Optimal Multi-Objective Power Scheduling of a Residential Microgrid Considering Renewable Sources and Demand Response Technique

Abstract

:1. Introduction

1.1. Greenhouse Gas Emissions

1.2. Renewable Energy

1.3. Microgrid

1.4. Motivations

1.5. Demand Response

1.6. Related Literature

1.7. Paper Contribution

- Multi-objective optimal power scheduling of a residential microgrid considering revenues and productivity maximization of the microgrid using seawater electrolyzer and biomass generation.

- The effects of load shifting techniques on reducing maximum demand and the grid’s power consumption, microgrid configuration, and emissions.

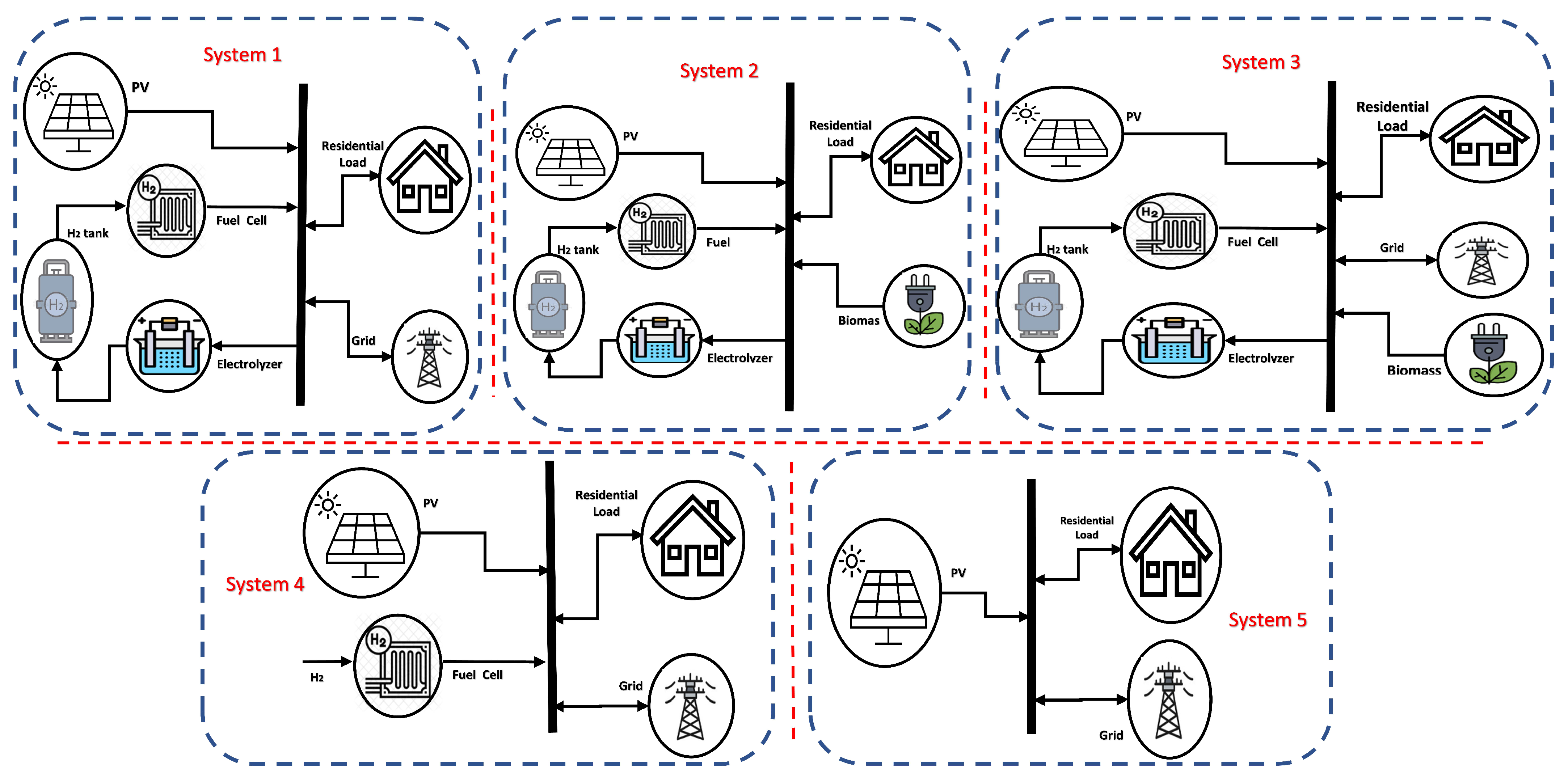

- Introducing a comparison between different configurations for system design to demonstrate the feasibility and productivity of the used technologies.

