1. Introduction

A cold chain aims at protecting products and maintaining their temperature within a certain range; these products are usually food/perishables or pharmaceutical/medical products [

1]. Recently, more attention is drawn to the field of cold chains due to increased demand for vaccines and grocery delivery due to the COVID-19 pandemic. The potency of the vaccines and perishability of the groceries will be harmed hugely without proper cold chains. However, cold chains still face many obstacles today, and cold chain disruptions are still common in everyday lives. The shelf life of the cold chain products is affected by many factors, like temperature, humidity, product type, durations, storage and transportation conditions, etc. Lack of packaging processing and packing methods are identified as one of the main causes of inefficient cold chains; a further issue is temperature disruptions during the cold chain operations [

2]. Research indicates that the occurrence of temperature disruptions during all the cold chain links are not the same and point out that temperature abuse happens most frequently during loading and unloading, displaying in cabinet and domestic refrigeration [

3]. Also, in remote areas where refrigeration is difficult due to limited power or electricity availability, cold chain conditions are hard to be maintained. Therefore, during moments when refrigeration is absent or not guaranteed, the maintenance of temperature will rely heavily on the packages of the products. The packaging has a strong impact on the robustness of the cold chain since proper packaging systems can protect the products from potential hazards (e.g., physical damages, temperature disruptions, etc.) along the cold chains, affecting the overall shelf life of the cold chain products. Also, the demand of value-added perishable products has risen tremendously in the past few years, increasing the need of cold chain packaging.

There are different levels of packaging: primary, secondary, tertiary, and quaternary packaging. Primary packaging offers protection from the environment and often contacts the products directly which also refers to the retail/consumer units. For food products, it is also important to consider the moisture barrier and microbial growth inhabitation properties. For vaccines and other pharmaceutical products, the design of the vials and other packaging related accessories should consider preventing issues like freezing and frauds [

4]. Secondary packaging offers additional protection from environmental and physical damages which often refers to the shipping units. Examples are the shipping parcel systems: tertiary and quaternary packaging are the packages used during distribution, such as the pallet shipping systems, which often refers to the logistical units. The conventional purpose of packaging is to provide fundamental protection and safety enhancing properties for the products along the supply chain. With the continuous improvement of technology and the increasing demand for high-quality product delivery, the required functionalities of the packaging have changed. Traditional packaging provides functions like containment, protection, communication, convenience, etc. [

5]. With the booming development of various novel materials and technologies, the trend of packaging has slowly transitioned from conventional passive packaging to smart packaging. Lydekaityte and Tambo (2020) propose a new model of packaging functions which include protection, communication, convenience, and interaction incorporating the concepts of smart packaging [

6]. The aim of the preservation function is to maintain product quality and extend shelf life; the communication function aims to identify and notify market relative information; the convenience function aims to make the packaging easier for handling, transportation and storage; the containment function aims to hold, carry and envelop products. The packaging alone is sometimes not enough for the preservation of the food and pharmaceuticals. Since cold temperature conditions are also required to maintain the product quality during transportation and storage besides the packages themselves, cold chain packaging plays an important role impacting the overall efficiency of the cold chain.

Perishable products need robust cold chain packaging with good protection properties as well as the ability to prevent or alleviate temperature disruptions during transportation and storage. The purpose of the cold chain packaging is to protect products from spoilage and damages, to maintain a temperature within the required range, to show robust performance during transportation and storage and to provide other value-added services, such as enhancing the convenience for handling and offering communication between the products and operators/consumers [

2,

6,

7]. Cold chain packaging differs from traditional packages due to its rigid temperature maintaining and monitoring characteristics and often contains temperature regulating materials (TRMs) inside the packaging [

8].

