Abstract

Achieving an economically feasible and environmentally robust model in agriculture while satisfying the expanding population’s food demands is a global challenge. Hence, a three-year (2014–2017) study was conducted at Punjab Agricultural University, Ludhiana to design environmentally clean, energy-efficient, and profitable cropping systems. Twelve cropping systems viz., rice-wheat (CS1), basmati rice-hayola (transplanted)-mung bean (CS2), basmati rice-radish-maize (CS3), maize-potato-maize (CS4), maize + turmeric-barley + linseed (CS5), maize + turmeric-wheat + linseed (CS6), maize + radish-wheat + linseed-mung bean (CS7), groundnut + pigeon pea (5:1)-wheat + sarson (9:1) (CS8), maize + black gram-pea (bed) + celery (furrows) (CS9),: maize + pigeon pea-chickpea (bed) + gobhi sarson (furrows) (CS10), maize (green cobs) + vegetable cowpea + dhaincha (Sesbania spp.)-chickpea + gobhi sarson (CS11) and sorghum + cowpea (fodder)-wheat + gobhi sarson (9:1) (CS12) were tested in a four-times-replicated randomized block design. CS11 had the maximum system productivity (28.57 Mg ha−1), production efficiency (78.27 Kg Day−1 ha−1), irrigation water use efficiency (2.38 kg m−3), system net returns (4413.3 US$ ha−1), and benefit to cost (B:C) ratio (2.83) over others. In comparison to the CS1 system, this cropping system required ~78% less irrigation water for a unit economic production. However, the cultivation of CS12 registered the highest energy use efficiency (49.06%), net energy returns (6.46 × 103 MJ ha⁻¹), and global warming potential (GWP) (Mg CO2 e ha−1) at spatial scale. Among all the intensified systems, CS11 had the lowest GHGI (0.29 kg CO2 e kg−1). Furthermore, cultivation of CS6 resulted in the maximum bacterial and actinomycetes population in the soil, while CS5 yielded the highest fungal count (23.8 × 103 cfu g−1 dry soil) in soil. Our study suggests that the cultivation of CS11 is a resource-efficient, economically viable, and environmentally clean production system and could be a potential alternative to rice-wheat systems for developing a green economy policy for agricultural development in the Indo-Gangetic Plains (IGP) of India.

1. Introduction

Food production and climate change are global concerns that need to be addressed properly in order to satisfy the calorie demand of the growing population and mitigate climate change [1]. Globally, millions of members of the populace are deprived of food accessibility and suffer from hunger [1,2,3]. Hence, global humanity is at a critical juncture and needs immediate technological interventions and policy support. To meet global food security needs while harmonizing the dwindling natural resources, agricultural production systems must become more productive and adaptable [2,3]. Ensuring maximum resource use efficiency is an important approach to mitigating climate adversities and to backstopping the sustainable development goals (SDGs) agenda envisioned by the United Nations (UN). In developing nations like India, agricultural production systems face the quadruple challenges of energy intensiveness, unemployment, declining factor productivity, and soil health deterioration [4]. Therefore, conventional linear economy-based crop production is not a profitable and environmentally safe business. Despite the dependence of ~70% of Indian families on agriculture, the contribution of agriculture to the Indian economy has gradually decreased (<15%). This indicates that agriculture in the country is at a crossroads [5]. India’s food and nutritional security depend on producing cereal crops along with pulses, oilseeds, spices, and vegetables. As a result, encouraging farmers to diversify the cereal production system with higher-value pulses, oilseeds, and spices will be a key factor in boosting agricultural growth. Crop diversification and intensification are essential for successful agricultural production [1]. Fertilizers and pesticide-dependent cereal cultivation deteriorated soil fertility, ramified groundwater pollution, and reduced farm profitability. On the contrary, induction of pulses in a cereal-based cropping system can potentially restore the degraded soil [3]. Inefficient input management and persistent pesticide use have resulted in a long-term decline in groundwater levels and soil fertility [1,2]. The agricultural production system must be redesigned as eco-friendly and profitable rather than profit-oriented alone. Furthermore, ever-increasing CO2 levels also impose a serious yield penalty on the agricultural system. Hence, the implementation of an ambitious climate mitigation program is dire in order to achieve environmental sustainability. Several researchers have suggested that, to control the rising temperature and total GHG emission, futuristic agricultural production systems must be carbon neutral or negative [3,4]. Global food and nutritional security can potentially be achieved through the adoption of conservation and effective cropping intensification practices [4]. However, increasing the number of crops can substantially increase input use, which might further accelerate energy consumption and GHG emissions. Therefore, besides economic returns and social acceptability, environmental indicators like energy dynamics and GHG emissions must be included while designing efficient production systems [3]. Intensive cropping along with the conservation of effective soil and crop management practices can be an environmentally friendly approach for achieving food security and zero hunger targets [4]. Increased cropping frequency accelerates the use of energy, labor, and other critical inputs, [5] hence the selection of crops is indispensable when determining the eco-efficiency of the designed system. Several researchers reported that GHGs emission is directly related to energy consumption in agricultural production systems [5,6]. From an environmental point of view, researchers and policy planners need low C emissions and an energy-efficient production system, but a system that needs lesser energy does not need to be always profitable and socially acceptable. Therefore, a relative assessment of different cropping systems in terms of energy use, soil health buildup, economic returns, and GHG emission is highly warranted for designing environmentally clean, economically efficient, and soil-supportive production systems. Globally, agricultural production systems accounted for ~10–12% of total GHGs emissions [7]. Carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) are the major GHGs emitted by agricultural systems [8,9,10]. Agricultural operations such as land clearing, crop cultivation, irrigation, animal husbandry, fisheries, and aquaculture all have a significant impact on GHG emissions and climate change [11]. Rice fields that have been flooded with water could potentially be a source of CH4 emission. The natural processes of nitrification and denitrification produce nitrous oxide in soils [8]. Plant residue burning, organic matter oxidation, and microbial decomposition are the major CO2 emitters [12,13]. However, puddled paddy cultivation and livestock rearing are the major CH4 emitters in agroecosystems [14,15]. Excess nitrogen use and wetland paddy cultivation are the major N2O emitters [16,17]. Earth radiative forcing is largely regulated by the concentration of these major gasses [18]. Hence there is a dire need for a systematic analysis of the carbon footprint (C equivalent of CH4, N2O, and CO2) involved in agricultural crop production systems for developing eco-friendly and carbon-neutral production systems [19,20,21]. Many researchers assessed the energy, economic, and carbon performance of designed cropping systems under different ecosystems [2,5,7], but very few or none of the studies assessed the performance of designed bio-intensive cropping systems in terms of energy dynamics, water use, GHG emission, and soil health buildup, especially in the Indo-Gangetic plains of India. Hence, we hypothesized that the intensification/diversification of existing production systems with the induction of resource-efficient crops will increase the economic returns and soil health besides reducing GHG emissions and water use. To prove this hypothesis, the present investigation was conducted with the objectives to (1) assess the productive capacity and economic competency of the designed cropping system with the existing rice-wheat system, (2) assess the energy dynamics and water use efficiency of the designed cropping systems, and (3) evaluate the effect of designed cropping systems on soil health. The findings of the present study will help policy planners to design eco-efficient agricultural planning for backstopping the SDGs and India’s COP-26 commitments.

