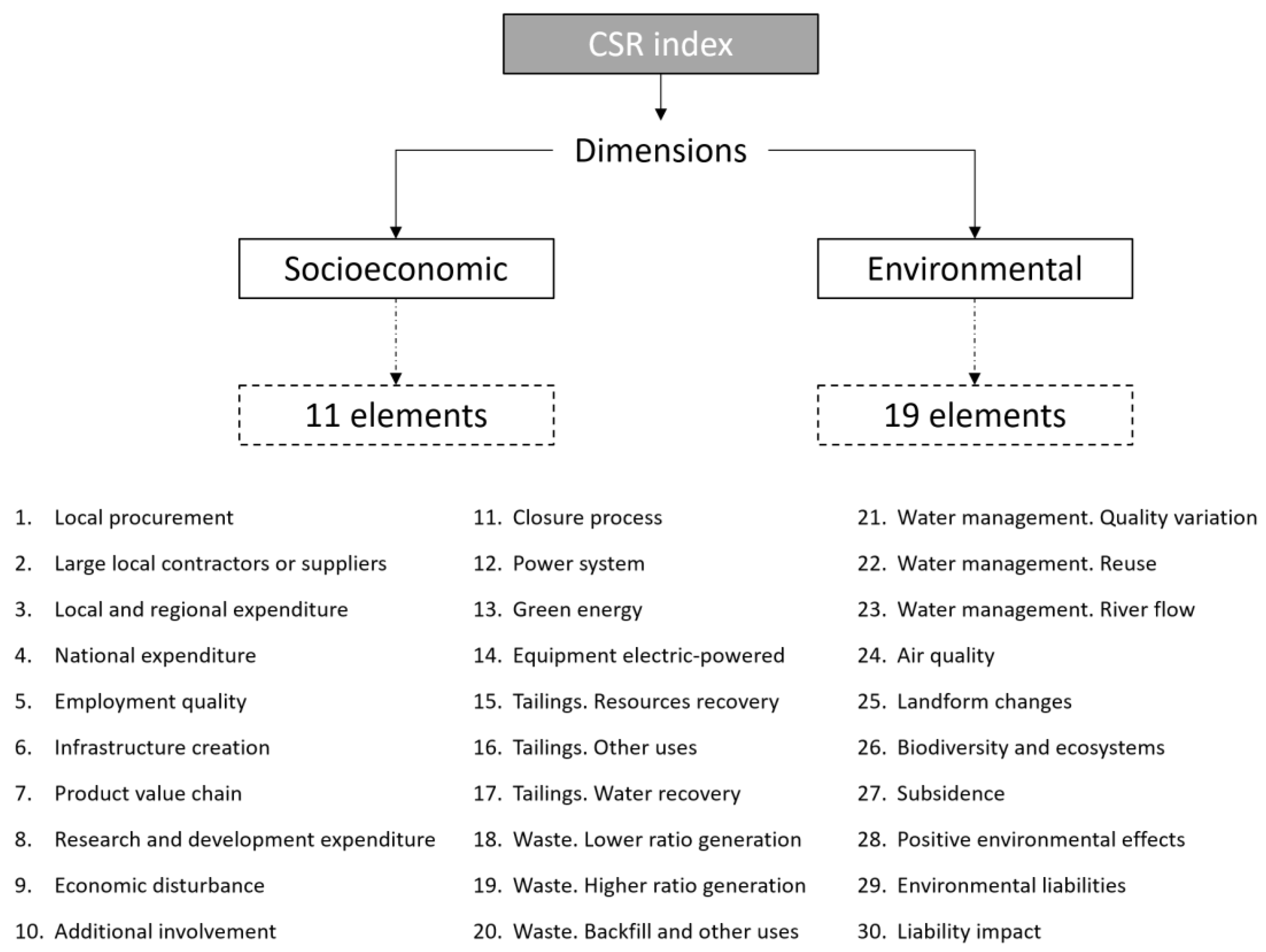

3. Index Proposal

3.1. Socio-Economic Dimension

3.1.1. Local Procurement

3.1.2. Local Expenditure

3.1.3. Permanent Infrastructures

3.1.4. Value Chain Creation

3.1.5. Economic Environment Disturbances

3.1.6. Additional Involvement

- -

- Mine project equity

- -

- Company shares

- -

- Environmental control participation

- -

- Involvement of indigenous/local communities and specialized NGO as part of the team in the development of the project

- -

- Assistance to preserve traditions and cultural heritage of the region. It can be an additional source of independent incomes for the region during the mining activity and afterwards

- -

- Render assistance in case of natural disaster

- -

- Volunteerism staff hours

3.1.7. Closure—Final Conditions

3.2. Environment

3.2.1. Energy

3.2.2. Tailings

3.2.3. Waste Management

3.2.4. Water Management

3.2.5. Air Quality

3.2.6. Landform Changes

3.2.7. Biodiversity and Ecosystems

3.2.8. Subsidence

3.2.9. Positive Environmental Effects

3.2.10. Environmental Liabilities

3.2.11. Other Elements

4. Discussion

Future Works

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Gandhi, S.M.; Sarkar, B.C. Mineral Deposits. Essent. Miner. Explor. Eval. 2016, 2016, 23–52. [Google Scholar] [CrossRef]

- Joyce, S.; Thomson, I. Earning a social licence to operate: Social acceptability and resource development in Latin America. Can. Min. Metall. Bull. 2000, 93, 1037. [Google Scholar]

