Abstract

Increasing demand for simplification of frequently used products promotes innovation with simple mechanisms. In this study, an attempt is made by amalgamating FMEA, QFD, TRIZ, LCA, and fuzzy TOPSIS for the development of sustainable products. The methodology is executed to redesign a simple pressure relief valve (PRV) in an economic, sustainable, and innovative manner. The failure modes of PRV are considered in FMEA and ranked by their RPN. The environmental voice of the customer is imbibed in ECQFD to correlate with the engineering specifications and obtain the critical zones of improvement. Possible innovations of the existing design based on the design option selected from ECQFD are considered by analyzing the design feature contradictions, and solutions are addressed using the TRIZ matrix. Four CAD models of improved designs were created and subjected to sustainability analysis and fatigue life analysis. The redesigns were evaluated using fuzzy TOPSIS, an MCDM approach, to obtain an unbiased ranking based on multiple criteria supported by the result analysis and expert opinions. The final design was selected for prototyping. This approach provides a holistic approach for innovative product design and development and a simplified approach for an innovative redesign of an existing product.

1. Introduction

The World Commission on Environment and Development defined sustainable development as “development that satisfies the demands of the present without compromising the ability of future generations to meet their own needs” in the Brundtland report “Our Common Future” from 1987. By sustaining both economic prosperity and social and environmental peace, it aims to establish a balance. Although it is not yet commonly used, sustainability in the design and production of new products is an approach that is largely acknowledged in theory. A new style of thinking and new decision-making techniques must be used to incorporate environmental criteria across a product’s full lifecycle. In this essay, the idea of a method for product development that is based on a paradigm for sustainable manufacturing is discussed.

Today, product development techniques are still largely focused on conventional cost-profit models, with the goal of producing high-quality products at low cost and high profit. Environmental standards are primarily seen as an inescapable “must”, which adds more costs and design limits. Environmental assessments are conducted somewhat late in the product development process when using this method. They do not fit in with current development activities, and they will probably raise the price of development. It seems unlikely that the low cost and high profit paradigm for product development will shift considerably anytime soon, if at all. Businesses must continue to turn a profit in order to stay in business. However, it is extremely possible that environmental standards will be included in every stage of product creation from the beginning, creating a new paradigm for sustainable production. Being an integrated approach, it will not only introduce certain restrictions; instead, it will find new environmental qualities of a product that could raise its perceived quality among consumers, opening up new market opportunities and financial benefits.

Over the past few decades, environmental sustainability has gained importance across a range of productive businesses. There is increased awareness of the need to reduce harmful environmental effects. A term used to describe the concept of environmentally friendly economic growth is “sustainable development”. Its goal is to create a balance between socio-political, economic, and environmental sustainability. We are constantly driven by sustainable development to safeguard and enhance our natural resources by gradually changing how we develop and use new technology. The developed framework for sustainable product development successfully integrates FMEA, ECQFD, TRIZ, and fuzzy TOPSIS. Critical zones of failure are identified using FMEA based on RPN ranking where frequent spill out and internal leakage are ranked the highest. Design options are evaluated and shortlisted based on ECQFD and it is deduced that the weight and defects should be reduced, and the strength of the component should be increased. TRIZ is deployed to resolve contradictions between features during redesigning, which results in the eight innovative solutions being obtained to solve all design contradictions for this particular case. The four feasible redesigns are subjected to sustainability analysis, which provides an overview of the environmental impact of the product throughout its lifetime, and fatigue life analysis, which examines the physical capability of the designs. Fuzzy TOPSIS is used to narrow down on the most suitable design, resulting in Redesign 4 being chosen. This case study proves the feasibility of the proposed framework model, which includes multiple facets of sustainability to support innovative product development.

Design study can be carried out on various other case components to establish the validity of this methodology by deploying it in multiple facets of engineering such as software development, network topology, and microchip manufacturing to name a few. This research has succeeded in partially automating the framework by case-specific programming using multiple software packages. Further developments can be carried out to automate the entire process to aid sustainable product development by providing an easy to adopt method to ensure an economical, safe, and sustainable product using design and industrial engineering approaches.

The term “over featuring” is used to describe a variety of excessive product development practices, including scope creep, overspecification, and feature creep [1]. Based on these presumptions, the current study defines and categorizes a set of tendencies that can harm the success of an NPD process as “over featuring”, encompassing the fields of innovation management, research and development (R&D) management, engineering, and design. One of the top 10 risks for new product development (NPD) failures is the development of new products and services beyond what is necessary to meet user wants, market demand, and company resources. Over featuring refers to a variety of situations that can arise at any stage of the NPD process, including during its ontogenesis, when a product or service is created beyond what is required by users, the market, plans, or strategies, in addition to what is practical given the company’s resources. Over featuring results in a pathological condition of the NPD process that manifests as a number of negative effects on product usability and quality and project performance [2].

RQ1. Can a framework be designed to aid sustainable product development?

RQ2. Can TRIZ be deployed to resolve contradictions between features during the redesign of components to attain a sustainable product?

The design of any product involves the incorporation of customer requirements, analysis of similar existing designs, and application of feasible design changes. Customer requirements are usually contradicting and to remove the conflicts and retain the parameters of the product and the production process while simultaneously meeting customer requirements and translating them into measurable engineering metrics, an innovative model integrating ECQFD, TRIZ, and FMEA is proposed [3]. This paper proposes the usage of the theory of innovative problem solving (TRIZ) in combination with a quality function deployment to redesign PRV and select the best design using fuzzy TOPSIS, a multicriteria decision-making approach.

FMEA is the most recognized means for the analysis and prevention of failure modes in engineering [4]. FMEA is recognized as an efficient technique for the analysis of any system to detect probable failure modes and their causes and effects on system performance [5]. FMEA is versatile in its ability to detect anomalies that can usually be avoided such as minor deviations from predicted values, absence of a process parameter, or human error in performing routine tasks [6].

QFD is an important method of product development that involves understanding customer requirements and needs and then evaluating the feasibility of the implementation of the said requirement on the product and its function [7]. QFD is a tool that helps the research and development team to design a product that caters to the end users’ specifications and requirements. Usually, QFD is deployed before the development of the new product or service to assess the nature of public demand and to obtain customer input in the initial design phase [8].

The theory of innovative problem solving (TRIZ) provides general solutions based on the pattern of innovations observed from 1926–1998 in patents globally to resolve conflicts in design. TRIZ involves the analysis of conflicts between design features, utilization of unused aspects of the design to serve value-adding functions, predictions that improve the ideal of the design, and 40 general principles that can be used to solve most contradictions [9]. TRIZ promotes a focus on design feature conflicts at the design stage rather than the final modification, which compromises the quality of the product in other aspects [10].

TOPSIS, a popular MCDM approach, is a popular choice for researchers in multiple facets of study. Competitive benchmarking led to the introduction of the technique for order preference by similarity to ideal solution (TOPSIS) to solve multiple criteria decision-making problems [11]. Kwong and Tam, (2002) employed TOPSIS to evaluate several case studies to select an ideal design solution [12].

Sustainable manufacturing is the order of the day. Commonly mistaken to just be following environmental standards, sustainability is much more than just making the product eco-friendly. Sustainability needs to be included right from the design stages to the end-of-life (EoL) disposal phase. The dearth of literature providing a valid methodology for sustainable product design was the major motivating factor for the consideration of this paper.

The research objectives of this study are as follows:

RO1. To provide a holistic framework methodology for sustainable product development by integrating FMEA, ECQFD, TRIZ, LCA, and fuzzy TOPSIS.

RO2. To aid sustainable product development by providing an easy to adopt method to ensure an economical, safe, and sustainable product using design and industrial engineering approaches.

Four CAD models of enhanced designs were produced and put through fatigue life and sustainability analyses. The redesigns were assessed using an MCDM method called fuzzy TOPSIS to obtain an objective ranking based on a number of criteria, supplemented by a result analysis and expert comments. The chosen design for prototyping is the final one. This method offers a comprehensive approach to the design and development of creative products and a condensed method for an inventive redesign of an already existing product.

Section 2 discusses the literature review, which examines previous work carried out using each technique and attempts to integrate techniques. The proposed methodology is briefly introduced, with a pictorial representation of the process flow, in Section 3. Section 4 explains the case component and the case study to be considered and the working procedure of FMEA, QFD, and TRIZ, respectively. Section 5 compiles the important results obtained in each stage of the framework and examines them. The implications of this study are briefed in Section 6. The conclusions derived from the results and discussions on possible work that could be carried out to improve the methodology in the future are mentioned in Section 7.

2. Literature Review

This review was conducted on relevant research involving sustainable product development, FMEA, QFD, TRIZ, LCA, and TOPSIS.

2.1. Sustainable Product Development

A specialized checklist was developed and tested on nine different automotive lightweight case studies to check the sustainable performance of an automotive design in the early stages of product development to compensate for the unavailability of a traditional sustainability check due to insufficient data [13]. LCA and its importance in sustainable product development have been discussed in the literature over the years [14]. After a review of over 100 studies, problems with the current approaches to LCA were revealed and analytical and theoretical solutions were provided. Research suggests that engineers involved in sustainable product development can benefit from the use of MCDM as a tool [15]. An integrated methodology was developed and tested for the material selection of a case component. The results proved that although not alone, when combined with other techniques, MCDM is a tool that can be used in any landscape.

2.2. FMEA

A procedure was devised to help managers decide on important quality control aspects, using RPN to define the relative importance of the factors involved such as suppliers and the creation of homogeneous families over the sole product code approach [16]. FMEA was used to improve OEE using a five-step approach to a bottleneck process by Chong et al. [17]. A potential problem in bearing manufacture was resolved by Thakore et al. (2015) using FMEA based on suggestions proposed to avoid long-term risk and losses. FMEA was applied to the Brazilian Automobile Industry to understand the sequence of events leading to failure in their analysis to understand the cause and effect [18].

2.3. QFD

A study of an electric vehicle dealing with the application of ECQFD to early product design to ensure sustainability was conducted by Vinodh and Rathod (2010) to ensure the effectiveness of applying a questionnaire-based validation to EMV [19]. The QFD Kano approach categorized product attributes efficiently [20]. This effectively employs complaints and claims as an alternative source of customer needs. A structure was proposed to relate the network and site viewpoints using QFD in various aspects [21]. This study also offers the basis of creating relationship maps of the site and network capabilities, network arrangement and coordination, and the auxiliary and infrastructural paradigms. A QFD approach was designed by Kuo et al. (2009) that combines environmental concerns in the design development stage [22]. To reduce uncertainty and bias, a fuzzy method was integrated into QFD.

2.4. TRIZ

The application of TRIZ was elucidated by deploying it for the innovative design of a butterfly valve [23]. TRIZ and a framework methodology with a case study were employed in the problem-solving and forecasting of chemical engineering commercial product development, and a systematic and reliable method of innovative design was proposed [24]. TRIZ and six sigma for the development of a new product were proposed by Wang et al. (2016) [25]. A technique was developed that first systematically integrated QFD and TRIZ for innovative product development and applied it to innovate an existing product by Yamashina et al. (2010) [26].

2.5. LCA

Environmental supply chain management (ESCM) has received more attention in recent years. Life cycle evaluation (LCA) is one of ESCM’s auxiliary tools. Research organizations and businesses are increasingly supporting the idea of incorporating LCA into supply chains. A method for evaluating the environmental effects of a product over its life cycle is life cycle assessment. This analysis of how the life cycle stages contribute to the overall environmental burden, typically with the goal of prioritizing improvements of products or processes, and the comparison of products for internal use are among the most crucial applications. The LCA method aids in the selection of key environmental behavior indicators for organizations, along with measurement and assessment methods, particularly in relation to the evaluation of the state of the environment, the search for the most suitable life cycles such as those that have little or no adverse environmental impact, and marketing with a connection to the creation of environmental declarations or eco-labeling. The results from LCA can guide strategic planning, inform public policy, and help identify opportunities for improvement in industrial processes. LCAs make it possible to compare various items. LCAs can also be used to identify regions of production with high environmental impact, allowing the design and evaluation of alternative production pathways. This helps to improve the design of products, processes, and systems.

2.6. TOPSIS

Fuzzy TOPSIS was used to rank barriers to environment conscious manufacturing based on different perspectives by Mittal and Sanghwan (2014) [27]. The fuzzy AHP and TOPSIS models were integrated to determine the assistance to the poor [28]. A comparison between fuzzy AHP and fuzzy TOPSIS with seven factors determined that overall, fuzzy TOPSIS offers better consistency in the results when additional alternatives, optimal or non-optimal, are introduced [29,30]. Fuzzy TOPSIS was applied to select optimal locations for electric vehicle charging stations and a sensitivity analysis was conducted to evaluate the robustness of the decision. The application was described as “reasonably effective, practical and robust” [31,32,33].