2. Materials and Methods

2.1. Experimental Site and Treatments

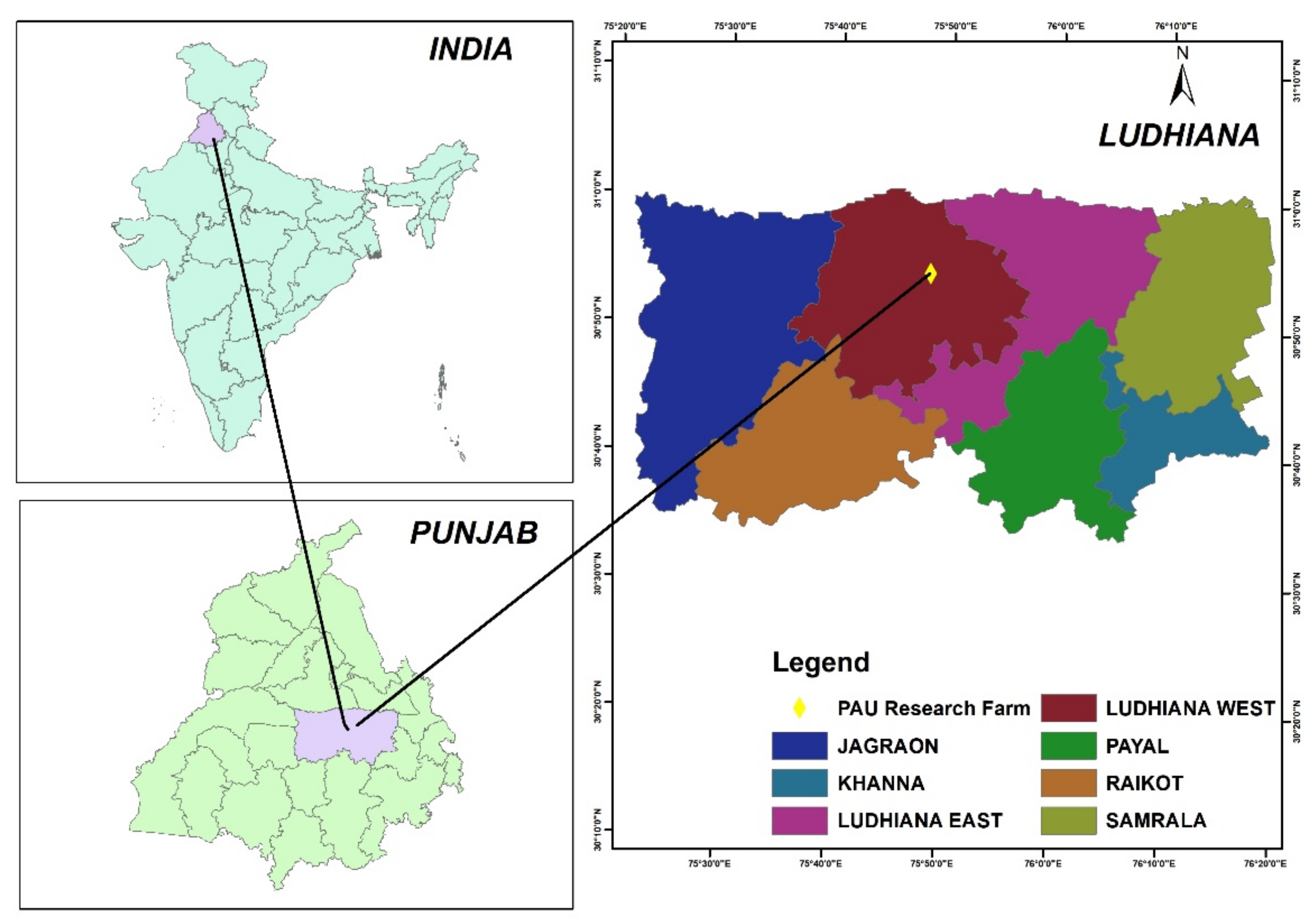

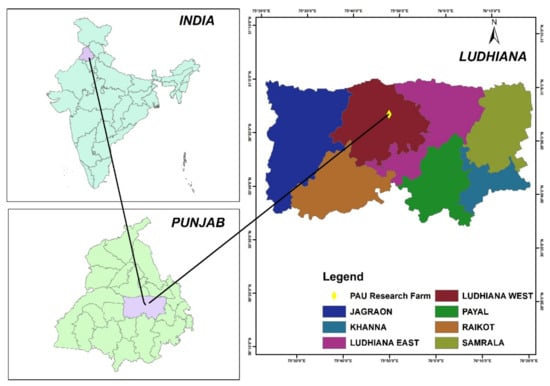

A three-year (2014–2017) field study was conducted at the research farm of Punjab Agricultural University (PAU), Ludhiana Center of All India Coordinated Research Project on Integrated Farming System (AICRP-IFS). The experimental site lies between 30°–32°56′ N and 75°–76°52′ E with 247 m amsl (Figure 1). The soil of the experimental field was sandy loam in texture. Ludhiana experiences a monsoon-influenced humid subtropical climate (cwa) with an average temperature of 23.5 °C. June was the hottest month, while January remains the coldest month in the years. The site received an average rainfall of 876 mm per annum. November was the driest month, while July was the wettest month during all the years of experimentation.

Figure 1.

Location of the study site.

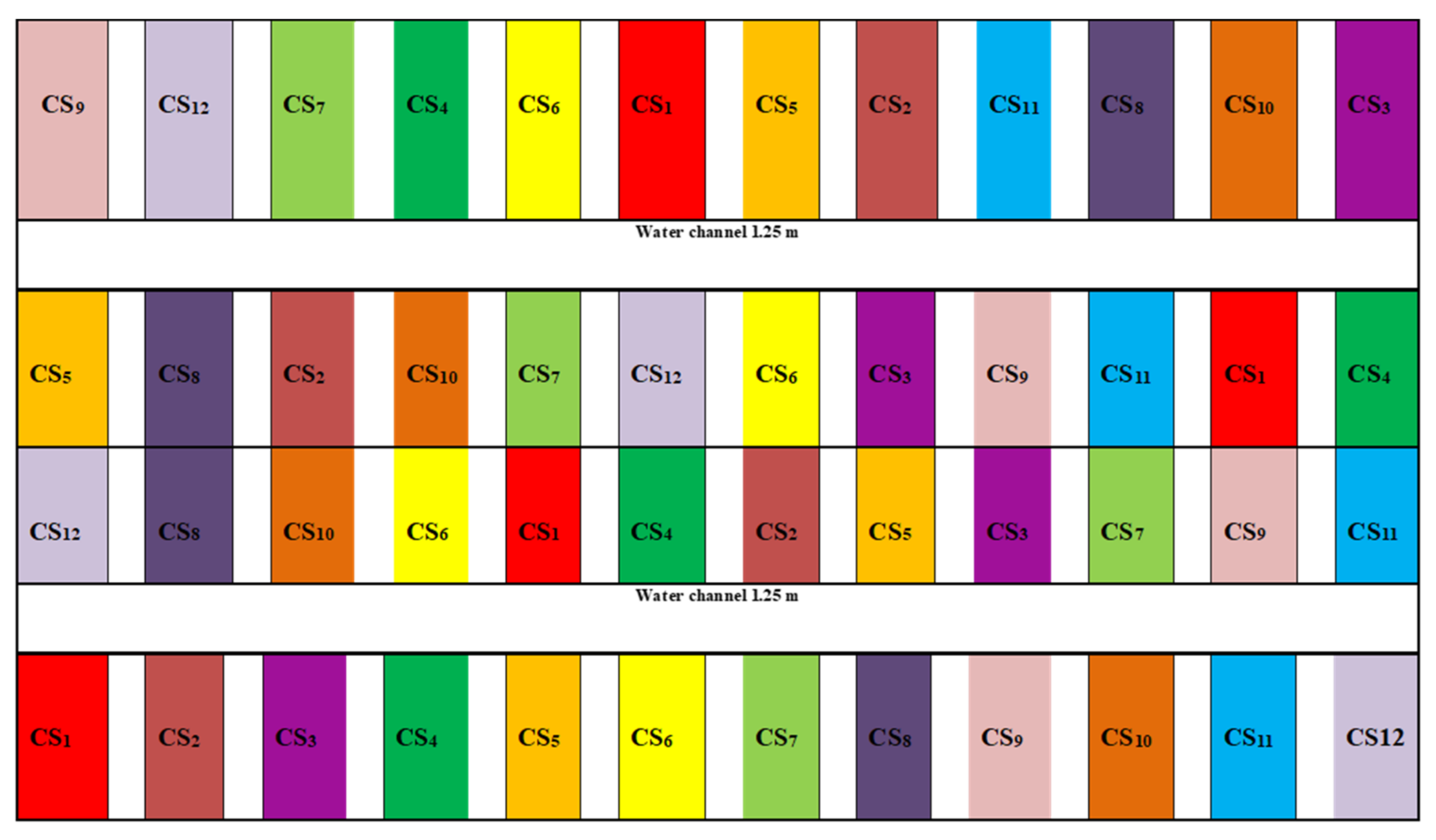

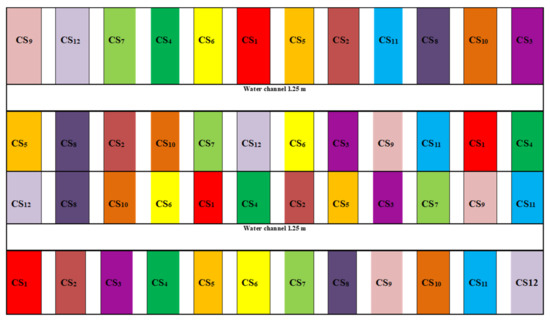

The word “cropping system” refers to the crops, crop rotations, and management strategies applied over many years to a specific agricultural field. Twelve cropping systems (Table 1) were evaluated with four replications in randomized block design (Figure 2). The standard growing techniques were adopted for the different crops under the experiment (Table 2). The recommended dose of nitrogen (N), phosphorus (P), and potassium (K) was applied by using urea, single super phosphate, and muriate of potash, respectively.

Table 1.

Cropping systems-wise details.

Figure 2.

The layout of field experimentation.

Table 2.

The improved package and practices of experimental crops.

2.2. Crop Yields, System Productivity, and Economic Assessment

Above-ground biomass (AGB) was recorded as harvest. Stover/straw samples from a 1 m2 area were obtained from every plot during the harvesting of every crop and oven-dried at 60 ± 1° C. For a comparative assessment of diverse cropping systems, an economic product from all the systems was converted into the common unit (rice equivalent yield-REY) on the price scale. The system productivity was calculated with the following expression [22].

where REY is the rice equivalent yield (Mg ha−1); RY is the rice economic yield (Mg ha−1); Yi is the economic yield of ith crop (Mg ha−1); Pi is the market monetary value of ith crop (US$); and Rm is the rice market value (US$).

The production efficiency (PE) (productive capacity of crops/cropping system over a day) of different cropping systems was also estimated for an overall estimation of cropping performance. Production efficiency was estimated by the following expression [22].

The irrigation water use efficiency was estimated by the following expression [3].

For financial auditing, the cost incurred by the cultivation of each crop (sowing to harvesting) and the economic value of all the outputs was calculated. The monetary expenditure and financial gain were converted into the US$ for better understanding. The monetary value of the total output was expressed as system gross returns (SGR-US$ ha−1), and the system net returns (SNR) and benefit-cost (B:C) ratio were calculated by the following equations [23,24].

2.3. Calculation of Energy Use Efficiencies

Energy coefficients [25] for the various inputs used and outputs generated were used for energy auditing in diverse cropping systems. The energy input and output were computed as mega joule (MJ). Input energy was the summation of energy incurred for raising the crops. Similarly, the energy output is the energy value of the main and by-products in each cropping system. The energy use efficiency (EUE), energy output efficiency (EOE) (MJ ha−1 day−1), and energy productivity (EP) (kg REY MJ−1) were calculated by using the following formulas [10,26].

2.4. Soil and Plant Analysis

After the completion of three cropping cycles, soil samples were collected from each plot (0−15 cm) to assess the effect of different cropping systems on SOC and available N, P, and K status. Collected soil samples were air-dried, grounded, and passed through 0.5 mm sieves. The SOC content was estimated by the oxidation method [27]. The 0.5 g sieved soil was employed in a 500 mL Erlenmeyer flask. Thereafter, 10 mL 0.167 K2Cr2O7 and 20 mL of concentrated H2SO4 were added and stirred well. The solution was cooled for 30 min on an asbestos sheet. After cooling, 200 mL distilled water, 10 ml concentrated H3PO4, and 1 mL of 0.16% diphenylamine were added. The solution was titrated by using Fe(NH4)2(SO4)2(H2O)6 (Mohr’s salt). The available nitrogen in the soil was measured by the alkaline potassium permanganate method [28]. The available phosphorus was estimated by the 0.5 M sodium bicarbonate method [29]. The determination of available potassium was estimated as per the procedure of Merwin and Peech [30]. Nutrient removal by different cropping systems was worked out by estimating the N, P, and K content in the grain and straw of crops. The N, P, and K contents in grain and straw/stover of different crops were done with standard procedures. Thereafter, N, P, and K uptake by different crops was estimated by multiplying the N, P, and K contents with grain and stover yields and was expressed in kg ha−1 [31].

