Matchmaking the Emerging Demand and Supply Need in the Maritime Supply Chain Domain: A System Design Framework

Abstract

1. Introduction

2. Materials and Methods

3. The System Design Framework

3.1. Actors within the Maritime Freight Transportation Process

3.2. Research Interviews

3.3. Emerging Needs

- Authentication/authorisation processes,

- The availability of actor profiles (including certification requirements, e.g., freight forwarders must meet ISO 9000 quality certification standards),

- The insertion of cargo details and transport characteristics,

- Features of the schedule,

- Capacity and cost details,

- The availability of transport options ranking,

- Price requests/quotations,

- Messaging capabilities,

- Order confirmation and capacity updates,

- Order editing and route recalculations,

- The provision of alternative transport modes and associated costs,

- The display of route characteristics (timing, stops, costs, etc.),

- Instant communication channels between shippers,

- Carriers and freight forwarders,

- The collection of datasets in a specific and unified format,

- The reporting of order details and automated invoicing.

3.4. Identification of System’s Scenarios

3.5. Elicitation and Prioritasion of Requirements

- Must have: Requirements labelled as MUST are considered high-priority items or key features. If even one MUST requirement is not included, the system development should be considered a failure.

- Should have: SHOULD requirements can add value to the system and make it more appealing and successful, and they are also considered important and of a high value to the user. However, the system can be launched without them.

- Could have: requirements described as COULD are desirable but not necessary and could improve the user experience or user satisfaction These will typically be included if time and resources permit.

- Won’t have: requirements labelled as Won’t have, have been described by the system actors as the least critical.

3.6. Modelling Diagrams

- An EPC diagram starts and ends with at least one event.

- The alternation of events and functions can only be interrupted by the use of logical connectors.

- Events and functions have only one input and one output.

- The creation of different paths (branches) and their reunification into one process is performed only by the use of logical connectors.

- Many events, combined with each other, can trigger a function only with the use of a logical connector.

- Logical connectors have either one input and many outputs or many inputs and one output.

- The logical connectors determine the permissible path of the process after a decision.

- The decision-making functions are always followed by a logical connector.

- Reconnecting a process that has followed different paths is conducted by using the same logical connector as the one responsible for its initial separation.

- Decisions are made only by functions.

- The use of logical connectors OR and XOR after an event is prohibited.

- The events after a logical connector shows the possible results of a decision.

- Any number of distinct branches is allowed in the branches.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Notteboom, T.; Pallis, A.; Rodrigue, J.-P. Port Economics, Management and Policy; Routledge: London, UK, 2022. [Google Scholar] [CrossRef]

- Arduino, G.; Carrillo Murillo, D.G. Dynamic Role of Actors in Freight Transport and Logistics. In Proceedings of the Società Italiana di Economia dei Trasporti e della Logistica—XII Riunione Scientifica; SIET: Rome, Italy, 18 June 2010; pp. 1–15. [Google Scholar]

- Freight Transportation and Distribution: Their Difference and Importance. Available online: https://corlettexpress.com/freight-transportation-and-distribution-their-difference-and-importance/ (accessed on 23 August 2022).

- Dong, B.; Christiansen, M.; Fagerholt, K.; Chandra, S. Design of a Sustainable Maritime Multi-Modal Distribution Network—Case Study from Automotive Logistics. Transp. Res. Part E Logist. Transp. Rev. 2020, 143, 102086. [Google Scholar] [CrossRef]

- Rodrigue, J.-P. The Geography of Transport Systems, 5th ed.; Routledge: London, UK, 2020; Volume 1, pp. 1–480. [Google Scholar]

- Common Transport Policy: Overview, Fact Sheets on the European Union, European Parliament. Available online: https://www.europarl.europa.eu/factsheets/en/sheet/123/common-transport-policy-overview (accessed on 23 August 2022).

