A Fuzzy Two-Echelon Model to Optimize Energy Consumption in an Urban Logistics Network with Electric Vehicles

Abstract

:1. Introduction

- ➢

- To consider recyclable wastes, speed of vehicles, quantity of energy consumption of the vehicle, and energy consumption rate depending on the value load of the vehicle in fuzzy form.

- ➢

- In the first echelon, the time windows are considered to pick up the recyclable waste from citizens of the city/wastebaskets (waste pickup points).

- ➢

- In the second echelon, the time windows are considered to deliver the recyclable waste to the central station.

- ➢

- To solve the models by both the grey wolf optimizer and tabu search algorithms.

2. Literature Review

2.1. EVRP/ELRP with and without TW

2.2. A Mixed Fleet of ICEVs and EVs

2.3. Related Review on the EVRP with Energy Consumption

2.4. Related Review on the EVRP under Uncertainty

2.5. Related Review on the 2E-EVRP

| Reference | Objective Function | Solution Method | Explanation |

|---|---|---|---|

| EVRP-MF (electric and conventional vehicles) | |||

| [48] | Min TOC | LS | Conventional, hybrid, or electric vehicles, E (electric)-urban freight |

| [47] | Min TOC | CWS + tree branching | |

| [44] | Min VN, EC, BSSC | ALNS | Multi-objective, TW |

| [46] | Min TOC, VN | Branch-and-price algorithm and ALNS | |

| [45] | Min TOC | Metaheuristic consists of a genetic algorithm, LS/LNS | Time windows, conventional, A plug-in hybrid and electric vehicles |

| EVRP uncertainty | |||

| [57] | UE | LR | Electric car, robust |

| [60] | Max AI | Robust optimization | |

| [59] | Min TOC | VNS, SA | Multi-depot electric vehicle routing problem with fuzzy time windows, pickup/delivery constraints |

| 2E-EVRP/2S-EVRP | |||

| [61] | Min TOC | LNS | Based on the method in Baldacci et al. [66], BSSs |

| [39] | Min TOC | BL | Electric buses in public transportation/2sEVRP with topography and speed profile, improve energy consumption Only uses EVs in the second echelon distribution stage |

| [63] | Min TOC, BSSC | CG + ALNS | EVs in both echelons |

| [62] | Min TOC | HG + LNS | Heterogeneous fleet |

| [67] | Min TOC | VNS | TW |

| This Paper | Min TOC | GWO, TS | Mix fleet, fuzzy numbers are used to express the rate and energy consumption depending on the amount of load, vehicle speed, and recyclable waste |

3. Problem Definition and Mathematical Modeling

3.1. First Echelon of Notation and Model

3.2. Second-Echelon of Notation and Model

3.3. Uncertainty in the First-Echelon Model

4. Solution Methods

4.1. Exact Method

4.2. Meta-Heuristic Algorithms

4.2.1. Tabu-Search Algorithm

| Algorithm 1: The TS pseudo-code |

| 1. Generating the initial solution X0, the best solution X*, tabu list T. 2. Generating a set of neighborhood solutions (multiple neighborhoods). 3. Choosing the best neighborhood from the set of neighborhood solutions X′. 4. Is X′ on the tabu list? Yes. 5. Is the aspiration criterion satisfied? Yes, go to 7. No, X′ will be removed from the set of neighborhood solutions. Then go to step 3. 6. Is X′ better than X*? Yes, go to 7. No, go to 8. 7. X′ replaces X*. 8. Then X′ replaces X. 9. Has the stopping criterion been reached? Yes, Go to 10 No Update the tabu list. No, back to step 2. 10. X* is selected. |

4.2.2. Grey Wolf Optimizer Algorithm

- ➢

- First, exploring the search space for prey;

- ➢

- Encircling the prey;

- ➢

- Attacking the prey.

| position vector of the gray wolf | |

| position vectors of prey | |

| distance between the wolf and the prey | |

| , | coefficient vectors |

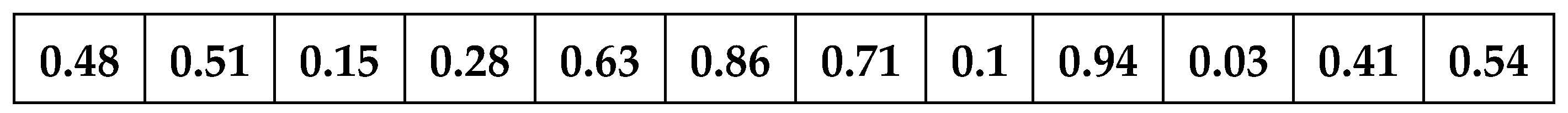

| , | random vectors in [0, 1] |

| distance control parameter | |

| current iteration | |

| maximum iteration |

| Algorithm 2: GWO pseudo-code. |

| Initialize the grey wolf population Greywolves_numi (I = 1, 2, …, n) Initialize the parameters Assessment the fitness function of search agents[each wolf) // The exploring for the prey // Encircling the prey(start) Select the best wolf Select the second-best wolf Select the third-best wolf // Encircling the prey(end) While (It_GWO < Maxit) For each wolf 1 in Greywolves_num do Update the position of current search // Attacking the prey End Update the parameters Assessment the fitness all wolves Update the best, second-best-third-best wolf It_GWO = It_GWO + 1 End while Return the best wolf |