Soil microbial populations were estimated using the serial-dilution-pour-plate method. In each case, three replicates were kept. The following formula was used for counting and the determination of populations in the colonies growing on the plates [32].

Isolation of soil bacteria (CFU per g of soil) was conducted on the nutrient agar using a dilution plate technique with 106 dilutions at 28 ± 1 °C for 3 days. Potato dextrose agar (PDA) was used for the isolation of soil fungi (CFU per g of soil) using the dilution plate technique with 105 dilutions at 27 ± 1 °C for 6 days. To prevent bacterial growth, the media were supplemented with 50 pg ml−1 of streptomycin sulfate. The actinomycetes populations were enumerated by growing them in an actinomycetes agar with 105 dilutions at 26 ± 1 °C for 7 days’ incubation period. To avoid the development of fungal and bacterial contaminants, the media were treated with cycloheximide and streptomycin (1 mg ml−1), respectively.

2.5. Greenhouse Gas Emission Estimation

The environmental performance of the designed systems was estimated by estimating the global warming potential (GWP) and greenhouse gas intensity (GHGI). The GWP is the estimated total quantity of major GHGs, i.e., methane (CH4), carbon dioxide (CO2), and nitrous oxide (N2O), emitted during the entire duration of crops/cropping systems in terms of CO2 equivalents (Mg CO2 e ha−1) [33]. The total quantity of CH4, N2O, and CO2 released from different crops/systems was transformed into CO2 equivalent by multiplying the GWP equivalent by 24, 265, and 1 for CH4, N2O, and CO2, respectively, for a 100 years’ time span [34]. The standard emission coefficient was used for the estimation of GHGs emissions [26,35,36,37,38]. The CH4 from the rice field and N2O emissions from applied nitrogen sources were calculated by the formula given by Tubiello et al. [39] with slight alterations [1]. To estimate the total N2O emission 0.01 (emission factor) was multiplied by the total amount of applied N [39].

CH4 emission (kg ha−1 yr−1) = EF × SFo × (Aij + [Aij × SFj]) / 10

Whereas:

- EF: Seasonal CH4 emission factor for India (10 g m−2 year−1)

- Aij: Rice area (ha year−1)

- SFo: Correction factor for organic sources (1.4)

- SFj: 0.7 scaling factor for Aj

2.6. Statistical Analysis

All the obtained data were statistically analyzed for the variance of the cropping system effect by employing an SAS 9.4 model. The correlation coefficients were also computed using SPSS software version 27.0 (IBM, New York, NY, USA). The correlation analysis was carried out among five variables viz. rice equivalent yield and soil fertility status for OC, N, P, and K by using the SAS software.

3. Results

3.1. System Productivity and Production Efficiency

Total above-ground biomass (ABG) production varied across the designed cropping systems. The fodder-based cropping system viz. CS12 registered the maximum ABG production, which was significantly better than all other cropping systems, followed by CS11. The CS11 recorded 65.6% higher AGB production over CS1 (business as usual). Among the tested cropping systems, cultivation of CS11 provided significantly higher system productivity (28.57 Mg ha−1) (Table 3). This was closely followed by CS4 (23.21 Mg ha−1), CS3 (21.07 Mg ha−1), CS5 (20.89 Mg ha−1), CS6 (20.68 Mg ha−1), CS9 (18.92 Mg ha−1), and CS2 (17.05 Mg ha−1). Conversely, the CS1 system had the lowest system productivity (12.94 Mg ha−1). Concerning production efficiency, CS12 outperformed other cropping systems, followed by CS11. CS12 registered 7.6 times higher production efficiency over the R-W system.

Table 3.

System productivity and economic returns of different cropping systems (3-year mean).

3.2. Irrigation Water Use Efficiency

The maize-based cropping system viz. CS11 showed significantly higher irrigation water use efficiency (2.381 kg grain per m3 irrigation water), with the requirement of 120 cm of irrigation water, followed by CS4 (1.934 kg grain per m3 irrigation water), CS9 (1.802 kg grain per m3 irrigation water), CS5 (1.709 kg grain per m3 irrigation water), and CS6 (1.656 kg grain per m3 irrigation water) (Table 3). CS8 proved to be another water efficient cropping system with a requirement of 82.50 cm for irrigation water and an irrigation water-use efficiency of 1.651 kg grain per m3 irrigation water. The lowest irrigation water use efficiency was recorded with the CS1 system (Table 4).

Table 4.

Energy dynamics of diverse cropping systems (3 year mean).

3.3. Economics Returns

The net returns was observed to be higher in maize-based cropping systems in comparison to the prevailing CS1 (Table 3). CS11 recorded significantly higher system gross returns (5974.4 US$ ha−1) and net returns (4413.29 US$ ha−1) over other tested cropping systems, followed by CS6 and CS5 (Table 3). Cultivation of CS4, CS7, and CS9 resulted in 1.23, 1.24, and 1.20 times higher net returns over conventional R−W systems, respectively. Similarly, CS11 registered a 49.8% higher B:C ratio over CS1, which was significantly higher compared to other tested systems. The lowest B:C ratio was recorded with CS4. This trend indicates the importance of the selection of crops in the cropping system while designing an economically efficient system over the prevailing production system.

3.4. Energy Dynamics

The total energy incurred in various systems varied from 23.05 × 103 to 50.30 × 103 MJ ha−1 (Table 4). The highest energy input was incurred in CS6 (50.30 × 103 MJ ha−1) followed by the CS4 (48.80 × 103 MJ ha−1), CS7 (46.33 × 103 MJ ha−1), and CS5 systems (44.55 × 103 MJ ha−1), respectively. CS2 had the lowest energy consumption.

However, the total energy requirement of the rice-wheat system was 28.66 × 103 MJ ha−1. Similarly, the total energy output of different cropping systems as estimated from the total output ranged from 361.82 × 103 to 1304.02 ×103 MJ ha−1 (Table 4). The maximum energy output was attained from the fodder-based cropping system viz. sorghum + cow-pea (fodder)-wheat + gobhi sarson (1304×103 MJ ha−1) followed by maize (cobs) + vegetable cowpea + sesbania-gram + gobhi sarson (871.33×103 MJ ha−1) and maize-potato-spring maize (690.08×103 MJ ha−1). The lowest energy output was recorded in maize + pigeon pea-chickpea (bed) + gobhi sarson (furrows) (404.88×103 MJ ha−1) and rice-wheat (411.01×103 MJ ha−1) systems. Fodder-based cropping systems, namely CS11 and CS12, registered 2-3 times higher gross energy output over the prevailing rice-wheat system. The fodder-based cropping system viz. sorghum + cowpea (fodder)-wheat + gobhi sarson showed the highest energy-use efficiency (49.06). Sorghum + cowpea (fodder)-wheat + gobhi sarson showed significantly higher energy output, energy use efficiency, and energy output efficiency over the other cropping systems, but significantly higher energy productivity was obtained in maize (cobs) + vegetable cowpea + sesbania-gram + gobhi sarson measured at 8.13 kg MJ−1, and this was mainly due to its higher system productivity. The other systems having significantly high energy productivity were CS2, CS3, and CS12.

