Abstract

To achieve the principles of reduction, resource, and harmless disposal of domestic waste, the circular economy prolongs the life cycle of resources by converting waste into renewable resources through sorting, recycling, and other ways. There are still noticeable problems in domestic waste recycling in China, such as poor waste classification and low recovery rate of resource-based waste with no or low economic value. In this paper, Van Waden’s seven-dimensional classification model of policy networks is adopted to analyze and compare domestic waste recycling (DWR) management modes at home and abroad. The domestic waste recycling mode of “pipeline collection and vehicle transfer” based on China’s national conditions is proposed. Then, the planning model of the domestic waste recycling network is further built. Taking Xiaolan Town, Zhongshan City as an example, the pipeline laying design and route planning of the pneumatic transportation and collection system for material in the new recycling mode are optimized. The examples verify the superiority of the greedy dropping heuristic algorithm in solving large-scale recycling network planning problems. This paper is of great significance to improve the recycling of renewable resources in domestic waste and realize the circular economy.

1. Introduction

Traditionally, the life cycle of resources is a linear process of “resources–products–waste–harmless disposal” [1,2], while in the circular economy, the cycle of “waste–renewable resources” is added based on the traditional economy [3,4]. According to statistics, the proportion of recyclable waste is not less than 33% of the total amount of daily domestic waste. So, garbage sorting and recycling play a critical role in eco-environmental conservation and resource reuse. In China, the proportion of urban residents and domestic waste increased significantly from 2014 to 2019. During the six years, the proportion of urban residents had increased by 6%, and the volume of domestic waste clean-up increased by about 36% (China Statistical Yearbook). In terms of China’s national harmless disposal capacity, the number of harmless treatment plants, mainly landfills and incineration plants, had increased by about 30%. The incineration power plants increased rapidly, but landfills did not increase significantly [5].

Since 2000, domestic waste classification has been piloted in eight cities, including Beijing and Shanghai [6]. However, the implementation effect is limited by the domestic waste recycling system. The source classification method of domestic waste in China generally changes with the type of terminal processor, and the domestic waste classification methods vary greatly from place to place. Therefore, the variable classification policies and complex classification standards have a negative impact on residents’ classification willingness [7]. Most renewable waste sold by residents to salvage stations and picked up by scavengers are high-value [8]. In contrast, low-value or noncommercial renewable waste mixed with non-renewable waste is often discarded without a second thought and then transported to harmless treatment plants by sanitation officers. Overall, the recovery rate of low-value or noncommercial renewable waste is low. In addition, when pushing the domestic waste collection and handling facilities, the number and distribution of recycling outlets are unreasonable in some areas where garbage classification is implemented as a trial [9]. There are also clutters such as inconsistent garbage bins and disorderly distribution. Thus far, a scientific and reasonable domestic waste recycling network has not been formed, which might easily cause secondary pollution during waste collection and transshipment.

Thus, a domestic waste recycling mode that highly matches the lifestyle of Chinese residents is important for simplifying the processes of domestic waste disposal, improving the accuracy of waste classification and reducing the complexity of garbage composition in the process of domestic waste recycling. Therefore, it will almost certainly help improve the resource utilization and harmless treatment efficiency of garbage, reducing its treatment cost and impact on the environment. In this paper, the intelligent trend of the domestic waste recycling network is considered, and the recycling mode of “pipeline collection and vehicle transfer” that suits China’s national conditions is designed to optimize the planning scheme of the domestic waste recycling network.

This paper is organized as follows. In Section 2, we review the related literature. In Section 3, we review the domestic waste recycling management modes in different countries and then design the domestic waste recycling mode of “pipeline collection and vehicle transfer” based on China’s national conditions. In Section 4, we construct the planning model of the domestic waste recycling network and verify the superiority of the greedy dropping heuristic algorithm proposed in this paper. The results based on the case of Xiaolan Town are stated in Section 5, and the practical contribution is presented in Section 6. Finally, Section 7 concludes the results.

2. Literature Review

Domestic waste includes the daily living activities of residents, and the productive activities of enterprises and institutions for serving the residents’ lives (such as industrial and commercial enterprises, street markets, factories and mines, schools, organs and public institutions, public places, etc.). More recent attention has focused on providing new technologies for domestic waste recycling, including a pneumatic pipe waste conveying system [10], a garbage classification system with intelligent identification and automatic sorting [11], and an automatic intelligence smart bin. The smart bin gets renewable energies from the solar panel, and the collective energies used to operate the smart bin are stored in the battery bank [12]. Based on the characteristics of the capacitive sensor, Daud and Razali presented an identification method for mixed domestic waste. Using the data of three household wastes, they compared different classification methods that can recognize multiple wastes. The results showed that the classification method based on the capacitance sensor is better than machine vision, the eddy current separator, and the capacitive proximity sensor [13]. By taking the characteristics of garbage images into account, a Depth-wise Separable Convolution Attention Module (DSCAM) is proposed to overcome the existing limitation [14]. However, the accuracy of the convolution neural network reached the bottleneck, so a waste classification method based on a visual transformer was proposed, which can improve the efficiency of garbage classification and reduce labor costs [15]. In order to evaluate the effect of different policies on urban waste management in China, a multi-agent simulation model was established for simulating the behavior changes of different agents (residents, recycling sites, and sanitation departments) in different strategy scenarios [16]. Regarding the domestic waste recycling management mode, developed countries started to pay attention to the waste recycling system relatively early and have made remarkable achievements, such as Germany, Brazil, Japan, Sweden, the United States, and other countries. Countries and regions establish different municipal recycling management modes based on local waste characteristics, qualification, cost, availability of local labor, and technical suitability [17]. For example, production responsibility is implemented in Sweden. So, manufacturers (enterprises producing packaging materials, tires, paper, batteries, electronic products, automobiles, etc.) need to recycle and dispose of their products. Except for waste for which the manufacturer is responsible, the municipal government is responsible for other domestic waste. Most municipal governments perform their duties by purchasing services in the form of specialized garbage collection services [18,19]. In Japan, in order to reduce fiscal expenditure, the municipal government and the private enterprises sign contracts to jointly take charge of most of the domestic waste collection work [20,21]. Brazil is different from Sweden and Japan in waste collection. The informal recycling sector is mainly responsible for collecting and sorting domestic waste in Brazil. The best feature of Brazil’s waste disposal model is probably to organize urban waste pickers into waste picker co-operatives, also known as CEMPRE. CEMPRE has contracted with 25 cities in Brazil for door-to-door selective collection of recyclables, so the utilization of recyclables is greatly improved by using a local waste collection mode [22]. Many relevant laws and regulations have been formulated in the above countries or regions. For example, Germany and Sweden are both subject to European Union targets for waste management, and both countries have aligned their legislation accordingly [23]. Germany is well known as one of the world’s references for the relevant legislation focused on responsibility, recycling, and treatment [24]. For reducing the amount of packaging waste, the Packaging Ordinance has been introduced to recycle and reuse packaging waste [25]. In the U.K., garbage classification is accomplished by legislation and has been made a national policy [26].

