Decision-Making Framework for Sustainable Construction Products Selection in SMEs

Abstract

:1. Introduction

2. Sustainable Products and Decision Methods

3. Framework Development

3.1. Decision Criteria—Economic Value, Obsolescence and Risk

3.1.1. Economic Value

3.1.2. Obsolescence

3.1.3. Risk

3.2. Factors Addressing Decision Criteria

3.2.1. Lifecycle Cost (LCC)

- C0 is the Initial capital cost;

- PV is the Present value;

- C1 is the Lifetime operating cost;

- C2 is the Lifetime maintenance cost;

- C3 is the Capital rehabilitation cost;

- C4 is the Disposal cost;

- C5 is the residual value.

3.2.2. Technology Growth Rate (TGR)

- Y is the performance of the significant feature of the product considered;

- c is the Initial performance value of the feature;

- e is the Exponential coefficient;

- b is the Technology growth rate;

- x is Time.

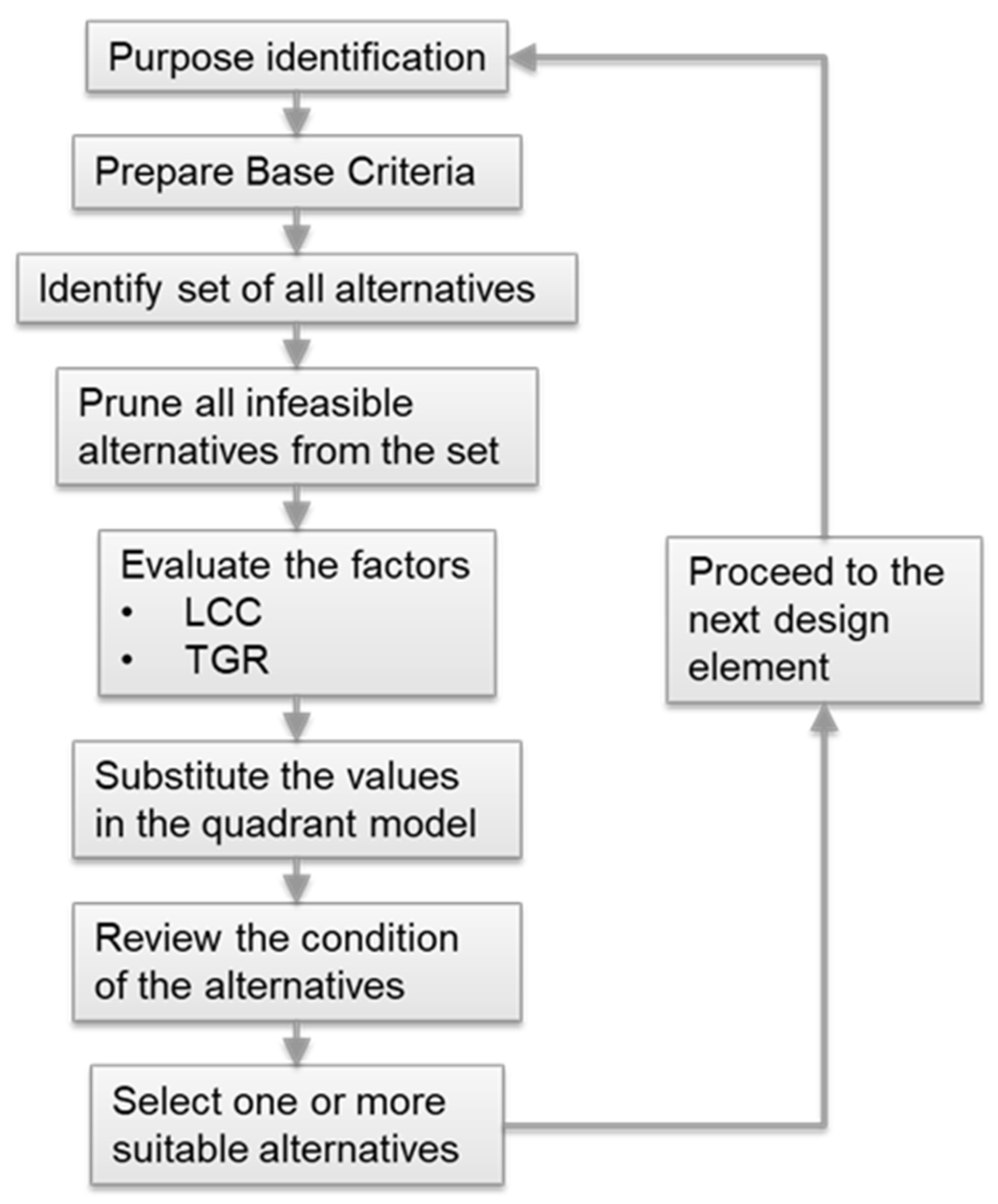

3.3. Framework Workflow

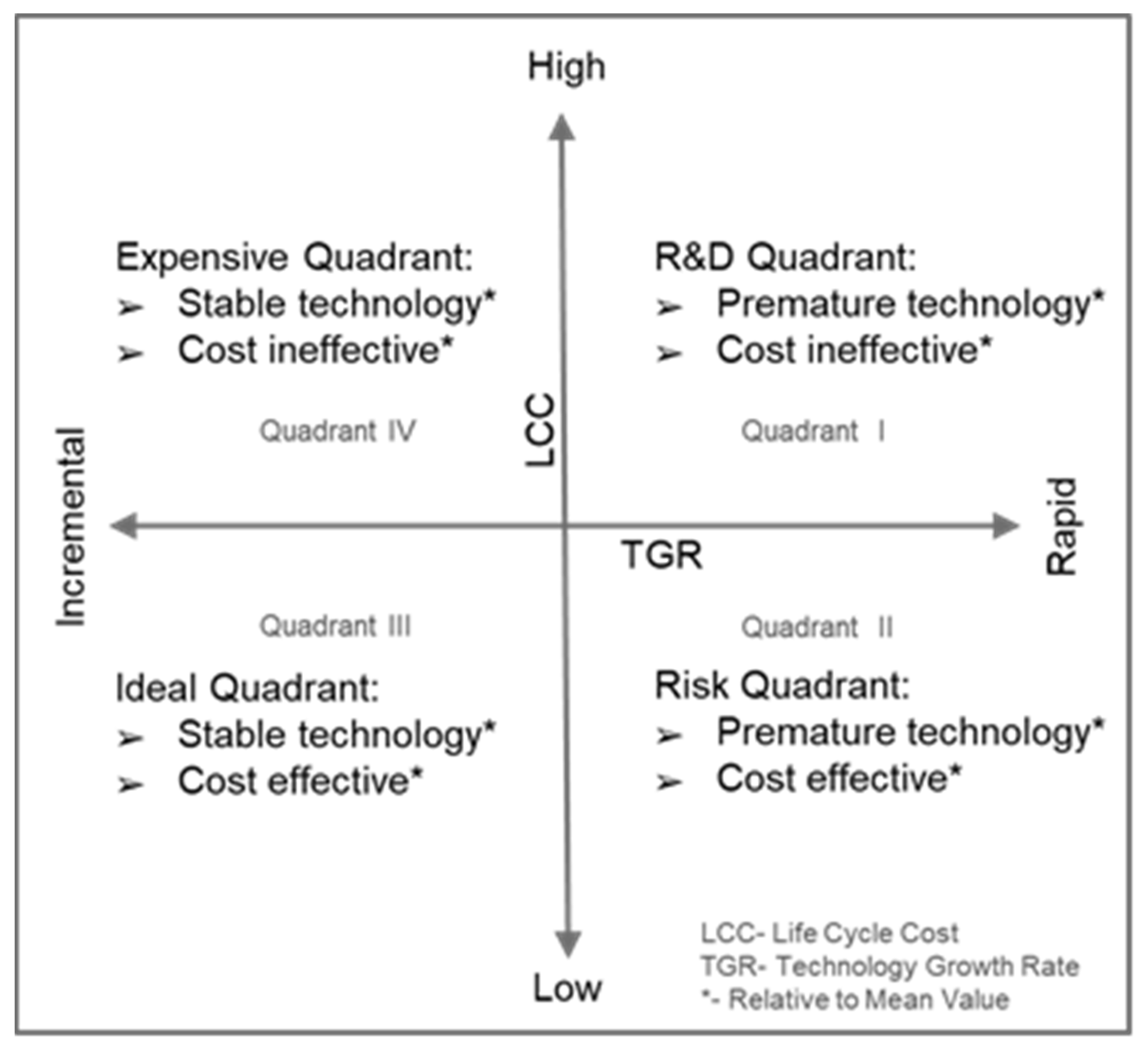

3.4. Decision-Making Model

4. Application

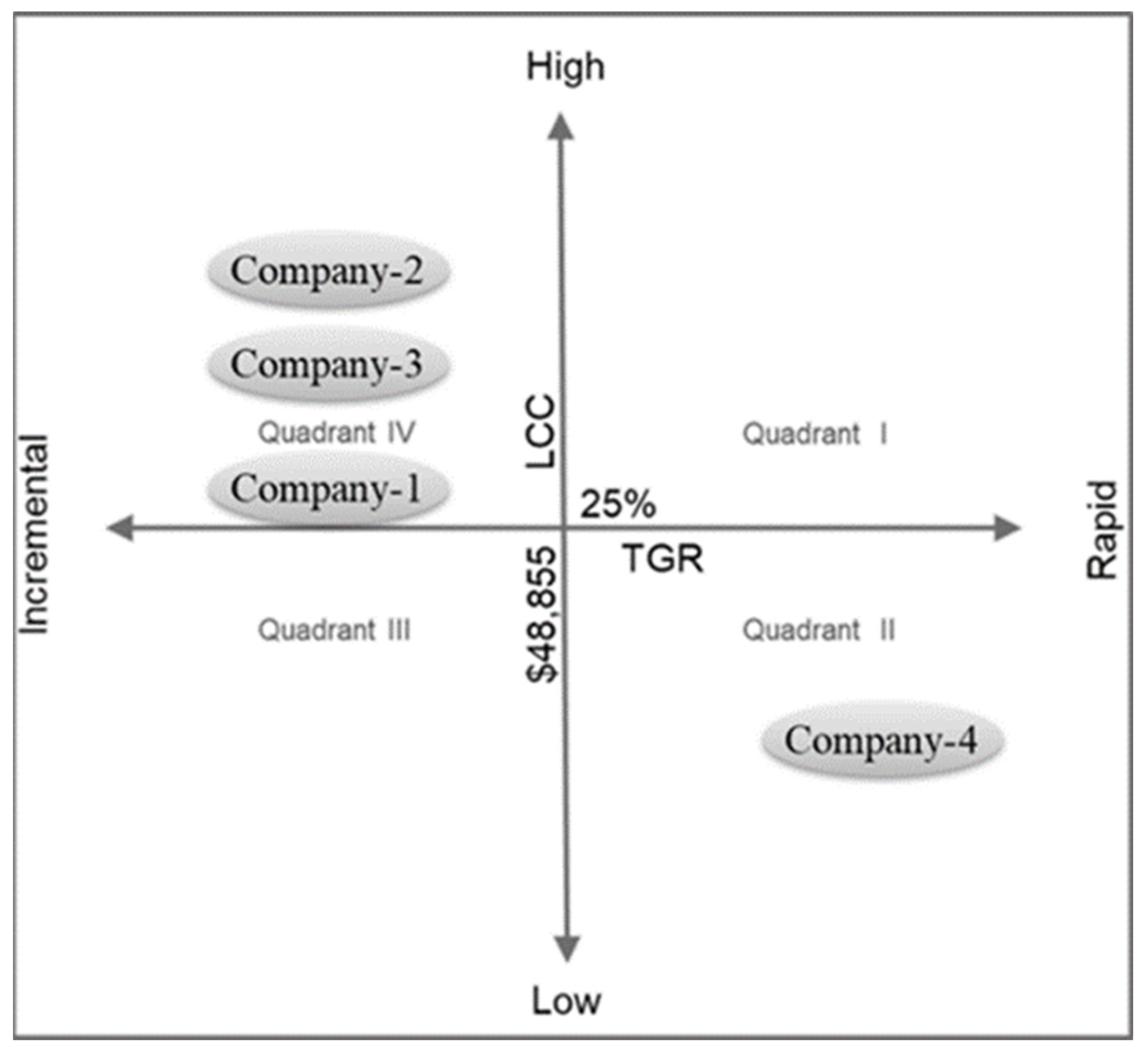

4.1. Case Study 1

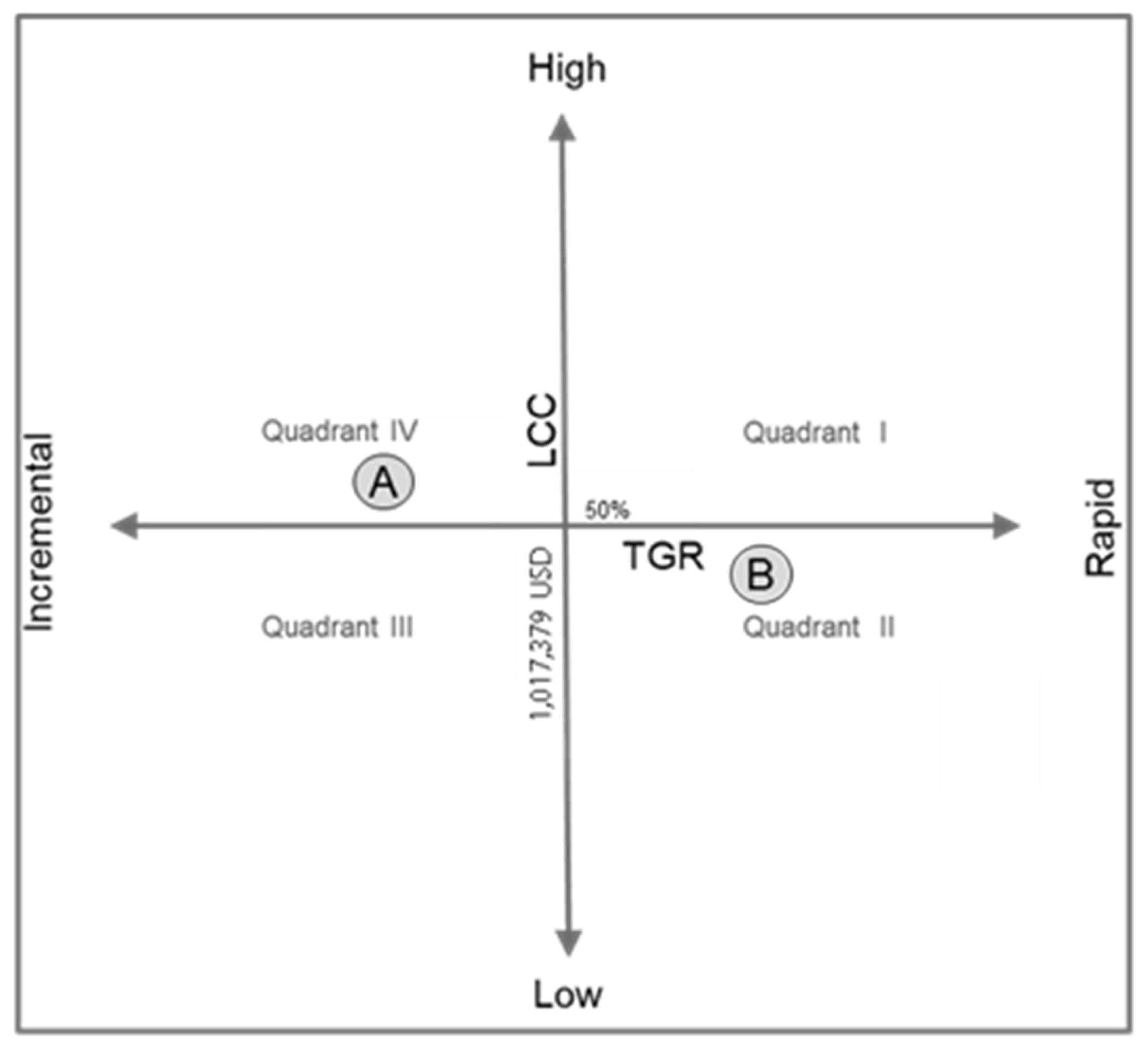

4.2. Case Study 2

5. Discussions

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hawken, P.; Lovins, A.B.; Lovins, L.H.; Lovins, A.B.; Lovins, L.H. Natural Capitalism: The Next Industrial Revolution; Routledge: London, UK, 2013; ISBN 978-1-134-03306-5. [Google Scholar]

- Hamner, B. Effects of Green Purchasing Strategies on Supplier Behaviour. In Greening the Supply Chain; Sarkis, J., Ed.; Springer: London, UK, 2006; pp. 25–37. ISBN 978-1-84628-299-7. [Google Scholar]

- Spiegel, R.; Meadows, D. Green Building Materials: A Guide to Product Selection and Specification; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-470-88055-5. [Google Scholar]

- Borregaard, N. Challenging Preconceptions about Trade in Sustainable Products: Towards Win-Win for Developing Countries; IIED: London, UK, 2005; ISBN 978-1-84369-581-3. [Google Scholar]

- Akadiri, P.O.; Olomolaiye, P.O. Development of sustainable assessment criteria for building materials selection. Eng. Constr. Archit. Manag. 2012, 19, 666–687. [Google Scholar] [CrossRef]

- Kibert, C.J. Sustainable Construction: Green Building Design and Delivery; John Wiley & Sons: Hoboken, NJ, USA, 2016; ISBN 978-1-119-05517-4. [Google Scholar]

- Akadiri, P.O. Understanding barriers affecting the selection of sustainable materials in building projects. J. Build. Eng. 2015, 4, 86–93. [Google Scholar] [CrossRef]

- Ecolabel Index. Available online: http://www.ecolabelindex.com/ (accessed on 29 October 2018).

