A Dynamic Dispatching Method for Large-Scale Interbay Material Handling Systems of Semiconductor FAB

Abstract

:1. Introduction

1.1. Scheduling Optimization Problem

1.2. Real-Time Production Scheduling Problem

1.3. Structure

2. Model Formulations

| . | |

| . | |

| . | |

| . | |

| . | |

| number of stockers in the interbay system. | |

| . | |

| . | |

| and the arrival of OHS vehicle. | |

| . | |

| . | |

| . | |

| number of waiting wafer lots in the interbay system. | |

| . | |

| number of wafer lots that complete all the processing. | |

| . | |

| . | |

| expected average waiting time. | |

| . | |

| . | |

| . | |

| = 0. | |

| . | |

| cost matrix. |

3. Dynamic Dispatching Methodology

3.1. Framework of Dynamic Dispatching Process

3.2. Weights Adjustment Method Based on Fuzzy Theory

3.2.1. Input Variables

- (1)

- Interbay system load ratio measures the current transportation load of the system.

- (2)

- Wafer lots due date factor measures the waiting lot’s due date satisfaction.is the due date slack coefficient of completed wafer lots.

- (3)

- Wafer lots waiting time factor measures the proportion of wafer lots with waiting time greater than the expected mean waiting time .

- (4)

- Interbay system buffer load balance factor measures the probability of stocker buffers being blocked or starvation.

3.2.2. Membership Functions

3.2.3. Rule Extraction

- (1)

- The definition of the front part of the rule.

- (2)

- The definition of the consequent part of the rule.

3.2.4. Fuzzy Inference

4. Simulation Models and Analysis

4.1. Simulation Model

- Stocker and battery of OHS are not considered, but MTBF and MTTR are considered.

- Three types of wafer lot (part A, B, and C) are processed in the system and account for 20%, 30%, and 50% of the total production volume, respectively. The process sequences of wafer lot are shown in Figure 7.

