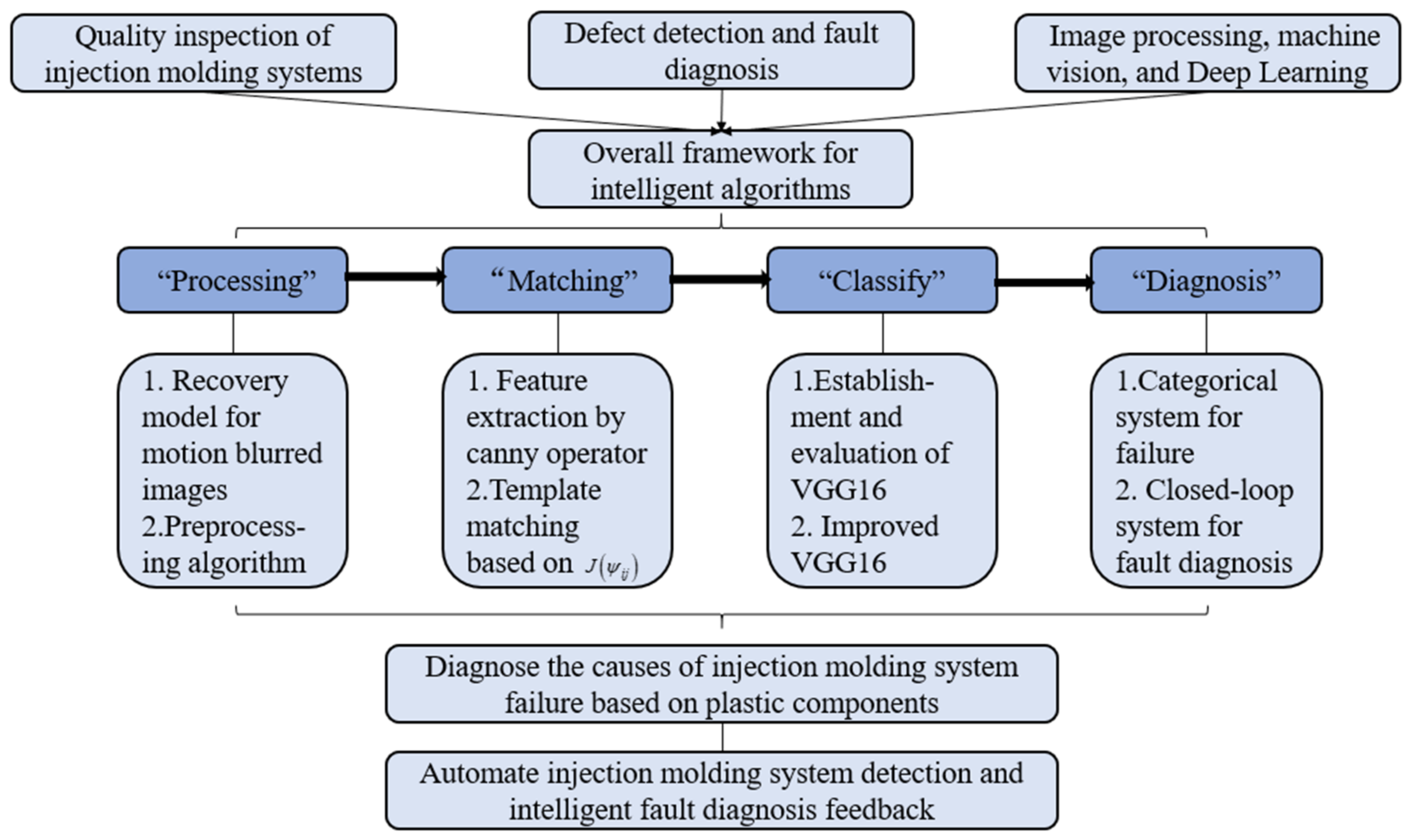

A Novel Method of Fault Diagnosis for Injection Molding Systems Based on Improved VGG16 and Machine Vision

Abstract

:1. Introduction

- (1)

- Reduce labor requirements at industrial production sites while enhancing production security.

- (2)

- Advance fully automated injection molding production.

- (3)

- Advance the automation and intelligence of fault diagnosis systems for injection molds and injection molding machines.

