Diffusion of Cement Kiln Co-Processing of Contaminated Soil in Selected Provinces of China: Engineering Practices, Modeling, and Driving Factors

Abstract

:1. Introduction

2. Materials and Methods

2.1. CKC Data

2.2. Data Cleaning

2.3. Diffusion Model

3. Results and Discussion

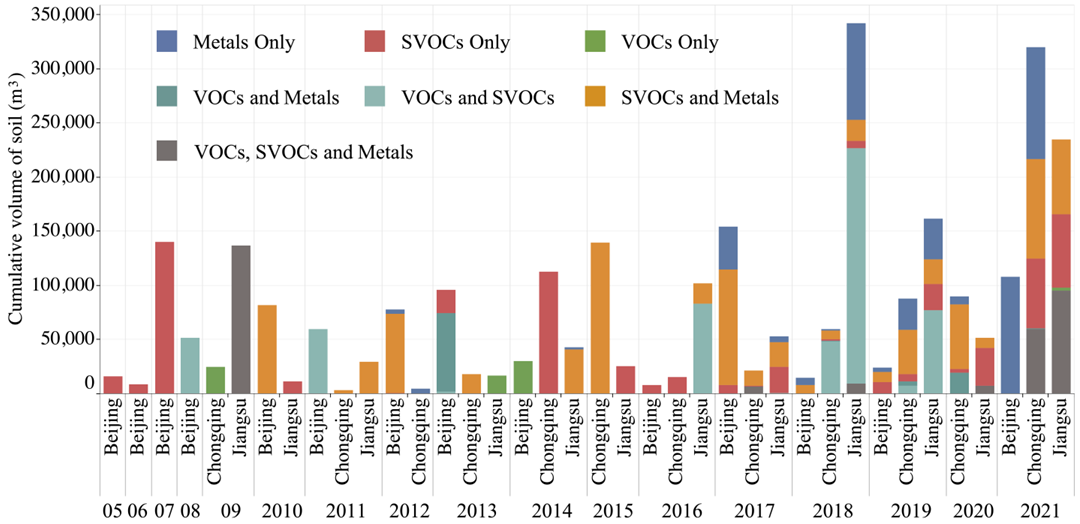

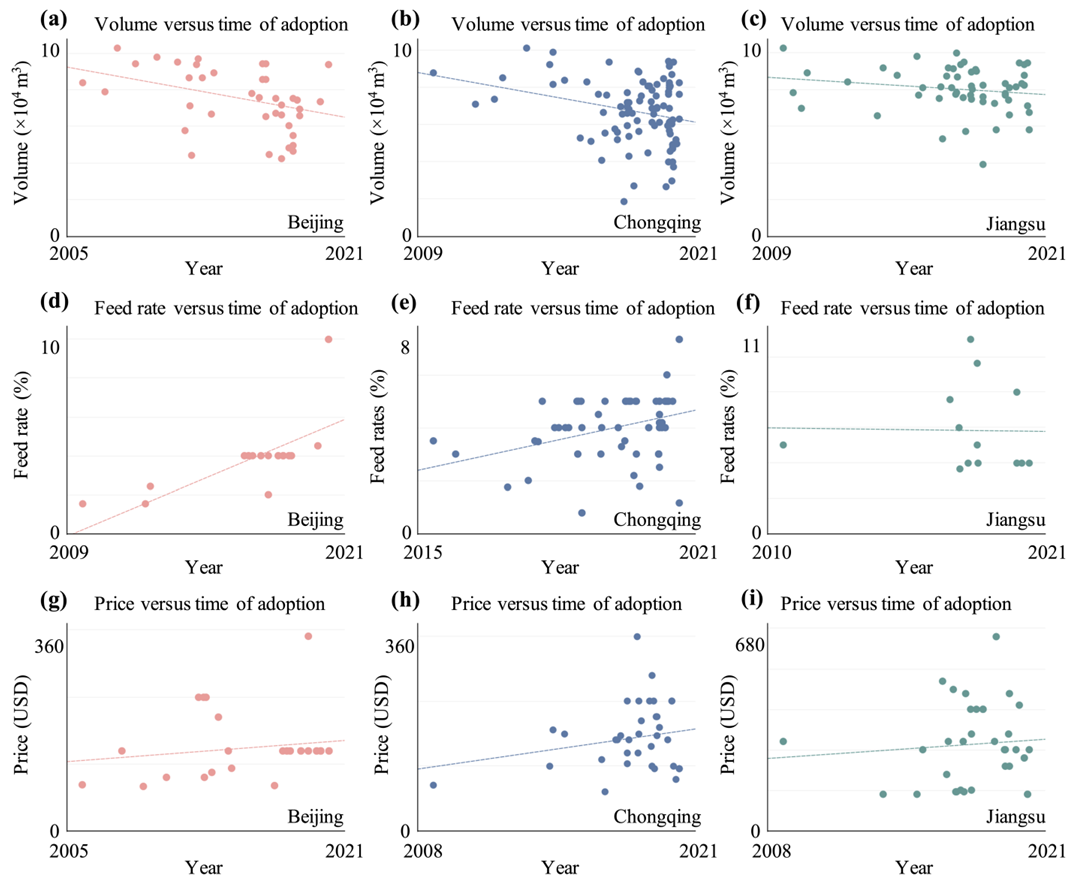

3.1. Changes in Contaminants, Volume, Feed Rate, and Price over Time

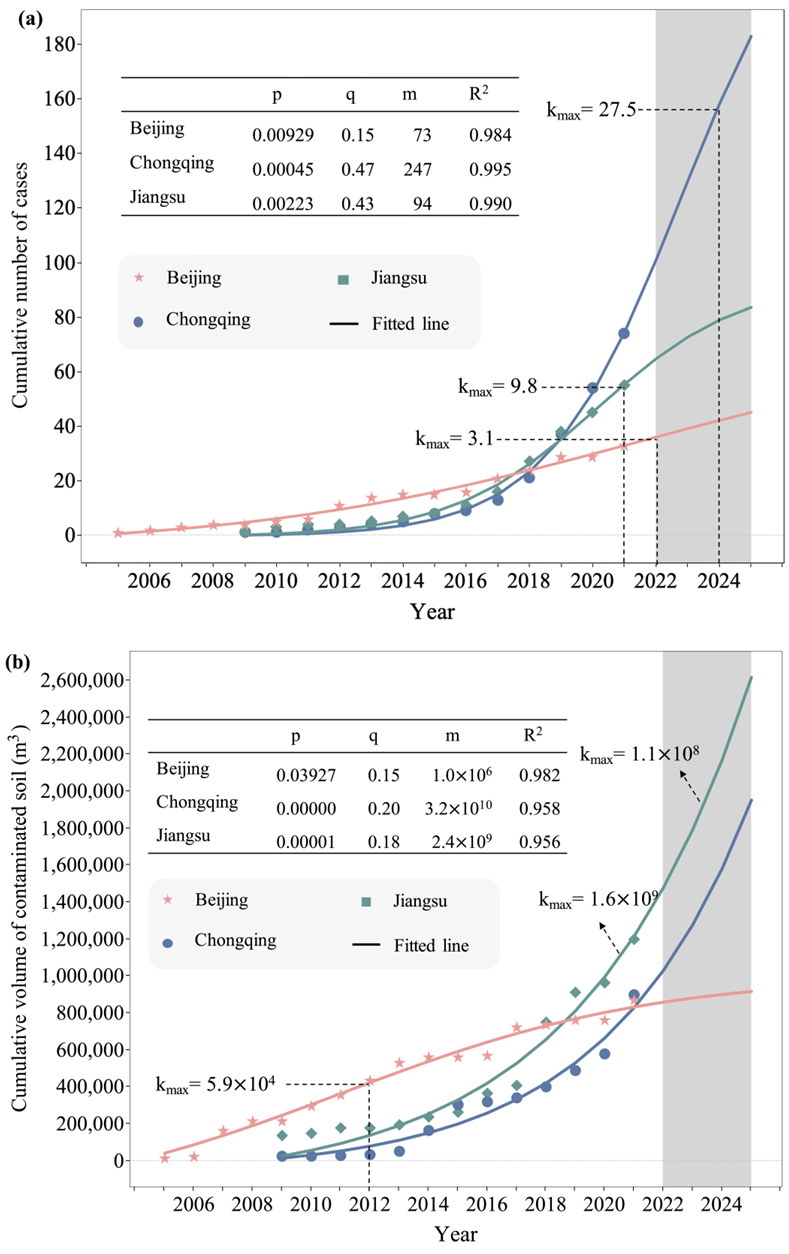

3.2. Diffusion Characteristics of CKC in Different Provinces of China

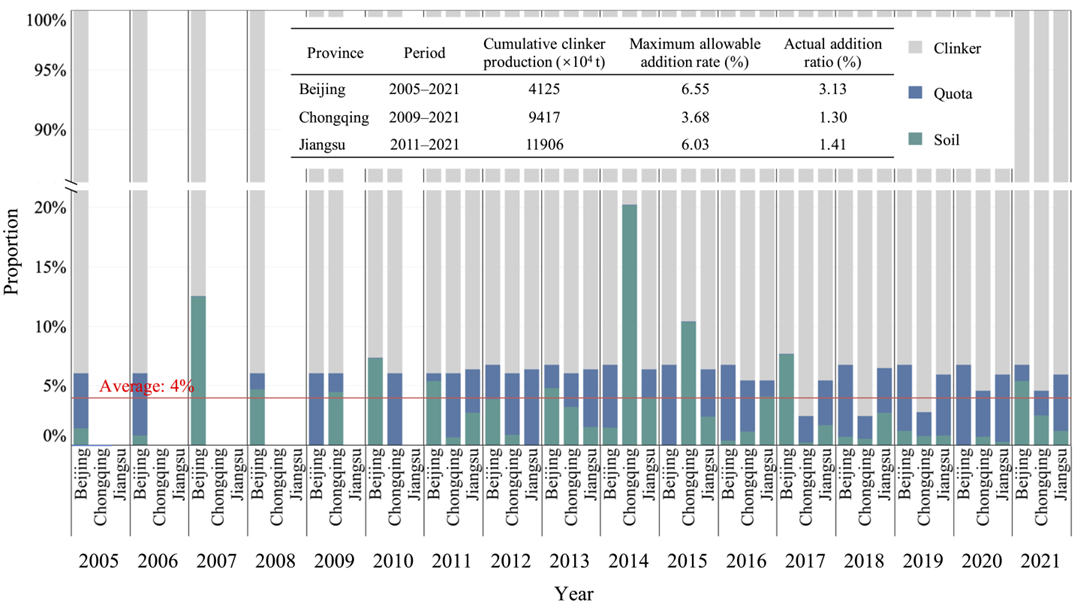