1.8. Paper Construction

2. Microgrid Modeling

2.1. Photovoltaic (PV) Modeling

2.2. Fuel Cell (FC) Modeling

2.3. Sea Water Electrolyzer Modeling

2.4. Electric Utility

2.5. Biomass Modeling

3. Demand Response

3.1. Time-of-Use (ToU) Demand Response

Elasticity Model

4. Objective Function

5. Constraints

6. Multi-Objective Genetic Algorithm (MOGA)

- Stage 1 (Initialization): generate an initial population.

- Stage 2 (Evaluation): calculate the values of the objective functions for the created population.

- Stage 3 (Selection): use random weights to determine each population’s fitness value; then, pick a pair of strings from the existing population.

- Stage 4 (Crossover and Mutation): a crossover strategy is implemented for each chosen pair to produce a new population via the crossover process; after that, the mutation process is carried out.

- Stage 5 (Elitist): delete some strings of created strings haphazardly and substitute them with elite strings picked at random from temporary Pareto optimal solutions.

- Stage 6 (Termination): if the stopping requirement is not satisfied, go to Stage 2.

- Stage 7 (Optimal Solution): the MOGA suggests the preferable options.

7. Results and Discussion

- By taking scenario 5 as a reference case study because it is the simplest system configuration with the minimum number of generating units, the FC integration with sea water electrolyzer and tanks reduces the system emissions by around 40% and slightly increases the cost by USD 0.093 million.

- If the microgrid that uses FC does not produce its own , its cost is increased due to the cost of purchasing . As seen from scenario 4’s results, its cost is greater than scenario 1’s cost by USD 0.246 million; the CO emissions are also higher by 150.6 kg/day.

- Relying on biomass has a great impact on cost and emissions. If biomass energy is used instead of depending on public grid power, the cost is decreased by 37.9%, as noticed by comparing scenarios 1 and 2. If both biomass power and electric utility are utilized in a hybrid microgrid as in scenario 3, the system has the lowest total cost of USD 1.186 million due to selling power back to the grid. Systems with biomass have zero emissions as they replace grid power use.

- The grid power share is decreased by using biomass energy and FC; it reached zero by integrating biomass energy units. It decreased by 6% and 10% when comparing scenario 5 with scenarios 4 and 1.

- Scenario 5 is the worst system configuration; it emits the highest emissions of 954.095 kg of CO per day. Scenario 4 has the highest system cost and a great amount of CO emissions, with roughly about 722.356 kg/day.

- By comparing the systems that have storage tanks (1, 2, and 3), scenario 1 has the largest storage tank capacity as it has the largest fuel cell capacity of 184 kW with a power share percentage of more than 10%, as clarified in Figure 9. Scenario 2 has the largest EL capacity of 701 kW as it produces more chemical substances and hydrogen to increase revenue and decrease the system cost, as there is no revenue from the grid in this scenario.

- In all the studied scenarios, the PV capacity ranges from 830 kW to 1000 kW. It provides more than 70% of the required power; the remaining percentage comes from the public grid, biomass, or stored energy in FC.

- The incorporation of biomass power decreases the dependence of FC; it reduces the FC energy share by around 50% by comparing scenario 1 and scenario 2.

- In scenario 3, the grid-connectivity is considered as a revenue tool to sell extra power back to the grid. It is regarded as a semi-grid-connected microgrid. Using seawater electrolyzers ensures the generation of the system’s required .

- In scenario 3, the integration of biomass with EL and tank reduces the dependence on fuel cell; the capacity of the fuel cell is reduced to 30 kW.

- Systems with seawater electrolyzers have the lowest CO emissions. They reach 571.752 kg/day for systems without biomass energy.

- The electrolyzing process is regarded not only as a means of producing hydrogen but also as a means of increasing system income. System productivity can be increased by selling extra power back to the public grid and selling NACLO and extra produced from the electrolyzing process.