TRMs are essential parts in cold chain packaging which have received increasing research attention. Phase change material (PCM) is one of the most popular TRM candidates today in academia and industry. The global PCM market is estimated to have a value of

$3.1 billion by 2026 [

9]. PCM changes its phase when the ambient temperature changes. The mechanism behind this involves latent heat, in which heat is released or absorbed by a system during a constant temperature [

10]. The unique phase changing property makes PCM a great candidate for the cold chain packaging. Some common PCMs are fatty acids, paraffin waxes, eutectics, etc. The applications of PCM in refrigeration aim at alleviating cooling load and maintaining a constant temperature at the same time. This can save energy costs and contribute to the sustainable development [

11]. To select suitable PCM, factors like costs, durability, corrosion, safety, sustainability and temperature maintaining ranges need to be considered.

The rest of the paper is structured as follows:

Section 2 offers a literature review on the topic of cold chain packaging and shipping solutions.

Section 3 discusses the research methodology. The results and discussion are presented in

Section 4. Finally,

Section 5 states the conclusion, which includes limitations and further work.

2. Background

Researchers in both academia and industry have studied cold chain packaging. In academia, the term ‘packaging in the cold chain’ is often used, while in industry, the term ‘cold chain shipping solution’ is used more frequently. Many cold chain products are discussed including fresh and frozen meat, seafood, poultry, desserts, dairies, vaccines, medical products, blood, organs, etc. Researchers tend to discuss food and pharmaceutical cold chains separately due to their different characteristics and cold chain requirements. Food cold chains usually begin at farms and end in hands of the consumers [

2]. Singh et al. [

8] summarize the applications of PCMs used in food packaging [

8]. Pharmaceutical cold chain begins right after being manufactured and normally ends in clinics and hospitals. The studies in academia mainly focus on PCM and other novel materials/technologies, while industry studies tend to focus more on providing overall cold chain shipping solutions and services. Few researchers have discussed the topics of commercialized cold chain packaging solutions. Singh et al. [

8] review PCM packaging classifications, technical approaches and commercial applications in food packaging systems which includes both packaging products that are commercialized already and the ones that are still in the research phase. They also come up with some PCM selection criteria, considering the thermal, physical, kinetic, chemical and economic property requirements. Chatterjee and Sasidharan [

7] discuss the physical behaviours and thermo-physical properties of the PCM from the perspective of Thermal Energy Storage (TES). The application of PCM in the packaging can improve the thermal energy storage efficiency, contributing to sustainable development. The effectiveness of PCMs depends on factors like the size of the transporting vehicle, desired temperature, product sitting on the vehicles, air distribution, the composition of PCM, etc., and common PCM applications include PCM pallets, PCM cold plates, PCM insulated thermal shells and the PCM insulated boxes [

7]. Companies have also come up with thermal packaging or PCM selection or evaluation criteria. For example, the 7-step thermal packaging evaluation criteria, involving thermal performance, system cost, freight optimization, payload optimization, pack-out simplicity, physical performance and environmental impact is proposed by Cold Chain Technologies, a thermal packaging and insulation solution company. Sub-parameters of each step are also stated. Take the thermal performance as an example, ambient temperature profiles, payloads and thermocouple wiring are three ways to evaluate the thermal performance of the packaging [

12].

There have been many real-life applications of PCM used in cold chain packaging as well. For instance, for perishable groceries ordered online, there will often be some ice bags or coolants within the packages. The earliest commercialized PCM product is PureTemp which was introduced in 2007 and is also the first 100% renewable commercially available PCM. Its applications involve warm blankets, cooling vests, thermal and refrigerator energy storage tanks, passive thermal packaging, etc [

13]. In the same year, Greenbox thermal container was introduced that contained the PureTemp and vacuum insulation panels (VIPs). This container can keep the product temperature for about 5 days with no electrical power [

8]. Today many companies have launched cold chain shipping solutions for a diverse range of applications. The ongoing COVID-19 pandemic has also boosted the fast development of cold chain packaging since they mostly have rigid temperature requirements, and some COVID-19 vaccines even require an ultra-low temperature environment during transportation/storage. KoolTemp EcoFlec 96 COVID-19 vaccine shipping parcel solutions have been used for air and land transportation/storage of the Pfizer, Moderna, Johnson & Johnson and AstraZeneca COVID-19 vaccines [