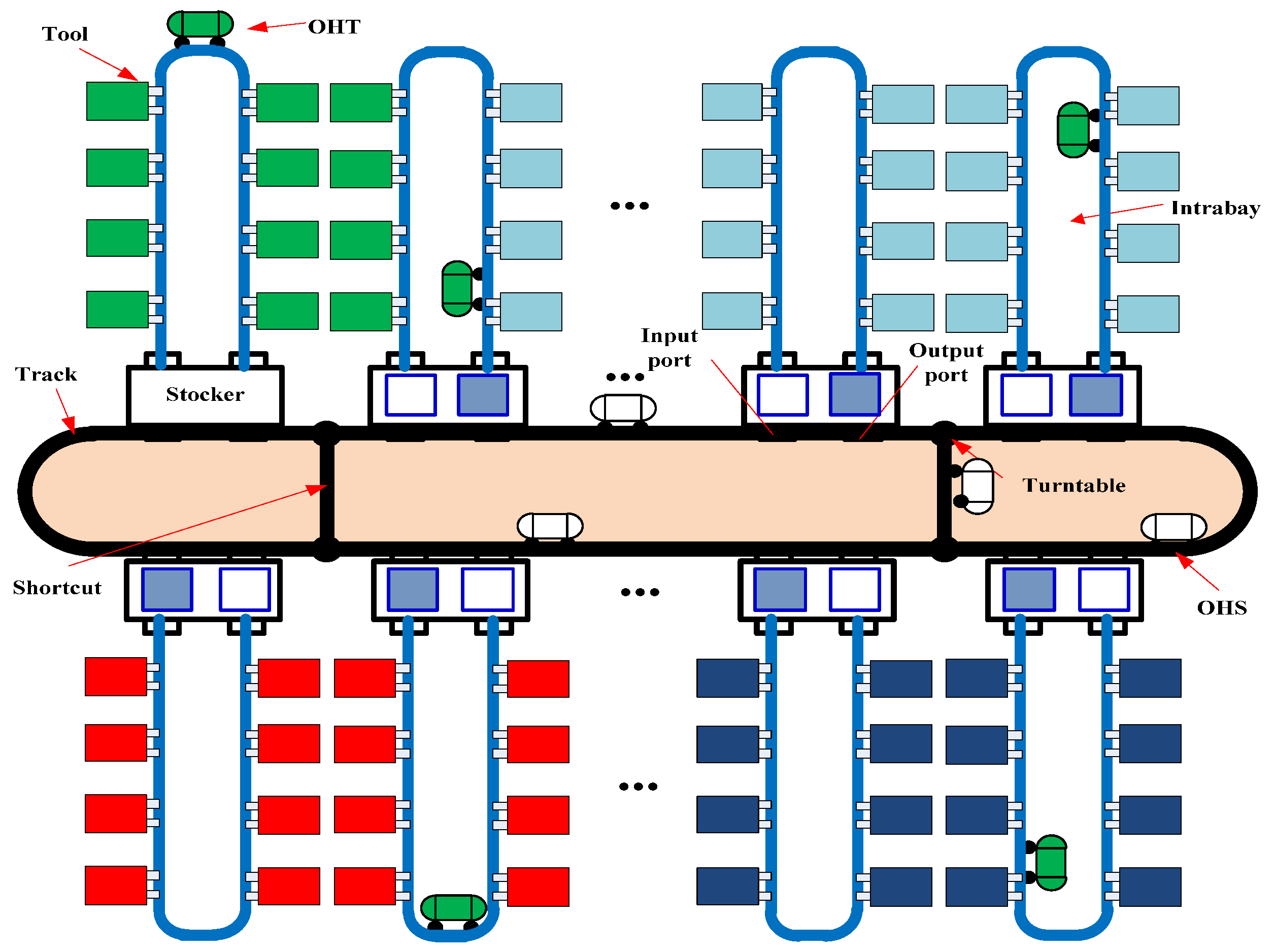

- The distance of the Interbay loop track is 456 m, including 24 Intrabay (workstation) subsystems, five shortcuts, 10 turntables, and 10 OHSs. The length between adjacent stockers is 18 m.

- The speed of OHS remains at 1 m/s.

- A FOUP passes through the turntable for 10 s.

- The OHS vehicle load/unload a FOUP for15 s.

- The process time of cranes in a stocker is assumed to be normally distributed. The mean is 18 s, and the standard deviation (STD) is 5 s.

- The input and output buffer are separated in a stocker. Stockers are assumed with limited capacity. Both input buffer and output buffer capacity are set to be 50.

- A deterministic time interval strategy is used to control the lot feed rate. The feed rate is 1.2 h/lot.

- The simulation time is 1500 h.

4.2. Simulation Results and Discussions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Agrawal, G.K.; Heragu, S.S. A Survey of Automated Material Handling Systems in 300 mm Semiconductor Fabs. IEEE Trans. Semicond. Manuf. 2006, 19, 112–120. [Google Scholar] [CrossRef]

- Haddadin, M.; Moreno, W. Automated Material Handling Systems: System of Systems Architecture Examination Semiconductor Manufacturing Perspective. In Proceedings of the 32nd Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC 2021), Milpitas, CA, USA, 10–12 May 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Wong, H.S.P.; Akarvardar, K.; Antoniadis, D.; Bokor, J.; Hu, C.; King-Liu, T.-J.; Mitra, S.; Plummer, J.D.; Salahuddin, S. A Density Metric for Semiconductor Technology [Point of View]. Proc. IEEE 2020, 108, 478–482. [Google Scholar] [CrossRef]

- Montoya-Torres, J.R. A literature survey on the design approaches and operational issues of automated wafer-transport systems for wafer fabs. Prod. Plan. Control 2007, 17, 648–663. [Google Scholar] [CrossRef]

- Yoon, H.J.; Chae, J. Simulation Study for Semiconductor Manufacturing System: Dispatching Policies for a Wafer Test Facility. Sustainability 2019, 11, 1119. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.-J.J.; Chung, H.C.; Wu, H.C. Evaluating the 300 mm wafer-handling task in semiconductor industry. Int. J. Ind. Ergon. 2004, 34, 459–466. [Google Scholar] [CrossRef]