- Scenario 1 has a total system cost of USD 3.672 million with 571.752 kg of CO emissions per day. By introducing biomass, both the emissions and the cost are enhanced. The cost is reduced by USD 1.394 million in scenario 2 and by USD 2.486 million in scenario 3 when compared with scenario 1.

- All systems create revenues of more than USD 4 million. Scenarios 1 and 2 have the highest revenues of USD 4.47 million and USD 4.34 million, respectively.

- The revenues from selling extra power back to the grid are decreased by introducing biomass to the system, in addition to the increase in selling chemical products and hydrogen produced from the seawater electrolyzer, as in scenario 3.

- Without seawater electrolyzers, the revenues are only from selling power back to the public grid or nearby microgrids.

- Demand response programs reshape the load patterns by shifting a portion of off-peak load, which is usually at night, to other periods. Biomass unit capacity is reduced by applying demand response as it is always used at night; it is reduced by 12.5% and 12.9% for scenarios 2 and 3.

- By applying demand response schemes, the load curve is modified; the peak load is reduced by 10.88%, as seen in Figure 11.

- The microgrids’ overall cost and CO emissions are decreased with time-of-use demand response.

- In most studied cases, the total system cost is reduced by TOU-DR with different values within USD 0.356 million, as in scenario 5, and USD 0.277 million, as in scenario 2.

- The CO emissions are reduced by 63.658, 20.763, and 71.819 kg/day for scenarios 1, 4, and 5, respectively. The maximum value of the grid’s purchased power is decreased by 13.71%, 8.6%, and 10.88% for scenarios 1, 4, and 5, respectively.

- For scenarios without biomass, the FC capacity is decreased by applying DR schemes, while it is slightly increased for scenarios with biomass units to manage the decrease in biomass capacity.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| GHGS | Greenhouse gas emissions |

| ESS | Energy storage system |

| HRES | Hybrid renewable energy systems |

| MBA | Modified bat algorithm |

| GOA | Grasshopper optimization |

| DR | Demand response |

| PV | Photovoltaic |

| The PV’s efficiency | |

| The PV’s rated capacity | |

| The incident solar radiation | |

| Solar radiation at the stc | |

| The capital cost of FC | |

| The investment cost of FC | |

| FC capacity | |

| Operating and maintenance cost of FC | |

| The annual operating and maintenance cost | |

| The escalation rate | |

| Interest rate | |

| N | The project lifetime |

| The grid cost | |

| Unit power purchasing price | |

| Purchased power | |

| Unit power selling price | |

| The sold power | |

| The biomass calorific valve | |

| The biogas overall conversion efficiency | |

| The annual fixed operation and maintenance cost of biogas generator (USD/kW/year) | |

