Waste-to-Energy Generation: Complex Efficiency Analysis of Modern Technologies

Abstract

:1. Introduction

2. Critical Review of Energy from MSW Technologies

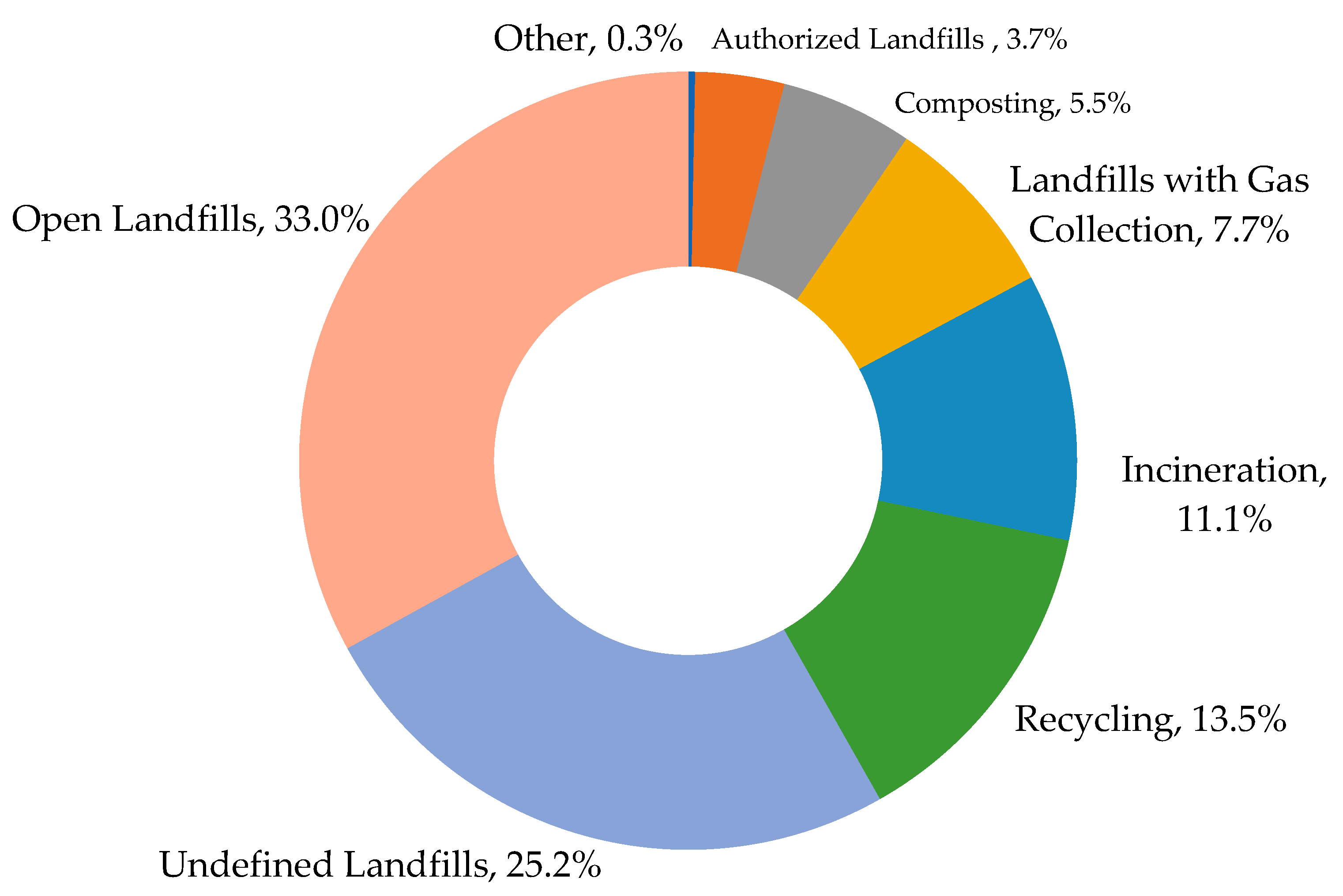

2.1. MSW Handling Methods

2.2. MSW Heat Treatment Types

2.2.1. Incineration

2.2.2. Gasification

2.2.3. Pyrolisys

3. Materials and Methods

3.1. Establishing the Dataset Frame

3.1.1. Economic Variables Defining

3.1.2. Environmental Variables Defining

- is imported energy (GJ/year);

- is energy consumed from fuels other than MSW (GJ/year);

- is energy from MSW (GJ/year);

- is the climate correction factor [35].

3.2. Collecting the Data

3.3. Preparing the Data

3.4. Assigning Weight to the BSC Parameters

4. Results and Discussion

4.1. Calculating Integral Efficiency Indicator

4.2. Comparative MSW Heat Methods Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Appendix A. A Set of Environmental Indicators for MSW Heat Treatment Enterprises

Appendix A.1. Enterprises’ Capacity and Efficiency Indicators

| Code | Type | Capacity | EER | HER | EE_EU |

|---|---|---|---|---|---|

| Efficiency | |||||

| - | categorical | tones annually | % | % | - |

| 567 | Pyrolysis | 287,000 | 22.0 | - | 0.8000 |

| 670 | Gasification | 193,675 | 27.4 | 61.4 | 0.9410 |

| 678 | Gasification | 374,000 | 47.0 | 45.0 | 0.9500 |

| 916 | Incineration moving grate | 500,000 | 24.2 | 5.5 | 0.8980 |

| 938 | Pyrolisys | 120,000 | 18.0 | - | 0.8000 |

| 1295 | Plasma Gasification | 193,450 | 23.0 | - | 0.6046 |

| 1876 | Pyrolisys | 1,000,000 | - | 70.0 | 0.8000 |

| 1961 | Incineration rotary kiln | 700,000 | 11.0 | 73.0 | 0.9100 |

| 1981 | Incineration rotary kiln | 182,500 | 13.0 | - | 0.9100 |

| 2117 | Incineration moving grate | 711,000 | 14.0 | 26.0 | 0.8980 |

| 2118 | Incineration fluidized bed | 75,000 | 15.0 | - | 0.6046 |

| 2119 | Incineration moving grate | 711,000 | 16.0 | 28.5 | 0.8980 |

| 2120 | Incineration rotary kiln | 365,000 | 20.0 | - | 0.9100 |

Appendix A.2. Enterprises’ Emissions Indicators

| Code | Dust | SO2 | NOx | CO | TOC | HCL | HF | Metals | Hg | PCDD/F | Cd |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Emissions | |||||||||||