Optimizing domestic waste recycling facilities’ distribution and domestic waste recycling network is the key to ensuring the effective recycling of domestic waste. Related models and characteristics of domestic waste recycling network planning are shown in Table 1. As for the waste recycling facilities’ distribution, Toso and Alem proposed a location model of the recycling center, integrating the location planning for reverse logistics, scenario-based stochastic programming, and risk modeling [27]. Gottinger described regional solid waste management as a grid flow model, which can help decision-makers to make decisions on waste management and facility location (such as intermediate treatment facilities and landfills) [28]. As for domestic waste recycling network planning, Lv et al. used the P-median model to optimize the domestic waste recycling network in Shanghai, and the optimal location of recycling centers and transfer stations can be identified [29]. Harijani et al. proposed a multi-period mixed integer programming (MILP) model to optimize the facility selection, capacity level and location of facilities, garbage distribution, and waste transportation among facilities [30]. Similarly, Garibay-Rodriguez et al. believed that landfilling is still the most functional solution to treat municipal solid waste (MSW). In order to obtain the optimal performance for MSW landfilling, they presented a MILP model to optimize the transport of MSW to a landfill operation and the processes of composting and recycling [31]. In order to minimize the total cost of the system, the renewable resource recycling logistics planning is divided into collection points, recycling centers, distribution markets, and deep processing centers [32]. Moreover, with the consideration of both environmental impacts and recycling cost impacts, the multi-objective programming model is suitable for the design and planning of waste management networks [33,34]. Considering the environment, economy, and social sustainability, Harijani and Mansour developed a comprehensive municipal solid waste recycling network and constructed a multi-period two-level stochastic mixed integer linear programming (TSSMILP) model to minimize the total cost of the recycling network [35]. In addition, uncertainty often exists in waste management. Therefore, the application of fuzzy mathematical programming in network planning has been of wide concern to scholars. For example, Wei and Zhang considered the uncertainty in the planning process and adopted the fuzzy multi-objective integer programming model to optimize the location and path in the waste collection network [36]. Moreover, many papers on domestic waste recycling network planning focus on a specific type of waste, such as plastic products [37], household appliances [38], or waste paper [39].

Table 1.

Planning model, problems and characteristics of domestic waste recycling network.

3. “Pipeline-Vehicle” Recycling Mode

3.1. Comparison of Different Domestic Waste Recycling Modes

In the domestic waste recycling (DWR) network, the relationship between the network compositions and participants is complex. Since domestic waste recycling management modes and policy promotion processes occur in the recycling network formed by interdependent participants, there are significant differences in domestic waste recycling management modes in different countries. For the management strategy of the domestic waste recycling network, three dimensions that have the most significant impact on the network are extracted from Van Waden’s classification: the actors, function, and power balance. A comparative analysis of the urban domestic waste recycling system is carried out, as shown in Table 2.

Table 2.

Comparison of different domestic waste recycling modes.

Japan’s domestic waste recycling mode is a mandatory classification mode dominated by the government. The main actors include municipal government, residents, front-end enterprises (such as manufacturers, packing companies, and sales companies), and back-end enterprises (such as recycling enterprises, processing enterprises, maintenance enterprises, reengineering enterprises, and harmless disposal plants). The recycling network function is mainly maintained through laws and regulations formulated by the municipal government and the cooperation among the sanitation department, enterprises, and residents, but the coordinator is lacking. In Japan, harmless treatment plants are constantly decentralized and miniaturized so that the classification function is lacking and classification responsibility is transferred to the residents. The severe penalty systems have been formulated by municipal governments to force residents to reduce waste, classify waste according to the guidelines strictly, and do simple processing (such as cleanout) before throwing waste into an appointed place within the stipulated time; residents can only buy designated garbage bags (the cost of domestic waste treatment is linked to the cost of garbage bags). Furthermore, the front-end enterprises conform to legal law to recycle product packaging, waste household appliances, etc.; and the back-end enterprises should collect and transfer waste at fixed times and places. The balance of power is dominated by state institutions (municipal governments).

In Finland, the pneumatic transport and collection system for material is used on streets and in buildings to clean up domestic waste. The domestic waste recycling mode is a pipeline transportation mode that belongs to the mandatory classification led by the government. The main actors include government, front-end enterprises, residents, and back-end enterprises. The recycling network function is mainly maintained by the Finnish government to formulate laws and regulations, with the cooperation between enterprises and residents, but the coordinator is lacking. In Finland, laws have been enacted to require residents to put garbage into different trash cans, and guidelines have been developed to educate residents on improving classification awareness. Law also stipulates that some front-end enterprises (such as household electric appliance plants and importers) are responsible for recycling, and recyclable handling charges are levied on front-end and back-end enterprises [40]. Rewards and subsidies are adopted to encourage recycling recyclables, such as lottery tickets (for consumption in stores or donating to public facilities construction) given in stores for recycling used equipment or old bottles, subsidies for recycling activities of front-end enterprises, etc. In addition, flea markets for waste and old materials still exist. The balance of power is dominated by state institutions (the government of Finland).

In Germany, the domestic waste recycling mode belongs to the producer responsibility based on market leading. The main actors include government, front-end enterprises, Duals System Deutschland (DSD, a non-governmental organization composed of more than 90 business enterprises), residents, and back-end enterprises. The recycling network function is mainly maintained through laws, regulations, guidelines, coordination of DSD, and cooperation between enterprises and residents. In 1986, the Waste Avoidance and Management Act was revised in Germany, and the focus shifted from end-of-pipe control to source control. In 1991, the Packaging Ordinance was enacted, and the producer responsibility system was introduced. Meanwhile, DSD was established to coordinate the recycling of discarded packaging. By adopting the producer responsibility, receiving the deposits of product packaging and bottles from consumers, and changing the waste recovery fee with the size and material of packaging, resource exploitation and garbage generation are effectively controlled. The power balance relationship is dominated by interest groups (front-end enterprises and DSD).

Brazil’s domestic waste recycling mode is the CEMPRE mode based on the socially dominated. The main actors include government, front-end enterprises, CEMPRE (non-governmental, non-profit Renewable Resources Association), residents, scavengers, and back-end enterprises. The recycling network function is mainly maintained through policies, regulations, and guidelines formulated by the Brazilian government, coordination of CEMPRE, and the cooperation between sanitation departments, enterprises, scavengers, and residents. In Brazil, a unified standard is used to build and manage recycling systems, so the division of labor is clear-cut, and each organization is charged with specific responsibilities, so the recycling market is in good order. Specifically, CEMPRE is responsible for the publicity and education of environmental protection knowledge, providing dry refuse sorting sites, and simple treatment equipment to waste picker co-operatives all over Brazil. CEMPRE also trains scavengers to sort, compress, and pack dry garbage. The municipal sanitation department is responsible for collecting and transporting the dry garbage to the co-operative free of charge. The enterprises are responsible for purchasing the simply treated garbage after the registration of the co-operatives. The power balance belongs to autonomy which is different from the state institutions and interest groups.

China’s domestic waste recycling mode is based on the socially leading spontaneous recycling mode. The main actors include government, front-end enterprises, residents, scavengers, salvage stations, and back-end enterprises. The recycling network function is mainly maintained through laws, regulations, guidelines, voluntary recycling of scavengers and salvage stations, and the cooperation of sanitation departments, but the coordinator is lacking. Sanitation departments and outsourcing clearance enterprises are responsible for the collection, transportation, and harmless treatment of domestic waste in streets and residential areas. A scientific domestic waste recycling network has not yet been formed. Scavengers pick up recyclables, and salvage stations take them over for processing or reselling. So, the operation mode in which the government deals with the low economic value of the domestic waste and waste pickers and waste collection stations spontaneously recycle waste of high economic value has preliminarily formed. In recent years, intelligent garbage houses and Internet booking recycling technology have emerged in China, and the domestic waste recycling network has the trend of intelligent development. The power balance belongs to autonomy, which is different from the state institutions and interest groups.