2. Pre-Processing Algorithms for Data Sets

2.1. Classification Theory and Setting of Image Dataset Labels

2.1.1. Dimensional Instability of the Plastic Components

- (1)

- Injection molding machine:

- (2)

- Injection mold:

- The mold lacks sufficient rigidity and strength, and the core and cavity materials have poor wear resistance.

- The “one mold with multiple cavities” mold gating system is unreasonable.

- Dimensional instability of the plastic components are caused by an uneven mold cooling system configuration and a sizable temperature differential around the mold.

2.1.2. Short Shot of the Plastic Components (Insufficient)

- (1)

- Injection molding machine:

- The injection molding machine’s plasticizing capacity is limited.

- The thermometer exhibits a fault, causing the actual temperature to be lower than the necessary working temperature.

- The nozzle’s inner hole’s diameter was improperly chosen.

- Too little time passes between injections.

- (2)

- Injection mold:

- The pouring system of the mold is designed absurdly.

- The mold structure is designed absurdly.

2.1.3. Buckling Deformation of the Plastic Components

- (1)

- Injection mold:

- Plastic components’ structural designs are illogical.

- Unbalanced temperature in the mold.

- The design of the pouring system is not suitable for this kind of component.

- The ejector system’s design is illogical.

- The exhaust system’s layout is unreasonable.

- The mold’s material strength is insufficient.

2.1.4. Flash of the Plastic Components

- (1)

- Injection molding machine:

- The injection molding machine’s clamping force is insufficient.

- The clamping mechanism needs to be better adjusted.

- Flash may be caused by severe check ring wear, spring failure in the spring nozzle, excessive barrel or screw wear, loss of heating system control, including the small buffer pad, etc.

- (2)

- Injection mold:

- The mold parting surface’s manufacturing accuracy is subpar.

- The mold’s design is absurd:

- 1.

- Local flash and insufficient local filling are caused by an unbalanced distribution of mold cavities or by poor parallelism.

- 2.

- The flash will be produced when the movable parts and sliding cores in the mold are out of balance.

- 3.

- Neglected mold exhaust.

- 4.

- When plastic components have uneven wall thickness.

- 5.

- It is customary to open a side gate on the inside of a large molding hole that is in or near the center of the product. It is simple to cause minor warping deformation and flash under high injection pressure if the clamping force and supporting force of this part of the mold are insufficient.

- 6.

- If the side of the mold has a movable member, the projected area of the side is also affected by the molding pressure, and flash will result if the supporting force is insufficient.

- 7.

- Flash can also be caused by the movable core’s poor matching accuracy or by an offset between the fixed core’s installation position and the cavity.

- 8.

- For multi-cavity molds, consideration should be given to the reasonable design of each runner and gate, as failure to do so will result in flash and uneven filling of the mold.

2.1.5. Shrinkage Depression of the Plastic Components

- (1)

- Injection molding machine:

- The size of the nozzle hole is inappropriate.

- Not enough clamping force.

- (2)

- Injection mold:

- The mold should have a uniform wall thickness at the design level and should not be too thick to ensure the isotropy of the shrinkage process in order to prevent shrinkage depression. If a thicker wall is necessary, think about creating a hollow structure; arcs in place of sharp corners at the shunt channel can significantly lessen the amount of denting that occurs there.

- The mold’s cooling and heating system should guarantee that the cavity is essentially the same temperature.

- The main channel, runner, and gate sizes should be appropriate, and the roughness should be reasonable in order to ensure that the melt is not obstructed and that the resistance is not excessive.

- The mold temperature should be appropriately lowered for thick-walled plastic components and raised for thin-walled plastic components.

- The gate should open as symmetrically as possible and, to the greatest extent possible, at the thick-walled part of the plastic part. Additionally, the cold well’s volume needs to be increased.

2.1.6. Crack of the Plastic Components

- (1)

- Injection molding machine:

- The injection molding machine’s plasticizing capacity needs to be appropriate. If it is too big, it will deteriorate. It will not become sufficiently plasticized if it is too small, and it will crack if it is not thoroughly mixed because it will become brittle.