- Tavasszy, L.; Reis, V. Chapter 8—Appraisal of freight projects and policies. In New Methods, Reflections and Application Domains in Transport Appraisal, 1st ed.; Mouter, N., Ed.; CA Elsevier: San Diego, CA, USA, 2010; Volume 1, pp. 205–233. [Google Scholar] [CrossRef]

- Rodrigue, J.-P.; Browne, M.; Knowles, R.; Shaw, J.; Docherty, I. Chapter 10 International Maritime Freight Transport and Logistics. In Transport Geographies: An Introduction; Knowles, R., Shaw, J., Docherty, I., Eds.; Blackwell Publishing: Hoboken, NJ, USA, 2008; Volume 1, pp. 1–22. [Google Scholar]

- Ocean Shipping Worldwide-Statistics & Facts, Statista. Available online: https://www.statista.com/topics/1728/ocean-shipping/ (accessed on 23 August 2022).

- Kim, J.-H. Studies on Supply and Demand Paradox in Shipping Market. Int. J. Ind. Distrib. Bus. 2019, 10, 19–27. [Google Scholar] [CrossRef]

- Romano, A.; Yang, Z. Decarbonisation of Shipping: A State of the Art Survey for 2000–2020. Ocean Coast Manag. 2021, 214, 105936. [Google Scholar] [CrossRef]

- Psaraftis, H.N. Shipping Decarbonization in the Aftermath of MEPC 76. Clean. Logist. Supply Chain 2021, 1, 100008. [Google Scholar] [CrossRef]

- Digital Ecosystems: A Data-Driven Approach to Decarbonizing Supply Chains. Available online: https://hbr.org/sponsored/2022/06/digital-ecosystems-a-data-driven-approach-to-decarbonizing-supply-chains (accessed on 23 August 2022).

- How Digitalization Acts as a Driver of Decarbonization, EY–Switzerland. Available online: https://www.ey.com/en_ch/decarbonization/how-digitization-acts-as-a-driver-of-decarbonization (accessed on 23 August 2022).

- Lun, Y.H.V.; Lai, K.H.; Cheng, T.C.E. Shipping and Logistics Management; Springer: London, UK, 2010; pp. 1–238. [Google Scholar] [CrossRef]

- Jugovic, A.; Komadina, N.; Hadzic, R.A. Factors influencing the formation of freight rates on maritime shipping markets. Sci. J. Marit. Res. 2015, 29, 23–29. [Google Scholar]

- Review of Maritime Transport. Available online: https://unctad.org/system/files/official-document/rmt2021_en_0.pdf (accessed on 23 August 2022).

- Papoutsidakis, M.; Sfyroera, E.; Alafodimos, N. Information Systems (ERP) for Shipping Companies. J. Multidiscip. Eng. Sci. Technol. (JMEST) 2019, 6, 2458–9403. [Google Scholar]

- Russo, F.; Musolino, G. The Role of Emerging ICT in the Ports: Increasing Utilities According to Shared Decisions. Front. Future Transp. 2021, 2, 72281. [Google Scholar] [CrossRef]

- Use of Big Data in the Maritime Industry. Available online: https://www.patersonsimons.com/wp-content/uploads/2018/06/TMS_SmartPort_InsightBee_Report-to-GUIDE_01.02.18.pdf (accessed on 23 August 2022).

- Zeng, F.; Chan, H.K.; Pawar, K. The Adoption of Open Platform for Container Bookings in the Maritime Supply Chain. Transp. Res. E Logist. Transp. Rev. 2020, 141, 102019. [Google Scholar] [CrossRef]

- Tijan, E.; Jović, M.; Aksentijević, S.; Pucihar, A. Digital Transformation in the Maritime Transport Sector. Technol. Forecast. Soc. Chang. 2021, 170, 120879. [Google Scholar] [CrossRef]

- Ichimura, Y.; Dalaklis, D.; Kitada, M.; Christodoulou, A. Shipping in the Era of Digitalization: Mapping the Future Strategic Plans of Major Maritime Commercial Actors. Digit. Bus. 2022, 2, 100022. [Google Scholar] [CrossRef]

- 4.0 System Design Processes-NASA. Website. Available online: https://www.nasa.gov/seh/4-design-process (accessed on 19 October 2022).