3.2. Recycling Mode of “Pipeline Collection and Vehicle Transfer”

In China, waste is divided into four parts, quartering is the main recycling method, but mixed collection and transportation are the most common. Currently, it is changing from varied collection and centralized classification to source classification and classified transportation. With the improvement of classified collection facilities and terminal treatment facilities, a domestic waste recycling mode of “village collection—town transfer—municipal treatment” has been gradually formed. Domestic waste recovery elements and processes are shown in Table 3. However, the domestic waste source collection workload is heavy, and the mixed loading of sanitation vehicles and other phenomena are still common, so the waste classification effect is poor.

Table 3.

Recycling elements and process of domestic waste.

The cleaning, transportation, and treatment process of domestic waste generally include collection, temporary storage in the waste storage yard, further classification, compression, packaging, recycling, regeneration or resource utilization, and harmless treatment. Therefore, in this paper, the domestic waste recycling network is divided into three layers: collection layer (source of refuse collection), transfer layer (including classification sites, compression transfer stations, etc.), and terminal treatment layer (terminal treatment facilities).

The existing domestic waste recycling mode has the following problems: first, the residents’ awareness of classification is weak, the participation rate is lower, and the precision classification is difficult. The complexity and diversity of domestic waste and the overly refined front-end classification of the domestic waste recycling network lead to incorrect or non-standard delivery in the actual delivery, which will affect the accuracy of classification, as well as the subsequent waste transfer and harmless treatment, further resulting in the lower recovery rate of low-value economic or noncommercial waste. Second, domestic waste collection requires that the transport equipment should have overall sealing to avoid waste leakage, scattering, and gas pollution. So, the garbage transfer vehicle should have an interface between the container and the discharge port. At present, due to the dietary habits and cooking methods of Chinese residents, domestic waste has the following characteristics: the water content is high (55–65%, twice that of western countries), the composition is complex, and the proportion of perishable domestic waste is high (45–55%, more than twice that of Western developed countries). However, domestic waste recycling in China mainly relies on traditional transportation facilities, including small and medium-sized motor vehicles and rickshaws. So, in the collection and transportation process, secondary pollution caused by leakage easily occurs.

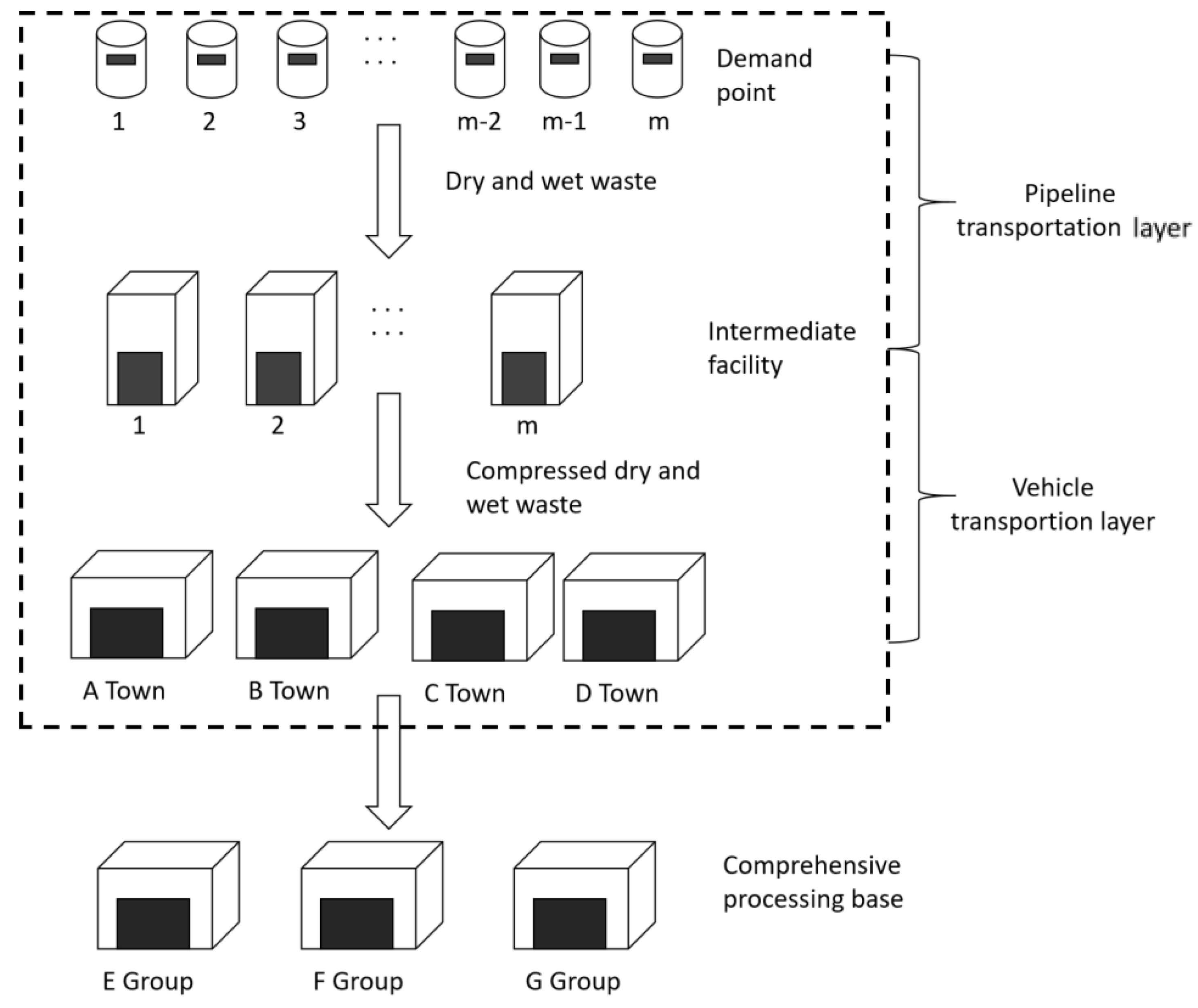

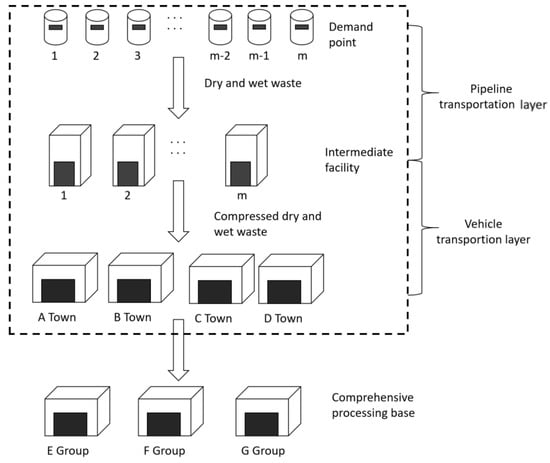

As previously stated, the “pipeline–vehicle” recycling mode has been established (see Figure 1). That is, the waste collection process is completed by pipeline transportation, and then the dry and wet waste with simple preliminary treatment is transferred through vehicle transport to terminal facilities (such as classification sites and compression transfer stations). After further classification and treatment, waste is transported to terminal treatment facilities for harmless treatment.

Figure 1.

Urban domestic waste recycling network hierarchy and waste flow chart in the new mode. Note: villages and towns are within the dotted line box, and provincial and municipal are outside the dotted line.

