The Carrot or the Stick? Stakeholder Support for Mandatory Regulations towards a Circular Fashion System

Abstract

:1. Introduction

“a fashion system that moves towards a regenerative model with an improved use of sustainable and renewable resources, reduction of non-renewable inputs, pollution and waste generation, while facilitating long product life and material circulation via sustainable fashion design strategies and effective reverse logistics processes. Application of circular fashion needs a system perspective where all the designers, manufacturers, suppliers, retailers and consumers are involved and committed with a positive shift in mind set.”

- RQ1—What policy instruments are preferred by various stakeholders for a transition to a circular fashion system?

- RQ2—What differences in policy instrument preferences do we notice between different aspects of a circular fashion system?

- RQ3—What is the relationship between personal, stakeholder, and company characteristics and policy instrument preferences?

2. Materials and Methods

2.1. Identifying Aspects of a Circular Fashion System

2.2. Screening Ambitions and Policy Instruments

“By 2030 textile products placed on the EU market are long-lived and recyclable, to a great extent made of recycled fibres, free of hazardous substances and produced in respect of social rights and the environment. Consumers benefit longer from high quality affordable textiles, fast fashion is out of fashion, and economically profitable re-use and repair services are widely available. In a competitive, resilient, and innovative textiles sector, producers take responsibility for their products along the value chain, including when they become waste. The circular textiles ecosystem is thriving, driven by sufficient capacities for innovative fibre-to-fibre recycling, while the incineration and landfilling of textiles is reduced to the minimum.”

2.3. Survey and Focus Group Research

| Aspects of a Circular Fashion System | EU Strategy 2022 [30] | EMF Vision 2020 [93] | GFA Agenda 2021 [94] | UNECE Pledge 2021 [97] | UNFCCC Fashion Charter 2021 [98] | WRAP 2021 [99] | OECD Due Diligence Guidance 2018 [95] | Circular Economy Action Agenda Textiles [96] |

|---|---|---|---|---|---|---|---|---|

| Low impact fibres | ||||||||

| Use of recycled fibres | MR | x | x | NA | x | x | NA | x |

| Use of renewable fibres | AB | x | x | NA | NA | NA | NA | NA |

| Reduce micro-fibre shedding | MR | x | x | NA | NA | NA | NA | NA |

| Low impact processes | ||||||||

| Sustainable agricultural practices | VIT | x | x | NA | x | NA | x | X |

| Efficient water use | AB | x | x | NA | NA | x | x | NA |

| Efficient energy use | AB | x | x | NA | x | x | x | NA |

| Phase out chemicals of concern | MR | x | x | NA | NA | x | x | NA |

| Reduce CO2 emissions | MR | x | x | NA | x | x | x | x |

| Reduce transport and logistics | NA | NA | NA | NA | x | NA | x | NA |

| Longer use of garments | ||||||||

| Design for durability | MR | x | x | NA | NA | x | x | x |

| Design for repair | MR | x | x | NA | NA | x | NA | x |

| Long-lasting fashion styles | AB | x | NA | NA | NA | x | NA | x |

| Re-use and second-hand markets | MR | x | x | NA | NA | x | X | x |

| Sharing models (e.g., garment rental systems) | AB | x | x | NA | NA | x | NA | x |

| Recycling | ||||||||

| Design for recycling | MR | x | x | NA | NA | x | x | x |

| Improved waste collection and sorting systems | MR | x | x | NA | NA | x | NA | x |

| High quality recycling technologies | MR | x | x | NA | NA | x | NA | x |

| Phasing out waste exports | MR | NA | x | NA | NA | NA | NA | x |

| Waste prevention | ||||||||

| Minimising overproduction | MR | x | x | NA | NA | NA | NA | NA |

| Minimising production waste | AB | x | x | NA | NA | x | NA | NA |

| Minimising packaging waste | NA | x | NA | NA | NA | NA | X | NA |

| Minimising post-consumer waste | NMP | x | x | NA | NA | x | NA | NA |

| Social justice | ||||||||

| Healthy and safe working conditions | VIT | NA | x | x | NA | NA | x | x |

| Fair wages | VIT | NA | x | NA | NA | NA | x | x |

| Increased social protection | NA | NA | x | NA | NA | NA | x | x |

| No forced labor, nor child labor | MR | NA | x | NA | NA | NA | x | x |

| Non-discrimination | VIT | NA | x | NA | NA | NA | x | x |

| Value chain collaboration | ||||||||

| Transparency throughout the value chain | MR | x | x | x | x | x | x | x |

| Traceability of the supply chain | MR | x | x | x | NA | x | x | x |

| Partnerships between producers and waste processors | AB | NA | x | x | x | x | x | x |

3. Results

3.1. Stakeholder Preferences on Policy Instruments

3.2. Profile Differences

4. Discussion

4.1. Significant Support for Mandatory Regulations

4.2. Investigating Profile Differences

4.3. Limitations and Suggestions for Further Research

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Variable (n = 321) | Frequency | % |

|---|---|---|

| Gender | ||

| - Male | 110 | 34.27% |

| - Female | 206 | 64.17% |

| - Non-binary | 0 | 0.00% |

| - Prefer not to share this information | 5 | 1.56% |

| Age | ||

| - <25 years | 30 | 9.35% |

| - 26–35 years | 86 | 26.79% |

| - 36–45 years | 83 | 25.86% |

| - 46–55 years | 74 | 23.05% |

| - 56–65 years | 44 | 13.71% |

| - >65 years | 4 | 1.25% |

| Number of years active in (or working on) the fashion industry | ||

| - <3 years | 55 | 17.13% |

| - 3–5 years | 34 | 10.59% |

| - 6–10 years | 31 | 9.66% |

| - 11–20 years | 37 | 11.53% |

| - +20 years | 63 | 19.63% |

| - I am not working in/on the fashion industry | 101 | 31.46% |

| Current professional position | ||

| - CEO/General Management | 52 | 16.20% |

| - Strategic Management | 32 | 9.97% |

| - Operational Management | 36 | 11.21% |

| - Expert | 78 | 24.30% |

| - Designer | 29 | 9.03% |

| - Operational or administrative co-workers | 41 | 12.77% |

| - Independent consultant | 35 | 10.90% |

| - Other | 18 | 5.61% |

| Country | ||

| - Belgium | 160 | 49.84% |

| - France | 42 | 13.08% |

| - Germany | 26 | 8.10% |

| - Ireland | 19 | 5.92% |

| - Netherlands | 12 | 3.75% |

| - Italy | 7 | 2.18% |

| - Countries with 6 respondents: Austria, Sweden | 12 | 3.75% |

| - Countries with 5 respondents: Switzerland | 5 | 1.56% |

| - Countries with 4 respondents: China, Denmark, Spain | 12 | 3.75% |

| - Countries with 3 respondents: Egypt, Portugal | 6 | 1.87% |

| - Countries with 2 respondents: Bulgaria, Poland, Turkey, United Arab Emirates | 8 | 2.5% |

| - Countries with 1 respondent: Afghanistan, Australia, Bangladesh, Brazil, Croatia, Greece, Luxembourg, North Macedonia, Romania, Serbia, Slovenia, United States of America | 12 | 3.75% |