| The power produced by biogas generator | |

| The interest rate | |

| The escalation rate | |

| The variable operation and maintenance cost of biogas generator (USD/kWh) | |

| The annual working power of biogas generator (kWh/year) | |

| The biomass fuel cost (USD/ton) | |

| The annual required biomass fuel (ton/year) | |

| The initial cost of biogas system (USD/kW) | |

| The resale price of the system (USD/kW) | |

| The inflation rate | |

| FC | Fuel cell |

| ToU | Time of use |

| El | Price elasticity of electrical demand |

| The electricity price | |

| The initial load demand | |

| The nominal price | |

| d | The load demand |

| The cross elasticity | |

| The customer benefits | |

| The total generated power | |

| PV cost | |

| Fuel cell cost | |

| Electrolyzer cost | |

| Grid cost | |

| Total biomass cost | |

| System’s revenue | |

| LoPS | Loss of power supply probability |

| Load power | |

| PV power | |

| FC power | |

| Biomass power | |

| Grid’s purchased power | |

| Grid’s sold power | |

| Electrolyzer power | |

| Grid power |

Appendix A

| Component and Economic Specification | ||

| Discount rate (r) | 5% | |

| Escalation rate | 7% | |

| PV Module | ||

| Investment cost | 1690 | USD/kW |

| Maintenance | 26 | USD/kW/yr |

| (PV) reduction factor | 84% | |

| lifetime | 25 | years |

| Biomass generator | ||

| Capital cost | 4500 | USD/kW |

| Operating and Maintenance | 0.03 | USD/kWh |

| Feedstock cost | 0.02 | USD/kWh |

| Calorific value | 14.5 | MJ·kg |

| Electrical conversion efficiency () | 0.3 | |

| Fuel cell | ||

| Capital cost | 2000 | USD/kW |

| Operating and Maintenance | 100 | USD/kW/yr |

| Replacement cost | 1500 | USD/kW |

| Efficiency | 0.5 | |

| H to kW | 0.6 | kWhNm |

| Electrolyzer | ||

| Capital cost | 1500 | USD/kW |

| Operating and Maintenance | 15 | USD/kW/yr |

| Replacement cost | 1500 | USD/kW |

| Efficiency | 0.9 | |

| kW to H | 0.09 | NmkWh |

| Final hydrogen pressure | 20 | MPa |

| Tank | ||

| Capital cost | 500 | USD/kg |

| Operating and Maintenance | 5 | USD/kg/yr |

References

- Amagai, K.; Takarada, T.; Funatsu, M.; Nezu, K. Development of low-CO2-emission vehicles and utilization of local renewable energy for the vitalization of rural areas in Japan. IATSS Res. 2014, 37, 81–88. [Google Scholar] [CrossRef] [Green Version]

- Deng, X.; Lv, T. Power system planning with increasing variable renewable energy: A review of optimization models. J. Clean. Prod. 2020, 246, 118962. [Google Scholar] [CrossRef]

- Dong, Y.; Shimada, K. Evolution from the renewable portfolio standards to feed-in tariff for the deployment of renewable energy in Japan. Renew. Energy 2017, 107, 590–596. [Google Scholar] [CrossRef]

- Yao, S.; Zhang, S.; Zhang, X. Renewable energy, carbon emission and economic growth: A revised environmental Kuznets Curve perspective. J. Clean. Prod. 2019, 235, 1338–1352. [Google Scholar] [CrossRef]

- Esteban, M.; Zhang, Q.; Utama, A. Estimation of the energy storage requirement of a future 100% renewable energy system in Japan. Energy Policy 2012, 47, 22–31. [Google Scholar] [CrossRef]

- Twidell, J.; Weir, T. Renewable Energy Resources; Routledge: London, UK, 2015. [Google Scholar]

- Panwar, N.; Kaushik, S.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Ullah, S.; Haidar, A.M.; Hoole, P.; Zen, H.; Ahfock, T. The current state of Distributed Renewable Generation, challenges of interconnection and opportunities for energy conversion based DC microgrids. J. Clean. Prod. 2020, 273, 122777. [Google Scholar] [CrossRef]

- Lehtveer, M.; Fridahl, M. Managing variable renewables with biomass in the European electricity system: Emission targets and investment preferences. Energy 2020, 213, 118786. [Google Scholar] [CrossRef]

- Jimenez, O.; Curbelo, A.; Suarez, Y. Biomass based gasifier for providing electricity and thermal energy to off-grid locations in Cuba. Conceptual design. Energy Sustain. Dev. 2012, 16, 98–102. [Google Scholar] [CrossRef]

- Stadler, M.; Cardoso, G.; Mashayekh, S.; Forget, T.; DeForest, N.; Agarwal, A.; Schönbein, A. Value streams in microgrids: A literature review. Appl. Energy 2016, 162, 980–989. [Google Scholar] [CrossRef]

- Masrur, H.; Senjyu, T.; Islam, M.R.; Kouzani, A.Z.; Mahmud, M.P. Resilience-oriented dispatch of microgrids considering grid interruptions. IEEE Trans. Appl. Supercond. 2021, 31, 1–5. [Google Scholar] [CrossRef]

- Siwal, S.S.; Thakur, S.; Zhang, Q.; Thakur, V.K. Electrocatalysts for electrooxidation of direct alcohol fuel cell: Chemistry and applications. Mater. Today Chem. 2019, 14, 100182. [Google Scholar] [CrossRef]

- Asokan, K.; Subramanian, K. Design of a tank electrolyser for in-situ generation of NaClO. In Proceedings of the World Congress on Engineering and Computer Science, San Francisco, CA, USA, 20–22 October 2009; Volume 1, pp. 139–142. [Google Scholar]

- Gad, Y.; Diab, H.; Abdelsalam, M.; Galal, Y. Smart Energy Management System of Environmentally Friendly Microgrid Based on Grasshopper Optimization Technique. Energies 2020, 13, 5000. [Google Scholar] [CrossRef]