The major advantages of the recycling mode of “pipeline collection and vehicle transfer” include simple classifications, convenient waste disposal, centralized treatment, and low secondary pollution risk. The pneumatic tube transportation and collection system is arranged at the collection layer of the domestic waste recycling network, and the feeding inlet is built in crowded streets and high-rise buildings. The dichotomy method is adopted at the feeding inlet to lead the residents to simply divide the domestic waste into dry waste and wet waste. Pipeline transportation is used to replace the source collection of dry and wet garbage, reducing the pressure of waste classification and improving residents’ participation. Therefore, the recovery rate of recyclable waste, such as kitchen waste and resource-based waste of low or no economic value, is improved. In addition, if the domestic waste after classification is mixed with impurities, it will cause serious damage to the waste treatment system. Hence, for ensuring the accuracy of garbage classification, in the collection layer, it is necessary that guidance personnel are arranged to instruct residents to dispose of waste properly. At the same time, guidance personnel need to conduct secondary sorting in each bin. For the pneumatic pipeline transportation and collection system for material, the automatic sorting equipment based on optical identification and image recognition is equipped to identify and classify automatically the garbage put by residents. Different types of garbage arrive at the temporary storage site of the intermediate facilities through different transportation pipelines, and the processing procedures such as sorting and compression are carried out intensively; then the treated waste is restored to storage containers. Eventually, the storage containers are regularly transported to the terminal facility treatment point by transport vehicles. The saved human resources will be allocated to the sorting transfer station of terminal facilities to classify further, compress, and pack the dry waste.

4. Domestic Waste Recycling Network Planning

4.1. Model of Domestic Waste Recycling Network Planning

In allusion to the recycling mode of “pipeline collection and vehicle transfer”, several estimations and assumptions were necessary before modeling.

- The demand points are of the same type and do not have service capacity limitations.

- The intermediate facilities are of the same type. The services of intermediate facilities are unrestricted, and the unit service capacity is 20 t.

- The service of terminal facilities is unlimited, and the service capacity is different. It is assumed that the capacity of terminal facilities is equal to the compression transfer capacity.

- The paths from the demand point to the intermediate facility are straight paths.

- Due to the capacity limitation of intermediate facilities, distribution schemes can be formulated at multiple time points every day.

Then, the model of domestic waste recycling network planning is proposed, and the model parameters are described in Table 4.

Table 4.

Parameters of the model of domestic waste recycling network planning.

A discrete multiple facility location-allocation model is presented to address the P-median problem of pipeline transportation layers. The objective function of the model is to minimize the sum of Euclidean distances.

where C1 represents total cost of pneumatic transport and collection system for material, including the construction cost of the pipeline and supporting demand points (feed inlet), and also the cost of intermediate facilities.

Function (1) represents the total construction cost of pipeline transportation system. Constraint (2) indicates that one demand point is only served by one intermediate facility. Constraint (3) indicates that the number of selected sites equals to the number of planned intermediate facilities N. Constraint (4) indicates that demand points can only be assigned to selected locations. Constraint (5) represents the a zero-one variable that equals one if the facility is built at point j, zero otherwise. Constraint (6) represents the A zero-one variable that equals one if demand point i is served by intermediate facility j, zero otherwise.

For the vehicle transfer layer of the waste recycling network, an integer linear programming model is constructed based on the multiple facility location-selection scheme. Moreover, the distribution scheme of intermediate facilities to terminal facilities is formulated according to the garbage collection amount of each intermediate facility (excluding under-filled containers) during each clearing and transportation of the system.

Function (7) represents the total freight from intermediate facilities to terminal facilities. Constraint (8) indicates that the amount of solid waste transported from intermediate facility j is equal to its collection amount. Constraint (9) indicates that the amount of solid waste transported into terminal facility q shall not exceed its capacity Sq. Constraint (10) indicates that the solid waste collection volume of intermediate facility j shall not exceed its capacity Sj. Constraint (11) indicates that the amount of solid waste transported from intermediate facility j to terminal facility q shall not exceed the total amount collected by intermediate facility j.