| Stakeholder Type | ||

| - Company | 121 | 37.69% |

| - Government | 13 | 4.05% |

| - Supranational organization (EC, UN, ILO, WTO, …) | 4 | 1.25% |

| - Non-governmental organization (NGO) | 32 | 9.97% |

| - Sector Federation | 22 | 6.85% |

| - Trade Union or Worker Movement | 7 | 2.18% |

| - Research Institute | 26 | 8.10% |

| - Myself, as a Fashion Customer | 77 | 23.99% |

| - Other | 19 | 5.92% |

| Variable (n = 118) | Frequency | % |

|---|---|---|

| Value chain activities | ||

| - Retail and sales | 41 | 34.75% |

| - Fashion designer | 39 | 33.05% |

| - Fashion manufacturer (finished goods) | 36 | 30.51% |

| - Textile manufacturer (yarn, fabric, …) | 20 | 16.95% |

| - Logistics and distribution | 19 | 16.10% |

| - Waste management | 16 | 13.56% |

| - Fibre producer | 9 | 7.63% |

| - Reuse shop | 6 | 5.08% |

| - Other | 22 | 18.64% |

| Type of market(s) | ||

| - BtC | 70 | 59.83% |

| - BtB | 80 | 68.38% |

| - BtBtC | 32 | 27.35% |

| - BtG | 14 | 11.97% |

| - Peer-to-Peer | 4 | 3.42% |

| Company size (number of employees) | ||

| - >1000 employees | 13 | 11.02% |

| - 251–1000 employees | 13 | 11.02% |

| - 51–250 employees | 31 | 26.27% |

| - 11–50 employees | 23 | 19.49% |

| - 1–10 employees | 27 | 22.88% |

| - No employees | 11 | 9.32% |

| Geographical scope of sourcing materials | ||

| - Local (<100 km) | 9 | 7.63% |

| - Regional (<500 km) | 18 | 15.25% |

| - Supra-regional (<5000 km) | 25 | 21.19% |

| - Global | 57 | 48.31% |

| - Not applicable | 9 | 7.63% |

| Geographical scope of operational activities (manufacturing/design) | ||

| - Local (<100 km) | 26 | 22.03% |

| - Regional (<500 km) | 15 | 12.71% |

| - Supra-regional (<5000 km) | 25 | 21.19% |

| - Global | 43 | 36.44% |

| - Not applicable | 9 | 7.63% |

| Geographical scope of sales activities | ||

| - Local (<100 km) | 9 | 7.63% |

| - Regional (<500 km) | 25 | 21.19% |

| - Supra-regional (<5000 km) | 26 | 22.03% |

| - Global | 55 | 46.61% |

| - Not applicable | 3 | 2.54% |

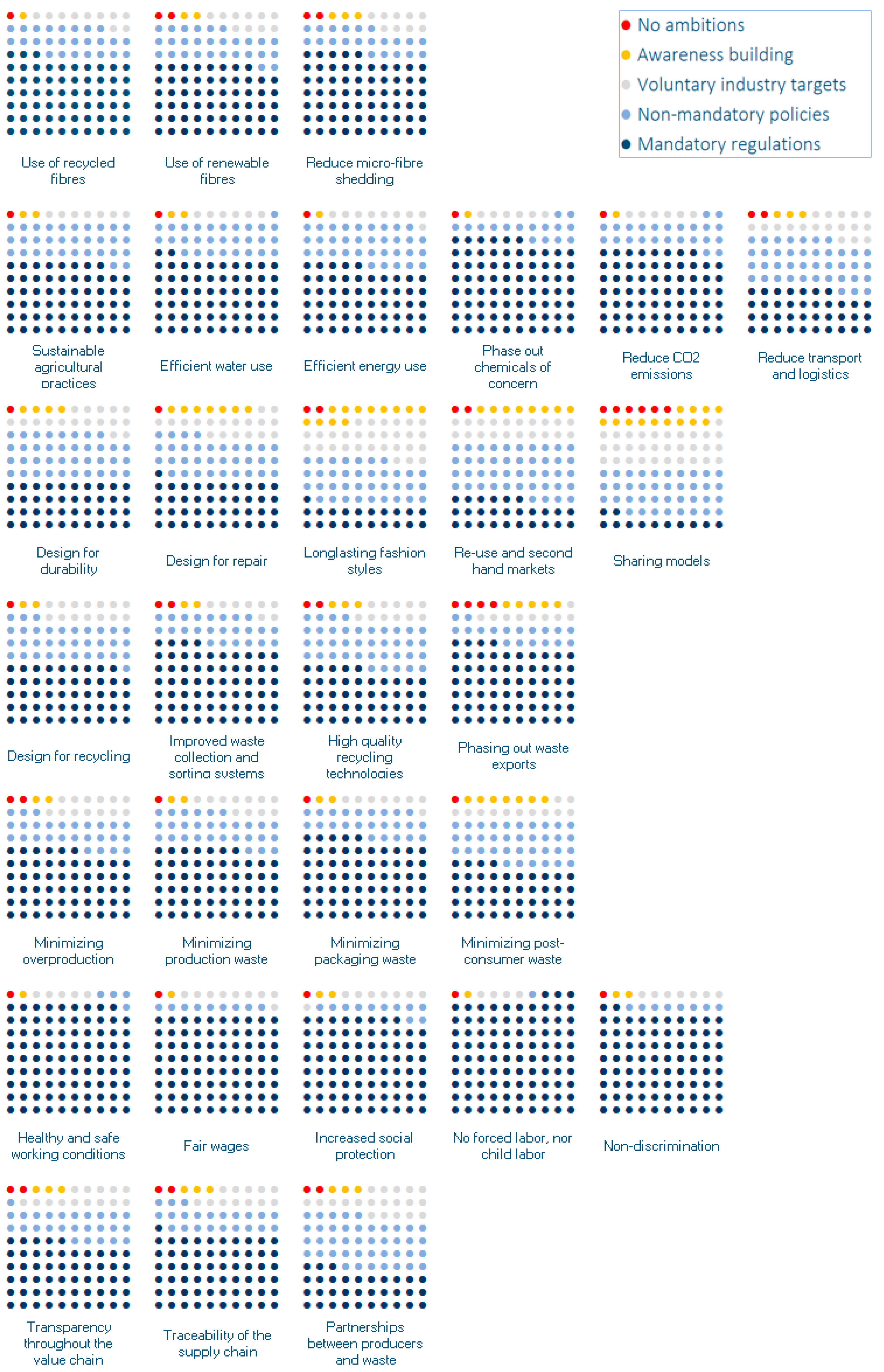

| Instrument choice: preferences (n = 261) 1 = No Ambition Levels, 2 = Awareness Building, 3 = Voluntary Industry Targets, 4 = Non-Mandatory Policies (e.g., Tax Incentives), 5 = Mandatory Regulations (e.g., Product Norms) | Average (stdev) | Median |

|---|---|---|

| Low impact fibres | ||

| - Use of recycled fibres | 4.49 (0.7776) | 5 |

| - Use of renewable fibres | 4.40 (0.8610) | 5 |

| - Reduce micro-fibre shedding | 4.42 (0.9439) | 5 |

| Low impact processes | ||

| - Sustainable agricultural practices | 4.43 (0.8269) | 5 |

| - Efficient water use | 4.49 (0.7777) | 5 |

| - Efficient energy use | 4.40 (0.7912) | 5 |

| - Phase out chemicals of concern | 4.64 (0.7387) | 5 |

| - Reduce CO2 emissions | 4.57 (0.7385) | 5 |

| - Reduce transport and logistics | 4.05 (0.9349) | 4 |

| Longer use of garments | ||

| - Design for durability | 4.10 (0.9119) | 4 |

| - Design for repair | 4.05 (1.0028) | 4 |

| - Long-lasting fashion styles | 3.63 (1.0057) | 4 |

| - Re-use and second-hand markets | 3.85 (0.9605) | 4 |

| - Sharing models (e.g., garment rental systems) | 3.38 (1.0528) | 4 |

| Recycling | ||

| - Design for recycling | 4.28 (0.8616) | 4 |

| - Improved waste collection and sorting systems | 4.47 (0.8570) | 5 |

| - High quality recycling technologies | 4.22 (0.8807) | 4 |

| - Phasing out waste exports | 4.36 (1.0522) | 5 |

| Waste prevention | ||

| - Minimizing overproduction | 4.35 (0.8798) | 5 |

| - Minimizing production waste | 4.38 (0.8405) | 5 |

| - Minimizing packaging waste | 4.49 (0.8209) | 5 |

| - Minimizing post-consumer waste | 4.14 (0.9603) | 4 |

| Social justice | ||

| - Healthy and safe working conditions | 4.78 (0.7101) | 5 |

| - Fair wages | 4.66 (0.8014) | 5 |

| - Increased social protection | 4.63 (0.8156) | 5 |

| - No forced labour, nor child labour | 4.83 (0.6715) | 5 |

| - Non-discrimination | 4.68 (0.7965) | 5 |

| Value chain collaboration | ||

| - Transparency throughout the value chain | 4.30 (0.9411) | 5 |

| - Traceability of the supply chain | 4.39 (0.9122) | 5 |

| - Partnerships between producers and waste processors | 4.02 (0.9049) | 4 |

Appendix B

Appendix B.1. Stakeholder Identification and Mapping

- C—Criteria: Defining a set of criteria and categories for stakeholder groups that are or could either be affecting the topic, be affected by it (or both), in order to map all relevant stakeholders,

- Q—Quotas: Setting specific minimum quotas for all categories for each engagement activity;

- I—Individuals: Identifying individuals that fit the categories, with the overall selection fitting the quotas set for each engagement activity.

Appendix B.2. Focus Groups—Vienna (11 and 12 May 2022)—Participants

| Stakeholder Type | Number of Participants |

|---|---|

| Production and sourcing of fibres and raw materials | 2 |

| Product design and textile production | 1 |

| Distribution, branding, and retail | 4 |

| Business models and innovation | 3 |

| Recyclers, reuse, and waste management | 6 |

| Civil Society | 2 |

| Policy Makers | 2 |

| Education and research | 3 |

| Finance | 1 |

| End-users and consumers | 1 |

Appendix B.3. Focus Groups—Session 1 (11 May 2022)

- What is a feasible ambition level for the 2030 vision? What could be concrete targets?

- What policy measures are most suited to support this transition to the vision?

Appendix B.4. Focus Groups—Session 2 (12 May 2022)

- What is the most important pain point for your organisation for the transition towards a circular fashion system?

- What is a concrete solution to address at least one of these pain points?

References

- Peleg Mizrachi, M.; Tal, A. Regulation for Promoting Sustainable, Fair and Circular Fashion. Sustainability 2022, 14, 502. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. A New Textiles Economy. 2017. Available online: https://emf.thirdlight.com/file/24/uiwtaHvud8YIG_uiSTauTlJH74/A%20New%20Textiles%20Economy%3A%20Redesigning%20fashion%E2%80%99s%20future.pdf (accessed on 26 September 2022).