- Boutilier, R.; Thomson, I. Encyclopedia of Business and Professional Ethics; Springer: Berlin/Heidelberg, Germany, 2020; Volume 1. [Google Scholar] [CrossRef] [Green Version]

- Banerjee, S.B. Whose land is it any way? National interest, Indigenous stakeholders, and colonial discourses: The case of the Jabiluka uranium mine. Organiz. Environ. 2000, 13, 3–38. [Google Scholar] [CrossRef] [Green Version]

- Barber, M.; Jackson, S. Indigenous engagement in Australian mine water management: The alignment of corporate strategies with national water reform objectives. Resour. Policy 2012, 37, 48–58. [Google Scholar] [CrossRef]

- Meissner, K.; Everingham, J.A. Information control and competence: Participant experience of public participation in EIA for proposed mining projects in Queensland. Australas. J. Environ. Manag. 2021, 28, 287–304. [Google Scholar] [CrossRef]

- Viveros, H. Responsibility in the mining sector. Resour. Policy 2017, 51, 1–12. [Google Scholar] [CrossRef]

- Parsons, R.; Lacey, J.; Moffat, K. Maintaining legitimacy of a contested practice: How the minerals industry understands its social licence to operate. Resour. Policy 2014, 41, 83–90. [Google Scholar] [CrossRef]

- Franks, D.M.; Cohen, T. Social licence in design: Constructive technology assessment within a mineral research and development institution. Technol. Forecast. Soc. Change 2012, 79, 1229–1240. [Google Scholar] [CrossRef]

- Porter, M.E.; Kramer, M.R. Strategy & society: The link between competitive advantage and corporate social responsibility. Harv. Bus. Rev. 2006, 84, 78–92. [Google Scholar]

- Hilson, G. Corporate social responsibility in the extractive industries: Experiences from developing countries. Resour. Policy 2012, 37, 131–137. [Google Scholar] [CrossRef]

- Andrews, N. Challenges of corporate social responsibility (CSR) in domestic settings: An exploration of mining regulation vis-à-vis CSR in ghana. Resour. Policy 2016, 47, 9–17. [Google Scholar] [CrossRef]

- Wilson, S.A. Measuring the effectiveness of corporate social responsibility initiatives in diamond mining areas of sierra leone. Resour. Policy 2022, 77, 102651. [Google Scholar] [CrossRef]

- Shipton, L.; Dauvergne, P. The influence of home country institutions on the adoption of corporate social responsibility policies by transnational mining corporations. Extr. Ind. Soc. 2022, 10, 101077. [Google Scholar] [CrossRef]

- Cheng, B.; Ioannou, I.; Serafeimi, G. Corporate social responsibility and access to finance. Strateg. Manag. J. 2014, 35, 1–23. [Google Scholar] [CrossRef]

- Deloitte. Tracking the Trends 2022: Redefining Mining. 2022. Available online: https://www2.deloitte.com/content/dam/Deloitte/au/Documents/energy-resources/deloitte-au-global-tracking-the-trends-2022-digital020222.pdf (accessed on 18 April 2022).

- Jenkins, H.; Yakovleva, N. Corporate social responsibility in the mining industry: Exploring trends in social and environmental disclosure. J. Clean. Prod. 2006, 14, 271–284. [Google Scholar] [CrossRef]

- Maloni, M.J.; Brown, M.E. Corporate social responsibility in the supply chain: An application in the food industry. J. Bus. Ethics 2006, 68, 35–52. [Google Scholar] [CrossRef]

- Khan, A.; Muttakin, M.B.; Siddiqui, J. Corporate governance and corporate social responsibility disclosures: Evidence from an emerging economy. J. Bus. Ethics 2013, 114, 207–223. [Google Scholar] [CrossRef]

- Xia, B.; Olanipekun, A.; Chen, Q.; Xie, L.; Liu, Y. Conceptualising the state of the art of corporate social responsibility (CSR) in the construction industry and its nexus to sustainable development. J. Clean. Prod. 2018, 195, 340–353. [Google Scholar] [CrossRef]

- Latif, K.F.; Sajjad, A. Measuring corporate social responsibility: A critical review of survey instruments. Corp. Soc. Responsib. Environ. Manag. 2018, 25, 1174–1197. [Google Scholar] [CrossRef]

- Ranängen, H.; Zobel, T.; Bergström, A. The merits of ISO 26000 for CSR development in the mining industry: A case study in the zambian copperbelt. Soc. Responsib. J. 2014, 10, 500–515. [Google Scholar] [CrossRef]

- European Commission, Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs, EU Principles for Sustainable Raw Materials, Publications Office of the European Union. 2022. Available online: https://data.europa.eu/doi/10.2873/789368 (accessed on 16 May 2022).