- Pay attention to some engineering techniques, such as lowering the injection pressure, slowing down the last stage’s injection, slowing down the ejection speed, prolonging the cooling period, etc.

- (2)

- Injection mold:

- The ejection should be balanced in mold. In particular, the quantity of push rods, cross-sectional area, demolding slope, and cavity surface all need to be adequate to effectively prevent the concentration of residual stress in the ejection, which will result in the cracking of the plastic components.

- The transition part should utilize a circular arc structure as much as feasible to reduce stress concentration. The plastic components’ structure shouldn’t be too thin. Use metal inserts sparingly to reduce the internal stress caused by the disparity in shrinkage rates between inserts and plastic components.

- Deep cavity plastic components should have appropriate demolding air inlets set to prevent the development of vacuum negative pressure, which would ultimately affect demolding.

- The sprue needs to be big enough to allow demolding of the pouring system’s condensate before it solidifies.

- The nozzle and main runner in the sprue sleeve should be in line.

2.1.7. Craze of the Plastic Components

- (1)

- Injection molding machine:

- The condition of the barrel, screw, and existence of a dead angle in the material flow through the rubber ring and head.

- The heating system is out of control, which results in an excessively high temperature and deterioration.

- To reduce the residence time as necessary.

- (2)

- Injection mold:

- Poor exhaust.

- The runner, gate, and cavity in the mold have high friction resistance, which leads to regional overheating and plastic degradation.

- An unreasonable cooling system, an unbalanced distribution of cavities and gates, and local overheating are all potential causes of airflow obstruction.

- The cavity is breached by a leak in the cooling water channel.

2.1.8. Blackspots Coking of the Plastic Components

- (1)

- Injection molding machine:

- The barrel of the machine becomes overheated as a result of the heating control system losing control, degrading the related materials and turning them black.

- The melt is stuck because of a screw or barrel defect, and it will degrade if it is heated for an extended period of time.

- High heat in the barrel causes some plastics, such as ABS, to become cross-linked and coked. It is difficult to melt under conditions in which the original particle shape is almost maintained and, after being crushed by the screw, it is entrained into the plastic part.

- (2)

- Injection mold:

- The mold should have more venting slots opened because it may be poorly vented and the trapped air easily combustible.

- The mold contains unsuitable oil lubricants and mold release agents.

2.1.9. Acquisition and Image Database Calibration

2.2. Image Restoration Technology for Fuzzy Images

2.2.1. Image Degradation Model

2.2.2. Blind Deconvolution Filtering Algorithm

2.2.3. Fuzzy Image Recovery Tests (Constrained and Unconstrained Methods)

2.3. Preprocessing of Plastic Components Images

2.3.1. Gamma Transform

2.3.2. Image Smoothing

2.4. Feature Extraction of Image Datasets Based on Canny Algorithm

- (1)

- The signal-to-noise ratio standard

- (2)

- Positioning Accuracy Guidelines

- (3)

- Single edge unique response criterion

3. Template Matching Mechanism Based on Arbitration Function

3.1. Matching Algorithm Based on Hu Invariant Moments

3.1.1. Numerical Calculation of Hu Moments

3.1.2. Contour Matching Algorithm Based on Hu Moments

3.2. Plastic Template Matching Mechanism Based on Arbitration Function

4. Fault Classification Based on Improved VGG16

4.1. VGG16 Convolutional Neural Network Overview

4.2. Fault Diagnosis Classification Test Based on Traditional VGG16

4.2.1. Data Set Preprocessing and VGG16 Network Parameters

4.2.2. Analysis of Test Results

- (1)

- The VGG16 convolutional neural network’s classification accuracy was insufficient. Before and after the 37th training, the accuracy on the test set increased from 13.33 percent to 43.33 percent, and, as a result of the overfitting issue, the fitting function of the accuracy oscillated with a significant amplitude for the last 10 pieces of training. The second training’s oscillation phenomenon was the worst, and it restricted the model’s ability to improve both its classification accuracy and the accuracy of its numerical values. The classification accuracy of VGG16 on this dataset is not high because, in the case of overfitting, the peak classification accuracy only reached 53.33 percent.