| - | mg/m3 | mg/m3 | mg/m3 | mg/m3 | mg/m3 | mg/m3 | mg/m3 | mg/m3 | mg/m3 | ng TEQ/m3 | mg/Nm3 |

| 567 | 0.95 | 8.00 | 166.90 | 10.00 | 0.00 | 5.10 | 0.00 | 0.03 | 0.01 | 0.00 | 0.01 |

| 670 | 0.13 | 1.06 | 133.00 | 8.01 | 0.38 | 0.13 | 0.00 | 1.44 | 0.00 | 0.00 | 0.00 |

| 678 | 0.13 | 0.70 | 2.50 | 1.50 | 0.00 | 0.13 | 0.00 | 1.44 | 33.02 | 0.00 | 0.06 |

| 916 | 0.44 | 0.40 | 41.40 | 5.50 | 1.87 | 1.90 | 0.46 | 99.22 | 0.00 | 0.01 | 0.00 |

| 938 | 0.33 | 0.52 | 104.42 | 1.77 | 0.25 | 3.74 | 0.14 | 27.47 | 0.39 | 0.00 | 0.19 |

| 1295 | 6.80 | 3.30 | 20.90 | 6.20 | 4.00 | 3.70 | 0.03 | 45.00 | 0.02 | 0.01 | 0.14 |

| 1876 | 2.90 | 9.29 | 148.86 | 24.52 | 0.88 | 7.54 | 78.90 | 13.75 | 3.86 | 0.00 | 0.45 |

| 1961 | 9.10 | 18.09 | 2.60 | 2.10 | 0.00 | 3.87 | 7.40 | 1.00 | 0.01 | 0.00 | 0.00 |

| 1981 | 35.70 | 8.70 | 46.66 | 11.37 | 0.20 | 3.87 | 7.62 | 2500.00 | 76.40 | 0.00 | 0.18 |

| 2117 | 8.70 | 51.00 | 927.00 | 51.00 | 0.96 | 18.30 | 0.90 | 684.00 | 10.00 | 0.00 | 0.01 |

| 2118 | 4.86 | 49.20 | 106.00 | 95.20 | 1.44 | 4.85 | 0.26 | 289.89 | 9.55 | 0.00 | 0.00 |

| 2119 | 0.00 | 15.00 | 850.00 | 200.00 | 0.96 | 10.10 | 0.68 | 684.00 | 10.00 | 0.00 | 0.00 |

| 2120 | 1.14 | 10.11 | 10.04 | 0.84 | 9.70 | 3.87 | 7.62 | 1.00 | 0.01 | 0.00 | 0.00 |

Appendix A.3. Enterprises’ Life Cycle Assessment Indicators

| Code | GW | AC | TE | POFh | HTa | HTs | ETs |

|---|---|---|---|---|---|---|---|

| LCA | |||||||

| - | kg CO2-equivalent | m2 unprotected ecosystem | m2 unprotected ecosystem | pers·ppm·hour | m3 air | m3 solid | m3 solid |

| 567 | 0.0050 | −0.0200 | −0.0035 | −0.0050 | −0.0020 | 0.4000 | None |

| 670 | −0.0500 | −0.0300 | −0.0100 | −0.0250 | −0.0040 | 0.3500 | None |

| 678 | 0.6250 | −0.0300 | −0.0100 | −0.0250 | −0.0040 | 0.3500 | None |

| 916 | −0.0100 | −0.0220 | −0.0070 | −0.0100 | −0.0030 | 0.0030 | None |

| 938 | 0.0024 | 0.0375 | 0.0375 | 0.0022 | 0.0684 | 0.0108 | None |

| 1295 | 0.0100 | −0.0180 | −0.0070 | −0.0750 | −0.0030 | 0.0250 | None |

| 1876 | 0.0400 | −1.0000 | −0.0370 | −1.0000 | −0.0450 | −0.0450 | None |

| 1961 | 0.6000 | 0.2188 | −0.0022 | 0.4520 | 0.0004 | 0.1117 | 0.000 |

| 1981 | 0.1393 | 0.4386 | −0.0013 | 0.4520 | 0.0004 | 0.1117 | 0.000 |

| 2117 | 0.0020 | −0.0070 | 0.0070 | 0.0070 | 0.0020 | 0.0170 | 0.000 |

| 2118 | 0.0110 | −0.0004 | 0.0090 | 0.0150 | 0.0040 | 0.0160 | 0.000 |

| 2119 | −0.0550 | 0.0000 | −0.0007 | 0.0003 | −0.0097 | −0.0097 | 0.000 |

| 2120 | −0.0500 | −0.0010 | −0.0013 | 0.4520 | 0.0004 | 0.1117 | 0.000 |

| Source: Compiled by the authors. | |||||||

Appendix B. A Set of Economic Indicators for MSW Heat Treatment Enterprises

| Code | Revenue | Expenses | ROI | Diesel_ash | Electricity_ash | Pre-Treatment |