- Overland, I.; Bourmistrov, A.; Dale, B.; Irlbacher-Fox, S.; Juraev, J.; Podgaiskii, E.; Stammler, F.; Tsani, S.; Vakulchuk, R.; Wilson, E.C. The Arctic Environmental Responsibility Index: A method to rank heterogenous extractive industry companies for governance purposes. Bus. Strategy Environ. 2021, 30, 1623–1643. [Google Scholar] [CrossRef]

- Amato, L.H.; Amato, C.H. Environmental policy, rankings and stock values. Bus. Strategy Environ. 2012, 21, 317–325. [Google Scholar] [CrossRef]

- Urueña, R. Indicators as political spaces: Law, international organizations, and the quantitative challenge in global governance. Int. Organ. Law Rev. 2015, 12, 1–18. [Google Scholar] [CrossRef]

- Dilling, P.F.A. Reporting on long-term value creation-The example of public canadian energy and mining companies. Sustainability 2016, 8, 938. [Google Scholar] [CrossRef] [Green Version]

- Bullock, G. Green Grades: Can Information Save the Earth? MIT Press: Cambridge, UK, 2017. [Google Scholar]

- Prakash, A.; Potoski, M. Voluntary environmental programs: A comparative perspective. J. Policy Anal. Manag. 2012, 31, 123–138. [Google Scholar] [CrossRef]

- Trumpp, C.; Guenther, T. Too little or too much? Exploring U- shaped relationships between corporate environmental performance and corporate financial performance. Bus. Strategy Environ. 2017, 26, 49–68. [Google Scholar] [CrossRef]

- Potts, J.; Wenban-Smith, M.; Turley, L.; Lynch, M. Standards and the extractive economy. In State of Sustainability Initiatives Series; International Institute for Sustainable Development: Winnipeg, MB, Canada, 2018. [Google Scholar]

- Ranängen, H.; Zobel, T. Revisiting the ‘how’ of corporate social responsibility in extractive industries and forestry. J. Clean. Prod. 2014, 84, 299–312. [Google Scholar] [CrossRef]

- Antão, M.; Carolino, A.; Vieira, R. The Strategic Importance of the Lithiniferous Deposits of Gonçalo (Guarda, Portugal) in Sustainable Development of Low Density Regions—The Lithium Project. Mod. Environ. Sci. Eng. 2018, 4, 590–599. [Google Scholar] [CrossRef]

- Lin, P.T.; Li, B.; Bu, D. The relationship between corporate governance and community engagement: Evidence from the Australian mining companies. Resour. Policy 2015, 43, 28–39. [Google Scholar] [CrossRef]

- Prno, J.; Pickard, M.; Kaiyogana, J. Effective community engagement during the environmental assessment of a mining project in the canadian arctic. Environ. Manag. 2021, 67, 1000–1015. [Google Scholar] [CrossRef]

- Cassotta, S.; Cueva, V.P.; Raftopoulos, M. Australia: Regulatory, human rights and economic challenges and opportunities of large-scale mining projects: A case study of the carmichael coal mine. Environ. Policy Law 2020, 50, 357–372. [Google Scholar] [CrossRef]

- Idahosa, P. Business ethics and development in conflict (zones): The case of talisman oil. J. Bus. Ethics 2002, 39, 227–246. [Google Scholar] [CrossRef]

- Xing, M.; Awuah-Offei, K.; Long, S.; Usman, S. The effect of local supply chain on regional economic impacts of mining. Extr. Ind. Soc. 2017, 4, 622–629. [Google Scholar] [CrossRef]

- McHenry, M.P.; Doepel, D.G.; Urama, K.C. Making extractive industries-led growth inclusive: An introduction. Extr. Ind. Soc. 2017, 4, 235–239. [Google Scholar] [CrossRef]

- Baumann, J.; Kritikos, A.S. The link between R&D, innovation and productivity: Are micro firms different? Res. Policy 2016, 45, 1263–1274. [Google Scholar] [CrossRef] [Green Version]

- Coval, J.; Tobias, M. The Geography of Investment: Informed Trading and Asset Prices. J. Political Econ. 2001, 109, 811–841. [Google Scholar] [CrossRef]

- Portes, R.; Rey, H. The determinants of cross-border equity flows. J. Int. Econ. 2005, 65, 269–296. [Google Scholar] [CrossRef] [Green Version]

- Monteiro, N.B.R.; da Silva, E.A.; Moita Neto, J.M. Sustainable development goals in mining. J. Clean. Prod. 2019, 228, 509–520. [Google Scholar] [CrossRef]

- Rolfe, J.; Miles, B.F.; Lockie, S.; Ivanova, G. Lessons from the Social and Economic Impacts of the Mining Boom in the Bowen Basin 2004–2006. Australas. J. Reg. Stud. 2007, 13, 134. [Google Scholar]

- Kamenopoulos, S.; Agioutantis, Z. The Importance of the Social License to Operate at the Investment and Operations Stage of Coal Mining Projects: Application using a Decision Support System. Extr. Ind. Soc. 2021, 8, 100740. [Google Scholar] [CrossRef]

- Fessehaie, J. What determines the breadth and depth of Zambia’s backward linkages to copper mining? The role of public policy and value chain dynamics. Resour. Policy 2012, 37, 443–451. [Google Scholar] [CrossRef]

- Lockie, S.; Franetovich, M.; Sharma, S.; Rolfe, J. Democratisation versus engagement? Social and economic impact assessment and community participation in the coal mining industry of the Bowen Basin, Australia. Impact Assess. Proj. Apprais. 2008, 26, 177–187. [Google Scholar] [CrossRef]

- MacInnes, A.; Colchester, M.; Whitmore, A. Free, prior and informed consent: How to rectify the devastating consequences of harmful mining for indigenous peoples. Perspect. Ecol. Conserv. 2017, 15, 152–160. [Google Scholar] [CrossRef]

- Martin, F. Aboriginal and torres strait islander peoplesʼ use of charities as a structure to receive mining payments: An evaluation of the rationale through three case studies. Griffith Law Rev. 2013, 22, 205–237. [Google Scholar] [CrossRef]