12]. For maintaining an ultra-low temperature during cold chain transportation/storage, dry ice is sometimes used within the packaging to reach and maintain an extreme low temperature. For example, the Pfizer COVID-19 vaccines use dry ice to maintain a temperature of −70 °C during cold chains. Also, companies have launched programs to further study PCM-based cold chain packaging solutions. For instance, Efficiency Vermont’s R&D project investigating refrigeration applications of PCM has shown that these packaging solutions can be beneficial in many ways including saving energy cost, improving cold chain efficiency, elongating equipment life and reducing maintenance costs, allowing flexible load management and minimizing damages during power outages.

Although many researchers and companies have investigated and reviewed the topics of PCMs and cold chain shipping solutions, most papers have focused on the PCMs or individual shipping solutions. There is no comprehensive review of the cold chain shipping solutions. The structure and components of the shipping solutions are not specified or standardized by any studies. Therefore, to fill those research gaps, this paper aims at offering an overview of the existing industry cold chain shipping solutions and discuss their characteristics, challenges and opportunities. A conceptual model detailing the classification of the cold chain shipping solutions is proposed. Specific materials and technologies will not be discussed in detail since they lay outside the scope of this study. Beside contributing new concepts and ideas to the literature on the topic of cold chain packaging, including the industry’s perspective improves the overall practicality of the study, providing stakeholders with practical guidelines.

4. Conceptual Model and Analytical Results

Packaging used in the cold chain not only has to consider the traditional protection features but must take the low temperature and logistical nature of the cold chain into consideration as well. From the packaging level perspective, the commercial cold chain shipping solutions are mainly concerned with the secondary, tertiary and quaternary packaging that concentrate on the shipment and distribution. From the packaging function perspective, the shipping solutions are concerned with all the functions of packaging, including protection, communication, convenience and interaction. The shipping solutions mainly focus on the protection and convenience functions. The interaction function normally happens at the primary packaging level since active substances are released directly to the products inside the packages to regulate. From the cold chain perspective, the cold chain shipping solutions are concerned with the transportation, storage, temperature regulation and monitor, loading and unloading, etc. involving all the links across the entire cold chain. Therefore, an overview of the structure, categories and components of the cold chain packaging is proposed and discussed below.