2.7. Integrated Frameworks

QFD and FMEA were combined to conduct a case study within Ford Motor Company to demonstrate the benefits of using both tools [34]. The integration of ECQFD and LCA has been suggested to be practically feasible for sustainable product development and validated with case studies [35]. The integration of QFD and TRIZ was proposed by Liu et al. (2009), with QFD being used to amend the correlation matrix obtained from TRIZ to attain the ideal result [10]. Hu et al. further integrated FMEA with QFD and TRIZ whereas Vinodh et al. (2013) integrated an MCDM approach (AHP) with QFD and TRIZ [3,36].

One of the most popular techniques for assisting risk analysis in corporate operations is FMEA. Some studies combine FMEA with multicriteria decision approaches in an effort to give it new characteristics. FMEA is an approach for identifying possible difficulties with reliability early in the development cycle, when it is simpler to take steps to address them, hence improving the dependability via the design. Potential failure modes are identified using FMEA, along with their impact on the product’s functionality and potential remedies. TRIZ has been marketed as a strategy or toolkit that offers a rational approach to fostering creativity for innovation and creative problem solving by a number of enthusiasts. Over 35 nations have adopted this approach since it first appeared in Russia in the 1960s. It is currently being taught at a number of universities and has been used by a number of international organizations, which have found it to be especially helpful in fostering the development of new products [37].

2.8. Gaps Identified

From the extensive literature review conducted, it was observed that researchers have tested multiple combinations of methodologies to create a framework for sustainable product development, but no work has combined the FMEA, QFD, TRIZ, and fuzzy TOPSIS techniques. In few studies, ECQFD has been underutilized in sustainable product development works and VOCs have only concentrated on remanufacturing. Additionally, customer requirements have been overlooked in many sustainable development projects to accommodate engineering requirements. Fuzzy theory MCDM approaches, which provide relatively indiscriminate results, have not been integrated with innovative product development. All the similar proposed methodologies involve a high level of complexity in their deployment to improve existing products. Hence, in this study, a novel attempt is made to provide an easy to adopt holistic framework methodology for sustainable product development by integrating FMEA, ECQFD, TRIZ, LCA, and fuzzy TOPSIS.

3. Proposed Methodology

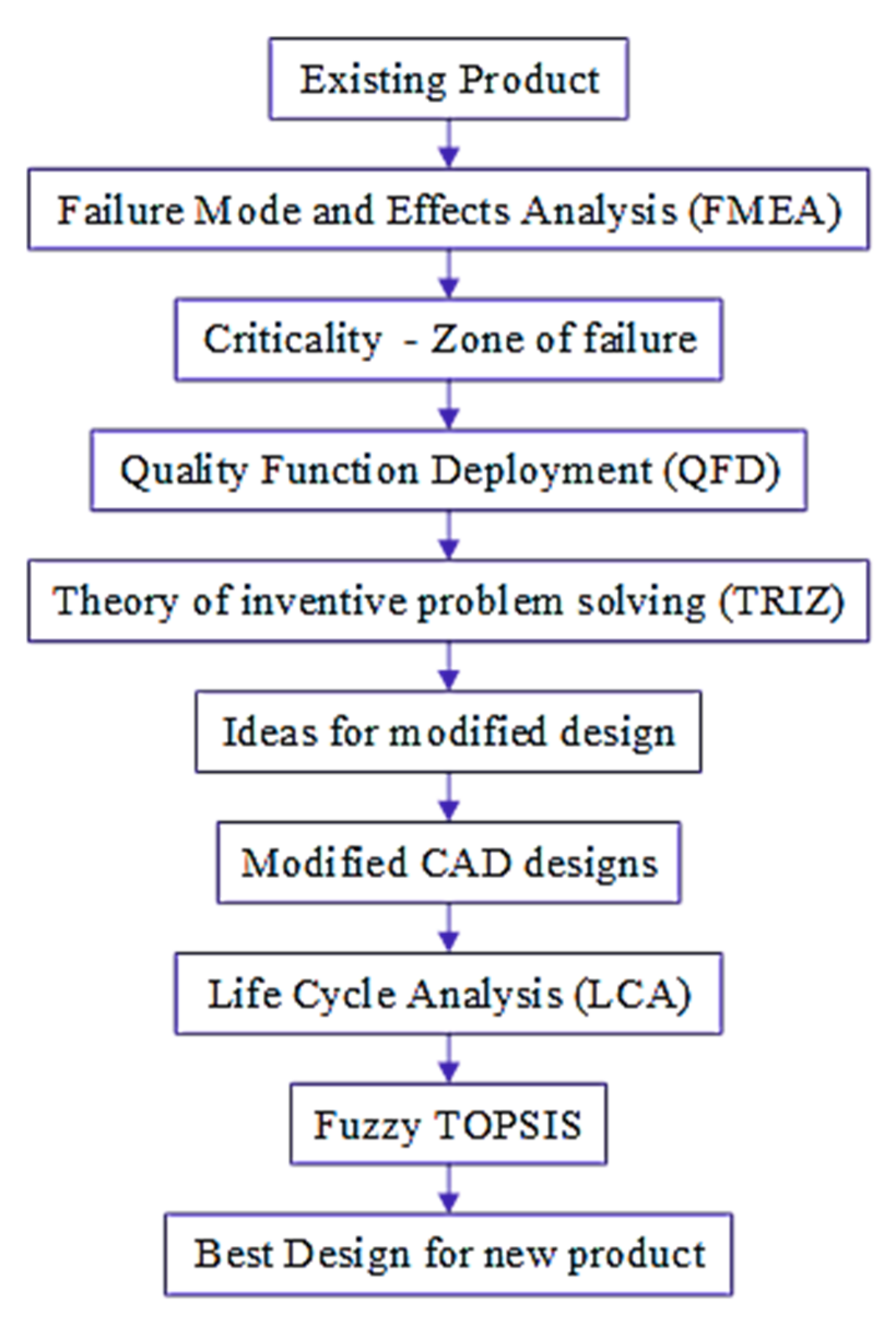

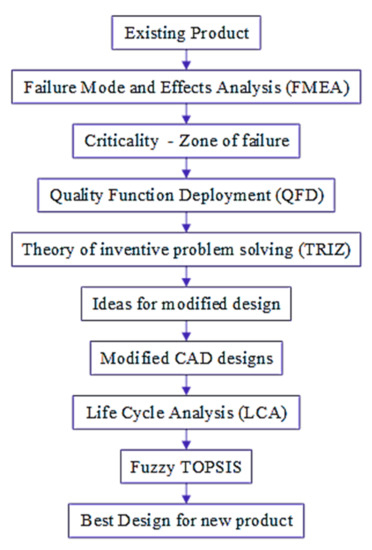

Figure 1 shows the methodology adopted in this study.

Figure 1.

Methodology adopted in this study.

An existing product is chosen, and its failure modes are analyzed. FMEA is conducted to quantify the criticality of the failure modes and utilized to identify probable faults and their effects on products and processes in order to reduce them and achieve continuous quality improvement. The zones of improvement in the design are identified with the correlation of VOC and EM in ECQFD and the identification of environmental VOC and environmental EM, and using ECQFD phases I and II, the target for design improvement was determined. The deployment of VOC to EM is demonstrated in Phase I, which explains how ECQFD is applied to the design. VOC products are typically weighed based on market research to determine their “consumer weights”. The idea of the product life cycle determines the significance of environmental VOCs. However, EM products also contain brand-new items. Numbers that represent factors chosen by the designer serve as markers for the mapping points between VOC and EM components. TRIZ is deployed to obtain general solutions for innovation in the design contradictions. The redesigns are rendered in CAD and LCA is conducted. The designs and relevant data are subjected to expert review through fuzzy TOPSIS, and the best design is selected.

4. Case Study and Analysis

To support the proposed model and validate the framework methodology, a case study was conducted in a precision products manufacturing organization in Bengaluru (hereafter called XYZ). XYZ are manufacturers of precision components, fuel filters, and subassemblies used in petrochemical applications. Their plants are ISO/TS 16,949 certified, environmental systems ISO-14001 certified, and VDA6.3 certified by their customers. All data used in this paper for techniques such as FMEA and ECQFD were obtained from subject matter experts from XYZ and they were major contributors to all brainstorming sessions.