|---|---|---|---|---|---|---|

| - | $ | $ | % | L/ton | kWh/ton | Boolean |

| 567 | 23,312,999 | 19,696,453 | 18.36% | 3.25 | 1.34 | 1 |

| 670 | 17,042,511 | 11,965,864 | 42.43% | 3.28 | 2.95 | 1 |

| 678 | 285,115,060 | 220,217,540 | 29.47% | 0.16 | 0.42 | 1 |

| 916 | 11,934,736,600 | 10,459,041,400 | 14.11% | 1.10 | 1.24 | 0 |

| 938 | 5,890,380 | 4,236,940 | 39.02% | 0.16 | 0.42 | 1 |

| 1295 | 48,472,172,162 | 42,301,654,078 | 14.59% | 0.74 | 1.15 | 0 |

| 1876 | 127,750,000 | 110,250,000 | 15.87% | 0.16 | 0.42 | 1 |

| 1961 | 754,715,700 | 602,775,900 | 25.21% | 0.16 | 0.42 | 0 |

| 1981 | 2,257,940 | 2,171,926 | 3.96% | 11.00 | 0.42 | 0 |

| 2117 | 49,433,805 | 47,156,088 | 4.83% | 5.60 | 1.30 | 0 |

| 2118 | 5,123,081 | 3,534,616 | 44.94% | 2.30 | 2.40 | 1 |

| 2119 | 49,433,805 | 47,156,088 | 4.83% | 0.16 | 0.42 | 0 |

| 2120 | 347,728,766 | 300,000,000 | 15.91% | 0.16 | 0.42 | 0 |

| Source: Compiled by the authors. | ||||||

Appendix C. Integral Indicator of the Thermal Waste-to-Energy Technologies Environmental and Economic Efficiency Calculation Based on BSC

Appendix C.1. Incineration on a Mechanical Moving Grate Technology

| Analysis | Analysis Weight | Indicator | Indicator Weight | Value | Assessment |

| Economic | 0.50 | ROI | 0.40 | 0.0000 | 0.000 |

| Diesel_ash | 0.01 | 0.5099 | −0.005 | ||

| Electricity_ash | 0.01 | 0.2862 | −0.003 | ||

| Pre-treatment | 0.08 | 0 | 0.000 | ||

| Environmental_Capacity | 0.04 | Capacity | 0.04 | 1.0000 | 0.040 |

| Environmental_Efficiency | 0.12 | EER | 0.04 | 0.1509 | 0.006 |

| HER | 0.04 | 0.0000 | 0.000 | ||

| EE_EU | 0.04 | 0.8607 | 0.034 | ||

| Environmental_Emissions | 0.17 | Dust | 0.01545 | 0.1921 | −0.003 |

| SO2 | 0.01545 | 0.4398 | −0.007 | ||

| NOx | 0.01545 | 1.0000 | −0.015 | ||

| CO | 0.01545 | 0.8928 | −0.014 | ||

| TOC | 0.01545 | 0.2819 | −0.004 | ||

| HCL | 0.01545 | 1.0000 | −0.015 | ||

| HF | 0.01545 | 0.0258 | 0.000 | ||

| Metals | 0.01545 | 0.5857 | −0.009 | ||

| Hg | 0.01545 | 0.2611 | −0.004 | ||

| PCDD/F | 0.01545 | 0.3333 | −0.005 | ||

| Cd | 0.01545 | 0.0058 | 0.000 | ||

| Environmental_LCA | 0.17 | GW | 0.02429 | 0.0000 | 0.000 |

| AC | 0.02429 | 0.5818 | −0.014 | ||

| TE | 0.02429 | 0.5134 | −0.012 | ||

| POFh | 0.02429 | 0.4240 | −0.010 | ||

| HTa | 0.02429 | 0.0389 | −0.001 | ||

| HTs | 0.02429 | 0.0000 | 0.000 | ||

| ETs | 0.02429 | 1.0000 | −0.024 | ||

| SUM | 1.0 | 1.0 | −0.067 |

Appendix C.2. Incineration in a Rotary Kiln Technology

| Analysis | Analysis Weight | Indicator | Indicator Weight | Value | Assessment |

| Economic | 0.50 | ROI | 0.40 | 0.1919 | 0.077 |

| Diesel_ash | 0.01 | 1.0000 | −0.010 | ||

| Electricity_ash | 0.01 | 0.0000 | 0.000 | ||

| Pre-treatment | 0.08 | 0 | 0.000 | ||

| Environmental_Capacity | 0.04 | Capacity | 0.04 | 0.6025 | 0.024 |

| Environmental_Efficiency | 0.12 | EER | 0.04 | 0.0000 | 0.000 |

| HER | 0.04 | 1.0000 | 0.040 | ||

| EE_EU | 0.04 | 0.8959 | 0.036 | ||

| Environmental_Emissions | 0.17 | Dust | 0.01545 | 1.0000 | −0.015 |

| SO2 | 0.01545 | 0.2363 | −0.004 | ||

| NOx | 0.01545 | 0.0000 | 0.000 | ||

| CO | 0.01545 | 0.0002 | 0.000 | ||

| TOC | 0.01545 | 0.8164 | −0.013 | ||

| HCL | 0.01545 | 0.3750 | −0.006 | ||

| HF | 0.01545 | 0.2864 | −0.004 | ||

| Metals | 0.01545 | 1.0000 | −0.015 | ||

| Hg | 0.01545 | 1.0000 | −0.015 | ||

| PCDD/F | 0.01545 | 0.0092 | 0.000 | ||

| Cd | 0.01545 | 0.2714 | −0.004 | ||

| Environmental_LCA | 0.17 | GW | 0.02429 | 0.8129 | −0.020 |

| AC | 0.02429 | 1.0000 | −0.024 | ||

| TE | 0.02429 | 0.4424 | −0.011 | ||

| POFh | 0.02429 | 1.0000 | −0.024 | ||

| HTa | 0.02429 | 0.3925 | −0.010 | ||

| HTs | 0.02429 | 0.3124 | −0.008 | ||

| ETs | 0.02429 | 0.6667 | −0.016 | ||

| SUM | 1.0 | 1.0 | −0.023 |

Appendix C.3. Incineration in a Circulating Fluidized Bed Technology

| Analysis | Analysis Weight | Indicator | Indicator Weight | Value | Assessment |