- (2)

- The early fitting effect of the loss function was quite impressive when compared with the results of the prediction accuracy. However, before and following the 14th training, a minor overfitting issue started to emerge. The number of training rounds was increased, which caused this phenomenon to worsen and ultimately prevented the loss function from converging. The model’s loss function value on the test set in the 12th training was 0.3667. Following that, oscillations with growing amplitude started to appear. Large outliers in the loss function value can be attributed to unreasonably high hyperparameter settings, such as the optimizer or network model’s learning rate, in the early stages of training.

- (3)

- The accuracy of the classification is positively correlated with the numerical value of the multi-class confusion matrix, which represents the classification result in Figure 13. However, it is possible to predict silver streaks, shrinkage depressions, flash edges, and surface black spots as qualified plastic components. Experiments show that the network has a better recognition effect on plastic components with unstable size, warpage deformation, poor filling, and qualified plastic components.

4.3. Improvements to the Traditional VGG16 Topology

4.3.1. Improvements I: Changing the Number of Layers and Convolutional Kernels

4.3.2. Improvements II: Introduction of Weight Regularization

4.3.3. Improvements III: Dropout Methods

4.4. Debugging of Hyperparameters

4.4.1. Changing the Optimizer

4.4.2. Changing the Activation Function

5. Results

5.1. Fault Diagnosis Classification Test Based on VGG16 after Structural Optimization

5.2. Fault Diagnosis Classification Test after Changing the Optimizer

5.3. Fault Diagnosis Classification Test Based on Improved VGG16 (Final Model)

6. Discussion and Conclusions

6.1. Discussion

- (1)

- Strengthen innovative research on image processing algorithms. Further research should focus on more efficient and comprehensive fuzzy image recovery algorithms and feature extraction algorithms with stronger resistance to noise interference. To increase matching accuracy and the classification efficiency of convolutional neural networks, it is crucial to build robust features that are more suited to matching.

- (2)

- Introducing a fresh method of template matching that considers multiple variables. After satisfying the dimensional invariance of imagerotation, translation, and scaling in this paper’s template matching method, which is still based on conventional machine vision, it does not account for environmental factors that may be present while taking photos for actual production. Further work should introduce a new approach to template matching that considers multiple variables, where the arbitration function should be a multivariate function.

- (3)

- Additional VGG16 network optimization about residual connections. Deep learning’s classification effectiveness can be somewhat increased through network topology optimization and hyperparameter tuning, but recent research has shown that residual connection structure can further resolve the gradient disappearance problem, leading to an essential improvement in the classification effectiveness of the model. This paper used deep learning algorithms to classify the defective images of plastic components. Residual connectivity will be the further prospect of the classification algorithm in this work.

- (4)

- The convergence trend and value of loss function should be further optimized. The convergence of the loss function of the model in this study is insufficient to pursue the generalizability of the model, and the convergence value of the loss function of the final accepted network structure is 1.1627. Further study can pay attention to ways to maintain classification accuracy while progressively reducing convergence value of the loss function.

6.2. Conclusions

- (1)

- This paper summarized a theoretical system for processing fault classification for plastic part failure to address the issue of processing an image dataset of injection-molded plastic components. This system emphasized the theoretical connection between the eight primary types of plastic part defects and the types of injection molding system failure. The dataset was sorted into nine categories using this theoretical framework (eight defective categories and one qualified category). The image dataset processing provides a realistic foundation for subsequent matching and detection operations. To fully recover fuzzy images, this paper firstly established an image degradation model in this study using a blind deconvolution approach. The gamma transform method was used to process the dataset in greyscale, the random noise of the dataset was removed by using a median filtering algorithm, and the geometric contour data were retrieved by the Canny algorithm for the subsequent matching procedure.

- (2)

- A matching mechanism between the images to be tested and the standard template was proposed for the detection of flaws in plastic components. The template matching method for plastic components was established by providing an arbitration function with the aid of the dimensional invariance of Hu moments such as rotation, translation, and scaling. This matching mechanism was inspired by conventional machine vision. It is possible to identify and initially classify problematic images of plastic components in the dataset using scientific methods. The plastic components were divided into two groups after being checked by this mechanism: qualifying and faulty.