- Shawren, S.; Kotze, P. An Overview of Systems Design and Development Methodologies with Regard to the Involvement of Users and Other Stakeholders. In Proceedings of the 2003 Annual Research Conference of the South African Institute of Computer Scientists and Information Technologists on Enablement through Technology SAICSIT, Johannesburg, South Africa, 17–19 September 2003; pp. 37–47. [Google Scholar]

- Hosono, S.; Hasegawa, M.; Hara, T.; Shimomura, Y.; Arai, T. A Methodology of Persona-Centric Service Design. In Proceedings of the 19th CIRP Design Conference, Nantes, France, 19–21 April 2010; pp. 277–292. [Google Scholar]

- Rosson, M.B.; Carroll, J.M. Usability Engineering: Scenario-Based Development of Human-Computer Interaction; Morgan Kaufmann: Burlington, MA, USA, 2002; p. 422. [Google Scholar]

- McKay, E.N. UI Is Communication : How to Design Intuitive, User Centered Interfaces by Focusing on Effective Communication, 1st ed.; Morgan Kaufmann: Burlington, MA, USA, 2013; pp. 1–378. [Google Scholar]

- Wazlawick, R.S. Object-Oriented Analysis and Design for Information Systems: Modeling with UML, OCL, and IFML, 1st ed.; Morgan Kaufmann: Burlington, MA, USA, 2014; pp. 1–376. [Google Scholar]

- Holbrook, H. A Scenario-Based Methodology for Conducting Requirements Elicitation. ACM SIGSOFT Softw. Eng. Notes 1990, 15, 95–104. [Google Scholar] [CrossRef]

- Berander, P.; Andrews, A. Requirements Prioritization. Eng. Manag. Softw. Requir. 2005, 69–94. [Google Scholar] [CrossRef]

- Bukhsh, F.A.; Bukhsh, Z.A.; Daneva, M. A Systematic Literature Review on Requirement Prioritization Techniques and Their Empirical Evaluation. Comput. Stand. Interfaces 2020, 69, 103389. [Google Scholar] [CrossRef]

- Khan, J.A.; Rehman, I.U.; Khan, Y.H.; Khan, I.J.; Rashid, S. Modern Education and Computer Science. Mod. Educ. Comput. Sci. 2015, 11, 53–59. [Google Scholar] [CrossRef]

- Santos, P.S.; Almeida, J.P.A.; Guizzardi, G. An Ontology-Based Semantic Foundation for ARIS EPCs. In Proceedings of the ACM Symposium on Applied Computing, Sierre, Switzerland, 22–26 March 2010; pp. 124–130. [Google Scholar] [CrossRef]

- Scheer, A.-W. ARIS—Business Process Modeling, 3rd ed.; Springer: Heidelberg, Germany, 2000; pp. 1–239. [Google Scholar]

- Mykoo, W.-A. The Role and Responsibility of Minor Stakeholders in the Elimination of Substandard Shipping: A Critical Analysis. Master’s Thesis, World Maritime University, Malmo, Sweden, 2003. [Google Scholar]

- How Does a Shipping Process Look Like? Available online: https://globalmaritimehub.com/what-is-the-difference-between-a-nvocc-and-a-freight-forwarder.html (accessed on 23 August 2022).