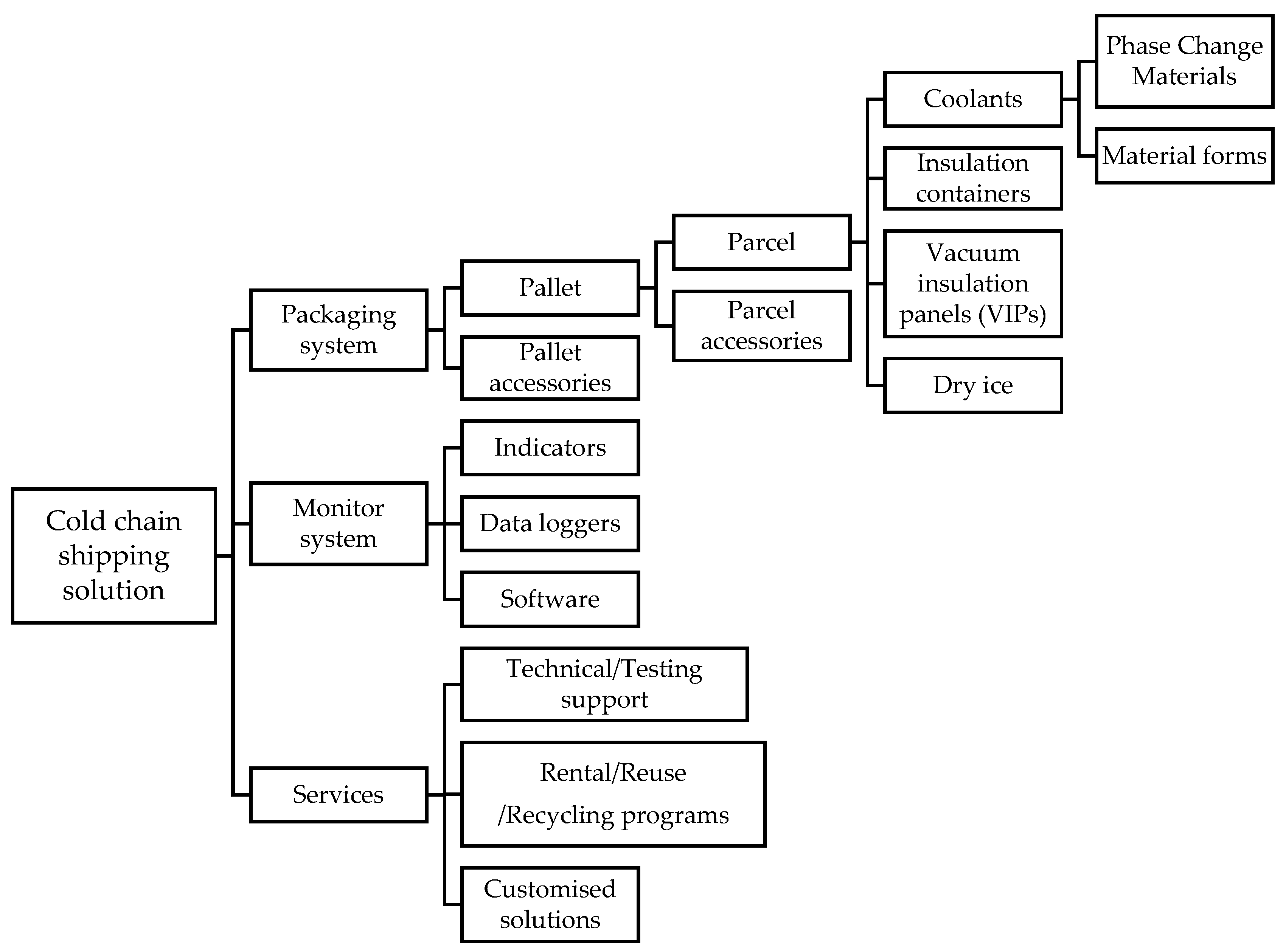

Since different companies offer various products and services, many terms have been used regarding the packaging solutions in cold chain transportation and storage, such as ‘pre-qualified cold chain shipping solutions’, ‘thermal systems’, ‘parcel shippers’, ‘cooling bags’, ‘passive cold storage systems’, ‘temperature control packaging system’, etc. In this paper, the term cold chain shipping solution is used for describing the comprehensive cold chain shipping solutions. In order to systematically review the cold chain shipping solution, a conceptual model is proposed in

Figure 1 to demonstrate the structure, components and categories of the shipping solutions.

The cold chain shipping solutions usually have a packaging system, a monitor system and some add-on services. The overall cold chain packaging system has a Pallet–Parcel–Coolant–PCM hierarchy structure, and the coolant is usually made of PCMs. Accessories and other technologies are often used to provide additional protections or enhance particular performances. The monitor system contains temperature/humidity indicators, data loggers and related management systems and software. The services that come with the shipping solution include reusing, recycling, training, testing, etc. programs. Many companies have launched different cold chain shipping solution products to suit various end needs, and both pre-qualified and customized cold chain shipping solution products and services are available, providing clients with the flexibility to choose the solutions that meet their needs. From all the components above, the PCM coolant is the core of the shipping solutions since it is the main source of temperature regulating for the cold chain shipping solutions.

Coolants originate from using ice for passive cooling of the cold chain products, and then water-based cool packs are used in some shipping solutions with the pros of freezing colder than regular ice and taking more time to warm up [

11]. Some current cold chain shipping solutions use water coolant that show good temperature maintaining properties. For instance, the AmbiTherm parcel solution use water-based cool packs and can maintain a temperature of 15 to 25 °C for up to 48 h [

15]. Today many non-water PCM coolants are produced and used to achieve superior thermal performances. Some coolants are renewable, which can significantly reduce the green gas emissions and enhance sustainability. For example, the Biochill coolant is made from 100% biobased feedstock. PureTemp is made from palm, coconut and soybean oils [

15,

16]. The PCM coolants have a wide range of temperature maintaining range from −26 to 25 °C to suit different product and transportation requirements [

17]. The list of commercial coolants is shown in

Table 1. The available material or storing forms and temperature ranges of the coolants are also listed.