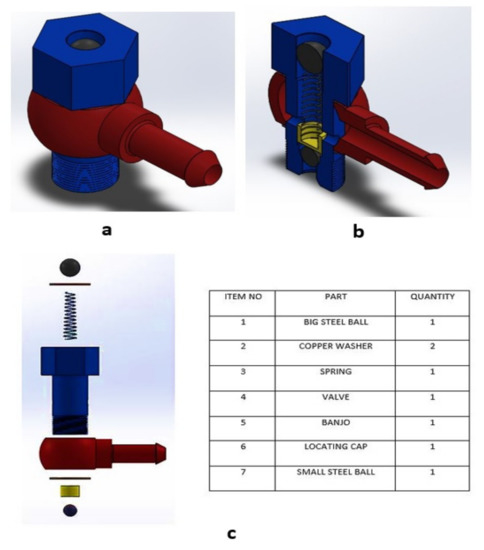

4.1. Case Component Details

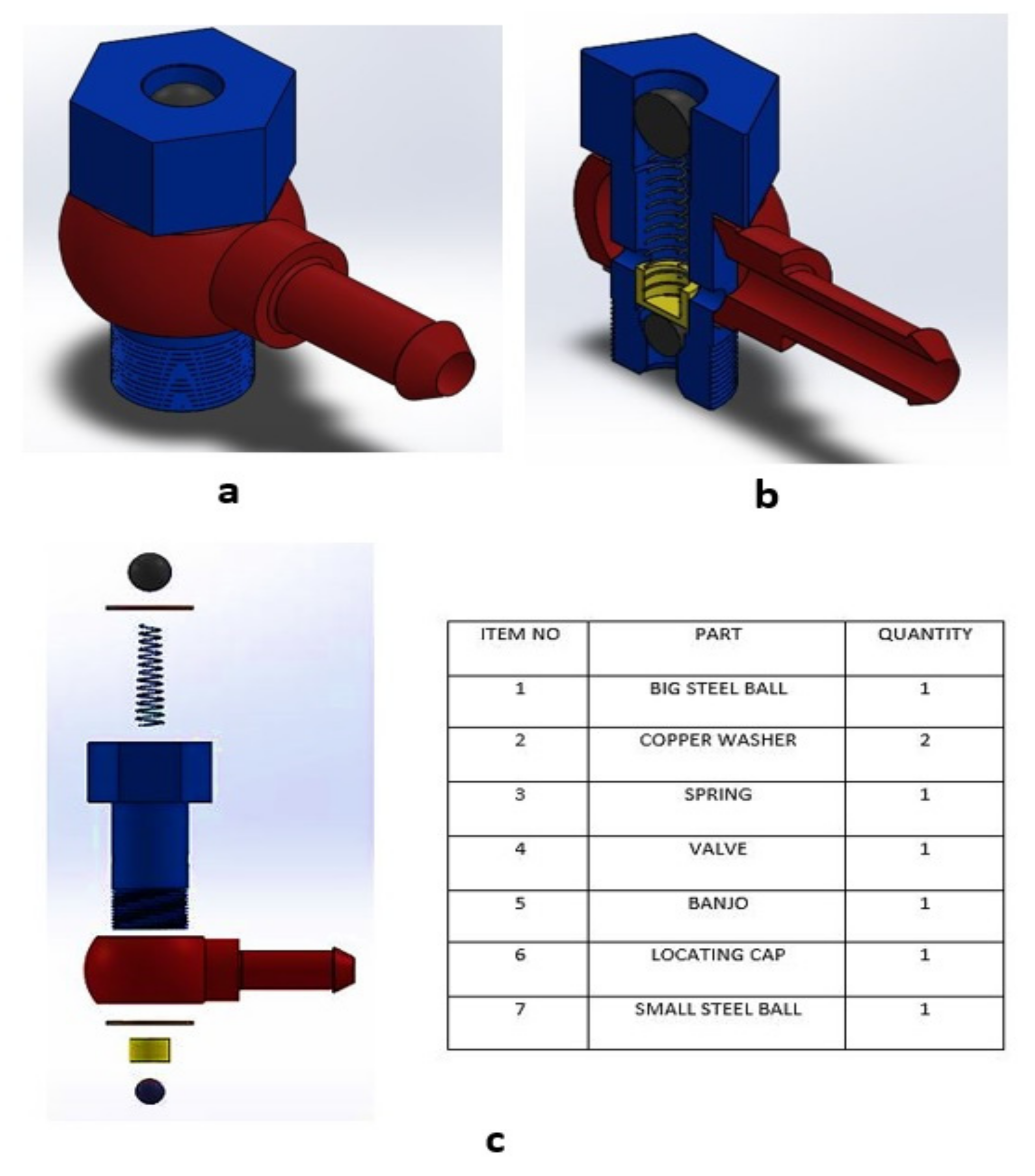

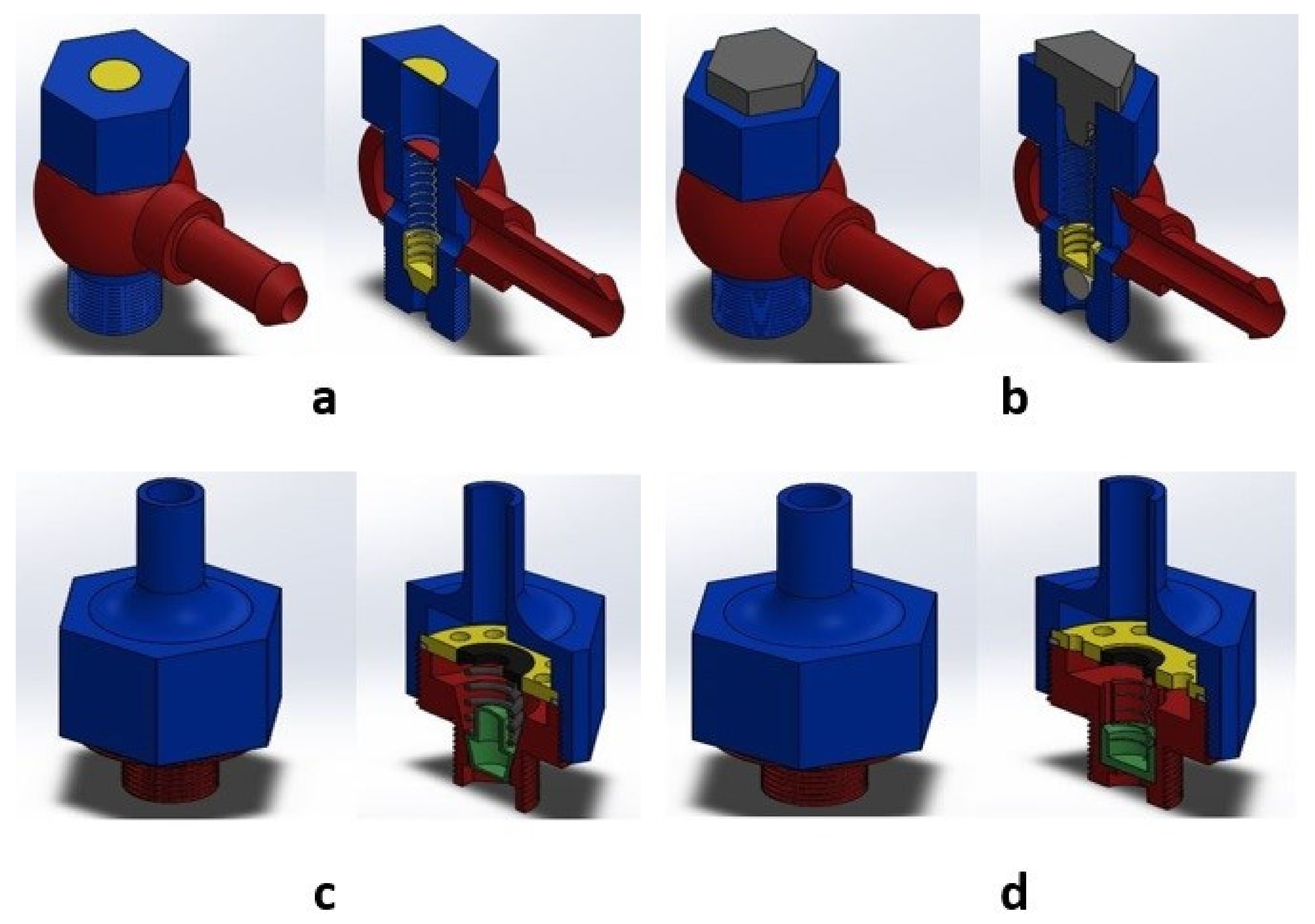

A pressure relief valve (Figure 2a) was considered as the case product for this study. A pressure relief valve (PRV), which is a vital excess-pressure relief system in industrial processes, is widely applied in boilers, pressure vessels, and pipelines [38]. PRV is used to avoid excess pressure accumulation, component dysfunction, and potential hazards. The valve relieves the pressure by discharging excess fluid to an auxiliary system. PRV is predetermined to open at a particular pressure to shield pressure vessels and other components from exposure to high pressures that exceed their physical limitations. It is a legal requirement to protect pressurized components in many countries. Organizations such as ASME and ISO (ISO 4126) specify the use of relief valves in their design standards. PRVs prevent damage to life and property. Hence, the improvement of PRV will help to reduce the possibility of further accidents occurring. Figure 2b,c shows a cross-sectional view and an exploded view with the bill of materials, respectively.

Figure 2.

(a) Banjo pressure relief valve. (b) Banjo pressure relief valve cross-sectional view. (c) Banjo pressure relief valve subassembly.

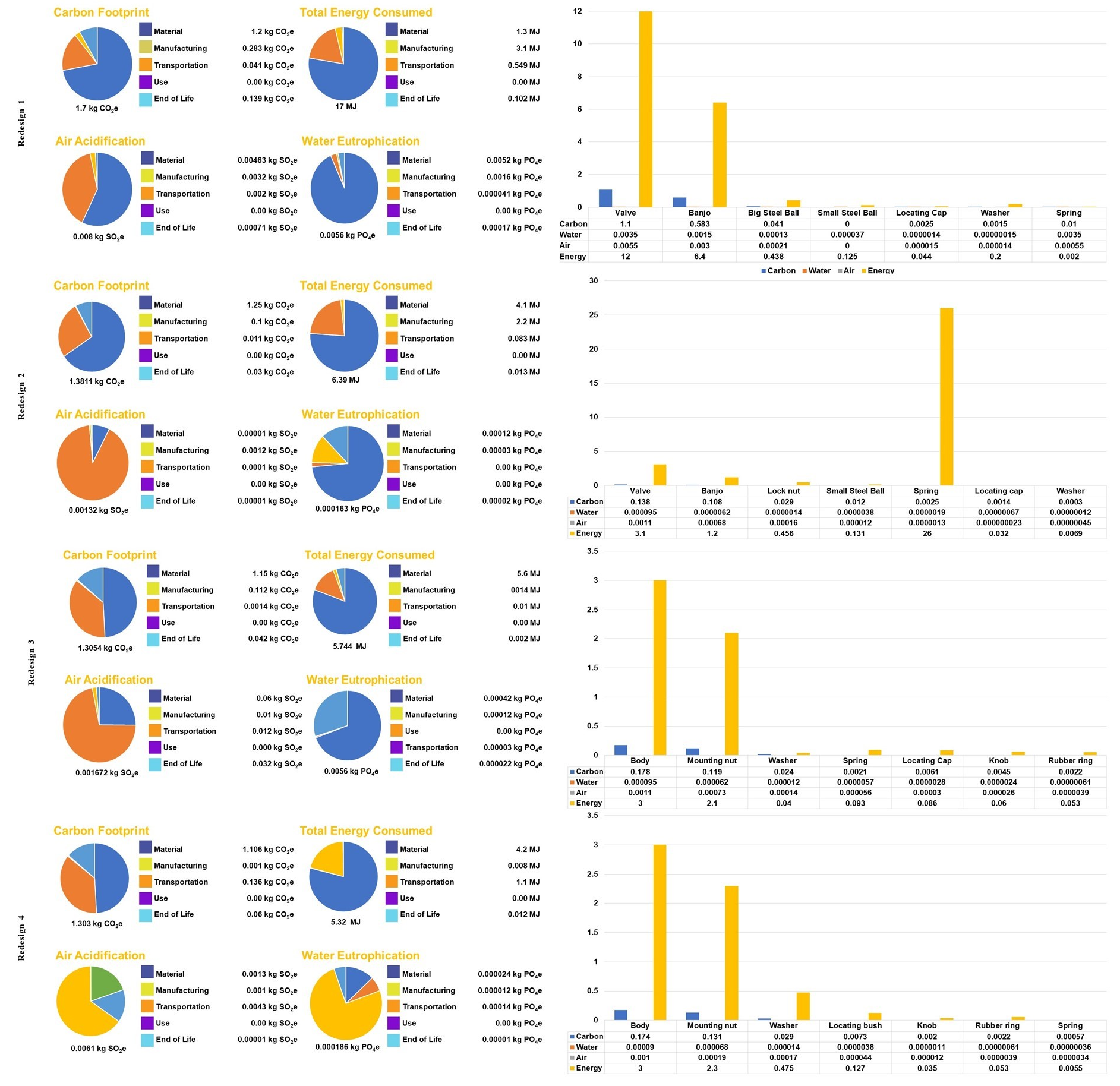

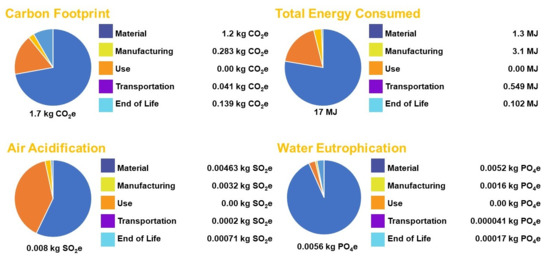

4.2. Initial Sustainability Analysis

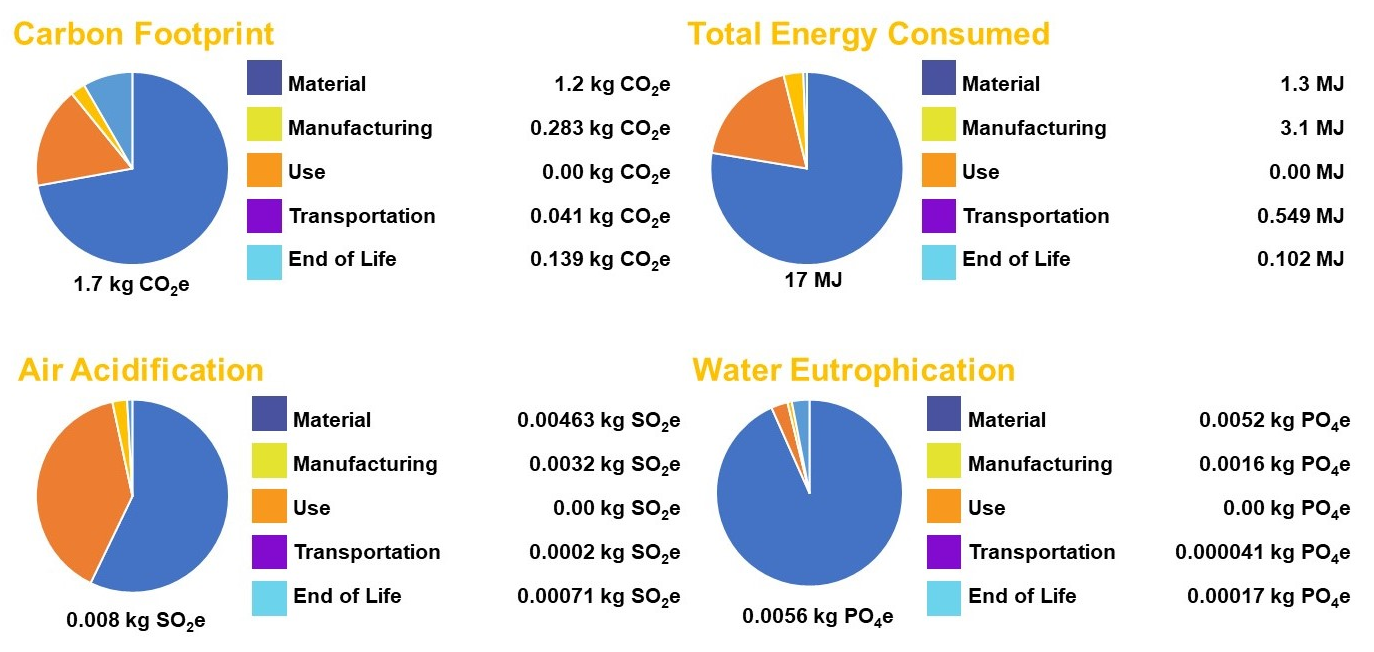

In maintaining the consumption of renewable resources, pollution and exhaustion of non-renewable resources are termed environmental sustainability [39]. Sustainability assessment renders the understanding of the original impact on the environment and on human development based on the resources and the ability of nature to absorb the pollutants [40]. The sustainability analysis of the existing component was carried out using Solidworks Sustainability Xpress 2018 analysis report feature. The Sustainability Xpress module was chosen due to its ability to provide both an overview of lifecycle analysis and detailed LCA of each individual part in the assembly. It helps product designers to validate how the design (CAD model) and manufacturing decisions can affect the environmental impact of their product. The choice of manufacturing region contributes to the process parameters and manufacturing of the case product across the product lifecycle.