|---|---|---|---|---|---|

| Economic | 0.50 | ROI | 0.40 | 1.0000 | 0.400 |

| Diesel_ash | 0.01 | 0.5143 | −0.005 | ||

| Electricity_ash | 0.01 | 1.0000 | −0.010 | ||

| Pre-treatment | 0.08 | 1 | −0.080 | ||

| Environmental_Capacity | 0.04 | Capacity | 0.04 | 0.0000 | 0.000 |

| Environmental_Efficiency | 0.12 | EER | 0.04 | 0.0148 | 0.001 |

| HER | 0.04 | - | − | ||

| EE_EU | 0.04 | 0.0000 | 0.000 | ||

| Environmental_Emissions | 0.17 | Dust | 0.01545 | 0.3116 | −0.005 |

| SO2 | 0.01545 | 1.0000 | −0.015 | ||

| NOx | 0.01545 | 0.1471 | −0.002 | ||

| CO | 0.01545 | 1.0000 | −0.015 | ||

| TOC | 0.01545 | 0.3289 | −0.005 | ||

| HCL | 0.01545 | 0.4734 | −0.007 | ||

| HF | 0.01545 | 0.0099 | 0.000 | ||

| Metals | 0.01545 | 0.3465 | −0.005 | ||

| Hg | 0.01545 | 0.3745 | −0.006 | ||

| PCDD/F | 0.01545 | 0.0000 | 0.000 | ||

| Cd | 0.01545 | 0.0000 | 0.000 | ||

| Environmental_LCA | 0.17 | GW | 0.02429 | 0.1037 | −0.003 |

| AC | 0.02429 | 0.5988 | −0.015 | ||

| TE | 0.02429 | 1.0000 | −0.024 | ||

| POFh | 0.02429 | 0.4442 | −0.011 | ||

| HTa | 0.02429 | 0.7186 | −0.017 | ||

| HTs | 0.02429 | 0.0363 | −0.001 | ||

| ETs | 0.02429 | 0.0000 | 0.000 | ||

| SUM | 1.0 | 1.0 | 0.174 |

Appendix C.4. Conventional Gasification Technology

| Analysis | Analysis Weight | Indicator | Indicator Weight | Value | Assessment |

|---|---|---|---|---|---|

| Economic | 0.50 | ROI | 0.40 | 0.7571 | 0.303 |

| Diesel_ash | 0.01 | 0.3231 | −0.003 | ||

| Electricity_ash | 0.01 | 0.6389 | −0.006 | ||

| Pre-treatment | 0.08 | 1 | −0.080 | ||

| Environmental_Capacity | 0.04 | Capacity | 0.04 | 0.3692 | 0.015 |

| Environmental_Efficiency | 0.12 | EER | 0.04 | 1.0000 | 0.040 |

| HER | 0.04 | 0.6264 | 0.025 | ||

| EE_EU | 0.04 | 1.0000 | 0.040 | ||

| Environmental_Emissions | 0.17 | Dust | 0.01545 | 0.0000 | 0.000 |

| SO2 | 0.01545 | 0.0000 | 0.000 | ||

| NOx | 0.01545 | 0.0818 | −0.001 | ||

| CO | 0.01545 | 0.0000 | 0.000 | ||

| TOC | 0.01545 | 0.0000 | 0.000 | ||

| HCL | 0.01545 | 0.0000 | 0.000 | ||

| HF | 0.01545 | 0.0000 | 0.000 | ||

| Metals | 0.01545 | 0.0000 | 0.000 | ||

| Hg | 0.01545 | 0.6478 | −0.010 | ||

| PCDD/F | 0.01545 | 0.3333 | −0.005 | ||

| Cd | 0.01545 | 0.1334 | −0.002 | ||

| Environmental_LCA | 0.17 | GW | 0.02429 | 1.0000 | −0.024 |

| AC | 0.02429 | 0.5446 | −0.013 | ||

| TE | 0.02429 | 0.0000 | 0.000 | ||

| POFh | 0.02429 | 0.3933 | −0.010 | ||

| HTa | 0.02429 | 0.0000 | 0.000 | ||

| HTs | 0.02429 | 1.0000 | −0.024 | ||

| ETs | 0.02429 | None | None | ||

| SUM | 1.0 | 1.0 | 0.243 |

Appendix C.5. Plasma Gasification Technology

| Analysis | Analysis Weight | Indicator | Indicator Weight | Value | Assessment |

