Measuring the Operational Efficiency and the Water Resources Management Efficiency for Industrial Parks: Empirical Study of Industrial Parks in Taiwan

Abstract

1. Introduction

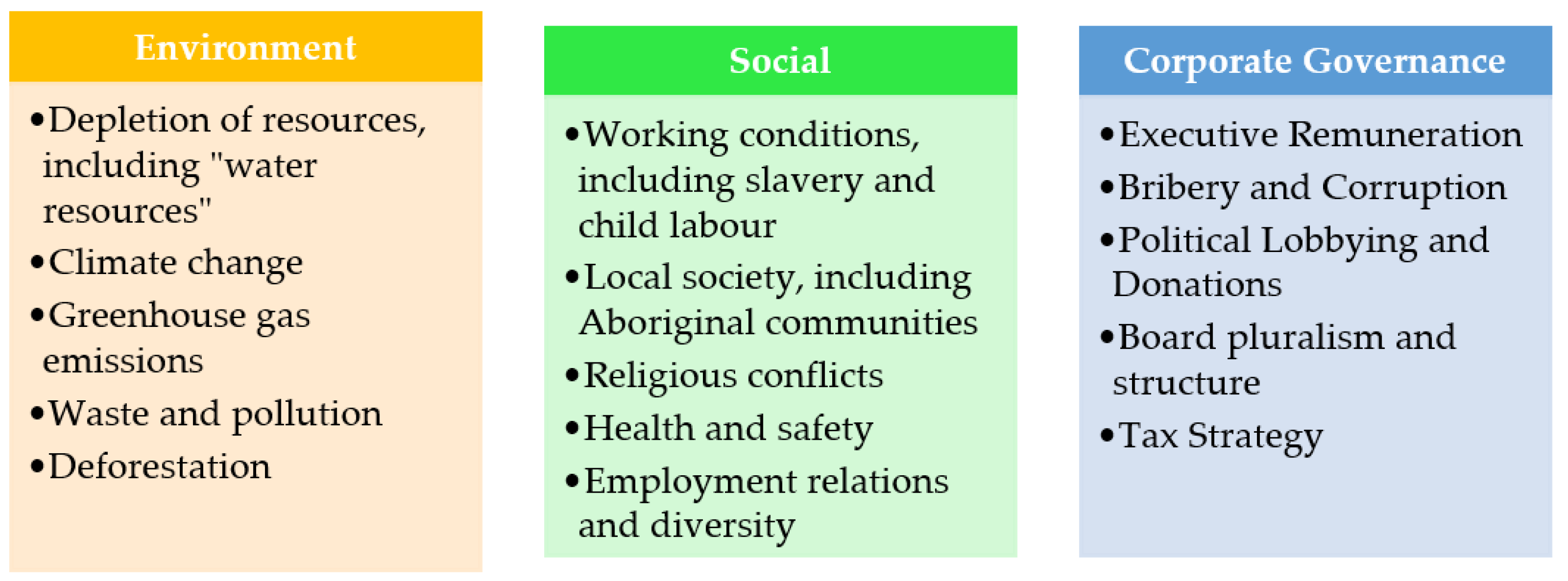

2. Literature Review

2.1. Industry Cluster

2.2. Industry Park

2.3. Water Resource Management

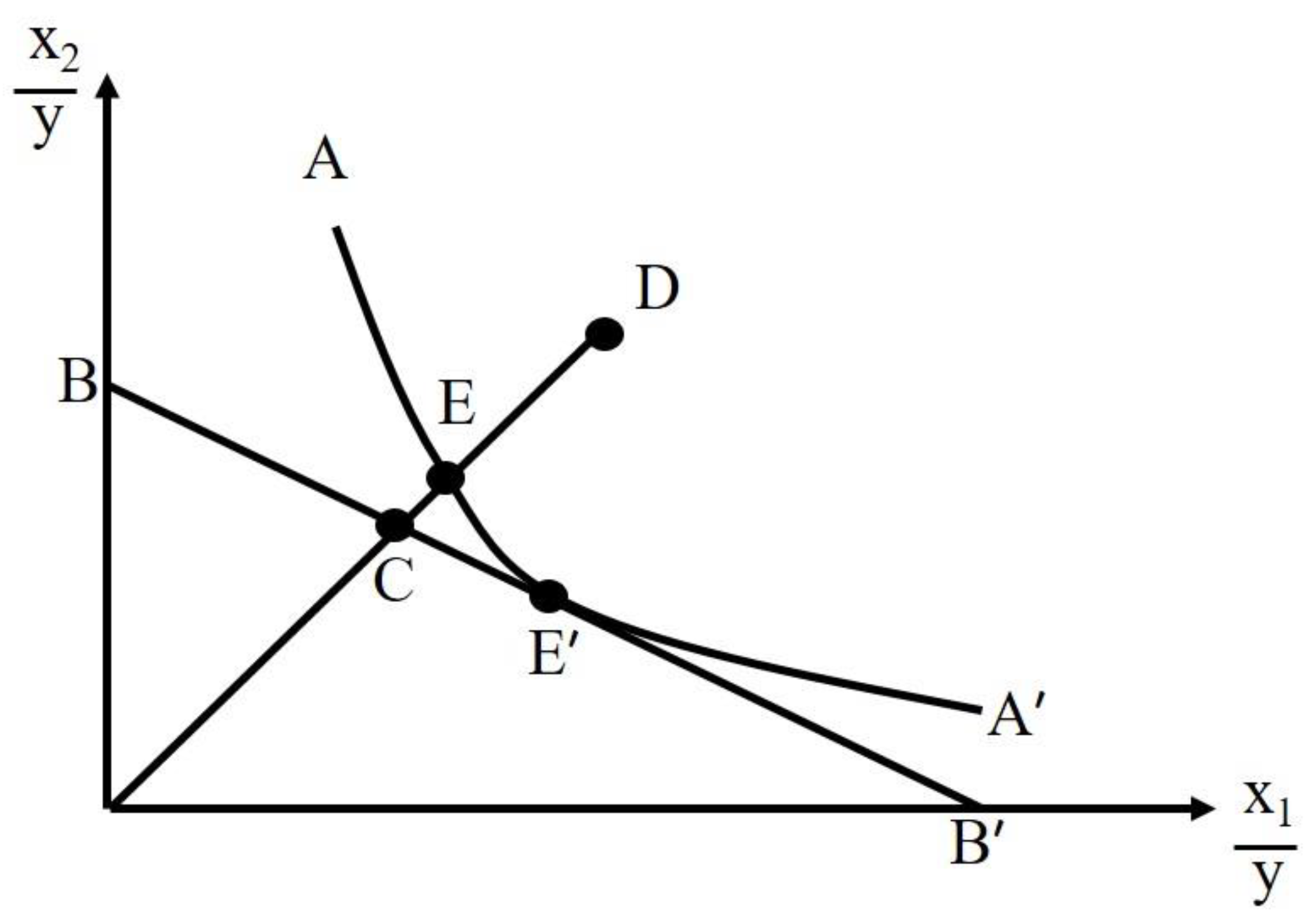

2.4. Operating Efficiency

- (1)

- The Productive Frontier is made up of the most efficient DMUs, with other inefficient units located outside this frontier.

- (2)

- Production technology is Constant Return to Scale (CRTS), i.e., an increase of one unit of input gives the same rate of output.

- (3)

- The leading edge of production is convex and the slope of each point is less than or equal to zero.