The parameters that are considered in Solidworks Sustainability Xpress for an evaluation of sustainability analysis are as follows:

Carbon Footprint: The carbon content emitted to the environment during the process (material, transport, etc.) is evaluated. Most research shows that the increase in CO2 in the atmosphere is due to the combustion of fossil fuels, which causes global warming [40].

Total energy consumed: An organization’s sustainability largely depends on the efficient use of energy [41]. The impact of energy used in the process and the downstream processes is also considered.

Air acidification: Due to pollutants such as SO2 being emitted during the manufacturing processes, air pollution occurs, which leads to acidification of air that causes acid rain, acidifying lakes and soil, and resulting in toxic inhalation by living beings [42].

Water eutrophication: When the nutrient level in water increases, eutrophication occurs. Water eutrophication leads to oxygen depletion in water, which affects the aquatic ecosystem, thereby affecting the food chain [43].

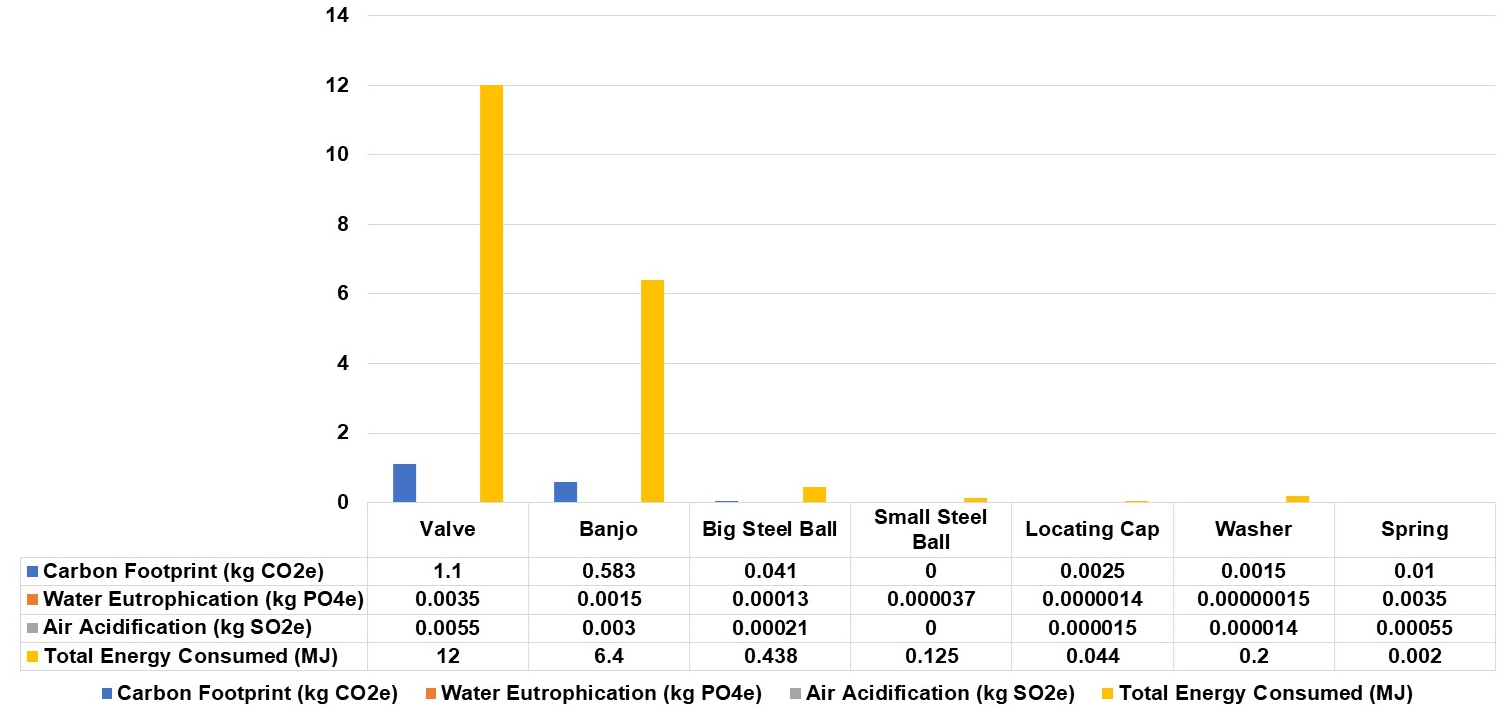

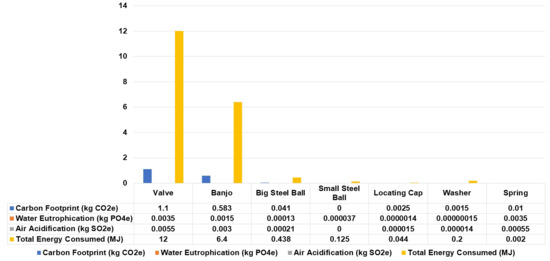

The results of the sustainability analysis of the case product (existing) are shown in Figure 3 and Figure 4, which shows the results of the sustainability analysis of all components. From these results, it was found that the valve and the banjo part have a high environmental impact: 1.1 kg CO2e and 12 MJ of the total of 1.7 kg CO2e and 17 MJ of energy are from the valve, which makes it a more prioritized component for modification of the design/process parameters, followed by the banjo, with 0.593 kg CO2e and 6.4 MJ.

Figure 3.

Sustainability analysis of the case component.

Figure 4.

Sustainability analysis of the case component sub assembly.

4.3. Failure Mode Effect Analysis (FMEA)

Process information for inspection, quality checks, and remedial actions were compiled and examined. From the information, potential failure modes and their respective failure effects were determined, for which the severity (S) rating was determined. The causes of each failure mode were determined, and the probability of occurrence (O) was quantified. The values of S, O, and D were assigned by SME based on the scale given in Appendix A Table A1. The current control action for the failure effects is tabulated in Table 1 and the detection (D) rating was determined. Based on the values of S, O, and D, RPN was calculated.

Table 1.

FMEA-RPN calculation.

4.3.1. Occurrence (O)

The cause of a failure mode was determined and the number of times it occurs was accounted for. All the potential causes for each failure mode were identified and documented in technical terms [44].

4.3.2. Severity (S)

After identifying all possible failure modes, the effect caused by these failures was identified and documented. These effects were given a number based on the severity of their effect on the outcome of the product/process [34].

4.3.3. Detection (D)

This shows the rating of how often the problem in a product/process is detected before it reaches the customer. During the inspection process, current control systems identify the error and the probability of identifying this fault is taken as detection [45].

4.3.4. Risk Priority Number (RPN)

RPN is the threshold value of the process. After calculating S, O, and D, RPN was calculated as the product of occurrence, severity, and detection. After calculating RPN for all the failures, they were prioritized based on the RPN value. The recommended action is considered to be the process with higher RPN [44]. RPN was calculated by the formula:

Scaling Table

Appendix ATable A1 shows the rating scale that is considered while rating the failure modes.

Sample calculation:

For a frequent spill out

Potential effect: fire hazard

Severity (S) = 9

Potential cause: wear of big steel ball

Occurrence (O) = 5

Current control: visual inspection

Detection (D) = 8

Substituting in the formula,

RPN = 9 × 5 × 8 = 360

Table 1 demonstrates the RPN calculation used in this study.

4.4. Environment Conscious Quality Function Deployment

With sustainability being part of the approach, ECQFD incorporates both sustainable and functional VOCs. Engineering metrics were deployed based on VOC obtained. The engineering metrics were determined and assigned to VOC based on brainstorming sessions with industry SME. Phase I was conducted to create a correlation between VOCs and EM while Phase II was conducted to create a correlation between EM and the parts of the subassembly. In Phase I and Phase II, the area where design improvement was required was identified. The RPN value from FMEA was used as a factor for VOC weights in Phase I. In Phase III and Phase IV, the target areas identified in Phase II were evaluated for design improvement. In Phase IV, the improvement rate of the customer requirement and its effect were determined.

4.4.1. ECQFD Phase I

Appendix ATable A2 shows Phase I of ECQFD deployed in the design of PRV. All seven identified VOCs were associated with the eight EM. Each criterion from the VOC was weighed based on the market survey. The important relation of VOC and EM was determined using a scale, with “9” indicating strong, “3” indicating moderate, and “1” indicating low relative importance. The Raw score was calculated using the following formula:

Sample calculation

Raw score = (9 × 3) + (3 × 9) + (9 × 9) + (9 × 3) + (3 × 3) + (1 × 9) + (3 × 9) = 207

Relative weight = = = 0.162

4.4.2. ECQFD Phase II

In Phase II of ECQFD, EM in this study was correlated to components of PRV (Appendix A Table A3). Each EM uses the weights that were obtained from Phase I. The importance relation between EM and the components of PRV is rated on the same scale as Phase I and the calculations were similarly carried out. After the calculation, components that have the highest weights were selected. However, since all components are indispensable, no component was left out. The valve is an irreplaceable component that needs to be improved based on the other components; hence, though it was ranked low, it was still taken into consideration.

Sample calculation

Raw score = (0.162 × 3) + (0.067 × 9) + (0.172 × 3) + (0.190 × 3) + (0.031 × 3) + (0.158 × 1) + (0.068 × 1) + (0.153 × 9) = 3.865

Relative weight = = = 0.135

4.4.3. ECQFD Phase III

In this phase, the effect of design improvement of PRV components on EM is discussed. In Phase III, two options were discussed by evaluating the most important components identified in Phase I. These design options were evaluated again for Phase II to quantify the improvement in EMs. EMs were categorized into two options:

Option I: weight, defects and strength.

Option II: number of parts, flow rate, and physical lifetime.

Phase III was carried out to examine the effect of each option on EM and is shown in Appendix A Table A4 and Table A5. The improvement rate for each EM was calculated by:

Option I

Sample calculation

Improvement rate calculation

For weight

From Phase III,

(0.162 × 3) + (0.162 × 1) + (0.162 × 3) + (0.162 × 1) + (0.162 × 3) + (0.162 × 1) +

(0.162 × 3) = 4.374

From Phase II,

(3 + 1 + 1 + 3 + 1 + 3) = 27

Improvement rate = = 0.162

Option II

Sample calculation

Improvement rate calculation

For flow rate

From Phase III,

(0.068 × 1) + (0.068 × 1) + (0.068 × 9) + (0.068 × 1) + (0.068 × 9) + (0.068 × 3) +

(0.068 × 3) = 1.836

From Phase II,

1 + 1 + 9 + 1 + 9 + 3 + 3 = 27

Improvement rate = = 0.068

4.4.4. ECQFD Phase IV

Phase IV for PRV is shown in Table 2 and Table 3, which was carried out to convert the effect of the design improvement of EM into the VOC criteria for each design option. Based on the calculation, it was found that the quantum of the improvement effect on VOC of Option I of Phase IV is higher than Option II. The improvement rate and effect for each VOC was calculated by the following formula:

Table 2.

ECQFD: Phase IV Option I.

Table 3.

ECQFD: Phase IV Option II.

Option I

Sample calculation

For cost efficiency

VOC improvement rate = (3 × 0.162) + (1 × 0) + (9 × 0.172) + (3 × 0.190) + (1 × 0) + (3 × 0) + (1 × 0) + (9 × 0)/(30 × 9) = 0.00964

Improvement effect of VOC = 0.00964 × 9 = 0.08676

Option II

Sample calculation

For reliability

VOC improvement rate = (3 × 0) + (3 × 0) + (9 × 0) + (9 × 0) + (1 × 0) + (9 × 0.158) + (3 × 0.068) + (3 × 0.153)/(40 × 9) = 0.0058

Improvement effect of VOC = 0.0058 × 9 = 0.0520

4.5. Theory of Inventive Problem Solving (TRIZ)

TRIZ offers general innovative solutions to design problems (Altschuller, 1998). The design option chosen in ECQFD was considered and the metrics chosen in Option I were correlated with the TRIZ matrix to identify the contradictions. The improvement feature was cross related with the worsening feature to access the prescribed principles of innovation. The contradiction can be solved by applying one or more applicable principles mentioned in the matrix for the specific problem. The 39 features of TRIZ are listed in Appendix A Table A6.

Sample Contradiction

An improvement of the strength would impact the stress or the pressure of the system, which is not ideal. To retain the current stress, the TRIZ matrix offers four possible innovative solutions

#10. Preliminary Action: Perform a specific set of actions before the process to ease the process flow.

#3. Local Quality: Modify the object and the environment to suit the process. Introduce additional functions or conditions to components to help idealize the environment.

