The Effects of Meridian Surface Shape on the Pressure Pulsation of a Multi-Stage Electric Submersible Pump

Abstract

1. Introduction

2. Physical Model

3. Numerical Simulation

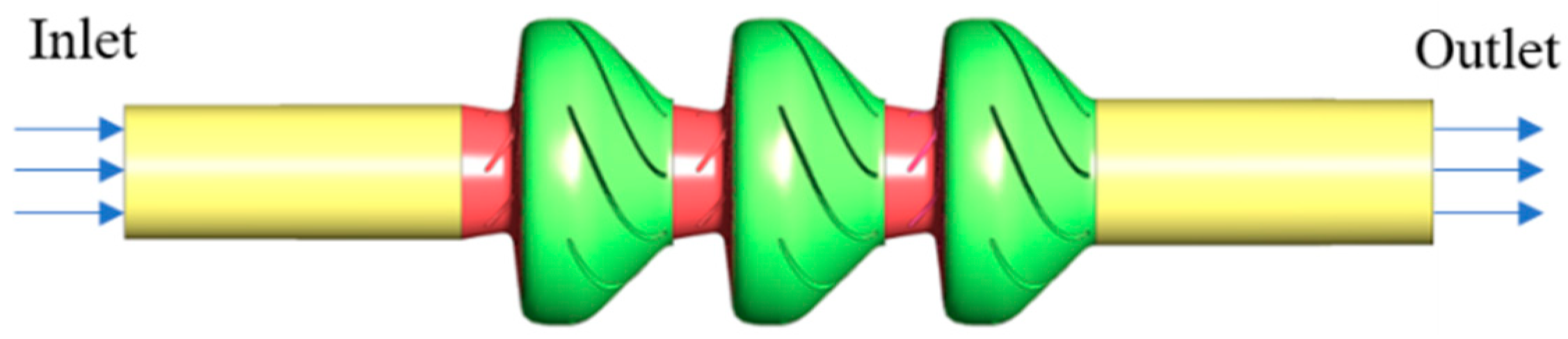

3.1. Computational Domain

3.2. Meshing and Independence Verification

3.3. Boundary Conditions

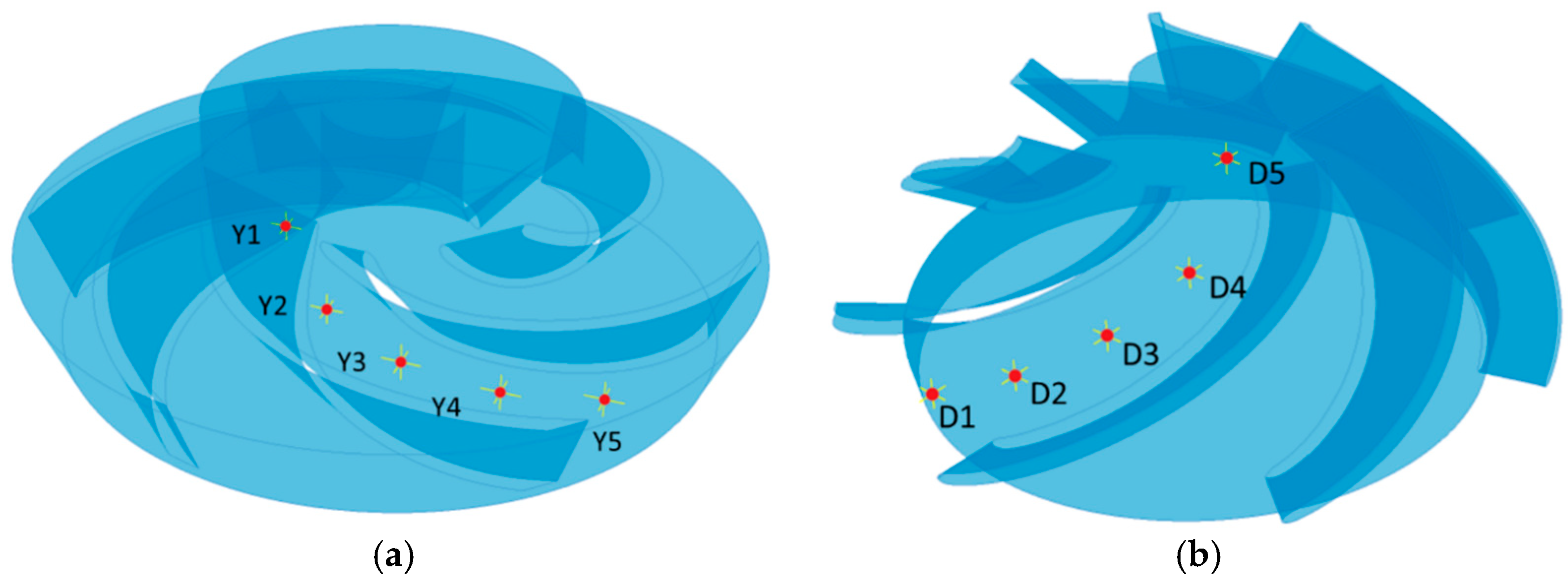