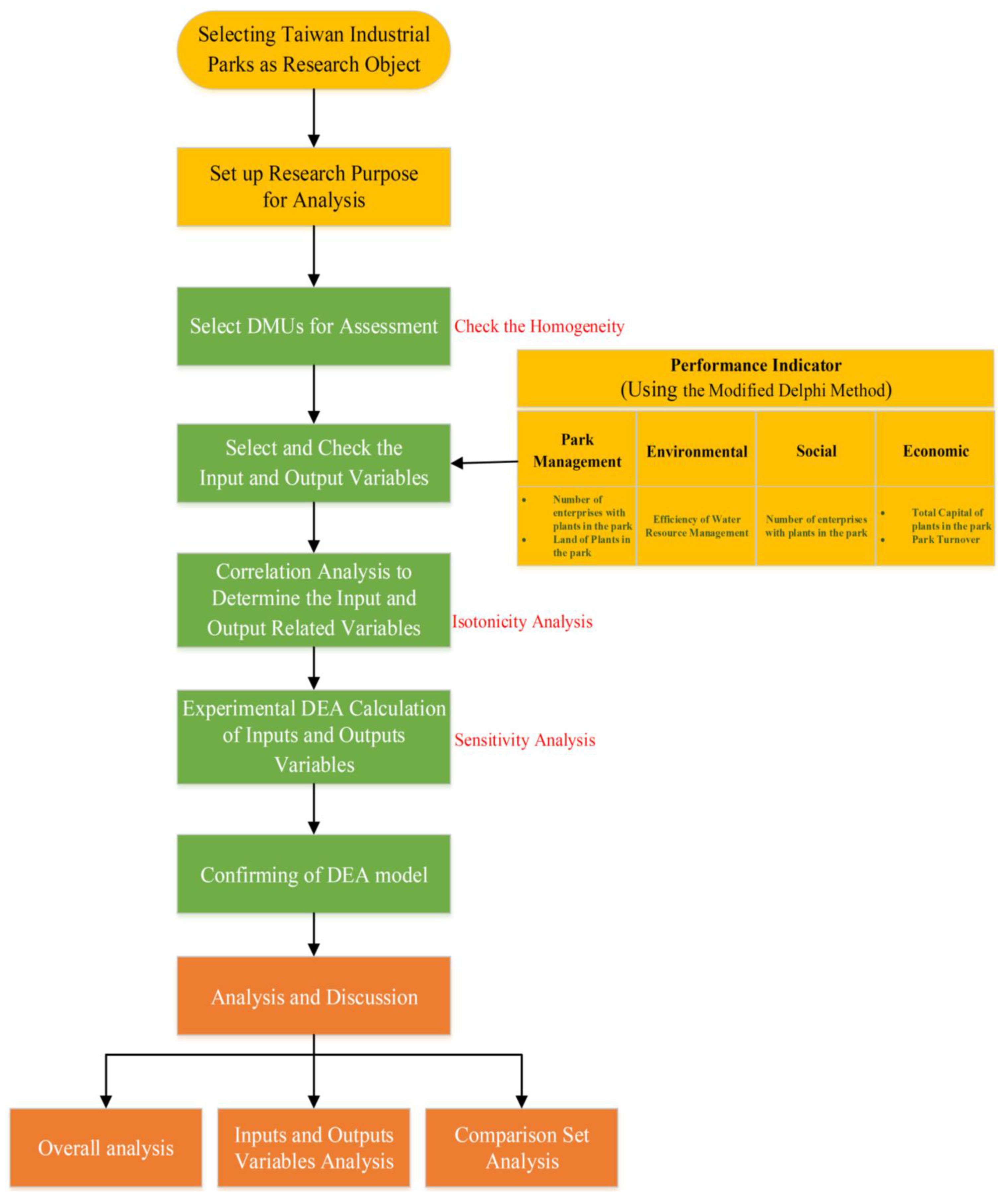

3. Research Methods

3.1. Developing Operational Efficiency Indicators

3.2. Efficiency of Water Resources Management

3.3. Industrial Park Operational Efficiency Model and the Evaluation Methodology

3.3.1. Identifying Output and Input Items and Build Production Function Models

3.3.2. Identifying Output and Input Items and Build Production Function Models

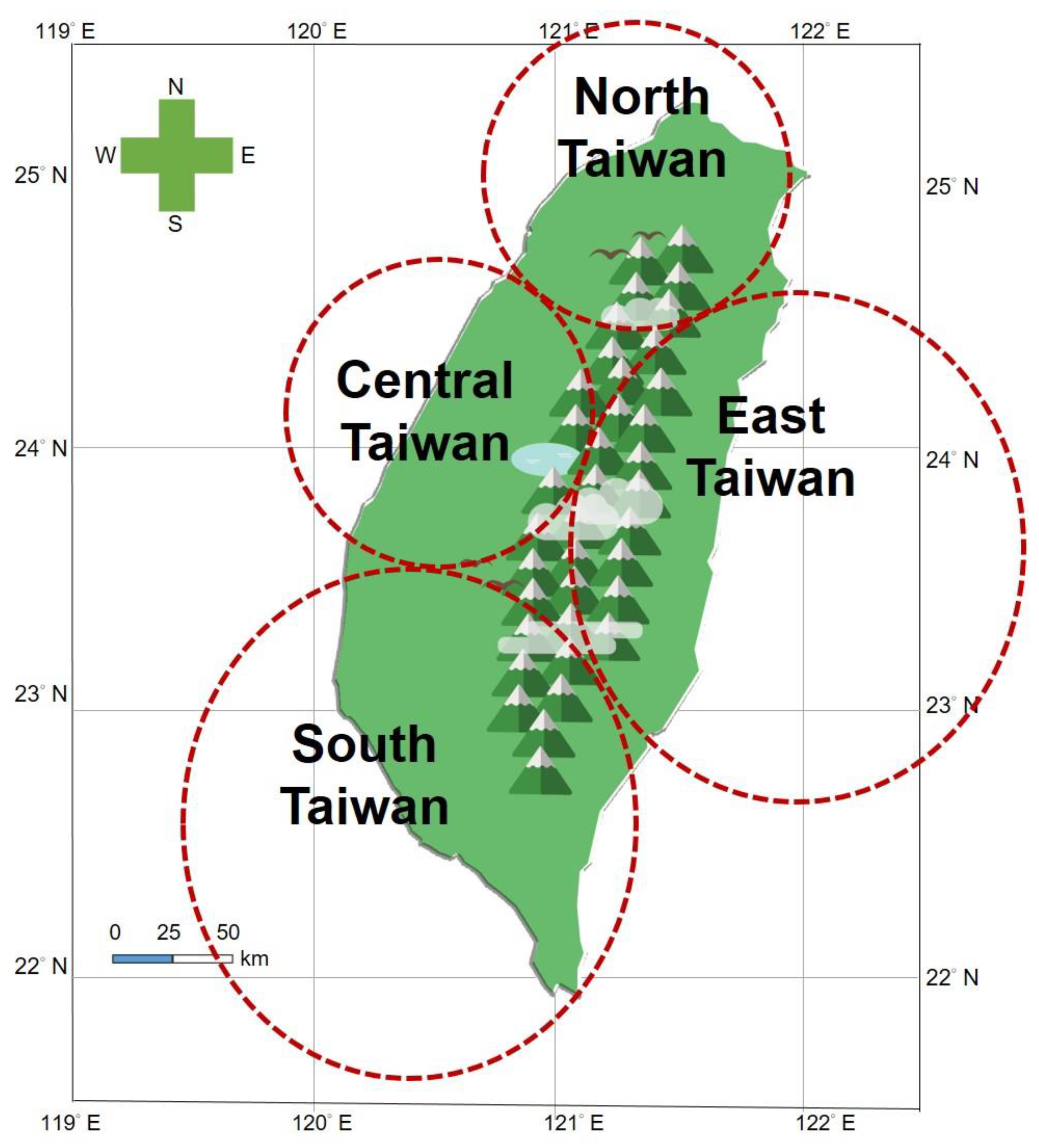

4. Case Study

4.1. Developing Operational Efficiency Indicators

4.2. Overview of Study Variables and Relevance Analysis

4.2.1. Overview of the Basic Values of the Variables Related to Water Resources Management Efficiency

4.2.2. Summary of Basic Values of Operating Efficiency-Related Variables in Industrial Areas

4.2.3. Correlation between Output Variables and Input Variables in Industrial Area Operating Efficiency

4.3. Sensitivity Analysis

4.4. Overall Analysis

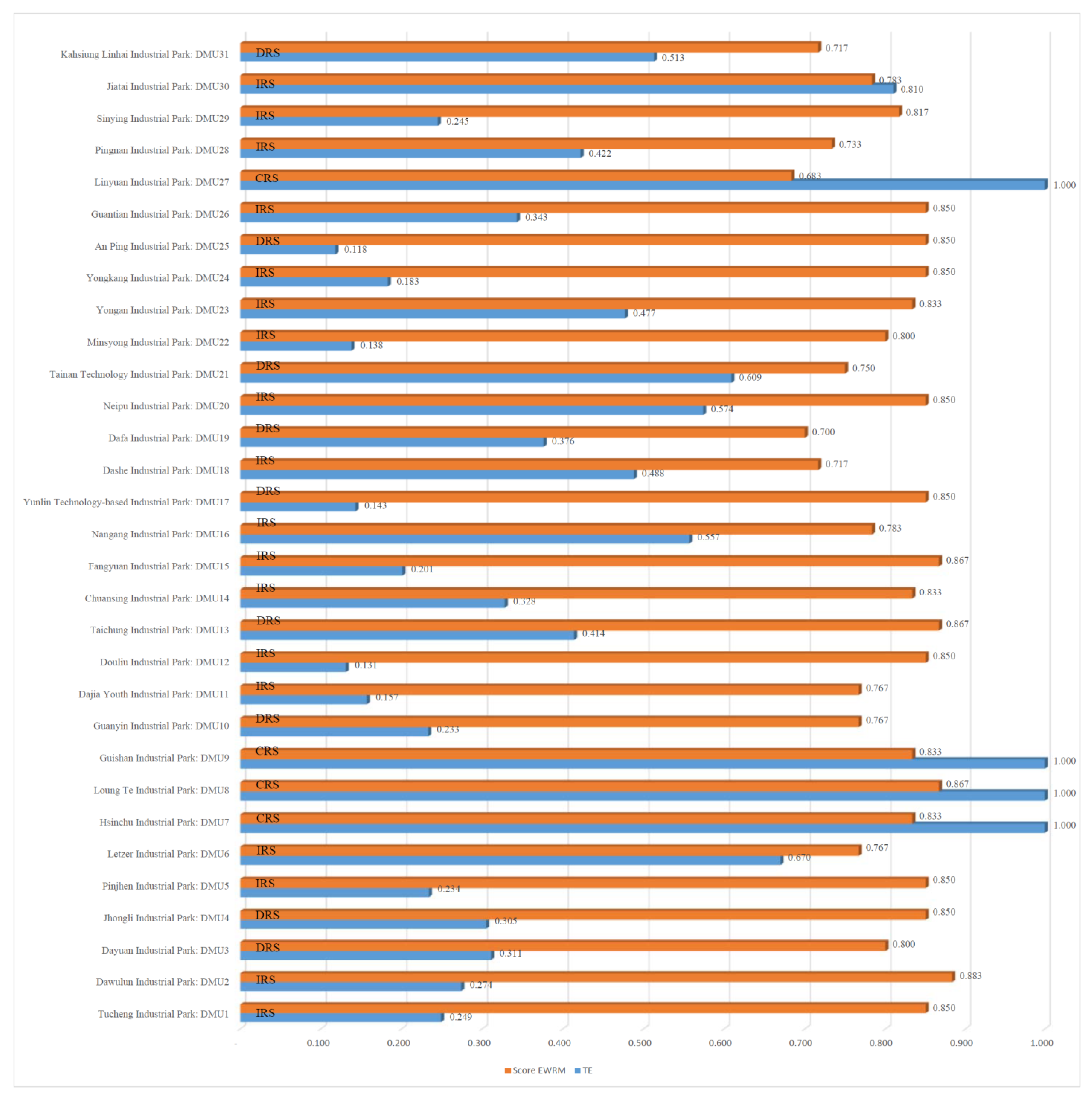

4.5. Individual Analysis

4.6. Comparative Set Analysis

5. Conclusions

5.1. Conclusions and Suggestions

5.1.1. Conclusions

5.1.2. Suggestions

5.2. Limitations of the Study

- This study only focuses on 31 manufacturing industrial zones in Taiwan, not on technology parks and other ecological parks.

- In applying the knowledge of the ESG domain, only the efficiency value of water resources management in the E environment dimension is used to investigate the efficiency of non-economic aspects.

- In this study, a model for evaluating the efficiency of water resources management was successfully constructed; the input variables in the model can be flexibly extended in the evaluation model with the data collection situation. The existing model uses three input variables, which have some shortcomings, mainly due to the limited resources and the inability to collect large-scale data values of indicators for water quality monitoring projects in industrial parks. According to the Environmental Protection Administration Executive Yuan for Taiwan, there should be 12 indicators for water quality monitoring projects, namely: (1) Biochemical Oxygen Demand, BOD; (2) Suspended Solids, SS; (3) Chemical Oxygen Demand, COD; (4) Temperature; (5) Turbidity; (6) pH; (7) Dissolved Oxygen, DO; (8) Electrical Conductivity, EC; (9) Ammonia Nitrogen; (10) Total Kjeldahl Nitrogen, TKN; (11) Phosphorus; and (12) River Pollution Index, RPI.