#18. Mechanical Vibrations: Use the object’s or components’ natural ability to undergo mechanical vibrations to a value.

#40. Composite materials: Change the material from uniform traditional materials to non-uniform composites to achieve desirable properties.

The most important contradictions to be solved are given in Table 4. These contradictions mark important decision points that were essential in redesigning the component. All applicable principles were handpicked following a brainstorming session with the SME involving the whole TRIZ matrix.

Table 4.

Important TRIZ contradictions.

The final abbreviated TRIZ matrix, in which the 39 features are narrowed down to 11 16 features, is shown in Table 5.

Table 5.

Abbreviated TRIZ matrix.

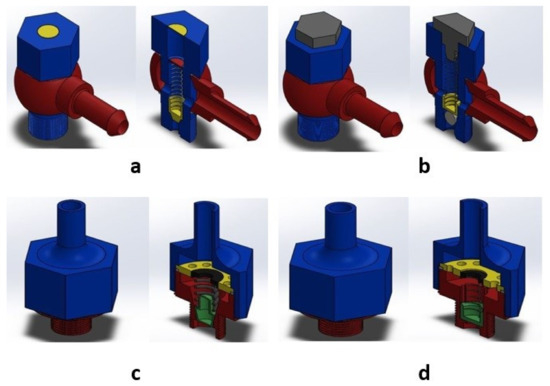

4.6. CAD Redesign of the Case Component

The TRIZ principles were considered and examined. Appropriate changes to the component design were considered in relation to the DFM principles. Ideas were brainstormed and executed. CAD designs were produced on Solidworks and verified by running a sustainability analysis in Solidworks Sustainability Xpress 2018 and a fatigue life analysis on Solidworks Simulation to obtain an overview of the lifetime feasibility of the product. Four primary redesigns were considered as potential replacement models. These four designs are shown in Figure 5a–d. Each redesign inculcates the improvements required and provides a different paradigm of a solution.

Figure 5.

(a) Redesign 1. (b) Redesign 2. (c) Redesign 3. (d) Redesign 4.

All four redesigns, as specified by principle 27 and 40 of TRIZ (Table 6), use acrylonitrile butadiene styrene (ABS) instead of AISI 304 steel, which is heavier and costlier. The washers are made from styrene-butadiene rubber (SBR) instead of copper to reduce the impact of torque. Redesign 1 removes the big steel ball and introduces a buckle lock mechanism to reduce frequent spills due to big steel ball wear (TRIZ principle 25). IThe small steel ball is also removed and its function integrated into the locating cap (TRIZ principle 6). Redesign 2 prevents spills using a top nut, which also serves the function (TRIZ principle 6) of adjusting the spring tension, which controls the valve opening pressure (TRIZ principle 15). Redesign 3 and 4 employ a change in shape (TRIZ principle 35) to reduce the complexity of the subassembly. Redesign 3 introduces a porous washer (TRIZ principle 31), which replaces the banjo to serve as the fluid outlet. Redesign 4 combines the porous washer and the buckle lock mechanism to form a multi-functional knob (TRIZ principle 5) that remains defect-free for multiple breakage cycles.

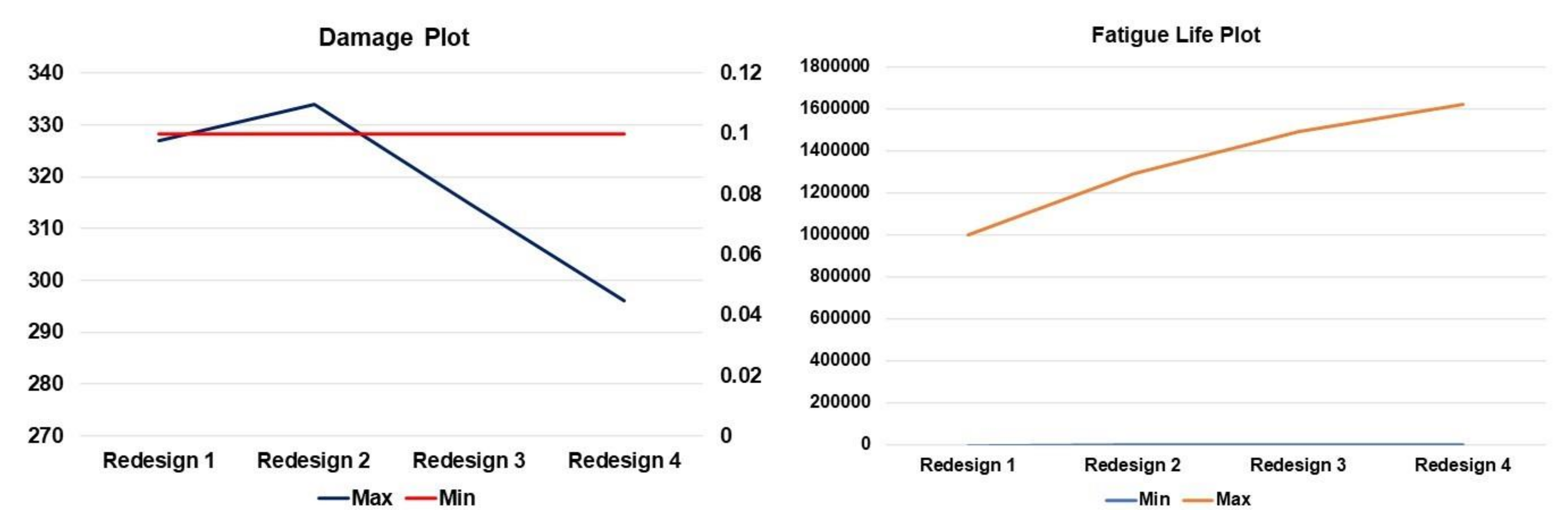

Table 6.

Fatigue life analysis: damage plot.

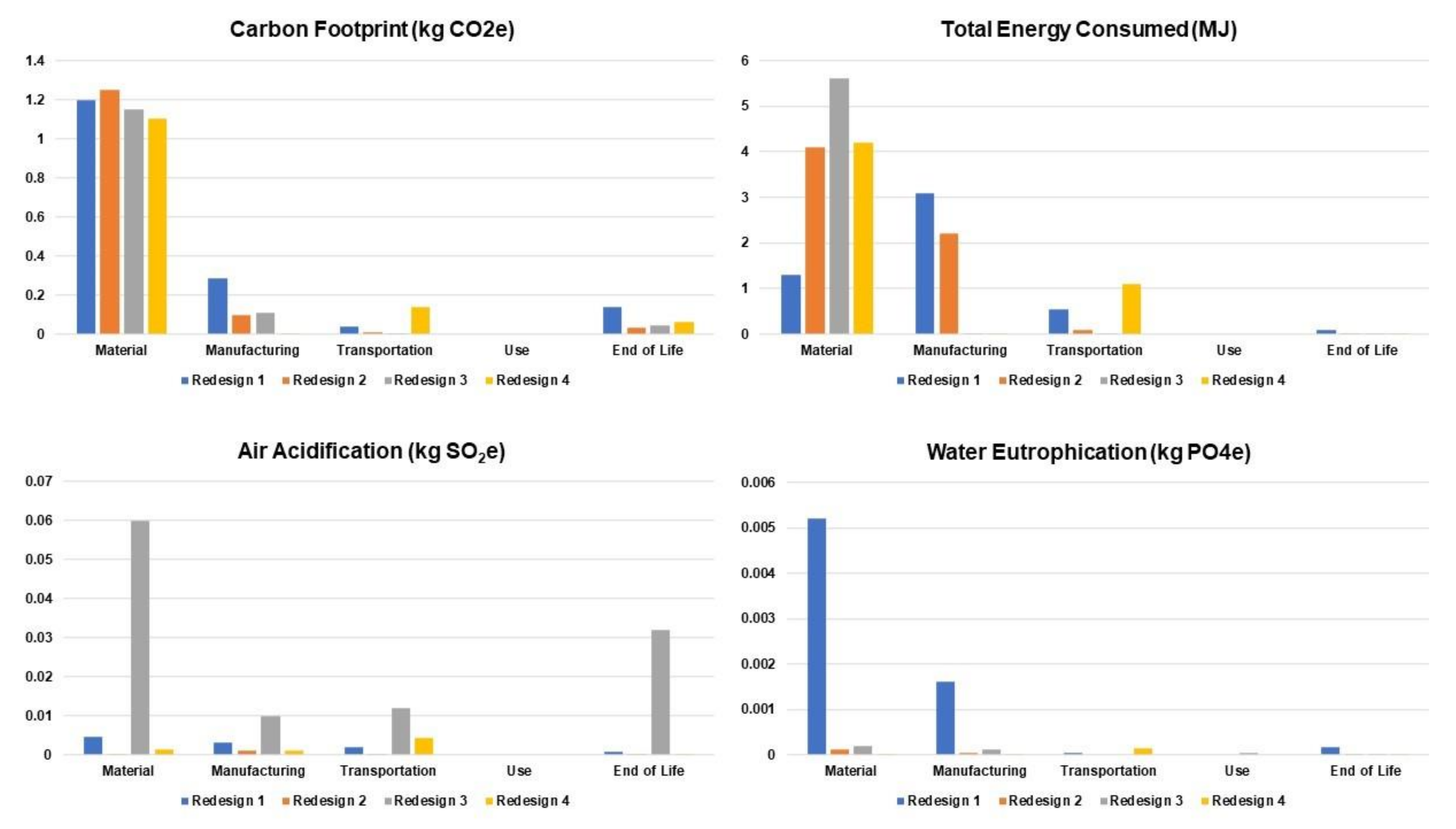

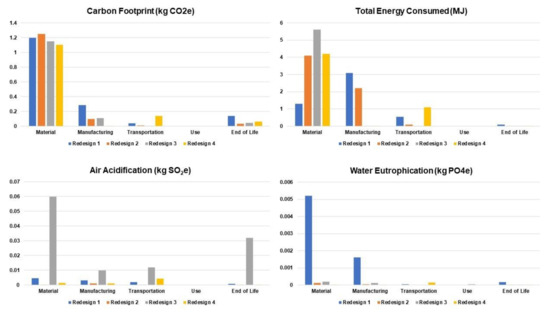

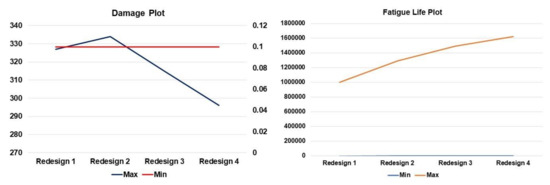

A fatigue study was conducted using Solidworks simulation for all four redesigns. This study obtained the stress and strain values of each node of the component. A static study was conducted by initially specifying the loads and fixtures. The results of the static study were then used to run the fatigue analysis for an event of 1000 cycles. The minimum and maximum damage cycles and life cycles were obtained as a result of the analysis. The results of the sustainability analysis are shown in Figure 6. The consolidated sustainability analysis comparative charts are shown in Figure 7 and Figure 8, which present the fatigue analysis results of all four proposed redesigns.

Figure 6.

Sustainability analysis.

Figure 7.

Sustainability analysis comparative charts.

Figure 8.

Fatigue life analysis comparative charts.

Table 6 and Table 7 tabulate the results of the fatigue life analysis of the damage and life plots, respectively.

Table 7.

Fatigue life analysis: life plot.

4.7. Fuzzy TOPSIS

The four redesigns were evaluated based on six criteria: weight (C1), sustainability (C2), product lifetime (C3), manufacturability (C4), cost effectiveness (C5), and ingenuity (C6). The decision-makers (SME), after perusal of the data, provided their ratings based on the linguistic ratings given in Appendix A Table A7.

The linguistic assessments were all converted to numerical data based on the fuzzy theory as a fuzzy number, a triplet. The linguistic assessment of all the criteria and the alternatives are given in Appendix A Table A8 and Table A9.

If the triangular fuzzy number is represented by , the aggregate fuzzy weights of the criteria can be calculated by the formula (a, b, c) as:

The aggregate fuzzy weights for the criteria are shown in Table 8.

Table 8.

Aggregate fuzzy weights for criteria.

The aggregate fuzzy weights for the alternatives are shown in Appendix A Table A10.

The weighted normalized matrix was calculated by multiplying the elements with the weights of the criteria, i.e., (refer to Appendix A Table A12).