- Owen, J.R.; Kemp, D. Social licence and mining: A critical perspective. Resour. Policy 2013, 38, 29–35. [Google Scholar] [CrossRef]

- Mehahad, M.S.; Bounar, A. Phosphate mining, corporate social responsibility and community development in the Gantour Basin, Morocco. Extr. Ind. Soc. 2020, 7, 170–180. [Google Scholar] [CrossRef]

- Laurence, D. Establishing a sustainable mining operation: An overview. J. Clean. Prod. 2011, 19, 278–284. [Google Scholar] [CrossRef]

- Hendrychová, M.; Svobodova, K.; Kabrna, M. Mine reclamation planning and management: Integrating natural habitats into post-mining land use. Resour. Policy 2020, 69, 101882. [Google Scholar] [CrossRef]

- Marot, N.; Harfst, J. Post-mining landscapes and their endogenous development potential for small- and medium-sized towns: Examples from Central Europe. Extr. Ind. Soc. 2021, 8, 168–175. [Google Scholar] [CrossRef]

- Arratia-Solar, A.; Svobodova, K.; Lèbre, É.; Owen, J.R. Conceptual framework to assist in the decision-making process when planning for post-mining land-uses. Extr. Ind. Soc. 2022, 10, 101083. [Google Scholar] [CrossRef]

- Pietrzykowski, M.; Krzaklewski, W. Reclamation of Mine Lands in Poland. In Bio-Geotechnologies for Mine Site Rehabilitation; Elsevier Inc.: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Frejowski, A.; Bondaruk, J.; Duda, A. Challenges and opportunities for end-of-life coal mine sites: Black-to-green energy approach. Energies 2021, 14, 1385. [Google Scholar] [CrossRef]

- Kelm, U.; Baumgartl, T.; Edraki, M.; Gutiérrez, L.; Jerez, O.; Morales, J.; Novoselov, A. Mineralogy of tailings: Challenges to usual routines of characterization. In Proceedings of the IMPC 2018-29th International Mineral Processing Congress, Moscow, Russia, 17–21 September 2018; pp. 108–114. [Google Scholar]

- Carmignano, O.R.; Vieira, S.S.; Teixeira, A.P.C.; Lameiras, F.S.; Brandão, P.R.G.; Lago, R.M. Iron ore tailings: Characterization and applications. J. Braz. Chem. Soc. 2021, 32, 1895–1911. [Google Scholar] [CrossRef]

- Rodrigues, P.M.; Antão, A.; Rodrigues, R. Evaluation of the impact of lithium exploitation at the C57 mine (Gonçalo, Portugal) on water, soil and air quality. Environ. Earth Sci. 2019, 78, 533. [Google Scholar] [CrossRef]

- Carvalho, M.; Romero, A.; Shields, G.; Millar, D.L. Optimal synthesis of energy supply systems for remote open pit mines. Appl. Therm. Eng. 2014, 64, 315–330. [Google Scholar] [CrossRef]

- Linkov, S.A.; Olizarenko, V.V.; Radionov, A.A.; Sarapulov, O.A. Energy-efficient power supply system for mines. Procedia Eng. 2015, 129, 63–68. [Google Scholar] [CrossRef] [Green Version]

- Ernst & Young (EY). Top 10 Business Risks and Opportunities for Mining and Metals in 2022; Ernst & Young (EY): London, UK, 2022. [Google Scholar]

- Gan, Y.; Griffin, W.M. Analysis of life-cycle GHG emissions for iron ore mining and processing in China—Uncertainty and trends. Resour. Policy 2018, 58, 90–96. [Google Scholar] [CrossRef]

- Kalantari, H.; Sasmito, A.P.; Ghoreishi-Madiseh, S.A. An overview of directions for decarbonization of energy systems in cold climate remote mines. Renew. Sustain. Energy Rev. 2021, 152, 111711. [Google Scholar] [CrossRef]

- Xu, Z.; Zhai, S.; Phuong, N.X. Research on green transition development of energy enterprises taking mining industry as an example. Nat. Environ. Pollut. Technol. 2019, 18, 1521–1526. [Google Scholar]

- Voronin, V.A.; Nepsha, F.S.; Ermakov, A.N.; Kantovich, L.I. Analysis of electrical equipment operating modes of the excavation site of a modern coal mine. Sustain. Dev. Mt. Territ. 2021, 13, 599–607. [Google Scholar] [CrossRef]

- Owen, J.R.; Kemp, D.; Lèbre, E.; Svobodova, K.; Pérez Murillo, G. Catastrophic tailings dam failures and disaster risk disclosure. Int. J. Disaster Risk Reduct. 2020, 42, 101361. [Google Scholar] [CrossRef]

- Laurence, D. The devolution of the social licence to operate in the Australian mining industry. Extr. Ind. Soc. 2021, 8, 100742. [Google Scholar] [CrossRef] [PubMed]

- Saes, B.M.; Muradian, R. What misguides environmental risk perceptions in corporations? Explaining the failure of Vale to prevent the two largest mining disasters in Brazil. Resour. Policy 2021, 72, 102022. [Google Scholar] [CrossRef]

- Islam, K.; Murakami, S. Global-scale impact analysis of mine tailings dam failures: 1915–2020. Glob. Environ. Change 2021, 70, 102361. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Valenzuela, F. Efficient use of water in tailings management: New technologies and environmental strategies for the future of mining. Water 2022, 14, 1741. [Google Scholar] [CrossRef]