While the properties of the cold chain shipping solutions highly depend on the coolant used, the PCM used inside the coolant and its storing form are the main factors affecting the temperature maintaining ranges of the coolants. In fact, there are different forms of PCM: liquid, gel, solid, foam, semi-foam, etc., and are stored and packed in different forms [

6]. Liquid PCM is usually stored in rigid bottles, while solid or gel PCM is often stored in plastic packages. Gel coolants are often used for ambient or chilled temperature ranges. They have the benefits of saving space due to the flexibility of their shape and received increasing attention in the past few years. Bottled coolants have the benefits of low cost but have the risk of liquid leakage during transportations. Some coolants are ready for usage just by themselves, while others are incorporated within the parcel or pallet solutions. Companies like Sonoco ThermoSafe, Cold Chain Technologies, Softbox, etc., have all launched cold chain shipping solutions incorporating PCM coolants. Depending on the specific requirements, different versions of coolants are available to accommodate different temperature ranges, durations, payload sizes etc. However, there are still some challenges with regards to these commercial PCM coolants. Leakage is the one of the main issues, which is also addressed from the PCMs in the developing phases found in the literature. Therefore, it is important to concentrate more on the refinement of the PCM. Researchers have studies on how to improve the thermal performance of phase change materials. Techniques or methods have been applied to improve the PCM properties, such as novel encapsulation methods, for example the addition of nano particles, micro encapsulation, electrospinning, vacuum impregnation etc. The addition of the nanoparticles increases the thermal conductivity in an efficient and cost-effective way. Therefore, industry practitioners should cooperate with academic researchers to increase knowledge sharing and work together to increase the overall performance of the PCM and speed up the commercialisation process.

Apart from the coolants, other accessories are also often used for better performance. Expanded polystyrene (EPS), polyurethane (PUR) and vacuum insulated panel (VIP) are some examples of the extra insulation used for both life sciences & healthcare products and food & perishables [

25]. EPS, along with corrugate and foam, can prevent chemical leaching during use and disposal, improving the overall safety and reducing cost. Compared to EPS, PUR performs even better in insulating. VIP offers superior heat damage protection during shipments [

14]. Cardboard or plastic outer containers are also often used for outer protection. For blood transportation and temporary storage, portable bags and boxes are used, mostly for ambient temperature maintaining. The packaging itself sometimes may still fail due to unexpected disruptions during the cold chain. Therefore, monitor technologies and management systems are often used inside the shipping solutions. Cryopak has launched data loggers like TimeSaver and Q pac to monitor and store the temperature data. Console Plus, a data management software is also available with the data loggers. The monitor systems can be categorised into temperature indicators, data loggers, management software and other advanced technologies, like the Internet of Things (IoT). The cold chain monitor system solutions are often integrated with the parcel or pallet solutions. Customisable products are available for manufacturers and end users to choose from. For data loggers, there are single-use, multi-use, real time monitoring software and accessories.

With the integration of insulation, coolants, other accessories and monitoring devices/system (e.g., data loggers, indicators), a parcel solution is designed. Both prequalified and customised parcel systems are available. Pallet solutions are also available that can be shipped in bulk by truck and plane, minimizing handling and making it easier to ship in large volumes. For example, Sonoco ThermoSafe has US and European-based pallet shippers that can transport pharmaceuticals with durations up to 7 days. Some pallet accessories are also used to protect the pallet. SilverSkin pallet covers by Softbox are manufactured from flexible and strong materials to provide extra protection under challenging transportation, packing and warehousing conditions. Other accessories are also available in many companies. The shipping solutions for vaccines or other pharmaceutical products differ from food shipping solutions due to their stricter temperature requirements. Many companies have launched vaccine carriers for shipping the vaccines, including shipping solutions for COVID-19 vaccines.