- Eurobarometer, F. Europeans’ Attitudes towards the Issue of Sustainable Consumption and Production; Directorate-General for Communication: Brussel, Belgium, July 2009; Volume 256, pp. 1–8. [Google Scholar]

- Kang, M.Y.; Guerin, D.A. The state of environmentally sustainable interior design practice. Am. J. Environ. Sci. 2009, 5, 179–186. [Google Scholar] [CrossRef]

- Lerma, B.; Giorgi, C.D.; Allione, C. Design and Materials. Sensory Perception Sustainability Project: Sensory Perception Sustainability Project; FrancoAngeli: Milan, Italy, 2013; ISBN 978-88-204-6239-0. [Google Scholar]

- Rao, P.B.; Pavan, B. Role of Contractors in Green Industrial Projects—An overview of difficulties challenged in green documentation. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 69–74. [Google Scholar]

- Williams, K.; Dair, C. What is stopping sustainable building in England? Barriers experienced by stakeholders in delivering sustainable developments. Sustain. Dev. 2007, 15, 135–147. [Google Scholar] [CrossRef]

- Dangana, Z.; Pan, W.; Goodhew, S. Delivering Sustainable Buildings in Retail Construction; Association of Researchers in Construction Management (ARCOM): Edinburgh, UK, 2012; ISBN 978-0-9552390-6-9. [Google Scholar]

- Beliz, O.; Kutluhan, O.; Sevilay, D. Investigating the Components of Innovation in Construction Projects. J. Manag. Eng. 2016, 32, 04015052. [Google Scholar] [CrossRef]

- Moore, S.B.; Manring, S.L. Strategy development in small and medium sized enterprises for sustainability and increased value creation. J. Clean. Prod. 2009, 17, 276–282. [Google Scholar] [CrossRef]

- NSDC. Human Resources and Skill Requirements in the Building Construction and Real Estate Sector; National Skill Development Corporation: New Delhi, India, 2017. [Google Scholar]

- Green Building and Climate Change|U.S. Green Building Council. Available online: https://www.usgbc.org/articles/green-building-and-climate-change (accessed on 29 October 2018).

- Nimse, P.; Vijayan, A.; Kumar, A.; Varadarajan, C. A review of green product databases. Environ. Prog. 2007, 26, 131–137. [Google Scholar] [CrossRef]

- Arroyo, P.; Tommelein, I.D.; Ballard, G. Deciding a Sustainable Alternative by ‘Choosing by Advantages’ in The Aec Industry. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Parrish, K.; Tommelein, I. Making design decisions using choosing by advantages. In Proceedings of the IGLC17: 17th Annual Conference of the International Group for Lean Construction, Taipei, Taiwan, 15–17 July 2009; pp. 501–510. [Google Scholar]

- Grant, E.J.; Jones, J.R. A Decision-making Framework for Vegetated Roofing System Selection. J. Green Build. 2008, 3, 138–153. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, H.V.; Lostuvali, B.; Tommelein, I.D. Decision analysis using virtual first-run study of a viscous damping wall system. In Proceedings of the 17th Annual Conference of the International Group for Lean Construction (IGLC 17), Taipei, Taiwan, 15–17 July 2009. [Google Scholar]

- Akadiri, P.O.; Olomolaiye, P.O.; Chinyio, E.A. Multi-criteria evaluation model for the selection of sustainable materials for building projects. Autom. Constr. 2013, 30, 113–125. [Google Scholar] [CrossRef]

- Lounis, Z.; McAllister, T.P. Risk-Based Decision Making for Sustainable and Resilient Infrastructure Systems. J. Struct. Eng. 2016, 142, F4016005. [Google Scholar] [CrossRef]

- Rosinski, P.; Brady, L.; Cotgrave, A.; Al-Shamma’a, A. Decision Making Aid for Selection of Renewable/Sustainable Energy Systems for Buildings. In Proceedings of the International Conference on Sustainable Design and Construction (ICSDC), Kansas City, MI, USA, 23–25 March 2011. [Google Scholar] [CrossRef] [Green Version]

