Abstract

The COVID-19 pandemic has led to major disruptions in workflows across all industries. All sectors are trying to sustain operations during this extremely difficult time and the healthcare sector is the most important of them. It is unthinkable to stop the operations of the health system because it serves human life. Health institutions must supply the products such as masks, gloves, and ventilators subject to service on time for certain activities to continue indefinitely under all conditions. By adopting modern logistics activities and technologies, healthcare organizations can provide sustainable diagnosis and treatments to patients by automating their various operations. With the COVID-19 pandemic, how to select an appropriate sustainable supplier has become an important task in the era of Logistics 4.0. From this viewpoint, a sustainable supplier selection framework is implemented for a health institution under the effect of the pandemic. To determine the direct effects of the pandemic in the health sector, fuzzy Multi-Criteria Decision-Making (MCDM) methods are utilized in the application. After a thorough review of the literature and interviews with experts, the criteria are organized in a comprehensive hierarchical structure. The fuzzy Best-Worst Method (F-BWM) technique is employed to find the weights for the determined criteria. Consequently, the fuzzy Additive Ratio Assessment Method (F-ARAS) method was applied to rank the alternative suppliers. In addition, with a comprehensive sensitivity analysis, alternative situations are examined against possible breaks in the supply chain. Thus, from the perspective of Logistics 4.0 and sustainability, this study contributes to the literature with an analysis of the health system’s survival in difficult and fragile periods, such as COVID-19. Investigating the importance of SSS can be a road map for the policymakers and the decision-makers is beneficial since the impact of COVID-19 on SSS is studied from the perspective of Logistics 4.0.

1. Introduction

The COVID-19 pandemic has altered the world order to a considerable extent since it started at the beginning of 2020, and new orders have been formed in many areas all over the world. After the pandemic was declared, each country took different steps to protect its own people, such as closing borders, social distancing, curfew, and stopping production. Undoubtedly, the most devastating effect of this pandemic has been the recorded fatalities. But on the other hand, global crises have emerged in line with the measures taken and have begun to have a devastating effect [1]. The most devastating effects were on the supply chain order due to the length of the quarantine period and the closure of borders. Never before has the supply chain been under such stress, and product flow has been impossible to achieve due to multiple constraints [2]. Many companies were unable to manufacture during this period owing to a scarcity of raw materials or intermediate products, resulting in a wide range of unmet product and service demands.

As a result, the disruption in the supply chain and global trade system has also affected various sectors. The most critical area in this scenario, however, is the healthcare sector. Because during the pandemic, a disruption in the supply chain for healthcare goods or medical products produced not just health problems, but also a public outrage. Several health institutions have confronted shortages in the procurement of medical supplies, such as personal protective equipment, ventilators, or drugs. However, the need for a long-term supply chain in the field of public health has to be highlighted once more, particularly at this time. Because hospitals and healthcare providers have had difficulty finding medical equipment and obtaining medications [3,4,5,6]. For example, personal protective equipment shortages have been observed in US healthcare systems, jeopardizing their capacity to keep healthcare workers safe. Additionally, China produces more than 70% of the respiratory protection products utilized in the United States. Orders could not be completed since manufacturing in China was substantially decreased due to COVID-19. Needed supplies for other healthcare systems, on the other hand, took 3 to 6 months to arrive [7,8]. Hence, health institutions have found new adaptations to improve their operations and supply chain system.

With the COVID-19 pandemic, the importance of supply chain sustainability in aiding satisfactory lifestyles during periods of crisis has become clearer to the world. This sustainability is also important for companies to continue making profits even during crisis times with minimal disruptions in target revenues, as in normal times. Additionally, environmental sustainability is also another important part of the discussion. During this time, companies that achieve a sustainable supply chain have seen short-term environmental sustainability improvements [9]. The sustainability of the supply chain may be ensured by every actor’s sustainability. Consequently, companies wishing to manage long-term supply chain operations must ensure that all chain links are sustainable. Sustainable Supplier Selection (SSS) is the most important issue in a sustainable supply chain since it is via supplier selection that companies ensure their chains are sustainable [10,11,12]. SSS is a viable topic to tackle since it entails analyzing and selecting suppliers in unpredictable and complex situations based on particular criteria [13,14]. Criteria and decision-making procedures are part of this process.

Notably, some disruptions, such as COVID-19 and global trade wars, have forced healthcare institutions to develop new strategies. While great attention has been paid to SSS by researchers and practitioners, the impact of advanced technologies and supply chain performance enhancers such as Logistics 4.0 has rarely been investigated [15,16]. However, smart technologies such as smart supply chain, big data analytics, cloud systems, and the Internet of Things (IoT) offer new and enormous opportunities, especially to the problem of sustainable supplier evaluation [17,18]. From this perspective, it is expected that health institutions will adapt new technologies into operations and supply chain systems.

In these contexts, the research questions of this study are as follows:

- RQ1: Which adjustments have occurred in the health system in terms of SSS as a result of the COVID-19 process in the era of Logistics 4.0?

- RQ2: Have innovative criteria been developed in the selection of SSS as an aspect of the COVID-19 process?

- RQ3: Has the significance of the concept of sustainability in the scope of the SSS diminished during the COVID-19 process?

- RQ4: What impact does the sensitivity analysis have on the supplier selection rankings that occur throughout the COVID-19 process?

- RQ5: What is the impact of BWM, and ARAS approaches have on ranking in the selection of SSS when there is uncertainty situation, as determined by their fuzzy state or scale?

Within the framework of these five questions, the health system’s SSS evaluation was conducted using F-BWM and F-ARAS methods. The study investigates the influence of the COVID-19 procedure on supplier selection. This paper’s reminder is as follows: Section 2 examines related literature, while Section 3 focuses on the research framework and methodologies. Section 4 contains the application, the application’s results, the findings, and the sensitivity analysis. Moreover, Section 5 continues with conclusions and recommendations for further research.

2. Materials and Methods

This section contributes the literature on the factors which are performing a remarkable role for increment the healthcare system survivability of SSS pre and post COVID-19 pandemic by the operating purchaser and supplier relationship.