Table 2 lists the commercial prequalified cold chain shipping solutions and services, including parcels, pallets, indicators, data loggers, management software packages, rental and training services/programs.

For the parcel and pallet shippers, many parameters affect their overall performance, including size, weight, capacity and capability that all need to be considered during the design of the packages. The components of the parcel are sometimes integrated and also consider ergonomic features for better handling and assembly. For example, Cold Chain Technologies’ KoolTemp EcoFlex 96 parcel contains the Koolit advanced PCM gel, VIPs and dry ice. The unique flexible design allows for multiple temperatures and durations [

19]. Compared to traditional packaging, the main advantages of these cold chain shipping systems include lightweight, space-saving, simple packing, reducing cost, increasing durability and flexibility, improving temperature regulating properties and improving sustainability. Both food/perishables and pharmaceutical/medical products are suitable to use these parcels and pallets. Pharmaceutical/medical products are the major targeting products due to their greater temperature sensitivity and the high demand for vaccines during pandemics. Some companies launched particular shipping solutions for the COVID-19 vaccines [

19]. Pandemic and expansion of global immunization programmes both promote the fast development of these shipping solutions.

The overall performance of the cold chain packaging can be improved with the aid of these shipping solutions, which specifically can increase the thermal performance, robustness, leak protection, duration, etc. Pharmtherm and CoolGuard Advanced solutions claim that their shipping solutions can provide superior performance without compromising other properties [

34]. Since some vaccines require ultra-low temperature during transportation and storage, some solutions provide deep frozen transportation and storage options, including Nordic Express, ORCA, Elite Cubic, Deepfreeze, Softbox Frozen Parcel Shippers, STS Frozen Parcel Family, etc. The majority of them [

19,

20] use dry ice to aid with achieving ultra-low temperatures during storage and transportation. Many vaccines are freeze-sensitive to low temperatures during transportation and storage, and freezing has found to be one main issue to cause vaccines to lose their potency, posing great threat to human bodies. Apart from the temperature regulation, the duration of the cold chain shipping solutions matters as well since a shipping solution with a longer duration will have more resilience from cold chain disruptions. Elite Cubic and Initial Express solutions both show great improved performance in durations, which can achieve a duration of up to 168 h. Besides thermal performance, the overall robustness of the cold chain packaging can be increased, as indicated by the Elite Cubic solution, which incorporates anti-shocks, anti-perforation technology, VIP, eutectic gels, PP or cardboard in its parcel solutions. AmbiThem is proven to show high puncture resistance and leak protection. EOS is shown to have rising insulation and cushioning properties [

19,

32]. The applications of these cold chain shipping solutions will greatly increase the thermal and insulation performance and prolong the shelf life of the cold chain products. Besides superior thermal performance, there are various shipping options available to choose from.

The cold chain shipping solutions provide flexibility to the overall cold chain operations on the aspects of temperature ranges, packing and assembly options, switching between durations, etc. Globalisation has encouraged a rising number of international trades, different countries may have different regulations on transport, storage, temperature and packaging of the perishable products, posing some additional challenges for international transportation. To solve this issue, many shipping solutions, in particular the parcel solutions, offer various sizes and payload options. The flexibility can greatly ease the tension caused by different requirements and regulations. Despite sizes and capacities, a variety of temperature maintaining ranges are provided by the shipping solutions. For example, the deep-frozen cold chain parcels and the cold boxes for medical products are available, increasing the resilience of the cold chain in case of any unexpected disruptions, such as power outages. Also, some parcel solutions offer alternatives to dry ice for frozen cold chains. FreezeTech uses FreezeSob, a nontoxic salt-based PCM, which can maintain a temperature range of −25 to 15 °C for 48 h. This helps alleviate the cold chain stress due to the high demand for COVID-19 vaccines. Between 2–8 °C is the typically recommended storage temperature range for most vaccines, and many shipping solutions have products within this temperature range [