- Hossaini, N.; Hewage, K. Sustainable Materials Selection for Canadian Construction Industry: An Emergy-Based Life-Cycle Analysis (Em-LCA) of Conventional and LEED Suggested Construction Materials. J. Sustain. Dev. 2011, 5, 2. [Google Scholar] [CrossRef]

- Govindan, K.; Madan Shankar, K.; Kannan, D. Sustainable material selection for construction industry—A hybrid multi criteria decision making approach. Renew. Sustain. Energy Rev. 2016, 55, 1274–1288. [Google Scholar] [CrossRef]

- Lippiatt Barbara, C. Selecting Cost-Effective Green Building Products: BEES Approach. J. Constr. Eng. Manag. 1999, 125, 448–455. [Google Scholar] [CrossRef]

- Srinivas, K.; Amaresh, C. Development of a Method for Estimating Uncertainty in Evaluation of environmental Impacts during Design. In Proceedings of the ICED 2007, the 16th International Conference on Engineering Design, Paris, France, 28–31 July 2007. [Google Scholar]

- AlWaer, K. Building sustainability assessment methods. Proc. Inst. Civ. Eng. Eng. Sustain. 2012, 165, 241–253. [Google Scholar] [CrossRef] [Green Version]

- Bond, S. Barriers and drivers to green buildings in Australia and New Zealand. J. Prop. Investig. Financ. 2011, 29, 494–509. [Google Scholar] [CrossRef]

- Ikediashi, D.I.; Ogunlana, S.O.; Oladokun, M.G.; Adewuyi, T. Assessing the level of commitment and barriers to sustainable facilities management practice: A case of Nigeria. Int. J. Sustain. Built Environ. 2012, 1, 167–176. [Google Scholar] [CrossRef] [Green Version]

- Sustainability and Interior Design |Sustainable Design| Green Building. Available online: https://www.scribd.com/document/7687294/sustainability-and-interior-design (accessed on 29 October 2018).

- Samari, M.; Ghodrati, N.; Esmaeilifar, R.; Olfat, P.; Shafiei, M.W.M. The Investigation of the Barriers in Developing Green Building in Malaysia. Mod. Appl. Sci. 2013, 7, 1. [Google Scholar] [CrossRef] [Green Version]

- Rai, R.; Terpenny, J. Principles for Managing Technological Product Obsolescence. IEEE Trans. Compon. Packag. Technol. 2008, 31, 880–889. [Google Scholar] [CrossRef]

- Aikivuori, A. Periods and demand for private sector housing refurbishment. Constr. Manag. Econ. 1996, 14, 3–12. [Google Scholar] [CrossRef]

- Romero Rojo, F.J.; Roy, R.; Shehab, E. Obsolescence management for long-life contracts: State of the art and future trends. Int. J. Adv. Manuf. Technol. 2010, 49, 1235–1250. [Google Scholar] [CrossRef] [Green Version]

- Ofori, G. Developing the Construction Industry in Ghana: The case for a central agency. Concept Pap. Prep. Improv. Constr. Ind. Ghana Natl. Univ. Singap. 2012, 13, 3–18. [Google Scholar]

- Doloi, H. Understanding impacts of time and cost related construction risks on operational performance of PPP projects. Int. J. Strateg. Prop. Manag. 2012, 16, 316–337. [Google Scholar] [CrossRef]

- Doherty, J.M. A Survey of Computer Use in the New Zealand Building and Construction Industry. J. Inf. Technol. Constr. 1997, 2, 73–86. [Google Scholar]

- Vanegas, J.A.; DuBose, J.R.; Pearce, A.R. Sustainable Technologies for the Building Construction Industry; Georgia Institute of Technology: Atlanta, GA, USA, 1996. [Google Scholar]

- Tatum, C.B. Managing for Increased Design and Construction Innovation. J. Manag. Eng. 1989, 5, 385–399. [Google Scholar] [CrossRef]

- Makhlouf, A.S.H.; Aliofkhazraei, M. Handbook of Materials Failure Analysis with Case Studies from the Aerospace and Automotive Industries; Butterworth-Heinemann: Oxford, UK, 2015; ISBN 978-0-12-801177-5. [Google Scholar]

- Norman, G. Life cycle costing. Prop. Manag. 1990, 8, 344–356. [Google Scholar] [CrossRef]