- Chen, W.; Yin, S.; Zhou, G.; Li, Z.; Song, Q. Copper recovery from tailings through bioleaching and further application of bioleached tailings residue: Comprehensive utilization of tailings. J. Clean. Prod. 2022, 332, 130129. [Google Scholar] [CrossRef]

- Sanders, J.; McLeod, H.; Small, A.; Strachotta, C. Mine closure residual risk management: Identifying and managing credible failure modes for tailings and mine waste. In Mine Closure 2019; Australian Centre for Geomechanics: Perth, WA, Australia, 2019; pp. 535–551. [Google Scholar]

- Falagán, C.; Grail, B.M.; Johnson, D.B. New approaches for extracting and recovering metals from mine tailings. Miner. Eng. 2017, 106, 71–78. [Google Scholar] [CrossRef]

- Behera, S.K.; Mishra, D.P.; Singh, P.; Mishra, K.; Mandal, S.K.; Ghosh, C.N.; Mandal, P.K. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Constr. Build. Mater. 2021, 309, 125120. [Google Scholar] [CrossRef]

- Song, X.; Pettersen, J.B.; Pedersen, K.B.; Røberg, S. Comparative life cycle assessment of tailings management and energy scenarios for a copper ore mine: A case study in northern Norway. J. Clean. Prod. 2017, 164, 892–904. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Li, X.; Guan, L.; Liu, P.; Wu, T.; Li, Z.; Lu, A. Low-cost and environment-friendly ceramic foams made from lead-zinc mine tailings and red mud: Foaming mechanism, physical, mechanical and chemical properties. Ceram. Int. 2016, 42, 1733–1739. [Google Scholar] [CrossRef]

- Pan, H.; Zhou, G.; Cheng, Z.; Yang, R.; He, L.; Zeng, D.; Sun, B. Advances in geochemical survey of mine tailings project in china. J. Geochem. Explor. 2014, 139, 193–200. [Google Scholar] [CrossRef]

- Golev, A.; Gallagher, L.; Vander Velpen, A.; Lynggaard, J.R.; Friot, D.; Stringer, M.; Chuah, S.; Arbelaez-Ruiz, D.; Mazzinghy, D.; Moura, L.; et al. Ore-Sand: A Potential New Solution to the Mine Tailings and Global Sand Sustainability Crises; The University of Queensland: Brisbane, QLD, Australia, 2022. [Google Scholar]

- Hustrulid, W.A.; Bullock, R.C. Underground Mining Methods: Engineering Fundamentals and International Case Studies; Society for Mining, Metallurgy and Exploration: Littleton, CO, USA, 2012. [Google Scholar]

- Kalisz, S.; Kibort, K.; Mioduska, J.; Lieder, M.; Małachowska, A. Waste management in the mining industry of metals ores, coal, oil and natural gas—A review. J. Environ. Manag. 2022, 304, 114239. [Google Scholar] [CrossRef] [PubMed]

- Kruukka, A.; Broicher, H.F. Kiruna mineral processing starts underground—bulk sorting by LIF. CIM Bull. 2002, 95, 79–84. [Google Scholar]

- Nassar, N.T.; Lederer, G.W.; Brainard, J.; Padilla, A.; Lessard, J. The rock-to-metal ratio—A foundational metric for understanding mine wastes. Environ. Sci. Technol. 2022, 56, 6710–6721. [Google Scholar] [CrossRef]

- Mudd, G.M. Sustainability and Mine Waste Management—A Snapshot of Mining Waste Issues. In Proceedings of the Waste Management & Infrastructure Conference, Tucson, Arizona, 25 February–1 March 2007; pp. 1–12. [Google Scholar]

- De la Vergne, J. Hard Rock Miner’s Handbook, 5th ed.; Stantec Engineering: Edmonton, AB, Canada, 2014; ISBN 0-9687006-1-6. [Google Scholar]

- Jiang, H.; Cao, Y.; Huang, P.; Fang, K.; Li, B. Characterisation of coal-mine waste in solid backfill mining in china. Trans. Inst. Min. Metall. Sect. A Min. Technol. 2015, 124, 56–63. [Google Scholar] [CrossRef]

- Krishna, R.S.; Mishra, J.; Meher, S.; Das, S.K.; Mustakim, S.M.; Singh, S.K. Industrial solid waste management through sustainable green technology: Case study insights from steel and mining industry in Keonjhar, India. Mater. Today Proc. 2020, 33, 5243–5249. [Google Scholar] [CrossRef]

- Sözen, S.; Orhon, D.; Dinçer, H.; Ateşok, G.; Baştürkçü, H.; Yalçın, T.; Yağcı, N. Resource recovery as a sustainable perspective for the remediation of mining wastes: Rehabilitation of the CMC mining waste site in northern Cyprus. Bull. Eng. Geol. Environ. 2017, 76, 1535–1547. [Google Scholar] [CrossRef]

- Sołtysiak, M.; Dąbrowska, D.; Krzykawski, T.; Barczyk, M.; Domagalska, P. Environmental effects of mining waste usage during a gravel pit reclamation in the vistula valley in Oswiecim (southern Poland). Int. Multidiscip. Sci. GeoConference Surv. Geol. Min. Ecol. Manag. 2019, 19, 199–206. [Google Scholar] [CrossRef]

- Szyplinska, P. CEO 360 Degree Perspective of the Global Mining Water and Wastewater Treatment Market; Frost Sullivan: San Antonio, TX, USA, 2012; p. 11. [Google Scholar]