4.2.3. Approach of Algorithms

Solution Methods (Decoding and Encoding of Problems)

Solution Representation Method with TS Algorithm for the First-Echelon Network

Solution Representation Method with GWO for First-Echelon Network

Solution Representation Method for the Second-Echelon Network

4.2.4. Parameter Tuning

5. Numerical Results

5.1. Different Size Instances

5.2. Sensitivity Analysis

5.3. Performance of Algorithms

6. Conclusions and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Overview of the EVRPs in This Paper

| Reference | Objective | Solution Method | Explanation |

|---|---|---|---|

| EVRP | |||

| [29] | Total costs: travel, charging, penalty, and fixed vehicle costs | Hybrid genetic algorithm | Fixed charging time |

| [4] | Minimize the total time (travel times + charging times) | ALNS | EVRP with non-linear charging and load-dependent discharging |

| EVRP-TW | |||

| [37] | Minimizes the total distance traveled | VNS/TS | Homogenous EV fleet |

| [40] | Vehicle number and total routing costs | Branch-price and-cut GENCOL + CPLEX | Four E-VRPTW variants recharge battery |

| [38] | Minimizes total distance traveled | ALNS | Time windows and partial recharging policy |

| [42] | Minimizes energy cost + vehicle acquisition cost + driver wage | ||

| ELRP/ELRP-TW | |||

| [36] | Total routing and construction costs | Combines tabu search algorithm and modified Clarke–Wright saving algorithm and SIGALNS | Locations of battery-swapping stations and EVRP |

| [35] | Total routing and construction costs | AVNS + LS | BSS-EV-LRP |

| [33] | Total travel and recharging time | ILS (VND) + heuristic concentration | EVRP with a non-linear recharging |

| [28] | Total distance, number of vehicles, and charge stations used | ALNS/LS | ELRP with time windows and partial recharging |

| [34] | Minimum cost number and location of battery-swapping stations (BSSs) | Hybrid heuristic composed of a binary PSO algorithm and VNS heuristic | Locations of BSSs, EVRP, and stochastic demands |

| [30] | Total travel, service, charging and waiting time | Heuristic for FRVCP | EVRP-NL |

| [31] | Minimize the sum of the fixed opening cost of charge stations and the driver cost | Multi-start ALNS heuristic | Locations of BSS, EVRP, multiple depots, and investment in charging stations |

| [32] | Minimize a cost function (energy cost, drivers’ wages, fixed cost) | VNS | Time-dependent electric vehicle routing, routing electric vehicles to serve a set of customers, and determining the speed |

| [43] | Minimizes BBS variable cost and shipping cost | Branch-and-price algorithm with an adaptive selection | ELRP, BSS LRP for mix fleet electric vehicles |

Appendix B. Other Equations for Fuzzy Model Calculation Formulas

References

- Nascimento, L.; Kuramochi, T.; Iacobuta, G.; den Elzen, M.; Fekete, H.; Weishaupt, M.; Höhne, N. Twenty years of climate pol-icy: G20 coverage and gaps. Clim. Policy 2022, 22, 158–174. [Google Scholar] [CrossRef]

- Sperling, D. Three Revolutions: Steering Automated, Shared, and Electric Vehicles to a Better Future; Island Press: Washington, DC, USA, 2018. [Google Scholar]

- Çabukoglu, E.; Georges, G.; Küng, L.; Pareschi, G.; Boulouchos, K. Battery electric propulsion: An option for heavy-duty vehcles? Results from a Swiss case-study. Transp. Res. Part C Emerg. Technol. 2018, 88, 107–123. [Google Scholar] [CrossRef]

- Kancharla, S.R.; Ramadurai, G. Electric vehicle routing problem with non-linear charging and load-dependent discharging. Expert Syst. Appl. 2020, 160, 113714. [Google Scholar] [CrossRef]

- Siskos, P.; Moysoglou, Y. Assessing the impacts of setting CO2 emission targets on truck manufacturers: A model implementation and application for the EU. Transp. Res. Part A Policy Pract. 2019, 125, 123–138. [Google Scholar] [CrossRef]

- Axsen, J.; Wolinetz, M. Reaching 30% plug-in vehicle sales by 2030: Modeling incentive and sales mandate strategies in Canada. Transp. Res. Part D Transp. Environ. 2018, 65, 596–617. [Google Scholar] [CrossRef]

- Mahesh, S.; Ramadurai, G.; Nagendra, S.S. On-board measurement of emissions from freight trucks in urban arterials: Effect of operating conditions, emission standards, and truck size. Atmos. Environ. 2019, 212, 75–82. [Google Scholar] [CrossRef]

- Erdinç, O.; Yetilmezsoy, K.; Erenoğlu, A.K.; Erdinç, O. Route optimization of an electric garbage truck fleet for sustainable environmental and energy management. J. Clean. Prod. 2019, 234, 1275–1286. [Google Scholar] [CrossRef]

- Sen, B.; Ercan, T.; Tatari, O. Does a battery-electric truck make a difference?—Life cycle emissions, costs, and externality analysis of alternative fuel-powered Class 8 heavy-duty trucks in the United States. J. Clean. Prod. 2017, 141, 110–121. [Google Scholar] [CrossRef]