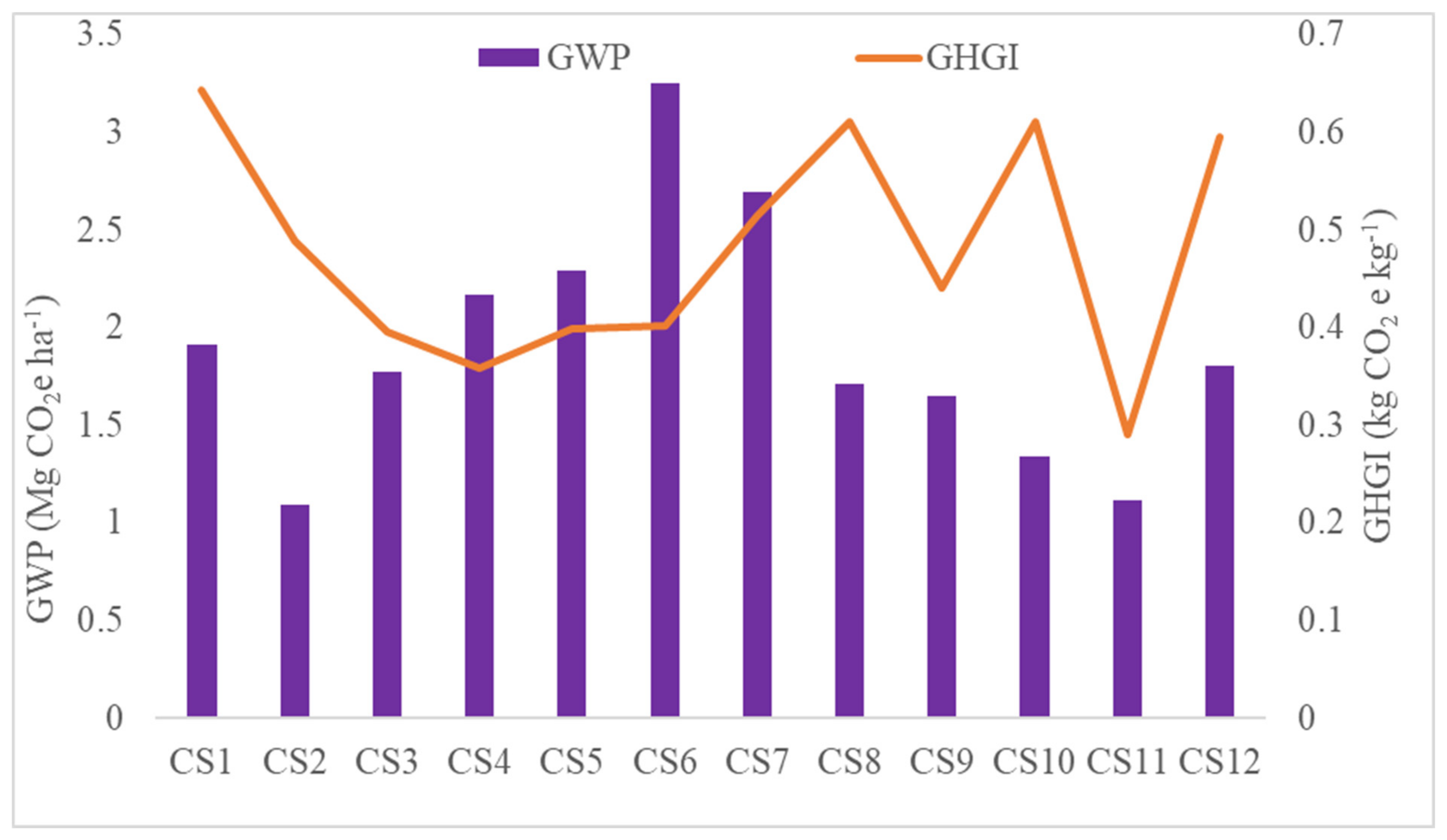

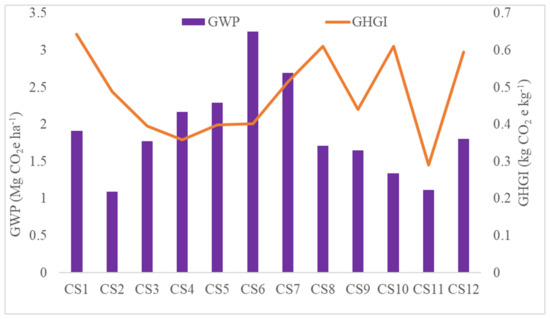

3.5. Global Warming Potential (GWP) and Greenhouse Gases Intensity (GHGI)

Wide variation in GWP (1.09 to 3.25 Mg CO2 eq ha−1 year-1) was noted among the tested cropping systems (Figure 3). Designed cropping systems had 31.8 to 69.1% higher GWP on spatial scale, but ~80% less GHGI over business as usual (CS1). Among the designed systems, the CS6 system had the highest GWPs (3.25 Mg CO2 e ha−1) followed by CS7 (2.69 Mg CO2 e ha−1). Although, all the designed systems had lower GHGI over prevailing CS1 (Figure 2). The induction of legumes like black gram and chickpea in maize-based cropping systems reduced the GHGI by 40.8% and 77.8%, respectively. However, the traditional rice-wheat system had the highest GHGI (0.643 kg CO2e kg−1 production). Among all the intensified cropping systems, maize (cobs) + vegetable cowpea + sesbania-gram + gobhi sarson, CS11 had the lowest GHGI (0.29 kg CO2 e kg−1).

Figure 3.

Global warming potential (GWP) and greenhouse gasses intensity (GHGI) of different cropping systems.