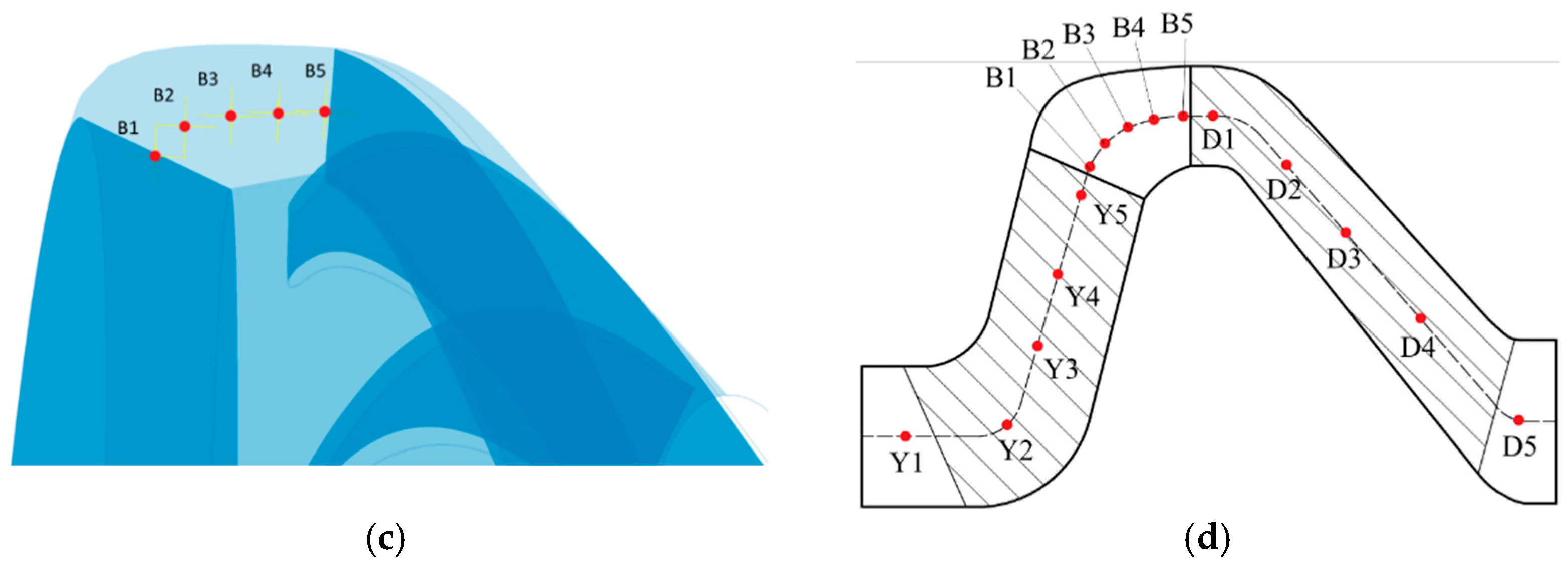

3.4. Monitoring Point

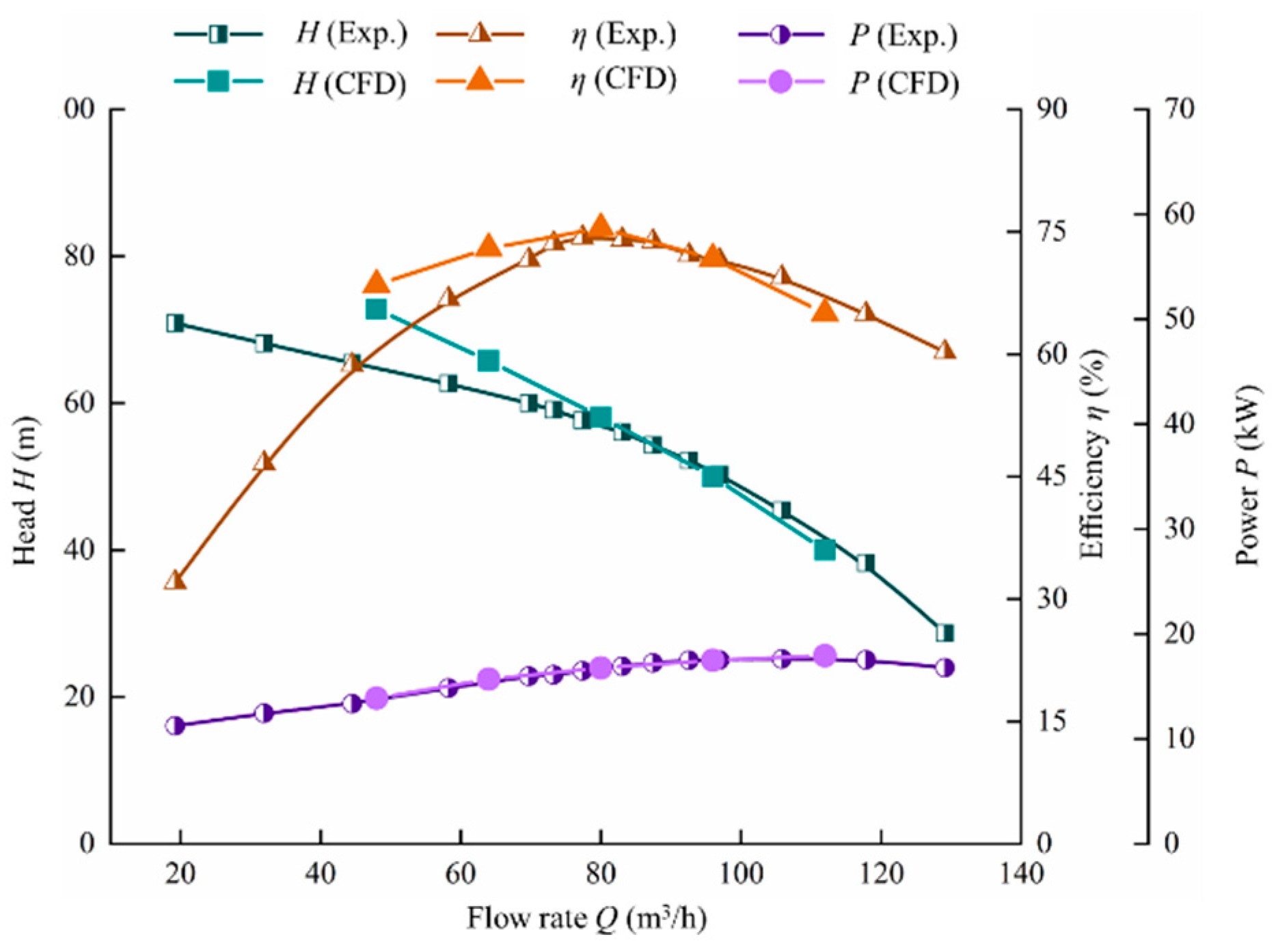

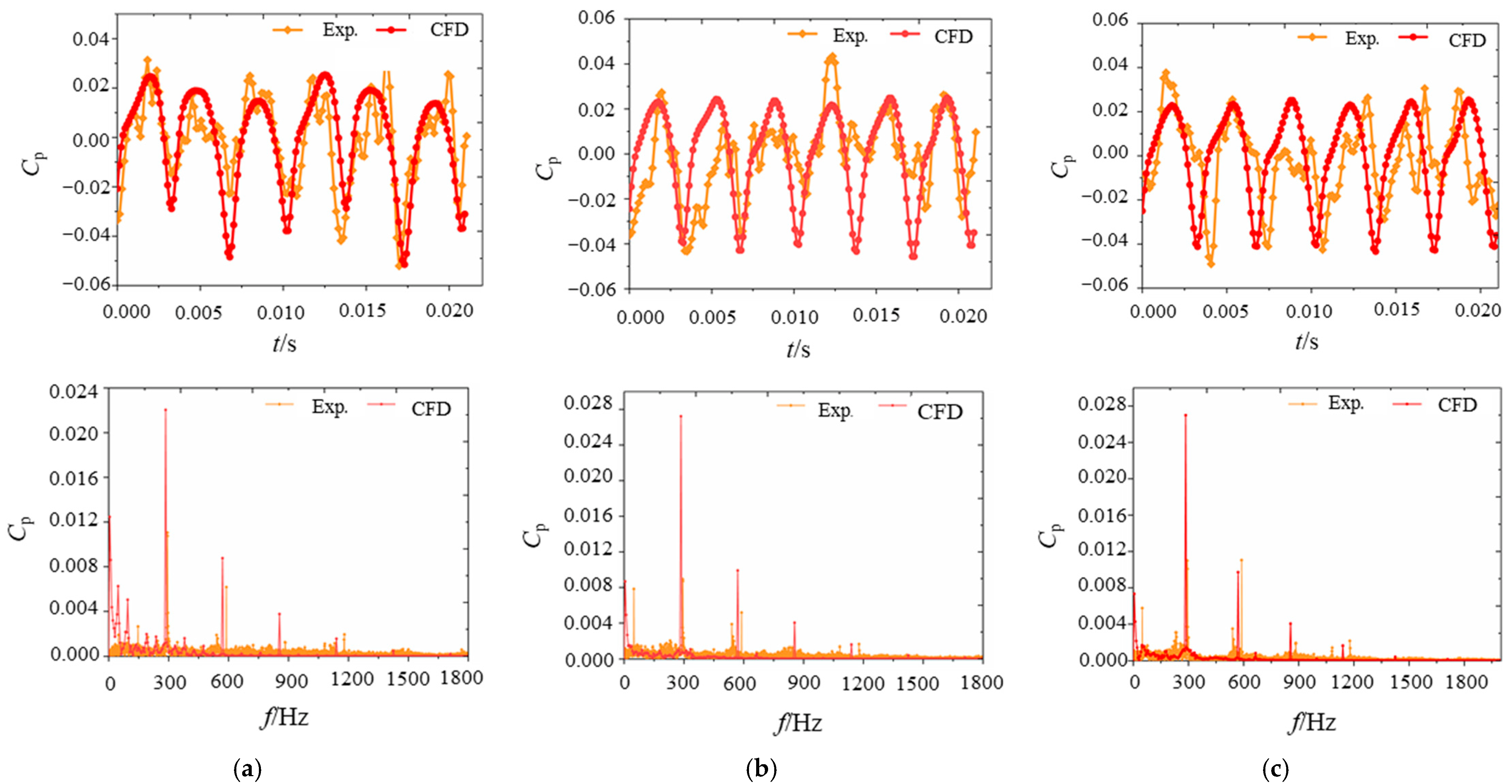

3.5. Simulation Accuracy Verification

4. Results and Discussion

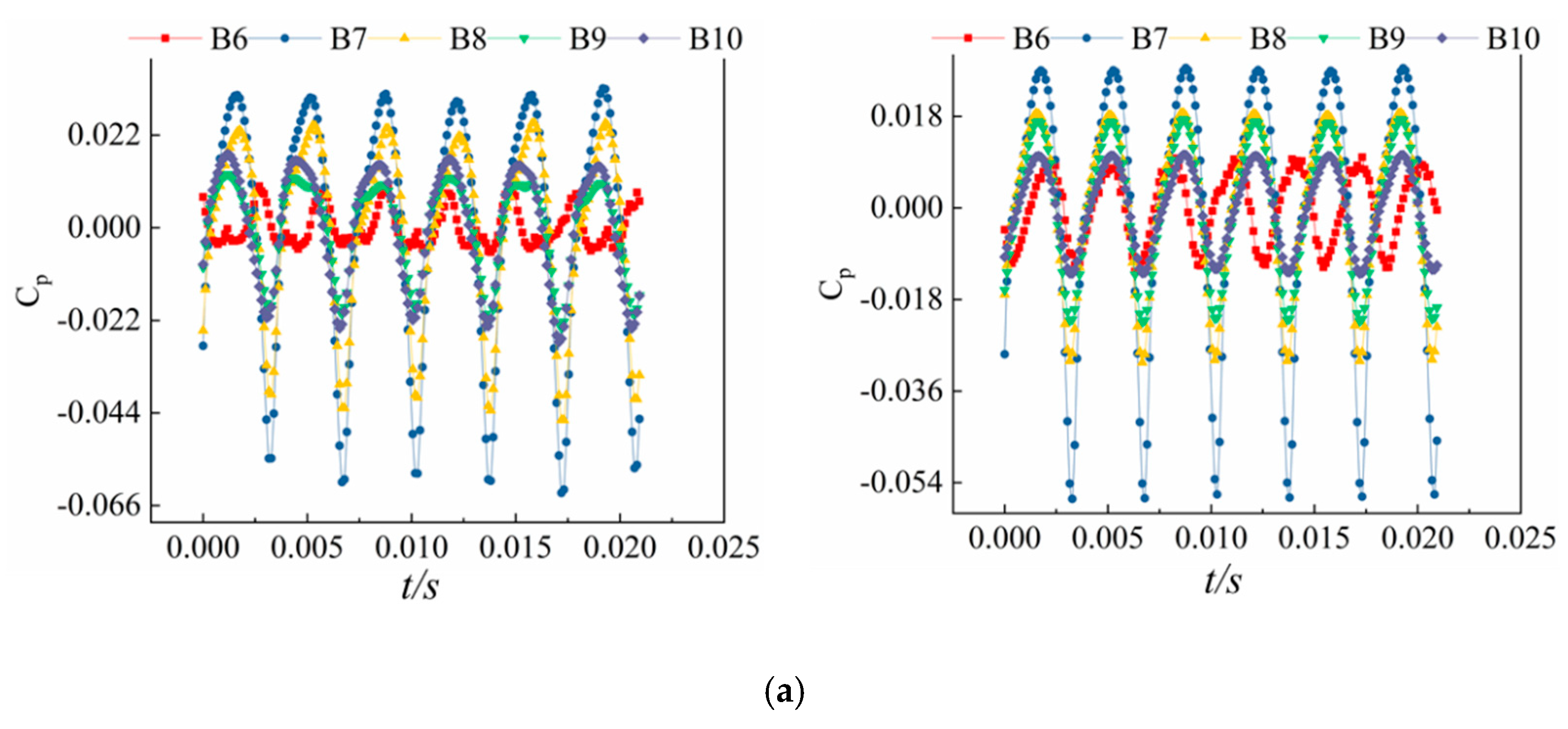

4.1. Pressure Pulsation Inside the Impeller

4.2. Pressure Pulsation Inside the Chamber

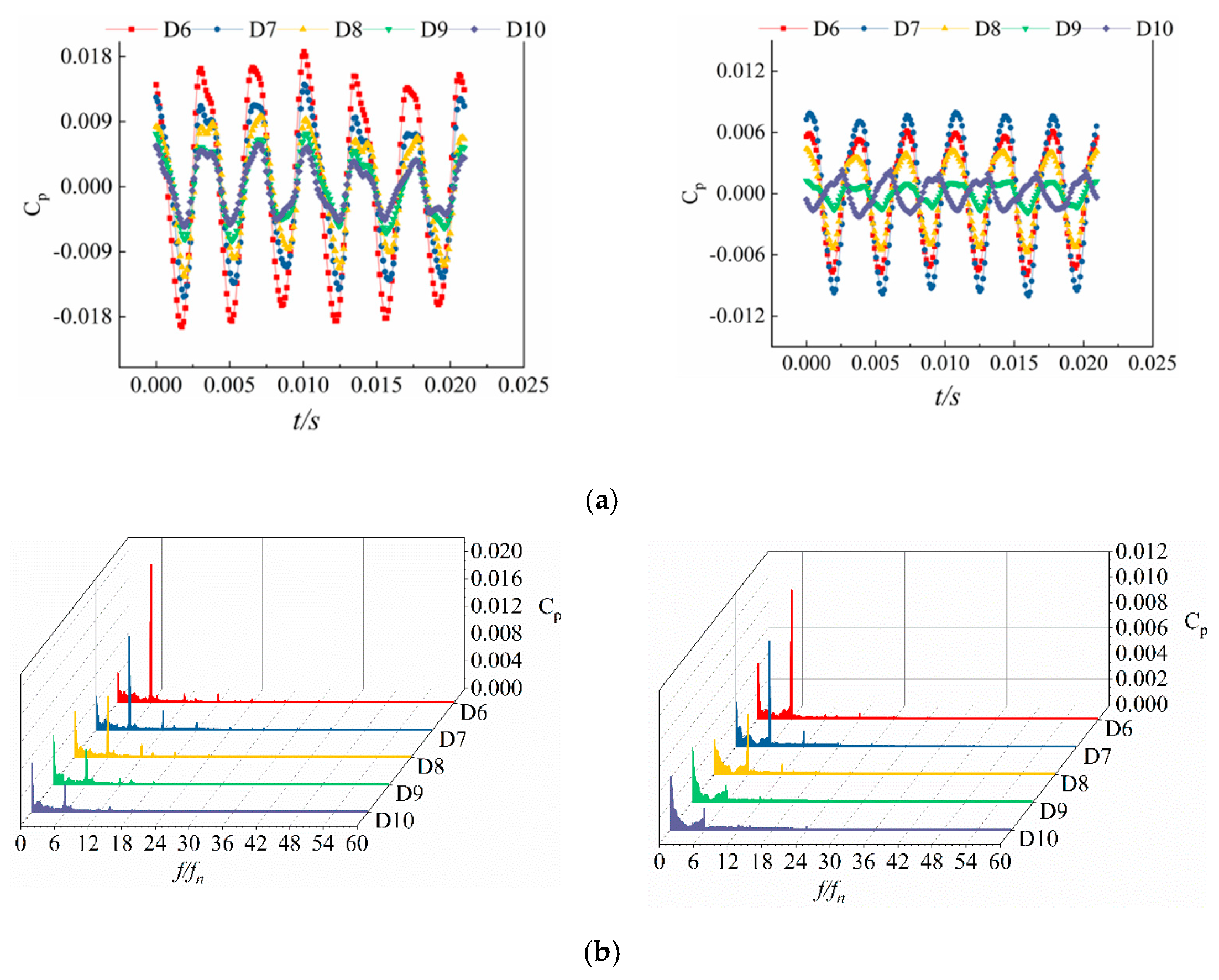