2.1. Factors for Incrementing Sustainability of Healthcare Supply Chains Pre-Pandemic Period

The survival of the healthcare system in chaotic times is of vital importance for a sustainable supply chain (SSC). Before the COVID-19 epidemic, certain criteria came to the fore in the sustainable supplier selection (SSS). It includes economic, environmental, and social criteria that regulate the relationship between suppliers and purchasers [19]. In the models of SSS studies, economic, social, and environmental criteria are included in mathematical models [20,21]. To determine the change in healthcare system SSSs after the pandemic, the pre-pandemic supplier selection criteria should be analyzed within the scope of Logistics 4.0. In a study in which the AHP method was applied in pre-pandemic conditions; a healthcare center in Nigeria had determined respectively quality, service, delivery, and price criteria for supplier selection [22]. In the SSS study applied with the Marcos method in the medical sector, 3 main and 21 sub-criteria were determined in the study. According to the results of the application, price and quality came to the fore as the most important criteria [23]. Application with Fuzzy Inference System (FIS) in the medical device industry; 3 mains, 9 middle and 24 sub-criteria have been determined in the production of medical devices. In addition to the main criteria, such as environmental, social and economic, there are sub-criteria, such as waste control, green image, customer complaints, and safety procedures [24]. An application has been employed for the supplier selection of certain medical devices with a group decision-making approach. The supplier selection problem was applied with 3 main and 16 sub-criteria. In the study, the most important criteria in SSS for medical devices were determined as accuracy, trust and safety, response time, precision, and provider reputation [25]. A study was conducted to determine the most suitable supplier for hospitals. AHP, TOPSIS, ELECTRE, GRA, SAW methods, which are MCDM (multi-criteria decision-making methods), were applied in the study. 5 main criteria and 15 sub-criteria were designated in a hierarchical structure. Logistics (0.513) was deduced by the decision-makers as the most important main and serves as the most important sub-criteria [26]. An application was enforced for the supply of orthopedic materials in a hospital in Andalusia, Spain. DEMATEL, BWM, EDAS methods were applied in supplier evaluation. The most important criteria are respectively in the study as price, quality, technology, stock capacity, degree of flexibility and batch volume [27]. Fuzzy MCDM methods were carried out in the study for the most potential supplier selection of health organizations. In the study, analysis was fulfilled with F-DELPHI, F-SWARA and F-COPRAS methods. Institutional trust, transformation and information technology expertise are the most important criteria in the supplier selection of healthcare organizations in the study. Company C has been selected as a potential supplier according to application [28]. In the supplier selection problem for a hospital in Istanbul, Turkey. Type-2 fuzzy set application from MCDM methods was performed in the study. Conclusion section demonstrated that the most important criteria in the hospital’s supplier selection were found price, quality, product suitability, customer support and the effectiveness of corrective action. According to these criteria, the most suitable supplier was determined as the 7th supplier company [29]. In another study, an application was performed with the F-VIKOR method for hospitals to find the best supplier. The application demonstrated that quality is the most important factor of hospitals’ SSS [30].

2.2. Factors for Incrementing Sustainability of Healthcare Supply Chains Post-Pandemic Period

Supply chains (SC) have become fragile after the COVID-19 outbreak. SC with the effect of the epidemic; started to be designed within the framework of a more agile, sustainable, and Logistics 4.0 concept [9]. The necessity of surviving SC during the pandemic period has affected the SSS in the healthcare system [31]. Research on green supplier selection (GSS) in the healthcare sector during the pandemic period, simultaneously considers the green and agile indicators in the sustainable supplier problem (SSP). While flexibility, green, and technology criteria are among the 5 main criteria, there are important factors such as green satisfaction, environmental performance evaluation, re-use, and after-sales service costs in the (25) sub-criteria [32]. In another study, pandemic factors in SS in the COVID-19 pandemic were analyzed with Fuzzy Geometric Mean (FGM), Fuzzy Weighted Intersection (FWI), F-TOPSIS (Chen, Wang, and Wu 2021). The Study demonstrated criteria affecting SS in the COVID-19 period, respectively, pandemic containment performance, pandemic severity, vaccine acquisition speed [33]. Some of the prominent criteria during the COVID-19 period in the application of health systems for vaccine supply are logistics, storage conditions, and price [34]. In research on SS in the COVID-19 period, some SS criteria for the pandemic period come to the fore. These criteria are delivery speed, buyer-supplier cooperation level, company reputation, and pandemic control performance [35]. Another COVID-19 study mentions a novel decision-making approach using Measuring attractiveness through a categorical-based evaluation technique (MACBETH) and a new combinative distance-based assessment method to address the supplier selection problem during the COVID-19 pandemic. There are 3 main and 16 sub-criteria in the study. The study demonstrated that training about green practices for stakeholders (SO14), ensuring rights of the stakeholders (SO15), and job creation (SO11) are top three criteria with highest weight coefficients for sustainable SSP [36]. In the study investigating increasing the agility of the supply chain after COVID-19, agile practices are included as the most important factors [37]. In the COVID-19 period, a model application was made for the SSC of hospitals with neutrosophic numbers. The results are for SSC efficiency and resilience in the COVID-19 era, demonstrating that fewer vehicles should be used to reduce Logistics 4.0 costs [38]. The existence of smart hospitals during the COVID-19 period facilitates the SSS. For this purpose, the AHP method was applied to the study. Among the main criteria, artificial intelligence, service technology innovations are important for SSS [39]. In the study conducted on supply chain resilience (SCR) in the Pakistani health system during the COVID-19 period, leadership and governance capacity was detected as the most important resilience criterion [40]. Another study was conducted on the resiliency of the US health system with MCDM methods during the COVID-19 period. Among the criteria that increase resiliency; agility, SC network design, speed, flexibility, collaboration, SCR management have come to the fore in terms of SSS [41].

2.3. Research Gap

Many researchers have examined supply chain affairs, network design, barriers, information system, system integration, buyer-supplier relationship [42,43,44,45,46]; supply chain risk [47]; crisis [48]; supply chain orientation [49]; resiliency [50,51,52,53]; sustainable SCM [9,16,54]; supply chain agility [55,56,57,58]. Technological advances affect the functioning and structure of SCs [59]; SCs waste management [60]; green management [61,62]; social issues and social responsibility [63].

The current literature addresses many issues related to SSS. However, there are very few studies on SSS in the healthcare industry. This study deals with the SSS of the healthcare system especially before and after the COVID-19 period. Thus, this study fills this gap and analyses factors that will provide new insights for the healthcare system to redesign SSS systems to survive in pre and post-COVID-19 situations. The implementation part of this study was carried out in a developing country thereby making a unique contribution to the literature.

3. Research Framework

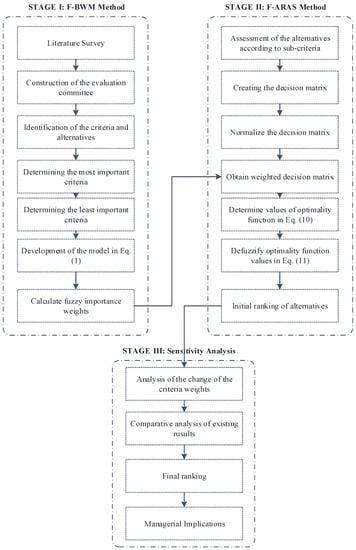

Figure 1 illustrates the different steps for implementing the proposed integrated MCDM framework. The methods used in the implementation of the proposed framework are explained in the following sections, along with the processing steps. To convert qualitative variables into quantitative variables and apply simple relative comparisons F-ARAS method is utilized. Additionally, BWM is chosen due to include fewer and easier pairwise comparisons. Both methods are handled in the fuzzy environment to reflect uncertainties in human judgment more effectively.