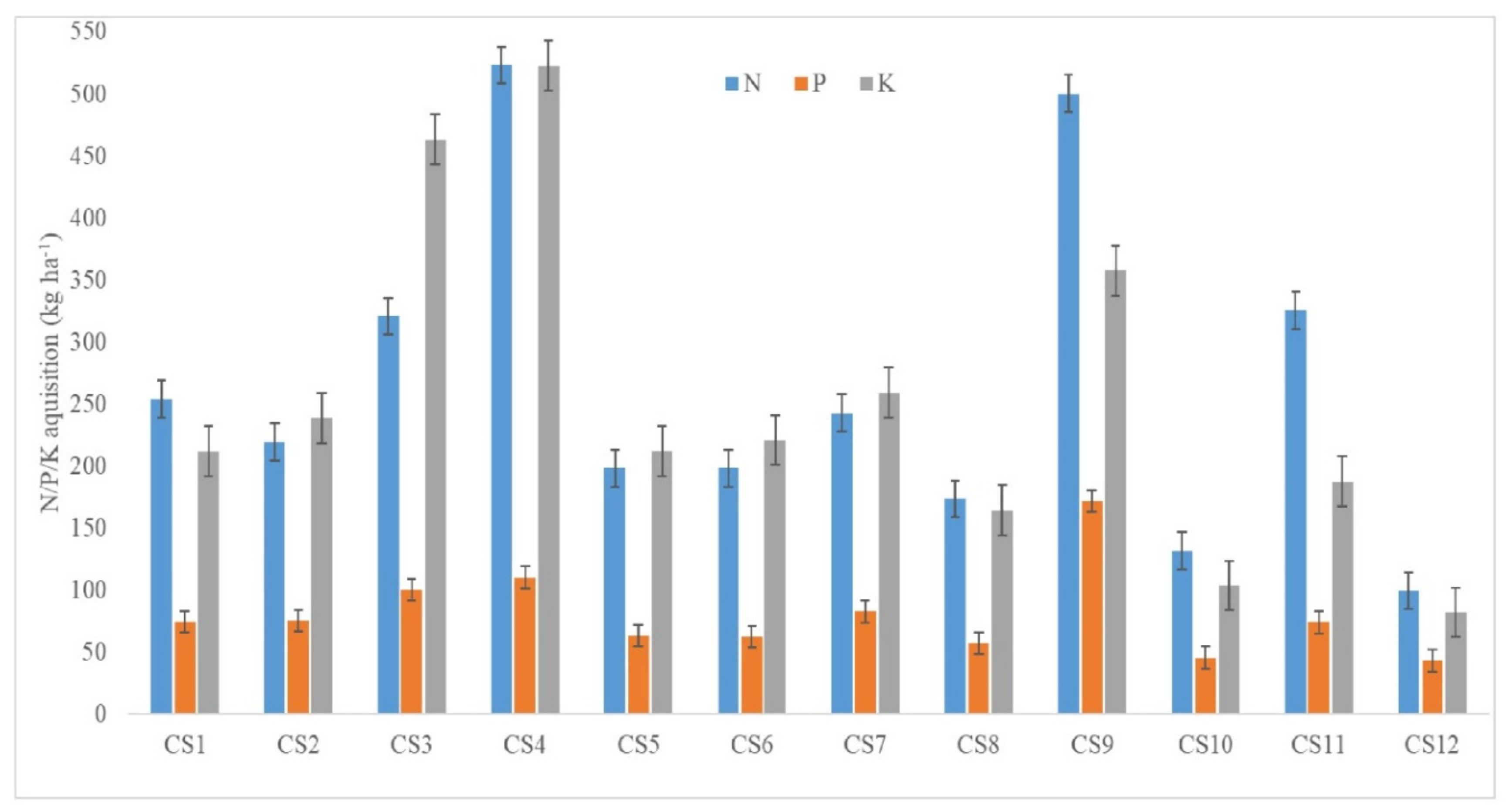

3.6. Nutrients Acquisition (Uptake), Soil Fertility Status, and Microbial Count

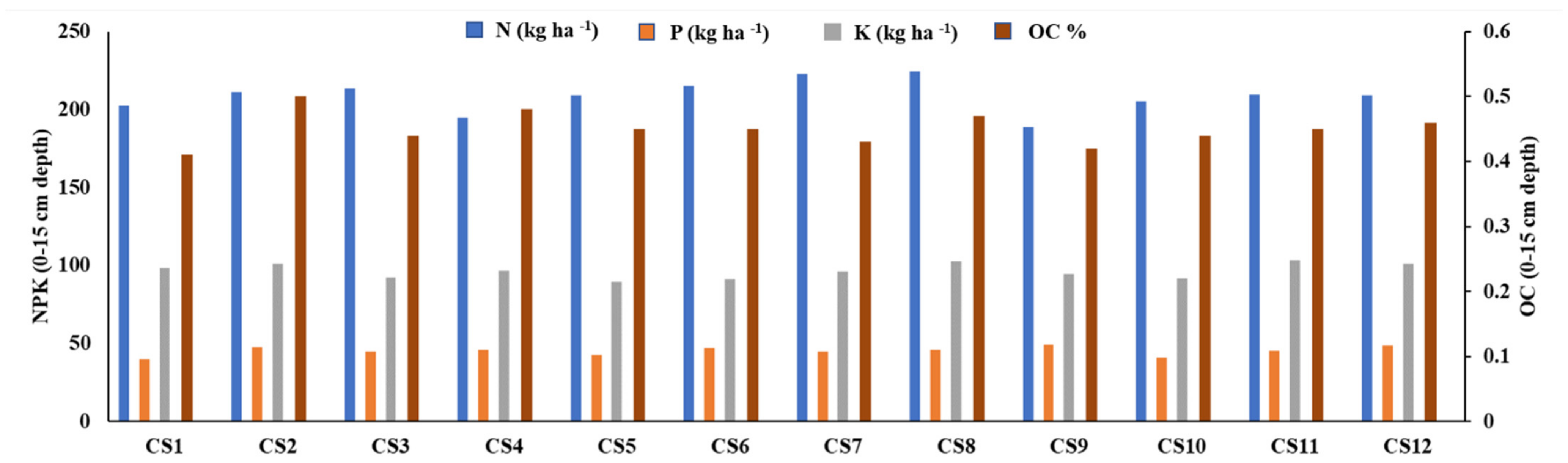

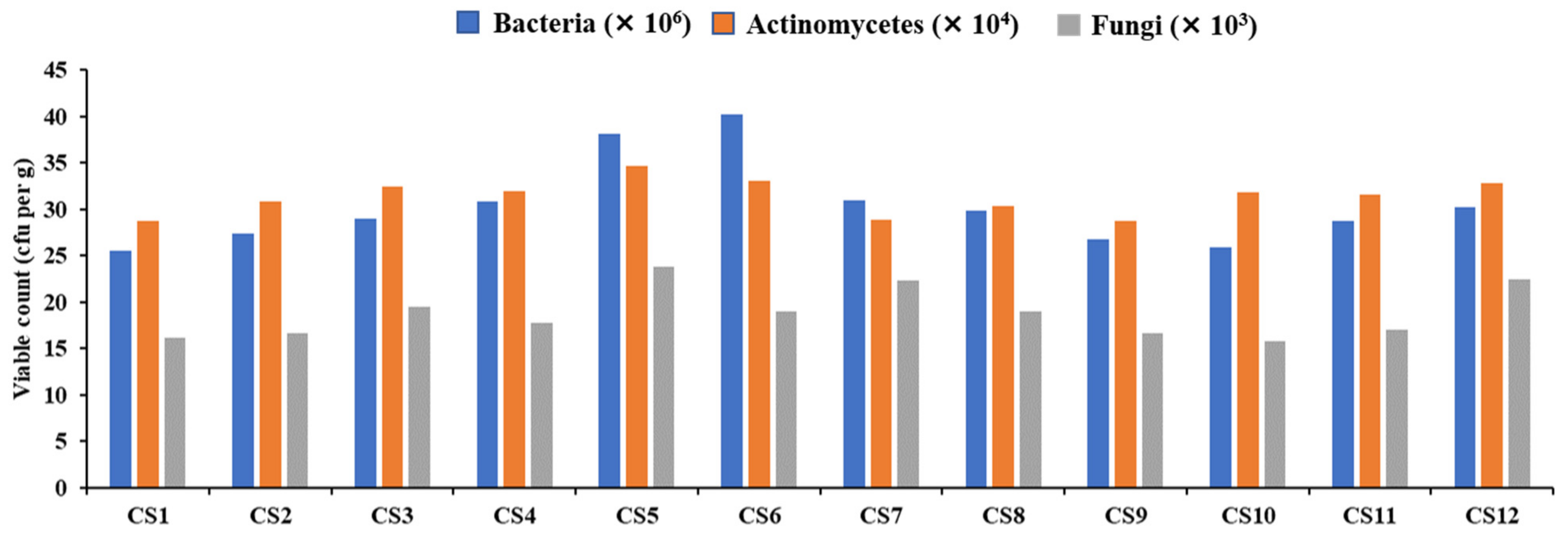

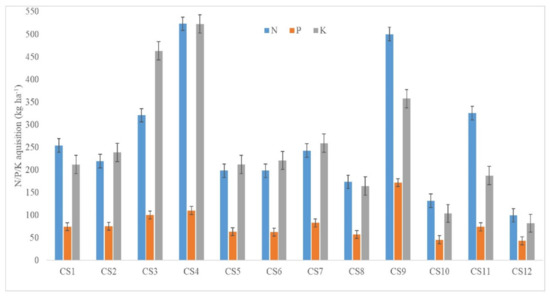

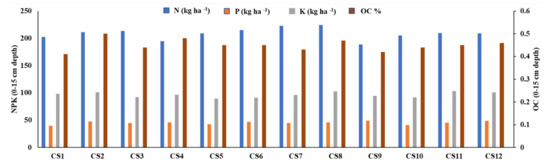

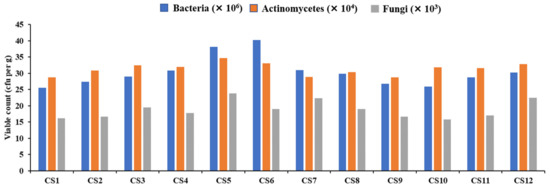

Among the tested systems, the nitrogen (523.29 kg ha−1 and potassium (522.63 kg ha−1) was the highest under CS4, while phosphorus uptake was the highest (171.98 kg ha−1) under CS9 (Figure 4). On the contrary, CS12 removed the lowest N (99.42 kg ha−1), P (43.03 kg ha−1), and K (82.16 kg ha−1). A diverse cropping system caused significant variation in the available nitrogen and phosphorus content at 0–15 cm soil depth after three years. The designed cropping system had failed to affect the SOC content after three years of cultivation. Although SOC content varied between 0.41–0.50%. Soils under the rice-wheat system had the lowest SOC content concerning the soil nitrogen availability during cultivation of the CS8 system (224.23 kg ha−1), while phosphorus availability was at its maximum (49.10 kg ha−1) in maize + black gram-peas + celery system and potassium availability was the highest under maize (cobs) + vegetable cowpea + sesbania-chickpea + gobhi sarson cropping system (Figure 5). The soil microbial count varied greatly between the different cropping systems (Figure 6). CS6 gave the maximum viable actinomycetes counts (33.1 × 104 cfu g−1 dry soil) and bacteria (40.2 × 106 cfu g−1 dry soil), whereas CS5 gave the highest count for fungi (23.8 × 103 cfu g−1 dry soil) over fungi (16.1 × 103 cfu g−1 dry soil), actinomycetes (28.8 × 104 cfu g−1 dry soil) and bacteria (25.5 × 106 cfu g−1 dry soil) in the CS1 system at 0–15 cm soil depth.

Figure 4.

Nutrients (NPK) acquisition by the different cropping systems. The error bar indicates the least significant difference (LSD) at p = 0.05.

Figure 5.

Soil fertility status (0–15 cm depth) after three cropping cycles. (OC: organic carbon; N: nitrogen; P: phosphorus; K: potassium).

Figure 6.

Soil microbial dynamics under different cropping systems after three cropping cycles.

3.7. Correlation Analysis

The correlation matrix of important characters viz. system productivity and soil fertility status after the rabi season 2017–2018 (OC, N, P, and K) was calculated (Table 5). The system productivity was positively correlated with N, P, and OC but negatively correlated with K, indicating that with an increase in system productivity, the soil becomes deficient in K and requires the application of potassium fertilizer. Additionally, N revealed a significant and positive correlation with OC and a negative correlation with P. In contrast to this, P had a negative correlation with K and OC, indicating that with an increase in P in the soil pool, OC and K content decreased. However, K showed a positive correlation with OC.

Table 5.

Correlation matrix among the variables (REY and soil fertility status after rabi season for N, P, K, and OC).

4. Discussion

Diversification and intensification of prevailing cropping systems is crucial for resource rationing, profitability maximization, and environmental sustainability. In the northwestern region of India, crop by-products, mainly stover/straw, are generally used as dry fodder, but rice straw is mostly disposed of by open-field burning [40]. The crop residue removal and intensive tillage practices have led to SOC depletion and soil fertility degradation [41,42]. Hence, the productivity of the prevailing rice-wheat system shows declining trends [43]. Therefore, the existing system must be replaced by more remunerative systems. Gill and Ahlawat [44] reported that soybean, maize, basmati rice, cotton, and summer groundnut in the rainy season and potato, Indian mustard, vegetable pea, grain pea, sunflower, and onion during the winter season are viable and remunerative alternatives to the nutrient- and water-exhaustive CS1 system. In the present study, the productivity of maize-based systems is significantly higher than traditional R-W systems. This was mainly due to the legume effect of the chickpea, pea, groundnut, and as well as green manuring (cowpea) in succeeding crops [45,46,47]. Legume induction in cereal-based systems increases the nutrients in the soil pool which facilitates the growth and development of succeeding crops. Singh and Sharma [48] also reported a beneficial effect of legumes on the succeeding crops. The improvement in productivity in non-legume crops in system mode can be described as nitrogen pumping in soil by legume crops. The price and higher productivity of inducted crops further augmented the land productivity and economic returns of the designed cropping systems over the traditional rice-wheat system. In contrast to R-W systems, the irrigation water productivity of maize-based cropping systems was almost doubled [49]. Diversification of the R-W system substantially increases water productivity over traditional systems [50]. Choudhary et al. [51] suggested that the substitution of wheat with potato and radish in the R-W system is a profitable and resource-saving venture.

The excessive water uses in prevailing cropping systems is a major reason for the implementation of an adequate cropping strategy in IGP. The continual rotation of rice-wheat systems is the major culprit raising concern. Intensified/diversified cropping substantially reduced water use and improved use efficiency [52,53]. The present study indicated that the induction of high-value low water requiring crops in existing systems has huge potential for reducing water and fertilizer use while achieving groundwater usage parity and economic and sustainable agricultural development targets [54]. Therefore, it is very pertinent to pursue the gradual shifting of the R-W system to diversified production systems in order to conserve natural resources while keeping productivity levels intact [23].

Diversification of existing cropping systems substantially increases economic output and profitability [23,48]. The present study revealed that the cultivation of maize (cobs) + vegetable cowpea + sesbania (broad bed furrow) recorded 2.78 times higher system net returns and 56.2% higher benefit-cost ratio over the conventional R-W system. Higher net returns in diversified systems over existing cropping systems were attributed due to higher system productivity [24]. Walia et al. [55] reported the increase in the number of crops substantially increases the cost of cultivation due to an increase in the total variable cost due to more fertilization and human labor requirements. However, the gross returns were also higher in diversified systems because of the higher value of produce. The inclusion of vegetables in crop sequences can boost the profitability of the sequences. These results confirm the findings of Samui et al. [56]. Rao and Willey [57] and Yadav et al. [46] also concluded that the intensification of the existing cereal based systems by inducting green gram/cowpea (fodder) is a profitable and environmentally safe practice.

In the present study, fodder-based cropping systems namely CS11 and CS12, registered 2–3 times higher gross energy output over the prevailing R-W system. This indicated that the induction of more productive crops in intensive cropping generated more energy. The higher bio-conversion efficiency of the intensified system was attributed to the higher energy returns over other systems in the study [58]. Significantly higher energy output under intensified cropping over conventional production systems was also reported by Babu et al. [22]. Differences in system productivity among the cropping systems caused significant variation in energy output [59]. The system energy returns from diverse cropping systems was regulated by the quality and quantity of the harvestable products [60,61]. The higher energy incurred in the cultivation of maize-based cropping systems may be due to the intensive use of energy-rich inputs like seed and fertilizer.