- Liimatainen, H.; van Vliet, O.; Aplyn, D. The potential of electric trucks—An international commodity-level analysis. Appl. Energy 2019, 236, 804–814. [Google Scholar] [CrossRef]

- Liu, B. An Introduction to its Axiomatic Foundations Uncertainty Theory; Springer: Berlin, Germany, 2004. [Google Scholar]

- Breunig, U.; Schmid, V.; Hartl, R.F.; Vidal, T. A large neighbourhood based heuristic for two-echelon routing problems. Comput. Oper. Res. 2016, 76, 208–225. [Google Scholar] [CrossRef]

- Hatta, N.M.; Zain, A.M.; Sallehuddin, R.; Shayfull, Z.; Yusoff, Y. Recent studies on optimisation method of Grey Wolf Optimiser (GWO): A review (2014–2017). Artif. Intell. Rev. 2019, 52, 2651–2683. [Google Scholar] [CrossRef]

- Alotaibi, Y. A New Meta-Heuristics Data Clustering Algorithm Based on Tabu Search and Adaptive Search Memory. Symmetry 2022, 14, 623. [Google Scholar] [CrossRef]

- Maghzi, P.; Mohammadi, M.; Pasandideh, S.H.R.; Naderi, B. Operating Room Scheduling Optimization Based on a Fuzzy Uncertainty Approach and Metaheuristic Algorithms. Int. J. Eng. 2022, 35, 258–275. [Google Scholar] [CrossRef]

- Movassaghi, M.; Darestani, S.A. Multiple Cross-docks Scheduling with Multiple Doors using Fuzzy Approach and Metaheuristic Algorithms. J. Oper. Res. Soc. China 2021, 6, 1–51. [Google Scholar] [CrossRef]

- Behnke, M.; Kirschstein, T. The impact of path selection on GHG emissions in city Logistics. Transp. Res. Part E Logist. Transp. Rev. 2017, 106, 320–336. [Google Scholar] [CrossRef]

- Dabaghian, N.; Tavakkoli-Moghaddam, R.; Taleizadeh, A.A.; Moshtagh, M.S. Channel coordination and profit distribution in a three-echelon supply chain considering social responsibility and product returns. Environ. Dev. Sustain. 2022, 24, 3165–3197. [Google Scholar] [CrossRef]

- Ganji, M.; Kazemipoor, H.; Molana, S.M.H.; Sajadi, S.M. A green multi-objective integrated scheduling of production and distribution with heterogeneous fleet vehicle routing and time windows. J. Clean. Prod. 2020, 259, 120824. [Google Scholar] [CrossRef]

- Laporte, G.; Gendreau, M.; Potvin, J.Y.; Semet, F. Classical and modern heuristics for the vehicle routing problem. Int. Trans. Oper. Res. 2000, 7, 285–300. [Google Scholar] [CrossRef]

- Perboli, G.; Tadei, R.; Vigo, D. The two-echelon capacitated vehicle routing problem: Models and math-based heuristics. Transp. Sci. 2011, 45, 364–380. [Google Scholar] [CrossRef] [Green Version]

- Ramezani, M.; Bashiri, M.; Tavakkoli-Moghaddam, R. A new multi-objective stochastic model for a forward/reverse logistic network design with responsiveness and quality level. Appl. Math. Model. 2013, 37, 328–344. [Google Scholar] [CrossRef]

- Suzuki, Y. A new truck-routing approach for reducing fuel consumption and pollutants emission. Transp. Res. Part D Transp. Environ. 2011, 16, 73–77. [Google Scholar] [CrossRef]

- Tao, N.; Shishasha, S.; Peng, Z.; Tao, G. Disruption management decision model for VRPSDP under changes of customer distribution demand. J. Ambient Intell. Humaniz. Comput. 2021, 12, 2053–2063. [Google Scholar] [CrossRef]

- Wang, R.; Zhou, J.; Yi, X.; Pantelous, A.A. Solving the green-fuzzy vehicle routing problem using a revised hybrid intelligent algorithm. J. Ambient Intell. Humaniz. Comput. 2019, 10, 321–332. [Google Scholar] [CrossRef]

- Zarbakhshnia, N.; Soleimani, H.; Goh, M.; Razavi, S.S. A novel multi-objective model for green forward and reverse logistics network design. J. Clean. Prod. 2019, 208, 1304–1316. [Google Scholar] [CrossRef]

- Worley, O.; Klabjan, D.; Sweda, T. Simultaneous Vehicle Routing and Charging Station Siting for Commercial Electric Vehicles. In Proceedings of the 2012 IEEE International Electric Vehicle Conference, Greenville, SC, USA, 4–8 March 2012. [Google Scholar] [CrossRef] [Green Version]

- Schiffer, M.; Walther, G. The electric location routing problem with time windows and partial recharging. Eur. J. Oper. Res. 2017, 260, 995–1013. [Google Scholar] [CrossRef]

- Shao, S.; Guan, W.; Bi, J. Electric vehicle-routing problem with charging demands and energy consumption. IET Intell. Transp. Syst. 2018, 12, 202–212. [Google Scholar] [CrossRef]

- Froger, A.; Mendoza, J.E.; Jabali, O.; Laporte, G. Improved formulations and algorithmic components for the electric vehicle routing problem with nonlinear charging functions. Comput. Oper. Res. 2019, 104, 256–294. [Google Scholar] [CrossRef] [Green Version]