4.3. Pressure Pulsation Inside the Diffuser

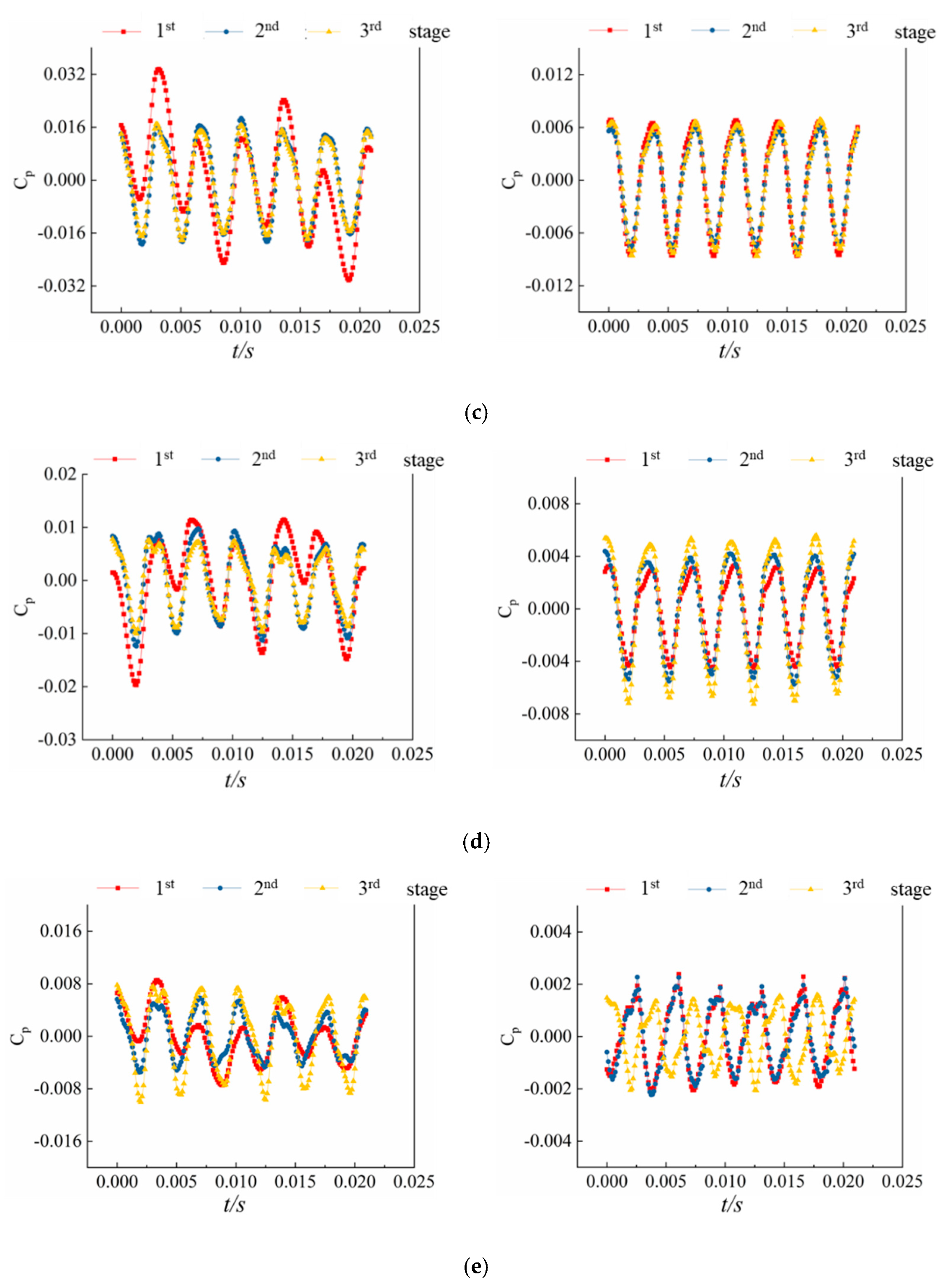

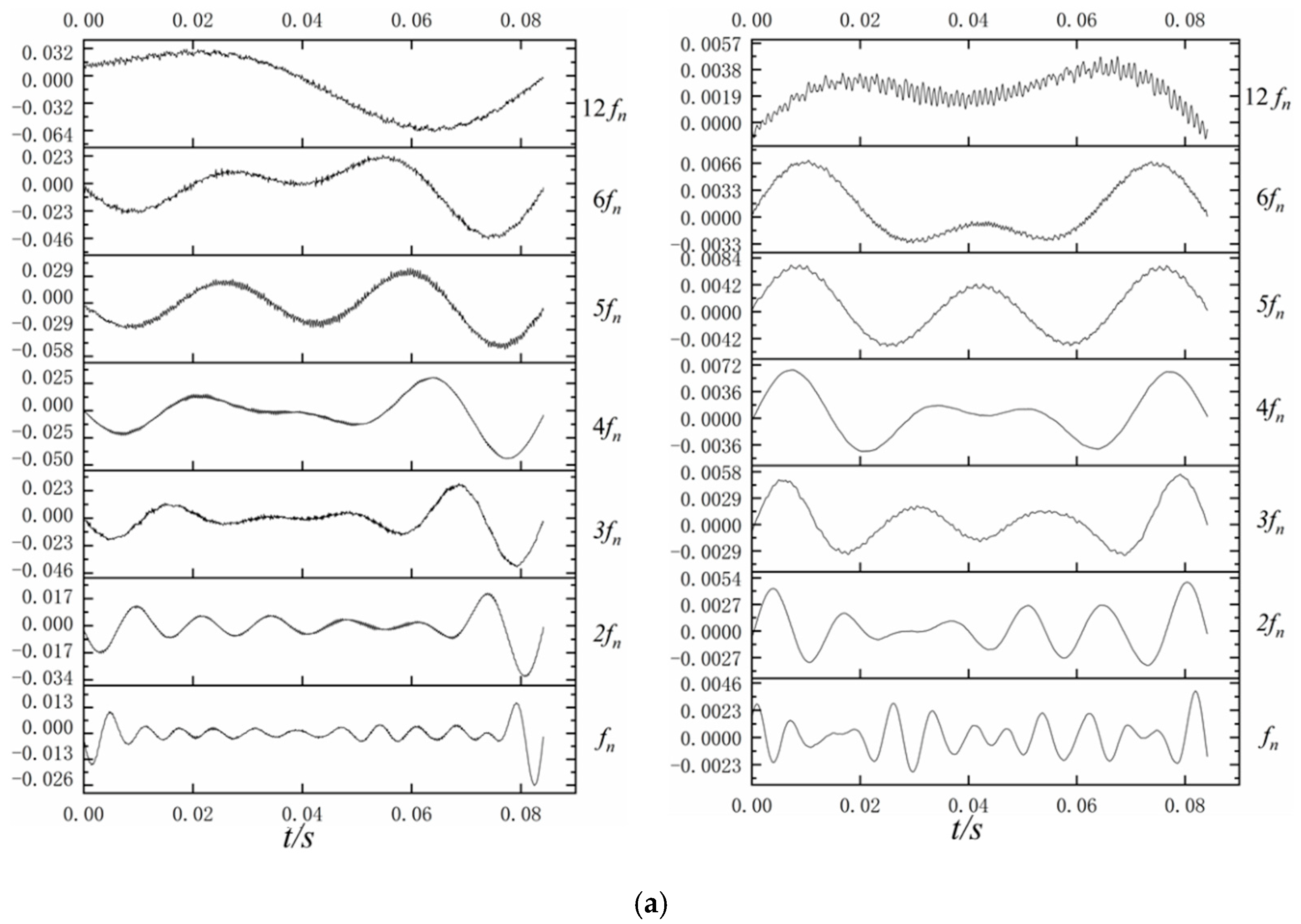

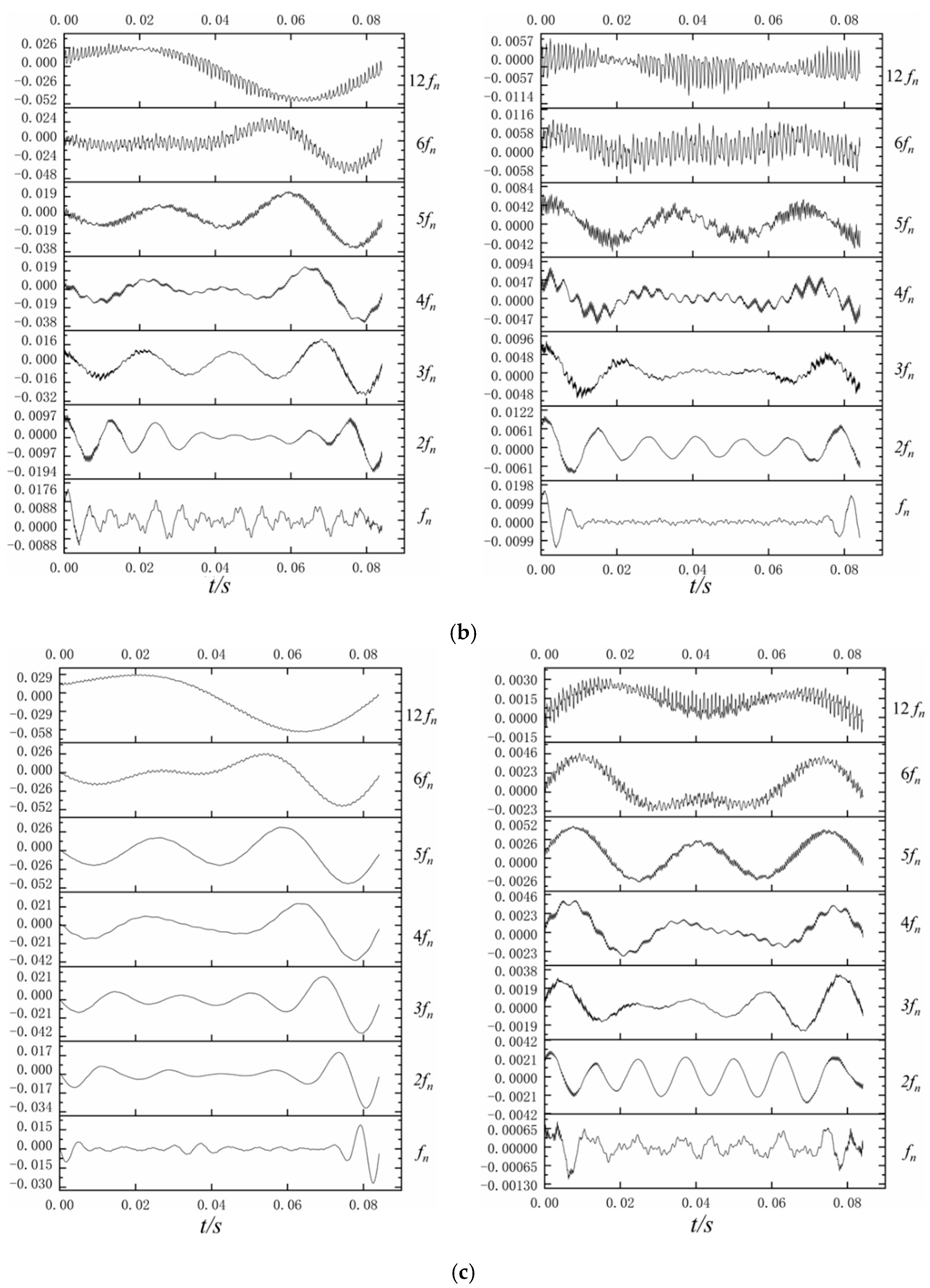

4.4. Analysis of CWT

5. Conclusions

- 1.

- The shape of the meridian of scheme 2 is more in line with the flow law, so the pulsation intensity in each component in the pump is smaller than that of scheme 1. Optimizing the shape of the meridian has a contribution to reducing the pulsation strength and increasing the operational stability, which improves the hydraulic performance. Transient pressure pulsation in the secondary and final stages of the pump is a key factor affecting the unsteady flow in the pump;

- 2.

- The pulsation amplitude peaks at the middle monitoring point in the pump chamber, which is caused by the rotor–stator interaction between the impeller and the diffuser. Because of the pulse source and pulse propagation coupling, the pressure pulsation period at the monitoring points in the impeller and pump cavity is the same as the number of diffuser blades, and the pressure pulsation period at the monitoring points in the diffuser is the same as the number of impeller blades;

- 3.

- The low-frequency pulsation signal after CWT is basically close to the pulsation law of the leaf frequency when the frequency is 3–6 times. At 1–2 times the rotation frequency, the regularity is relatively complicated due to various pulsation sources and low-frequency propagation coupling between stages.