- Talaat, M.; Alsayyari, A.S.; Alblawi, A.; Hatata, A. Hybrid-cloud-based data processing for power system monitoring in smart grids. Sustain. Cities Soc. 2020, 55, 102049. [Google Scholar] [CrossRef]

- Balijepalli, V.M.; Pradhan, V.; Khaparde, S.A.; Shereef, R. Review of demand response under smart grid paradigm. In Proceedings of the ISGT2011-India, Kollam, India, 1–3 December 2011; pp. 236–243. [Google Scholar]

- Gao, J.; Ma, Z.; Guo, F. The influence of demand response on wind-integrated power system considering participation of the demand side. Energy 2019, 178, 723–738. [Google Scholar] [CrossRef]

- Cagnano, A.; De Tuglie, E.; Mancarella, P. Microgrids: Overview and guidelines for practical implementations and operation. Appl. Energy 2020, 258, 114039. [Google Scholar] [CrossRef]

- Alsaidan, I.; Alanazi, A.; Gao, W.; Wu, H.; Khodaei, A. State-of-the-art in microgrid-integrated distributed energy storage sizing. Energies 2017, 10, 1421. [Google Scholar] [CrossRef] [Green Version]

- Bukar, A.L.; Tan, C.W.; Lau, K.Y. Optimal sizing of an autonomous photovoltaic/wind/battery/diesel generator microgrid using grasshopper optimization algorithm. Sol. Energy 2019, 188, 685–696. [Google Scholar] [CrossRef]

- Nurunnabi, M.; Roy, N.K.; Pota, H.R. Optimal sizing of grid-tied hybrid renewable energy systems considering inverter to PV ratio—A case study. J. Renew. Sustain. Energy 2019, 11, 013505. [Google Scholar] [CrossRef]

- Logenthiran, T.; Srinivasan, D. Optimal selection and sizing of distributed energy resources for distributed power systems. J. Renew. Sustain. Energy 2012, 4, 053119. [Google Scholar] [CrossRef]

- Saiprasad, N.; Kalam, A.; Zayegh, A. Triple bottom line analysis and optimum sizing of renewable energy using improved hybrid optimization employing the genetic algorithm: A case study from India. Energies 2019, 12, 349. [Google Scholar] [CrossRef] [Green Version]

- Ecike, D. Using microgrids featuring PV panels and batteries connected to the grid to improve the reliability of a low-voltage feeder in Kinshasa. Energy Procedia 2019, 159, 117–122. [Google Scholar] [CrossRef]

- Luo, L.; Abdulkareem, S.S.; Rezvani, A.; Miveh, M.R.; Samad, S.; Aljojo, N.; Pazhoohesh, M. Optimal scheduling of a renewable based microgrid considering photovoltaic system and battery energy storage under uncertainty. J. Energy Storage 2020, 28, 101306. [Google Scholar] [CrossRef]

- Singh, S.; Slowik, A.; Kanwar, N.; Meena, N.K. Techno-Economic Feasibility Analysis of Grid-Connected Microgrid Design by Using a Modified Multi-Strategy Fusion Artificial Bee Colony Algorithm. Energies 2021, 14, 190. [Google Scholar] [CrossRef]

- Li, S.; Shi, L.; Yao, Z. multi-objective optimal scheduling of microgrid considering distributed generation uncertainty. In Proceedings of the 10th Renewable Power Generation Conference (RPG 2021), Online, 14–15 October 2021; pp. 35–43. [Google Scholar]

- Barik, A.K.; Das, D.C. Integrated resource planning in sustainable energy-based distributed microgrids. Sustain. Energy Technol. Assess. 2021, 48, 101622. [Google Scholar] [CrossRef]

- Chen, H.; Gao, L.; Zhang, Z. Multi-objective optimal scheduling of a microgrid with uncertainties of renewable power generation considering user satisfaction. Int. J. Electr. Power Energy Syst. 2021, 131, 107142. [Google Scholar] [CrossRef]

- Yang, M.; Cui, Y.; Wang, J. Multi-Objective optimal scheduling of island microgrids considering the uncertainty of renewable energy output. Int. J. Electr. Power Energy Syst. 2023, 144, 108619. [Google Scholar] [CrossRef]