4.2. Greedy Dropping Heuristic Algorithm

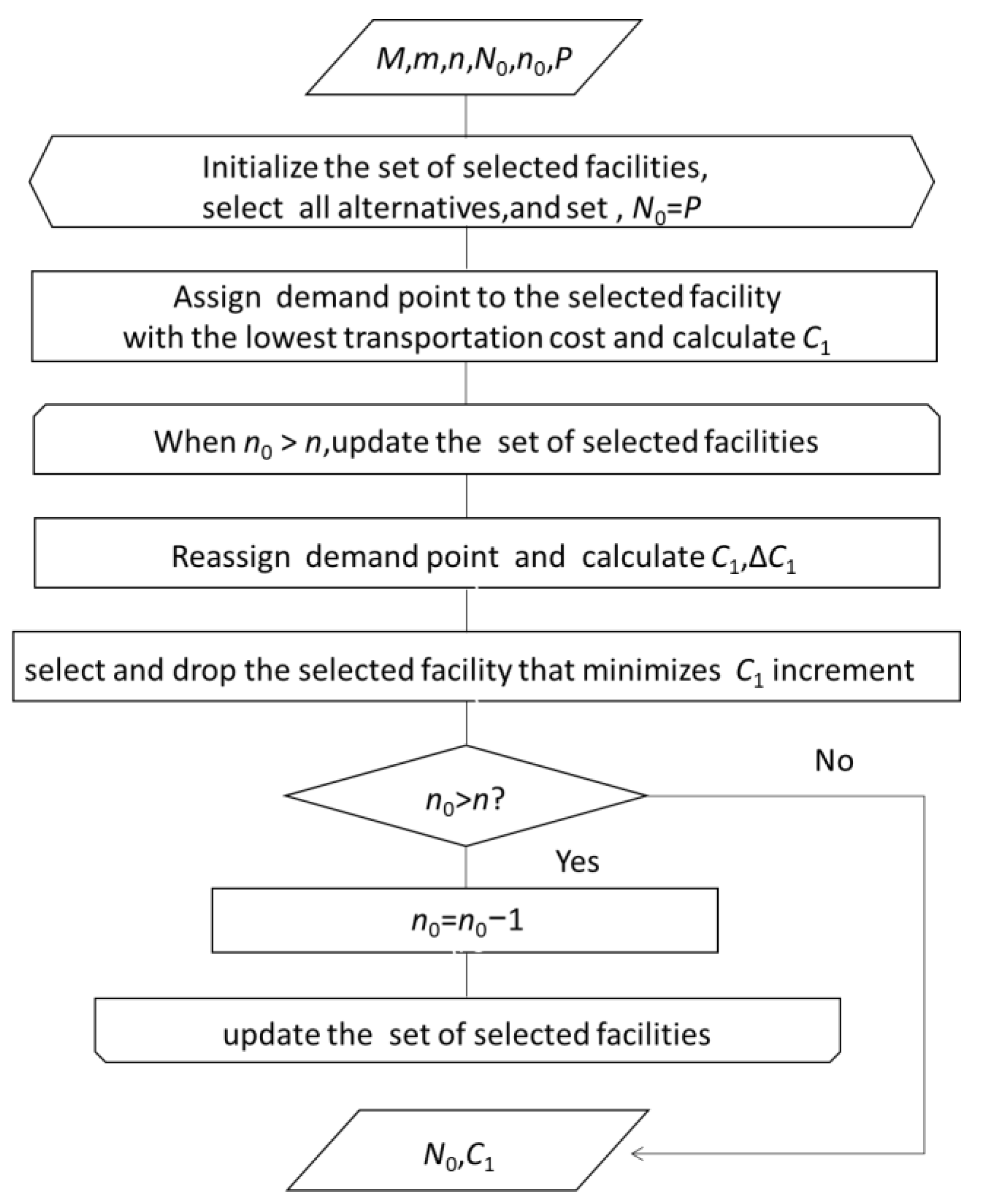

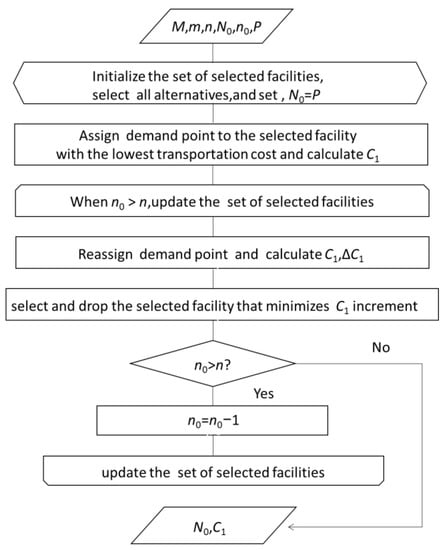

In the recycling mode of “pipeline collection–vehicle transfer”, the location and spatial distribution of the pneumatic transport and collection system for material, as well as vehicle transportation and distribution optimization, belong to the P-median problem. More specifically, given a set of demand points M and a set of alternative sites P with determined positions and quantities, facilities are built in N sites that are selected from alternative sites, and each demand point is assigned to a facility that has been built. The objective is to minimize the gross freight between the demand point and the facility (the freight is replaced by the pipeline laying cost in this model). The objective belongs to the N-P hard. The larger the problem scale, the longer the computation time. The heuristic algorithm can greatly shorten the time to obtain a satisfactory solution. Therefore, in this paper, the greedy dropping heuristic algorithm (GDHA) is used to solve the discrete multiple facility location-allocation model. The advantages of GDHA can be discussed under three headings, which are: few reaction steps, low computational complexity, and easily making a qualitative and quantitative analysis. The principle of GDHA is to calculate the current solution and take this solution as the initial state of the optimal choice in the feasible greed criterion and definite solution objective [41]. Only the local optimum is considered, the search continues from the initial state, and the optimal choice is constantly updated until a satisfactory solution is obtained. As shown in Figure 2, the specific algorithm steps are as follows:

Figure 2.

Flow chart of greedy dropping heuristic algorithm.

- (Initialization) Let N0 = P. Namely, all sites in the set for alternative locations are selected;

- (Calculation) Allocate the demand point to the corresponding selected facility with the lowest transportation cost, and calculate the objective function value C1;

- (Loop) Recalculate C1 and △C1. Select and drop one of the selected facilities that minimize △C1 after redistributing demand points;

- (Judgment) If n0 > n, let n0 = n0 − 1, delete the points drop from the selected facility set, and go to Step (3). If n0 <= n, end.

5. Results

Since 2002, the domestic waste classification has been implemented in Zhongshan City, Guangdong Province. Domestic waste transfer stations and temporary warehouses of hazardous waste and of recyclable waste (at least one for each) are provided in every town. At least one waste collection site is provided in the village. At present, incineration power, slag brick, and landfill are mainly used to treat domestic waste in Zhongshan. The design treatment capacity is 5460 t/day, which has reached basically the target for the domestic waste disposed of each day. The treatment capacity of Zhongshan City is expected to reach 8700 t/day by the end of 2021. Table 5 illustrates the terminal treatment facilities in use and construction.

Table 5.

Terminal processing facilities in use or construction in Zhongshan City.

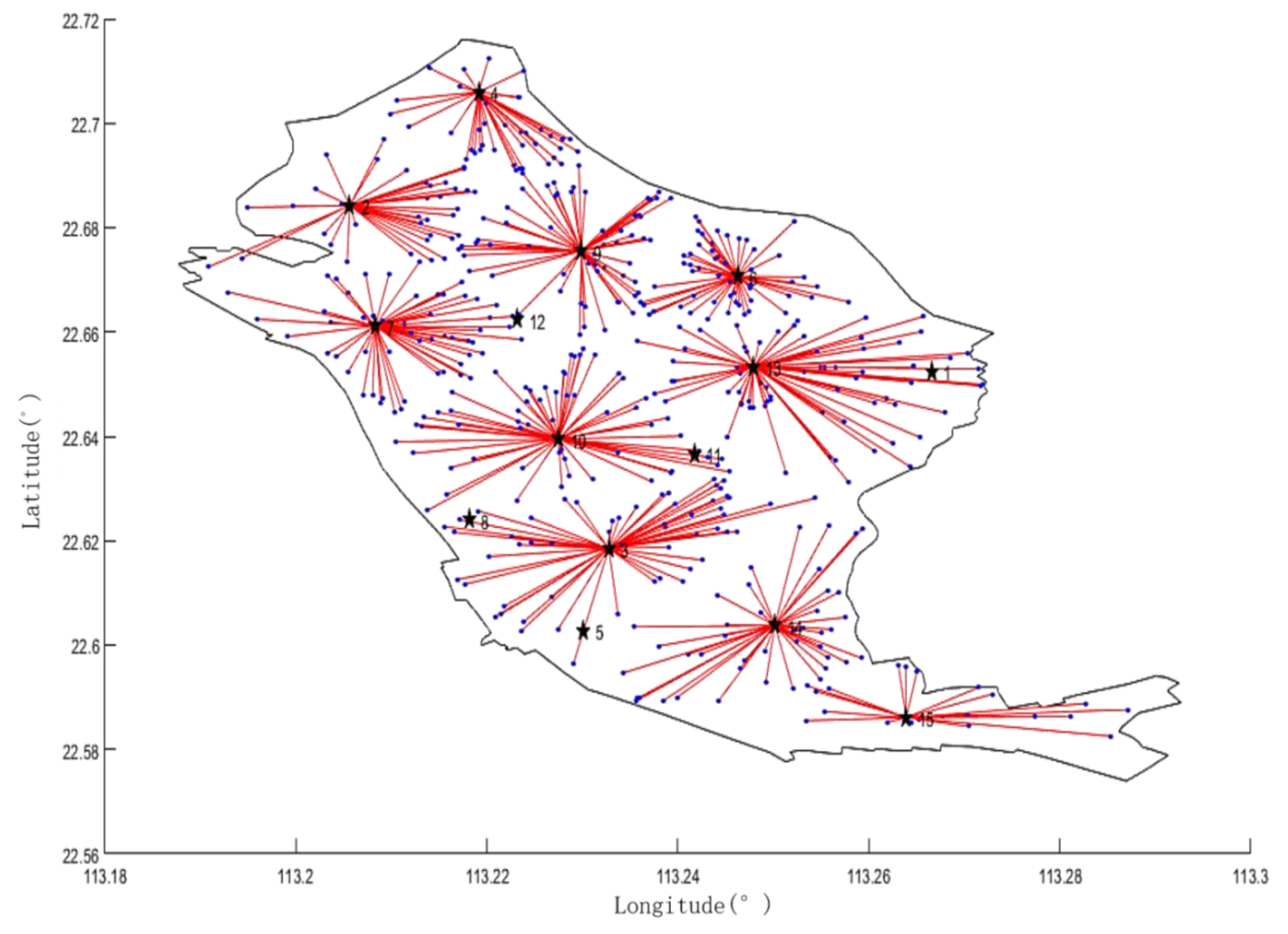

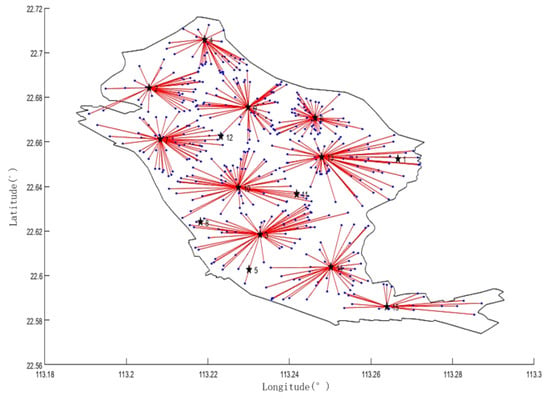

The population of permanent residents in Xiaolan Town amounts to about 329,000 (2017), with an area of 75.4 square kilometers. The average daily waste production in 2014, 2015, and 2016 was 738.28 t, 746.33 t, and 784.29 t, respectively. Currently, four waste transfer stations that compress and transfer domestic and industrial waste have been put into use (see Table 6). The hierarchy of the domestic waste recycling network and waste flow are presented in Figure 3.