- Tezuka, K. Rationale for Utilizing 3PL in Supply Chain Management: A Shippers’ Economic Perspective. IATSS Res. 2011, 35, 24–29. [Google Scholar] [CrossRef][Green Version]

- Stopford, M. Maritime Economics, 3rd ed.; Routledge: London, UK, 2018; pp. 1–840. [Google Scholar]

- Schramm, H.-J. Freight Forwarder’s Intermediary Role in Multimodal Transport Chains, 1st ed.; Springer: Heidelberg, Germany, 2012; pp. 1–380. [Google Scholar]

- Olesen, T.R. Value Creation in the Maritime Chain of Transportation: The Role of Carriers, Ports and Third Parties in Liner and Bulk Shipping, 1st ed.; CBS Maritime: Copenhagen, Denmark, 2015; pp. 1–39. [Google Scholar]

- Deloitte 2019. Digitalization in Freight Forwarding–Beyond the Platform Hype. Available online: https://www2.deloitte.com/content/dam/Deloitte/de/Documents/consumer-business/Deloitte_%20Digitalization%20in%20freight%20forwarding_PoV.pdf (accessed on 23 August 2022).

- Port Technology, Digital Freight Forwarding: Becoming a Freight Forwarder for the 21st Century. Available online: https://wpassets.porttechnology.org/wp-content/uploads/2019/05/25184830/FAST.pdf (accessed on 23 August 2022).

- Digital Freight Communications Management: Tips for Success. Available online: https://www.cargologik.com/digital-freight-communications/ (accessed on 23 August 2022).

- Homepage-CLUSTERS 2.0. Available online: https://www.clusters20.eu/ (accessed on 23 August 2022).

- Cargostream Website. Available online: http://www.cargostream.net/ (accessed on 23 August 2022).

- MixMoveMatch Client Case Website. Available online: https://www.syone.com/media/client-cases-mix-move-match (accessed on 23 August 2022).

- AEOLIX Website. Available online: https://aeolix.eu/ (accessed on 23 August 2022).

- Tradelens Website. Available online: https://www.tradelens.com/ (accessed on 23 August 2022).

- Naviporta Website. Available online: https://naviporta.com/ (accessed on 23 August 2022).

- Myecustoms Website. Available online: https://myecustoms.com/en/home/ (accessed on 23 August 2022).

- Entrance Platform Website. Available online: https://www.entrance-platform.eu/ (accessed on 23 August 2022).

- van Arjen Klink, H.; van den Berg, G.C. Gateways and Intermodalism. J. Transp. Geogr. 1998, 6, 1–9. [Google Scholar] [CrossRef]

- Interaction Design Foundation, User Scenarios. Available online: https://www.interaction-design.org/literature/topics/user-scenarios (accessed on 23 August 2022).

- Panayiotou, N.; Ponis, S.; Gayialis, S. Business Process Documentation for ERP- Supported Organisations. WSEAS Trans. Comput. 2004, 3, 1512–1519. [Google Scholar]

- Brennen, J.S.; Kreiss, D. Digitalization. Int. Encycl. Commun. Theory Philos. 2016, 1–11. [Google Scholar] [CrossRef]

- Feibert, D.C.; Hansen, M.S.; Jacobsen, P. An Integrated Process and Digitalization Perspective on the Shipping Supply Chain-a Literature Review. In Proceedings of the International Conference on Industrial Engineering and Engineering Management IEEM, Singapore, 10–13 December 2017. [Google Scholar]

| Scenario 1: Account/profile creation process | The user needs to enter into the system. The system requires the acquisition of the user’s credentials. The user’s credentials are generated from a profile/account creation process by requesting a number of obligatory parameters, such as name, surname, email, user name, and password. When finalising the signing up and before using the system, the user is asked to set his/her profile and provide the corresponding mandatory details (the category he/she belongs to, the name of the company, location, contact email, certification ((if it is a freight forwarder)), and a short description of activities). |