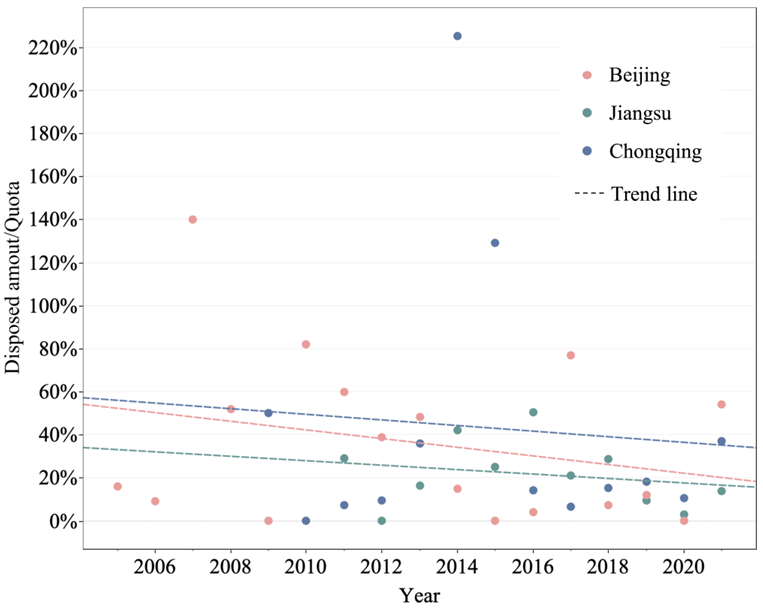

3.3. Capacity of Cement Plants to Co-Process Contaminated Soil

3.4. Drivers for CKC Diffusion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- CSER. China’s Soil Remediation Technology and Market Development Research Report 2016–2020; China Solid Waste Network: Beijing, China, 2016. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations, 5th ed.; Free Press: New York, NY, USA, 2003; ISBN 978-0-7432-2209-9. [Google Scholar]

- Kumar, A.; Takeshima, H.; Thapa, G.; Adhikari, N.; Saroj, S.; Karkee, M.; Joshi, P.K. Adoption and Diffusion of Improved Technologies and Production Practices in Agriculture: Insights from a Donor-Led Intervention in Nepal. Land Use Policy 2020, 95, 104621. [Google Scholar] [CrossRef]

- Li, Y.; Khalkhali, M.; Mo, W.; Lu, Z. Modeling Spatial Diffusion of Decentralized Water Technologies and Impacts on the Urban Water Systems. J. Clean. Prod. 2021, 315, 128169. [Google Scholar] [CrossRef]

- She, Z.-Y.; Cao, R.; Xie, B.-C.; Ma, J.-J.; Lan, S. An Analysis of the Wind Power Development Factors by Generalized Bass Model: A Case Study of China’s Eight Bases. J. Clean. Prod. 2019, 231, 1503–1514. [Google Scholar] [CrossRef]