Table 6.

Information on waste transfer stations in Xiaolan Town.

Figure 3.

Location and allocation scheme of pipeline facilities. Note: in the figure, the abscissa and ordinate are longitude and latitude, respectively; the little dot is the demand point, the asterisk is the intermediate facility, and the number next to the asterisk is the intermediate facility number.

First of all, several locations are selected from the set of alternative locations to build pipeline terminal collection points (hereinafter referred to as “intermediate facilities”) and assigned to the inlet (hereinafter referred to as “demand points”) with the purpose of minimizing the total construction cost of the pneumatic transportation collection system for material. Then, according to the daily waste production, the selected intermediate facilities will be allocated to different town transfer stations (hereinafter referred to as “terminal facilities”), and the allocation scheme of waste will be determined to minimize the total distribution cost. The estimated parameters are listed below:

- The unit construction cost is ten thousand yuan;

- The unit construction cost of intermediate facilities is one hundred thousand. Within the intermediate facility are several compacting collectors, and the unit capacity of the waste compacting collector is 1 t. (waste is transported out in the unit of collectors);

- The capacity of Shengfeng and Baofeng garbage transfer stations are both set to 100 t;

- The construction cost of the pipeline is set as 500 yuan per meter;

- The vehicle transportation cost is assumed to be 3 RMB/t·km.

In order to verify the effectiveness of the GDHA, 15 groups of examples at different scales are designed. The effectiveness of the GDHA is evaluated by comparing the results of the GDHA with the results of the satisfactory solution of Intlinprog and the exact solution.

The exact solution and average satisfactory solution are both expressed by V, and the average running time is expressed by . The results of calculation examples are shown in Table 7, and the average running time of each example is shown in Table 8.

Table 7.

The calculation results of the scale example.

Table 8.

Comparison of average operation time between Intlinprog and GDHA.

Analysis of the variance of the results showed that F < F crit and p > 0.05. It is considered that there is no significant difference in the data of the three groups at the level of 0.05, so it is feasible to solve the P-median problem with Intlinprog or GDHA.

Comparing the running time of the same example, strong evidence was found that when the problem scale is small, the solving efficiency of calling the Intlinprog function in MATLAB is slightly higher than that using GDHA; when the problem scale is large, the solving efficiency of GDHA is higher than that of the Intlinprog function. The larger the problem scale, the more visible the difference in solving efficiency.

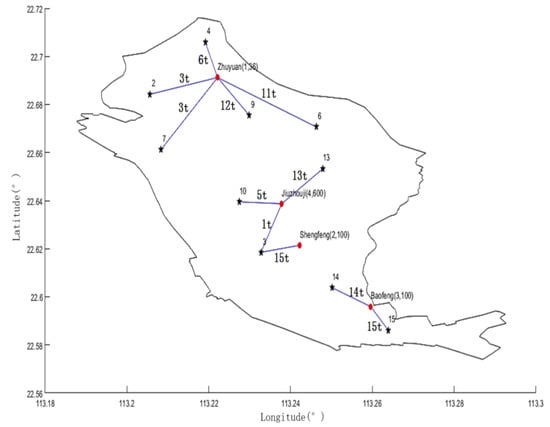

Xiaolan Town, Zhongshan City, comprises 500 demand points according to travel communities and assuming 15 alternative sites and 15 intermediate facilities planned to be built. By analyzing the solution results of GDHA, it can be seen in this example that the total construction cost of the pneumatic transportation collection system for material is 264.96235 million yuan. The coordinates and selection results of the alternative locations are shown in Table 9. The visualization of the site selection-distribution results is shown in Figure 4.

Table 9.

Coordinates of alternative sites and selection results.

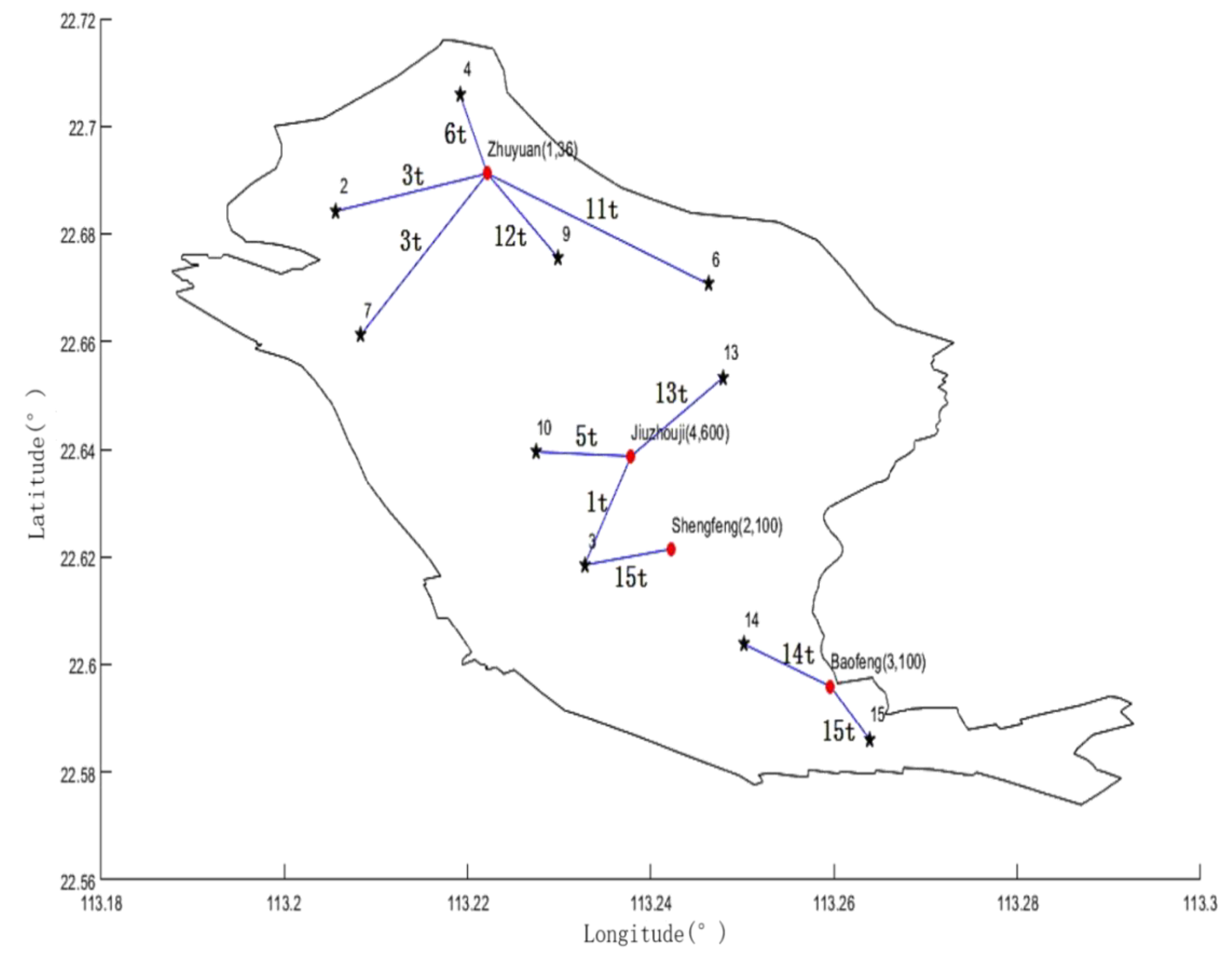

Figure 4.