5.3. Management Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| WRM | Water Resource Management |

| DEA | Data Envelopment Analysis |

| ESG | Environmental, Social and Governance |

| EIPs | Eco-Industrial Parks |

| SDGs | Sustainable Development Goals |

| DMU | Decision Making Unit |

| DMUs | Decision Making Units |

| CRS | Constant Returns to Scale |

| VRS | Variable Returns to Scale |

| TE | Technical Efficiency |

| SE | Scale Efficiency |

| PTE | Pure Technical Efficiency |

| IRS | Increasing Returns to Scale |

| DRS | Decreasing Returns to Scale |

| BOD | Biochemical Oxygen Demand |

| SS | Suspended Solids |

| COD | Chemical Oxygen Demand |

| DO | Dissolved Oxygen |

| EC | Electrical Conductivity |

| TKN | Total Kjeldahl Nitrogen |

| RPI | River Pollution Index |

References

- Doeffinger, T.; Hall, J.W. Water Stress and Productivity: An Empirical Analysis of Trends and Drivers. Water Resour. Res. 2020, 56, e2019WR025925. [Google Scholar] [CrossRef]

- Wu, T.; Song, H.; Wang, J.; Friedler, E. Framework, Procedure, and Tools for Comprehensive Evaluation of Sustainable Stormwater Management: A Review. Water 2020, 12, 1231. [Google Scholar] [CrossRef]

- Intaraburt, W.; Sangsanont, J.; Limpiyakorn, T.; Ruangrassamee, P.; Suttinon, P.; Suwannasilp, B.B. Feasibility Study of Water Reclamation Projects in Industrial Parks Incorporating Environmental Benefits: A Case Study in Chonburi, Thailand. Water 2022, 14, 1172. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, Y.; Li, Y.; Zhou, B. Achieving win-win policy outcomes for water resource management and economic development: The experience of Chinese cities. Sustain. Prod. Consum. 2021, 27, 873–888. [Google Scholar] [CrossRef]

- Cotterill, S.; Bracken, L.J. Assessing the Effectiveness of Sustainable Drainage Systems (SuDS): Interventions, Impacts and Challenges. Water 2020, 12, 3160. [Google Scholar] [CrossRef]

- Tumilar, A.S.; Milani, D.; Cohn, Z.; Florin, N.; Abbas, A. A Modelling Framework for the Conceptual Design of Low-Emission Eco-Industrial Parks in the Circular Economy: A Case for Algae-Centered Business Consortia. Water 2021, 13, 69. [Google Scholar] [CrossRef]

- van Beers, D.; Tyrkko, K.; Flammini, A.; Barahona, C.; Susan, C. Results and Lessons Learned from Assessing 50 Industrial Parks in Eight Countries against the International Framework for Eco-Industrial Parks. Sustainability 2020, 12, 10611. [Google Scholar] [CrossRef]

- Chen, S.C.; Huang, C.Y.; Lee, D.S. Integrating the Diamond Model and PDSA to Explore the Sustainable Competitiveness of Industrial Clusters-Mask Machine Alliance in Taiwan during COVID-19. J. JINWEN Univ. Sci. Technol. 2021, 31, 1–14. (In Chinese) [Google Scholar]

- Ng, K.M. Strategic Planning of China’s First Special Economic Zone: Shenzhen City Master Plan (2010–2020). Plan. Theory Pract. 2011, 12, 638–642. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, H.; Su, Y.; Zhou, X.; Li, Z.; Chen, C. Assessment and Decomposition of Regional Land Use Efficiency of the Service Sector in China. Land 2022, 11, 1911. [Google Scholar] [CrossRef]

- Vabuolytė, V.; Burinskienė, M.; Sousa, S.; Petrakovska, O.; Trehub, M.; Tiboni, M. Increase in the Value Added of Land Due to the Establishment of Industrial Parks. Sustainability 2021, 13, 8541. [Google Scholar] [CrossRef]

- Alexakis, D.E. Meta-Evaluation of Water Quality Indices. Application into Groundwater Resources. Water 2020, 12, 1890. [Google Scholar] [CrossRef]

- Chen, S.-C.; Lee, D.-S.; Huang, C.-Y. Evaluating the Sustainable Operating Performance of Electronics Industry Groups: Taiwanese Firms in Mainland China. Sustainability 2021, 13, 12030. [Google Scholar] [CrossRef]

- Luo, L.; Zheng, Z.; Luo, J.; Jia, Y.; Zhang, Q.; Wu, C.; Zhang, Y.; Sun, J. Spatial Agglomeration of Manufacturing in the Wuhan Metropolitan Area: An Analysis of Sectoral Patterns and Determinants. Sustainability 2020, 12, 8005. [Google Scholar] [CrossRef]

- Baldwin, R.E.; Krugman, P. Agglomeration, Integration and Tax Harmonization. Eur. Econ. Rev. 2004, 48, 1–23. [Google Scholar] [CrossRef]

- Moses, L.N. Location and the Theory of Production. Q. J. Econ. 1958, 72, 259–272. [Google Scholar] [CrossRef]

- Henderson, J.V. Marshall’s scale economies. J. Urban Econ. 2003, 53, 1–28. [Google Scholar] [CrossRef]

- Mori, T.; Smith, T.E. On the spatial scale of industrial agglomerations. J. Urban Econ. 2015, 89, 1–20. [Google Scholar] [CrossRef]

- Andersson, M.; Klaesson, J.; Larsson, J.P. How local are spatial density externalities? Neighbourhood effects in agglomeration economies. Reg. Stud. 2016, 50, 1082–1095. [Google Scholar] [CrossRef]

- Hobbs, K.G.; Link, A.N.; Scott, J.T. Science and technology parks: An annotated and analytical literature review. J. Technol. Transf. 2017, 42, 957–976. [Google Scholar] [CrossRef]

- He, C.; Zhu, S. Evolutionary Economic Geography in China; Springer: Singapore, 2019. [Google Scholar]

- Gerschenkron, A. Economic Backwardness in Historical Perspective—The Political Economy Reader: Markets as Institutions; Routledge: London, UK, 1962; pp. 211–228. [Google Scholar]

- Castells, M. Technopoles of the World: The Making of 21st Century Industrial Complexes; Routledge: London, UK, 2014. [Google Scholar]

- Liu, Q.L.; Wang, Q. How China achieved its 11th Five-Year Plan emissions reduction target: A structural decomposition analysis of industrial SO2 and chemical oxygen demand. Sci. Total Environ. 2017, 574, 110–1116. [Google Scholar] [CrossRef]

- Xiao, Z.Y.; Shen, Z.C. The temporal and spatial evolution of population & industrial agglomeration and environmental pollution and the relevance analysis. J. Arid Resour. Environ. 2019, 33, e8. [Google Scholar]

- Elbers, C.; Withagen, C. Environmental policy, population dynamics and agglomeration. Contrib. Econ. Anal. Policy 2003, 3. [Google Scholar] [CrossRef]

- Hamaguchi, Y. Polluting firms’ location choices and pollution havens in an R&D-based growth model for an international emissions trading market. J. Int. Trade Econ. Dev. 2021, 30, 625–642. [Google Scholar]

- Lange, A.; Quaas, M.F. Economic geography and the effect of environmental pollution on agglomeration. BE J. Econ. Anal. Policy 2007, 7, 1724. [Google Scholar] [CrossRef]

- Chen, F.-H.; Liu, H.-R. Evaluation of Sustainable Development in Six Transformation Fields of the Central Taiwan Science Park. Sustainability 2021, 13, 4336. [Google Scholar] [CrossRef]

- Löfsten, H.; Lindelöf, P. Science Parks and the Growth of New Technology-Based Firms—Academic-Industry Links, Innova-tion and Markets. Res. Policy 2002, 31, 859–876. [Google Scholar] [CrossRef]

- Lee, W.-H.; Yang, W.-T. The cradle of Taiwan high technology industry development—Hsinchu Science Park (HSP). Technovation 2000, 20, 55–59. [Google Scholar] [CrossRef]

- Lin, S.W.; Ben, T.M. Impact of Government and Industrial Agglomeration on Industrial Land Prices: A Taiwanese Case Study. Habitat Int. 2009, 33, 412–418. [Google Scholar] [CrossRef]