| Economic | 0.50 | ROI | 0.40 | 0.1800 | 0.072 |

| Diesel_ash | 0.01 | 0.0000 | 0.000 | ||

| Electricity_ash | 0.01 | 0.3687 | −0.004 | ||

| Pre-treatment | 0.08 | 0 | 0.000 | ||

| Environmental_Capacity | 0.04 | Capacity | 0.04 | 0.2094 | 0.008 |

| Environmental_Efficiency | 0.12 | EER | 0.04 | 0.3698 | 0.022 |

| HER | 0.04 | - | − | ||

| EE_EU | 0.04 | 0.0000 | 0.000 | ||

| Environmental_Emissions | 0.17 | Dust | 0.01545 | 0.4393 | −0.007 |

| SO2 | 0.01545 | 0.0501 | −0.001 | ||

| NOx | 0.01545 | 0.0019 | 0.000 | ||

| CO | 0.01545 | 0.0160 | 0.000 | ||

| TOC | 0.01545 | 1.0000 | −0.015 | ||

| HCL | 0.01545 | 0.3581 | −0.006 | ||

| HF | 0.01545 | 0.0011 | 0.000 | ||

| Metals | 0.01545 | 0.0523 | −0.001 | ||

| Hg | 0.01545 | 0.0000 | 0.000 | ||

| PCDD/F | 0.01545 | 1.0000 | −0.015 | ||

| Cd | 0.01545 | 0.6478 | −0.010 | ||

| Environmental_LCA | 0.17 | GW | 0.02429 | 0.1005 | −0.002 |

| AC | 0.02429 | 0.5666 | −0.014 | ||

| TE | 0.02429 | 0.1579 | −0.004 | ||

| POFh | 0.02429 | 0.3297 | −0.008 | ||

| HTa | 0.02429 | 0.0898 | −0.002 | ||

| HTs | 0.02429 | 0.0622 | −0.002 | ||

| ETs | 0.02429 | None | None | ||

| SUM | 1.0 | 1.0 | 0.012 |

Appendix C.6. Pyrolysis Technology

| Analysis | Analysis Weight | Indicator | Indicator Weight | Value | Assessment |

| Economic | 0.50 | ROI | 0.40 | 0.4456 | 0.178 |

| Diesel_ash | 0.01 | 0.1484 | −0.001 | ||

| Electricity_ash | 0.01 | 0.1549 | −0.002 | ||

| Pre-treatment | 0.08 | 1 | −0.080 | ||

| Environmental_Capacity | 0.04 | Capacity | 0.04 | 0.6965 | 0.028 |

| Environmental_Efficiency | 0.12 | EER | 0.04 | 0.2367 | 0.009 |

| HER | 0.04 | 0.9434 | 0.038 | ||

| EE_EU | 0.04 | 0.5732 | 0.023 | ||

| Environmental_Emissions | 0.17 | Dust | 0.01545 | 0.0832 | −0.001 |

| SO2 | 0.01545 | 0.1046 | −0.002 | ||

| NOx | 0.01545 | 0.2052 | −0.003 | ||

| CO | 0.01545 | 0.0812 | −0.001 | ||

| TOC | 0.01545 | 0.0489 | −0.001 | ||

| HCL | 0.01545 | 0.5347 | −0.008 | ||

| HF | 0.01545 | 1.0000 | −0.015 | ||

| Metals | 0.01545 | 0.0148 | 0.000 | ||

| Hg | 0.01545 | 0.0550 | −0.001 | ||

| PCDD/F | 0.01545 | 0.1664 | −0.003 | ||

| Cd | 0.01545 | 1.0000 | −0.015 | ||

| Environmental_LCA | 0.17 | GW | 0.02429 | 0.1193 | −0.003 |

| AC | 0.02429 | 0.0000 | 0.000 | ||

| TE | 0.02429 | 0.4737 | −0.012 | ||

| POFh | 0.02429 | 0.0000 | 0.000 | ||

| HTa | 0.02429 | 1.0000 | −0.024 | ||

| HTs | 0.02429 | 0.3419 | −0.008 | ||

| ETs | 0.02429 | None | None | ||

| SUM | 1.0 | 1.0 | 0.095 | ||

| Source: Compiled by the authors. | |||||

References

- Tsai, F.M.; Bui, T.D.; Tseng, M.L.; Wu, K.J. A Causal Municipal Solid Waste Management Model for Sustainable Cities in Vietnam under Uncertainty: A Comparison. Resour. Conserv. Recycl. 2020, 154, 104599. [Google Scholar] [CrossRef]

- Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/ (accessed on 29 September 2022).

- Ternald, D. International Environmental Technology Centre. In Annual Report 2020; United Nations Environment Programme: Osaka, Japan, 2020. [Google Scholar]

- UN Habitat. Solid Waste Management in the World’s Cities: Water and Sanitation in the World’s Cities 2010; Earthscan for UN-Habitat: London, UK, 2010. [Google Scholar]

- Michaels, T.; Krishnan, K. 2018 Directory of Waste-to-Energy Facilities; Energy Recovery Council: New York, NY, USA, 2018. [Google Scholar]

- Mayer, F.; Bhandari, R.; Gäth, S. Critical Review on Life Cycle Assessment of Conventional and Innovative Waste-to-Energy Technologies. Sci. Total Environ. 2019, 672, 708–721. [Google Scholar] [CrossRef] [PubMed]

- Cudjoe, D.; Acquah, P.M. Environmental Impact Analysis of Municipal Solid Waste Incineration in African Countries. Chemosphere 2021, 265, 129186. [Google Scholar] [CrossRef] [PubMed]

- Shunko, K.A.; Bolshakova, I.V. Economic Feasibility of Using Solid Municipal Waste as Fuel for Electric and Thermal Energy Production. In Trends of Economic Development in the XXI Century; Koroleva, A.A., Ed.; Belarusian State University: Minsk, Belarus, 2021; pp. 368–371. (In Russian) [Google Scholar]

- Potravny, I.M.; Baah, D. Energy Management of Municipal Solid Waste in the Context of Low Carbon Development. Manag. Sci. 2021, 11, 6–22. (In Russian) [Google Scholar] [CrossRef]

- Morero, B.; Montagna, A.F.; Campanella, E.A.; Cafaro, D.C. Optimal Process Design for Integrated Municipal Waste Management with Energy Recovery in Argentina. Renew. Energy 2020, 146, 2626–2636. [Google Scholar] [CrossRef]

- Trends in Solid Waste Management. Available online: https://datatopics.worldbank.org/what-a-waste/trends_in_solid_waste_management.html (accessed on 29 September 2022).