- Admiraal, R.; Sequeira, A.R.; McHenry, M.P.; Doepel, D. Maximizing the impact of mining investment in water infrastructure for local communities. Extr. Ind. Soc. 2017, 4, 240–250. [Google Scholar] [CrossRef] [Green Version]

- Edwards, H.G.M.; Vandenabeele, P.; Jorge-Villar, S.E.; Carter, E.A.; Perez, F.R.; Hargreaves, M.D. The rio tinto mars analogue site: An extremophilic raman spectroscopic study. Spectrochim. Acta-Part A Mol. Biomol. Spectrosc. 2007, 68, 1133–1137. [Google Scholar] [CrossRef] [Green Version]

- Rufo, L.; Rodríguez, N.; de la Fuente, V. Plant communities of extreme acidic waters: The Rio Tinto case. Aquat. Bot. 2011, 95, 129–139. [Google Scholar] [CrossRef]

- Tharme, R.E. A global perspective on environmental flow assessment: Emerging trends in the development and application of environmental flow methodologies for rivers. River Res. Appl. 2003, 19, 397–441. [Google Scholar] [CrossRef]

- Asif, Z.; Chen, Z.; Han, Y. Air quality modeling for effective environmental management in the mining region. J. Air Waste Manag. Assoc. 2018, 68, 1001–1014. [Google Scholar] [CrossRef] [PubMed]

- Tukiainen, H.; Kiuttu, M.; Kalliola, R.; Alahuhta, J.; Hjort, J. Landforms contribute to plant biodiversity at alpha, beta and gamma levels. J. Biogeogr. 2019, 46, 1699–1710. [Google Scholar] [CrossRef]

- Sonter, L.J.; Ali, S.H.; Watson, J.E.M. Mining and biodiversity: Key issues and research needs in conservation science. Proc. R. Soc. B Biol. Sci. 2018, 285, 20181926. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Sillanpää, M.; Gjessing, E.T.; Peräniemi, S.; Vogt, R.D. Environmental impact of mining activities on the surface water quality in Tibet: Gyama valley. Sci. Total Environ. 2010, 408, 4177–4184. [Google Scholar] [CrossRef]

- Rigina, O. Environmental impact assessment of the mining and concentration activities in the kola peninsula, Russia by multidate remote sensing. Environ. Monit. Assess. 2002, 75, 11–31. [Google Scholar] [CrossRef]

- Sanmiquel, L.; Bascompta, M.; Vintró, C.; Yubero, T. Subsidence Management System for Underground Mining. Minerals 2018, 8, 243. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Han, C.; Li, P.; Zhang, J.; Liu, D.; Jiang, M.; Zheng, L.; Zhang, J.; Song, J. Quantitative prediction of mining subsidence and its impact on the environment. Int. J. Min. Sci. Technol. 2012, 22, 69–73. [Google Scholar] [CrossRef]

- Ishchenko, M. Mining and beneficiation companies liabilities figures correction. Econ. Ann.-XXI 2013, 11–12, 58–61. [Google Scholar]

- Cardoso, A. Behind the life cycle of coal: Socio-environmental liabilities of coal mining in Cesar, Colombia. Ecol. Econ. 2015, 120, 71–82. [Google Scholar] [CrossRef]

- Burger-Helmchen, T.; Siegel Erica, J. Some thoughts On CSR in relation to B Corp Labels. Entrep. Res. J. 2020, 10, 1–19. [Google Scholar] [CrossRef]

| Rating | Description |

|---|---|

| 1 | Less than 20% of the sections/departments |

| 2 | 20% to 40% of the sections/departments |

| 3 | 40% to 60% of the sections/departments |

| 4 | 60% to 80% of the sections/departments |

| 5 | More than 80% of the sections/departments |

| Rating | Description |

|---|---|

| 1 | In less than 20% of the sections/departments |

| 2 | Between 20% and 40% of the sections/departments |

| 3 | More than 80% of the sections/departments |

| 4 | Between 60% and 80% of the sections/departments |

| 5 | Between 40% and 60% of the sections/departments |

| Rating | Description |

|---|---|

| 1 | 10% to 20% of the mine site |

| 2 | 20% to 40% of the mine site |

| 3 | 40% to 60% of the mine site |

| 4 | 60% to 80% of the mine site |

| 5 | Higher than 80% of the mine site |

| Rating | Description |

|---|---|

| 1 | Between 20% and 40% of the mine site |

| 2 | Between 40% and 60% of the mine site |

| 3 | More than 60% of the mine site |

| 4 | N/D |

| 5 | N/D |

| Rating | Description |

|---|---|

| 1 | Less than 20% of the intermediary staff and technical and senior positions are local, regional or national |

| 2 | Between 20% and 40% of the intermediary staff and technical and senior positions are local, regional or national |

| 3 | Between 40% and 60% of the intermediary staff and technical and senior positions are local, regional or national |

| 4 | Between 60% and 80% of the intermediary staff and technical and senior positions are local, regional or national |

| 5 | More than 80% of the intermediary staff and technical and senior positions are local, regional or national |

| Rating | Description |

|---|---|

| 1 | Non-improvement or difference with respect to the previous mine site construction or expansion. No deterioration either |

| 2 | Slight improvement in the current infrastructure in any level (local, regional or national). Such as the creation of schools, hospitals, improvement of the current roads or railway |

| 3 | Improvements in the infrastructure system or creation of new infrastructures (with a positive impact on any level local, regional or national), useful to boost the economy |