| Scenario 2: New order initiation | The user (in this case, a shipper or a freight forwarder) enters into the systems, using his/her credentials, and starts a new order. The system opens the order unified interface and asks the user to insert input parameters regarding his/her cargo (type, volume, weight) and the details of the required transportation (origin, destination, departure/arrival). The system then provides the available transportation options and requests the user to select the preferred criteria (cost, total duration, emissions). The system analyses and presents the routes that fulfil the requested order’s input parameters and sorts them in order of preference based on the defined selection criteria. Each route includes information regarding the mode of transport (or possible combination), the total cost, the total duration, and the total emissions. The system asks the user to assess the available routes and their characteristics and select the preferred one. The system confirms the order and exports a report with the selected route, along with its characteristics. The user receives the payment invoice and then proceeds to the payment in order to confirm the order. The system transfers the user to a secure environment, where he/she executes the payment. Then, the user receives proof of payment, and the transportation request is sent to the selected carrier. |

| Scenario 3: Rating of provided service | When the order reaches its destination, the system notifies the user, and a rating process is available so as to give his/her feedback on the selected carrier(s), based on the service provided. |

| Scenario 4: Edit order | The user enters into the system by using his/her credentials. The user (in this case, a shipper or a freight forwarder) requests to edit an existing order. The system asks the user to edit the required parameters regarding his/her cargo (type, volume, weight) and the details of the required transportation (origin, destination, date, etc.). The system analyses and presents the routes that fulfil the requested order input parameters and sorts them in order of preference based on the defined selection criteria. Each route includes information regarding the mode of transport (or possible combination), the total cost, the total duration, and the total emissions. The system asks the user to assess the available routes and their characteristics and select the preferred one. The system confirms the order and exports a report with the selected route, along with its characteristics. The user then proceeds to pay (if required) in order to confirm the order. The system transfers the user to a secure environment, where he/she executes the payment. If the payment balance is positive, the user is asked to pay it, while if the balance is negative, the credited amount is stored in the payment system to be redeemed on the next order. Then, the user receives proof of payment, and the updated transportation request is sent to the selected carrier. |