- Le-Anh, T.; De Koster, M.B.M. On-line dispatching rules for vehicle-based internal transport systems. Int. J. Prod. Res. 2005, 43, 1711–1728. [Google Scholar] [CrossRef]

- Yu, Q.; Li, L.; Zhao, H.; Liu, Y.; Lin, K.Y. Evaluation System and Correlation Analysis for Determining the Performance of a Semiconductor Manufacturing System. Complex Syst. Model. Simulation. 2021, 1, 218–231. [Google Scholar] [CrossRef]

- Yu, Q.Y.; Yang, H.Y.; Lin, K.Y.; Li, L. A self-organized approach for scheduling semiconductor manufacturing systems. J. Intell. Manuf. 2020, 32, 689–706. [Google Scholar] [CrossRef]

- Huh, J.; Park, I.; Lim, S.; Paeng, B.; Park, J.; Kim, K. Learning to Dispatch Operations with Intentional Delay for Re-Entrant Multiple-Chip Product Assembly Lines. Sustainability 2018, 10, 4123. [Google Scholar] [CrossRef]

- Pan, C.; Zhang, J.; Qin, W. Real-time OHT Dispatching Mechanism for the Interbay Automated Material Handling System with Shortcuts and Bypasses. Chin. J. Mech. Eng. 2017, 30, 663–675. [Google Scholar] [CrossRef]

- Li, L.; Min, Z. An efficient adaptive dispatching method for semiconductor wafer fabrication facility. Int. J. Adv. Manuf. Technol. 2016, 84, 315–325. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, W.; Wu, L.H. A performance analytical model of automated material handling system for semiconductor wafer fabrication system. Int. J. Prod. Res. 2017, 54, 1650–1669. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhou, B.H. An impending deadlock-free scheduling method in the case of unified automated material handling systems in 300 mm wafer fabrications. J. Intell. Manuf. 2018, 29, 155–164. [Google Scholar] [CrossRef]

- Huang, C.J.; Chang, K.H.; Lin, J.T. Optimal vehicle allocation for an Automated Materials Handling System using simulation optimisation. Int. J. Prod. Res. 2012, 50, 5734–5746. [Google Scholar] [CrossRef]

- Gupta, S.; Hasenbein, J.J.; Park, S. Improving scheduling and control of the OHTC controller in wafer fab AMHS systems. Simul. Model. Pract. Theory 2021, 107, 102190. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J. Big data analytics for forecasting cycle time in semiconductor wafer fabrication system. Int. J. Prod. Res. 2016, 54, 7231–7244. [Google Scholar] [CrossRef]

- Lin, J.T.; Wu, C.H.; Huang, C.W. Dynamic vehicle allocation control for automated material handling system in semiconductor manufacturing. Comput. Oper. Res. 2013, 40, 2329–2339. [Google Scholar] [CrossRef]

- Wang, C.N.; Chen, L.C. The heuristic preemptive dispatching method of material transportation system in 300 mm semiconductor fabrication. J. Intell. Manuf. 2011, 23, 2047–2056. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, W.; Wu, L.H.; Zhai, W.B. Fuzzy neural network-based rescheduling decision mechanism for semiconductor manufacturing. Comput. Ind. 2014, 65, 1115–1125. [Google Scholar] [CrossRef]

- Li, L.; Sun, Z.; Zhou, M.C.; Qiao, F. Adaptive Dispatching Rule for Semiconductor Wafer Fabrication Facility. IEEE Trans. Autom. Sci. Eng. 2013, 10, 354–364. [Google Scholar] [CrossRef]

- Tyan, J.C.; Du, T.C.; Chen, J.C.; Chang, I.H. Multiple response optimization in a fully automated FAB: An integrated tool and vehicle dispatching strategy. Comput. Ind. Eng. 2004, 46, 121–139. [Google Scholar] [CrossRef]