- Kirk, S.J.; Dell’isola, A.J. Life Cycle Costing for Design Professionals, 2nd Revised Edition; McGraw-Hill Companies: New York, NY, USA, 1995; ISBN 978-0-07-034804-2. [Google Scholar]

- Woodward, D.G. Life cycle costing—Theory, information acquisition and application. Int. J. Proj. Manag. 1997, 15, 335–344. [Google Scholar] [CrossRef]

- Gluch, P.; Baumann, H. The life cycle costing (LCC) approach: A conceptual discussion of its usefulness for environmental decision-making. Build. Environ. 2004, 39, 571–580. [Google Scholar] [CrossRef] [Green Version]

- Soni, V.; Dash, A.P.; Singh, S.P.; Banwet, D.K. Life Cycle Costing Analysis of Energy Options: In Search of Better Decisions towards Sustainability in Indian Power & Energy Sector. Glob. J. Manag. Bus. Res. 2014, 14. [Google Scholar]

- Bartels, B.; Ermel, U.; Sandborn, P.; Pecht, M.G. Strategies to the Prediction, Mitigation and Management of Product Obsolescence; John Wiley & Sons: Hoboken, NJ, USA, 2012; ISBN 978-1-118-27546-7. [Google Scholar]

- Cooper, T. Longer Lasting Products: Alternatives to the Throwaway Society; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1-317-10354-7. [Google Scholar]

- Kali Charan, A.K.; Singh, R. Risk and Innovation—Case for Building a Methodology Tool to Assist Informed Decision Making for Managers; Social Science Research Network: Rochester, NY, USA, 2006. [Google Scholar]

- Josias, C.; Terpenny, J.P.; Mclean, K.J. Component obsolescence risk assessment. In Proceedings of the 2004 Industrial Engineering Research Conference (IERC), Houston, TX, USA, 16–19 May 2004; pp. 15–19. [Google Scholar]

- Pearce, A.R.; Hastak, M.; Vanegas, J.A. A decision support system for construction materials selection using sustainability as a criterion. In Proceedings of the NCSBCS Conference on Building Codes and Standards, Albuquerque, NM, USA, 1–2 November 1995; pp. 1–4. [Google Scholar]

- M-Brain Market & Media Intelligence Solutions, Knowledge Gap Hinders India Construction Industry’s Progress in Going Green. Available online: https://www.m-brain.com/insights/industries/construction-property-development/knowledge-gap-hinders-india-construction-industrys-progress-in-going-green/ (accessed on 1 September 2022).

- Schumann, D.W.; Thorson, E.E. Internet Advertising Theory and Research; Lawrence Erlbaum Associates Publishers: Mahwah, NJ, USA, 2007; ISBN 978-0-8058-5109-0. [Google Scholar]

- Griffin, C.; Knowles, C.; Theodoropoulos, C.; Allen, J.H. Barriers to the implementation of sustainable structural materials in green buildings. In Proceedings of the Structures and Architecture, 1st International Conference on Structures and Architecture ICSA, Guimaraes, Portugal, 21–23 July 2010; pp. 1349–1357. [Google Scholar] [CrossRef]

- Gillengerten, J.D. Design of Nonstructural Systems and Components. In The Seismic Design Handbook; Naeim, F., Ed.; Springer: Boston, MA, USA, 2001; pp. 681–721. ISBN 978-1-4615-1693-4. [Google Scholar]

| Author | Decision for | Method Used | Evaluation Criteria/ Factors | Scope | Observations |

|---|---|---|---|---|---|

| Arroyo et al. [20]; Parrish et al. [21]; Grant [22]; Nguyen et al. [23] | Sustainable Alternatives | Choosing by Advantage (CBA) | Product /component/system specific | Comprehensive/undefined | Data intensive |

| Dangana et al. [14] | Sustainable technology for retail buildings | Multi-Criteria Decision Analysis (MCDA) | Value Tree Developed | Limited/well defined | Simplified and transparent |

| Akadiri et al. [24] | Sustainable materials for building projects | Fuzzy extended AHP (FEAHP) | Sustainable Triple bottom line based (TBL) | Comprehensive/well defined | Knowledge intensive |

| Lounis et al. [25] | Sustainable and resilient infrastructures | Risk-Informed Decision Making | Product /component/system specific | Comprehensive/undefined | Knowledge and data intensive |

| Piotr et al. [26] | Renewable/ Sustainable Energy Systems | Borland Delphi | Product /component/system specific | Limited/well defined | Data intensive |