- Zakir, M.; Arshad, A.; Sher, H.A.; Lehtonen, M. An Optimal Power Management System Based on Load Demand and Resources Availability for PV Fed DC-Microgrid with Power-Sharing among Multiple Nanogrids. In Proceedings of the 2021 IEEE PES Innovative Smart Grid Technologies Europe (ISGT Europe), Espoo, Finland, 18–21 October 2021; pp. 1–5. [Google Scholar]

- Sibtain, D.; Murtaza, A.F.; Ahmed, N.; Sher, H.A.; Gulzar, M.M. Multi control adaptive fractional order PID control approach for PV/wind connected grid system. Int. Trans. Electr. Energy Syst. 2021, 31, e12809. [Google Scholar] [CrossRef]

- Sediqi, M.M.; Howlader, H.O.R.; Ibrahimi, A.M.; Danish, M.S.S.; Sabory, N.R.; Senjyu, T. Development of renewable energy resources in Afghanistan for economically optimized cross-border electricity trading. Aims Energy 2017, 5, 691–717. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Z.; Zhong, Z. CO2 emissions, economic growth, renewable and non-renewable energy production and foreign trade in China. Renew. Energy 2019, 131, 208–216. [Google Scholar] [CrossRef]

- Uddin, M.; Taweekun, J.; Techato, K.; Rahman, M.; Mofijur, M.; Rasul, M. Sustainable biomass as an alternative energy source: Bangladesh perspective. Energy Procedia 2019, 160, 648–654. [Google Scholar] [CrossRef]

- Kyriakopoulos, G.L.; Arabatzis, G.; Chalikias, M. Renewables exploitation for energy production and biomass use for electricity generation. AIMS Energy 2016, 4, 762–803. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, A.; Long, B. Energy from combustion of rice straw: Status and challenges to China. Energy Power Eng. 2011, 3, 325. [Google Scholar] [CrossRef] [Green Version]

- Elmouatamid, A.; Ouladsine, R.; Bakhouya, M.; El Kamoun, N.; Khaidar, M.; Zine-Dine, K. Review of Control and Energy Management Approaches in Micro-Grid Systems. Energies 2021, 14, 168. [Google Scholar] [CrossRef]

- Tabar, V.S.; Abbasi, V. Energy management in microgrid with considering high penetration of renewable resources and surplus power generation problem. Energy 2019, 189, 116264. [Google Scholar] [CrossRef]

- Fukuzumi, S.; Lee, Y.M.; Nam, W. Fuel production from seawater and fuel cells using seawater. ChemSusChem 2017, 10, 4264–4276. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Srisiriwat, A.; Pirom, W. Feasibility study of seawater electrolysis for photovoltaic/fuel cell hybrid power system for the coastal areas in Thailand. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: London, UK, 2017; Volume 241, p. 012041. [Google Scholar]

- Morris, P.; Vine, D.; Buys, L. Residential consumer perspectives of effective peak electricity demand reduction interventions as an approach for low carbon communities. AIMS Energy 2016, 4, 536–556. [Google Scholar] [CrossRef] [Green Version]

- Harsh, P.; Das, D. Energy management in microgrid using incentive-based demand response and reconfigured network considering uncertainties in renewable energy sources. Sustain. Energy Technol. Assess. 2021, 46, 101225. [Google Scholar] [CrossRef]

- Jordehi, A.R. Optimisation of demand response in electric power systems, a review. Renew. Sustain. Energy Rev. 2019, 103, 308–319. [Google Scholar] [CrossRef]

- Davarzani, S.; Pisica, I.; Taylor, G.A.; Munisami, K.J. Residential Demand Response Strategies and Applications in Active Distribution Network Management. Renew. Sustain. Energy Rev. 2020, 138, 110567. [Google Scholar] [CrossRef]

- Patnam, B.S.K.; Pindoriya, N.M. Demand response in consumer-Centric electricity market: Mathematical models and optimization problems. Electr. Power Syst. Res. 2020, 193, 106923. [Google Scholar] [CrossRef]

- Yan, X.; Ozturk, Y.; Hu, Z.; Song, Y. A review on price-driven residential demand response. Renew. Sustain. Energy Rev. 2018, 96, 411–419. [Google Scholar] [CrossRef]

- Cardoso, C.A.; Torriti, J.; Lorincz, M. Making demand side response happen: A review of barriers in commercial and public organisations. Energy Res. Soc. Sci. 2020, 64, 101443. [Google Scholar] [CrossRef]