Figure 1.

Proposed integrated MCDM framework.

3.1. The Calculation Procedure of the F-BWM Method

The steps of F-BWM are delineated as follows:

- Step 1: Identify decision criteria for the decision-making problem. The criteria () are defined to reach a decision.

- Step 2: Determine the best (most important) and the worst (least important) criteria.

- Step 3: Execute the fuzzy reference comparisons for the best criterion. As a result, fuzzy Best-to-Others (BO) vector would be ), where demonstrates the fuzzy preference of the best criterion over criterion , and it is clear that .

- Step 4: Execute the fuzzy reference comparisons for the worst criterion. As a result, fuzzy others-to-Worst (OW) vector would be , where demonstrates the preference of the criterion j over the worst criterion and it is clear that .

- Step 5: Calculate the optimal fuzzy weights of criteria. Concerning Guo and Zhao [64], the following nonlinear programming model can be constructed based on the BO and OW vectors’ obtained elements.

min ξ*

By solving model (1), the optimal weights and the optimal consistency index can be obtained. Considering a given (CI), the consistency ratio (CR) can be calculated based on the formula, . Finally, fuzzy weights are defuzzified as given in Equation (2) [64]:

3.2. The Calculation Procedure of the F-ARAS Method

The F-ARAS method has been introduced in the literature by [65]. Because the method is based on basic relative comparisons by comparing alternative values to optimal values, it is quite straightforward to implement. The method’s steps are as follows: [65]

- Step 1: The fuzzy decision-making matrix is created as the first step as given in Equation (3). The rows of the matrix represent m alternatives, while the columns perform n criteria.where is the fuzzy value performance value of the i alternative in terms of j criterion, is the optimal value of j criterion. If the optimal value of j criterion is unknown, then:

- Step 2: The normalized decision-making matrix is determined as given in Equation (5):

The criteria with maxima as preferred values are normalized as follows (6):

A two-stage method is used to normalize the criteria whose preferred values are minima:

- Step 3: The normalized-weighted matrix is defined as follows (7) in the third stage. The weight of the criterion is developed with . The sum of the weights is limited as given in Equation (8):

All of the criteria’s normalized-weighted values are determined as follows in Equation (9):

- Step 4: The optimality function values are calculated as shown in Equation (10).where is the value of the optimality function of i-th alternative. Furthermore, because the found values are fuzzy, defuzzification is necessary. The defuzzification is carried out according to Equation (11).

The utility degree of an alternative is calculated using Equation (12).

where: Si and S0 are the optimal criterion values. The calculated Ki is [0, 1]. As a result, the values can be sorted in ascending order.

4. Case Study

The identification of main and sub-criteria for the SSS has started through a comprehensive literature review of “Sustainable Supplier Selection”, “Healthcare System”, and “MCDM” keywords through the Scopus, Web of Science, and Google Scholar databases. Then, an evaluation committee consisting of three decision-makers working in a hospital in Turkey was formed for criteria detection and evaluation. Extraction process of evaluation criteria is performed by nominal group technique. It became determined that having at least 15 years of experience in the field is necessary for the study’s conclusions to be reliable. Because there are so few experts with this degree in the healthcare sector, three qualified experts are chosen for the study. Expert 1 has 15 years of experience in the healthcare industry. Currently, she works in a 600-bed capacity hospital in Istanbul, Turkey. Expert 2 has 24 years of experience in the healthcare industry. Currently, he works in a hospital with a capacity of 850 beds in Istanbul, Turkey. Expert 3 has 28 years of experience in the healthcare industry. Currently, he works in a hospital with a capacity of 1000 beds in Ankara, Turkey.

Among three experts, one of them is the hospital manager, one is the purchasing director, and one is a doctor. After that, a meeting was planned to narrow the main and sub-criteria. At the beginning of the meeting, various criteria were determined and presented to the evaluation committee, and after the negotiations -with the MDCM assessment form-, a consensus was reached, and the main criteria were divided into five main dimensions. Table 1 shows the main and sub-criteria identified, with their brief descriptions and references.

Table 1.

Criteria of Healthcare SSS.

The study has been evaluated according to these alternatives according to expert evaluations; there are seven other suppliers who can supply these massive demands.

4.1. Results of F-BWM

After the main and sub-criteria are determined, F-BWM is used to determine the importance levels of the criteria. Using the opinions of the experts, the best and worst criteria were determined, and the importance levels of the relevant criteria were calculated. First of all, the best and worst main criteria opinions were obtained by three experts. After determining the best and worst criteria, the experts were asked to indicate their BO and OW preferences using the linguistic scale shown in Table 2. Table 3 shows the results from all experts. Then, the evaluations shown in Table 2 are converted into triangular fuzzy numbers. Later, the F-BWM model specified in Equation (1) is created with these numbers. Equation (1) is solved with the Sparse Nonlinear Optimizer (SNOPT) solver in the General Algebraic Modelling System (GAMS) software. The fuzzy weights of the criteria are calculated and are presented in Table 4. Finally, the fuzzy weights are defuzzified, and the crisp weights are presented in Table 4.

Table 2.

Fuzzy linguistic scale [64].

Table 3.

F Linguistic assessments of decision-makers.

Table 4.

Fuzzy and crisp weights of criteria.

Similar procedures are implemented for the sub-criteria, and the relative weight of each sub-criterion is obtained. The global weights of each sub-criteria are obtained by multiplying the relative weights of the relevant main criteria. Table 5 shows the relative and global weights of the main and sub-criteria.

Table 5.

The priority weights of the SSS criteria.

4.2. Results of F-ARAS

Among the alternatives, the key sustainable supplier is selected using the F-ARAS method. The assessment matrix of the alternatives is created using the linguistic rating scale given in Table 6. Then, the evaluations of the experts are obtained as seen in Table 7. After that, the evaluations are collected, and the decision matrix was formed, as shown in Table 8. Finally, the steps of F-ARAS given in Section 3.2 are followed and rankings of suppliers are calculated as shown in Table 9.

Table 6.

Linguistic scale and fuzzy numbers.

Table 7.

Assessment matrix of the alternatives.

Table 8.

Aggregate fuzzy decision matrix of the alternatives.

Table 9.

Ranking of suppliers with F-ARAS method.