| Hossaini et al. [27] | Sustainable Materials | Energy-Based Life Cycle Analysis (Em-LCA) | Product /component/system specific | Comprehensive/undefined | Knowledge and data intensive |

| Govindan et al. [28] | Sustainable Materials | DNAP 1 and TOPSIS 2 | Product /component/system specific | Comprehensive/undefined | Knowledge and data intensive |

| Lippiatt [29] | Green building products | LCA 3 and LCC | Product /component/system specific | Comprehensive/well defined | Knowledge and data intensive |

| Project Characteristics | Description |

|---|---|

| Location | San Diego, California, USA |

| Project Type | Single-Family House |

| Area | 245 square meters (US Average as of 2016) 1 |

| Stakeholders | Owner, Architect, LEED Professional and General Contractor |

| Product | Roof Tiles/Shingles |

| 2 Roof Area | 319 square meter (average for 39.81° roof slope) |

| Available solar energy | 1900 kW/kW-yr. (California-Average) |

| Climate | Mild and sunny weather throughout the year |

| Purpose | Sustainable Weather Protection (Particularly Heat Insulation) |

|---|---|

| Base Criteria |

|

| Total no. of products considered | 21 |

| Shortlisted based on Base criteria | 7 |

| Shortlisted due to historical information shortage | 4 |

| Alternatives | Company 1 | Company 2 | Company 3 | Company 4 |

|---|---|---|---|---|

| Product Name | Slate | Single width Slate | Roof Slate | Solar Roof |

| C0 | USD 27,440 | USD 30,870 | USD 38,141.6 | USD 69,594 |

| C1 | - | - | - | −USD 98,900 * |

| C2 | USD 16,464 | USD 18,522 | USD 22,884 | USD 41,756.4 |

| C3 | - | - | - | - |

| C4 | USD 13,720 | USD 13,720 | USD 13,720 | USD 13,720 |

| C5 | −USD 10,976 | - | USD 15,256 | - |

| LCC | USD 46,648 | USD 63,112 | USD 59,489.6 | USD 26,170.4 |

| Alternatives | Company 1 | Company 2 | Company 3 | Company 4 |

|---|---|---|---|---|

| Product Name | Slate | Single width Slate | Roof Slate | Solar Roof |

| Product’s date of introduction | 2013 | 1997 | 1988 | 2017 |

| Criteria | Recycled materials used | Fire Rating | Recycled materials used | Recycled materials used |

| Current functionality value of criteria | 25% | Class A | 100% | Undisclosed |

| TGR | 0% | 0% | 0% | 100% |

| Characteristics of Alternative B over Alternative A | Values |

|---|---|

| Annual power savings | 475,698 kWh/year |

| Estimated amount of annual power savings | 50,900 USD/year |

| Recovery period for return on investment | 3.59 year |

| Reduction rate compared to power usage as of 2016 | 1.45% |

| Estimated annual reduction rate of greenhouse gas emissions by power reduction | 54.25% |

| Specs\Alternatives | Alternative A | Alternative B |

|---|---|---|

| Product Name | fluorescent lighting | LED lighting |

| C0 | 38,615 USD | 182,937 USD |

| C1 | 884,566 USD | 629,860 USD |

| C2 | - | - |

| C3 | 115,844 USD | 182,931 USD |

| C4 | - | - |

| C5 | - | - |

| LCC | 1,039,025 USD | 995,733 USD |

| Specs\Alternatives | Alternative A | Alternative B |

|---|---|---|

| Product Name | fluorescent lighting | LED lighting |

| Product’s Date of introduction | 2007 | 2017 |

| Criteria | Light intensity/unit power | New smart dimming energy saving |

| Current functionality value of Criteria | 65.45 Lm/W | - |

| TGR | 0 | 100% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sivasubramanian, D.; Lee, J.G. Decision-Making Framework for Sustainable Construction Products Selection in SMEs. Sustainability 2022, 14, 14264. https://doi.org/10.3390/su142114264

Sivasubramanian D, Lee JG. Decision-Making Framework for Sustainable Construction Products Selection in SMEs. Sustainability. 2022; 14(21):14264. https://doi.org/10.3390/su142114264

Chicago/Turabian StyleSivasubramanian, Dharmaraj, and Jin Gang Lee. 2022. "Decision-Making Framework for Sustainable Construction Products Selection in SMEs" Sustainability 14, no. 21: 14264. https://doi.org/10.3390/su142114264