The geometric distance between the weighted alternative and FNIS and FPIS was calculated by Equations (10)–(12) and is presented in Appendix A Table A13 and Table A14:

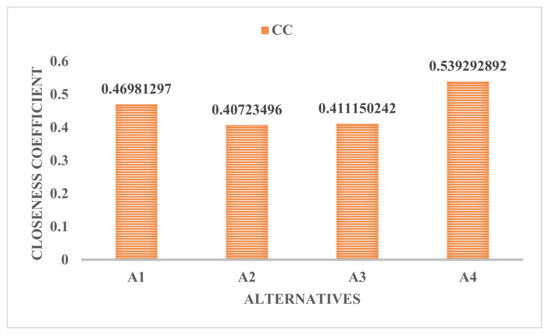

The closeness coefficient represents the geometric distance to FNIS and FPIS simultaneously and listed in Table 9. It was calculated by Equation (13):

Table 9.

Closeness coefficients for alternatives.

The alternatives were then ranked based on their CC. The C++ code used to conduct fuzzy TOPSIS is provided in the Appendix A.

5. Results and Discussions

This study provides a systematic approach to the integration of FMEA, ECQFD, TRIZ, LCA, and TOPSIS for the development of an innovative product. For a product to be successful, the design phase should consider the environmental, economic, and social aspects. Based on the factors considered and the data obtained from TRIZ on the input of failure modes, VOCs, and EM, the case component was modified and redesigned.

5.1. FMEA Results

From Table 10, it is found that frequent spills, internal leakage, and jamming are critical failure modes as they have high RPN values when compared to the other failure modes. The failure modes with high RPN values were considered within ECQFD as VOC and further analysis was carried out. The rating of these failure modes was also based on their RPN values.

Table 10.

Ranked failure modes.

5.2. ECQFD Design Options

From Phase I and Phase II, we identified two design options:

Option I:

- -

- The strength of the component should be high.

- -

- Defects and weight must be reduced.

Option II:

- -

- The number of parts must be reduced.

- -

- The physical lifetime of the component should be increased.

- -

- An improved flow rate must be obtained.

Following Phase III and Phase IV, it was found that Option I has a VOC improvement effect of 0.610, whereas Option II has an improvement effect of 0.398. Hence, Option I was selected.

5.3. Innovative TRIZ Solutions

Based on Option I, the TRIZ features applicable to the case were shortlisted. After considering all the contradictions between features in the TRIZ matrix, a set of applicable principles for the current problem were considered. They are listed in Table 11.

Table 11.

Applicable TRIZ principles.

5.4. CAD Redesign and Analysis of the Case Component

The TRIZ principles were applied to obtain four primary redesigns of PRV. All redesigns underwent sustainability and fatigue life analysis. Based on the data obtained from the analysis, it can be concluded that overall, the material consumed has a major environmental impact, followed by the manufacturing process and end-of-life disposal stage. Transportation has a very minimal effect whereas usage of the component has no effect on the environment for any factor. Concerning the redesigns, visibly, they cannot be discerned as specific major contributors. Thus, additional data is required to ratify them.

The lifecycle analysis also involves a fatigue life study, which deals with the feasibility of the redesign. The changed material leads to a difference in the damage and lifetime from the original. The plot of the damage cycles shows that Redesign 2 has the maximum damage over 1000 cycles and Redesign 2 has the minimum damage. The plot of the lifetime shows that Redesign 4 has the maximum lifetime and Redesign 1 has the minimum lifetime. This demonstrates that Redesign 4 has the highest physical lifetime of all the redesigns.

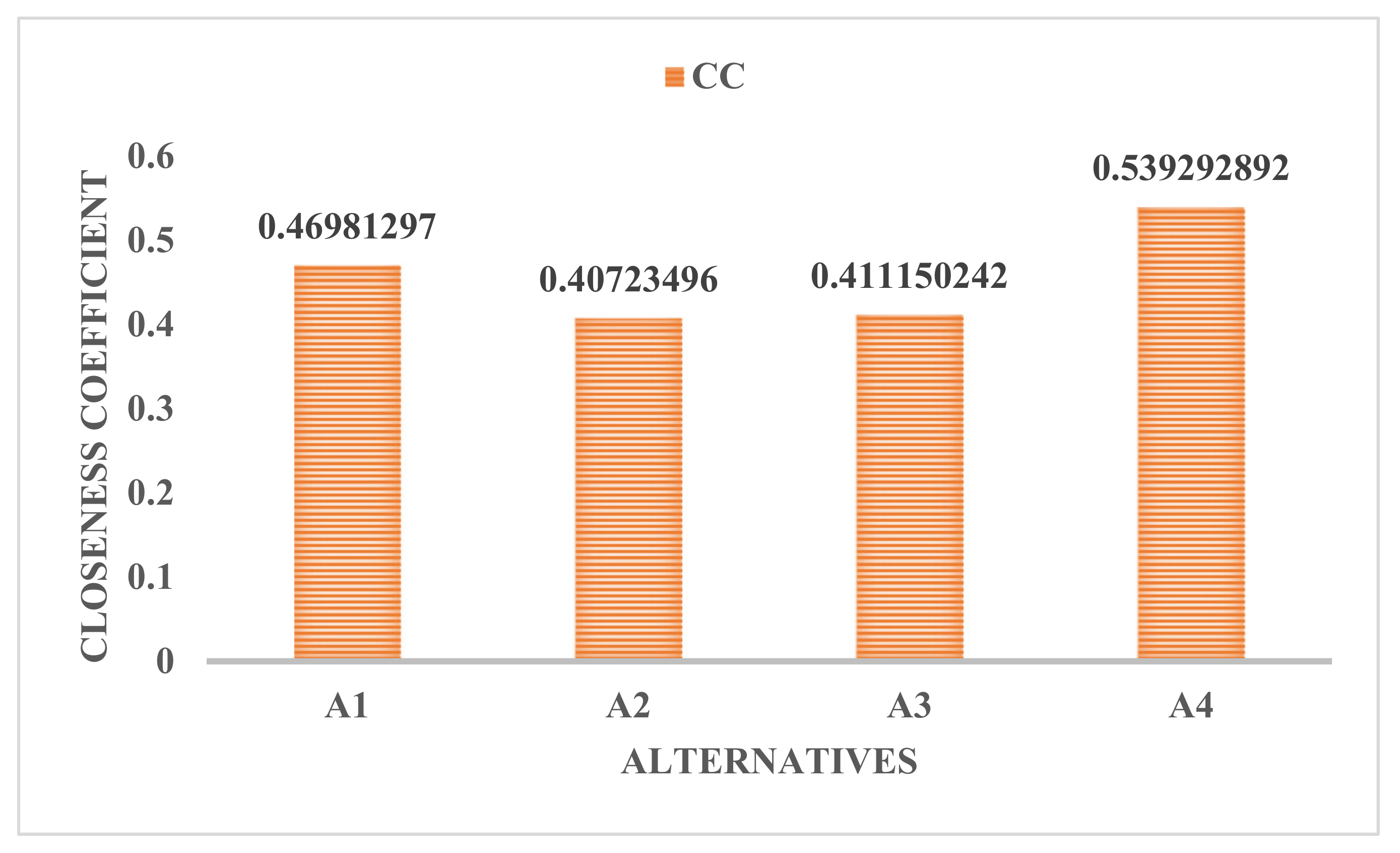

5.5. TOPSIS Ranking

The four redesigns were subjected to expert review based on data obtained throughout the process. After fuzzy TOPSIS was deployed, all four alternatives were ranked based on their CC. Redesign 4 was selected as it was the closest to FPIS and furthest from FNIS.

Figure 9 shows, to a great extent, the actual difference between the ratings for all the redesigns. They are all close and all possess their individual attributes, which contribute to their superiority, but Redesign 4 offers greater feasibility and hence was selected as the best design among the four alternatives.

Figure 9.

Closeness coefficients.

6. Implications

6.1. Theoretical Implications

In terms of theoretical contributions, this study has several significant implications. Most importantly, this study creates a framework for sustainable product development combining the FMEA, QFD, TRIZ, and fuzzy TOPSIS techniques. Manufacturing and product development continue to play a significant role in the socio-ecological issues and difficulties that our planet faces today. In order for products to contribute to sustainability, socio-ecological lifecycle consequences must not only be taken into account at the outset of the product invention process but also be kept as fundamental product criteria. Although there are many strategies, techniques, and resources available from research for the development of sustainable products, the industry adoption is still quite low. The execution of sustainable product development, the management of needs identification, and the dissemination of design requirements are the main areas of this study’s attention. The goal is to promote the enhancement of the engineering design requirements of management process design, encompassing activities and competencies.

6.2. Practical Implications

The findings of this study have important ramifications for industry practitioners and decision-makers. Depending on the resources, competencies, strategies, and needs of the business, innovation may involve a range of transformations. As a result, throughout the commercial exploitation of a variety of innovations, the open innovation process evolves and adapts to the needs of creativity as decided by management demands. In recent years, one of the primary strategic and operational objectives of manufacturers has been to improve the environmental performance of products and services. This is because a variety of stakeholders, such as the government, customers, societies, and business partners, have an influence. Evidently, based on many driving forces, including customer awareness, law, economic rewards, and competitive tactics, among others, different manufacturers execute their environmental policies for sustainable product development differently. According to theory, firms who include lifecycle thinking into their processes can generate sustainable products effectively. They can successfully reduce the environmental impact by monitoring the environmental hot spots throughout a product’s lifecycle. This is where ‘over featuring’ becomes a challenge. The term ‘over featuring’ is used to describe a variety of excessive product development practices, including scope creep, overspecification, and feature creep. Based on these presumptions, the current study defined and categorized a set of tendencies that can harm the success of an NPD process as ‘over featuring’, encompassing the fields of innovation management, research and development (R & D) management, engineering, and design [46,47,48,49,50]. One of the top 10 risks for new product development (NPD) failures is the development of new products and services beyond what is necessary to meet user wants, market demand, and company resources. OVF refers to a variety of situations that can arise at any stage of the NPD process, including during its ontogenesis, when a product or service is created beyond what is required by users, the market, plans, or strategies, in addition to what is practical given the company’s resources. OVF results in a pathological condition of the NPD process that manifests as a number of negative effects on the product usability and quality and the project performance. Thus far, many papers have addressed the implementation of sustainable product development while attempting to accommodate the constraints and demands. This paper aimed to specifically introduce sustainable product development into practice while simultaneously meeting customer requirements and translating them into measurable engineering metrics using an innovative model integrating ECQFD, TRIZ, and FMEA.

7. Conclusions

Over the past few decades, environmental sustainability has gained importance across a range of productive businesses. There is an increased awareness of the need to reduce harmful environmental effects. A term used to describe the concept of environmentally friendly economic growth is ‘sustainable development’. Its goal is to create a balance between socio-political, economic, and environmental sustainability. We are constantly driven by sustainable development to safeguard and enhance our natural resources by gradually changing how we develop and use new technology.

The developed framework for sustainable product development successfully integrates FMEA, ECQFD, TRIZ, and fuzzy TOPSIS. Critical zones of failure were identified using FMEA based on the RPN ranking, where frequent spills and internal leakage were ranked the highest. Design options were evaluated and shortlisted based on ECQFD and it was deduced that the weight and defects should be reduced, and the strength of the component should be increased. TRIZ was deployed to resolve contradictions between features during redesigning, which resulted in eight innovative solutions being obtained to solve all design contradictions for this particular case. The four feasible redesigns were subjected to sustainability analysis, which provided an overview of the environmental impact of the product throughout its lifetime, and fatigue life analysis, which examined the physical capability of the designs. Fuzzy TOPSIS was used to narrow down on the most suitable design, which resulted in Redesign 4 being chosen. This case study proves the feasibility of the proposed framework model, which includes multiple facets of sustainability to support innovative product development.

Design study can be carried out on various other case components to establish the validity of this methodology by deploying it in multiple facets of engineering such as software development, network topology, and microchip manufacturing to name a few. This research has succeeded in partially automating the framework by case-specific programming using multiple software packages. Further developments can be carried out to automate the entire process.

Author Contributions

Conceptualization & Computation A.Z.H., M.A.S. and M.A.B.; Funding acquisition, A.Z.H., M.A.S. and M.A.B.; Methodology, J.K. and S.A.R.; Validation, J.K. and S.A.R.; Writing—original draft, J.K. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to the Deanship for Research and Innovation, Ministry of Education in Saudi Arabia, for funding this research work through the project number IFPRC-022-135-2020 and King Abdulaziz University, DSR, Jeddah, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AFW | Aggregate Fuzzy Weights |

| AHP | Analytic Hierarchy Process |

| CAD | Computer Aided Design |

| CC | Closeness Coefficient |

| CO2e | Carbon Dioxide Emission |

| DFM | Design for Manufacture |

| ECQFD | Environment Conscious Quality Function Deployment |

| EM | Engineering Metrics |

| FMEA | Failure Modes and Effects Analysis |

| FNIS | Fuzzy Negative Ideal Solution |

| FPIS | Fuzzy Positive Ideal Solution |

| LCA | Life Cycle Analysis |

| MCDM | Multi Criteria Decision Making |

| MJ | Megajoules |

| NA | Not Applicable |

| PO4e | Phosphate Emission |

| PRV | Pressure Relief Valve |

| QFD | Quality Function Deployment |

| RPN | Risk Priority Number |

| SME | Subject Matter Experts |

| SO2e | Sulphur Dioxide Emission |

| TOPSIS | Technique for Order of Preference by Similarity to Ideal Solution |

| TRIZ | Teoriya Resheniya Izobretatelskikh Zadach (Russian)/ Theory of Inventive Problem Solving (English) |

| VOC | Voice of Customer |

Appendix A

Table A1.