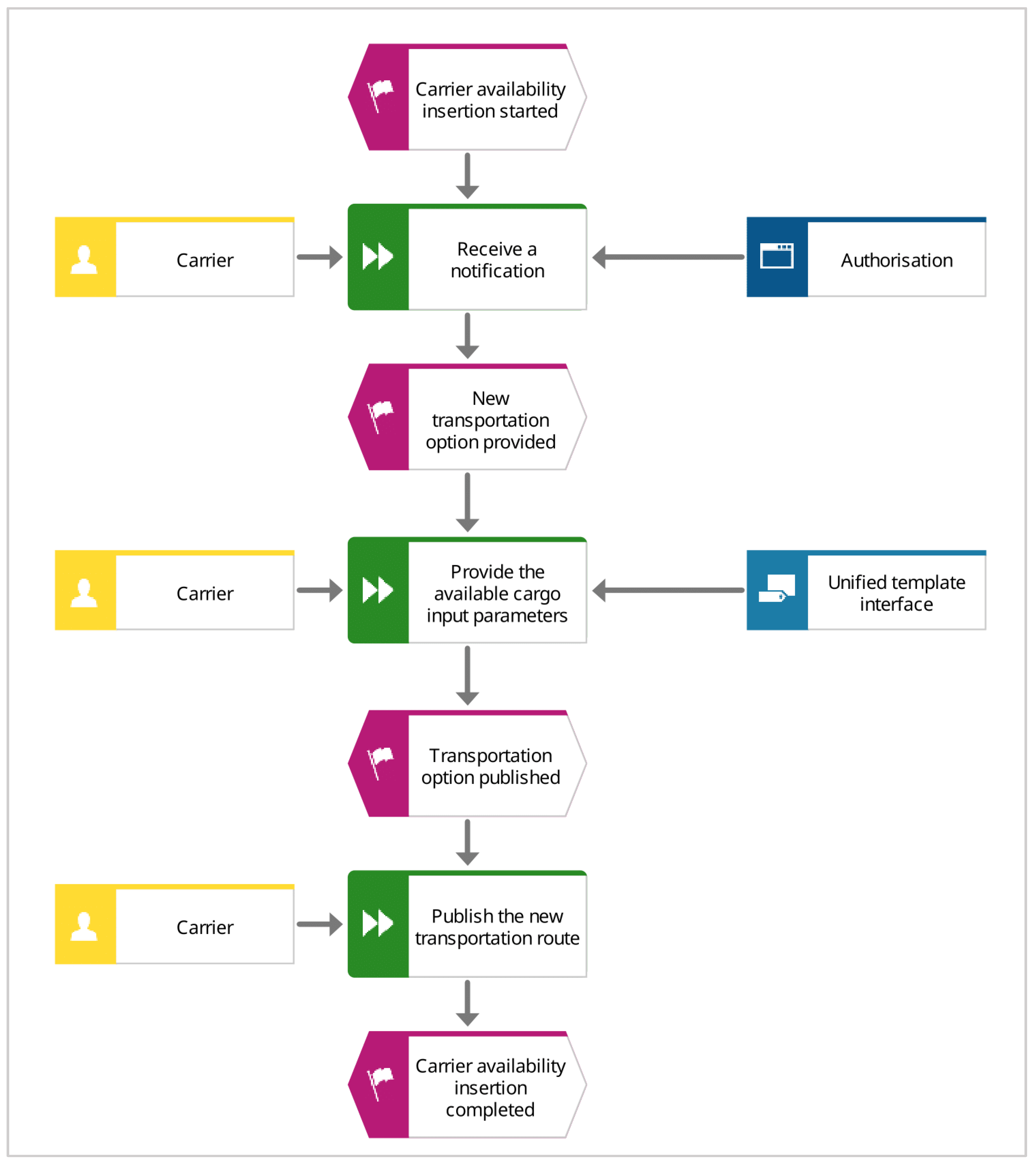

| Scenario 5: Carrier availability insertion | The user enters into the system by using his/her credentials. The user (in this case, a carrier) requests to add a new transportation option. The system opens the transportation option unified interface and requests the user to insert the input parameters regarding the new transportation option (means, route ((origin-destination)), duration, time schedule, capacity, cost, emissions, etc.). The system creates the new route and makes it available. |

| Scenario 6: Order assignment | The user (in this case, a carrier) enters into the system using his/her credentials. The user receives a notification about the receipt of a new order request based on one of the available transportation options. The system requests the user to accept the assignment. Once the assignment is accepted, the system asks the carrier to update the transportation status, so the order can be easily tracked by all involved actors (the shipper or freight forwarder and carrier(s)) and provides him with an assignment confirmation report. |

| Scenario 7: Messaging functionality | The system is initiated, and the user logs in to the system using his/her credentials. The user selects the messaging functionality and types the name of the user he/she would like to contact in order to react to the aspects that are not covered by the standardised elements of the systems (e.g., price negotiation, customs arrangements, cargo insurance, etc.) and communicates the message. The system provides a notification to the communicating parties when a new message is available. |

| Scenario 8: Occurrence of an unexpected event | The carrier is informed about an unexpected event during the cargo transportation (severe weather) that causes its immobility. The user initiates the system and logs in using his/her credentials. An instant updated notification is sent to the shipper or the freight forwarder. |

| ID | Key Functionalities (KF)/ Requirements | Related Scenario (SC) Reference | MoSCoW Prioritisation |

|---|---|---|---|

| KF1 | Authentication/Authorisation | SC1 | MUST |

| KF2 | Actor profiles (with dedicated interfaces for the insertion and updating of profile details, incl. certification requirements) | SC1 | SHOULD |

| KF3 | Insertion of cargo details and transport characteristics (e.g., cargo type, volume, weight, destination, departure/arrival dates, etc.) | SC2, SC4, SC5 | MUST |