- Franklin Associates. Characterization of Municipal Solid Waste in the United States: 1998 Update; United States Environmental Protection Agency: Prairie Village, KS, USA, 1999. [Google Scholar]

- EEA. Managing Municipal Solid Waste—A Review of Achievements in 32 European Countries; European Environment Agency Publications Office: Copenhagen, Denmark, 2013. [Google Scholar]

- Ladder van Lansink. Available online: https://www.adlansink.nl/voorbeeld-pagina/ (accessed on 29 September 2022).

- Mohammed, H.; Majid, Z.; Yamusa, Y.; Ariff, M.; Idris, K.; Darwin, N. Sanitary Landfill Siting Using GIS and AHP: A Case Study in Johor Bahru, Malaysia. Eng. Technol. Appl. Sci. Res. 2019, 9, 4100–4104. [Google Scholar] [CrossRef]

- Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste. Available online: https://eur-lex.europa.eu/eli/dir/1999/31/oj (accessed on 29 September 2022).

- Municipal Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics#Municipal_waste_treatment (accessed on 29 September 2022).

- de Titto, E.; Savino, A. Environmental and Health Risks Related to Waste Incineration. Waste Manag. Res. 2019, 37, 976–986. [Google Scholar] [CrossRef]

- Islamova, S.I.; Muhametshina, E.I. Municipal Solid Waste Treatment, Recycling and Energy Recovery. Akad. Proc. 2012, 4, 88–96. (In Russian) [Google Scholar]

- Waste to Energy Market Outlook 2027. Available online: https://www.alliedmarketresearch.com/waste-to-energy-market (accessed on 29 September 2022).

- Makarichi, L.; Jutidamrongphan, W.; Techato, K.A. The Evolution of Waste-to-Energy Incineration: A Review. Renew. Sustain. Energy Rev. 2018, 91, 812–821. [Google Scholar] [CrossRef]

- Leckner, B.; Lind, F. Combustion of Municipal Solid Waste in Fluidized Bed or on Grate—A Comparison. Waste Manag. 2020, 109, 94–108. [Google Scholar] [CrossRef]

- Magnanelli, E.; Tranås, O.L.; Carlsson, P.; Mosby, J.; Becidan, M. Dynamic Modeling of Municipal Solid Waste Incineration. Energy 2020, 209, 118426. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Chi, Y.; Zhou, Z.; Tang, Y.; Zhang, H. Life Cycle Assessment of Advanced Circulating Fluidized Bed Municipal Solid Waste Incineration System from an Environmental and Exergetic Perspective. Int. J. Environ. Res. Public Health 2021, 18, 10432. [Google Scholar] [CrossRef] [PubMed]

- El-Haggar, S.M. Sustainable Industrial Design and Waste Management: Cradle-to-Cradle for Sustainable Development; Elsevier Academic Press: San Diego, CA, USA, 2010. [Google Scholar]

- Salaudeen, S.A.; Arku, P.; Dutta, A. Gasification of Plastic Solid Waste and Competitive Technologies. In Plastics to Energy; Al-Salem, S.M., Ed.; William Andrew Publishing: Cambridge, UK, 2019; pp. 269–293. [Google Scholar]

- Munir, M.T.; Mardon, I.; Al-Zuhair, S.; Shawabkeh, A.; Saqib, N.U. Plasma Gasification of Municipal Solid Waste for Waste-to-Value Processing. Renew. Sustain. Energy Rev. 2019, 116, 109461. [Google Scholar] [CrossRef]

- Sipra, A.T.; Gao, N.; Sarwar, H. Municipal Solid Waste (MSW) Pyrolysis for Bio-Fuel Production: A Review of Effects of MSW Components and Catalysts. Fuel Process. Technol. 2018, 175, 131–147. [Google Scholar] [CrossRef]

- Madadian, E.; Haelssig, J.B.; Pegg, M. A Comparison of Thermal Processing Strategies for Landfill Reclamation: Methods, Products, and a Promising Path Forward. Resour. Conserv. Recycl. 2020, 160, 104876. [Google Scholar] [CrossRef]

- Mertens, R. Press Release Waste to Energy 2021/2022; EcoProg GmbH: Cologne, Germany, 2021. [Google Scholar]

- Tsai, F.M.; Bui, T.D.; Tseng, M.L.; Wu, K.J.; Chiu, A.S. A Performance Assessment Approach for Integrated Solid Waste Management Using a Sustainable Balanced Scorecard Approach. J. Clean. Prod. 2020, 251, 119740. [Google Scholar] [CrossRef]

- Mendes, P.; Santos, A.C.; Perna, F.; Teixeira, M.R. The Balanced Scorecard as an Integrated Model Applied to the Portuguese Public Service: A Case Study in the Waste Sector. J. Clean. Prod. 2012, 24, 20–29. [Google Scholar] [CrossRef]

- Waste to Energy Facilities Worldwide. Available online: http://www.coenrady.com/ (accessed on 29 September 2022).

- Zhao, X.G.; Jiang, G.W.; Li, A.; Wang, L. Economic Analysis of Waste-to-Energy Industry in China. Waste Manag. 2016, 48, 604–618. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: http://data.europa.eu/eli/dir/2008/98/oj (accessed on 29 September 2022).