- (3)

- To address the issue of fault diagnosis in plastic components, this paper began with the matching mechanism, classified the initially discovered defect images using the convolutional neural network method in deep learning, and determined the causes of each type of defect in conjunction with the processing fault classification theoretical system. This paper proposed an improved VGG16 network from the conventional VGG16 convolutional neural network by adjusting its network topology and hyperparameters. The improved VGG16 achieved defect image classification and fault diagnosis with a high quality of 96.67% classification accuracy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward new-generation intelligent manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Dang, X.P. General frameworks for optimization of plastic injection molding process parameters. Simul. Model. Pract. Theory 2014, 41, 15–27. [Google Scholar] [CrossRef]

- Kurt, M.; Kamber, O.S.; Kaynak, Y.; Atakok, G.; Girit, O. Experimental investigation of plastic injection molding: Assessment of the effects of cavity pressure and mold temperature on the quality of the final products. Mater. Des. 2009, 30, 3217–3224. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Anomaly detection and classification in a laser powder bed additive manufacturing process using a trained computer vision algorithm. Addit. Manuf. 2018, 19, 114–126. [Google Scholar] [CrossRef]

- Park, C.H.; Kim, N.H. Precise and reliable positioning based on the integration of navigation satellite system and vision system. Int. J. Automot. Technol. 2014, 15, 79–87. [Google Scholar] [CrossRef]

- Zhou, Y.; Pei, Y.; Li, Z.; Fang, L.; Zhao, Y.; Yi, W. Vehicle weight identification system for spatiotemporal load distribution on bridges based on non-contact machine vision technology and deep learning algorithms. Measurement 2020, 159, 107801. [Google Scholar] [CrossRef]

- Taweelerd, S.; Chang, C.; Tzou, G. Vision system based on deep learning for product inspection in casting manufacturing: Pump impeller images. In Proceedings of the Journal of Physics: Conference Series. Taiwan, China, 21–23 May 2021. [Google Scholar]

- Geronimo, D.; Lopez, A.M.; Sappa, A.D.; Graf, T. Survey of pedestrian detection for advanced driver assistance systems. IEEE Trans. Pattern Anal. Mach. Intell. 2009, 32, 1239–1258. [Google Scholar] [CrossRef] [Green Version]

- Habib, M.T.; Majumder, A.; Jakaria, A.; Akter, M.; Uddin, M.S.; Ahmed, F. Machine vision based papaya disease recognition. J. King Saud Univ.-Comput. Inf. Sci. 2020, 32, 300–309. [Google Scholar] [CrossRef]

- Liu, G.; Shen, W.; Gao, L.; Kusiak, A. Knowledge transfer in fault diagnosis of rotary machines. IET Collab. Intell. Manuf. 2022, 4, 17–34. [Google Scholar] [CrossRef]

- Liu, Q.; Dong, R.; Liu, H.; Wang, F.; Tian, Y.; Hu, D.; Ding, C. A detection method of weak and small defects based on fluo-rescence imaging technology. In Proceedings of the Pacific Rim Laser Damage 2021: Optical Materials for High-Power Lasers, Hangzhou, China, 9 August 2021. [Google Scholar]

- Torres, F.; Sebastian, J.M.; Aracil, R.; Jiménez, L.M.; Reinoso, O. Automated real-time visual inspection system for high-resolution superimposed printings. Image Vis. Comput. 1998, 16, 947–958. [Google Scholar] [CrossRef]

- Li, D.; Liang, L.Q.; Zhang, W.J. Defect inspection and extraction of the mobile phone cover glass based on the principal components analysis. Int. J. Adv. Manuf. Technol. 2014, 73, 1605–1614. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. A multi-scale convolutional neural network for autonomous anomaly detection and classification in a laser powder bed fusion additive manufacturing process. Addit. Manuf. 2018, 24, 273–286. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Using machine learning to identify in-situ melt pool signatures indicative of flaw formation in a laser powder bed fusion additive manufacturing process. Addit. Manuf. 2019, 25, 151–165. [Google Scholar] [CrossRef]

- Scime, L.; Siddel, D.; Baird, S.; Paquit, V. Layer-wise anomaly detection and classification for powder bed additive manufacturing processes: A machine-agnostic algorithm for real-time pixel-wise semantic segmentation. Addit. Manuf. 2020, 36, 101453. [Google Scholar] [CrossRef]