4.3. Sensitivity Analysis

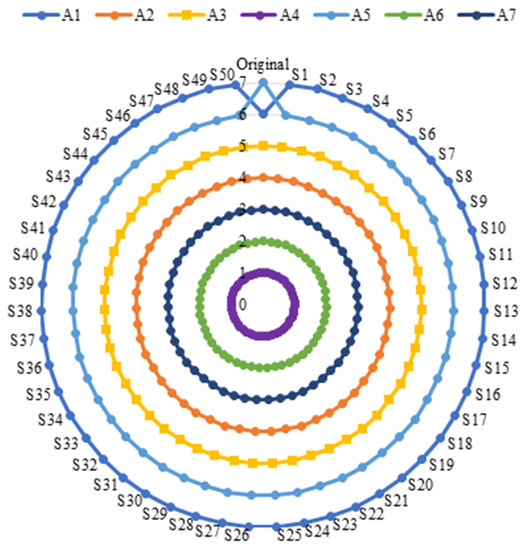

How the alternative rankings affect the results of the proposed integrated fuzzy model was investigated by sensitivity analysis. While adjusting the scenarios, the weight of the most effective (important) criterion is changed. 50 scenarios are simulated by reducing the weight of the criterion C2 with a rate of 2%. The new rankings of alternatives are shown in Figure 2.

Figure 2.

Impact of change of the most important criterion.

The results display that the first three alternatives (A4, A6, and A7) keep their positions through all 50 scenarios, i.e., they depict a set of dominant alternatives. The worst alternative (A5) has placed its position to A1 for the values below .

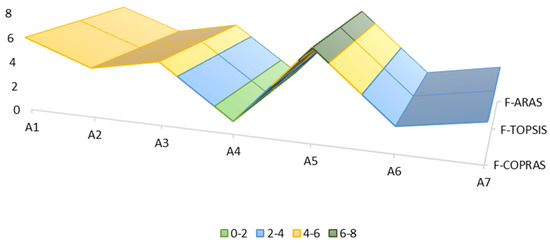

Since fuzzy numbers were used in this study for expressing opinions of decision-makers, two different MCDM methods were chosen to compare the results: F-TOPSIS and F-COPRAS. The comparative result obtained as a result of applying these fuzzy MCDM methods is shown in Figure 3. When observed from Figure 3, it is clear that the results of the three fuzzy methods utilized are very equivalent. In all three fuzzy MCDM methods, the same results are obtained in the application. A4 should be selected as the health provider based on F-ARAS, F-TOPSIS, F-COPRAS findings. During and after the COVID-19 process, A4 is the best supplier for healthcare providers’ solutions. The pandemic process, on the other hand, is a process marked by vulnerabilities and extraordinary circumstances, particularly in terms of supply. It must maintain active business relations with A6, the second-best supplier, in order to be prepared for these possibilities. As a result, it may be able to provide some health-related products from this supplier on a sporadic basis.

Figure 3.

The results of the fuzzy MCDM.

4.4. Managerial Implications

The COVID-19 outbreak has deeply affected the dynamics of many industries around the world. The healthcare system is among the most affected sectors by the epidemic. Therefore, measuring the dynamics of the health system is important for the sustainability of the health supply chain. In this study, the effects of the health system on the supply chain process were examined during the COVID-19 pandemic period. Since such an examination should include detailed decision-making processes, F-MDCM methods have been applied as a decision-making method in the literature. The weights derived from these approaches were calculated using the F-BWM method, and supplier alternatives were determined using the F-ARAS, F-TOPSIS, and F-COPRAS procedures. The results acquired in unusual scenarios, such as COVID-19, are analyzed utilizing sensitivity analysis.

The most essential criteria in the SSS process in the health system is established in the F-BWM study. The most important main criteria are found in Table 5 to be Economic (C1) and Health Measures (C4) (0.2250, 0.2743, 0.2944—0.2432, 0.2709, 0.2898). The economic and health-related criteria were found to be quantitatively quite near to each other. Many pieces of research in the literature on health have used economic factors [23,26,27,30,32] to arrive at conclusions. However, health measurements are one of the most relevant parameters in this study throughout the post-COVID-19 period. COVID-19 Innovations (C4-2); (0.0927, 0.1138, 0.1297), Health Measures (C4-1); (0.0866, 0.1061, 0.1206), Velocity and Logistics Speed (C5-2); (0.0578, 0.0828, 0.1047) are the most important sub-criteria, according to the global weight results. Other important major sub-criteria include Transport Quality (C5-1), Complex Situation Adoption (C5-3), and Pollution Control (C3-2). Health measurements have been determined as the most essential criterion in the selection of sustainable providers for the health system, according to these findings, while the repercussions of the COVID-19 epidemic continue. Simultaneously, because time is such a key notion in the healthcare industry, logistics criteria are one of the most important findings, emphasizing the importance of speed and automation in the COVID-19 process.

Alternative 4 is chosen as the best provider based on the F-ARAS analysis results. According to the findings, Alternatif-4 is the provider that can best adapt to the COVID-19 pandemic and complicated situations. The Alternative 6 firm is the second-best supplier that can adapt to these conditions.

The first managerial implication concerns economic and health measures from the main criteria. With COVID-19, healthcare centers’ need for medical supplies such as gloves, face masks, and ventilators has increased. The expenditures of health centers on medical supplies have increased significantly due to the sudden increase in COVID-19 cases. For this reason, the main economic criterion has emerged as the most important. In fact, since the sudden increase in demand for medical supplies caused prices to rise, the price of the product (C1-1) took first place among the economic criteria. Some executives noted that procurement costs had doubled [90]. For this reason, some companies even went to search for new suppliers.

When we look at the social dimension, reputation is weighted as the most significant sub-criteria. While hospitals were experiencing a serious shortage of ventilators at the beginning of the COVID-19 pandemic, they cooperated to overcome this problem. Health centers lacking respirators were supplied from other centers, even from centers in other countries. Examples demonstrating the importance of cooperation in supplier selection became more visible with the COVID-19 pandemic. The partnership needs to be leveraged to optimize and overcome procurement challenges [91].

While the COVID-19 pandemic has been challenging for many societies and industries, it has also unlocked new opportunities for innovation through collaborations and technological advances. In just a few months, innovators have come up with countless solutions. For example, many digital health approaches were targeted towards reducing the negative impacts of the COVID-19 pandemic. Surveillance tools, testing (diagnostic) solutions, therapeutic innovations, and communication aids and isolation mechanisms are examples [92]. In times of crisis like this, we need innovative tools and skills.

The results obtained in the sustainable supplier selection studies for the health sector support the results of this study. In the study conducted for the health industry related to this study, the technical main criterion, including the economic sub-criteria, is obtained as the most important main criteria [36]. The price criteria determined to be the most significant sub-criteria in another important study SSS for the healthcare industry. The outcome supports up the findings of this investigation [23]. In the study, the results of which are illuminating for the health sector, logistics and cost criteria is obtained as the most important criteria. This result supports the results of the study by showing similarities with the results of this study [26]. Results show that the study is inclusive for the healthcare industry compared to other leading SSS studies.