| 4 | Important improvements or new infrastructures that have a positive impact in more than one level (local, regional or national), boosting the economy and creating emerging economic changes |

| 5 | Crucial improvements or new infrastructures that have a positive impact in all the levels (local, regional or national), that can also modify and boost the economy in the long term |

| Rating | Description |

|---|---|

| 1 | Obtaining a refined product that requires additional processes, but it has higher added value than the mineral concentrate. Process done in the same region or nation |

| 2 | Final product sold to another industry as a raw material or with the whole metallurgic process done in the same nation of the mine site, but far from it |

| 3 | Final product sold to another industry as a raw material or with the whole metallurgic process done in the same nation of the mine site, but far from it. Moreover, the product created is a raw material crucial for the development of the national industry, or supranational organizations such as the EU |

| 4 | Final product sold to another industry as a raw material or with the whole metallurgic process done in the regional area of the mine site. Moreover, the product created is a raw material crucial for the development of the national industry, or supranational organizations such as the EU |

| 5 | All the requirements of the previous point are met and, in addition, it is essential for the sustainable development of society |

| Rating | Description |

|---|---|

| 1 | Less than 20% of mine expenditure in R&D projects and specialized training in national universities and research centres |

| 2 | Between 20% and 40% of mine expenditure in R&D projects and specialized training in national universities and research centres |

| 3 | Between 40% and 60% of mine expenditure in R&D projects and specialized training in national universities and research centres |

| 4 | Between 60% and 80% of mine expenditure in R&D projects and specialized training in national universities and research centres |

| 5 | More than 80% of mine expenditure in R&D projects and specialized training in national universities and research centres |

| Rating | Description |

|---|---|

| 1 | N/D |

| 2 | Small impact: it partially jeopardizes the socioeconomic way of living during all the mine life, without having an equivalent option aside from the mining activity. Considering that the quantity of families affected is lower than 25% of the local employment created by the mine |

| 3 | Medium impact: it jeopardizes the socioeconomic way of living during all the mine life, without having an equivalent option aside from the mining activity of less than 25% or it partially jeopardize the socioeconomic way of living during all the mine life between 25–50% of the local employment created by the mine |

| 4 | Large impact: it jeopardizes the socioeconomic way of living during all the mine life, without having an equivalent way of living aside from the mining activity. Considering that the quantity of families affected is between 25–50% of the local employment created by the mine |

| 5 | Extremely large impact: it jeopardizes the socioeconomic way of living in the long term, even after the closure, without having an equivalent way of living aside from the mining activity. Considering that the quantity of families affected is, at least, 25% of the local employment created by the mine |

| Rating | Description |

|---|---|

| 1 | At least one additional element |

| 2 | Two additional elements |

| 3 | Three additional elements |

| 4 | Four additional elements |

| 5 | Five or more additional elements |

| Rating | Description |

|---|---|

| 1 | Slight added long-term value |

| 2 | Moderate added long-term value |

| 3 | High added long-term value |

| 4 | High added long-term value, with a partial synergy with the specific context |

| 5 | High added long-term value, with an important synergy with the specific context |

| Rating | Description |

|---|---|

| 1 | Only present in up to 20% of the mining operations |

| 2 | 20% to 40% of the mining operations |

| 3 | 40% to 60% of the mining operations |

| 4 | 60% to 80% of the mining operations |

| 5 | More than 80% of the mining operations |

| Rating | Description |

|---|---|

| 1 | Up to 20% of the mining operations |

| 2 | 20% to 40% of the mining operations |

| 3 | 40% to 60% of the mining operations |

| 4 | 60% to 80% of the mining operations |

| 5 | More than 80% of the mining operations |

| Rating | Description |

|---|---|

| 1 | Green energy used in up to 20% of the fleet |

| 2 | Green energy used between 20% to 40% of the fleet |

| 3 | Green energy used between 40% to 60% of the fleet |

| 4 | Green energy used between 60% to 80% of the fleet |

| 5 | Green energy used in more than 80% of the fleet |

| Rating | Description |

|---|---|

| 1 | 8–10 times higher |

| 2 | 6–8 times higher |

| 3 | 4–6 times higher |

| 4 | 2–4 times higher |

| 5 | up to 2 times higher |

| Rating | Description |

|---|---|

| 1 | Up to 10% of the total volume |

| 2 | 10% to 20% of the total volume |

| 3 | 20% to 35% of the total volume |

| 4 | 35% to 50% of the total volume |

| 5 | More than 50% of the total volume |

| Rating | Description |

|---|---|

| 1 | Up to 20% of the total volume used |

| 2 | 20% to 40% of the total volume used |

| 3 | 40% to 60% of the total volume used |

| 4 | 60% to 80% of the total volume used |

| 5 | More than 80% of the total volume used |

| Rating | Description |

|---|---|

| 1 | Reduced up to 20% compared to the mean value of the industry |

| 2 | Reduced between 20% and 40% compared to the mean value of the industry |

| 3 | Reduced between 40% and 60% compared to the mean value of the industry |

| 4 | Reduced between 60% and 80% compared to the mean value of the industry |

| 5 | Reduced more than 80% compared to the mean value of the industry |

| Rating | Description |

|---|---|

| 1 | Increased up to 20% compared to the mean value of the industry |

| 2 | Increased between 20% and 40% compared to the mean value of the industry |

| 3 | Increased between 20% and 40% compared to the mean value of the industry |

| 4 | Increased between 40% and 60% compared to the mean value of the industry |

| 5 | Increased more than 80% compared to the mean value of the industry |

| Rating | Description |

|---|---|

| 1 | Up to 20% of the total amount |

| 2 | 20% to 40% of the total amount |

| 3 | 40% to 60% of the total amount |

| 4 | 60% to 80% of the total amount |

| 5 | More than 80% of the total amount |

| Rating | Description |

|---|---|

| 1 | Water characteristics variation lower than 10% with respect to the upstream conditions |