- Remy, N.; Speelman, E.; Swartz, S. Style That’s Sustainable: A New Fast-Fashion Formula; McKinsey & Company: New York, NY, USA, 2016. [Google Scholar]

- Garcia-Torres, S.; Rey-Garcia, M.; Albareda-Vivo, L. Effective Disclosure in the Fast-Fashion Industry: From Sustainability Reporting to Action. Sustainability 2017, 9, 2256. [Google Scholar] [CrossRef]

- Wang, B.; Luo, W.; Zhang, A.; Tian, Z.; Li, Z. Blockchain-Enabled Circular Supply Chain Management: A System Architecture for Fast Fashion. Comput. Ind. 2020, 123, 103324. [Google Scholar] [CrossRef]

- Centobelli, P.; Abbate, S.; Nadeem, S.P.; Garza-Reyes, J.A. Slowing the Fast Fashion Industry: An All-Round Perspective. Curr. Opin. Green Sustain. Chem. 2022, 38, 100684. [Google Scholar] [CrossRef]

- Balchandani, A.; Lau, B.; Nguyen, H.-L.; Toma, B. Six Vectors of Success in Online Fashion-McKinsey, 2021. Available online: https://www.mckinsey.com/business-functions/growth-marketing-and-sales/our-insights/six-vectors-of-success-in-online-fashion (accessed on 5 July 2022).

- Monroe, R. Ultra-Fast Fashion Is Eating the World. Available online: https://www.theatlantic.com/magazine/archive/2021/03/ultra-fast-fashion-is-eating-the-world/617794/ (accessed on 5 July 2022).

- Bakshi, S. Fashion Industry in 2022 & Beyond. Available online: www.fibre2fashion.com (accessed on 26 September 2022).

- Chen, X.; Memon, H.A.; Wang, Y.; Marriam, I.; Tebyetekerwa, M. Circular Economy and Sustainability of the Clothing and Textile Industry. Mater. Circ. Econ. 2021, 3, 12. [Google Scholar] [CrossRef]

- Provin, A.P.; de Aguiar Dutra, A.R.; de Sousa e Silva Gouveia, I.C.A.; Cubas, e.A.L.V. Circular Economy for Fashion Industry: Use of Waste from the Food Industry for the Production of Biotextiles. Technol. Forecast. Soc. Change 2021, 169, 120858. [Google Scholar] [CrossRef]

- Global Fashion Agenda. Pulse of the Fashion Industry 2017; Global Fashion Agenda & The Boston Consulting Group: Copenhagen, Denmark, 2018. [Google Scholar]

- SITRA; Circle Economy. Service-Based Business Models & Circular Strategies for Textiles. 2015. Available online: https://s3-eu-west-1.amazonaws.com/stjm/20160330092502/Service-based-business-models-and-circular-strategies-for-textiles-2015-SITRA-STJM.pdf (accessed on 26 September 2022).

- Duhoux, T.; Maes, E.; Hirschnitz-Garbers, M.; Peeters, K.; Asscherickx, L.; Christis, M.; Stubbe, B.; Colignon, P.; Hinzmann, M.; Sachdeva, A. Study on the Technical, Regulatory, Economic and Environmental Effectiveness of Textile Fibres Recycling; European Commission, Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs: Brussels, Belgium, 2021. [Google Scholar]

- Manshoven, S.; Smeets, A.; Malarciuc, C.; Tenhunen, A.; Mortensen, L.F. Microplastic Pollution from Textile Consumption in Europe; European Topic Centre Circular Economy and Resource Use: Copenhagen, Denmark, 2022; Available online: https://www.eionet.europa.eu/etcs/etc-ce/products/etc-ce-products/etc-ce-report-1-2022-microplastic-pollution-from-textile-consumption-in-europe (accessed on 26 September 2022).

- Manshoven, S.; Christis, M.; Vercalsteren, A.; Arnold, M.; Nicolau, M.; Lafond, E.; Mortensen, L.F.; Coscieme, L. Textiles and the Environment in a Circular Economy; European Topic Centre for Waste and Materials in a Green Economy: Copenhagen, Denmark, 2019; Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/textiles-and-the-environment-in-a-circular-economy (accessed on 26 September 2022).

- Eunomia ICF. Measuring the Impacts of Microplastics. 2018. Available online: https://www.eunomia.co.uk/reports-tools/investigating-options-for-reducing-releases-in-the-aquatic-environment-of-microplastics-emitted-by-products/ (accessed on 26 September 2022).

- Kant, R. Textile Dyeing Industry an Environmental Hazard. Nat. Sci. 2011, 4, 22–26. [Google Scholar] [CrossRef] [Green Version]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- O’Connor, M.P.; Zimmerman, J.B.; Anastas, P.T.; Plata, D.L. A Strategy for Material Supply Chain Sustainability: Enabling a Circular Economy in the Electronics Industry through Green Engineering. ACS Sustain. Chem. Eng. 2016, 4, 5879–5888. [Google Scholar] [CrossRef]

- Bachér, J.; Dams, Y.; Duhoux, T.; Deng, Y.; Teittinen, T. Electronic Products and Obsolescence in a Circular Economy; European Topic Centre Waste and Materials in a Green Economy: Copenhagen, Denmark, 2020; Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/electronics-and-obsolescence-in-a-circular-economy (accessed on 26 September 2022).

- European Environment Agency. Plastics, the Circular Economy and Europe′s Environment; European Environment Agency: Copenhagen, Denmark, 2020; Available online: https://www.eea.europa.eu/publications/plastics-the-circular-economy-and (accessed on 26 September 2022).

- Kaur, G.; Uisan, K.; Ong, K.L.; Ki Lin, C.S. Recent Trends in Green and Sustainable Chemistry & Waste Valorisation: Rethinking Plastics in a Circular Economy. Curr. Opin. Green Sustain. Chem. 2018, 9, 30–39. [Google Scholar] [CrossRef]

- López Ruiz, L.A.; Roca Ramón, X.; Gassó Domingo, S. The Circular Economy in the Construction and Demolition Waste Sector—A Review and an Integrative Model Approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Wählström, M.; Bergmans, J.; Teittinen, T.; Bachér, J.; Smeets, A.; Paduart, A. Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; European Topic Centre Waste and Materials in a Green Economy: Copenhagen, Denmark, 2020; Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/construction-and-demolition-waste-challenges-and-opportunities-in-a-circular-economy (accessed on 26 September 2022).

- den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Harris, S.; Martin, M.; Diener, D. Circularity for Circularity’s Sake? Scoping Review of Assessment Methods for Environmental Performance in the Circular Economy. Sustain. Prod. Consum. 2021, 26, 172–186. [Google Scholar] [CrossRef]

- Dissanayake, K.; Weerasinghe, D. Towards Circular Economy in Fashion: Review of Strategies, Barriers and Enablers. Circ. Econ. Sustain. 2022, 2, 25–42. [Google Scholar] [CrossRef]

- European Commission. EU Strategy for Sustainable and Circular Textiles; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- European Environmental Agency. Textiles in Europe’s Circular Economy; European Environment Agency: Copenhagen, Denmark, 2019; Available online: https://www.eea.europa.eu/publications/textiles-in-europes-circular-economy (accessed on 26 September 2022).

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. Textiles Ecosystem Transition Pathway Cocreation Process. Available online: https://single-market-economy.ec.europa.eu/sectors/fashion/textiles-transition-pathway_en (accessed on 8 September 2022).

- Textile Exchange. 2025 Recycled Polyester Challenge, 2021. Available online: https://textileexchange.org/2025-recycled-polyester-challenge/ (accessed on 5 July 2022).

- Macintosh, E. Reuse, Repair, Remake Is the Future of Fashion. META. 2020. Available online: https://meta.eeb.org/2020/07/16/reuse-repair-remake-is-the-future-of-fashion/ (accessed on 5 July 2022).

- Fashion Positive. Circular Materials: The Foundation of Circular Fashion 2020. Available online: https://fashionpositive.org/ (accessed on 5 July 2022).

- Sustainable Apparel Coalition. The Higg Index, 2022. Available online: https://apparelcoalition.org/the-higg-index/ (accessed on 5 July 2022).

- Bell, J. Fashion Rules: Why We Need Tougher Laws and Regulations in the Fashion Industry. 2022. Available online: https://goodmakertales.com/laws-and-regulations-in-the-fashion-industry/ (accessed on 1 September 2022).

- Beall, A. Why Clothes Are so Hard to Recycle. Available online: https://www.bbc.com/future/article/20200710-why-clothes-are-so-hard-to-recycle (accessed on 17 October 2022).

- Marsh, S.; Redwan, A. Workers Making £88 Lululemon Leggings Claim They Are Beaten. The Guardian, 2019. Available online: https://www.theguardian.com/global-development/2019/oct/14/workers-making-lululemon-leggings-claim-they-are-beaten(accessed on 23 September 2022).

- McFall-Johnsen, M. The Fashion Industry Emits More Carbon than International Flights and Maritime Shipping Combined. Here Are the Biggest Ways It Impacts the Planet. Available online: https://www.businessinsider.com/fast-fashion-environmental-impact-pollution-emissions-waste-water-2019-10 (accessed on 17 October 2022).

- Schlossberg, T. How Fast Fashion Is Destroying the Planet. The New York Times, 3 September 2019. Available online: https://www.nytimes.com/2019/09/03/books/review/how-fast-fashion-is-destroying-the-planet.html(accessed on 17 October 2022).