- Li, L.; Sun, Z.; Ni, J.; Fei, Q. Data-based scheduling framework and adaptive dispatching rule of complex manufacturing systems. Int. J. Adv. Manuf. Technol. 2013, 66, 1891–1905. [Google Scholar] [CrossRef]

- Qin, W.; Zhang, J.; Sun, Y. Dynamic dispatching for interbay material handling by using modified Hungarian algorithm and fuzzy-logic-based control. Int. J. Adv. Manuf. Technol. 2013, 67, 295–309. [Google Scholar] [CrossRef]

- Rong, L.; Wang, Z. An algorithm of extracting fuzzy rules directly from numerical examples by using FN-N. In Proceedings of the IEEE International Conference on Systems (CS 1996), Beijing, China, 14–17 October 1996; pp. 1067–1072. [Google Scholar]

- Qin, W.; Zhang, J.; Sun, Y. Multiple-objective scheduling for interbay AMHS by using genetic-programming-based composite dispatching rules generator. Comput. Ind. 2013, 64, 694–707. [Google Scholar] [CrossRef]

- Park, T. Effective vehicle dispatching method minimising the blocking and delivery times in automatic material handling systems of 300 mm semiconductor fabrication. Int. J. Prod. Res. 2009, 47, 3997–4011. [Google Scholar]

- Wu, L.H.; Mok, P.Y.; Zhang, J. An adaptive multi-parameter based dispatching strategy for single-loop interbay material handling systems. Comput. Ind. 2011, 62, 175–186. [Google Scholar] [CrossRef]

- Yugma, C.; Blue, J.; Dauzère-Pérès, S.; Vialletelle, P. Integration of scheduling and advanced process control in semiconductor manufacturing: Review and outlook. In Proceedings of the IEEE International Conference on Automation Science and Engineering (CASE 2015), Taipei, Taiwan, 18–22 August 2015; pp. 93–98. [Google Scholar]

- Mittler, M.; Schoemig, A.K. Comparison of dispatching rules for semiconductor manufacturing using large facility models. In Proceedings of the 31st Winter Simulation Conference (WSC 1999), Pheonix, AZ, USA, 5–8 December 1999; pp. 709–713. [Google Scholar]

- Kim, B.; Shin, J.; Jeong, S.; Koo, J. Effective overhead hoist transport dispatching based on the Hungarian algorithm for a large semiconductor FAB. Int. J. Prod. Res. 2009, 47, 2823–2834. [Google Scholar] [CrossRef]

- Derringer, G.; Suich, R. Simultaneous Optimization of Several Response Variables. J. Qual. Technol. 1980, 12, 214–219. [Google Scholar] [CrossRef]