Scaling table.

Table A1.

Scaling table.

| Rate | S | O | D |

|---|---|---|---|

| 1 | No | Almost never | Almost certain |

| 2 | Very slight | Remote | Very high |

| 3 | Slight | Very slight | High |

| 4 | Minor | Slight | Moderate high |

| 5 | Moderate | Low | Medium |

| 6 | Significant | Medium | Low |

| 7 | Major | Moderately high | Slight |

| 8 | Extreme | High | Very slight |

| 9 | Serious | Very high | Remote |

| 10 | Hazardous | Almost certain | Almost impossible |

Table A2.

ECQFD: Phase I.

Table A2.

ECQFD: Phase I.

| Voice of Customer | Customer Weights | Engineering Metrics (EM) | Physical Lifetime | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Weight | Temperature | Defects | Strength | Rate of Recycled Material | Number of Parts | Flow Rate | |||

| Cost efficiency | 9 | 3 | 1 | 9 | 3 | 1 | 3 | 1 | 9 |

| Ease of use | 3 | 9 | 3 | 3 | 3 | 1 | 9 | 3 | 1 |

| Safety | 9 | 9 | 3 | 3 | 9 | 1 | 3 | 3 | 3 |

| Reliability | 9 | 3 | 3 | 9 | 9 | 1 | 9 | 3 | 3 |

| Serviceability | 3 | 3 | 1 | 3 | 3 | 1 | 9 | 1 | 9 |

| Design of assembly | 1 | 9 | 1 | 3 | 9 | 3 | 9 | 3 | 3 |

| Product lifetime | 3 | 9 | 3 | 3 | 9 | 1 | 1 | 3 | 9 |

| Raw score | 207 | 85 | 219 | 243 | 39 | 201 | 87 | 195 | |

| Relative weight | 0.162 | 0.067 | 0.172 | 0.190 | 0.031 | 0.158 | 0.068 | 0.153 | |

| Rank | 3 | 7 | 2 | 1 | 8 | 4 | 6 | 5 | |

Table A3.

ECQFD: Phase II.

Table A3.

ECQFD: Phase II.

| Engineering Metrics | Phase I Relative Weight | Components Characteristics | ||||||

|---|---|---|---|---|---|---|---|---|

| Big Steel Ball | Valve | Spring | Locating Cap | Small Steel Ball | Banjo | Copper Washer | ||

| Weight | 0.162 | 3 | 1 | 3 | 1 | 9 | 1 | 9 |

| Temperature | 0.067 | 9 | 1 | 9 | 3 | 3 | 3 | 3 |

| Defects | 0.172 | 3 | 1 | 1 | 9 | 1 | 9 | 3 |

| Strength | 0.190 | 3 | 1 | 9 | 1 | 9 | 9 | 1 |

| Rate of recycled material | 0.031 | 3 | 1 | 9 | 9 | 3 | 1 | 9 |

| Number of parts | 0.158 | 1 | 9 | 1 | 1 | 1 | 1 | 1 |

| Flow rate | 0.068 | 1 | 1 | 9 | 1 | 9 | 3 | 3 |

| Physical lifetime | 0.153 | 9 | 3 | 3 | 3 | 3 | 9 | 9 |

| Raw score | 3.865 | 2.566 | 4.476 | 3.056 | 4.867 | 5.389 | 4.378 | |

| Relative weight | 0.135 | 0.090 | 0.157 | 0.107 | 0.170 | 0.188 | 0.153 | |

| Rank | 5 | 7 | 3 | 6 | 2 | 1 | 4 | |

Table A4.

ECQFD: Phase III Option I.

Table A4.

ECQFD: Phase III Option I.

| Engineering Metrics | Phase I Relative Weight | Component Characteristics | Score | EM Improvement Rating | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Big Steel Ball | Valve | Spring | Locating Cap | Small Steel Ball | Banjo | Copper Washer | ||||

| Weight | 0.162 | 3 | 1 | 3 | 1 | 9 | 1 | 9 | 27 | 0.162 |

| Temperature | 0.067 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Defects | 0.172 | 3 | 1 | 1 | 9 | 1 | 9 | 3 | 27 | 0.172 |

| Strength | 0.190 | 3 | 1 | 9 | 1 | 9 | 9 | 1 | 33 | 0.19 |

| Rate of recycled material | 0.031 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Number of parts | 0.158 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Flow rate | 0.068 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Physical lifetime | 0.153 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Table A5.

ECQFD: Phase III Option II.

Table A5.

ECQFD: Phase III Option II.

| Engineering Metrics | Phase I Relative Weight | Component Characteristics | Score | EM Improvement Rating | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Big Steel Ball | Valve | Spring | Locating Cap | Small Steel Ball | Banjo | Copper Washer | ||||

| Weight | 0.162 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Temperature | 0.067 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Defects | 0.172 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Strength | 0.190 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Rate of recycled material | 0.031 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Number of parts | 0.158 | 1 | 9 | 1 | 1 | 1 | 1 | 1 | 15 | 0.158 |

| Flow rate | 0.068 | 1 | 1 | 9 | 1 | 9 | 3 | 3 | 27 | 0.068 |

| Physical lifetime | 0.153 | 9 | 3 | 3 | 3 | 3 | 9 | 9 | 39 | 0.153 |

Table A6.

TRIZ factors.

Table A6.

TRIZ factors.

| 1: Weight of moving object | 14: Strength | 27: Reliability |

| 2: Weight of stationary | 15: Durability of moving obj. | 28: Measurement accuracy |

| 3: Length of moving object | 16: Durability of non-moving obj. | 29: Manufacturing precision |

| 4: Length of stationary | 17: Temperature | 30: Object-affected harmful |

| 5: Area of moving object | 18: Illumination intensity | 31: Object-generated harmful |

| 6: Area of stationary | 19: Use of energy by moving | 32: Ease of manufacture |

| 7: Volume of moving object | 20: Use of energy by stationary | 33: Ease of operation |

| 8: Volume of stationary | 21: Power | 34: Ease of repair |

| 9: Speed | 22: Loss of energy | 35: Adaptability or versatility |

| 10: Force (intensity) | 23: Loss of substance | 36: Device complexity |

| 11: Stress or pressure | 24: Loss of information | 37: Difficulty of detecting |

| 12: Shape | 25: Loss of time | 38: Extent of automation |

| 13: Stability of the object | 26: Quantity of substance | 39: Productivity |

Table A7.

Linguistic ratings chart.

Table A7.

Linguistic ratings chart.

| Linguistic Term for Criteria Rating | Linguistic Term for Alternative Rating | ||

|---|---|---|---|

| Linguistic Term | Membership Function | Linguistic Term | Membership Function |

| NI | (1, 1, 3) | VL | (1, 1, 3) |

| LI | (1, 3, 5) | L | (1, 3, 5) |

| FI | (3, 5, 7) | M | (3, 5, 7) |

| I | (5, 7, 9) | H | (5, 7, 9) |

| VI | (7, 9, 9) | VH | (7, 9, 9) |

Table A8.

Linguistic ratings for criteria.

Table A8.

Linguistic ratings for criteria.

| Criteria | D1 | D2 | D3 | |

|---|---|---|---|---|

| C1 | Weight | I | I | VI |

| C2 | Sustainability | VI | FI | FI |

| C3 | Product lifetime | VI | I | VI |

| C4 | Manufacturability | NI | VI | LI |

| C5 | Cost effectiveness | LI | I | VI |

| C6 | Ingenuity | I | VI | LI |

Table A9.

Linguistic ratings for alternatives.

Table A9.

Linguistic ratings for alternatives.

| Alternatives | C1 | C2 | C3 | C4 | C5 | C6 | |

|---|---|---|---|---|---|---|---|

| A1 | Redesign 1 | VH | VH | L | L | M | H |

| A2 | Redesign 2 | H | M | VL | H | M | L |

| A3 | Redesign 3 | L | L | H | M | L | H |

| A4 | Redesign 4 | M | H | VH | H | H | VH |

Table A10.

Aggregate fuzzy weights for alternatives.

Table A10.

Aggregate fuzzy weights for alternatives.

| Alternatives | C1 | C2 | C3 | C4 | C5 | C6 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | Redesign 1 | 7 | 9 | 9 | 7 | 9 | 9 | 1 | 3 | 5 | 1 | 3 | 5 | 3 | 5 | 7 | 5 | 7 | 9 |

| A2 | Redesign 2 | 5 | 7 | 9 | 3 | 5 | 7 | 1 | 1 | 3 | 5 | 7 | 9 | 3 | 5 | 7 | 1 | 3 | 5 |

| A3 | Redesign 3 | 1 | 3 | 5 | 1 | 3 | 5 | 5 | 7 | 9 | 3 | 5 | 7 | 1 | 3 | 5 | 5 | 7 | 9 |

| A4 | Redesign 4 | 3 | 5 | 7 | 5 | 7 | 9 | 7 | 9 | 9 | 5 | 7 | 9 | 5 | 7 | 9 | 7 | 9 | 9 |

Table A11.

Normalized fuzzy matrix.

Table A11.

Normalized fuzzy matrix.

| C1 | C2 | C3 | C4 | C5 | C6 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.78 | 1 | 1 | 0.78 | 1 | 1 | 0.11 | 0.33 | 0.56 | 0.11 | 0.33 | 0.56 | 0.33 | 0.56 | 0.78 | 0.56 | 0.78 | 1 |

| A2 | 0.56 | 0.78 | 1 | 0.33 | 0.56 | 0.78 | 0.11 | 0.11 | 0.33 | 0.56 | 0.78 | 1 | 0.33 | 0.56 | 0.78 | 0.11 | 0.33 | 0.56 |

| A3 | 0.11 | 0.33 | 0.56 | 0.11 | 0.33 | 0.56 | 0.56 | 0.78 | 1 | 0.33 | 0.56 | 0.78 | 0.11 | 0.33 | 0.56 | 0.56 | 0.78 | 1 |

| A4 | 0.33 | 0.56 | 0.78 | 0.56 | 0.78 | 1 | 0.78 | 1 | 1 | 0.56 | 0.78 | 1 | 0.56 | 0.78 | 1 | 0.78 | 1 | 1 |

Table A12.

Weighted normalized fuzzy matrix.

Table A12.

Weighted normalized fuzzy matrix.

| C1 | C2 | C3 | C4 | C5 | C6 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 3.9 | 7.7 | 9 | 2.3 | 6.3 | 9 | 0.6 | 2.8 | 5 | 0.1 | 1.4 | 5 | 0.3 | 3.5 | 7 | 0.6 | 4.9 | 9 |

| A2 | 2.8 | 6 | 9 | 1 | 3.5 | 7 | 0.6 | 0.9 | 3 | 0.6 | 3.4 | 9 | 0.3 | 3.5 | 7 | 0.1 | 2.1 | 5 |

| A3 | 0.6 | 2.6 | 5 | 0.3 | 2.1 | 5 | 2.8 | 6.5 | 9 | 0.3 | 2.4 | 7 | 0.1 | 2.1 | 5 | 0.6 | 4.9 | 9 |

| A4 | 1.7 | 4.3 | 7 | 1.7 | 4.9 | 9 | 3.9 | 8.3 | 9 | 0.6 | 3.4 | 9 | 0.6 | 4.9 | 9 | 0.8 | 6.3 | 9 |

| FPIS | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 9 |

| FNIS | 0.6 | 0.6 | 0.6 | 0.3 | 0.3 | 0.3 | 0.6 | 0.6 | 0.6 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

Table A13.

Distance matrix for d+.

Table A13.

Distance matrix for d+.

| Distance | C1 | C2 | C3 | C4 | C5 | C6 | d+ |

|---|---|---|---|---|---|---|---|

| d (A1, A+) | 3.05 | 4.146 | 6.481 | 7.12 | 6.032 | 5.413 | 32.24 |

| d (A2, A+) | 3.997 | 5.717 | 7.583 | 5.86 | 6.032 | 6.891 | 36.08 |

| d (A3, A+) | 6.553 | 6.796 | 3.876 | 6.392 | 6.891 | 5.413 | 35.92 |

| d (A4, A+) | 5.172 | 4.843 | 2.976 | 5.86 | 5.413 | 4.991 | 29.25 |

Table A14.