- Koç, Ç.; Bektaş, T.; Jabali, O.; Laporte, G. The fleet size and mix location-routing problem with time windows: Formulations and a heuristic algorithm. Eur. J. Oper. Res. 2016, 248, 33–51. [Google Scholar] [CrossRef] [Green Version]

- Lu, J.; Chen, Y.; Hao, J.-K.; He, R. The Time-dependent Electric Vehicle Routing Problem: Model and solution. Expert Syst. Appl. 2020, 161, 113593. [Google Scholar] [CrossRef]

- Montoya, A.; Gu’eret, C.; Mendoza, J.E.; Villegas, J.G. The electric vehicle routing problem with nonlinear charging function. Transp. Res. Part B Methodol. 2017, 103, 87–110. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Chen, M.; Zhang, W. A novel location-routing problem in electric vehicle transportation with stochastic demands. J. Clean. Prod. 2019, 221, 567–581. [Google Scholar] [CrossRef]

- Hof, J.; Schneider, M.; Goeke, D. Solving the battery swap station location-routing problem with capacitated electric vehicles using an AVNS algorithm for vehicle-routing problems with intermediate stops. Transp. Res. Part B Methodol. 2017, 97, 102–112. [Google Scholar] [CrossRef]

- Yang, J.; Sun, H. Battery swap station location-routing problem with capacitated electric vehicles. Comput. Oper. Res. 2015, 55, 217–232. [Google Scholar] [CrossRef]

- Schneider, M.; Stenger, A.; Goeke, D. The electric vehicle-routing problem with time windows and recharging stations. Transp. Sci. 2014, 48, 500–520. [Google Scholar] [CrossRef] [Green Version]

- Keskin, M.; Çatay, B. Partial recharge strategies for the electric vehicle routing problem with time windows. Transp. Res. Part C Emerg. Technol. 2016, 65, 111–127. [Google Scholar] [CrossRef]

- Basso, R.; Kulcsár, B.; Egardt, B.; Lindroth, P.; Sanchez-Diaz, I. Energy consumption estimation integrated into the Electric Vehicle Routing Problem. Transp. Res. Part D Transp. Environ. 2019, 69, 141–167. [Google Scholar] [CrossRef]

- Desaulniers, G.; Errico, F.; Irnich, S.; Schneider, M. Exact algorithms for electric vehicle-routing problems with time windows. Oper. Res. 2016, 64, 1388–1405. [Google Scholar] [CrossRef] [Green Version]

- Keskin, M.; Çatay, B. A matheuristic method for the electric vehicle routing problem with time windows and fast chargers. Comput. Oper. Res. 2018, 100, 172–188. [Google Scholar] [CrossRef]

- Keskin, M.; Çatay, B.; Laporte, G. A simulation-based heuristic for the electric vehicle routing problem with time windows and stochastic waiting times at recharging stations. Comput. Oper. Res. 2021, 125, 105060. [Google Scholar] [CrossRef]

- Chen, Y.; Li, D.; Zhang, Z.; Wahab, M.; Jiang, Y. Solving the battery swap station location-routing problem with a mixed fleet of electric and conventional vehicles using a heuristic branch-and-price algorithm with an adaptive selection scheme. Expert Syst. Appl. 2021, 186, 115683. [Google Scholar] [CrossRef]

- Goeke, D.; Schneider, M. Routing a mixed fleet of electric and conventional vehicles. Eur. J. Oper. Res. 2015, 245, 81–99. [Google Scholar] [CrossRef]

- Hiermann, G.; Hartl, R.F.; Puchinger, J.; Vidal, T. Routing a mix of conventional, plug-in hybrid, and electric vehicles. Eur. J. Oper. Res. 2019, 272, 235–248. [Google Scholar] [CrossRef] [Green Version]

- Hiermann, G.; Puchinger, J.; Ropke, S.; Hartl, R.F. The Electric Fleet Size and Mix Vehicle Routing Problem with Time Windows and Recharging Stations. Eur. J. Oper. Res. 2016, 252, 995–1018. [Google Scholar] [CrossRef] [Green Version]

- Lebeau, P.; De Cauwer, C.; Van Mierlo, J.; Macharis, C.; Verbeke, W.; Coosemans, T. Conventional, Hybrid, or Electric Vehicles: Which Technology for an Urban Distribution Centre? Sci. World J. 2015, 2015, 302867. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Van Duin, J.H.R.; Tavasszy, L.A.; Quak, H.J. Towards E (lectric)-urban freight: First promising steps in the electric vehicle revolution. Eur. Transp. Trasp. Eur. 2013, 54, 1–19. [Google Scholar]

- Barth, M.; Younglove, T.; Scora, G. Development of a Heavy-Duty Diesel Modal Emissions and Fuel Consumption Model; Technical Report; California Partners for Advanced Transit and Highways (PATH): Berkeley, CA, USA, 2005. [Google Scholar]

- Yi, Z.; Bauer, P.H. Effects of environmental factors on electric vehicle energy consumption: A sensitivity analysis. IET Electr. Syst. Transp. 2017, 7, 3–13. [Google Scholar] [CrossRef]