- Benvenutti, L.M.M.; Ribeiro, A.B.; Uriona, M. Long Term Diffusion Dynamics of Alternative Fuel Vehicles in Brazil. J. Clean. Prod. 2017, 164, 1571–1585. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Swami, S. Diffusion of Green Products in Industry 4.0: Reverse Logistics Issues during Design of Inventory and Production Planning System. Int. J. Prod. Econ. 2020, 223, 107519. [Google Scholar] [CrossRef]

- Gao, X.; Zheng, Z.; Chu, Q.; Tang, S.; Chen, G.; Deng, Q. Popularity Prediction for Single Tweet Based on Heterogeneous Bass Model. IEEE Trans. Knowl. Data Eng. 2021, 33, 2165–2178. [Google Scholar] [CrossRef]

- Lim, H.; Jun, D.B.; Hamoudia, M. A Choice-Based Diffusion Model for Multi-Generation and Multi-Country Data. Technol. Forecast. Soc. Chang. 2019, 147, 163–173. [Google Scholar] [CrossRef]

- Mohan, P.; Strobl, E.; Watson, P. Innovation, Market Failures and Policy Implications of KIBS Firms: The Case of Trinidad and Tobago’s Oil and Gas Sector. Energy Policy 2021, 153, 112250. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, S.-H.; Cha, K.C. Impact of Online Information on the Diffusion of Movies: Focusing on Cultural Differences. J. Bus. Res. 2021, 130, 603–609. [Google Scholar] [CrossRef]

- Singhal, S.; Anand, A.; Singh, O. SDE Based Generalized Innovation Diffusion Modeling. Int. J. Math. Eng. Manag. Sci. 2019, 4, 697–707. [Google Scholar] [CrossRef]

- Bass, F.M. Comments on “A New Product Growth for Model Consumer Durables the Bass Model”. Manag. Sci. 2004, 50, 1833–1840. [Google Scholar] [CrossRef] [Green Version]

- Hou, D.; O’Connor, D.; Al-Tabbaa, A. Modeling the Diffusion of Contaminated Site Remediation Technologies. Water. Air. Soil Pollut. 2014, 225, 2111. [Google Scholar] [CrossRef]

- Zambrano-Gutiérrez, J.C.; Nicholson-Crotty, S.; Carley, S.; Siddiki, S. The Role of Public Policy in Technology Diffusion: The Case of Plug-in Electric Vehicles. Environ. Sci. Technol. 2018, 52, 10914–10922. [Google Scholar] [CrossRef]

- van Ewijk, S.; McDowall, W. Diffusion of Flue Gas Desulfurization Reveals Barriers and Opportunities for Carbon Capture and Storage. Nat. Commun. 2020, 11, 4298. [Google Scholar] [CrossRef] [PubMed]

- Liang, T.; Yang, F.; Ding, A.; Li, F. Cement Kiln Co-Processing Promotes the Redevelopment of Industrially Contaminated Land in China: Spatio-Temporal Features and Efficiency Analysis. Sci. Total Environ. 2022, 817, 152788. [Google Scholar] [CrossRef]

- Xinmin Evening Post Pollution Incident at Beijing Songjiazhuang Metro Station. Available online: http://xmwb.xinmin.cn/html/2013-05/19/content_15_2.htm (accessed on 1 October 2021).

- MEE National Soil Environmental Management System for Contaminated Land. Available online: http://114.251.10.109/page/shareuserlogin.html (accessed on 27 August 2022).

- Rao, K.U.; Kishore, V.V.N. A Review of Technology Diffusion Models with Special Reference to Renewable Energy Technologies. Renew. Sustain. Energy Rev. 2010, 14, 1070–1078. [Google Scholar] [CrossRef]

- Peres, R.; Muller, E.; Mahajan, V. Innovation Diffusion and New Product Growth Models: A Critical Review and Research Directions. Int. J. Res. Mark. 2010, 27, 91–106. [Google Scholar] [CrossRef]

- Wang, H.S.; Noble, C.H.; Dahl, D.W.; Park, S. Successfully Communicating a Cocreated Innovation. J. Mark. 2019, 83, 38–57. [Google Scholar] [CrossRef]

- Li, W.; Tian, L.; Liu, H.; Su, Q. Heterogeneous Adoption of Eco-Innovation Considering Commuting Mobility Patterns. J. Clean. Prod. 2020, 250, 119499. [Google Scholar] [CrossRef]

- Zhang, H.; Vorobeychik, Y. Empirically Grounded Agent-Based Models of Innovation Diffusion: A Critical Review. Artif. Intell. Rev. 2019, 52, 707–741. [Google Scholar] [CrossRef]