Distance matrix for d−.

Table A14.

Distance matrix for d−.

| Distance | C1 | C2 | C3 | C4 | C5 | C6 | d− |

|---|---|---|---|---|---|---|---|

| d (A1, A−) | 6.658 | 6.194 | 2.869 | 2.926 | 4.439 | 5.842 | 28.93 |

| d (A2, A−) | 5.93 | 4.283 | 1.427 | 5.472 | 4.439 | 3.05 | 24.6 |

| d (A3, A−) | 2.814 | 2.883 | 6.093 | 4.194 | 3.05 | 5.842 | 24.88 |

| d (A4, A−) | 4.339 | 5.715 | 6.902 | 5.472 | 5.842 | 6.276 | 34.55 |

References

- Marzi, G. On the nature, origins and outcomes of Over Featuring in the new product development process. J. Eng. Technol. Manag. 2022, 64, 101685. [Google Scholar] [CrossRef]

- Marzi, G. Uncertainty-Driven Innovation: Managing the New Product Development Processes in an Unpredictable Environment; Palgrave Macmillan: Cham, Switzerland, 2022; ISBN 978-3-030-99533-1/978-3-030-99534-8. [Google Scholar] [CrossRef]

- Hu, C.-M.; Lin, C.-A.; Chang, C.-H.; Cheng, Y.-J.; Tseng, P.-Y. Integration with QFDs, TRIZ and FMEA for Control Valve Design. Adv. Mater. Res. 2014, 1021, 167–180. [Google Scholar] [CrossRef]

- McDermott, R.E.; Mikulak, R.J.; Beauregard, M.R. The Basics of FMEA, 2nd ed.; Productivity Press: Tunceli, Turkey, 2008; ISBN 9781563273773. [Google Scholar]

- Gandhi, O.P.; Agrawal, V.P. FMEA-A digraph and matrix approach. Reliab. Eng. Syst. Saf. 1992, 35, 147–158. [Google Scholar] [CrossRef]

- Hippel, J. Predictive Failure Analysis: How to use the TRIZ in Reverse. 2006. Available online: www.triz-journal.com/archives/2006/09/06.pdf (accessed on 5 August 2022).

- Cohen, L. Quality Function Deployment: How to Make QFD Work for You; Addison Wasley Publishing Company: Boston, MA, USA, 1996. [Google Scholar]

- Clausing, D.; Pugh, S. Enhanced Quality Function Deployment; Design and Productivity International Conference: Honolulu, HI, USA, 2011. [Google Scholar]

- Clark, K.B.; Wheelwright, S.C. Managing New Product and Process Development: Text and Cases; Harvard Business School: Boston, MA, USA, 1992. [Google Scholar]

- Liu, S.; Shi, D.; Zhang, Y. A Planning Approach of Engineering Characteristics Based on QFD-TRIZ Integrated. In Growth and Development of Computer-Aided Innovation; Springer: Berlin/Heidelberg, Germany, 2009; pp. 117–126. [Google Scholar]

- Lin, M.-C.; Wang, C.-C.; Chen, M.-S.; Chang, C.A. Using AHP and TOPSIS approaches in customer-driven product design process. Comput. Ind. 2008, 59, 17–31. [Google Scholar] [CrossRef]

- Kwong, C.K.; Tam, S.M. Case-based reasoning approach to concurrent design of low power transformers. J. Mater. Process. Technol. 2002, 128, 136–141. [Google Scholar] [CrossRef]

- Schöggl, J.-P.; Baumgartner, R.J.; Hofer, D. Improving sustainability performance in early phases of product design: A checklist for sustainable product development tested in the automotive industry. J. Clean. Prod. 2017, 140, 1602–1617. [Google Scholar] [CrossRef]

- Chang, D.; Lee, C.K.M.; Chen, C.-H. Review of life cycle assessment towards sustainable product development. J. Clean. Prod. 2014, 83, 48–60. [Google Scholar] [CrossRef]

- Buchert, T.; Neugebauer, S.; Schenker, S.; Lindow, K.; Stark, R. Multi-criteria decision making as a tool for sustainable product development–Benefits and obstacles. Procedia CIRP 2015, 26, 70–75. [Google Scholar] [CrossRef]

- Paciarotti, C.; Mazzuto, G.; D′Ettorre, D. A revised FMEA application to the quality control management. Int. J. Qual. Reliab. Manag. 2014, 31, 788–810. [Google Scholar] [CrossRef]

- Chong, K.E.; Ng, K.C.; Goh, G.G.G. Improving Overall Equipment Effectiveness (OEE) through Integration of Maintenance Failure Mode and Effect Analysis (Maintenance-FMEA) in a Semiconductor Manufacturer: A Case Study. In Proceedings of the 2015 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 6–9 December 2015; pp. 1427–1431. [Google Scholar]

- De Aguiar, D.C.; Salomon, V.A.P.; Mello, C.H.P. An ISO 9001 based approach for the implementation of process FMEA in the Brazilian automotive industry. Int. J. Qual. Reliab. Manag. 2015, 32, 589–602. [Google Scholar] [CrossRef]

- Vinodh, S.; Rathod, G. Application of ECQFD for enabling environmentally conscious design and sustainable development in an electric vehicle. Clean Technol. Environ. Policy 2011, 13, 381–396. [Google Scholar] [CrossRef]

- Suef, M.; Suparno, S.; Singgih, M.L. Categorizing product attributes efficiently in QFD-Kano: A case analysis in telecommunication. TQM J. 2017, 29, 512–527. [Google Scholar] [CrossRef]

- Scherrer, M.; Deflorin, P. Linking QFD and the manufacturing network strategy: Integrating the site and network perspectives. Int. J. Oper. Prod. Manag. 2017, 37, 226–255. [Google Scholar] [CrossRef]

- Kuo, T.-C.; Wu, H.-H.; Shieh, J.-I. Integration of environmental considerations in quality function deployment by using fuzzy logic. Expert Syst. Appl. 2009, 36, 7148–7156. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, R.; Jiang, P.; Dai, J. Innovative Design of the Seal Structure of Butterfly Valve Based on TRIZ. In Intelligent Strategies in Product Design, Manufacturing, and Management; Knowledge Enterprise: Arlington, VA, USA, 2006; pp. 450–456. [Google Scholar]

- Rahim, Z.A.; Sheng, I.L.S.; Nooh, A.B. TRIZ methodology for applied chemical engineering: A case study of new product development. Chem. Eng. Res. Des. 2015, 103, 11–24. [Google Scholar] [CrossRef]

- Wang, F.-K.; Yeh, C.-T.; Chu, T.-P. Using the design for Six Sigma approach with TRIZ for new product development. Comput. Ind. Eng. 2016, 98, 522–530. [Google Scholar] [CrossRef]

- Yamashina, H.; Ito, T.; Kawada, H. Innovative product development process by integrating QFD and TRIZ. Int. J. Prod. Res. 2002, 40, 1031–1050. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S. Prioritizing drivers for green manufacturing: Environmental, social and economic perspectives. Procedia CIRP 2014, 15, 135–140. [Google Scholar] [CrossRef]

- Sudiatmika, I.B.K.; Jimbara, R.; Setyohadi, D.B. Determination of assistance to the poor by integrating fuzzy AHP and TOPSIS models:(Case study Bali Province). In Proceedings of the 2017 1st International Conference on Informatics and Computational Sciences (ICICoS), Semarang, Indonesia, 15–16 November 2017. [Google Scholar]

- Wailoni, X.; Swain, S.; Lafanama, S.; Muduli, K. Analytical Approach for Prioritizing Waste Management Practices: Implications for Sustainable Development Exercises in Healthcare Sector. Int. J. Soc. Ecol. Sustain. Dev. 2022, 13, 1–12. [Google Scholar] [CrossRef]

- Junior, F.R.L.; Osiro, L.; Carpinetti, L.C.R. A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Muduli, K.; Barve, A. Analysis of critical activities for GSCM implementation in mining supply chains in India using fuzzy analytical hierarchy process. Int. J. Bus. Excell. 2015, 8, 767–797. [Google Scholar] [CrossRef]

- Guo, S.; Zhao, H. Optimal site selection of electric vehicle charging station by using fuzzy TOPSIS based on sustainability perspective. Appl. Energy 2015, 158, 390–402. [Google Scholar] [CrossRef]

- Ray, M.; Ray, M.; Muduli, K.; Banaitis, A.; Kumar, A. Integrated Approach of Fuzzy Multi-Attribute Decision Making and Data Mining for Customer Segmentation; Technická Univerzita Liberci: Liberec, Czech, 2021; Volume 4, pp. 174–188. Available online: https://otik.uk.zcu.cz/handle/11025/46502 (accessed on 1 August 2022). [CrossRef]

- Ginn, D.M.; Jones, D.V.; Rahnejat, H.; Zairi, M. The “qfd/fmea interface”. Eur. J. Innov. Manag. 1998, 1, 7–20. [Google Scholar] [CrossRef]

- Rathod, G.; Vinodh, S.; Madhyasta, U.R. Integration of ECQFD and LCA for enabling sustainable product design in an electric vehicle manufacturing organisation. Int. J. Sustain. Eng. 2011, 4, 202–214. [Google Scholar] [CrossRef]

- Vinodh, S.; Kamala, V.; Jayakrishna, K. ECQFD-TRIZ-AHP integrated approach for innovative and sustainable product development. Appl. Math. Model. 2013, 38, 2758–2770. [Google Scholar] [CrossRef]

- Ilevbare, I.M.; Probert, D.; Phaal, R. A review of TRIZ, and its benefits and challenges in practice. Technovation 2013, 33, 30–37. [Google Scholar] [CrossRef]

- Bao, S.; Li, Z.; Luo, L.; Gao, Z. Reliability Analysis of Spring Operated Pressure Relief Valve. In Proceedings of the ASME 2013 Pressure Vessels and Piping Conference, Paris, France, 14–18 July 2013; Volume 1A: Codes and Standards. V01AT01A069. ASME: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Fernandes, P.T.; Canciglieri, O. Sustainable Product Design: The Development of a Conceptual Model. Appl. Mech. Mater. 2014, 518, 335–342. [Google Scholar] [CrossRef]

- Anderson, T.R.; Hawkins, E.; Jones, P.D. CO2, the greenhouse effect and global warming: From the pioneering work of Arrhenius and Callendar to today’s Earth System Models. Endeavour 2016, 40, 178–187. [Google Scholar] [CrossRef]

- Coady, D.; Gillingham, R.; Ossowski, R.; Piotrowski, J.; Tareq, S.; Tyson, J. Petroleum Product Subsidies: Costly, Inequitable, and Rising; International Monetary Fund: Washington, DC, USA, 2010. [Google Scholar]

- Kumar, S. Acid Rain-The Major Cause of Pollution: Its Causes, Effects. Int. J. Appl. Chem. 2017, 13, 53–58. [Google Scholar]

- Rosen, M.A.; Kishawy, H.A. Sustainable manufacturing and design: Concepts, practices and needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

- Riddhish, T.; Dave, R.; Parsana, T. A Case Study: A Process FMEA Tool to Enhance Quality and Efficiency of the Bearing Manufacturing Industry. Sch. J. Eng. Technol. 2015, 3, 413–418. [Google Scholar]

- Karabay, S.; Baynal, K.; Igdeli, C. Detecting Groan Sources in Drum Brakes of Commercial Vehicles by TVA-FMEA: A Case Study. Stroj. Vestn. -J. Mech. Eng. 2013, 59, 375–386. [Google Scholar] [CrossRef]

- Francia, D.; Caligiana, G.; Liverani, A.; Frizziero, L.; Donnici, G. PrinterCAD: A QFD and TRIZ integrated design solution for large size open moulding manufacturing. Int. J. Interact. Des. Manuf. 2018, 12, 81–94. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Tseng, M.L.; Wong, W.P. Sustainable product design and development: A review of tools, applications and research prospects. Resour. Conserv. Recycl. 2018, 132, 49–61. [Google Scholar] [CrossRef]

- Watz, M.; Hallstedt, S.I. Towards sustainable product development–Insights from testing and evaluating a profile model for management of sustainability integration into design requirements. J. Clean. Prod. 2022, 346, 131000. [Google Scholar] [CrossRef]

- Bigolin, M.; Danilevicz, Â.D.M.F.; Weiss, M.A.; Silva Filho, L.C.P. Sustainable New Product Development: A decision-making tool for the construction industry. Int. J. Sustain. Eng. 2021, 14, 618–629. [Google Scholar] [CrossRef]

- Vinodh, S.; Jayakrishna, K. Development of integrated ECQFD, LCA and sustainable analysis model: A case study in an automotive component manufacturing organization. J. Eng. Des. Technol. 2014, 12, 102–127. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).