- Bovea, M.D.; Ibáñez-Forés, V.; Gallardo, A.; Colomer-Mendoza, F.J. Environmental Assessment of Alternative Municipal Solid Waste Management Strategies. A Spanish Case Study. Waste Manag. 2010, 30, 2383–2395. [Google Scholar]

- Omelchenko, I.N.; Brom, A.E. System of an Assessment of Life Cycle of Production. Volzhsky Univ. Bull. V.N. Tatischev 2013, 2, 29–34. (In Russian) [Google Scholar]

- Ghinea, C.; Petraru, M.; Bressers, H.T.A.; Gavrilescu, M. Environmental Evaluation of Waste Management Scenarios-Significance of the Boundaries. J. Environ. Eng. Landsc. Manag. 2012, 20, 76–85. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life Cycle Assessment of Pyrolysis, Gasification and Incineration Waste-to-Energy Technologies: Theoretical Analysis and Case Study of Commercial Plants. Sci. Total Environ. 2018, 626, 744–753. [Google Scholar] [CrossRef] [PubMed]

- IlTermovalorizzatore Silla2. Available online: https://www.a2aambiente.eu/servizi/servizi-territori/recupero-energia/silla2 (accessed on 29 September 2022).

- Impianto Di Termovalorizzazione Milano “Silla 2”; A2A S.p.A.: Milano, Italy, 2022.

- Comune Milano. a2a BilancioIntegrato 2020; A2A S.p.A.: Milano, Italy, 2021. [Google Scholar]

- Enel. RelazioneFinanziaria Annual Consolidata; A2A S.p.A.: Milano, Italy, 2021. [Google Scholar]

- Umwelt Emissionswerte. Available online: http://www.mva-hamm.de (accessed on 29 September 2022).

- MHB Hamm Betriebsführungsgesellschaft mbH. Ergebnisse der Emissionsmessungen an der Müllverbrennungsanlage Hamm für das Jahr 2021; MHB Hamm Betriebsführungsgesellschaft mbH: Hamm, Germany, 2022. [Google Scholar]

- Recherchiere Firmen Bekanntmachungen und Finanzielle Kennzahlen, MHB Hamm Betriebsführungsgesellschaft mbH, Hamm. Available online: https://www.northdata.de/MHB+Hamm+Betriebsf%C3%BChrungsgesellschaft+mbH,+Hamm/HRB+2293 (accessed on 29 September 2022).

- Beteiligungsbericht für das Geschäftsjahr 2016; Kreis Unna—Der Landrat Steuerungsdienst: Unna, Germany, 2017.

- Westenergy Brochure. Available online: https://westenergy.fi/en/westenergy-brochure-en/ (accessed on 29 September 2022).

- Westenergy. 20 Annual Report; Westenergy OY AB: Koivulahti, Finland, 2021. [Google Scholar]

- Direct Melting System. Available online: https://www.eng.nipponsteel.com/english/whatwedo/wastetoenergy/wtoeplant/direct_melting_system/ (accessed on 29 September 2022).

- Nippon Steel Corporation. FORM 20-F. United States Securities and Exchange Commission: Washington DC, USA, 2019. Available online: https://www.sec.gov/Archives/edgar/data/1140471/000119312519194531/d771607d20f.htm (accessed on 29 September 2022).

- Dahlbo, H.; Koskela, S.; Laukka, J.; Myllymaa, T.; Jouttijärvi, T.; Melanen, M.; Tenhunen, J. Life Cycle Inventory Analyses for Five Waste Management Options for Discarded Newspaper. Waste Manag. Res. 2005, 23, 291–303. [Google Scholar] [CrossRef] [PubMed]

- JätevoimalaAntaaRoskalleUudenElämän. Available online: https://www.vantaanenergia.fi/jatevoimala-antaa-roskalle-uuden-elaman/ (accessed on 29 September 2022).

- HUS. TilinpäätösJaToimintakertomus 2021; VantaanEnergia Oy: Vantaa, Finland, 2022. [Google Scholar]

- VantaanJätevoimalaitos. Available online: https://afry.com/fi-fi/projektit/vantaan-jatevoimalaitos (accessed on 29 September 2022).

- Högdalenverket. Available online: https://www.stockholmexergi.se/om-stockholm-exergi/vara-anlaggningar/hogdalenverket/ (accessed on 29 September 2022).

- Stockholmexergi. Year-End Report 2021; Stockholm Exergi Holding AB: Stockholm, Sweden, 2022. [Google Scholar]

- SEK. Års—OchHållbarhetsredovisning 2021; Stockholm Exergi Holding AB: Stockholm, Sweden, 2022. [Google Scholar]

- Maria, F.D.; Fantozzi, F. Life Cycle Assessment of Waste to Energy Micro-Pyrolysis System: Case Study for an Italian Town. Int. J. Energy Res. 2004, 28, 449–461. [Google Scholar] [CrossRef]

- Terni Plant. Available online: https://www.gruppo.acea.it/en/serving-people/enviroment/waste-to-energy/terni-plant (accessed on 29 September 2022).

- ACEA AMBIENTE Srl. UL1—Impianto Di Termovalorizzazione Di RifiutiSpeciali Non Pericolosi Di Terni; AceaAmbienteSrl: Terni, Italy, 2021. [Google Scholar]

- ACEA. Consolidated Financial Statements Acea Group 2021; Acea Spa: Rome, Italy, 2021. [Google Scholar]

- Saft, R.J. Life Cycle Assessment of a Pyrolysis/Gasification Plant for Hazardous Paint Waste. Int. J. Life Cycle Assess. 2007, 12, 230–238. [Google Scholar] [CrossRef]

- Key Figures and Investments. Available online: https://www.attero.nl/nl/over-ons/kerncijfers-en-investeringen/ (accessed on 29 September 2022).