- Abdelmeguid, A.; Afy-Shararah, M.; Salonitis, K. Investigating the Challenges of Applying the Principles of the Circular Economy in the Fashion Industry: A Systematic Review. Sustain. Prod. Consum. 2022, 32, 505–518. [Google Scholar] [CrossRef]

- de Aguiar Hugo, A.; de Nadae, J.; da Silva Lima, R. Can Fashion Be Circular? A Literature Review on Circular Economy Barriers, Drivers, and Practices in the Fashion Industry’s Productive Chain. Sustainability 2021, 13, 12246. [Google Scholar] [CrossRef]

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The Circular Economy in the Textile and Apparel Industry: A Systematic Literature Review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Kazancoglu, I.; Sagnak, M.; Kumar Mangla, S.; Kazancoglu, Y. Circular Economy and the Policy: A Framework for Improving the Corporate Environmental Management in Supply Chains. Bus. Strategy Environ. 2021, 30, 590–608. [Google Scholar] [CrossRef]

- Kazancoglu, I.; Kazancoglu, Y.; Yarimoglu, E.; Kahraman, A. A Conceptual Framework for Barriers of Circular Supply Chains for Sustainability in the Textile Industry. Sustain. Dev. 2020, 28, 1477–1492. [Google Scholar] [CrossRef]

- Kumar, V.; Sezersan, I.; Garza-Reyes, J.A.; Gonzalez, E.D.R.S.; AL-Shboul, M.A. Circular Economy in the Manufacturing Sector: Benefits, Opportunities and Barriers. Manag. Decis. 2019, 57, 1067–1086. [Google Scholar] [CrossRef] [Green Version]

- Van Buren, N.; Demmers, M.; Van der Heijden, R.; Witlox, F. Towards a Circular Economy: The Role of Dutch Logistics Industries and Governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef] [Green Version]

- Chowdury, M.H.; Hossain, M.M. A Framework for Selecting Optimal Strategies to Mitigate the Corporate Sustainability Barriers. Corp. Ownersh. Control 2015, 13, 462–481. [Google Scholar]

- Hyder, A.S.; Chowdhury, E.; Sundström, A. Balancing Control and Trust to Manage CSR Compliance in Supply Chains. Int. J. Supply Chain. Manag. 2017, 6, 1–14. [Google Scholar]

- Lazarevic, D.; Valve, H. Narrating Expectations for the Circular Economy: Towards a Common and Contested European Transition. Energy Res. Soc. Sci. 2017, 31, 60–69. [Google Scholar] [CrossRef]

- Perry, P.; Wood, S.; Fernie, J. Corporate Social Responsibility in Garment Sourcing Networks: Factory Management Perspectives on Ethical Trade in Sri Lanka. J. Bus. Ethics 2015, 130, 737–752. [Google Scholar] [CrossRef]

- Casiano Flores, C.; Bressers, H.; Gutierrez, C.; de Boer, C. Towards Circular Economy—A Wastewater Treatment Perspective, the Presa Guadalupe Case. Manag. Res. Rev. 2018, 41, 554–571. [Google Scholar] [CrossRef] [Green Version]

- Patwa, N.; Sivarajah, U.; Seetharaman, A.; Sarkar, S.; Maiti, K.; Hingorani, K. Towards a Circular Economy: An Emerging Economies Context. J. Bus. Res. 2021, 122, 725–735. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pontrandolfo, P.; Pujari, D. Developing Sustainable New Products in the Textile and Upholstered Furniture Industries: Role of External Integrative Capabilities. J. Prod. Innov. Manag. 2013, 30, 642–658. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef] [Green Version]

- Sivaprakasam, R.; Selladurai, V.; Sasikumar, P. Implementation of Interpretive Structural Modelling Methodology as a Strategic Decision Making Tool in a Green Supply Chain Context. Ann. Oper. Res. 2015, 233, 423–448. [Google Scholar] [CrossRef]

- Brunnhofer, M.; Gabriella, N.; Schöggl, J.-P.; Stern, T.; Posch, A. The Biorefinery Transition in the European Pulp and Paper Industry—A Three-Phase Delphi Study Including a SWOT-AHP Analysis. For. Policy Econ. 2020, 110, 101882. [Google Scholar] [CrossRef]

- Hina, M.; Chauhan, C.; Kaur, P.; Kraus, S.; Dhir, A. Drivers and Barriers of Circular Economy Business Models: Where We Are Now, and Where We Are Heading. J. Clean. Prod. 2022, 333, 130049. [Google Scholar] [CrossRef]

- Shao, J.; Huang, S.; Lemus-Aguilar, I.; Ünal, E. Circular Business Models Generation for Automobile Remanufacturing Industry in China: Barriers and Opportunities. J. Manuf. Technol. Manag. 2019, 31, 542–571. [Google Scholar] [CrossRef]

- Nayak, R.; Akbari, M.; Maleki Far, S. Recent Sustainable Trends in Vietnam’s Fashion Supply Chain. J. Clean. Prod. 2019, 225, 291–303. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; RINALDI, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef] [Green Version]

- Warasthe, R.; Schulz, F.; Enneking, R.; Brandenburg, M. Sustainability Prerequisites and Practices in Textile and Apparel Supply Chains. Sustainability 2020, 12, 9960. [Google Scholar] [CrossRef]

- Brydges, T. Closing the Loop on Take, Make, Waste: Investigating Circular Economy Practices in the Swedish Fashion Industry. J. Clean. Prod. 2021, 293, 126245. [Google Scholar] [CrossRef]

- Sandvik, I.M.; Stubbs, W. Circular Fashion Supply Chain through Textile-to-Textile Recycling. J. Fash. Mark. Manag. Int. J. 2019, 23, 366–381. [Google Scholar] [CrossRef]

- Coscieme, L.; Manshoven, S.; Gillabel, J.; Grossi, F.; Mortensen, L.F. A Framework of Circular Business Models for Fashion and Textiles: The Role of Business-Model, Technical, and Social Innovation. Sustain. Sci. Pract. Policy 2022, 18, 451–462. [Google Scholar] [CrossRef]

- Dragomir, V.D.; Dumitru, M. Practical Solutions for Circular Business Models in the Fashion Industry. Clean. Logist. Supply Chain. 2022, 4, 100040. [Google Scholar] [CrossRef]

- García-Quevedo, J.; Jové-Llopis, E.; Martínez-Ros, E. Barriers to the Circular Economy in European Small and Medium-Sized Firms. Bus. Strategy Environ. 2020, 29, 2450–2464. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, R.K.; Kumar, V. Managing Supply Chains for Sustainable Operations in the Era of Industry 4.0 and Circular Economy: Analysis of Barriers. Resour. Conserv. Recycl. 2021, 164, 105215. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking Circular Business: A Framework of Barriers and Drivers. J. Clean. Prod. 2019, 212, 90–98. [Google Scholar] [CrossRef]

- Turker, D.; Altuntas, C. Sustainable Supply Chain Management in the Fast Fashion Industry: An Analysis of Corporate Reports. Eur. Manag. J. 2014, 32, 837–849. [Google Scholar] [CrossRef]

- Stahel, W. Policy for Material Efficiency—Sustainable Taxation as a Departure from the Throwaway Society. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2013, 371, 20110567. [Google Scholar] [CrossRef] [Green Version]

- Nordin, N.; Ashari, H.; Hassan, M.G. Drivers and Barriers in Sustainable Manufacturing Implementation in Malaysian Manufacturing Firms. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 687–691. [Google Scholar]

- Jakhar, S.K.; Mangla, S.K.; Luthra, S.; Kusi-Sarpong, S. When Stakeholder Pressure Drives the Circular Economy: Measuring the Mediating Role of Innovation Capabilities. Manag. Decis. 2018, 57, 904–920. [Google Scholar] [CrossRef]

- Milios, L. Advancing to a Circular Economy: Three Essential Ingredients for a Comprehensive Policy Mix. Sustain. Sci. 2018, 13, 861–878. [Google Scholar] [CrossRef] [Green Version]

- Kautto, P.; Lazarevic, D. Between a Policy Mix and a Policy Mess: Policy Instruments and Instrumentation for the Circular Economy. In Handbook of the Circular Economy; Edward Elgar: Northampton, MA, USA, 2020; pp. 207–223. [Google Scholar]

- Ekvall, T.; Hirschnitz-Garbers, M.; Eboli, F.; Śniegocki, A. A Systemic and Systematic Approach to the Development of a Policy Mix for Material Resource Efficiency. Sustainability 2016, 8, 373. [Google Scholar] [CrossRef] [Green Version]

- Cortes, A. A Triple Bottom Line Approach for Measuring Supply Chains Sustainability Using Data Envelopment Analysis. Eur. J. Sustain. Dev. 2017, 6, 119–128. [Google Scholar] [CrossRef] [Green Version]

- Granados Aguero, A.; Niemenoja, K.; Kufrej, M.; De Wée, T. Report on the Value Chain Stakeholder Mapping, 2022.