5. Conclusions

The COVID-19 pandemic has caused disruptions and changes in all sectors, from manufacturing to service. Especially in the health sector, there has been an increase in demand for medical supplies such as gloves, face masks, ventilators, and other personal protective equipment with the pandemic. Demand increases have caused disruptions in supply chains and difficulties in the supply of such products have made health centers face various challenges. In order to overcome the challenges, the adoption and implementation of sustainable operations by all actors in the supply chain provide an opportunity for modern manufacturing processes. Thus, SSS is a strategic key to an inefficient supply chain.

The importance levels of some criteria in the COVID-19 process were addressed with expert opinions in this study, and some F-MDCM methods available in the literature were used for sustainable supplier selection. This study aims to examine the impact of COVID-19 on SSS. The SSS may change depending on expert opinion. As a result, this system utilizes multi-criteria decision-making methods. In this study, the COVID-19 process’s SSS was performed with expert advice, so that the impacts of COVID-19 on sustainable supplier selection could be detected through comparisons with previous studies. The F-BMW method was implemented to determine criterion weights, and the F-ARAS method was utilized to select suppliers among the multi-criteria decision-making methods. Moreover, the results of the F-ARAS method were compared to those of the F-TOPSIS and F-COPRAS methods in order to evaluate their effectiveness. Additionally, sensitivity analysis including 50 scenarios was performed to evaluate how the rankings of alternatives affect the fuzzy model’s results.

This study contributes to the literature by analyzing the healthcare systems’ survivability in complex and fragile processes like COVID-19 from the perspective of Logistics 4.0 and sustainability. In this study, since innovations have been detected to protect and avoid the effects of COVID-19 during the pandemic period, Logistics 4.0 has come to the forefront. Because Logistics 4.0 tries to minimize supply chain disruptions and create digital systems. This ensures better healthcare administration, especially during times of pandemics. The results of this study can also be useful to experts in the field because they provide information about SSS.

Limitations and Directions for Future Studies

This study has some limitations. First, this study was conducted in a hospital in Turkey, and generalizing the results to every healthcare provider can be a challenge. In addition, criteria were determined by literature review and expert opinions. According to other experts, different criteria may be included in the studies. In addition, new Logistics 4.0 for sustainable supplier selection is based on Logistics 4.0 criteria. Finally, since this study was carried out during the pandemic period, a comparison can be made by researching it in the pre-pandemic period.

This study can be extended to some points. Firstly, different fuzzy set theories (e.g., fuzzy neutrosophic, pentagonal fuzzy) may be employed to get results that can be compared to the findings of this study. Secondly, a system that exclusively evaluates Logistics 4.0 and the health system may be developed, and the results compared to the findings of this study. Furthermore, this study was only conducted using one major hospital; however, this analysis might be expanded to examine several hospitals throughout a region.

Author Contributions

Conceptualization, E.B. and S.Ç.; methodology, E.B.; software, S.Ç.; validation, E.B., S.Ç. and A.Ç.; formal analysis, E.B. and S.Ç.; investigation, E.B.; resources, S.Ç.; data curation, E.B and A.Ç.; writing—original draft preparation, E.B, S.Ç. and A.Ç.; writing—review and editing, A.Ç.; visualization, E.B.; supervision, A.Ç.; project administration, E.B.; funding acquisition, E.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

No applicable.

Informed Consent Statement

No applicable.

Data Availability Statement

No applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mena, C.; Karatzas, A.; Hansen, C. International Trade Resilience and the Covid-19 Pandemic. J. Bus. Res. 2022, 138, 77–91. [Google Scholar] [CrossRef]

- Ivanov, D. Predicting the Impacts of Epidemic Outbreaks on Global Supply Chains: A Simulation-Based Analysis on the Coronavirus Outbreak (COVID-19/SARS-CoV-2) Case. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101922. [Google Scholar] [CrossRef]

- Anser, M.K.; Yousaf, Z.; Khan, M.A.; Sheikh, A.Z.; Nassani, A.A.; Abro, M.M.Q.; Zaman, K. Communicable Diseases (Including COVID-19)—Induced Global Depression: Caused by Inadequate Healthcare Expenditures, Population Density, and Mass Panic. Front. Public Health 2020, 18, 398. [Google Scholar] [CrossRef] [PubMed]

- Francis, J.R. COVID-19: Implications for Supply Chain Management. Front. Health Serv. Manag. 2020, 37, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Sriyanto, S.; Lodhi, M.S.; Salamun, H.; Sardin, S.; Pasani, C.F.; Muneer, G.; Zaman, K. The Role of Healthcare Supply Chain Management in the Wake of COVID-19 Pandemic: Hot off the Press. Foresight 2021, 24, 429–444. [Google Scholar] [CrossRef]

- Spieske, A.; Gebhardt, M.; Kopyto, M.; Birkel, H. Improving Resilience of the Healthcare Supply Chain in a Pandemic: Evidence from Europe during the COVID-19 Crisis. J. Purch. Supply Manag. 2022, 100748, (in press). [Google Scholar] [CrossRef]

- Mehrotra, P.; Malani, P.; Yadav, P. Personal Protective Equipment Shortages during COVID-19—Supply Chain–Related Causes and Mitigation Strategies. JAMA Health Forum 2020, 1, e200553. [Google Scholar] [CrossRef] [PubMed]

- Finkenstadt, D.J.; Handfield, R. Blurry Vision: Supply Chain Visibility for Personal Protective Equipment during COVID-19. J. Purch. Supply Manag. 2021, 27, 100689. [Google Scholar] [CrossRef]

- Sarkis, J. Supply Chain Sustainability: Learning from the COVID-19 Pandemic. Int. J. Oper. Prod. Manag. 2020, 41, 63–73. [Google Scholar] [CrossRef]

- Vanalle, R.M.; Santos, L.B. Green Supply Chain Management in Brazilian Automotive Sector. Manag. Environ. Qual. 2014, 25, 523–541. [Google Scholar] [CrossRef]

- Sarkis, J.; Dhavale, D.G. Supplier Selection for Sustainable Operations: A Triple-Bottom-Line Approach Using a Bayesian Framework. Int. J. Prod. Econ. 2015, 166, 177–191. [Google Scholar] [CrossRef]

- Fallahpour, A.; Udoncy Olugu, E.; Nurmaya Musa, S.; Yew Wong, K.; Noori, S. A Decision Support Model for Sustainable Supplier Selection in Sustainable Supply Chain Management. Comput. Ind. Eng. 2017, 105, 391–410. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Chiang, J.H.; Lan, L.W. Selection of Optimal Supplier in Supply Chain Management Strategy with Analytic Network Process and Choquet Integral. Comput. Ind. Eng. 2009, 57, 330–340. [Google Scholar] [CrossRef]