| Input Variables | Fuzzy Sets | Membership Functions |

|---|---|---|

| Low Load (LL) | , 0, 0.219, 0.914) | |

| Middle Load (ML) | (0.219, 0.914, 2.035) | |

| High Load (HL) | ) | |

| Urgent Due Date (UDD) | , 0, 3.488, 7.224) | |

| Normal Due Date (NDD) | (3.488, 7.224, 12.26) | |

| Slow Due Date (SDD) | ) | |

| Short Waiting Time (SWT) | , 0, 0.566, 2.214) | |

| Normal Waiting Time (NWT) | (0.566, 2.214, 4.838) | |

| Long Waiting Time (LWT) | ) | |

| Good Load Balancing (GB) | , 0, 0.025, 0.139) | |

| Normal Load Balancing (NB) | (0.025, 0.139, 0.33) | |

| Bad Load Balancing (BB) | ) |

| Case | Fuzzy Rules | n | Prob (%) | (%) | |||

|---|---|---|---|---|---|---|---|

| 1 | LL | SDD | LWT | GB | 111046 | 29.636 | - |

| 2 | HL | SDD | NWT | GB | 94360 | 25.183 | 54.819 |

| 3 | ML | SDD | LWT | GB | 72076 | 19.236 | 74.055 |

| 4 | HL | SDD | SWT | GB | 20931 | 5.586 | 79.641 |

| 5 | LL | SDD | LWT | NB | 20130 | 5.372 | 85.013 |

| 6 | ML | SDD | LWT | NB | 19653 | 5.245 | 90.258 |

| ML | SDD | NWT | GB | 19295 | 5.15 | 95.408 | |

| 8 | HL | SDD | LWT | GB | 6357 | 1.697 | 97.105 |

| 9 | HL | SDD | LWT | NB | 4824 | 1.287 | 98.392 |

| 10 | HL | SDD | NWT | NB | 3634 | 0.97 | 99.362 |

| 11 | ML | SDD | NWT | NB | 2102 | 0.561 | 99.923 |

| 12 | LL | SDD | NWT | GB | 181 | 0.048 | 99.971 |

| 13 | HL | SDD | SWT | NB | 80 | 0.021 | 99.992 |

| 14 | LL | SDD | SWT | GB | 26 | 0.008 | 100 |

| Rule No. | Input Variable | Output Variable | Rule No. | Input Variable | Output Variable | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | LL/SDD/LWT/GB | (0.49, 0.49, 0.01, 0.01) | 15 | LL/SDD/LWT/GB | (0.49, 0.25, 0.25, 0.01) | ||||||||||||

| 2 | (0.49, 0.01, 0.49, 0.49) | 16 | (0.49, 0.25, 0.01, 0.25) | ||||||||||||||

| 3 | (0.49, 0.01, 0.01, 0.49) | 17 | (0.49, 0.01, 0.25, 0.25) | ||||||||||||||

| 4 | (0.01, 0.49, 0.01, 0.49) | 18 | (0.25, 0.49, 0.25, 0.01) | ||||||||||||||

| 5 | (0.01, 0.49, 0.49, 0.01) | 19 | (0.25, 0.49, 0.01, 0.25) | ||||||||||||||

| 6 | (0.01, 0.01, 0.49, 0.49) | 20 | (0.25, 0.25, 0.49, 0.01) | ||||||||||||||

| 7 | (0.97, 0.01, 0.01, 0.01) | 21 | (0.25, 0.25, 0.01, 0.49) | ||||||||||||||

| 8 | (0.01, 0.97, 0.01, 0.01) | 22 | (0.25, 0.01, 0.49, 0.25) | ||||||||||||||

| 9 | (0.01, 0.01, 0.97, 0.01) | 23 | (0.25, 0.01, 0.25, 0.49) | ||||||||||||||

| 10 | (0.01, 0.01, 0.01, 0.97) | 24 | (0.01, 0.49, 0.25, 0.25) | ||||||||||||||

| 11 | (0.33, 0.33, 0.33, 0.01) | 25 | (0.01, 0.25, 0.25, 0.49) | ||||||||||||||

| 12 | (0.01, 0.33, 0.33, 0.33) | 26 | (0.01, 0.25, 0.49, 0.25) | ||||||||||||||

| 13 | (0.33, 0.01, 0.33, 0.33) | 27 | (0.25, 0.25, 0.25, 0.25) | ||||||||||||||

| 14 | (0.33, 0.33, 0.01, 0.33) | ||||||||||||||||

| Rule No. | Input Variables | Output Variables | Rule No. | Input Variables | Output Variables | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | LL | SDD | LWT | GB | 0.01 | 0.49 | 0.49 | 0.01 | 8 | HL | SDD | LWT | GB | 0.01 | 0.01 | 0.49 | 0.49 |