- Smeets, A.; Asscherickx, L.; Van Hoof, V.; Duhoux, T. Fibre Footprint at Garment Level of Six SCIRT Prototypes; VITO: Mol, Belgium, 2022. [Google Scholar]

- Ciasullo, M.V.; Cardinali, S.; Cosimato, S. A Strenuous Path for Sustainable Supply Chains in the Footwear Industry: A Business Strategy Issue. J. Glob. Fash. Mark. 2017, 8, 143–162. [Google Scholar] [CrossRef]

- Gazzola, P.; Pavione, E.; Pezzetti, R.; Grechi, D. Trends in the Fashion Industry. The Perception of Sustainability and Circular Economy: A Gender/Generation Quantitative Approach. Sustainability 2020, 12, 2809. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Mäkinen, S.J. Creating Value in the Circular Economy: A Structured Multiple-Case Analysis of Business Models. J. Clean. Prod. 2018, 201, 988–1000. [Google Scholar] [CrossRef]

- Crow, D.A.; Baysha, O. “Conservation” as a Catalyst for Conflict: Considering Stakeholder Understanding in Policy Making. Rev. Policy Res. 2013, 30, 302–320. [Google Scholar] [CrossRef] [Green Version]

- Koebele, E.A. Policy Learning in Collaborative Environmental Governance Processes. J. Environ. Policy Plan. 2019, 21, 242–256. [Google Scholar] [CrossRef]

- van de Kerkhof, M. Making a Difference: On the Constraints of Consensus Building and the Relevance of Deliberation in Stakeholder Dialogues. Policy. Sci. 2006, 39, 279–299. [Google Scholar] [CrossRef]

- Pahl-Wostl, C. Participative and Stakeholder-Based Policy Design, Evaluation and Modeling Processes. Integr. Assess. 2002, 3, 3–14. [Google Scholar] [CrossRef] [Green Version]

- Schalk, J. Linking Stakeholder Involvement to Policy Performance: Nonlinear Effects in Dutch Local Government Policy Making. Am. Rev. Public Adm. 2017, 47, 479–495. [Google Scholar] [CrossRef]

- Capano, G.; Howlett, M. The Knowns and Unknowns of Policy Instrument Analysis: Policy Tools and the Current Research Agenda on Policy Mixes. SAGE Open 2020, 10, 2158244019900568. [Google Scholar] [CrossRef] [Green Version]

- Dermont, C.; Ingold, K.; Kammermann, L.; Stadelmann-Steffen, I. Bringing the Policy Making Perspective in: A Political Science Approach to Social Acceptance. Energy Policy 2017, 108, 359–368. [Google Scholar] [CrossRef]

- Ingold, K.; Stadelmann-Steffen, I.; Kammermann, L. The Acceptance of Instruments in Instrument Mix Situations: Citizens’ Perspective on Swiss Energy Transition. Res. Policy 2019, 48, 103694. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Vision of a Circular Economy for Fashion. 2020. Available online: https://emf.thirdlight.com/link/nbwff6ugh01m-y15u3p/@/preview/1?o (accessed on 6 July 2022).

- Global Fashion Agenda. Fashion CEO Agenda—Priorities for a Prosperous Industry; Global Fashion Agenda & The Boston Consulting Group: Copenhagen, Denmark, 2021. [Google Scholar]

- OECD. OECD Due Diligence Guidance for Responsible Supply Chains in the Garment and Footwear Sector; OECD Publishing: Paris, France, 2018; ISBN 978-92-64-29057-0. [Google Scholar]

- PACE Accenture. Circular Economy Action Agenda Textiles. 2021. Available online: https://pacecircular.org/sites/default/files/2021-02/circular-economy-action-agenda-textiles.pdf (accessed on 6 July 2022).

- UNECE. Call to Action for Traceability, Transparency, Sustainability and Circularity of Value Chains in the Garment and Footwear Sector—“The Sustainability Pledge”; UNECE: Geneva, Switzerland, 2021. [Google Scholar]

- UNFCCC. Fashion Industry Carter for Climate Action; UNFCCC: Bonn, Germany, 2021. [Google Scholar]

- WRAP. Textiles 2030 Circularity Roadmap. 2021. Available online: https://wrap.org.uk/sites/default/files/2022-04/WRAP-textiles-2030-circularity-roadmap-20220331.pdf (accessed on 6 July 2022).

- Mishra, S.; Jain, S.; Malhotra, G. The Anatomy of Circular Economy Transition in the Fashion Industry. Soc. Responsib. J. 2020, 17, 524–542. [Google Scholar] [CrossRef]

- Manshoven, S.; Van Opstal, W. Vision and Roadmap Towards a Circular Fashion System, 2022.

- Duhoux, T.; Le Blévennec, K.; Manshoven, S.; Grossi, F.; Arnold, M.; Mortensen, L.F. Textiles and the Environment—The Role of Design in Europe’s Circular Economy; European Topic Centre Circular Economy and Resource Use: Mol, Belgium, 2022. [Google Scholar]

- Manshoven, S.; Smeets, A.; Arnold, M.; Mortensen, L.F. Plastic in Textiles: Potentials for Circularity and Reduced Environmental and Climate Impacts; European Topic Centre on Waste and Materials in a Green Economy: Copenhagen, Denmark, 2021; Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/plastic-in-textiles-potentials-for-circularity-and-reduced-environmental-and-climate-impacts (accessed on 1 September 2022).

- Botta, V.; Cabral, I. Durable, Repairable and Mainstream—How Ecodesign Can Make Our Textiles Circular; ECOS: Brussels, Belgium, 2021; Available online: https://ecostandard.org/wp-content/uploads/2021/04/ECOS-REPORT-HOW-ECODESIGN-CAN-MAKE-OUR-TEXTILES-CIRCULAR.pdf (accessed on 5 July 2022).

- Berg, A.; Hedrich, S.; Ibanez, P.; Kappelmark, S.; Magnus, K.-H.; Seeger, M. Fashion’s New Must-Have: Sustainable Sourcing at Scale; McKinsey & Company: Atlanta, GA, USA, 2019; Available online: https://www.mckinsey.com/~/media/mckinsey/industries/retail/our%20insights/fashions%20new%20must%20have%20sustainable%20sourcing%20at%20scale/fashions-new-must-have-sustainable-sourcing-at-scale-vf.pdf (accessed on 7 July 2022).

- Oliveira Duarte, L.; Kohan, L.; Pinheiro, L.; Fonseca Filho, H.; Baruque-Ramos, J. Textile Natural Fibers Production Regarding the Agroforestry Approach. SN Appl. Sci. 2019, 1, 914. [Google Scholar] [CrossRef] [Green Version]

- Periyasamy, A.P.; Tehrani-Bagha, A. A Review on Microplastic Emission from Textile Materials and Its Reduction Techniques. Polym. Degrad. Stab. 2022, 199, 109901. [Google Scholar] [CrossRef]

- Altenbuchner, C.; Vogel, S.; Larcher, M. Social, Economic and Environmental Impacts of Organic Cotton Production on the Livelihood of Smallholder Farmers in Odisha, India. Renew. Agric. Food Syst. 2018, 33, 373–385. [Google Scholar] [CrossRef]

- Trejo, H.X.; Lewis, T.L. Slow Fashion and Fiber Farming: Nexus for Community Engagement. Fash. Pract. 2017, 9, 120–142. [Google Scholar] [CrossRef]

- Chapagain, A.K.; Hoekstra, A.Y.; Savenije, H.H.G.; Gautam, R. The Water Footprint of Cotton Consumption: An Assessment of the Impact of Worldwide Consumption of Cotton Products on the Water Resources in the Cotton Producing Countries. Ecol. Econ. 2006, 60, 186–203. [Google Scholar] [CrossRef]

- Chico, D.; Aldaya, M.M.; Garrido, A. A Water Footprint Assessment of a Pair of Jeans: The Influence of Agricultural Policies on the Sustainability of Consumer Products. J. Clean. Prod. 2013, 57, 238–248. [Google Scholar] [CrossRef] [Green Version]

- Raja, A.S.M.; Arputharaj, A.; Saxena, S.; Patil, P.G. 9—Water Requirement and Sustainability of Textile Processing Industries. In Water in Textiles and Fashion; Muthu, S.S., Ed.; Woodhead Publishing: Cambridge, UK, 2019; pp. 155–173. ISBN 978-0-08-102633-5. [Google Scholar]

- Çay, A. Energy Consumption and Energy Saving Potential in Clothing Industry. Energy 2018, 159, 74–85. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L. A Technical Review of Emerging Technologies for Energy and Water Efficiency and Pollution Reduction in the Textile Industry. J. Clean. Prod. 2015, 95, 30–44. [Google Scholar] [CrossRef] [Green Version]

- Oelze, N. Sustainable Supply Chain Management Implementation–Enablers and Barriers in the Textile Industry. Sustainability 2017, 9, 1435. [Google Scholar] [CrossRef] [Green Version]

- KEMI. Chemicals in Textiles—Risks to Human Health and the Environment; Swedish Chemicals Agency: Stockholm, Sweden, 2014.

- Nijkamp, M.M.; Maslankiewicz, L.; Delmaar, J.E.; Muller, J.J.A. Hazardous Substances in Textile Products; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2014; Volume 68, Available online: https://www.rivm.nl/bibliotheek/rapporten/2014-0155.html (accessed on 7 July 2022).

- Berg, A.; Granskog, A.; Lee, L.; Magnus, K.-H. How the Fashion Industry Can Reduce Its Carbon Footprint; McKinsey: Atlanta, GA, USA, 2020; Available online: https://www.mckinsey.com/industries/retail/our-insights/fashion-on-climate (accessed on 14 September 2022).