- Xiao, Y.; Zuo, X.; Kaku, I.; Zhou, S.; Pan, X. Development of energy consumption optimization model for the electric vehicle routing problem with time windows. J. Clean. Prod. 2019, 225, 647–663. [Google Scholar] [CrossRef]

- Lin, J.; Zhou, W.; Wolfson, O. Electric vehicle routing problem. Transp. Res. Procedia 2016, 12, 508–521. [Google Scholar] [CrossRef] [Green Version]

- Pelletier, S.; Jabali, O.; Laporte, G. The electric vehicle routing problem with energy consumption uncertainty. Transp. Res. Part B Methodol. 2019, 126, 225–255. [Google Scholar] [CrossRef]

- Vahedi-Nouri, B.; Arbabi, H.; Jolai, F.; Tavakkoli-Moghaddam, R.; Bozorgi-Amiri, A. Bi-objective collaborative electric vehicle routing problem: Mathematical modeling and matheuristic approach. J. Ambient Intell. Humaniz. Comput. 2022, 237, 1–21. [Google Scholar] [CrossRef]

- Zhang, S.; Gajpal, Y.; Appadoo, S.S.; Abdulkader, M.M.S. Electric vehicle routing problem with recharging stations for minimizing energy consumption. Int. J. Prod. Econ. 2018, 203, 404–413. [Google Scholar] [CrossRef]

- Nejad, M.M.; Mashayekhy, L.; Grosu, D.; Chinnam, R.B. Optimal routing for plug-in hybrid electric vehicles. Transp. Sci. 2017, 51, 1304–1325. [Google Scholar] [CrossRef]

- Fontana, M.W. Optimal Routes for Electric Vehicles Facing Uncertainty, Congestion, and Energy Constraints. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2013. [Google Scholar]

- Zhang, S.; Chen, M.; Zhang, W.; Zhuang, X. Fuzzy optimization model for electric vehicle routing problem with time windows and recharging stations. Expert Syst. Appl. 2020, 145, 113123. [Google Scholar] [CrossRef]

- Ghobadi, A.; Moghadam, R.T.; Fallah, M.; Kazemipoor, H. Multi-depot electric vehicle routing problem with fuzzy time windows and pickup/delivery constraints. J. Appl. Res. Ind. Eng. 2021, 8, 1–18. [Google Scholar] [CrossRef]

- Zhang, M.; Li, W.; Yu, S.S.; Wen, K.; Zhou, C.; Shi, P. A unified configurational optimization framework for battery swapping and charging stations considering electric vehicle uncertainty. Energy 2021, 218, 119536. [Google Scholar] [CrossRef]

- Breunig, U.; Baldacci, R.; Hartl, R.; Vidal, T. The electric two-echelon vehicle routing problem. Comput. Oper. Res. 2019, 103, 198–210. [Google Scholar] [CrossRef] [Green Version]

- Cao, S.; Liao, W.; Huang, Y. Heterogeneous fleet recyclables collection routing optimization in a two-echelon collaborative reverse logistics network from circular economic and environmental perspective. Sci. Total Environ. 2021, 758, 144062. [Google Scholar] [CrossRef]

- Jie, W.; Yang, J.; Zhang, M.; Huang, Y. The two-echelon capacitated electric vehicle routing problem with battery swapping stations: Formulation and efficient methodology. Eur. J. Oper. Res. 2019, 272, 879–904. [Google Scholar] [CrossRef]

- Erdelić, T.; Carić, T. A Survey on the Electric Vehicle Routing Problem: Variants and Solution Approaches. J. Adv. Transp. 2019, 2019, 5075671. [Google Scholar] [CrossRef]

- Qin, H.; Su, X.; Ren, T.; Luo, Z. A review on the electric vehicle routing problems: Variants and algorithms. Front. Eng. Manag. 2021, 8, 370–389. [Google Scholar] [CrossRef]

- Baldacci, R.; Mingozzi, A.; Roberti, R.; Calvo, R.W. An exact algorithm for the two-echelon capacitated vehicle routing problem. Oper. Res. 2013, 61, 298–314. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Zhou, H. A Two-Echelon Electric Vehicle Routing Problem with Time Windows and Battery Swapping Stations. Appl. Sci. 2021, 11, 10779. [Google Scholar] [CrossRef]

- Jiménez, M.; Arenas, M.; Bilbao, A.; Rodrı, M.V. Linear programming with fuzzy parameters: An interactive method resolution. Eur. J. Oper. Res. 2007, 177, 1599–1609. [Google Scholar] [CrossRef]

- Glover, F. Future paths for integer programming and links to artificial intelligence. Comput. Oper. Res. 1986, 13, 533–549. [Google Scholar] [CrossRef]

- Glover, F. Tabu search—Part I. ORSA J. Comput. 1989, 1, 190–206. [Google Scholar] [CrossRef] [Green Version]

- Glover, F. Tabu search—Part II. ORSA J. Comput. 1990, 2, 4–32. [Google Scholar] [CrossRef] [Green Version]

- Hertz, A.; de Werra, D. The tabu search metaheuristic: How we used it. Ann. Math. Artif. Intell. 1990, 1, 111–121. [Google Scholar] [CrossRef]

- Glover, F. Tabu Search and Adaptive Memory Programming—Advances, Applications and Challenges. In Interfaces in Computer Science and Operations Research; Springer: Boston, MA, USA, 1997; pp. 1–75. [Google Scholar]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey wolf optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef] [Green Version]