Crop productive capacity, GWP, and GHGI were mostly determined by the plant’s ability to transform ingested nutrients into the grain. Our findings support the notion that the GHGI of existing systems can be reduced through conservation and effective crop management practices [62]. Fertilizer use was the major GWPs contributor in all the designed systems, followed by diesel and machines [13]. Hence, greater focus must be given to crop selection while designing intensified cropping systems. The selected crop must require less tilling and less nitrogen fertilizer and have a higher conversion efficiency. Energy consumption increases corresponding to an increase in GWP was reported by many workers [26,63]. As GWP and energy input were positively associated, this was attributable to variations in input and management approaches [64]. An increase in cropping frequency corresponds to an increase in the GWP [65] and energy intensiveness [22]. Higher energy demand amplified the GWP under intensified systems over conventional production systems [66]. Zhang et al. [64] reported the wide variations in GWP (1.25 to 2.14 Mg CO2 eq ha−1 yr−1) among the tested cropping systems, and this was mainly attributed to variations in the agronomic practices adopted and input use. Similarly, in our study, intensified systems had a higher GWP than less-diversified systems like the R-W system. On the contrary, diversified systems substantially reduce GHGI and increase energy production. Huang et al. [67] also reported that the GWP and GHGI are associated with economic output and have an inverse relationship [59]. The intensified system reduces the GHGI by 75% over exiting non-intensive systems in China [68]. Thus, the results indicated that the induction of legumes substantially curtails the GHGI of the traditional R-W system. Intensive crop cultivation removed more soil nutrients as compared to less intensive cropping. Hence, selected crops must store more nutrients in the soil than they remove, which helps in nutrient conservation and soil fertility restoration. Legume induction in the existing cereal-based system recycled more nitrogen in the soil and improved soil N-supplying capacity [69]. Under intensified systems, inclusion of chickpea and other legumes substantially improves the soil N availability after three cropping cycles. Furthermore, the incorporation of green manure also accelerates the soil N supply capacity over cereal–cereal systems. Higher available N in legume plots may also be attributed to more residue recycling and N fixation. Roots of legume crops secrete the organic acid, which facilitates the P availability in the active soil pool and increases the P intensity in soil. Furthermore, the extensive and deep root system of legumes can potentially break down the soil’s hardpan and alter the soil’s physical properties. Organic acid secretion from legume roots might dissolve the native potassium in soil and thereby increase K availability [70]. These results aligned with the study by Bhunia et al. [71] and revealed that OC concentration was positively correlated with N. Mahapatra et al. [72] also reported beneficial effects of legumes in the rice-wheat system on soil organic carbon and available N, P, and K. Kumari et al. [73] also reported that Bacillus thuringiensis (Bt) cotton + green gram (1:3) system removed slightly more nitrogen than the legume–legume system. Pal [74] also found that the legume-based crop rotations increase the SOC content, nitrogen, phosphorus, and potassium availability in soil over non-legume-based systems. Crop rotations and plant genotype selection can thus be utilized to increase soil biodiversity and encourage beneficial soil fungus [75]. It may also be inferred that factor like the type of crop, the cropping system, the soil, and nutrients contribute differently to the development of microflora [76]. Hence, the alternate cropping system therefore clearly demonstrates the supremacy of diversified/intensified systems over rice-wheat, as it also serves to improve the soil’s microbial state, encouraging greater soil health.

5. Conclusions

The rice-wheat system (RWS) is a life-supporting production model that covers ~13.5 Mha in Asia [77], out of which 57% of the area is spread over South Asia. More interestingly, out of the total RWS area in South Asia, IGP accounted for 85% of total coverage [78]. In India, RWS is cultivated in a ~9.2 Mha area. The statistics clearly indicate the importance of this particular model in food security [79]. However, the sustainability of RWS is often questioned due high nutrients, water, and energy demand per unit production. In India, agriculture contributed ~16% of total GHG emissions, out of which methane accounted for 74% of total GHG emissions (38.9%through livestock and 36.9% through rice) [80]. Furthermore, leftover rice residue burning increases the pollution load in the atmosphere, which causes several human health-related problems. Therefore, there is a dire need to design and develop an alternative energy-efficient, economically feasible, and environmentally robust productive production system, especially for the IGP of India to overcome and/or minimize these issues.

The findings of the present study suggested that alternative cropping systems have a strong and positive impact on system productivity, water use efficiency, net returns, energy use efficiency, energy output efficiency, energy productivity, and soil fertility status over the RWS in IGP of India. The maize (green cobs) + vegetable cowpea + sesbania-chickpea + gobhi sarson recorded significantly higher system productivity (28.57 Mg ha−1) and water use efficiency (2.381 kg grain per m3 irrigation water), followed by maize-potato-maize (23.21 Mg ha−1), basmati rice-radish-spring maize (21.07 Mg ha−1), CS5 20.89 Mg ha−1), CS6 (20.68 Mg ha−1), respectively. Besides that, the maize-based cropping system viz. maize + pigeon pea-chickpea (bed) + gobhi sarson (furrows) and maize-potato-maize system saved 150 cm and 127.5 cm of irrigation water, respectively. Cultivation of maize (cobs) + vegetable cowpea + sesbania-chickpea + gobhi sarson system registered 64.4% higher system net returns over RWS (business as usual). However, the sorghum + cowpea (fodder)-wheat + gobhi sarson cropping system had 3.42 times higher energy use efficiency and 4.16 times higher energy output efficiency than the RWS. The maximum average energy productivity was obtained in maize (cobs) + vegetable cowpea + sesbania-chickpea + gobhi sarson (8.13 kg MJ−1), therefore, it is concluded that diversified/intensified systems can potentially reduce the water use and energy use for unit production and improve soil fertility status over traditional RWS of IGP of India. Thus, the cultivation of intensified systems as an alternative to the RWS can be promoted in a phased manner to fetch maximum profit, resource use, and environmental sustainability in IGP of India.

Author Contributions

Data curation, S.S.W. and T.K.; formal analysis, M.A.A., S.B. and K.K.; funding acquisition, A.S.P. and N.R.; investigation, S.S.W.; methodology, S.S.W.; project administration, S.S.W., A.S.P., N.R., and K.K.; resources, A.S.P., N.R. and K.K.; software, R.S.G. and K.K.; supervision, N.R.; writing—original draft, R.S.G., S.B. and N.K.; writing—review and editing, T.K., N.K., D.K.Y., S.K., M.A.A., and M.H.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted under All India Coordinated Research Project on Integrated Farming Systems (AICRP-IFS) under the aegis of ICAR-Indian Institute of Farming Systems Research, Uttar Pradesh, India.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data concerning the experiment were statistically analyzed and presented in this article.

Acknowledgments

Authors expressed their gratitude and sincere thanks to the Director of the ICAR-Indian Institute of Farming Systems Research, Modipuram, Uttar Pradesh, India, and the Vice-Chancellor of the Punjab Agricultural University, Ludhiana, Punjab India for providing the necessary facilities for conducting this research.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Babu, S.; Singh, R.; Yadav, D.; Rathore, S.S.; Raj, R.; Avasthe, R.; Yadav, S.K.; Das, A.; Yadav, V.; Yadav, B.; et al. Nanofertilizers for agricultural and environmental sustainability. Chemosphere 2022, 292, 133451. [Google Scholar] [CrossRef] [PubMed]

- Gill, S.S. Water crisis in Punjab and Haryana. Econ. Polit. Wkly. 2016, 51, 37–41. [Google Scholar]

- Yadav, G.S.; Das, A.; Kandpal, B.K.; Babu, S.; Lal, R.; Datta, M.; Das, B.; Singh, R.; Singh, V.K.; Mohapatra, K.P.; et al. The food-energy-water-carbon nexus in a maize-maize-mustard cropping sequence of the Indian Himalayas: An impact of tillage-cum-live mulching. Renew. Sustain. Energy Rev. 2021, 151, 111602. [Google Scholar] [CrossRef]

- Yadav, G.S.; Das, A.; Lal, R.; Babu, S.; Datta, M.; Meena, R.S.; Patil, S.B.; Singh, R. Impact of no-till and mulching on soil carbon sequestration under rice (Oryza sativa L.)-rapeseed (Brassica campestris L. var. rapeseed) cropping system in hilly agro-ecosystem of the Eastern Himalayas, India. Agric. Ecosyst. Environ. 2019, 275, 81–92. [Google Scholar] [CrossRef]

- Suresh, A.; Raju, S.S.; Chauhan, S.; Chaudhary, K.R. Rainfed agriculture in India: An analysis of performance and implications. Indian J. Agric. Sci. 2004, 84, 1415–1422. [Google Scholar]

- Sehgal, J.L.; Abrol, I.P.; Saxena, R.K.; Pofali, R.M. Soil Degradation in India; Oxford & IBH Publishing Co. Pvt. Ltd.: New Delhi, India, 1994. [Google Scholar]

- Sharma, S.K.; Choudhury, A.; Sarkar, P.; Biswas, S.; Singh, A.; Dadhich, P.K.; Singh, A.K.; Majumdar, S.; Bhatia, A.; Mohini, M.; et al. Greenhouse gas inventory estimates for India. Curr. Sci. 2011, 101, 405–415. [Google Scholar]

- Cole, C.V.; Duxbury, J.; Freney, J.; Heinemeyer, O.; Minami, K.; Mosier, A.; Paustian, K.; Rosenberg, N.; Sampson, N.; Sauerbeck, D.; et al. Global estimates of potential mitigation of greenhouse gas emissions by agriculture. Nutr. Cycl. Agroecosys. 1997, 49, 221–228. [Google Scholar] [CrossRef]

- Smithson, P.A. IPCC, 2001: Climate Change 2001: The Scientific Basis. Contribution of Working Group 1 to the Third Assessment Report of the Intergovernmental Panel on Climate Change; Houghton, J.T., Ding, Y., Griggs, D.J., Noguer, M., van der Linden, P.J., Dai, X., Maskell, K., Johnson, C.A., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2002; p. 881. [Google Scholar] [CrossRef]

- Yadav, G.S.; Babu, S.; Das, A.; Mohapatra, K.P.; Singh, R.; Avasthe, R.K.; Roy, S. No till and mulching enhance energy use efficiency and reduce carbon footprint of a direct-seeded upland rice production system. J. Clean. Prod. 2020, 271, 122700. [Google Scholar] [CrossRef]