- Quantis. Measuring Fashion: Insights from the Environmental Impact of the Global Apparel and Footwear Industries Study. 2018. Available online: https://quantis-intl.com/measuring-fashion-report-2018/ (accessed on 7 July 2022).

- Bouzon, M.; Govindan, K. Reverse Logistics as a Sustainable Supply Chain Practice for the Fashion Industry: An Analysis of Drivers and the Brazilian Case. In Sustainable Fashion Supply Chain Management: From Sourcing to Retailing; Choi, T.-M., Cheng, T.C.E., Eds.; Springer Series in Supply Chain Management; Springer International Publishing: Cham, Switzerland, 2015; pp. 85–104. ISBN 978-3-319-12703-3. [Google Scholar]

- McDonald, S.D.; Manh Hung, N.; Akbari, M. Transportation and Logistics for a Sustainable Fashion Sector. In Supply Chain Management and Logistics in the Global Fashion Sector; Routledge: London, UK, 2020; p. 300. ISBN 978-1-00-308906-3. [Google Scholar]

- Bakker, C.A.; Wang, F.; Huisman, J.; den Hollander, M. Products That Go Round: Exploring Product Life Extension through Design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; Grinten, B. van der Product Design and Business Model Strategies for a Circular Economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Fletcher, K. Durability, Fashion, Sustainability: The Processes and Practices of Use. Fash. Pract. J. Des. Creat. Process Fash. 2012, 4, 221–238. [Google Scholar] [CrossRef]

- Colucci, M.; Vecchi, A. Close the Loop: Evidence on the Implementation of the Circular Economy from the Italian Fashion Industry. Bus. Strategy Environ. 2021, 30, 856–873. [Google Scholar] [CrossRef]

- Pal, R.; Gander, J. Modelling Environmental Value: An Examination of Sustainable Business Models within the Fashion Industry. J. Clean. Prod. 2018, 184, 251–263. [Google Scholar] [CrossRef] [Green Version]

- Hernandez, R.J.; Miranda, C.; Goñi, J. Empowering Sustainable Consumption by Giving Back to Consumers the ‘Right to Repair’. Sustainability 2020, 12, 850. [Google Scholar] [CrossRef] [Green Version]

- Colasante, A.; D’Adamo, I. The Circular Economy and Bioeconomy in the Fashion Sector: Emergence of a “Sustainability Bias”. J. Clean. Prod. 2021, 329, 129774. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, Y.; Burman, R.; Zhao, H. Second-Hand Clothing Consumption: A Cross-Cultural Comparison between American and Chinese Young Consumers. Int. J. Consum. Stud. 2014, 38, 670–677. [Google Scholar] [CrossRef]

- Liu, N.; Lin, J.; Guo, S.; Shi, X. Fashion Platform Operations in the Sharing Economy with Digital Technologies: Recent Development and Real Case Studies. Ann. Oper. Res. 2022, 1–21. [Google Scholar] [CrossRef]

- Gillabel, J.; Manshoven, S.; Grossi, F.; Mortensen, L.F.; Coscieme, L. Business Models in a Circular Economy; European Topic Centre on Waste and Materials in a Green Economy: Copenhagen, Denmark, 2021; Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/business-models-in-a-circular-economy (accessed on 23 September 2022).

- Diddi, S.; Yan, R.-N.; Bloodhart, B.; Bajtelsmit, V.; McShane, K. Exploring Young Adult Consumers’ Sustainable Clothing Consumption Intention-Behavior Gap: A Behavioral Reasoning Theory Perspective. Sustain. Prod. Consum. 2019, 18, 200–209. [Google Scholar] [CrossRef]

- Munir, S. Eco-Fashion Adoption in the UAE: Understanding Consumer Barriers and Motivational Factors. Fash. Pract. 2020, 12, 371–393. [Google Scholar] [CrossRef]

- Roos, S.; Sandin, G.; Peters, G.; Spak, B.; Bour, L.; Perzon, E.; Jönsson, C. Guidance for Fashion Companies on Design for Recycling; RISE IVF: Mölndal, Sweden, 2019. [Google Scholar]

- Bell, S.; Davis, B.; Javaid, A.; Essadiqi, E. Final Report on Design of Recyclable Products; Goverment of Canada: Ottawa, ON, Canada, 2006. [CrossRef]

- Nørup, N.; Pihl, K.; Damgaard, A.; Scheutz, C. Development and Testing of a Sorting and Quality Assessment Method for Textile Waste. Waste Manag. 2018, 79, 8–21. [Google Scholar] [CrossRef] [PubMed]

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The Environmental Price of Fast Fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef] [Green Version]

- Wolff, E.A. The Global Politics of African Industrial Policy: The Case of the Used Clothing Ban in Kenya, Uganda and Rwanda. Rev. Int. Political Econ. 2021, 28, 1308–1331. [Google Scholar] [CrossRef] [Green Version]

- EEA. Progressing towards Waste Prevention in Europe—The Case of Textile Waste Prevention; European Environment Agency: Copenhagen, Denmark, 2021. [Google Scholar]

- EEB. Policy Brief on Prohibiting the Destruction of Unsold Goods, 2021. Available online: https://eeb.org/wp-content/uploads/2021/10/Prohibiting-the-destruction-of-unsold-goods-Policy-brief-2021.pdf (accessed on 7 July 2022).

- Napier, E.; Sanguineti, F. Fashion Merchandisers’ Slash and Burn Dilemma: A Consequence of Over Production and Excessive Waste? Rutgers Bus. Rev. 2018, 3, 2. [Google Scholar]

- Chi Xu, D. Unwrapping Plastic Fashion Packaging: What Are the Eco-Friendly Alternatives? Ecocult 2021. Available online: https://ecocult.com/sustainable-fashion-packaging/ (accessed on 7 July 2022).

- Han, S.L.C.; Chan, P.Y.L.; Venkatraman, P.; Apeagyei, P.; Cassidy, T.; Tyler, D.J. Standard vs. Upcycled Fashion Design and Production. Fash. Pract. 2017, 9, 69–94. [Google Scholar] [CrossRef]

- Riba, J.-R.; Cantero, R.; Canals, T.; Puig, R. Circular Economy of Post-Consumer Textile Waste: Classification through Infrared Spectroscopy. J. Clean. Prod. 2020, 272, 123011. [Google Scholar] [CrossRef]

- Padilla-Rivera, A.; Russo-Garrido, S.; Merveille, N. Addressing the Social Aspects of a Circular Economy: A Systematic Literature Review. Sustainability 2020, 12, 7912. [Google Scholar] [CrossRef]

- Minney, S. Slave to Fashion; New Internationalist: Oxford, England, 2017; ISBN 1-78026-398-8. [Google Scholar]

- Tridimas, B. How the Fashion Industry Interferes with Human Rights. Available online: https://keiseimagazine.com/how-the-fashion-industry-interferes-with-human-rights/ (accessed on 23 September 2022).

- Alamgir, F.; Banerjee, S.B. Contested Compliance Regimes in Global Production Networks: Insights from the Bangladesh Garment Industry. Hum. Relat. 2019, 72, 272–297. [Google Scholar] [CrossRef] [Green Version]

- Bick, R.; Halsey, E.; Ekenga, C.C. The Global Environmental Injustice of Fast Fashion. Env. Health 2018, 17, 92. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fuxman, L.; Mohr, I.; Mahmoud, A.B.; Grigoriou, N. The New 3Ps of Sustainability Marketing: The Case of Fashion. Sustain. Prod. Consum. 2022, 31, 384–396. [Google Scholar] [CrossRef]

- Morris, J.; Koep, L.; Damert, M. Labels in the Textile and Fashion Industry: Communicating Sustainability to Effect Sustainable Consumption. In Sustainable Textile and Fashion Value Chains: Drivers, Concepts, Theories and Solutions; Matthes, A., Beyer, K., Cebulla, H., Arnold, M.G., Schumann, A., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 257–274. ISBN 978-3-030-22018-1. [Google Scholar]

- Araujo, M.J.F.D.; Araujo, M.V.F.D.; Carvalho, M.A.S.R.D. Unsustainability in the Current Fast-Fashion Industry: The Social Pillar. Int. J. Environ. Sci. 2020, 5, 285–292. [Google Scholar]

- Feng, P.; Ngai, C.S. Doing More on the Corporate Sustainability Front: A Longitudinal Analysis of CSR Reporting of Global Fashion Companies. Sustainability 2020, 12, 2477. [Google Scholar] [CrossRef] [Green Version]

- James, M.A. Child Labor in Your Closet: Efficacy of Disclosure Legislation and a New Way Forward to Fight Child Labor in Fast Fashion Supply Chains. J. Gend. Race Justice 2022, 25, 245. [Google Scholar]

- Clube, R.K.M.; Tennant, M. Social Inclusion and the Circular Economy: The Case of a Fashion Textiles Manufacturer in Vietnam. Bus. Strategy Dev. 2022, 5, 4–16. [Google Scholar] [CrossRef]

- Garcia-Torres, S.; Rey-Garcia, M.; Sáenz, J.; Seuring, S. Traceability and Transparency for Sustainable Fashion-Apparel Supply Chains. J. Fash. Mark. Manag. Int. J. 2021, 26, 344–364. [Google Scholar] [CrossRef]