Distribution diagram of vehicle transshipment and distribution scheme. Note: the asterisk is the intermediate facility, and the dot is the terminal facility; (a, b) indicates that the capacity of the terminal facility a is b; the number on the connection is the volume of freight transport.

In order to simulate the reality of waste collection, the garbage collection amount is generated randomly within the capacity range of each intermediate facility. Based on the location and distribution scheme of intermediate facilities, the optimal solution of the transfer scheme is determined. The collection number of intermediate facilities, the capacity of terminal facilities, and the distribution volume are shown in Table 10, and the objective function value is 476.218 yuan.

Table 10.

Vehicle transshipment and distribution scheme.

6. Practical Contribution

With the development of the economy and the improvement of urbanization level, the domestic waste produced by residents increases rapidly, which has caused great hidden dangers to the environment. Currently, China’s domestic waste collection and transportation modes rely mainly on garbage trucks or collection stations. Although there is a certain flexibility, the recycling efficiency is strictly limited. Meanwhile, it is easy to produce leakage pollution during the domestic waste transshipment process, which is harmful to the fragile environment. The proposed “pipeline–vehicle” recycling mode has a certain superiority in view of the existing problems. It is an important improvement of waste collection and recycling in achieving sustainable cities and communities (SDG11) and implementing the sustainable development goals (SDGs). It is also a reference mode for countries with large numbers of scavengers, waste delivery workers, or inefficient waste sorting. On the residential side, the traditional domestic waste collection tools are replaced by public pipelines, which simplify the waste classification for residents. Residents’ participation will be increased. The domestic waste stream can be completely isolated from the living area, and the secondary pollution in the waste collection process can be effectively eliminated. The negative impacts of changeable weather would also be diminished. In addition, due to the long-term shortage of waste disposal capacity, scavengers and waste collection stations play an essential role in sorting and recycling domestic waste. At the present stage, there are more than two million scavengers in China. It is estimated that 60% of the recyclable domestic waste could be effectively recycled with all scavengers’ active participation, and the government would save 15−20% of the waste management budget. Nevertheless, it is difficult to retrain scavengers’ behavior, because there are no effective management schemes. There are potential health and safety hazards in the existing domestic waste mode. The innovative “pipeline–vehicle” recycling mode is helpful for achieving the automation of domestic waste collection and the transshipment process within the living area. Such automatic modes significantly reduce the labor intensity of domestic waste collection. The labor force could be transferred to the centralized classification sites to process solid waste after introducing pipeline technology. It can not only make full use of precious labor resources, but also significantly improve the working environment of workers. In order to improve the recycling system of domestic waste, an optimized domestic waste recycling network is supposed to be designed with the consideration of the distribution characteristics of functional areas in different cities and the estimated domestic waste amount. It is also a necessary basis to ensure the implementation of the “pipeline–vehicle” recycling mode.

7. Conclusions

With the increase in the amount and types of domestic waste, improper recycling and treatment will cause severe threats to the environment. Currently, China’s domestic waste recycling mode has some obvious problems, such as variable waste classification policies, weak awareness, the non-motivated willingness of residents, and a high risk of secondary pollution. In the trend of waste collection and treatment facilities towards gradually becoming intelligent, a waste recycling mode of “pipeline collection and vehicle transfer”, which matches the lifestyle of Chinese residents, is put forward in this paper. Specifically, the domestic waste recycling network is divided into the collection, transfer, and terminal treatment layers. The collection layer is equipped with a pneumatic transport and collection system for material and automatic sorting equipment that rely on image recognition to complete the garbage collection at the source in the pipeline. In the transfer layer, vehicles are used to transfer the initially classified waste to the terminal treatment facilities for centralized treatment. This new recycling mode is helpful in simplifying the launch process of household waste, increasing the recycling rate of waste with no or low economic value, and strengthening the recycling of resources. At the same time, based on the new recycling mode, this paper presents the model of domestic waste recycling network planning, designs GDHA to solve the location-allocation of pipeline facilities and develops the vehicle distribution optimization scheme. At the significance level of 0.05, there is no significant difference among the satisfactory solution of GDHA, the exact solution, and the satisfactory solution of Intlinprog. Moreover, the larger the scale of the problem, the more pronounced the advantage of the high efficiency of GDHA. Taking Xiaolan Town of Zhongshan City as an example, the paper puts forward the location and distribution of pipeline facilities and vehicle transfer distribution scheme. The effectiveness of the domestic waste recycling network planning model is also verified in this paper. Facing China’s national conditions, scientific and reasonable domestic waste recycling network planning is conducive to improving the effectiveness of domestic waste classification and realizing the circular economy. The path planning of pipelines in the model of domestic waste recycling network planning is an intriguing one that could be usefully explored in further research.

Author Contributions

Conceptualization, C.Q. and L.L.; methodology, L.L.; software, L.L.; validation, C.Q., L.L. and Z.W.; formal analysis, Z.W.; investigation, C.Q. and L.L.; data curation, C.Q. and L.L.; writing—original draft preparation, C.Q. and Z.W.; writing—review and editing, C.Q.; visualization, L.L.; supervision, C.Q.; funding acquisition, C.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 72101043; the Fundamental Research Funds for the Central Universities, grant numbers 3132022264 and 3132022606.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pennington, D.W.; Potting, J.; Finnveden, G.; Lindeijer, E.; Jolliet, O.; Rydberg, T.; Rebitzer, G. Life cycle assessment Part 2: Current impact assessment practice. Environ. Int. 2004, 30, 721–739. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A. Waste management, waste resource facilities and waste conversion processes. Energy Convers. Manag. 2011, 52, 1280–1287. [Google Scholar] [CrossRef]

- Savini, F. The circular economy of waste: Recovery, incineration and urban reuse. Environ. Plan. Manag. 2021, 64, 2114–2132. [Google Scholar] [CrossRef]

- Domenech, T.; Borrion, A. Embedding circular economy principles into urban regeneration and waste management: Framework and metrics. Sustainability 2022, 14, 1293. [Google Scholar] [CrossRef]

- Zhao, X.G.; Jiang, G.W.; Li, A.; Wang, L. Economic analysis of waste-to-energy industry in China. Waste Manag. 2016, 48, 604–618. [Google Scholar] [CrossRef] [PubMed]

- Xiao, S.J.; Dong, H.J.; Geng, Y.; Tian, X.; Liu, C.; Li, H.F. Policy impacts on Municipal Solid Waste management in Shanghai: A system dynamics model analysis. J. Clean. Prod. 2020, 262, 121366. [Google Scholar] [CrossRef]

- Jia, Y.J.; Cheng, S.J.; Shi, R. Decision-making behavior of rural residents’ domestic waste classification in Northwestern of China--analysis based on environmental responsibility and pollution perception. J. Clean. Prod. 2021, 326, 129374. [Google Scholar] [CrossRef]

- Zhang, H.; Wen, Z.G. The consumption and recycling collection system of PET bottles: A case study of Beijing, China. Waste Manag. 2014, 34, 987–998. [Google Scholar] [CrossRef]

- Weng, X.F. Research on the treatment of municipal solid waste source classification behavior based on institutional engineering—Comment on “Shanghai municipal domestic waste management regulations”. Pol. J. Environ. Stud. 2022, 31, 883–898. [Google Scholar] [CrossRef]