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, J.; Zhu, H.; Zhang, J.; Zhang, H.Q. A numerical study on flow patterns inside an electrical submersible pump (ESP) and comparison with visualization experiments. J. Petrol. Sci. Eng. 2019, 173, 339–350. [Google Scholar] [CrossRef]

- Spence, R.; Amaral-Teixeira, J. A CFD parametric study of geometrical variations on the pressure pulsations and performance characteristics of a centrifugal pump. Comput. Fluids 2009, 38, 1243–1257. [Google Scholar] [CrossRef]

- Guan, D.; Cong, X.; Li, J.; Niu, Z. Experimental test and theoretical modeling on the working characteristics of spherical water pump. Flow Meas. Instrum. 2022, 85, 102162. [Google Scholar] [CrossRef]

- Zhou, L.; Hang, J.; Bai, L.; Krzemianowski, Z.; El-Emam, M.A.; Yasser, E.; Agarwal, R. Application of entropy production theory for energy losses and other investigation in pumps and turbines: A review. Appl. Energy 2022, 318, 119211. [Google Scholar] [CrossRef]

- Guelich, J.; Bolleter, U. Pressure pulsations in centrifugal pumps. ASME J. Vib. Acoust. 1992, 318, 272–279. [Google Scholar] [CrossRef]

- Li, D.; Qin, Y.; Wang, J.; Zhu, Y.; Wang, H.; Wei, X. Optimization of blade high-pressure edge to reduce pressure fluctuations in pump-turbine hump region. Renew. Energy 2022, 181, 24–38. [Google Scholar] [CrossRef]

- Shim, H.S.; Kim, K.Y. Effects of the number of blades on impeller-volute interaction and flow instability of a centrifugal pump. Proc Inst. Mech. Eng. A-J. Power Energy 2022, 09576509221094951. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, Y.; Mao, X.; Wang, H.; Shi, W.; Kan, K.; Zhang, Y. Pressure pulsation characteristics and its impact on flow-induced noise in mixed-flow pump. Trans. Chin. Soc. Agric. Eng. 2015, 31, 67–73. [Google Scholar]

- Shi, L.; Yuan, Y.; Jiao, H.; Tang, F.; Cheng, L.; Yang, F.; Zhu, J. Numerical investigation and experiment on pressure pulsation characteristics in a full tubular pump. Renew. Energy 2021, 163, 987–1000. [Google Scholar] [CrossRef]

- Guan, D.; Wu, J.H.; Jing, L.; Hilton, H.H.; Lu, K. Kinematic modeling, analysis and test on a quiet spherical pump. J. Sound Vib. 2016, 383, 146–155. [Google Scholar] [CrossRef]

- Dring, R.; Joslyn, H.; Hardin, L.; Wagner, J. Turbine rotor-stator interaction. ASME J. Eng. Power 1982, 104, 729–742. [Google Scholar] [CrossRef]

- Chalghoum, I.; Kanfoudi, H.; Elaoud, S.; Akrout, M.; Zgolli, R. Numerical Modeling of the Flow Inside a Centrifugal Pump: Influence of Impeller–Volute Interaction on Velocity and Pressure Fields. Arab. J. Sci. Eng. 2016, 41, 1–14. [Google Scholar] [CrossRef]

- Arndt, N.; Acosta, A.; Brennen, C.; Caughey, T. Experimental investigation of rotor-stator interaction in a centrifugal pump with several vaned diffusers. ASME J. Turbomach. 1990, 112, 98–108. [Google Scholar] [CrossRef]

- Brennen, C.; Franz, R.; Arndt, N. Rotor/Stator Unsteady Pressure Interaction. 1988. Available online: https://www.researchgate.net/publication/30759128_RotorStator_Unsteady_Pressure_Interaction (accessed on 22 September 2022).

- Khalifa, A.; Al-Qutub, A.; Ben-Mansour, R. Experiments on pressure fluctuations in a high pressure-double volute centrifugal pump under part load conditions. In Proceedings of the 4th International Conference on Thermal Energy: Theory and Applications, Abu-Dhabi, United Arab Emirates; 2009. Available online: https://www.researchgate.net/publication/281902977_Experiments_on_Pressure_Fluctuations_in_a_High_Pressure-Double_Volute_Centrifugal_Pump_under_Part_Load_Conditions (accessed on 22 September 2022).

- Solis, M.; Bakir, F.; Khelladi, S.; Noguera, R. Numerical study on pressure fluctuations reduction in centrifugal pumps: Influence of radial gap and splitter blades. Int. Sch. Res. Not. 2011, 2011, pp. 1–14. Available online: https://downloads.hindawi.com/archive/2011/479594.pdf (accessed on 22 September 2022).

- Rutter, R.; Sheth, K.; O’Bryan, R. Numerical flow simulation and validation of an electrical submersible pump//Fluids Engineering Division Summer Meeting. Am. Soc. Mech. Eng. Digit. Collect. 2013, 55546, V01AT03A005. [Google Scholar]

- Bai, L.; Zhou, L.; Han, C.; Zhu, Y.; Shi, W. Numerical study of pressure fluctuation and unsteady flow in a centrifugal pump. Processes 2019, 7, 354. [Google Scholar] [CrossRef]

- Muggli, F.A.; Holbein, P.; Dupont, P. CFD calculation of a mixed flow pump characteristic from shutoff to maximum flow. J. Fluids Eng. 2002, 12, 798–802. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Q.; Yang, Y.; Wang, C. Performance Differences of Electrical Submersible Pump under Variable Speed Schemes. Int. J. Simul. Model. 2021, 20, 76–86. [Google Scholar] [CrossRef]

- Maitelli, C.W.S.P.; Bezerra, F.V.M.; Mata, W. Simulation of flow in a centrifugal pump of esp systems using computational fluid dynamics. Braz. J. Pet. Gas 2010, 4, 001–009. [Google Scholar]

- Hammer, S.; Phan, D.; Peter, J.; Werder, T.; Meyer, R.; Liebich, R.; Thamsen, P. Active Flow Control by Adaptive Blade Systems in Periodic Unsteady Flow Conditions. 2014. Available online: http://www.depositonce.tu-berlin.de/handle/11303/197 (accessed on 22 September 2022).