- Ki, C.-W.; Chong, S.M.; Ha-Brookshire, J.E. How Fashion Can Achieve Sustainable Development through a Circular Economy and Stakeholder Engagement: A Systematic Literature Review. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2401–2424. [Google Scholar] [CrossRef]

- Mejías, A.M.; Bellas, R.; Pardo, J.E.; Paz, E. Traceability Management Systems and Capacity Building as New Approaches for Improving Sustainability in the Fashion Multi-Tier Supply Chain. Int. J. Prod. Econ. 2019, 217, 143–158. [Google Scholar] [CrossRef]

- Manninen, K.; Koskela, S.; Antikainen, R.; Bocken, N.; Dahlbo, H.; Aminoff, A. Do Circular Economy Business Models Capture Intended Environmental Value Propositions? J. Clean. Prod. 2018, 171, 413–422. [Google Scholar] [CrossRef] [Green Version]

- Lieder, M.; Rashid, A. Towards Circular Economy Implementation: A Comprehensive Review in Context of Manufacturing Industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Ozdamar Ertekin, Z.; Atik, D. Sustainable Markets: Motivating Factors, Barriers, and Remedies for Mobilization of Slow Fashion. J. Macromarketing 2015, 35, 53–69. [Google Scholar] [CrossRef]

- Siemieniuch, C.E.; Sinclair, M.A.; Henshaw, M.J.d. Global Drivers, Sustainable Manufacturing and Systems Ergonomics. Appl. Ergon. 2015, 51, 104–119. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- de Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Eco-Innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef] [Green Version]

- Rizos, V.; Behrens, A.; Drabik, E.; Rinaldi, D.; Tuokko, K. Role of Business in the Circular Economy: Markets, Processes and Enabling Policies. Report of a CEPS Task Force; Centre for European Policy Studies: Brussels, Belgium, 2016; p. 68. [Google Scholar]

- Salvador, R.; Barros, M.V.; da Luz, L.M.; Piekarski, C.M.; de Francisco, A.C. Circular Business Models: Current Aspects That Influence Implementation and Unaddressed Subjects. J. Clean. Prod. 2020, 250, 119555. [Google Scholar] [CrossRef]

- Atalay Onur, D. Integrating Circular Economy, Collaboration and Craft Practice in Fashion Design Education in Developing Countries: A Case from Turkey. Fash. Pract. 2020, 12, 55–77. [Google Scholar] [CrossRef]

- Govindan, K.; Hasanagic, M. A Systematic Review on Drivers, Barriers, and Practices towards Circular Economy: A Supply Chain Perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- Colucci, M.; Tuan, A.; Visentin, M. An Empirical Investigation of the Drivers of CSR Talk and Walk in the Fashion Industry. J. Clean. Prod. 2020, 248, 119200. [Google Scholar] [CrossRef]

- Esken, B.; Franco-García, M.-L.; Fisscher, O.A.M. CSR Perception as a Signpost for Circular Economy. Manag. Res. Rev. 2018, 41, 586–604. [Google Scholar] [CrossRef]

- Lawrence, J.E.S.; Cook, T.J. Designing Useful Evaluations: The Stakeholder Survey. Eval. Program Plan. 1982, 5, 327–336. [Google Scholar] [CrossRef]

- Yamane, T.; Kaneko, S. The Sustainable Development Goals as New Business Norms: A Survey Experiment on Stakeholder Preferences. Ecol. Econ. 2022, 191, 107236. [Google Scholar] [CrossRef]

- Yamane, T.; Kaneko, S. Impact of Raising Awareness of Sustainable Development Goals: A Survey Experiment Eliciting Stakeholder Preferences for Corporate Behavior. J. Clean. Prod. 2021, 285, 125291. [Google Scholar] [CrossRef]

- Michalak, J.; Michałowski, B. Understanding Sustainability of Construction Products: Answers from Investors, Contractors, and Sellers of Building Materials. Sustainability 2022, 14, 3042. [Google Scholar] [CrossRef]

- Gramberger, M.; Zellmer, K.; Kok, K.; Metzger, M.J. Stakeholder Integrated Research (STIR): A New Approach Tested in Climate Change Adaptation Research. Clim. Change 2015, 128, 201–214. [Google Scholar] [CrossRef]

- Stewart, D.W.; Shamdasani, P.N. Focus Groups: Theory and Practice; SAGE Publications: New York, NY, USA, 2014; ISBN 978-1-4833-1268-2. [Google Scholar]

- Bocken, N.M.P.; Weissbrod, I.; Antikainen, M. Business Model Experimentation for the Circular Economy: Definition and Approaches. Circ. Econ. Sust. 2021, 1, 49–81. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Schuit, C.S.C.; Kraaijenhagen, C. Experimenting with a Circular Business Model: Lessons from Eight Cases. Environ. Innov. Soc. Transit. 2018, 28, 79–95. [Google Scholar] [CrossRef] [Green Version]

- Toxopeus, H.; Achterberg, E.; Polzin, F. How Can Firms Access Bank Finance for Circular Business Model Innovation? Bus. Strategy Environ. 2021, 30, 2773–2795. [Google Scholar] [CrossRef]

- Van Opstal, W.; Smeets, A. Market-Specific Barriers and Enablers for Organizational Investments in Solar PV—Lessons from Flanders. Sustainability 2022, 14, 13069. [Google Scholar] [CrossRef]

- Van Opstal, W.; Smeets, A. Circular Economy Strategies as Enablers for Solar PV Adoption in Organizational Market Segments. Sustain. Prod. Consum. 2023, 35, 40–45. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular Economy in the Construction Industry: An Overview of United States Stakeholders’ Awareness, Major Challenges, and Enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Bernon, M.; Tjahjono, B.; Ripanti, E.F. Aligning Retail Reverse Logistics Practice with Circular Economy Values: An Exploratory Framework. Prod. Plan. Control 2018, 29, 483–497. [Google Scholar] [CrossRef] [Green Version]

- Stumpf, L.; Schöggl, J.-P.; Baumgartner, R.J. Climbing up the Circularity Ladder?—A Mixed-Methods Analysis of Circular Economy in Business Practice. J. Clean. Prod. 2021, 316, 128158. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Multivariate Data Analysis, Subsequent ed.; Pearson College Div: Upper Saddle River, NJ, USA, 2006; ISBN 978-0-13-032929-5. [Google Scholar]

- Endres, A. Game Theory and Global Environmental Policy. Poiesis Prax. 2004, 3, 123–139. [Google Scholar] [CrossRef]

- Hanley, N.; Folmer, H. Game Theory and the Environment. Available online: https://eprints.gla.ac.uk/160041/ (accessed on 13 October 2022).

- Akerlof, G.A.; Kranton, R.E. Economics and Identity. Q. J. Econ. 2000, 115, 715–753. [Google Scholar] [CrossRef]

- Bowles, S.; Gintis, H. The Moral Economy of Communities: Structured Populations and the Evolution of Pro-Social Norms. Evol. Hum. Behav. 1998, 19, 3–25. [Google Scholar] [CrossRef]

- Gintis, H. Game Theory Evolving: A Problem-Centered Introduction to Modeling Strategic Behavior; Princeton University Press: Princeton, NJ, USA, 2000; ISBN 978-0-691-00943-8. [Google Scholar]

- Robèrt, K.-H.; Broman, G. Prisoners’ Dilemma Misleads Business and Policy Making. J. Clean. Prod. 2017, 140, 10–16. [Google Scholar] [CrossRef]

- Menashe, M. The Race to the Bottom Revisited: International Labour Law, Global Trade and Evolutionary Game Theory. Oxf. J. Leg. Stud. 2020, 40, 53–81. [Google Scholar] [CrossRef]

- Akerlof, G.A. The Market for “Lemons”: Quality Uncertainty and the Market Mechanism. Q. J. Econ. 1970, 84, 488–500. [Google Scholar] [CrossRef]

- Lopatta, K.; Buchholz, F.; Kaspereit, T. Asymmetric Information and Corporate Social Responsibility. Bus. Soc. 2016, 55, 458–488. [Google Scholar] [CrossRef]

- Yang, D.; Xiao, T.; Choi, T.-M.; Cheng, T.C.E. Optimal Reservation Pricing Strategy for a Fashion Supply Chain with Forecast Update and Asymmetric Cost Information. Int. J. Prod. Res. 2018, 56, 1960–1981. [Google Scholar] [CrossRef]

- Espínola-Arredondo, A.; Muñoz-García, F. Free-Riding in International Environmental Agreements: A Signaling Approach to Non-Enforceable Treaties. J. Theor. Politics 2011, 23, 111–134. [Google Scholar] [CrossRef]

- Irfanoglu, Z.B.; Sesmero, J.P.; Golub, A. Potential of Border Tax Adjustments to Deter Free Riding in International Climate Agreements. Environ. Res. Lett. 2015, 10, 024009. [Google Scholar] [CrossRef]

- Nordhaus, W. Climate Clubs: Overcoming Free-Riding in International Climate Policy. Am. Econ. Rev. 2015, 105, 1339–1370. [Google Scholar] [CrossRef]

- Fowler, J.H. Altruistic Punishment and the Origin of Cooperation. Proc. Natl. Acad. Sci. USA 2005, 102, 7047–7049. [Google Scholar] [CrossRef] [Green Version]