- Martín Gómez, A.M.; Aguayo González, F.; Marcos Bárcena, M. Smart eco-industrial parks: A circular economy implementation based on industrial metabolism. Resour. Conserv. Recycl. 2018, 135, 58–69. [Google Scholar] [CrossRef]

- Alabaeva, N.S.; Velitskaya, S.V.; Malahova, O.S.; Koroliova, C.P. Development of eco-industrial parks in Russia and abroad. J. Econ. Bus. 2019, 6, 19–22. [Google Scholar]

- Al-Quradaghi, S.; Zheng, Q.P.; Elkamel, A. Generalized framework for the design of eco-industrial parks: Case study of end-of-life vehicles. Sustainability 2020, 12, 6612. [Google Scholar] [CrossRef]

- Mousqué, F.; Boix, M.; Négny, S.; Montastruc, L.; Genty, L.; Domenech, S. Optimal On-Grid Hybrid Power System for Eco-Industrial Parks Planning and Influence of Geographical Position. In Proceedings of the 28th European Symposium on Computer Aided Process Engineering, Graz, Austria, 10–13 June 2018; Elsevier Masson SAS: Issy-les-Moulineaux, France, 2018; Volume 43, ISBN 9780444642356. [Google Scholar]

- Zhang, L.; Nian, Y.; Pi, J.; Zhou, Y. Land policy, land supply structure and housing prices. China J. Econ. 2017, 4, 91–118. [Google Scholar]

- Flores Casamayor, H.; Morales Martínez, J.L.; Mora-Rodríguez, J.; Delgado-Galván, X. Assessing Industrial Impact on Water Sustainability in El Bajío, Guanajuato State, Mexico. Sustainability 2021, 13, 6161. [Google Scholar] [CrossRef]

- Jiang, W.; Cao, K.; Jin, L.; Cheng, Y.; Xu, Q. How Do China’s Development Zones Affect Environmental Pollution under Government Domination. Sustainability 2022, 14, 3790. [Google Scholar] [CrossRef]

- Mendoza Gómez, M.; Tagle-Zamora, D.; Morales Martínez, J.L.; Caldera Ortega, A.R.; Mora Rodríguez, J.d.J.; Delgado-Galván, X. Water Supply Management Index: Leon, Guanajuato, Mexico. Water 2022, 14, 919. [Google Scholar] [CrossRef]

- Zhu, H.; Zhu, J.; Zou, Q. Comprehensive Analysis of Coordination Relationship between Water Resources Environment and High-Quality Economic Development in Urban Agglomeration in the Middle Reaches of Yangtze River. Water 2020, 12, 1301. [Google Scholar] [CrossRef]

- Li, W.; Xi, Y.; Wu, F.; Masoud, M.; Liu, S. Green development performance of water resources and its economic-related determinants. J. Clean. Prod. 2019, 239, 118048. [Google Scholar] [CrossRef]

- Gassert, F.; Luck, M.; Landis, M.; Reig, P.; Shiao, T. Aqueduct Global Maps 2.1: Constructing Decision-Relevant Global Water Risk Indicators; World Resources Institute: Washington, DC, USA, 2014. [Google Scholar]

- Service, R.F. Desalination freshens up. Science 2006, 313, 1088–1090. [Google Scholar] [CrossRef]

- United Nations Department of Economic and Social Affairs. Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 22 July 2022).

- Liu, J.; Mooney, H.; Hull, V.; Davis, S.J.; Gaskell, J.; Hertel, T.; Lubchenco, J.; Seto, K.C.; Gleick, P.; Kremen, C.; et al. Systems integration for global sustainability. Science 2015, 347, 1258832. [Google Scholar] [CrossRef]

- Zand, M.; Nasab, M.A.; Hatami, A.; Kargar, M.; Chamorro, H.R. Using adaptive fuzzy logic for intelligent energy management in hybrid vehicles. In Proceedings of the 2020 28th Iranian Conference on Electrical Engineering (ICEE), Tabriz, Iran, 4–6 August 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–7. [Google Scholar]

- Zand, M.; Nasab, M.A.; Sanjeevikumar, P.; Maroti, P.K.; Holm-Nielsen, J.B. Energy management strategy for solid-state transformer-based solar charging station for electric vehicles in smart grids. IET Renew. Power Gener. 2020, 14, 3843–3852. [Google Scholar] [CrossRef]

- Masuda, S.; Sano, I.; Hojo, T.; Li, Y.Y.; Nishimura, O. The comparison of greenhouse gas emissions in sewage treatment plants with different treatment processes. Chemosphere 2018, 193, 581–590. [Google Scholar] [CrossRef] [PubMed]

- Rehana, S.; Rajulapati, C.R.; Ghosh, S.; Karmakar, S.; Mujumdar, P. Uncertainty Quantification in Water Resource Systems Modeling: Case Studies from India. Water 2020, 12, 1793. [Google Scholar] [CrossRef]

- Hoekstra, A.; Chapagain, A.; Van Oel, P. Advancing Water Footprint Assessment Research: Challenges in Monitoring Progress towards Sustainable Development Goal 6. Water 2017, 9, 438. [Google Scholar] [CrossRef]

- Song, J.; Yin, Y.; Xu, H.; Wang, Y.; Wu, P.; Sun, S. Drivers of domestic grain virtual water flow: A study for China. Agric. Water Manag. 2020, 239, 106175. [Google Scholar] [CrossRef]

- Du, Y.; Lv, X.-T.; Wu, Q.-Y.; Zhang, D.-Y.; Zhou, Y.-T.; Peng, L.; Hu, H.-Y. Formation and control of disinfection byproducts and toxicity during reclaimed water chlorination: A review. J. Environ. Sci. 2017, 58, 51–63. [Google Scholar] [CrossRef]

- Salgot, M.; Folch, M. Wastewater treatment and water reuse. Curr. Opin. Environ. Sci. Health 2018, 2, 64–74. [Google Scholar] [CrossRef]

- Racar, M.; Dolar, D.; Farkas, M.; Milcic, N.; Spehar, A.; Kosutic, K. Rendering plant wastewater reclamation by coagulation, sand filtration, and ultrafiltration. Chemosphere 2019, 227, 207–215. [Google Scholar] [CrossRef]

- Li, Q.; Wang, W.; Jiang, X.; Lu, D.; Zhang, Y.; Li, J. Analysis of the potential of reclaimed water utilization in typical inland cities in northwest China via system dynamics. J. Environ. Manag. 2020, 270, 110878. [Google Scholar] [CrossRef]

- Cherchi, C.; Kesaano, M.; Badruzzaman, M.; Schwab, K.; Jacangelo, J.G. Municipal reclaimed water for multi-purpose applications in the power sector: A review. J. Environ. Manag. 2019, 236, 561–570. [Google Scholar] [CrossRef]

- Revollar, S.; Meneses, M.; Vilanova, R.; Vega, P.; Francisco, M. Eco-Efficiency Assessment of Control Actions in Wastewater Treatment Plants. Water 2021, 13, 612. [Google Scholar] [CrossRef]

- Jorge, C.; Almeida, M.d.C.; Covas, D. Performance Assessment System for Energy Efficiency in Wastewater Systems. Water 2021, 13, 1807. [Google Scholar] [CrossRef]

- Seidl, C.; Wheeler, S.A.; Zuo, A. High turbidity: Water valuation and accounting in the Murray-Darling Basin. Agric. Water Manag. 2020, 230, 105929. [Google Scholar] [CrossRef]