| KF4 | Schedule, capacity and cost details | SC2, SC4, SC5 | MUST |

| KF5 | Available transport options | SC2, SC4 | MUST |

| KF6 | Price request/quotation | SC2, SC4 | SHOULD |

| KF7 | Messaging capabilities | SC2, SC4, SC7 | MUST |

| KF8 | Order confirmation and capacity update | SC2, SC4, SC5 | MUST |

| KF9 | Order editing and route recalculation | SC4 | MUST |

| KF10 | Provision of alternative transport modes and associated costs | SC4 | SHOULD |

| KF11 | Display of route characteristics (timing, stops, costs, etc.) | SC6 | MUST |

| KF12 | Reporting of transport services, including emission savings | SC2, SC4, SC5 | SHOULD |

| KF13 | Reporting of order details | SC2, SC4, SC6 | SHOULD |

| KF14 | Template for unified data format | SC2, SC3, SC4, SC5 | SHOULD |

| KF15 | Automated communication | SC2, SC4, SC6, SC7 | COULD |

| KF16 | Direct access to information related to transport means and details—less manual communication | SC2, SC4, SC5 | MUST |

| KF17 | Dynamic update of transport details | SC5 | SHOULD |

| KF18 | Near real-time information for unexpected events | SC8 | SHOULD |

| KF19 | Feedback about transport status | SC3, SC6, SC8 | COULD |

| KF20 | Transparency in available transport services | SC5, SC6 | MUST |

| KF21 | Publication of all available service providers | SC5 | SHOULD |

| KF22 | Provision of multimodal options | SC2, SC4, SC5 | SHOULD |

| KF23 | Access to all transport routes and rates | SC2, SC4, SC5 | SHOULD |

| KF24 | Combination of orders—empty container management | SC5 | SHOULD |

| KF25 | Classification rating scheme for carriers | SC3 | COULD |

| KF26 | GHG emissions estimation | SC2, SC4 | COULD |

| KF27 | Automated invoicing | SC2, SC4 | SHOULD |

| EPC Element | Key Functionalities (KF)/ Requirements |

|---|---|

| An event describes a state that controls or influences the progression of the process. They trigger functions and are the results of functions. |

| A function is a task or activity performed to deliver process outputs and support business objectives. |

| The system is a software system that is used to support the execution of a function. |

| The internal person illustrates the specific person who is performing an activity. |

| A document carrier stores knowledge/data. |

| An entity type is a group of related real or abstract objects that play a specific role in the function of a system or part of it. |

| OR considers at least one path |

| AND considers all paths |

| XOR (exclusive or) considers exactly one path. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krikigianni, E.S.; Latsa, E.; Gayialis, S.P.; Panayiotou, N.A.; Kostovasili, M.; Kanellopoulos, I.; Amditis, A. Matchmaking the Emerging Demand and Supply Need in the Maritime Supply Chain Domain: A System Design Framework. Sustainability 2022, 14, 14622. https://doi.org/10.3390/su142114622

Krikigianni ES, Latsa E, Gayialis SP, Panayiotou NA, Kostovasili M, Kanellopoulos I, Amditis A. Matchmaking the Emerging Demand and Supply Need in the Maritime Supply Chain Domain: A System Design Framework. Sustainability. 2022; 14(21):14622. https://doi.org/10.3390/su142114622

Chicago/Turabian StyleKrikigianni, Eleni S., Evangelia Latsa, Sotiris P. Gayialis, Nikolaos A. Panayiotou, Margarita Kostovasili, Ioannis Kanellopoulos, and Angelos Amditis. 2022. "Matchmaking the Emerging Demand and Supply Need in the Maritime Supply Chain Domain: A System Design Framework" Sustainability 14, no. 21: 14622. https://doi.org/10.3390/su142114622

APA StyleKrikigianni, E. S., Latsa, E., Gayialis, S. P., Panayiotou, N. A., Kostovasili, M., Kanellopoulos, I., & Amditis, A. (2022). Matchmaking the Emerging Demand and Supply Need in the Maritime Supply Chain Domain: A System Design Framework. Sustainability, 14(21), 14622. https://doi.org/10.3390/su142114622