- Gul, F.; Rahiman, W.; Alhady, S.S.N.; Ali, A.; Mir, I.; Jalil, A. Meta-heuristic approach for solving multi-objective path planning for autonomous guided robot using PSO–GWO optimization algorithm with evolutionary programming. J. Ambient Intell. Humaniz. Comput. 2021, 12, 7873–7890. [Google Scholar] [CrossRef]

- Rathee, P.; Garg, R.; Meena, S. Using grey wolf optimizer for image registration. Int. J. Adv. Res. Sci. Eng. 2015, 4, 360–364. [Google Scholar]

- Gupta, P.; Kumar, V.; Rana, K.P.S.; Mishra, P. Comparative Study of Some Optimization Techniques Applied to Jacketed CSTR Control. In Proceedings of the 2015 4th International Conference on Reliability, Infocom Technologies and Optimization (ICRITO) (Trends and Future Directions), Noida, India, 2–4 September 2015; pp. 1–6. [Google Scholar]

- Ghobadi, A.; Darestani, S.A.; Shahroudi, K. Impact of Closed–Loop Supply Chains on Reducing Carbon Emission and Gaining Competitive Advantage: NSGA-II and MOPSO Solutions. Indian J. Sci. Technol. 2015, 8, 1–12. [Google Scholar] [CrossRef]

- Taguchi, G. Introduction to Quality Engineering: Designing Quality into Products and Processes; Asian Productivity Organization: Tokyo, Japan, 1986. [Google Scholar]

| Notations | Definition |

|---|---|

| Sets: | |

| Sets of nodes of all waste pickup points in one area and recycling station relating to areas . | |

| Sets of the nodes of candidates for charge stations. | |

| Sets of the nodes of candidates for charge station and virtual nodes relating to all of charge stations. | |

| Sets of the nodes of relating to each charge station (including node itself and its related virtual nodes. | |

| Set of the nodes of all waste pickup points in one area and recycling station relating to areas . | |

| Set of the nodes of waste pickup points. | |

| Recycling collection station node. | |

| Set of fleet vehicle . | |

| Heterogeneous fleet electric vehicle . | |

| Vehicle type . | |

| Recyclable wastes class in waste pickup points (the recyclable wastes divided in three groups of 1, 2, and 3) . | |

| Parameters: | |

| Amount of recyclable waste of class in waste pickup point (kg). | |

| Distance between nodes of (m). | |

| Unit cost of transportation between two nodes relating to vehicle type . | |

| Cost of energy consumption. | |

| Cost of recharge unit. | |

| Speed of vehicle type (m/s) | |

| Cost of using vehicle type . | |

| Cost of constructing each charge station. | |

| Loading capacity of each transportation means of vehicle type (kg). | |

| Earliest time to arrive to waste pickup point (lower limit of the acceptable time windows of the node) (s). | |

| Latest time to arrive to waste pickup point (upper limit of the expected time windows of the node) (s). | |

| Penalty cost relating to time windows being exceeded. | |

| A very large number. | |

| Efficiency rate of a generator of vehicle type . | |

| Weight of vehicle type (kg). | |

| Acceleration of vehicle type (m/s 2). | |

| Acceleration of type of vehicle between nodes and (m/s 2). | |

| Gravitational constant (9.81 m/s2). | |

| Average the angle of road between nodes and (m/s2). | |

| Level in frontal surface area of vehicle type (kg). | |

| Air density (kg/m3). | |

| Coefficient relating to rolling resistance of vehicle type . | |

| Coefficient relating to rolling drag of vehicle type . | |

| Constant quality of energy consumption of the vehicle between nodes and after simplification of Formula (2) . | |

| Energy consumption coefficient depends on the weight load of the vehicle between nodes and after simplification of Formula (3) . | |

| Battery capacity type of vehicle. | |

| Recharge speed of battery in the charge station. | |

| Decision Variables: | |

| 1 if vehicle leaves from node to node j; 0, otherwise. | |

| 1 if vehicle is used; 0, otherwise. | |

| Continuous variable shows at what time recyclable wastes carried in vehicle arrived in node . | |

| Continuous variable is used to eliminate the sub-tour. | |

| 1 if waste pickup point is visited in time interval ; 0, otherwise. | |

| 1 if waste pickup point is visited in time interval ; 0, otherwise. | |

| 1 if waste pickup point is visited in time interval ; 0, otherwise. | |

| Continuous variable is used to linearize the expression of . | |

| Continuous variable is used to linearize the expression of . | |

| Continuous variable shows vehicle for transporting the recyclable wastes from node to node with how much load. | |

| Continuous variable shows vehicle for transporting the recyclable wastes and how much energy consumed while moving from node to node . | |

| Continuous variable shows the total amount of consuming charge by vehicle in the arrival node. | |

| Continuous variable is related to the node of the charge station and its virtual node, showing how the quantity of vehicle charge is consumed to the node before the charge station. | |