- Solomon, S.; Qin, D.; Manning, M.; Chen, Z.; Marquis, M.; Averyt, K.B.; Tignor, M.; Miller, H.L. IPCC, Climate Change 2007: The Physical Science Basis, Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007; p. 18. [Google Scholar]

- Janzen, H.H. Carbon cycling in earth systems-a soil science perspective. Agric. Ecosyst. Environ. 2004, 104, 399–417. [Google Scholar] [CrossRef]

- Smith, P. Engineered biological sinks on land. In The Global Carbon Cycle: Integrating Humans, Climate, and the Natural World; Field, C.B., Raupach, M.R., Eds.; Scientific Committee on Problems of the Environment (SCOPE); Island Press: Washington, DC, USA, 2004; Volume 62, pp. 479–491. [Google Scholar]

- Ferry, J.G. Biochemistry of methanogenesis. Crit. Rev. Biochem. Mol. Biol. 1992, 27, 473–503. [Google Scholar] [CrossRef] [PubMed]

- Mosier, A.R.; Duxbury, J.M.; Freney, J.R.; Heinemeyer, O.; Minami, K.; Johnson, D.E. Mitigating agricultural emissions of methane. Clim. Change 1998, 40, 39–80. [Google Scholar] [CrossRef]

- Oenema, O.; Wrage, N.; Velthof, G.L.; van Groenigen, J.W.; Dolfing, J.; Kuikman, P.J. Trends in global nitrous oxide emissions from animal production systems. Nutr. Cycl. Agroecosyst. 2005, 72, 51–65. [Google Scholar] [CrossRef]

- Smith, K.A.; Conen, F. Impacts of land management on fluxes of trace greenhouse gases. Soil Use Manag. 2004, 20, 255–263. [Google Scholar] [CrossRef]

- Wassmann, R.; Lantin, R.S.; Neue, H.U.; Buendia, L.V.; Corton, T.M.; Lu, Y. Characterization of methane emissions from rice fields in Asia. III. Mitigation options and future research needs. Nutr. Cycl. Agroecosyst. 2000, 58, 23–36. [Google Scholar] [CrossRef]

- Druckman, A.; Jackson, T. The carbon footprint of UK households 1990–2004: A socio-economically disaggregated, quasi-multi-regional input–output model. Ecol. Econ. 2009, 68, 2066–2077. [Google Scholar] [CrossRef]

- Hillier, J.; Hawes, C.; Squire, G.; Hilton, A.; Wale, S.; Smith, P. The carbon footprints of food crop production. Int. J. Agric. Sustain. 2009, 7, 107–118. [Google Scholar] [CrossRef]

- Perry, S.; Klemes, J.; Bulatov, I. Integrating waste and renewable energy to reduce the carbon footprint of locally integrated energy sectors. Energy 2008, 33, 1489–1497. [Google Scholar] [CrossRef]

- Babu, S.; Mohapatra, K.P.; Das, A.; Yadav, G.S.; Tahasildar, M.; Singh, R.; Panwar, A.S.; Yadav, V.; Chandra, P. Designing energy-efficient, economically sustainable and environmentally safe cropping system for the rainfed maize-fallow land of the Eastern Himalayas. Sci. Total Environ. 2020, 722, 137874. [Google Scholar] [CrossRef]

- Yadav, G.S.; Babu, S.; Das, A.; Datta, M.; Mohapatra, K.P.; Singh, R.; Rathore, S.S.; Chakraborty, M. Productivity, soil health, and carbon management index of Indian Himalayan intensified maize-based cropping systems under live mulch-based conservation tillage practices. Field Crops Res. 2021, 264, 108080. [Google Scholar] [CrossRef]

- Jat, R.K.; Sapkota, T.B.; Singh, R.G.; Jat, M.L.; Kumar, M.; Gupta, R.K. Seven years of conservation agriculture in a rice-wheat rotation of Eastern Gangetic Plains of South Asia: Yield trends and economic profitability. Field Crops Res. 2014, 164, 199–210. [Google Scholar] [CrossRef]

- Devasenapathy, P.; Senthilkumar, G.; Shanmugam, P.M. Energy management in crop production. Indian J. Agron. 2009, 54, 80–90. [Google Scholar]

- Yadav, G.S.; Das, A.; Lal, R.; Babu, S.; Meena, R.S.; Saha, P.; Singh, R.; Datta, M. Energy budget and carbon footprint in a no-till and mulch based rice-mustard cropping system. J. Clean. Prod. 2018, 191, 144–157. [Google Scholar] [CrossRef]

- Walkley, A.; Black, I.A. An examination of the Degtjareff method for determining soil organic matter, and a proposed modification of the chromic acid titration method. Soil Sci. 1934, 37, 29–38. [Google Scholar] [CrossRef]

- Subbiah, B.V.; Asija, G.L. A rapid method for the estimation of nitrogen in soil. Curr. Sci. 1956, 26, 259–260. [Google Scholar]

- Olsen, S.R.; Cole, C.V.; Watanabe, F.S.; Dean, L.A. Estimation of Available Phosphorus in Soil by Extraction with Sodium Bicarbonate; USDA: Washington, DC, USA, 1954. [Google Scholar]

- Merwin, H.D.; Peech, M. Exchangeability of soil potassium in the sand, silt, and clay fractions as influenced by the nature of the complementary exchangeable cation. Soil Sci. Soc. Am. J. 1951, 15, 125–128. [Google Scholar] [CrossRef]

- Micle, V.; Sur, I.M.; Criste, A.; Senila, M.; Levei, E.; Marinescu, M.; Rogozan, G.C. Lab-scale experimental investigation concerning ex-situ bioremediation of petroleum hydrocarbons-contaminated soils. Soil Sediment Contam. Int. J. 2018, 27, 692–705. [Google Scholar] [CrossRef]

- Thomas, P.; Sekhar, A.C.; Upreti, R.; Mujawar, M.M.; Pasha, S.S. Optimization of single plate-serial dilution spotting (SP-SDS) with sample anchoring as an assured method for bacterial and yeast cfu enumeration and single colony isolation from diverse samples. Biotechnol. Rep. 2015, 8, 45–55. [Google Scholar] [CrossRef]

- Pratibha, G.; Srinivas, I.; Rao, K.V.; Shanker, A.K.; Raju, B.M.K.; Choudhary, D.K.; Rao, K.S.; Srinivasarao, C.; Maheswari, M. Net global warming potential and greenhouse gas intensity of conventional and conservation agriculture system in rainfed semi-arid tropics of India. Atmos. Environ. 2016, 145, 239–250. [Google Scholar] [CrossRef]

- Stocker, T.F.; Qin, D.; Plattner, G.K.; Tignor, M.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y.; Bex, V.; Midglev, P.M. IPCC, Climate Change 2013: The Physical Science Basis. In Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; pp. 710–716. [Google Scholar]

- West, T.O.; Marland, G. A synthesis of carbon sequestration, carbon emissions, and net carbon flux in agriculture: Comparing tillage practices in the United States. Agric. Ecosyst. Environ. 2002, 91, 217–232. [Google Scholar] [CrossRef]

- Lal, R. Carbon emission from farm operations. Environ. Int. 2004, 30, 981–990. [Google Scholar] [CrossRef]

- Gao, B.; Ju, X.; Meng, Q.; Cui, Z.; Christie, P.; Chen, X.; Zhang, F. The impact of alternative cropping systems on global warming potential, grain yield and groundwater use. Agric. Ecosyst. Environ. 2015, 203, 46–54. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Y.; Zhang, X.; Tian, G. Carbon footprint analysis for mechanization of maize production based on life cycle assessment: A case study in Jilin Province, China. Sustainability 2015, 7, 15772–15784. [Google Scholar] [CrossRef]

- Tubiello, F.N.; Condor-Golec, R.D.; Salvatore, M.; Piersante, A.; Federici, S.; Ferrara, A.; Rossi, S.; Flammini, A.; Cardenas, P.; Biancalani, R.; et al. Estimating Greenhouse Gas Emissions in Agriculture: A Manual to Address Data Requirements for Developing Countries; FAO: Rome, Italy, 2015; p. 193. [Google Scholar]

- Singh, V.K.; Dwivedi, B.S.; Singh, S.K.; Majumdar, K.; Jat, M.L.; Mishra, R.P.; Rani, M. Soil physical properties, yield trends and economics after five years of conservation agriculture-based rice-maize system in north-western India. Soil Till. Res. 2016, 155, 133–148. [Google Scholar] [CrossRef]

- Beri, V.; Sidhu, B.S.; Gupta, A.P.; Tiwari, R.C.; Pareek, R.P.; Rupela, O.P.; Khera, R.; Singh, J. Organic Resources of a Part of Indo-Gangetic Plain and Their Utilization; Panjab Agricultural University, Department of Soils: Ludhiana, India, 2003. [Google Scholar]

- Thind, H.S.; Sharma, S.; Singh, Y.; Sidhu, H.S. Rice-wheat productivity and profitability with residue, tillage and green manure management. Nutr. Cycl. Agroecosyst. 2019, 113, 13–125. [Google Scholar] [CrossRef]

- Gathala, M.K.; Kumar, V.; Sharma, P.C.; Saharawat, Y.S.; Jat, H.S.; Singh, M.; Kumar, A.; Jat, M.L.; Humphreys, E.; Sharma, D.K.; et al. Optimizing intensive cereal-based cropping systems addressing current and future drivers of agricultural change in the northwestern Indo-Gangetic Plains of India. Agric. Ecosyst. Environ. 2013, 177, 85–97. [Google Scholar] [CrossRef]

- Gill, M.S.; Ahlawat, I.P.S. Crop diversification-its role towards sustainability and profitability. Indian J. Fertil. 2006, 2, 125–138. [Google Scholar]

- Purushothaman, S. Studies on Rice-Based Multiple Cropping System. Ph.D. Thesis, TNAU, Coimbatore, India, 1979. [Google Scholar]