- Nasab, M.A.; Zand, M.; Padmanaban, S.; Bhaskar, M.S.; Guerrero, J.M. An efficient, robust optimization model for the unit commitment considering renewable uncertainty and pumped-storage hydropower. Comput. Electr. Eng. 2022, 100, 107846. [Google Scholar] [CrossRef]

- Zhang, B.; Meng, Z.; Zhang, L.; Sun, X.; Hayat, T.; Alsaedi, A.; Ahmad, B. Exergy-based systems account of national resource utilization: China 2012. Resour. Conserv. Recycl. 2018, 132, 324–338. [Google Scholar] [CrossRef]

- Huang, X.; Hua, W.; Dai, X. Performance Evaluation of Watershed Environment Governance—A Case Study of Taihu Basin. Water 2022, 14, 158. [Google Scholar] [CrossRef]

- Lee, M.; Kim, H.; Lee, J.Y.; Yang, J.E.; Lim, C. A Shift Towards Integrated and Adaptive Water Management in South Korea: Building Resilience Against Climate Change. Water Resour. Manag. 2022, 36, 1611–1625. [Google Scholar] [CrossRef]

- Hu, J.; Wang, S.; Yeh, F.Y. Total-factor water efficiency of regions in China. Resour. Policy 2006, 31, 217–230. [Google Scholar] [CrossRef]

- Li, M.; Long, K. Direct or Spillover Effect: The Impact of Pure Technical and Scale Efficiencies of Water Use on Water Scarcity in China. Int. J. Environ. Res. Public Health 2019, 16, 3401. [Google Scholar] [CrossRef]

- Geng, Q.; Ren, Q.; Nolan, R.H.; Wu, P.; Yu, Q. Assessing China’s agricultural water use efficiency in a green-blue water perspective: A study based on data envelopment analysis. Ecol. Indic. 2019, 96, 329–335. [Google Scholar] [CrossRef]

- Deng, G.; Li, L.; Song, Y. Provincial water use efficiency measurement and factor analysis in China: Based on SBM-DEA model. Ecol. Indic. 2016, 69, 12–18. [Google Scholar] [CrossRef]

- Zhang, L.; Luan, X.; Chen, X.; Zhang, S.; Liang, Y.; Cui, Z. Water Footprint Inventory Construction of Cathode Copper Products in a Chinese Eco-Industry. Sustainability 2022, 14, 5962. [Google Scholar] [CrossRef]

- Muratoglu, A. Applications and Response Formulations of Water Footprint Methodology for Conservation of Water Resources. Imp. Encycl. Conserv. 2021, 360–370. [Google Scholar] [CrossRef]

- Muratoglu, A. Water Footprint: Concept and Methodology. Imp. Encycl. Conserv. 2021, 351–359. [Google Scholar] [CrossRef]

- She, Y.; Liu, Y.; Deng, Y.; Jiang, L. Can China’s Government-Oriented Environmental Regulation Reduce Water Pollution? Evidence from Water Pollution Intensive Firms. Sustainability 2020, 12, 7841. [Google Scholar]

- EBA. EBA Report on Management and Supervision of ESG Risks for Credit Institutions and Investment Firms. Available online: https://www.eba.europa.eu/sites/default/documents/fifiles/document_library/Publications/Reports/2021/1015656/EBA%20Report%20on%20ESG%20risks%20management%20and%20supervision.pdf (accessed on 22 July 2022).

- EBA. Environmental Social and Governance Disclosures. Available online: https://www.eba.europa.eu/sites/default/documents/files/document_library/Publications/Consultations/2021/Consultation%20on%20draft%20ITS%20on%20Pillar%20disclosures%20on%20ESG%20risk/963626/Factsheet%20-%20ESG%20disclosures.pdf (accessed on 22 July 2022).

- Daugaard, D. Emerging new themes in environmental, social and governance investing: A systematic literature review. Account. Financ. 2020, 60, 1501–1530. [Google Scholar] [CrossRef]

- Yan, S. Basic Functions and Normative Development of Logistics Park. Qual. Stand. 2006, 8, 17–21. [Google Scholar]

- Zhang, S.; Hou, Y.; Gu, C. Research on the Development and Countermeasures of Jiangsu Cultural and Creative Industry Park. China Stand. 2013, 12, 105–108. [Google Scholar]

- An, J.; Liang, Y.; Yang, R.; Zhai, H. Research on Standardized Construction and Evaluation Path of Modern Ecological Circular Agriculture Park. China Stand. 2018, 1, 64–68. [Google Scholar]

- Duan, J.; Lu, Q. New Process of Group Standards. Urban Plan. 2019, 43, 33–39. [Google Scholar]

- United Nations Industrial Development Organization; World Bank Group; Deutsche Gesellschaft für Internationale Zusammenarbeit. An International Framework for Eco-Industrial Parks; World Bank: Washington, DC, USA, 2017. [Google Scholar]

- Tian, J.; Liu, W.; Lai, B.; Li, X.; Chen, L. Study of the performance of eco-industrial park development in China. J. Clean. Prod. 2014, 64, 486–494. [Google Scholar] [CrossRef]

- Farrell, M.J. The measurement of productive efficiency. J. R. Stat. Soc. 1957, 120, 253–281. [Google Scholar] [CrossRef]

- Hsieh, J.-C.; Ma, L.-H.; Chiu, Y.-H. Assessing China’s Use Efficiency of Water Resources from the Resampling Super Data Envelopment Analysis Approach. Water 2019, 11, 1069. [Google Scholar] [CrossRef]

- Mardani, A.; Edmundas, K.Z.; Dalia, S.; Ahmad, J.; Masoumeh, K. A comprehensive review of data envelopment analysis (DEA) approach in energy efficiency. Renew. Sustain. Energy Rev. 2017, 70, 1298–1322. [Google Scholar] [CrossRef]

- Mardani, A.; Streimikiene, D.; Balezentis, T.; Saman, M.Z.M.; Nor, K.M.; Khoshnava, S.M. Data envelopment analysis in energy and environmental economics: An overview of the state-of-the-art and recent development trends. Energies 2018, 11, 2002. [Google Scholar] [CrossRef]

- Ablanedo-Rosas, J.H.; Guerrero Campanur, A.; Olivares-Benitez, E.; Sánchez-García, J.Y.; Nuñez-Ríos, J.E. Operational Efficiency of Mexican Water Utilities: Results of a Double-Bootstrap Data Envelopment Analysis. Water 2020, 12, 553. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some Models for Estimating Technical and Scale Inefficiencies in Data Envelopment Analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef]

- Yang, H.; Pollitt, M. Incorporating both undesirable outputs and uncontrollable variables into DEA: The performance of Chinese coal-fired power plants. Eur. J. Oper. Res. 2009, 197, 1095–1105. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, W.; Ren, J. Efficiency Analysis of the Input for Water-Saving Agriculture in China. Water 2020, 12, 207. [Google Scholar] [CrossRef]

- Ali, M.K.; Klein, K.K. Water use efficiency and productivity of the irrigation districts in Southern Alberta. Water Resour. Manag. 2014, 28, 2751–2766. [Google Scholar] [CrossRef]

- Azad, M.A.S.; Ancev, T.; Hernández-Sancho, F. Efficient water use for sustainable irrigation industry. Water Resour. Manag. 2015, 29, 1683–1696. [Google Scholar] [CrossRef]