- Aalami, H.; Yousefi, G.; Moghadam, M.P. Demand response model considering EDRP and TOU programs. In Proceedings of the 2008 IEEE/PES Transmission and Distribution Conference and Exposition, Bogota, Colombia, 13–15 August 2008; pp. 1–6. [Google Scholar]

- Jalili, H.; Sheikh-El-Eslami, M.K.; Moghaddam, M.P.; Siano, P. Modeling of demand response programs based on market elasticity concept. J. Ambient Intell. Humaniz. Comput. 2019, 10, 2265–2276. [Google Scholar] [CrossRef]

- Nakabi, T.A.; Toivanen, P. Deep reinforcement learning for energy management in a microgrid with flexible demand. Sustain. Energy Grids Netw. 2021, 25, 100413. [Google Scholar] [CrossRef]

- El Mentaly, L.; Amghar, A.; Sahsah, H. The prediction of the maximum power of PV modules associated with a static converter under different environmental conditions. Mater. Today Proc. 2020, 24, 125–129. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Renewable Energy Outlook: Egypt; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2018. [Google Scholar]

- Gamil, M.M.; Senjyu, T.; Takahashi, H.; Hemeida, A.M.; Krishna, N.; Lotfy, M.E. Optimal multi-objective sizing of a residential microgrid in Egypt with different ToU demand response percentages. Sustain. Cities Soc. 2021, 75, 103293. [Google Scholar] [CrossRef]

- Guaitolini, S.V.M.; Yahyaoui, I.; Fardin, J.F.; Encarnação, L.F.; Tadeo, F. A review of fuel cell and energy cogeneration technologies. In Proceedings of the 2018 9th International Renewable Energy Congress (IREC), Hammamet, Tunisia, 20–22 March 2018; pp. 1–6. [Google Scholar]

- Abdel-Aal, H.; Zohdy, K.; Kareem, M.A. Hydrogen production using sea water electrolysis. Open Fuel Cells J. 2010, 3, 1–7. [Google Scholar] [CrossRef]

- Donado, K.; Navarro, L.; Quintero M, C.G.; Pardo, M. HYRES: A multi-objective optimization tool for proper configuration of renewable hybrid energy systems. Energies 2019, 13, 26. [Google Scholar] [CrossRef] [Green Version]

- Casson, L.W.; Bess, J.W. On-Site Sodium Hypochlorite Generation; Water Environment Federation: Alexandria, VA, USA, 2006; pp. 6335–6352. [Google Scholar]

- Amos, W.A. Costs of Storing and Transporting Hydrogen; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 1999. [Google Scholar]

- Li, Z.; Xu, Y. Optimal coordinated energy dispatch of a multi-energy microgrid in grid-connected and islanded modes. Appl. Energy 2018, 210, 974–986. [Google Scholar] [CrossRef]

- Hossain, M.A.; Pota, H.R.; Squartini, S.; Abdou, A.F. Modified PSO algorithm for real-time energy management in grid-connected microgrids. Renew. Energy 2019, 136, 746–757. [Google Scholar] [CrossRef]

- Singh, S.; Singh, M.; Kaushik, S.C. Feasibility study of an islanded microgrid in rural area consisting of PV, wind, biomass and battery energy storage system. Energy Convers. Manag. 2016, 128, 178–190. [Google Scholar] [CrossRef]

- Heydari, A.; Askarzadeh, A. Optimization of a biomass-based photovoltaic power plant for an off-grid application subject to loss of power supply probability concept. Appl. Energy 2016, 165, 601–611. [Google Scholar] [CrossRef]

- Kirschen, D.; Strbac, G. Fundamentals of Power System Economics; John Wiley & Sons Ltd.: Chichester, UK, 2004. [Google Scholar]

- Kiptoo, M.K.; Adewuyi, O.B.; Lotfy, M.E.; Senjyu, T.; Mandal, P.; Abdel-Akher, M. Multi-objective optimal capacity planning for 100% renewable energy-based microgrid incorporating cost of demand-side flexibility management. Appl. Sci. 2019, 9, 3855. [Google Scholar] [CrossRef] [Green Version]

- Aalami, H.; Moghaddam, M.P.; Yousefi, G. Demand response modeling considering interruptible/curtailable loads and capacity market programs. Appl. Energy 2010, 87, 243–250. [Google Scholar] [CrossRef]