- Beil, D.R. Supplier Selection. In The Wiley Encyclopedia of Operations Research and Management Science; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Fallahpour, A.; Wong, K.Y.; Rajoo, S.; Fathollahi-Fard, A.M.; Antucheviciene, J.; Nayeri, S. An Integrated Approach for a Sustainable Supplier Selection Based on Industry 4.0 Concept. Environ. Sci. Pollut. Res. Int. 2021, 1–19. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Gupta, H.; Khan, S.A.; Chiappetta Jabbour, C.J.; Rehman, S.T.; Kusi-Sarpong, H. Sustainable Supplier Selection Based on Industry 4.0 Initiatives within the Context of Circular Economy Implementation in Supply Chain Operations. Prod. Plan. Control 2021, 1–21. [Google Scholar] [CrossRef]

- Çalık, A. A Novel Pythagorean Fuzzy AHP and Fuzzy TOPSIS Methodology for Green Supplier Selection in the Industry 4.0 Era. Soft Comput. 2021, 25, 2253–2265. [Google Scholar] [CrossRef]

- Ghadimi, P.; Wang, C.; Lim, M.K.; Heavey, C. Intelligent Sustainable Supplier Selection Using Multi-Agent Technology: Theory and Application for Industry 4.0 Supply Chains. Comput. Ind. Eng. 2019, 127, 588–600. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An Integrated Framework for Sustainable Supplier Selection and Evaluation in Supply Chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Amindoust, A.; Ahmed, S.; Saghafinia, A.; Bahreininejad, A. Sustainable Supplier Selection: A Ranking Model Based on Fuzzy Inference System. Appl. Soft Comput. J. 2012, 12, 1668–1677. [Google Scholar] [CrossRef]

- Awasthi, A.; Govindan, K.; Gold, S. Multi-Tier Sustainable Global Supplier Selection Using a Fuzzy AHP-VIKOR Based Approach. Int. J. Prod. Econ. 2018, 195, 106–117. [Google Scholar] [CrossRef]

- Fashoto, S.G.; Akinnuwesi, B.; Owolabi, O.; Adelekan, D. Decision Support Model for Supplier Selection in Healthcare Service Delivery Using Analytical Hierarchy Process and Artificial Neural Network. Afr. J. Bus. Manag. 2016, 10, 209–232. [Google Scholar]

- Stević, Ž.; Pamučar, D.; Puška, A.; Chatterjee, P. Sustainable Supplier Selection in Healthcare Industries Using a New MCDM Method: Measurement of Alternatives and Ranking According to COmpromise Solution (MARCOS). Comput. Ind. Eng. 2020, 140, 106231. [Google Scholar] [CrossRef]

- Ghadimi, P.; Heavey, C. Sustainable Supplier Selection in Medical Device Industry: Toward Sustainable Manufacturing. Procedia CIRP 2014, 15, 165–170. [Google Scholar] [CrossRef]

- Radulescu, C.Z.; Radulescu, M. A Group Decision Approach for Supplier Selection Problem Based on a Multi-Criteria Model. Stud. Inform. Control 2020, 29, 35–44. [Google Scholar] [CrossRef]

- Akcan, S.; Güldeş, M. Integrated Multicriteria Decision-Making Methods to Solve Supplier Selection Problem: A Case Study in a Hospital. J. Healthc. Eng. 2019, 2019, 5614892. [Google Scholar] [CrossRef] [PubMed]

- Yazdani, M.; Torkayesh, A.E.; Chatterjee, P. An Integrated Decision-Making Model for Supplier Evaluation in Public Healthcare System: The Case Study of a Spanish Hospital. J. Enterp. Inf. Manag. 2020, 33, 965–989. [Google Scholar] [CrossRef]

- Sumrit, D. Supplier Selection for Vendor-Managed Inventory in Healthcare Using Fuzzy Multi-Criteria Decision-Making Approach. Decis. Sci. Lett. 2020, 9, 233–256. [Google Scholar] [CrossRef]

- Karsak, E.E.; Dursun, M. An Integrated Fuzzy MCDM Approach for Supplier Evaluation and Selection. Comput. Ind. Eng. 2015, 82, 82–93. [Google Scholar] [CrossRef]

- Bahadori, M.; Hosseini, S.M.; Teymourzadeh, E.; Ravangard, R.; Raadabadi, M.; Alimohammadzadeh, K. A Supplier Selection Model for Hospitals Using a Combination of Artificial Neural Network and Fuzzy VIKOR. Int. J. Healthc. Manag. 2020, 13, 286–294. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of Intertwined Supply Networks: Extending the Supply Chain Resilience Angles towards Survivability. A Position Paper Motivated by COVID-19 Outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef]

- Alamroshan, F.; La’li, M.; Yahyaei, M. The Green-Agile Supplier Selection Problem for the Medical Devices: A Hybrid Fuzzy Decision-Making Approach. Environ. Sci. Pollut. Res. 2021, 29, 6793–6811. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Wang, Y.-C.; Wu, H.-C. Analyzing the Impact of Vaccine Availability on Alternative Supplier Selection amid the COVID-19 Pandemic: A CFGM-FTOPSIS-FWI Approach. Healthcare 2021, 9, 71. [Google Scholar] [CrossRef] [PubMed]

- Ecer, F. An Extended MAIRCA Method Using Intuitionistic Fuzzy Sets for Coronavirus Vaccine Selection in the Age of COVID-19. Neural Comput. Appl. 2022, 34, 5603–5623. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-C.; Chen, T. A Bi-Objective AHP-MINLP-GA Approach for Flexible Alternative Supplier Selection amid the COVID-19 Pandemic. Soft Comput. Lett. 2021, 3, 100016. [Google Scholar] [CrossRef]

- Pamucar, D.; Torkayesh, A.E.; Biswas, S. Supplier Selection in Healthcare Supply Chain Management during the COVID-19 Pandemic: A Novel Fuzzy Rough Decision-Making Approach. Ann. Oper. Res. 2022, 1–43, (Epub ahead of print). [Google Scholar]

- Alzoubi, H.M.; Elrehail, H.; Hanaysha, J.R.; Al-Gasaymeh, A.; Al-Adaileh, R. The Role of Supply Chain Integration and Agile Practices in Improving Lead Time During the COVID-19 Crisis. Int. J. Serv. Sci. Manag. Eng. Technol. 2022, 13, 1–11. [Google Scholar] [CrossRef]

- Szmelter-Jarosz, A.; Ghahremani-Nahr, J.; Nozari, H. A Neutrosophic Fuzzy Optimisation Model for Optimal Sustainable Closed-Loop Supply Chain Network during COVID-19. J. Risk Financ. Manag. 2021, 14, 519. [Google Scholar] [CrossRef]