- Li, W.; Zuo, Q.; Jiang, L.; Zhang, Z.; Ma, J.; Wang, J. Evaluation of Regional Water Resources Management Performance and Analysis of the Influencing Factors: A Case Study in China. Water 2022, 14, 574. [Google Scholar] [CrossRef]

- Gungor-Demirci, G.; Lee, J.; Keck, J. Assessing the performance of a California water utility using two-stage data envelopment analysis. J. Water Res. Plan. Manag. 2018, 144, 1943–5452. [Google Scholar] [CrossRef]

- Kamarudin, N.; Ismail, W.R. Establishment of performance indicators for Malaysian water utilities with the presence of undesirable output. J. Teknol. 2016, 78, 99–105. [Google Scholar] [CrossRef]

- Chen, C.-G.; Cheng, W.-Y.; Chen, S.-C. The establishment of cost-effectiveness, objective oriented LSP performance measurement. In Proceedings of the IIE Annual Conference and Expo 2007—Industrial Engineering’s Critical Role in a Flat World—Conference Proceedings, Nashville, TN, USA, 19–23 May 2007. [Google Scholar]

- Norman, M.; Stoker, B. Data Envelopment Analysis: The Assessment of Performance; John Wiley & Sons: New York, NY, USA, 1991. [Google Scholar]

| Item | Qualifications | Experiences | Seniority | |||

|---|---|---|---|---|---|---|

| Description | Master | Ph.D. | Academic Specialists | Practical Specialists | 10~20 years | Over 20 years |

| Number of Persons | 4 | 3 | 2 | 5 | 2 | 5 |

| Remark | The average length of service of an expert is 18.6 years | |||||

| Four Key Performance Components | Indicators for This Research | Definition of Indicators |

|---|---|---|

| Park Management | Number of enterprises with plants in the park | Total number of enterprises with factories in the park |

| Land of plants in the park | Total area of factories in the park (hectares) | |

| Social | Number of employees in park | Total number of employees of the enterprises in the Park |

| Economic | Total capital of plants in the park | Factory capital of enterprises in the Park |

| Park turnover | Total revenue of enterprises in the park | |

| Environmental | Efficiency of water resource management | The management attitude of water resources is described in Section 3.2 |

| Remark | The research is based on industrial parks under the direct management of the government, so the issue of service quality is not considered. | |

| Industrial Park | Conductivity (μ s/cm) | Score | Hydrogen Ion Concentration Index | Score | Water Temperature (°C) | Score |

|---|---|---|---|---|---|---|

| AAA | 5289 | 0.7 | 6.48 | 0.85 | 29.69 | 0.80 |

| Goal Attainment | 22.28% higher than target (AL7) | 8.1% lower than target (AL4) | 0.98% higher than target (AL5) | |||

| Average | 4325 | 7.05 | 29.4 | |||

| Water Resource Management Efficiency Values | (0.7 + 0.85 + 0.8)/3 = 0.78 | |||||

| Indicators for This Research | Indicator Abbreviation | Variables: Output/Input |

|---|---|---|

| Park turnover | Park T | Output |

| Number of enterprises with plants in the park | Park N | Input |

| Land of plants in the park | Park L | Input |

| Number of employees in park | Park E | Input |

| Total capital of plants in the park | Park C | Input |

| DMU | Name of Industrial Park | Location in Taiwan | City |

|---|---|---|---|

| DMU1 | Tucheng Industrial Park | North | New Taipei City |

| DMU2 | Dawulun Industrial Park | North | Keelung City |

| DMU3 | Dayuan Industrial Park | North | Taoyuan City |

| DMU4 | Jhongli Industrial Park | North | Taoyuan City |

| DMU5 | Pinjhen Industrial Park | North | Taoyuan City |

| DMU6 | Letzer Industrial Park | East | Yilan County |

| DMU7 | Hsinchu Industrial Park | North | Hsinchu County |

| DMU8 | Loung Te Industrial Park | East | Yilan County |

| DMU9 | Guishan Industrial Park | North | Taoyuan City |

| DMU10 | Guanyin Industrial Park | North | Taoyuan City |

| DMU11 | Dajia Youth Industrial Park | Central | Taichung City |

| DMU12 | Douliu Industrial Park | Central | Taichung City |

| DMU13 | Taichung Industrial Park | Central | Taichung City |

| DMU14 | Chuansing Industrial Park | Central | Changhua County |

| DMU15 | Fangyuan Industrial Park | Central | Changhua County |

| DMU16 | Nangang Industrial Park | Central | Nantou County |

| DMU17 | Yunlin Technology-based Industrial Park | South | Yunlin County |

| DMU18 | Dashe Industrial Park | South | Kaohsiung City |

| DMU19 | Dafa Industrial Park | South | Kaohsiung City |

| DMU20 | Neipu Industrial Park | South | Pingtung County |

| DMU21 | Tainan Technology Industrial Park | South | Tainan City |

| DMU22 | Minsyong Industrial Park | South | Chiayi County |

| DMU23 | Yongan Industrial Park | South | Kaohsiung City |

| DMU24 | Yongkang Industrial Park | South | Tainan City |

| DMU25 | An Ping Industrial Park | South | Tainan City |

| DMU26 | Guantian Industrial Park | South | Tainan City |

| DMU27 | Linyuan Industrial Park | South | Kaohsiung City |

| DMU28 | Pingnan Industrial Park | South | Pingtung County |

| DMU29 | Sinying Industrial Park | South | Tainan City |

| DMU30 | Jiatai Industrial Park | South | Chiayi County |

| DMU31 | Kahsiung Linhai Industrial Park | South | Kaohsiung City |

| Hydrogen Ion Concentration Index | Conductivity (μ s/cm) | Water Temperature (°C) | |