- Conteh, A.; Lotfy, M.E.; Adewuyi, O.B.; Mandal, P.; Takahashi, H.; Senjyu, T. Demand Response Economic Assessment with the Integration of Renewable Energy for Developing Electricity Markets. Sustainability 2020, 12, 2653. [Google Scholar] [CrossRef]

- Murata, T.; Ishibuchi, H. MOGA: Multi-objective genetic algorithms. In Proceedings of the IEEE International Conference on Evolutionary Computation, Perth, Australia, 29 November–1 December 1995; IEEE: Piscataway, NJ, USA, 1995; pp. 289–294. [Google Scholar]

| Peak | Off-Peak | Low | |

|---|---|---|---|

| Peak | −0.1 | 0.016 | 0.012 |

| Off-Peak | 0.008 | −0.1 | 0.01 |

| Low | 0.006 | 0.008 | −0.1 |

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | |

|---|---|---|---|---|---|

| Cost (million USD) | 3.672 | 2.278 | 1.186 | 3.918 | 3.579 |

| CO emissions (kg/day) | 571.752 | 0 | 0 | 722.356 | 954.095 |

| PV capacity (kW) | 986.553 | 830.866 | 901.435 | 995.850 | 1000 |

| FC capacity (kW) | 184 | 66 | 30 | 97 | 0 |

| EL capacity (kW) | 294 | 701 | 336 | 0 | 0 |

| Tank capacity (kg) | 147.5 | 22 | 10 | 0 | 0 |

| Maximum grid power (kW) | 229.810 | 0 | 0 | 273.310 | 321.810 |

| Biomass capacity (kW) | 0 | 288.972 | 306.861 | 0 | 0 |

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | |

|---|---|---|---|---|---|

| Grid revenue | 2.104 | 0 | 1.469 | 4.232 | 4.253 |

| Electrolyzing process revenue | 2.366 | 4.182 | 2.875 | 0 | 0 |

| Case 1 | Case 2 | Case3 | Case4 | Case5 | |

|---|---|---|---|---|---|

| Cost (million USD) | 3.331 | 2.001 | 1.388 | 3.562 | 3.247 |

| CO emissions (kg/day) | 508.094 | 0 | 0 | 701.593 | 882.276 |

| PV capacity (kW) | 980.965 | 932.368 | 874.959 | 963.199 | 993.292 |

| FC capacity (kW) | 177 | 68 | 39 | 74 | 0 |

| EL capacity (kW) | 285 | 783 | 168 | 0 | 0 |

| Tank capacity (kg) | 147 | 23 | 83 | 0 | 0 |

| Maximum grid power (kW) | 198.297 | 0 | 0 | 249.797 | 286.797 |

| Biomass capacity (kW) | 0 | 252.934 | 267.413 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gamil, M.M.; Ueda, S.; Nakadomari, A.; Konneh, K.V.; Senjyu, T.; Hemeida, A.M.; Lotfy, M.E. Optimal Multi-Objective Power Scheduling of a Residential Microgrid Considering Renewable Sources and Demand Response Technique. Sustainability 2022, 14, 13709. https://doi.org/10.3390/su142113709

Gamil MM, Ueda S, Nakadomari A, Konneh KV, Senjyu T, Hemeida AM, Lotfy ME. Optimal Multi-Objective Power Scheduling of a Residential Microgrid Considering Renewable Sources and Demand Response Technique. Sustainability. 2022; 14(21):13709. https://doi.org/10.3390/su142113709

Chicago/Turabian StyleGamil, Mahmoud M., Soichirou Ueda, Akito Nakadomari, Keifa Vamba Konneh, Tomonobu Senjyu, Ashraf M. Hemeida, and Mohammed Elsayed Lotfy. 2022. "Optimal Multi-Objective Power Scheduling of a Residential Microgrid Considering Renewable Sources and Demand Response Technique" Sustainability 14, no. 21: 13709. https://doi.org/10.3390/su142113709

APA StyleGamil, M. M., Ueda, S., Nakadomari, A., Konneh, K. V., Senjyu, T., Hemeida, A. M., & Lotfy, M. E. (2022). Optimal Multi-Objective Power Scheduling of a Residential Microgrid Considering Renewable Sources and Demand Response Technique. Sustainability, 14(21), 13709. https://doi.org/10.3390/su142113709