| 2 | Water characteristics variation between 10% to 20% with respect to the upstream conditions |

| 3 | Water characteristics variation between 20% to 30% with respect to the upstream conditions |

| 4 | Water characteristics variation between 20% to 30% with respect to the upstream conditions |

| 5 | Water characteristics variation higher than 30% with respect to the upstream conditions |

| Rating | Description |

|---|---|

| 1 | Up to 20% reuse |

| 2 | Between 20% and 40% |

| 3 | Between 40% and 60% |

| 4 | Between 60% and 80% |

| 5 | Higher than 80% |

| Rating | Description |

|---|---|

| 1 | 60 to 100% waterflow reduction between previous conditions and the minimum ecological river flow |

| 2 | 35 to 60% waterflow reduction between previous conditions and the minimum ecological river flow |

| 3 | 20 to 35% waterflow reduction between previous conditions and the minimum ecological river flow |

| 4 | 10 to 20% waterflow reduction between previous conditions and the minimum ecological river flow |

| 5 | No appreciable/minor variation from the previous waterflow |

| Rating | Description |

|---|---|

| 1 | 0 to 20% of the difference between previous air quality and the maximum admissible |

| 2 | 20 to 40% of the difference between previous air quality and the maximum admissible |

| 3 | 40 to 60% of the difference between previous air quality and the maximum admissible |

| 4 | 60 to 80% of the difference between previous air quality and the maximum admissible |

| 5 | Higher than 80% of the difference between previous air quality and the maximum admissible |

| Rating | Description |

|---|---|

| 1 | Small impact: Modifications of the land form, affecting less than 20% of the land used by the mine, recovering it after the mine life time or having an equivalent landform |

| 2 | Medium impact: Modifications of the land form, affecting between 20% to 40% of the land used by the mine, recovering it after the mine life time or having an equivalent landform |

| 3 | Important impact: Modifications of the land form, affecting more than 40% of the land used by the mine, recovering it after the mine life time or having an equivalent landform |

| 4 | Very important impact: Modifications of the land form, affecting more than 60% of the land used by the mine, recovering it after the mine life time or having an equivalent landform |

| 5 | Extremely important impact: Modifications of the land form, affecting more than 60% of the land used by the mine, without full recovery after the mine life time or having an equivalent landform |

| Rating | Description |

|---|---|

| 1 | Slight biodiversity loss during the mining activity. |

| 2 | Moderate biodiversity loss during the mining activity. |

| 3 | Important biodiversity loss during the mining activity. |

| 4 | Very important biodiversity loss during the mining activity. |

| 5 | Extremely important loss of biodiversity, not totally recovered after the mine reclamation process. |

| Rating | Description |

|---|---|

| 1 | Slightly better |

| 2 | Moderately better |

| 3 | Better |

| 4 | Much Better |

| 5 | Extremely better |

| Rating | Description |

|---|---|

| 1 | Less than 20% of the area affected during the extraction stage |

| 2 | Between 20% and 40% of the area affected during the extraction stage |

| 3 | Between 40% and 60% of the area affected during the extraction stage |

| 4 | Between 60% and 80% of the area affected during the extraction stage |

| 5 | More than 80% of the area affected during the extraction stage |

| Rating | Description |

|---|---|

| 1 | Small impact. The potential risk does not affect the characteristics of the environment in the long term and can be easily amended |

| 2 | Medium impact: The potential risk does not affect the characteristics of the environment in the long term, but could require large amounts of money to repair it |

| 3 | Important impact: The potential risk could affect the characteristics of the environment in the long term and the way of living of the surrounding communities. Moreover, it could require large amounts of money to repair it |

| 4 | Very important impact: The potential risk could affect the characteristics of the environment in the long term and the way of living of the surrounding communities and at national or international scale. Moreover, it could require large amounts of money to repair it |

| 5 | Extremely important impact: The potential risk could affect the characteristics of the environment in the long term and the way of living of the surrounding communities and at national or international scale. Moreover, there is a high possibility that it could not be repaired, even with large amounts of money |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bascompta, M.; Sanmiquel, L.; Vintró, C.; Yousefian, M. Corporate Social Responsibility Index for Mine Sites. Sustainability 2022, 14, 13570. https://doi.org/10.3390/su142013570

Bascompta M, Sanmiquel L, Vintró C, Yousefian M. Corporate Social Responsibility Index for Mine Sites. Sustainability. 2022; 14(20):13570. https://doi.org/10.3390/su142013570

Chicago/Turabian StyleBascompta, Marc, Lluís Sanmiquel, Carla Vintró, and Mohammad Yousefian. 2022. "Corporate Social Responsibility Index for Mine Sites" Sustainability 14, no. 20: 13570. https://doi.org/10.3390/su142013570

APA StyleBascompta, M., Sanmiquel, L., Vintró, C., & Yousefian, M. (2022). Corporate Social Responsibility Index for Mine Sites. Sustainability, 14(20), 13570. https://doi.org/10.3390/su142013570