4]. For the cold chains of blood, specimens, organs, and other medical products, usually, specially made boxes are designed and used. For example, Via parcels are designed for the cold chains of packed red blood cells, organs, specimens, platelets, etc. It is reusable, and the ZERO BEN-TIME refrigerant technology cuts assembly time, improving the overall manufacturing efficiency. Besides the various temperature ranges, different load sizes and duration options are also available for the shipping parcel solutions. For example, AmbiTech, the PCM-based CRT shippers, has three versions, which the durations and sizes of each version are different. AmbiTech Regional has a duration of 72 h and has five payload sizes ranging from 9 L to 71 L; AmbiTech has a duration of 90 h and has four payload sizes ranging from 5 L to 35 L; AmbiTech Global has a duration of 120 h+ and has seven payload sizes ranging from 4 L to 65 L. The various shipping solutions available with various temperature ranges, durations and capacities provide companies an easier and more convenient way to create and maintain a robust and smooth supply chain.

In addition, the design of the shipping solutions takes ergonomics and safety into consideration. Tsang, Y. et al. [

44] have found that occupational safety is a main risk of the cold chain since working under an extraordinary environment can potentially cause harm to the working personnel [

44]. Standardized components of parcels make them universally or seasonally packable, making it easier for handling and saving time. Some parcel solutions can use the same packout for refrigerated, CRT and frozen cold chains, e.g., Greenbox, Certis and Envoy parcel solutions. The PCMs inside are sometimes interchangeable to accommodate the changes of temperature and duration expectations. Some parcels have off-the-shelf use conveniences, such as Envoy and Chill-pak. The NanoCool parcels do not require preconditioning the coolant gel and is portable. All these ergonomic features of the shipping solutions will make handling and assembling much easier and decrease the overall operational safety risks since working with or in a cold environment can be challenging [

14].

The lightweights, space-saving and reusability of some parcels increase the overall sustainability and cost-efficiency of the cold chain, and add-on services and programs can increase the knowledge sharing of cold chain packaging. Some shipping solutions claim to be environmentally friendly and cost-efficient. Tempcell ECO solution claims to be 100% recyclable, and Initial Freight Forwarding and Initial Express solutions claim to be both 70% recyclable. Many shipping solutions can be reused/recycled, and related programs are offered by some companies. For instance, a ReNew service program is provided along with the KoolTemp EcoFlex 96 family parcel system. The ReNew program encourages the parcels to be reused, making them environmentally friendly and reducing cost burdens. Also, most shipping solutions incorporate monitoring devices and systems. For example, ORCA parcels have multiple data loggers integrated with the parcels for monitoring of the temperatures. Effective temperature monitoring can save product losses during transportation and storage, saving cost and waste [

19,

31]. Besides reusing and recycling programs, other additional services are also available, such as training and tutorial programs, rental services, consulting, monitoring and management systems, technical support, etc., meeting various end-user needs. Add-on programs/services can enhance knowledge sharing in the field of cold chain packaging. GTS Rx Family offers some training videos and studying kits, and pack-out instructions are provided by TimeSaver and Q-pac parcels. Cold Chain Technologies hold regular educational seminars. Softbox and Intelsius both provide technical consultation support. Cryopak provides trouble shooting, knowledge and training support.

Despite of all the advantages of cold chain shipping solutions, there are still challenges due to the complexity of the cold chain. Although many solutions claim to be cost-efficient, the commercialization of the PCMs and the overall shipping solutions remain not easy and can be costly sometimes. Therefore, further studies are needed. More empirical studies are needed to further validate the knowledge in this field of the study. Also due to cost and environmental considerations, the commercialisation of the PCMs and shipping solutions is not easy. Also, novel materials and technologies are continuously developing, and studying how the new technologies affect the development of the cold chain packaging is essential. Tsang et al. [

44] propose an IoT-based cold chain monitoring system to manage risk along the cold chain. The application of Internet of Things (IoT) on cold chain packaging can have a huge impact on the further trend of the cold chain packaging [

44].