- Hwang, J.; Choi, J.K. An Investigation of Passengers’ Psychological Benefits from Green Brands in an Environmentally Friendly Airline Context: The Moderating Role of Gender. Sustainability 2018, 10, 80. [Google Scholar] [CrossRef] [Green Version]

- Obermiller, C.; Isaac, M.S. Are Green Men from Venus? J. Manag. Glob. Sustain. 2018, 6, 45–66. [Google Scholar] [CrossRef] [Green Version]

- Brough, A.R.; Wilkie, J.E.B.; Ma, J.; Isaac, M.S.; Gal, D. Is Eco-Friendly Unmanly? The Green-Feminine Stereotype and Its Effect on Sustainable Consumption. J. Consum. Res. 2016, 43, 567–582. [Google Scholar] [CrossRef] [Green Version]

- Pucheta-Martínez, M.C.; Gallego-Álvarez, I. An International Approach of the Relationship between Board Attributes and the Disclosure of Corporate Social Responsibility Issues. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 612–627. [Google Scholar] [CrossRef]

- Uyar, A.; Kilic, M.; Koseoglu, M.A.; Kuzey, C.; Karaman, A.S. The Link among Board Characteristics, Corporate Social Responsibility Performance, and Financial Performance: Evidence from the Hospitality and Tourism Industry. Tour. Manag. Perspect. 2020, 35, 100714. [Google Scholar] [CrossRef]

- Noja, G.G.; Cristea, M.; Jurcut, C.N.; Buglea, A.; Lala Popa, I. Management Financial Incentives and Firm Performance in a Sustainable Development Framework: Empirical Evidence from European Companies. Sustainability 2020, 12, 7247. [Google Scholar] [CrossRef]

- Todeschini, B.V.; Cortimiglia, M.N.; Callegaro-de-Menezes, D.; Ghezzi, A. Innovative and Sustainable Business Models in the Fashion Industry: Entrepreneurial Drivers, Opportunities, and Challenges. Bus. Horiz. 2017, 60, 759–770. [Google Scholar] [CrossRef]

- Moorhouse, D.; Moorhouse, D. Sustainable Design: Circular Economy in Fashion and Textiles. Des. J. 2017, 20, S1948–S1959. [Google Scholar] [CrossRef] [Green Version]

- Claxton, S.; Kent, A. The Management of Sustainable Fashion Design Strategies: An Analysis of the Designer’s Role. J. Clean. Prod. 2020, 268, 122112. [Google Scholar] [CrossRef]

- Corvellec, H.; Stål, H.I. Evidencing the Waste Effect of Product-Service Systems (PSSs). J. Clean. Prod. 2017, 145, 14–24. [Google Scholar] [CrossRef] [Green Version]

- Freudenreich, B.; Schaltegger, S. Developing Sufficiency-Oriented Offerings for Clothing Users: Business Approaches to Support Consumption Reduction. J. Clean. Prod. 2020, 247, 119589. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef] [Green Version]

- Arrigo, E. Global Sourcing in Fast Fashion Retailers: Sourcing Locations and Sustainability Considerations. Sustainability 2020, 12, 508. [Google Scholar] [CrossRef] [Green Version]

- Ülgen, V.S.; Forslund, H. Logistics Performance Management in Textiles Supply Chains: Best-Practice and Barriers. Int. J. Product. Perform. Manag. 2015, 64, 52–75. [Google Scholar] [CrossRef]

- Neumann, H.L.; Martinez, L.M.; Martinez, L.F. Sustainability Efforts in the Fast Fashion Industry: Consumer Perception, Trust and Purchase Intention. Sustain. Account. Manag. Policy J. 2020, 12, 571–590. [Google Scholar] [CrossRef]

- McNeill, L.; Moore, R. Sustainable Fashion Consumption and the Fast Fashion Conundrum: Fashionable Consumers and Attitudes to Sustainability in Clothing Choice. Int. J. Consum. Stud. 2015, 39, 212–222. [Google Scholar] [CrossRef]

| Topic | Mandatory Instruments | Non-Mandatory Instruments |

|---|---|---|

| Low impact fibres | Design requirements on the use of recycled and renewable fibres | Including recycled content criteria in public tenders |

| Mandatory uniform digital product passports for all new products | Labels with % recycled content | |

| Import regulations on fibre quality | Training for designers and toolkit development for material choice | |

| Low impact processes | Ban on the use of chemicals of concern | Certification schemes |

| Carbon taxes on imported garments | R&D support on technology development | |

| Longer use of garments | Design requirements for longer product lifespans | Offering repair schemes and tutorials |

| Mandatory repair services by retailers | EPR-schemes including durability and repairability requirements | |

| Cap on the number of fashion collections per year | ||

| Recycling | Design requirements for recyclability | R&D support for recycling technologies |

| Separate waste disposal obligations and mandatory collection of used textiles | Support market development for recycled fibres | |

| Ban on the export of textile waste | Local e-mobility solutions for collection | |

| Waste prevention | Restrictions on discount sales | On-demand production (e.g., with 3D sizing avatars) |

| Ban on the destruction of unsold items | EPR schemes with eco-modulation | |

| Import controls on textile quality | Educational contributions on overconsumption | |

| Social justice | Implementation of social protection and working conditions along ILO guidelines | Voluntary Human Rights and Environmental Due Diligence (HREDD) |

| Taxes that internalise social costs in product pricing | Awareness building on true costs | |

| Value chain collaboration | Mandatory product passports to enable traceability and transparency | Match-making apps and events to connect (small) retailers with producers |

| Blockchain solutions that enable traceability of disposed textiles |

| All Respondents | Companies | |

|---|---|---|

| n | 260 | 105 |

| Prob > chi2 | 0.0000 | 0.0000 |

| Pseudo R2 | 0.0634 | 0.1471 |

| Dependent variable: the number of times a respondent prefers a non-mandatory policy instrument | ||

| Constant term | 2.7093 (0.2231) ** | 2.9817 (0.2290) ** |

| Male | 0.1312 (0.0380) ** | 0.0545 (0.0594) |

| Age (ordinal) | 0.0491 (0.0157) ** | 0.0266 (0.0283) |

| Position: CEO | −0.0482 (0.1599) | 0.0346 (0.1039) |

| Position: Strategic management | −0.1098 (0.1616) | 0.2539 (0.1082) * |

| Position: Operational management | −0.1840 (0.1596) | 0.0963 (0.1060) |

| Position: Operational or administrative co-worker | −0.2337 (0.1576) | −0.0017 (0.1268) |

| Position: Designer | −0.3537 (0.1691) * | −0.4099 (0.1498) ** |

| Position: Expert | −0.2762 (0.1561) | |

| Position: Independent consultant | −0.2902 (0.1615) | |

| Position: Student | −0.3327 (0.1793) | |

| Country: EU | −0.0888 (0.0787) | −0.1707 (0.1737) |

| Stakeholder: Company | −0.0177 (0.1545) | |

| Stakeholder: Government | 0.1108 (0.1726) | |

| Stakeholder: Supranational organisation | −0.1419 (0.2325) | |

| Stakeholder: NGO | −0.4074 (0.1632) * | |

| Stakeholder: Sector Federation | 0.1330 (0.1670) | |

| Stakeholder: Research Institute | −0.0509 (0.1647) | |

| Stakeholder: Customer | −0.0899 (0.1599) | |

| Value Chain: design | −0.0310 (0.0875) | |

| Value Chain: fibre producer | −0.0706 (0.1090) | |

| Value Chain: textile manufacturer | 0.0536 (0.0851) | |

| Value Chain: fashion manufacturer | −0.0635 (0.0685) | |

| Value Chain: logistics | −0.2047 (0.0852) * | |

| Value Chain: retail | −0.1723 (0.0769) * | |

| Value Chain: reuse centre | −0.4312 (0.1621) * | |

| Value Chain: waste management | 0.0514 (0.0948) | |

| BtC-market | −0.0689 (0.0719) | |

| BtB-market | 0.0178 (0.0720) | |

| BtBtC-market | 0.1756 (0.0621) ** | |

| BtG-market | −0.1146 (0.0874) | |

| Size (ordinal) | −0.0496 (0.2777) | |

| Geographical scope of sourcing materials (ordinal) | −0.0071 (0.0017) ** | |

| Geographical scope of operational activities (ordinal) | 0.0030 (0.0012) ** | |

| Geographical scope of sales activities (ordinal) | −0.0055 (0.0026) * | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manshoven, S.; Van Opstal, W. The Carrot or the Stick? Stakeholder Support for Mandatory Regulations towards a Circular Fashion System. Sustainability 2022, 14, 14671. https://doi.org/10.3390/su142214671

Manshoven S, Van Opstal W. The Carrot or the Stick? Stakeholder Support for Mandatory Regulations towards a Circular Fashion System. Sustainability. 2022; 14(22):14671. https://doi.org/10.3390/su142214671

Chicago/Turabian StyleManshoven, Saskia, and Wim Van Opstal. 2022. "The Carrot or the Stick? Stakeholder Support for Mandatory Regulations towards a Circular Fashion System" Sustainability 14, no. 22: 14671. https://doi.org/10.3390/su142214671

APA StyleManshoven, S., & Van Opstal, W. (2022). The Carrot or the Stick? Stakeholder Support for Mandatory Regulations towards a Circular Fashion System. Sustainability, 14(22), 14671. https://doi.org/10.3390/su142214671