- Sundholm, G. Method and Apparatus in a Pneumatic Pipe Transport System for Material, and a Conveying System for Wastes. U.S. Patent 9546041 A1, 3 January 2013. [Google Scholar]

- Lukka, T.J.; Tossavainen, T.; Kujala, J.V.; Raiko, T. Zenrobotics recycler-robotic sorting using machine learning. In Proceedings of the International Conference on Sensor-Based Sorting, Aachen, Germany, 1113 March 2014. [Google Scholar]

- Ashwin, M.; Alqahtani, A.S.; Mubarakali, A. Iot based intelligent route selection of wastage segregation for smart cities using solar energy. Sustain. Energy Technol. 2021, 46, 101281. [Google Scholar] [CrossRef]

- Daud, M.H.; Razali, Z.B. Optimum identification method of sorting green household waste. In Proceedings of the 2nd International Conference on Green Design and Manufacture 2016, Phuket, Thailand, 1–2 May 2016. [Google Scholar]

- Liu, F.C.; Xu, H.; Qi, M.; Liu, D.; Wang, J.Z.; Kong, J. Depth-Wise Separable Convolution Attention Module for Garbage Image Classification. Sustainability 2022, 14, 3099. [Google Scholar] [CrossRef]

- Huang, K.; Lei, H.; Jiao, Z.Y.; Zhong, Z.Y. Recycling waste classification using vision transformer on portable device. Sustainability 2021, 13, 11572. [Google Scholar] [CrossRef]

- Meng, X.Y.; Wen, Z.G.; Qian, Y. Multi-agent based simulation for household solid waste recycling behavior. Resour. Conserv. Recycl. 2016, 128, 535–545. [Google Scholar] [CrossRef]

- Campos, H.K.T. Recycling in Brazil: Challenges and prospects. Resour. Conserv. Recycl. 2014, 85, 130–138. [Google Scholar] [CrossRef]

- Stoeva, K.; Alriksson, S. Influence of recycling programmes on waste separation behaviour. Waste Manag. 2017, 68, 732–741. [Google Scholar] [CrossRef]

- Corvellec, H.; Bramryd, T.; Hultman, J. The business model of solid waste management in Sweden-a case study of two municipally-owned companies. Waste Manag. Res. 2012, 30, 512–518. [Google Scholar] [CrossRef]

- Honma, S.; Hu, J.L. Cost efficiency of recycling and waste disposal in Japan. J. Clean. Prod. 2021, 284, 125274. [Google Scholar] [CrossRef]

- Chifari, R.; Lo Piano, S.; Matsumoto, S.; Tasaki, T. Does recyclable separation reduce the cost of municipal waste management in Japan? Waste Manag. 2017, 60, 32–41. [Google Scholar] [CrossRef]

- Rutkowski, J.E.; Rutkowski, E.W. Expanding worldwide urban solid waste recycling: The Brazilian social technology in waste pickers inclusion. Waste Manag. Res. 2015, 33, 1084–1093. [Google Scholar] [CrossRef]

- Muhle, S.; Balsam, I.; Cheeseman, C.R. Comparison of carbon emissions associated with municipal solid waste management in Germany and the U.K. Resour. Conserv. Recycl. 2010, 54, 793–801. [Google Scholar] [CrossRef]

- Azevedo, B.D.; Scavarda, L.F.; Caiado, R.G.G.; Fuss, M. Improving urban household solid waste management in developing countries based on the German experience. Waste Manag. 2021, 120, 772–783. [Google Scholar] [CrossRef] [PubMed]

- Livingstone, S.; Sparks, L. The new German packaging laws: Effects on firms exporting to Germany. Int. J. Phys. Distr. Log. 1994, 24, 15–25. [Google Scholar] [CrossRef]

- Slack, R.J.; Gronow, J.R.; Voulvoulis, N. The management of household hazardous waste in the United Kingdom. J. Environ. Manag. 2009, 90, 36–42. [Google Scholar] [CrossRef] [PubMed]

- Toso, E.A.V.; Alem, D. Effective location models for sorting recyclables in public management. Eur. J. Oper. Res. 2014, 234, 839–860. [Google Scholar] [CrossRef]

- Gottinger, H.W. A computational model for solid waste management with application. Eur. J. Oper. Res. 1988, 35, 350–364. [Google Scholar] [CrossRef]

- Lv, J.Y.; Dong, H.J.; Geng, Y.; Li, H.F. Optimization of recyclable MSW recycling network: A Chinese case of Shanghai. Waste Manag. 2018, 102, 763–772. [Google Scholar] [CrossRef]

- Harijani, A.M.; Mansour, S.; Karimi, B.; Lee, C.G. Multi-period sustainable and integrated recycling network for municipal solid waste-A case study in Tehran. J. Clean. Prod. 2017, 151, 96–108. [Google Scholar] [CrossRef]

- Garibay-Rodriguez, J.; Laguna-Martinez, M.G.; Rico-Ramirez, V.; Botello-Alvarez, J.E. Optimal municipal solid waste energy recovery and management: A mathematical programming approach. Comput. Chem. Eng. 2018, 119, 394–405. [Google Scholar] [CrossRef]

- Yousefloo, A.; Babazadeh, R. Mathematical Model for Optimizing Green Waste Recycling Networks Considering Outsourcing. Ind. Eng. Chem. Res. 2020, 59, 8259–8280. [Google Scholar] [CrossRef]

- Caruso, C.; Colorni, A.; Paruccini, M. The regional urban solid waste management system: A modelling approach. Eur. J. Oper. Res. 1993, 70, 16–30. [Google Scholar] [CrossRef]

- Chang, X.Y.; Fan, T.J.; Xia, Y. A goal programming model for reverse logistics network planning. In Proceedings of the 2nd International Conference on Information Management, Innovation Management and Industrial Engineering, Xi’an, China, 26–27 December 2009. [Google Scholar]

- Harijani, A.M.; Mansour, S. Municipal solid waste recycling network with sustainability and supply uncertainty considerations. Sustain. Cities Soc. 2022, 81, 103857. [Google Scholar] [CrossRef]

- Chang, N.B.; Wei, Y.L. Siting recycling drop-off stations in urban area by genetic algorithm-based fuzzy multi-objective nonlinear integer programming modeling. Fuzzy Set. Syst. 1998, 114, 133–149. [Google Scholar] [CrossRef]

- Sheriff, K.M.M.; Subramanian, N.; Rahman, S.; Jayaram, J. Integrated optimization model and methodology for plastics recycling: Indian empirical evidence. J. Clean. Prod. 2016, 153, 707–717. [Google Scholar] [CrossRef]

- Yang, L.J.; Guo, J.H.; Zhan, C.; Wan, P.; Li, H. Optimization of location-routing for the waste household appliances recycling logistics under the uncertain condition. Teh. Vjesn. 2022, 29, 127–138. [Google Scholar]

- Rahman, M.O.; Hussain, A.; Scavino, E.; Basri, H.; Hannan, M.A. Intelligent computer vision system for segregating recyclable waste papers. Sustain. Energy Technol. 2019, 38, 10398–10407. [Google Scholar] [CrossRef]

- Salmenpera, H. Different pathways to a recycling society- Comparison of the transitions in Austria, Sweden and Finland. J. Clean. Prod. 2021, 292, 125986. [Google Scholar] [CrossRef]

- Huang, S.M.; Batta, R.; Nagi, R. Simultaneous siting and sizing of distribution centers on a plane. Ann. Oper. Res. 2009, 167, 157–170. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).