- Dauphin, Y.N.; Fan, A.; Auli, M.; Grangier, D. Language modeling with gated convolutional networks. In Proceedings of the International Conference on Machine Learning, Sydney, Australia, 6–11 August 2017. [Google Scholar]

- Gehring, J.; Auli, M.; Grangier, D.; Yarats, D.; Dauphin, Y.N. Convolutional sequence to sequence learning. In Proceedings of the International Conference on Machine Learning, Sydney, Australia, 6–11 August 2017. [Google Scholar]

- Zhang, X.; Zhao, J.; LeCun, Y. Character-level convolutional networks for text classification. In Proceedings of the Annual Conference on Neural Information Processing Systems (NIPS), Montreal, Canada, 7–12 December 2015. [Google Scholar]

- Chen, C.; Seff, A.; Kornhauser, A.; Xiao, J. DeepDriving: Learning Affordance for Direct Perception in Autonomous Driving. In Proceedings of the IEEE International Conference on Computer Vision (ICCV), Santiago, Chile, 11–18 December 2015. [Google Scholar]

- Hinton, G.E.; Salakhutdinov, R.R. Reducing the dimensionality of data with neural networks. Science 2006, 313, 504–507. [Google Scholar] [CrossRef] [Green Version]

- LeCun, Y.; Boser, B.; Denker, J.; Henderson, D.; Howard, R.; Hubbard, W.; Jackel, L. Handwritten digit recognition with a back-propagation network. In Proceedings of the 2nd International Conference on Neural Information Processing Systems, Cambridge, MA, USA, 1 January 1989. [Google Scholar]

- Soukup, D.; Huber-Mörk, R. Convolutional neural networks for steel surface defect detection from photometric stereo images. In Proceedings of the International Symposium on Visual Computing, Las Vegas, NV, USA, 8–10 December 2014. [Google Scholar]

- Masci, J.; Meier, U.; Fricout, G.; Schmidhuber, J. Multi-scale pyramidal pooling network for generic steel defect classification. In Proceedings of the 2013 International Joint Conference on Neural Networks (IJCNN), Dallas, TX, USA, 4–9 August 2013. [Google Scholar]

- Chen, C.C.; Su, P.L.; Lin, Y.C. Analysis and modeling of effective parameters for dimension shrinkage variation of injection molded part with thin shell feature using response surface methodology. Int. J. Adv. Manuf. Technol. 2009, 45, 1087–1095. [Google Scholar] [CrossRef]

- Song, M.; Liu, Y.; Chang, H. Development of high pressure injection technology for normal hydraulic injection molding machines. Int. Polym. Process. 2018, 33, 52–59. [Google Scholar] [CrossRef]

- Zhao, N.y.; Lian, J.y.; Wang, P.f.; Xu, Z.b. Recent progress in minimizing the warpage and shrinkage deformations by the optimization of process parameters in plastic injection molding: A review. Int. J. Adv. Manuf. Technol. 2022, 120, 85–101. [Google Scholar] [CrossRef]

- Büttner, H.; Maradia, U.; Suarez, M.; Stirnimann, J.; Wegener, K. Development of Process Chain for Micro-Injection Molding. Procedia CIRP 2020, 95, 584–589. [Google Scholar] [CrossRef]

- Mohan, M.; Ansari, M.; Shanks, R.A. Review on the effects of process parameters on strength, shrinkage, and warpage of injection molding plastic component. Polym.-Plast. Technol. Eng. 2017, 56, 1–12. [Google Scholar] [CrossRef]

- Edirisinghe, M.; Evans, J. Review: Fabrication of engineering ceramics by injection moulding, II Techniques. Int. J. High Technol. Ceram. 1986, 2, 249–278. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, G.; Dong, G.; Li, S.; Wang, G. Bubble morphological evolution and surface defect formation mechanism in the microcellular foam injection molding process. RSC Adv. 2015, 5, 70032–70050. [Google Scholar] [CrossRef]