| Continuous variable is used to linearize the expression of . | |

| Notations | Definition |

|---|---|

| Sets: | |

| Sets of nodes of all recycle stations and recycle center station . | |

| Set of recycling stations. | |

| Recycle center station node. | |

| Set of vehicles conventional fleet . | |

| Parameters: | |

| Amount of recyclable waste in recycle center . | |

| Distance between nodes and . | |

| Cost of transportation unit between two nodes and . | |

| Speed of the vehicles. | |

| Cost of using vehicles. | |

| Loading capacity of each vehicle. | |

| Earliest time to arrive to waste pickup point (lower limit of acceptable time windows of nodes). | |

| Latest time to arrive to waste pickup point (upper limit of expected time windows of the nodes). | |

| The penalty cost relating to time windows being exceeded. | |

| A very large number. | |

| Decision variables: | |

| 1 if vehicle leaves from node to ; 0, otherwise. | |

| 1 if vehicle is used; 0, otherwise. | |

| Continuous variable shows at what time that recyclable wastes carried by vehicle arrived in node . | |

| Continuous variable is used to eliminate the sub-tour. | |

| 1 if waste pickup point is visited in time interval ; 0, otherwise. | |

| 1 if waste pickup point is visited in time interval ; 0, otherwise. | |

| 1 if waste pickup point is visited in time interval ; 0, otherwise. | |

| Continuous variable is used to linearize the expression of | |

| Continuous variable is used to linearize the expression of | |

| Notations | Definition |

|---|---|

| Amount of recyclable waste class in waste pickup point (kg). | |

| Speed of type of vehicle (m/s). | |

| Constant quality of energy consumption of vehicle between nodes and after simplification of Formula (2) . | |

| Energy consumption coefficient depends on the weight load of vehicle between nodes and after simplification of Formula (3) . |

| Level | The Algorithm GWO | The Algorithm TS | ||

|---|---|---|---|---|

| Greywolves_Num | MaxIt | MaxIt_Ts | Tabu_Length | |

| 1 | 10 | 15 | 10 | 0.25 |

| 2 | 30 | 35 | 25 | 0.4 |

| 3 | 50 | 55 | 40 | 0.55 |

| 4 | 70 | 75 | 65 | 0.75 |

| Values selected | 70 | 75 | 10 | 0.75 |

| GWO | TS | ||

|---|---|---|---|

| Parameter | Value | Parameter | Value |

| Greywolves_num | 70 | Tabu_lengh | 0.75 |

| MaxIt | 75 | MaxIt_Ts | 10 |

| Number of Waste Pickup Points | Number of Small Vehicles | Number of Medium Vehicles | Number of Large Vehicles |

|---|---|---|---|

| 5 | 0 | 1 | 1 |

| 5 | 1 | 1 | 1 |

| 10 | 1 | 2 | 1 |

| 10 | 1 | 1 | 2 |

| 15 | 2 | 1 | 1 |

| 15 | 2 | 2 | 1 |

| 25 | 1 | 1 | 1 |

| 25 | 1 | 1 | 1 |

| 50 | 1 | 1 | 1 |

| 50 | 1 | 1 | 1 |

| 75 | 2 | 2 | 2 |

| 75 | 2 | 2 | 2 |

| 100 | 2 | 1 | 1 |

| 100 | 1 | 2 | 1 |

| Air Density (kg/m3) | Gravitational Constant (m/s2) | Unit Cost of Energy Consumption ($) |

|---|---|---|

| 1.2041 | 9.81 | 4 |

| The Cost of Constructing Each Charging Station (1000$) | Recharge Unit Cost ($) | The Penalty Cost for Violation of the Time Window ($) |

|---|---|---|

| 25 | 0.12 | 20 |

| Recyclable Waste Amount of Class 1 | Recyclable Waste Amount of Class 2 | Recyclable Waste Amount of Class 3 |

|---|---|---|

| [0, 20] | [20, 40] | [40, 70] |

| Parameter Description | Small Vehicle | Medium Vehicle | Large Vehicle |

|---|---|---|---|

| Cost of the transport unit between the two nodes | 0.5 | 1 | 1.5 |

| Vehicle speed | 1 | 1 | 2 |

| Cost of using a vehicle | 20 | 30 | 50 |

| Load capacity | 100 | 300 | 500 |

| Vehicle engine efficiency rate | 0.7 | 0.75 | 0.79 |

| Vehicle curb weight (tons) | 3.322 | 3.629 | 3.855 |

| Acceleration (m/s2) | 0.011 | 0.013 | 0.015 |

| Front surface of vehicles (m2) | 5 | 8 | 10 |

| Coefficient of rolling resistance (unitless) | 0.01 | 0.015 | 0.018 |

| Coefficient of rolling drag (unitless) | 0.6 | 0.7 | 0.8 |

| Battery capacity (kwh) | 20 | 25 | 30 |

| Battery recharge rate at the charging station | 210 | 225 | 250 |

| Recyclable Waste Amount | Penalty Cost for Violation of the Time Windows ($) | Load Capacity | Cost of Using a Vehicle | Vehicle Speed | Unit Cost of Energy Consumption | Latest Time to Arrive the Node | Earliest Time to Arrive at the Node | Distance between the Nodes |