- Lin, C.-L.; Chen, J.K.C.; Ho, H.-H. BIM for Smart Hospital Management during COVID-19 Using MCDM. Sustainability 2021, 13, 6181. [Google Scholar] [CrossRef]

- Khan, F.; Ali, Y.; Pamucar, D. A New Fuzzy FUCOM-QFD Approach for Evaluating Strategies to Enhance the Resilience of the Healthcare Sector to Combat the COVID-19 Pandemic. Kybernetes 2021, 51, 1429–1451. [Google Scholar] [CrossRef]

- Zamiela, C.; Hossain, N.U.I.; Jaradat, R. Enablers of Resilience in the Healthcare Supply Chain: A Case Study of US Healthcare Industry during COVID-19 Pandemic. Res. Transp. Econ. 2021, 93, 101174. [Google Scholar] [CrossRef]

- Farahani, R.Z.; Rezapour, S.; Drezner, T.; Fallah, S. Competitive Supply Chain Network Design: An Overview of Classifications, Models, Solution Techniques and Applications. Omega 2014, 45, 92–118. [Google Scholar] [CrossRef]

- Frohlich, M.T. E-integration in the Supply Chain: Barriers and Performance. Decis. Sci. 2002, 33, 537–556. [Google Scholar] [CrossRef]

- Hoseini, S.A.; Fallahpour, A.; Wong, K.Y.; Mahdiyar, A.; Saberi, M.; Durdyev, S. Sustainable Supplier Selection in Construction Industry through Hybrid Fuzzy-Based Approaches. Sustainability 2021, 13, 1413. [Google Scholar] [CrossRef]

- Hwarng, H.B.; Xie, N. Understanding Supply Chain Dynamics: A Chaos Perspective. Eur. J. Oper. Res. 2008, 184, 1163–1178. [Google Scholar] [CrossRef]

- Novais, L.; Maqueira, J.M.; Ortiz-Bas, Á. A Systematic Literature Review of Cloud Computing Use in Supply Chain Integration. Comput. Ind. Eng. 2019, 129, 296–314. [Google Scholar] [CrossRef]

- Fan, Y.; Stevenson, M. Reading on and between the Lines: Risk Identification in Collaborative and Adversarial Buyer–Supplier Relationships. Supply Chain Manag. 2018, 23, 351–376. [Google Scholar] [CrossRef]

- Armani, A.M.; Hurt, D.E.; Hwang, D.; McCarthy, M.C.; Scholtz, A. Low-Tech Solutions for the COVID-19 Supply Chain Crisis. Nat. Rev. Mater. 2020, 5, 403–406. [Google Scholar]

- Jadhav, A.; Orr, S.; Malik, M. The Role of Supply Chain Orientation in Achieving Supply Chain Sustainability. Int. J. Prod. Econ. 2019, 217, 112–125. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of Quantitative Methods for Supply Chain Resilience Analysis. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 285–307. [Google Scholar]

- Lotfi, R.; Kargar, B.; Hoseini, S.H.; Nazari, S.; Safavi, S.; Weber, G. Resilience and Sustainable Supply Chain Network Design by Considering Renewable Energy. Int. J. Energy Res. 2021, 45, 17749–17766. [Google Scholar] [CrossRef]

- Min, H. Blockchain Technology for Enhancing Supply Chain Resilience. Bus. Horiz. 2019, 62, 35–45. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The Evolution of Resilience in Supply Chain Management: A Retrospective on Ensuring Supply Chain Resilience. J. Bus. Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Roy, S.A.; Ali, S.M.; Kabir, G.; Enayet, R.; Suhi, S.A.; Haque, T.; Hasan, R. A Framework for Sustainable Supplier Selection with Transportation Criteria. Int. J. Sustain. Eng. 2020, 13, 77–92. [Google Scholar] [CrossRef]

- Aslam, H.; Blome, C.; Roscoe, S.; Azhar, T.M. Dynamic Supply Chain Capabilities: How Market Sensing, Supply Chain Agility and Adaptability Affect Supply Chain Ambidexterity. Int. J. Oper. Prod. Manag. 2018, 38, 2266–2285. [Google Scholar] [CrossRef]

- Chen, C.-J. Developing a Model for Supply Chain Agility and Innovativeness to Enhance Firms’ Competitive Advantage. Manag. Decis. 2019, 57, 1511–1534. [Google Scholar] [CrossRef]

- Dubey, R.; Bryde, D.J.; Foropon, C.; Tiwari, M.; Dwivedi, Y.; Schiffling, S. An Investigation of Information Alignment and Collaboration as Complements to Supply Chain Agility in Humanitarian Supply Chain. Int. J. Prod. Res. 2021, 59, 1586–1605. [Google Scholar] [CrossRef]

- Gligor, D.; Gligor, N.; Holcomb, M.; Bozkurt, S. Distinguishing between the Concepts of Supply Chain Agility and Resilience: A Multidisciplinary Literature Review. Int. J. Logist. Manag. 2019, 30, 467–487. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Wamba, S.F. Blockchain Adoption Challenges in Supply Chain: An Empirical Investigation of the Main Drivers in India and the USA. Int. J. Inf. Manag. 2019, 46, 70–82. [Google Scholar] [CrossRef]

- Mohammadi, M.; Jämsä-Jounela, S.-L.; Harjunkoski, I. Optimal Planning of Municipal Solid Waste Management Systems in an Integrated Supply Chain Network. Comput. Chem. Eng. 2019, 123, 155–169. [Google Scholar] [CrossRef]

- Çankaya, S.Y.; Sezen, B. Effects of Green Supply Chain Management Practices on Sustainability Performance. J. Manuf. Technol. Manag. 2019, 30, 98–121. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.-L.; Yuen, T.W.W.; Lim, M.K.; Hu, J. Do Green Practices Really Attract Customers? The Sharing Economy from the Sustainable Supply Chain Management Perspective. Resour. Conserv. Recycl. 2019, 149, 177–187. [Google Scholar] [CrossRef]

- Mani, V.; Gunasekaran, A.; Delgado, C. Enhancing Supply Chain Performance through Supplier Social Sustainability: An Emerging Economy Perspective. Int. J. Prod. Econ. 2018, 195, 259–272. [Google Scholar] [CrossRef]

- Guo, S.; Zhao, H. Fuzzy Best-Worst Multi-Criteria Decision-Making Method and Its Applications. Knowl. Based Syst. 2017, 121, 23–31. [Google Scholar] [CrossRef]

- Turskis, Z.; Zavadskas, E.K. A new fuzzy additive ratio assessment method (ARAS-F). Case study: The analysis of fuzzy multiple criteria in order to select the logistic centers location. Transport 2010, 25, 423–432. [Google Scholar] [CrossRef]

- Chen, Y.-J. Structured Methodology for Supplier Selection and Evaluation in a Supply Chain. Inf. Sci. 2011, 181, 1651–1670. [Google Scholar] [CrossRef]