- Hui, Z.H.U.; Shujun, Y.E.; Jichun, W.U.; Haizhen, X.U. Characteristics of Soil Lithology and Pollutants in Typical Contamination Sites in China. Earth Sci. Front. 2021, 28, 26. [Google Scholar] [CrossRef]

- Chang, J.-S.; Cho, Y.-C.; Lin, Y.-P. Regeneration of Heavy Metal Contaminated Soils for Cement Production by Cement Kiln Co-Processing. Resour. Conserv. Recycl. 2022, 176, 105909. [Google Scholar] [CrossRef]

- Suksanguan, U.; Siwadamrongpong, S.; Champahom, T.; Jomnonkwao, S.; Boonyoo, T.; Ratanavaraha, V. Structural Equation Model of Factors Influencing the Selection of Industrial Waste Disposal Service in Cement Kilns. Sustainability 2022, 14, 4109. [Google Scholar] [CrossRef]

- Losacker, S. ‘License to Green’: Regional Patent Licensing Networks and Green Technology Diffusion in China. Technol. Forecast. Soc. Chang. 2022, 175, 121336. [Google Scholar] [CrossRef]

- Verpaalen, I.A.M.; Holland, R.W.; Ritter, S.; van Hooff, M.; Ebbers, W.; Hooft, L.; Metting, E.; van der Laan, L.N. Resistance to Contact Tracing Applications: The Implementation Process in a Social Context. Comput. Hum. Behav. 2022, 134, 107299. [Google Scholar] [CrossRef]

- Usha Rao, K.; Kishore, V.V.N. Wind Power Technology Diffusion Analysis in Selected States of India. Renew. Energy 2009, 34, 983–988. [Google Scholar] [CrossRef]

- Bertotti, M.L.; Modanese, G. On the Evaluation of the Takeoff Time and of the Peak Time for Innovation Diffusion on Assortative Networks. Math. Comput. Model. Dyn. Syst. 2019, 25, 482–498. [Google Scholar] [CrossRef]

- Taylor, M.R.; Rubin, E.S.; Hounshell, D.A. Regulation as the Mother of Innovation: The Case of SO2 Control. Law Policy 2005, 27, 348–378. [Google Scholar] [CrossRef]

- Kosajan, V.; Wen, Z.; Fei, F.; Doh Dinga, C.; Wang, Z.; Zhan, J. The Feasibility Analysis of Cement Kiln as an MSW Treatment Infrastructure: From a Life Cycle Environmental Impact Perspective. J. Clean. Prod. 2020, 267, 122113. [Google Scholar] [CrossRef]

- Yang, Y.; Xue, J.; Huang, Q. Studies on the Solidification Mechanisms of Ni and Cd in Cement Clinker during Cement Kiln Co-Processing of Hazardous Wastes. Constr. Build. Mater. 2014, 57, 138–143. [Google Scholar] [CrossRef]

| Province | Period | Takeoff Time a | t* | (dN/dt)t= t* |

|---|---|---|---|---|

| Beijing | 2005–2021 | 2 | 7 | 5.9 × 104 |

| Chongqing | 2009–2021 | 4 | 64 | 1.6 × 109 |

| Jiangsu | 2009–2021 | 7 | 55 | 1.1 × 108 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, T.; Yang, B.; Deng, C.; Du, P.; Wang, T.; Zhou, H.; Wang, P.; Yu, J.; Ding, A.; Ma, F.; et al. Diffusion of Cement Kiln Co-Processing of Contaminated Soil in Selected Provinces of China: Engineering Practices, Modeling, and Driving Factors. Sustainability 2022, 14, 14887. https://doi.org/10.3390/su142214887

Liang T, Yang B, Deng C, Du P, Wang T, Zhou H, Wang P, Yu J, Ding A, Ma F, et al. Diffusion of Cement Kiln Co-Processing of Contaminated Soil in Selected Provinces of China: Engineering Practices, Modeling, and Driving Factors. Sustainability. 2022; 14(22):14887. https://doi.org/10.3390/su142214887

Chicago/Turabian StyleLiang, Tian, Bin Yang, Chenning Deng, Ping Du, Tuqiang Wang, Hongxing Zhou, Panpan Wang, Jingjing Yu, Aizhong Ding, Fujun Ma, and et al. 2022. "Diffusion of Cement Kiln Co-Processing of Contaminated Soil in Selected Provinces of China: Engineering Practices, Modeling, and Driving Factors" Sustainability 14, no. 22: 14887. https://doi.org/10.3390/su142214887