|---|---|---|---|---|---|---|---|---|

| [0, 70] | 20 | 300 | 80 | 30 | 2.5 | [85, 179] | [12, 96] | [0, 20] |

| Vehicle Used | ||||

|---|---|---|---|---|

| Problem | Large Vehicle | Medium Vehicle | Small Vehicle | Deterministic |

| 1 | 1 | 1 | 0 | 4159.65 |

| 2 | 1 | 1 | 1 | 4365.75 |

| 3 | 1 | 2 | 1 | 5122.33 |

| 4 | 2 | 1 | 1 | 5195.15 |

| 5 | 1 | 1 | 2 | 5495.22 |

| 6 | 1 | 2 | 2 | 5845.15 |

| Vehicle Used | ||||

|---|---|---|---|---|

| Problem | Large Vehicle | Medium Vehicle | Small Vehicle | Fuzzy |

| 1 | 1 | 1 | 0 | 5012.66 |

| 2 | 1 | 1 | 1 | 5294.58 |

| 3 | 1 | 2 | 1 | 6102.47 |

| 4 | 2 | 1 | 1 | 6325.42 |

| 5 | 1 | 1 | 2 | 7215.68 |

| 6 | 1 | 2 | 2 | 8307.18 |

| Problem | Capacity of Vehicles | Deterministic |

|---|---|---|

| 1 | 50 | 3456.00 |

| 2 | 60 | 4851.00 |

| 3 | 80 | 5264.00 |

| 4 | 85 | 5451.00 |

| 5 | 95 | 5621.95 |

| 6 | 115 | 6514.54 |

| 7 | 130 | 7458.26 |

| Problem | Capacity of Vehicles | Fuzzy |

|---|---|---|

| 1 | 50 | 4100.56 |

| 2 | 60 | 5151.25 |

| 3 | 80 | 5364.45 |

| 4 | 85 | 6582.39 |

| 5 | 95 | 6825.13 |

| 6 | 115 | 7915.41 |

| 7 | 130 | 8416.44 |

| Zone | Small Vehicle | Medium Vehicle | Large Vehicle |

|---|---|---|---|

| 1 | 0 | 0 | 1 |

| 2 | 1 | 0 | 1 |

| 3 | 0 | 1 | 1 |

| 4 | 1 | 0 | 1 |

| 5 | 1 | 2 | 1 |

| Zone | Total Cost (GWO) | Total Cost (TS) |

|---|---|---|

| 1 | 448,000 | 469,855 |

| 2 | 219,727 | 249,658 |

| 3 | 1,571,059 | 1,653,230 |

| 4 | 2,306,301 | 2,631,415 |

| 5 | 1,757,962 | 1,846,522 |

| Zone | One Type of Vehicles | Three Types of Vehicles |

|---|---|---|

| 1 | 651,911.68 | 451,599.56 |

| 2 | 558,941.40 | 193,391.26 |

| 3 | 2,018,662.50 | 1,580,968.86 |

| 4 | 2,842,020.49 | 2,309,129.95 |

| 5 | 2,187,199.97 | 1,740,298.76 |

| Number of Small Vehicles | Vehicle Used | First-Echelon Cost | ||

|---|---|---|---|---|

| Large Vehicle | Medium Vehicle | Small Vehicle | ||

| 0 | 2 | 1 | 0 | 85,317 |

| 1 | 1 | 1 | 0 | 94,250 |

| 2 | 1 | 1 | 0 | 79,558 |

| 3 | 1 | 1 | 0 | 95,992 |

| 4 | 2 | 0 | 1 | 82,408 |

| 5 | 1 | 1 | 1 | 12,739 |

| Problem | |||||

|---|---|---|---|---|---|

| 1 | 8144.68 | 4236.65 | 4236.65 | 0.00 | 92.24 |

| 2 | 4165.41 | 4987.95 | 4165.41 | 19.75 | 0.00 |

| 3 | 4468.56 | 8265.85 | 4468.56 | 84.98 | 0.00 |

| 4 | 8154.22 | 4896.74 | 4896.74 | 0.00 | 66.52 |

| 5 | 4565.74 | 7236.14 | 4565.74 | 58.49 | 0.00 |

| 6 | 4562.17 | 5167.52 | 4562.17 | 13.27 | 0.00 |

| 7 | 7268.46 | 4898.66 | 4898.66 | 0.00 | 48.38 |

| 8 | 7636.54 | 7821.84 | 7636.54 | 2.43 | 0.00 |

| 9 | 8234.19 | 4986.15 | 4986.15 | 0.00 | 65.14 |

| 10 | 4985.33 | 5236.14 | 4985.33 | 5.03 | 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghobadi, A.; Fallah, M.; Tavakkoli-Moghaddam, R.; Kazemipoor, H. A Fuzzy Two-Echelon Model to Optimize Energy Consumption in an Urban Logistics Network with Electric Vehicles. Sustainability 2022, 14, 14075. https://doi.org/10.3390/su142114075

Ghobadi A, Fallah M, Tavakkoli-Moghaddam R, Kazemipoor H. A Fuzzy Two-Echelon Model to Optimize Energy Consumption in an Urban Logistics Network with Electric Vehicles. Sustainability. 2022; 14(21):14075. https://doi.org/10.3390/su142114075

Chicago/Turabian StyleGhobadi, Azra, Mohammad Fallah, Reza Tavakkoli-Moghaddam, and Hamed Kazemipoor. 2022. "A Fuzzy Two-Echelon Model to Optimize Energy Consumption in an Urban Logistics Network with Electric Vehicles" Sustainability 14, no. 21: 14075. https://doi.org/10.3390/su142114075