- Pei, Y.; Huang, Y.; Zou, Q.; Zhang, X.; Wang, S. Effects of image degradation and degradation removal to CNN-based image classification. IEEE Trans. Pattern Anal. Mach. Intell. 2019, 43, 1239–1253. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Jiang, Z.; Zhang, J.M.; Zhang, Y.; Wu, P. Remote sensing image watermarking based on motion blur degeneration and restoration model. Optik 2021, 248, 168018. [Google Scholar] [CrossRef]

- Canny, J. A computational approach to edge detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, PAMI-8, 679–698. [Google Scholar] [CrossRef]

- Adamo, F.; Attivissimo, F.; Di Nisio, A.; Savino, M. A low-cost inspection system for online defects assessment in satin glass. Measurement 2009, 42, 1304–1311. [Google Scholar] [CrossRef]

- Cha, Y.J.; Choi, W.; Büyüköztürk, O. Deep learning-based crack damage detection using convolutional neural networks. Comput.-Aided Civil Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Ko, B.C.; Gim, J.W.; Nam, J.Y. Automatic white blood cell segmentation using stepwise merging rules and gradient vector flow snake. Micron 2011, 42, 695–705. [Google Scholar] [CrossRef]

- Hu, M.K. Visual pattern recognition by moment invariants. IEEE Trans. Inf. Theory 1962, 8, 179–187. [Google Scholar]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Sharma, S.; Sharma, S.; Athaiya, A. Activation functions in neural networks. IJEAST 2017, 6, 310–316. [Google Scholar] [CrossRef]

- Nasiri, S.; Khosravani, M.R. Faults and failures prediction in injection molding process. Int. J. Adv. Manuf. Technol. 2019, 103, 2469–2484. [Google Scholar] [CrossRef]

- Kozjek, D.; Kralj, D.; Butala, P.; Lavrač, N. Data mining for fault diagnostics: A case for plastic injection molding. Procedia CIRP 2019, 81, 809–814. [Google Scholar] [CrossRef]

| Failure Name | Number of Images | Locking Tags |

|---|---|---|

| Dimensional instability | 16 | Dimensional_instability |

| Short shot | 16 | Short_shot |

| Buckling deformation | 16 | Buckling_deformation |

| Flash | 17 | flash |

| Shrinkage depression | 16 | Shrinkage_depression |

| Crack | 16 | Crack |

| Craze | 17 | Craze |

| Blackspots coking | 17 | Blackspots_coking |

| Qualified data | 16 | Qualified_data |

| HU Moment | Numerical Results |

|---|---|

| Hu1 (1) | 2.02425 |

| Hu1 (2) | 4.46429 |

| Hu1 (3) | 8.01779 |

| Hu1 (4) | 8.98081 |

| Hu1 (5) | 18.0195 |

| Hu1 (6) | 11.5543 |

| Hu1 (7) | 17.499 |

| Failure Name | Matching Accuracy |

|---|---|

| Dimensional instability | 0.1970 |

| Short shot | 1.2874 |

| Buckling deformation | 0.4767 |

| Flash | 0.6806 |

| Shrinkage depression | 0.7619 |

| Crack | 1.0137 |

| Craze | 0.7046 |

| Blackspots coking | 0.3175 |

| Qualified data | 0.0871 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Yin, Z.; Qin, L.; Xu, F. A Novel Method of Fault Diagnosis for Injection Molding Systems Based on Improved VGG16 and Machine Vision. Sustainability 2022, 14, 14280. https://doi.org/10.3390/su142114280

Hu Z, Yin Z, Qin L, Xu F. A Novel Method of Fault Diagnosis for Injection Molding Systems Based on Improved VGG16 and Machine Vision. Sustainability. 2022; 14(21):14280. https://doi.org/10.3390/su142114280

Chicago/Turabian StyleHu, Zhicheng, Zhengjie Yin, Ling Qin, and Fengxiang Xu. 2022. "A Novel Method of Fault Diagnosis for Injection Molding Systems Based on Improved VGG16 and Machine Vision" Sustainability 14, no. 21: 14280. https://doi.org/10.3390/su142114280

APA StyleHu, Z., Yin, Z., Qin, L., & Xu, F. (2022). A Novel Method of Fault Diagnosis for Injection Molding Systems Based on Improved VGG16 and Machine Vision. Sustainability, 14(21), 14280. https://doi.org/10.3390/su142114280