| 2 | HL | SDD | NWT | GB | 0.97 | 0.01 | 0.01 | 0.01 | 9 | HL | SDD | LWT | NB | 0.49 | 0.01 | 0.49 | 0.01 |

| 3 | ML | SDD | LWT | GB | 0.97 | 0.01 | 0.01 | 0.01 | 10 | HL | SDD | NWT | NB | 0.01 | 0.01 | 0.49 | 0.49 |

| 4 | HL | SDD | SWT | GB | 0.49 | 0.01 | 0.49 | 0.01 | 11 | ML | SDD | NWT | NB | 0.01 | 0.49 | 0.01 | 0.49 |

| 5 | LL | SDD | LWT | NB | 0.01 | 0.49 | 0.01 | 0.49 | 12 | LL | SDD | NWT | GB | 0.01 | 0.49 | 0.01 | 0.49 |

| 6 | ML | SDD | LWT | NB | 0.49 | 0.01 | 0.49 | 0.01 | 13 | HL | SDD | SWT | NB | 0.01 | 0.49 | 0.01 | 0.49 |

| 7 | ML | SDD | NWT | GB | 049 | 0.49 | 0.01 | 0.01 | 14 | LL | SDD | SWT | GB | 0.01 | 0.01 | 0.01 | 0.97 |

| Workstation/Bay | Description | Number of Tools | MPT (min) | MTBF (h) | MTTR (h) | Number of Visits | |||

|---|---|---|---|---|---|---|---|---|---|

| NO. | Name | A | B | C | |||||

| 1 | CLEAN_DEPOSITION | Clean wet bench for OXI/DIFF tubes | 32 | 2.91 | 39.96 | 2.22 | 19 | 22 | 1 |

| 2 | TMGOX_DEPOSITION | / | 32 | 9.34 | 91.11 | 10.00 | 5 | 7 | 3 |

| 3 | TMNOX_DEPOSITION | N-well drive-in tube | 32 | 10.22 | 108.04 | 5.21 | 5 | 5 | 4 |

| 4 | TMFOX_DEPOSITION | Field oxidation tube | 16 | 17.55 | 91.18 | 12.56 | 3 | 3 | 3 |

| 5 | TU11_DEPOSITION | Metal ally tube | 16 | 23.03 | 93.56 | 6.99 | 1 | 1 | 1 |

| 6 | TU43_DEPOSITION | Annealing for silicides | 16 | 29.10 | 108.04 | 5.21 | 2 | 2 | 2 |

| 7 | TU72_DEPOSITION | Low-pressure CVD tube | 16 | 23.36 | 12.40 | 4.38 | 1 | 2 | 1 |

| 8 | TU73_DEPOSITION | Low-pressure SINI CVD tube | 16 | 16.31 | 9.79 | 3.43 | 3 | 3 | 2 |

| 9 | TU74_DEPOSITION | Low-pressure SI02 CVD tube | 16 | 17.66 | 6.85 | 3.74 | 2 | 2 | 1 |

| 10 | PLM5L_DEPOSITION | Plasma enhanced CVD lower tube | 16 | 15.19 | 34.82 | 12.71 | 3 | 3 | 3 |

| 11 | PLM5U_DEPOSITION | Plasma enhanced CVD upper tube | 16 | 29.48 | 32.89 | 19.78 | 1 | 1 | 1 |

| 12 | SPUT_DEPOSITION | PerkinElmer 4400 sputter | 16 | 22.88 | 63.14 | 9.43 | 2 | 2 | 2 |

| 13 | PHPPS_LITHOGRAPY | Pre-bake/negative spin resist | 64 | 3.97 | 21.22 | 1.15 | 13 | 12 | 11 |

| 14 | PHGCA_LITHOGRAPHY | Two GCA align/developers | 96 | 4.89 | 16.95 | 4.81 | 12 | 12 | 10 |

| 15 | PHHB_LITHROGRAPHY | Hardbake station | 16 | 3.26 | 374.4 | 12.80 | 15 | 13 | 12 |

| 16 | PHBI_LITHOGRAPHY | Bake inspect | 32 | 5.55 | No Failure | 11 | 11 | 8 | |

| 17 | PHFI_LITHOGRAPHY | Final inspect | 16 | 5.85 | 117.63 | 1.57 | 10 | 11 | 8 |

| 18 | PHJPS_LITHOGRAPHY | / | 16 | 13.46 | No Failure | 4 | 3 | 4 | |

| 19 | PLM6_ETCHING | Plasma etcher for aluminum | 32 | 26.03 | 28.96 | 17.42 | 2 | 2 | 2 |