|---|---|---|---|

| Average | 7.10 | 4869 | 28.38 |

| Maximum value | 7.65 | 10,433 | 34.57 |

| Minimum value | 6.44 | 1290 | 23.76 |

| Park T | Park N | Park L | Park E | Park C | |

|---|---|---|---|---|---|

| Average | 2241.32 | 181.55 | 166.71 | 13,581.45 | 25,198,591.32 |

| Maximum value | 9416.00 | 739 | 1204.20 | 38,671 | 423,977,587.00 |

| Minimum value | 100.00 | 14 | 15.42 | 1219 | 202,282.00 |

| Park N | Park L | Park E | Park C | |

|---|---|---|---|---|

| Park T | 0.402 * | 0.677 ** | 0.701 ** | 0.213 |

| Park N | Park L | Park E | Park C | |

|---|---|---|---|---|

| Score EWRM | 0.098 | −0.394 * | 0.075 | −0.182 |

| DMU | Name of Industrial Park | Pre-Test | Post-Test | ||

|---|---|---|---|---|---|

| TE | Peer Count | TE | Peer Count | ||

| DMU1 | Tucheng Industrial Park | 0.249 | 0 | 0.275 | 0 |

| DMU2 | Dawulun Industrial Park | 0.274 | 0 | 0.348 | 0 |

| DMU3 | Dayuan Industrial Park | 0.311 | 0 | 0.492 | 0 |

| DMU4 | Jhongli Industrial Park | 0.305 | 0 | 0.524 | 0 |

| DMU5 | Pinjhen Industrial Park | 0.234 | 0 | 0.327 | 0 |

| DMU6 | Letzer Industrial Park | 0.670 | 0 | 1.000 | 10 |

| DMU7 | Hsinchu Industrial Park | 1.000 | 27 | -- | -- |

| DMU8 | Loung Te Industrial Park | 1.000 | 14 | 1.000 | 15 |

| DMU9 | Guishan Industrial Park | 1.000 | 3 | 1.000 | 16 |

| DMU10 | Guanyin Industrial Park | 0.233 | 0 | 0.320 | 0 |

| DMU11 | Dajia Youth Industrial Park | 0.157 | 0 | 0.203 | 0 |

| DMU12 | Douliu Industrial Park | 0.131 | 0 | 0.181 | 0 |

| DMU13 | Taichung Industrial Park | 0.414 | 0 | 0.742 | 0 |

| DMU14 | Chuansing Industrial Park | 0.328 | 0 | 0.500 | 0 |

| DMU15 | Fangyuan Industrial Park | 0.201 | 0 | 0.265 | 0 |

| DMU16 | Nangang Industrial Park | 0.557 | 0 | 0.681 | 0 |

| DMU17 | Yunlin Technology-based Industrial Park | 0.143 | 0 | 0.272 | 0 |

| DMU18 | Dashe Industrial Park | 0.488 | 0 | 0.599 | 0 |

| DMU19 | Dafa Industrial Park | 0.376 | 0 | 0.577 | 0 |

| DMU20 | Neipu Industrial Park | 0.574 | 0 | 0.590 | 0 |

| DMU21 | Tainan Technology Industrial Park | 0.609 | 0 | 1.000 | 9 |

| DMU22 | Minsyong Industrial Park | 0.138 | 0 | 0.188 | 0 |

| DMU23 | Yongan Industrial Park | 0.477 | 0 | 0.710 | 0 |

| DMU24 | Yongkang Industrial Park | 0.183 | 0 | 0.243 | 0 |

| DMU25 | An Ping Industrial Park | 0.118 | 0 | 0.172 | 0 |

| DMU26 | Guantian Industrial Park | 0.343 | 0 | 0.482 | 0 |

| DMU27 | Linyuan Industrial Park | 1.000 | 10 | 1.000 | 16 |

| DMU28 | Pingnan Industrial Park | 0.422 | 0 | 0.501 | 0 |

| DMU29 | Sinying Industrial Park | 0.245 | 0 | 0.323 | 0 |

| DMU30 | Jiatai Industrial Park | 0.810 | 0 | 0.964 | 0 |

| DMU31 | Kahsiung Linhai Industrial Park | 0.513 | 0 | 0.722 | 0 |

| Mean | 0.436 | 0.540 | |||

| DMU | Name of Industrial Park | TE | PTE | SE |

|---|---|---|---|---|

| DMU1 | Tucheng Industrial Park | 0.249 | 0.270 | 0.924 |

| DMU2 | Dawulun Industrial Park | 0.274 | 1.000 | 0.274 |

| DMU3 | Dayuan Industrial Park | 0.311 | 0.312 | 0.997 |

| DMU4 | Jhongli Industrial Park | 0.305 | 0.640 | 0.476 |

| DMU5 | Pinjhen Industrial Park | 0.234 | 0.239 | 0.980 |

| DMU6 | Letzer Industrial Park | 0.670 | 0.694 | 0.966 |

| DMU7 | Hsinchu Industrial Park | 1.000 | 1.000 | 1.000 |

| DMU8 | Loung Te Industrial Park | 1.000 | 1.000 | 1.000 |

| DMU9 | Guishan Industrial Park | 1.000 | 1.000 | 1.000 |

| DMU10 | Guanyin Industrial Park | 0.233 | 0.419 | 0.557 |

| DMU11 | Dajia Youth Industrial Park | 0.157 | 0.159 | 0.989 |

| DMU12 | Douliu Industrial Park | 0.131 | 0.133 | 0.991 |

| DMU13 | Taichung Industrial Park | 0.414 | 1.000 | 0.414 |

| DMU14 | Chuansing Industrial Park | 0.328 | 0.376 | 0.872 |

| DMU15 | Fangyuan Industrial Park | 0.201 | 0.218 | 0.921 |

| DMU16 | Nangang Industrial Park | 0.557 | 0.585 | 0.952 |

| DMU17 | Yunlin Technology-based Industrial Park | 0.143 | 0.204 | 0.701 |

| DMU18 | Dashe Industrial Park | 0.488 | 1.000 | 0.488 |

| DMU19 | Dafa Industrial Park | 0.376 | 0.432 | 0.871 |

| DMU20 | Neipu Industrial Park | 0.574 | 1.000 | 0.574 |

| DMU21 | Tainan Technology Industrial Park | 0.609 | 0.813 | 0.749 |

| DMU22 | Minsyong Industrial Park | 0.138 | 0.152 | 0.911 |

| DMU23 | Yongan Industrial Park | 0.477 | 0.578 | 0.825 |

| DMU24 | Yongkang Industrial Park | 0.183 | 0.207 | 0.885 |

| DMU25 | An Ping Industrial Park | 0.118 | 0.125 | 0.941 |

| DMU26 | Guantian Industrial Park | 0.343 | 0.364 | 0.942 |

| DMU27 | Linyuan Industrial Park | 1.000 | 1.000 | 1.000 |

| DMU28 | Pingnan Industrial Park | 0.422 | 0.492 | 0.858 |

| DMU29 | Sinying Industrial Park | 0.245 | 0.296 | 0.827 |

| DMU30 | Jiatai Industrial Park | 0.810 | 1.000 | 0.810 |

| DMU31 | Kahsiung Linhai Industrial Park | 0.513 | 1.000 | 0.513 |

| Mean | 0.436 | 0.571 | 0.813 |

| Classification | DMU |

|---|---|

| Robustly Efficient Units TE = 1 and peer reference > 3 times | DMU7, DMU8, DMU27 |

| Marginal Efficient Units TE = 1 and peer reference < 3 times | DMU9 |

| Marginal Inefficient Units 0.8 < TE < 1 | DMU30 |

| Distinctly Inefficient Units TE < 0.8 | DMU1, DMU2, DMU3, DMU4, DMU5, DMU6, DMU10, DMU11, DMU12, DMU13, DMU14, DMU15, DMU16, DMU17, DMU18, DMU19, DMU20, DMU21, DMU22, DMU23, DMU24, DMU25, DMU26, DMU27, DMU28, DMU29, DMU31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiu, C.-Y.; Tang, W. Measuring the Operational Efficiency and the Water Resources Management Efficiency for Industrial Parks: Empirical Study of Industrial Parks in Taiwan. Sustainability 2022, 14, 14198. https://doi.org/10.3390/su142114198

Chiu C-Y, Tang W. Measuring the Operational Efficiency and the Water Resources Management Efficiency for Industrial Parks: Empirical Study of Industrial Parks in Taiwan. Sustainability. 2022; 14(21):14198. https://doi.org/10.3390/su142114198

Chicago/Turabian StyleChiu, Chui-Yu, and William Tang. 2022. "Measuring the Operational Efficiency and the Water Resources Management Efficiency for Industrial Parks: Empirical Study of Industrial Parks in Taiwan" Sustainability 14, no. 21: 14198. https://doi.org/10.3390/su142114198

APA StyleChiu, C.-Y., & Tang, W. (2022). Measuring the Operational Efficiency and the Water Resources Management Efficiency for Industrial Parks: Empirical Study of Industrial Parks in Taiwan. Sustainability, 14(21), 14198. https://doi.org/10.3390/su142114198