- Wang, T.-Y.; Yang, Y.-H. A Fuzzy Model for Supplier Selection in Quantity Discount Environments. Expert Syst. Appl. 2009, 36, 12179–12187. [Google Scholar] [CrossRef]

- Li, L.; Zabinsky, Z.B. Incorporating Uncertainty into a Supplier Selection Problem. Int. J. Prod. Econ. 2011, 134, 344–356. [Google Scholar] [CrossRef]

- Badi, I.; Ballem, M. Supplier Selection Using the Rough BWM-MAIRCA Model: A Case Study in Pharmaceutical Supplying in Libya. Decis. Mak. Appl. Manag. Eng. 2018, 1, 16–33. [Google Scholar] [CrossRef]

- Orji, I.J.; Wei, S. An Innovative Integration of Fuzzy-Logic and Systems Dynamics in Sustainable Supplier Selection: A Case on Manufacturing Industry. Comput. Ind. Eng. 2015, 88, 1–12. [Google Scholar] [CrossRef]

- Arabsheybani, A.; Paydar, M.M.; Safaei, A.S. An Integrated Fuzzy MOORA Method and FMEA Technique for Sustainable Supplier Selection Considering Quantity Discounts and Supplier’s Risk. J. Clean. Prod. 2018, 190, 577–591. [Google Scholar] [CrossRef]

- Kirytopoulos, K.; Leopoulos, V.; Voulgaridou, D. Supplier Selection in Pharmaceutical Industry: An Analytic Network Process Approach. Benchmarking An Int. J. 2008, 15, 494–516. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Developing a Framework for Enhancing Survivability of Sustainable Supply Chains during and Post-COVID-19 Pandemic. Int. J. Logist. Res. Appl. 2020, 25, 433–453. [Google Scholar] [CrossRef]

- Vahidi, F.; Torabi, S.A.; Ramezankhani, M.J. Sustainable Supplier Selection and Order Allocation under Operational and Disruption Risks. J. Clean. Prod. 2018, 174, 1351–1365. [Google Scholar] [CrossRef]

- Chaharsooghi, S.K.; Ashrafi, M. Sustainable Supplier Performance Evaluation and Selection with Neofuzzy TOPSIS Method. Int. Sch. Res. Not. 2014, 2014, 434168. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Mardani, A.; Dashtian, Z.; Soltani, M.; Weber, G.-W. A Novel Hybrid Method Using Fuzzy Decision Making and Multi-Objective Programming for Sustainable-Reliable Supplier Selection in Two-Echelon Supply Chain Design. J. Clean. Prod. 2020, 250, 119517. [Google Scholar] [CrossRef]

- Ishtiaq, P.; Khan, S.A.; Haq, M. A Multi-Criteria Decision-Making Approach to Rank Supplier Selection Criteria for Hospital Waste Management: A Case from Pakistan. Waste Manag. Res. 2018, 36, 386–394. [Google Scholar] [CrossRef]

- Burney, S.A.; Ali, S.M. Fuzzy Multi-Criteria Based Decision Support System for Supplier Selection in Textile Industry. IJCSNS 2019, 19, 239. [Google Scholar]

- Hudnurkar, M.; Ambekar, S.S. Framework for Measurement of Supplier Satisfaction. Int. J. Product. Perform. Manag. 2019, 68, 1475–1492. [Google Scholar] [CrossRef]

- Linder, C.; Seidenstricker, S. How Does a Component from a Supplier with High Reputation for Product Innovation Improve the Perception of a Final Offering? A Process Perspective. Eur. Manag. J. 2018, 36, 288–299. [Google Scholar] [CrossRef]

- Manello, A.; Calabrese, G. The Influence of Reputation on Supplier Selection: An Empirical Study of the European Automotive Industry. J. Purch. Supply Manag. 2019, 25, 69–77. [Google Scholar] [CrossRef]

- van der Westhuizen, J.; Ntshingila, L. The Effect Of Supplier Selection, Supplier Development And Information Sharing On Sme’s Business Performance In Sedibeng. Int. J. Econ. Financ. Stud. 2020, 12, 153–167. [Google Scholar]

- Gupta, S.; Soni, U.; Kumar, G. Green Supplier Selection Using Multi-Criterion Decision Making under Fuzzy Environment: A Case Study in Automotive Industry. Comput. Ind. Eng. 2019, 136, 663–680. [Google Scholar] [CrossRef]

- Rashidi, K.; Cullinane, K. A Comparison of Fuzzy DEA and Fuzzy TOPSIS in Sustainable Supplier Selection: Implications for Sourcing Strategy. Expert Syst. Appl. 2019, 121, 266–281. [Google Scholar] [CrossRef]

- Chaabane, A.; Ramudhin, A.; Paquet, M. Designing Supply Chains with Sustainability Considerations. Prod. Plan. Control 2011, 22, 727–741. [Google Scholar] [CrossRef]

- Petrudi, S.H.H.; Ahmadi, H.B.; Rehman, A.; Liou, J.J.H. Assessing Suppliers Considering Social Sustainability Innovation Factors during COVID-19 Disaster. Sustain. Prod. Consum. 2021, 27, 1869–1881. [Google Scholar] [CrossRef]

- Machiavelli, N. Covidinnovation (Covid-Innovation). In The Last Technological Innovations and Its Effects on Growth Process, Labor Market and Society; Livre de Lyon: Lyon, France, 2020; p. 73. [Google Scholar]

- Azadnia, A.H.; Saman, M.Z.M.; Wong, K.Y. Sustainable Supplier Selection and Order Lot-Sizing: An Integrated Multi-Objective Decision-Making Process. Int. J. Prod. Res. 2015, 53, 383–408. [Google Scholar] [CrossRef]

- Bjelobrk, N.; Nabavi, M.; Poulikakos, D. Acoustic Levitator for Contactless Transport and Mixing of Droplets in Air. J. Acoust. Soc. Am. 2011, 130, 2370. [Google Scholar] [CrossRef]

- Harrop, C. Medical Supply Costs Still High amid COVID-19 Spikes—Will Omicron Add to Supply Chain Disruptions? Available online: https://www.mgma.com/data/data-stories/medical-supply-costs-still-high-amid-covid-19-spik (accessed on 16 September 2022).

- The Global Fund. COVID-19 Impact on Health Product Supply: Assessment and Recommendations. 2021. Available online: https://www.theglobalfund.org/Media/9440/Psm_Covid-19Impactonsupplychainlogistics_Report_En.Pdf (accessed on 15 September 2022).

- Merten, M.; Roth, S.; Allaudin, F.S. Public Health Innovations for COVID-19 Finding, Trusting, and Scaling Innovation; Asian Development Bank: Mandaluyong, Philippines, 2020. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).