- Joslyn, D.; Dring, R. Three-Dimensional Flow in an Axial Turbine: Part 1—Aerodynamic Mechanisms. J. Turbomach. 1992, 114, 61–70. [Google Scholar] [CrossRef]

- Iino, T.; Kasai, K. An analysis of unsteady flow induced by interaction between a centrifugal impeller and a vaned diffuser (1st report, Measurement of pressure fluctuations in pump impellers). Trans. Jpn. Soc. Mech. Eng. Part B 1985, 51, 3748–3753. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, H.; Tsukamoto, H. Unsteady Hydrodynamic Forces due to Rotor-Stator Interaction on a Diffuser Pump with Identical Number of Vanes on the Impeller and Diffuser. Trans. Jpn. Soc. Mech. Eng. Part B 2005, 127, 2020–2027. [Google Scholar] [CrossRef]

- Zhou, L.; Shi, W.; Lu, W. Performance analysis on deep-well centrifugal pump guide vanes based on numerical simulation. Trans. Chin. Soc. Agric. Eng. 2011, 27, 38–42. [Google Scholar]

- Yang, Y.; Zhou, L.; Shi, W.; He, Z.; Han, Y.; Xiao, Y. Interstage difference of pressure pulsation in a three-stage electrical submersible pump. J. Petrol. Sci. Eng. 2021, 196, 107653. [Google Scholar] [CrossRef]

- Bai, L.; Yang, Y.; Zhou, L.; Li, Y.; Xiao, Y.; Shi, W. Optimal design and performance improvement of an electric submersible pump impeller based on Taguchi approach. Energy 2022, 252, 124032. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, L.; Hang, J.; Du, D.; Shi, W.; He, Z. Energy characteristics and optimal design of diffuser meridian in an electrical submersible pump. Renew. Energy 2021, 167, 718–727. [Google Scholar] [CrossRef]

- Kan, K.; Zhang, Q.; Zheng, Y.; Xu, H.; Xu, Z.; Zhai, J.; Muhirwa, A. Investigation into Influence of Wall Roughness on the Hydraulic Characteristics of an Axial Flow Pump as Turbine. Sustainability 2022, 14, 8459. [Google Scholar] [CrossRef]

- Zuo, Z.; Tan, L.; Shi, W.; Chen, C.; Ye, J.; Francis, E.M. Transient Characteristic Analysis of Variable Frequency Speed Regulation of Axial Flow Pump. Sustainability 2022, 14, 11143. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Zheng, J.; Zhang, J.; Zheng, Y.; Zang, W.; Lin, X.; Fernandez-Rodriguez, E. Experimental investigation into effects of boundary proximity and blockage on horizontal-axis tidal turbine wake. Ocean. Eng. 2021, 225, 108829. [Google Scholar] [CrossRef]

- Zhang, Y.; Zang, W.; Zheng, J.; Cappietti, L.; Zhang, J.; Zheng, Y.; Fernandez-Rodriguez, E. The influence of waves propagating with the current on the wake of a tidal stream turbine. Appl. Energy 2021, 290, 116729. [Google Scholar] [CrossRef]

- Han, Y.; Zhou, L.; Bai, L.; Shi, W.; Agarwal, R. Comparison and validation of various turbulence models for U-bend flow with a magnetic resonance velocimetry experiment. Phys. Fluids 2021, 33, 125117. [Google Scholar] [CrossRef]

- El-Emam, M.A.; Zhou, L.; Yasser, E.; Bai, L.; Shi, W. Computational methods of erosion wear in centrifugal pump: A state-of-the-art review. Arch. Comput. Method. E. 2022, 29, 1–26. [Google Scholar] [CrossRef]

- Deyou, L.; Hongjie, W.; Gaoming, X.; Ruzhi, G.; Xianzhu, W.; Zhansheng, L. Unsteady simulation and analysis for hump characteristics of a pump turbine model. Renew. Energy 2015, 77, 32–42. [Google Scholar] [CrossRef]

- Gao, B.; Zhang, N.; Li, Z.; Ni, D.; Yang, M. Influence of the blade trailing edge profile on the performance and unsteady pressure pulsations in a low specific speed centrifugal pump. J. Fluids Eng. 2016, 138, 051106. [Google Scholar] [CrossRef]

- Zhao, X.; Xiao, Y.; Wang, Z.; Luo, Y.; Cao, L. Unsteady flow and pressure pulsation characteristics analysis of rotating stall in centrifugal pumps under off-design conditions. J. Fluids Eng. 2018, 140, 021105. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, L.; Han, Y.; Hang, J.; Lv, W.; Shi, W.; He, Z.; Pan, B. Pressure pulsation investigation in an electrical submersible pump based on Morlet continuous wavelet transform. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2021, 235, 6069–6079. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Zhang, J.; Zhang, H.Q. Intelligent fault diagnosis of hydraulic piston pump based on wavelet analysis and improved alexnet. Sensors 2021, 21, 549. [Google Scholar] [CrossRef] [PubMed]

| Size/mm | 1.4 | 1.7 | 2.0 | 2.3 | 2.6 |

|---|---|---|---|---|---|

| Impeller | 573,678 | 454,745 | 349,804 | 279,843 | 184,696 |

| Diffuser | 590,164 | 468,813 | 354,508 | 286,473 | 189,041 |

| Head/m | 58.19 | 58.05 | 58.11 | 56.65 | 55.08 |

| Efficiency/% | 75.49 | 75.55 | 75.45 | 74.18 | 73.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, D.; Han, Y.; Xiao, Y.; Yang, L.; Shi, X. The Effects of Meridian Surface Shape on the Pressure Pulsation of a Multi-Stage Electric Submersible Pump. Sustainability 2022, 14, 14950. https://doi.org/10.3390/su142214950

Du D, Han Y, Xiao Y, Yang L, Shi X. The Effects of Meridian Surface Shape on the Pressure Pulsation of a Multi-Stage Electric Submersible Pump. Sustainability. 2022; 14(22):14950. https://doi.org/10.3390/su142214950

Chicago/Turabian StyleDu, Danyang, Yong Han, Yu Xiao, Lu Yang, and Xuanwei Shi. 2022. "The Effects of Meridian Surface Shape on the Pressure Pulsation of a Multi-Stage Electric Submersible Pump" Sustainability 14, no. 22: 14950. https://doi.org/10.3390/su142214950

APA StyleDu, D., Han, Y., Xiao, Y., Yang, L., & Shi, X. (2022). The Effects of Meridian Surface Shape on the Pressure Pulsation of a Multi-Stage Electric Submersible Pump. Sustainability, 14(22), 14950. https://doi.org/10.3390/su142214950