- 3i-infrastructure. Annual Report and Accounts 2019; 3i Infrastructure: St. Helier, Jersey, 2020. [Google Scholar]

- Liamsanguan, C.; Gheewala, S.H. Environmental Assessment of Energy Production from Municipal Solid Waste Incineration. Int. J. Life Cycle Assess. 2007, 12, 529–536. [Google Scholar] [CrossRef]

- Liamsanguan, C.; Gheewala, S.H. LCA: A Decision Support Tool for Environmental Assessment of MSW Management Systems. J. Environ. Manag. 2008, 87, 132–138. [Google Scholar] [CrossRef]

- Vanapruk, P. A Decade of Waste to Energy Plant of Phuket. GMSARN Int. J. 2011, 5, 195–200. [Google Scholar]

- Clean Land การกำจัดขยะมูลฝอยจังหวัดภูเก็ต. ระบบเตาเผา (Kiln System. Garbage Disposal Phuket Province). Available online: https://www.phuketcity.go.th/eco/detail/4/data.html (accessed on 29 September 2022).

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M.; Zhou, Z. Comparison of Waste-to-Energy Technologies of Gasification and Incineration Using Life Cycle Assessment: Case Studies in Finland, France and China. J. Clean. Prod. 2018, 203, 287–300. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S.A.; Himanshu, H.; Stobernack, N. Economic and Environmental Life Cycle Assessment of Organic Waste Treatment by Means of Incineration and Biogasification. Is Source Segregation of Biowaste Justified in Germany? Sci. Total Environ. 2020, 721, 137731. [Google Scholar]

- Assamoi, B.; Lawryshyn, Y. The Environmental Comparison of Landfilling VS. Incineration of MSW Accounting for Waste Diversion. Waste Manag. 2012, 32, 1019–1030. [Google Scholar]

- Di Maria, F.; Sisani, F.; Contini, S. Are EU Waste-to-Energy Technologies Effective for Exploiting the Energy in Bio-Waste? Appl. Energy 2018, 230, 1557–1572. [Google Scholar] [CrossRef]

- Münster, M.; Lund, H. Comparing Waste-to-Energy Technologies by Applying Energy System Analysis. Waste Manag. 2010, 30, 1251–1263. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Young, G.C. Municipal Solid Waste to Energy Conversion Processes: Economic, Technical, and Renewable Comparisons; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Supplementary Material for Life Cycle Assessment of Thermal Waste-to-Energy Technologies: Review and Recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef] [Green Version]

- Escamilla-García, P.E.; Camarillo-López, R.H.; Carrasco-Hernández, R.; Fernández-Rodríguez, E.; Legal-Hernández, J.M. Technical and Economic Analysis of Energy Generation from Waste Incineration in Mexico. Energy Strategy Rev. 2020, 31, 100542. [Google Scholar] [CrossRef]

- Ionescu, G.; Rada, E.C.; Ragazzi, M.; Mărculescu, C.; Badea, A.; Apostol, T. Integrated Municipal Solid Waste Scenario Model Using Advanced Pretreatment and Waste to Energy Processes. Energy Convers. Manag. 2013, 76, 1083–1092. [Google Scholar] [CrossRef]

- Kharitonov, M.S.; Demidov, N.A. Prospects for the Development of Electricity Generation on MSW in the Kaliningrad Region. Mod. Sci. 2020, 7, 411–417. (In Russian) [Google Scholar]

- Cekirge, H.M.; Ouda, O.K.; Elhassan, A. Economic Analysis of Solid Waste Treatment Plants Using Pyrolysis. Am. J. Energy Eng. 2015, 3, 11–15. [Google Scholar] [CrossRef] [Green Version]

- Evangelisti, S.; Lettieri, P.; Borello, D.; Clift, R. Life Cycle Assessment of Energy from Waste via Anaerobic Digestion: A UK Case Study. Waste Manag. 2014, 34, 226–237. [Google Scholar] [CrossRef] [PubMed]

- Generowicz, A. Multi-Criteria Analysis of Waste Management in Szczecin. Pol. J. Environ. Stud. 2014, 23, 57–63. [Google Scholar]

| Analysis | Analysis Weight | Assessment for Incineration Moving Grate | Assessment for Incineration Rotary Kiln | Assessment for Fluidized Bed | Assessment for Gasification | Assessment for Plasma Gasification | Assessment for Pyrolysis |

|---|---|---|---|---|---|---|---|

| Economic | 0.50 | −0.008 | 0.067 | 0.305 | 0.213 | 0.068 | 0.095 |

| Environmental_Capacity | 0.04 | 0.040 | 0.024 | 0.000 | 0.015 | 0.008 | 0.028 |

| Environmental_Efficiency | 0.12 | 0.040 | 0.076 | 0.001 | 0.105 | 0.022 | 0.070 |

| Environmental_Emissions | 0.17 | −0.078 | −0.077 | −0.062 | −0.018 | −0.055 | −0.051 |

| Environmental_LCA | 0.17 | −0.062 | −0.112 | −0.070 | −0.071 | −0.032 | −0.047 |

| SUM | 1.0 | −0.067 | −0.023 | 0.174 | 0.243 | 0.012 | 0.095 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vukovic, N.; Makogon, E. Waste-to-Energy Generation: Complex Efficiency Analysis of Modern Technologies. Sustainability 2022, 14, 13814. https://doi.org/10.3390/su142113814

Vukovic N, Makogon E. Waste-to-Energy Generation: Complex Efficiency Analysis of Modern Technologies. Sustainability. 2022; 14(21):13814. https://doi.org/10.3390/su142113814

Chicago/Turabian StyleVukovic, Natalia, and Evgenia Makogon. 2022. "Waste-to-Energy Generation: Complex Efficiency Analysis of Modern Technologies" Sustainability 14, no. 21: 13814. https://doi.org/10.3390/su142113814

APA StyleVukovic, N., & Makogon, E. (2022). Waste-to-Energy Generation: Complex Efficiency Analysis of Modern Technologies. Sustainability, 14(21), 13814. https://doi.org/10.3390/su142113814