| 20 | PLM7_ETCHING | / | 16 | 20.29 | 27.09 | 9.49 | 2 | 1 | 2 |

| 21 | PLM8_ETCHING | Oxide/nitride dry TEK etch | 32 | 14.21 | 27.09 | 9.49 | 4 | 3 | 3 |

| 22 | PHWET_ETCHING | Wet etch station | 32 | 1.95 | 117.84 | 1.08 | 21 | 18 | 18 |

| 23 | PHPLO_RESIST STRIP | Etchers and strip/clean for plasma etch | 32 | 2.04 | No Failure | 13 | 21 | 18 | |

| 24 | IMP_IONIMPLANT | Ion implanter | 32 | 7.24 | 42.32 | 12.86 | 8 | 10 | 4 |

| Dispatching Method | TT (min) | WT (min) | Cycle Time (min) | TH | Movement | VU (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| AVG | STD | AVG | STD | AVG | STD | ||||

| FWD | 399.48 | 1906.14 | 25.23 | 588.95 | 141.32 | 3873.7 | 1041 | 175159 | 52.29 |

| Former | 396.38 | 1897.47 | 11.39 | 110.66 | 88.07 | 612.37 | 1138 | 182943 | 54.41 |

| MMDD | 398.99 | 1898.96 | 10.50 | 35.49 | 84.1 | 308.62 | 1173 | 184830 | 54.94 |

| Dispatching Method | TT (min) | WT (min) | Cycle Time (min) | TH | Movement | VU (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| AVG | STD | AVG | STD | AVG | STD | ||||

| FWD | 402.53 | 1926.54 | 44.6 | 655.63 | 225.09 | 3677.1 | 1110 | 182698 | 54.72 |

| Former | 401.47 | 1959.74 | 46.73 | 589.98 | 210.27 | 2820.82 | 1156 | 194797 | 58.35 |

| MMDD | 399.62 | 1899.04 | 23.69 | 224.59 | 202.79 | 2252.09 | 1206 | 195977 | 58.35 |

| Dispatching Method | TT (min) | WT (min) | Cycle Time (min) | TH | Movement | VU (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| AVG | STD | AVG | STD | AVG | STD | ||||

| FWD | 400.44 | 2110.25 | 28.26 | 714.13 | 154.8 | 4758.1 | 1023 | 173949 | 52.26 |

| Former | 401.41 | 1891.27 | 13.15 | 129.6 | 109.18 | 921.65 | 1146 | 184143 | 54.76 |

| MMDD | 397.14 | 1897.59 | 10.18 | 41.98 | 84.15 | 240.61 | 1173 | 184617 | 54.87 |

| Dispatching Method | TT (min) | WT (min) | Cycle Time (min) | TH | Movement | VU (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| AVG | STD | AVG | STD | AVG | STD | ||||

| FWD | 403.14 | 2048.63 | 51.28 | 777.02 | 221.2 | 3469.79 | 1082 | 183856 | 55.31 |

| Former | 402.73 | 2200.97 | 52.49 | 664.36 | 208.03 | 2677.2 | 1157 | 194856 | 58.47 |

| MMDD | 397.23 | 1898.2 | 23.14 | 181.02 | 204.09 | 2700.5 | 1192 | 194485 | 57.88 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, B.; Tian, T.; Gao, Y.; Zhang, M.; Peng, Y. A Dynamic Dispatching Method for Large-Scale Interbay Material Handling Systems of Semiconductor FAB. Sustainability 2022, 14, 13882. https://doi.org/10.3390/su142113882

Xia B, Tian T, Gao Y, Zhang M, Peng Y. A Dynamic Dispatching Method for Large-Scale Interbay Material Handling Systems of Semiconductor FAB. Sustainability. 2022; 14(21):13882. https://doi.org/10.3390/su142113882

Chicago/Turabian StyleXia, Beixin, Tong Tian, Yan Gao, Mingyue Zhang, and Yunfang Peng. 2022. "A Dynamic Dispatching Method for Large-Scale Interbay Material Handling Systems of Semiconductor FAB" Sustainability 14, no. 21: 13882. https://doi.org/10.3390/su142113882