- Yadav, M.P.; Rai, J.; Kushwaha, S.P.; Singh, G.K. Production potential and economic analysis of various cropping systems for central plains zone of Uttar Pradesh. Indian J. Agron. 2005, 50, 83–85. [Google Scholar]

- Congreves, K.A.; Hayes, A.; Verhallen, E.A.; Van Eerd, L.L. Long-term impact of tillage and crop rotation on soil health at four temperate agroecosystems. Soil Till. Res. 2015, 152, 17–28. [Google Scholar] [CrossRef]

- Singh, V.K.; Sharma, B.B. Economic evaluation of rice (Oryza sativa)-based cropping sequences in the foothills of Himalayas. Indian J. Agron. 2002, 47, 12–19. [Google Scholar]

- Gill, M.S.; Sharma, G.C. Cropping systems diversification opportunities and conservation agriculture. J. Farming Syst. Res. Dev. 2005, 11, 127–134. [Google Scholar]

- Walia, S.S.; Gill, M.S.; Dhaliwal, S.S. Production potential and economics of different cropping systems and their impact on soil health. Indian J. Ecol. 2010, 37, 23–26. [Google Scholar]

- Choudhary, J.B.; Thakur, R.C.; Bhargava, M.; Sood, R.D. Production potential and economics of rice (Oryza sativa)-based cropping systems on farmers’ fields under mid-hill conditions of Himachal Pradesh. Himachal J. Agric. Res. 2001, 27, 31–35. [Google Scholar]

- Padhi, A.K. Productivity and economics of rice (Oryza sativa) based cropping sequences. Indian J. Agron. 1993, 38, 351–356. [Google Scholar]

- Zhang, H.; Pala, M.; Oweis, T.; Harris, H. Water use and water-use efficiency of chickpea and lentil in a Mediterranean environment. Aust. J. Agric. Res. 2000, 51, 295–304. [Google Scholar] [CrossRef]

- Meng, Q.; Sun, Q.; Chen, X.; Cui, Z.; Yue, S.; Zhang, F.; Romheld, V. Alternative cropping systems for sustainable water and nitrogen use in the North China Plain. Agric. Ecosyst. Environ. 2012, 146, 93–102. [Google Scholar] [CrossRef]

- Walia, S.S.; Gill, M.S.; Bhushan, B.; Phutela, R.P.; Aulakh, C.S. Alternate cropping systems to rice (Oryza sativa)-wheat (Triticum aestivum) for Punjab. Indian J. Agron. 2011, 56, 20–27. [Google Scholar]

- Samui, R.C.; Kundu, A.L.; Majumder, D.; Mani, P.K.; Sahu, P.K. Diversification of rice (Oryza sativa)-based cropping system in new alluvial zone of West Bengal. Indian J. Agron. 2004, 49, 71–73. [Google Scholar]

- Rao, M.R.; Willey, R.W. Evaluation of Yield Stability in Intercropping: Studies on Sorghum/Pigeonpea. Exp. Agric. 1980, 16, 105–116. [Google Scholar] [CrossRef]

- Bohra, J.S.; Singh, R.K.; Singh, U.N.; Singh, K.; Singh, R.P. Effect of crop diversification in rice-wheat cropping system on productivity, economics, land use and energy use efficiency under irrigated ecosystem of Varanasi. Oryza 2007, 44, 320–324. [Google Scholar]

- Meena, J.R.; Behera, U.K.; Chakraborty, D.; Sharma, A.R. Tillage and residue management effect on soil properties, crop performance and energy relations in green gram (Vigna radiata L.) under maize-based cropping systems. Int. Soil Water Conserv. Res. 2015, 3, 261–272. [Google Scholar] [CrossRef]

- Hatirli, S.A.; Ozkan, B.; Fert, C. Energy inputs and crop yield relationship in greenhouse tomato production. Renew. Energy 2006, 31, 427–438. [Google Scholar] [CrossRef]

- Gelfand, I.; Snapp, S.S.; Robertson, G.P. Energy efficiency of conventional, organic, and alternative cropping systems for food and fuel at a site in the US Midwest. Environ. Sci. Technol. 2010, 44, 4006–4011. [Google Scholar] [CrossRef] [PubMed]

- Gan, Y.; Liang, C.; Hamel, C.; Cutforth, H.; Wang, H. Strategies for reducing the carbon footprint of field crops for semiarid areas: A review. Agron. Sustain. Dev. 2011, 31, 643–656. [Google Scholar] [CrossRef]

- Pishgar-Komleh, S.H.; Ghahderijani, M.; Sefeedpari, P. Energy consumption and CO2 emissions analysis of potato production based on different farm size levels in Iran. J. Clean. Prod. 2012, 33, 183–191. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Pu, C.; Zhao, X.; Xue, J.F.; Zhang, R.; Nie, Z.J.; Chen, F.; Lal, R.; Zhang, H.L. Tillage effects on carbon footprint and ecosystem services of climate regulation in a winter wheat-summer maize cropping system of the North China Plain. Ecol. Indic. 2016, 67, 821–829. [Google Scholar] [CrossRef]

- Plaza-Bonilla, D.; Nogue-Serra, I.; Raffaillac, D.; Cantero-Martínez, C.; Justes, E. Carbon footprint of cropping systems with grain legumes and cover crops: A case-study in SW France. Agric. Syst. 2018, 167, 92–102. [Google Scholar] [CrossRef]

- Prechsl, U.E.; Wittwer, R.; van der Heijden, M.G.; Lüscher, G.; Jeanneret, P.; Nemecek, T. Assessing the environmental impacts of cropping systems and cover crops: Life cycle assessment of FAST, a long-term arable farming field experiment. Agric. Syst. 2017, 157, 39–50. [Google Scholar] [CrossRef]

- Rathore, S.S.; Babu, S.; Shekhawat, K.; Singh, R.; Yadav, S.K.; Singh, V.K.; Singh, C. Designing energy cum carbon-efficient environmentally clean production system for achieving green economy in agriculture. Sustain. Energy Technol. Assess. 2022, 52, 102190. [Google Scholar] [CrossRef]

- Yang, X.; Gao, W.; Zhang, M.; Chen, Y.; Sui, P. Reducing agricultural carbon footprint through diversified crop rotation systems in the North China Plain. J. Clean. Prod. 2014, 76, 131–139. [Google Scholar] [CrossRef]

- Porpavai, S.; Devasenapathy, P.; Siddeswaran, K.; Jayaraj, T. Impact of various rice-based cropping systems on soil fertility. J. Cereals Oilseeds 2011, 2, 43–46. [Google Scholar]

- Nagoli, S.A.; Basavanneppa, M.A.; Sawargaonkar, G.; Biradar, D.P.; Biradar, S.A.; Navyashree, M.R. Soil fertility as influenced by alternate sequential cropping systems to rice-rice (Oryza sativa L.) In Tunga Bhadra project area. Ecol. Environ. Conserv. 2016, 22, 445–448. [Google Scholar]

- Bhunia, G.S.; Shit, P.K.; Chattopadhyay, R. Assessment of spatial variability of soil properties using geostatistical approach of lateritic soil (West Bengal, India). Ann. Agrar. Sci. 2018, 16, 436–443. [Google Scholar] [CrossRef]

- Mahapatra, B.S.; Kandpal, B.K.; Sharma, G.L. Summer legumes in relation to productivity and fertility in rice-wheat cropping system. Ann. Agric. Res. 2002, 23, 365–370. [Google Scholar]

- Kumari, C.P.; Goverdhan, M.; Reddy, G.K.; Nthebere, K.; Sharma, S.H.K.; Qureshi, A.A.; Alibaba, M.; Chiranjeevi, K. Different Cropping System Effect on Available NPK Post-harvest and their Uptake on Sandy Loam Soil of Southern Telangana Zone, India. Int. Res. J. Pure Appl. Chem. 2020, 21, 56–65. [Google Scholar] [CrossRef]

- Pal, M.S. Alternative crop production strategies for rice-wheat cropping systems in the Indo-Gangetic plains of India. Aust. J. Exp. Agric. 2003, 43, 605–615. [Google Scholar] [CrossRef]

- Ellouze, W.; Esmaeili Taheri, A.; Bainard, L.D.; Yang, C.; Bazghaleh, N.; Navarro-Borrell, A.; Hanson, K.; Hamel, C. Soil fungal resources in annual cropping systems and their potential for management. BioMed Res. Int. 2014, 2014, 531824. [Google Scholar] [CrossRef]

- Bhatt, R.; Singh, P.; Hossain, A.; Timsina, J. Rice-wheat system in the northwest Indo-Gangetic plains of South Asia: Issues and technological interventions for increasing productivity and sustainability. Paddy Water Environ. 2021, 19, 345–365. [Google Scholar] [CrossRef]

- Ladha, J.K.; Kumar, V.; Alam, M.M.; Sharma, S.; Gathala, M.; Chandna, P.; Saharawat, Y.S.; Balasubramanian, V. Integrating crop and resource management technologies for enhanced productivity, profitability, and sustainability of the rice-wheat system in South Asia. In Integrated Crop and Resource Management in the Rice-wheat System of South Asia; International Rice Research Institute (IRRI): Los Baños, Philippine, 2009; pp. 69–108. [Google Scholar]

- Banjara, T.R.; Bohra, J.S.; Kumar, S.; Singh, T.; Shori, A.; Prajapat, K. Sustainable alternative crop rotations to the irrigated rice-wheat cropping system of Indo-Gangetic Plains of India. Arch. Agron. Soil Sci. 2021, 67, 1–18. [Google Scholar] [CrossRef]

- Jat, M.L.; Chakarborty, D.; Ladha, J.K.; Rana, D.S.; Gathala, M.K.; McDonald, A.; Bruno, G. Conservation agriculture for sustainable intensification in South Asia. Nat. Sustain. 2020, 3, 336–343. [Google Scholar] [CrossRef]

- Dhanda, S.; Yadav, A.; Yadav, D.B.; Chauhan, B.S. Emerging issues and potential opportunities in the rice-wheat cropping system of North-Western India. Front. Plant Sci. 2022, 13, 832683. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).