Examining Criteria for Choosing Subcontractors for Complex and Multi-Systems Projects

Abstract

1. Introduction

2. Literature Review

2.1. Subcontracting

- Changes in the management process: A controversy about changes in the scope of work influences the level of trust between the two parties. The main contractor must be aware of unexpected changes in the scope of work, while the subcontractor must be honest regarding added costs, if any.

- Payment practices: The subcontractor must be paid on time for the work done. This will reduce the subcontractor’s financial stress and increase his trust in the main contractor.

- Changes in the economic climate: Negative changes (such as a recession) generally cause project managers to prefer incurring costs (at least in the short-term) rather than become dependent on quality subcontractors who are more expensive, but also provide higher quality work in the long run.

- Future business opportunities: Successful past projects and prospects of a continuous stream of sizeable projects in the future will increase a subcontractor’s trust in the main contractor.

- Quality performance: If problems arise, the main contractor expects transparency from subcontractors but also expects them to know how to respond and solve problems by hiring stable high-quality workers.

- Specific project-related circumstances: Hiring new subcontractors, whether local or foreign, is often accompanied by significant concern about their suitability for the task, especially in large, complex projects that require subcontractors with specific skills. The trust built with subcontractors will help determine the project’s success [39]. Akal emphasizes that all tender documents relevant to a subcontract must be intelligible and written so as to ensure that both parties interpret their terms in the same way [40].

2.2. Complex Projects

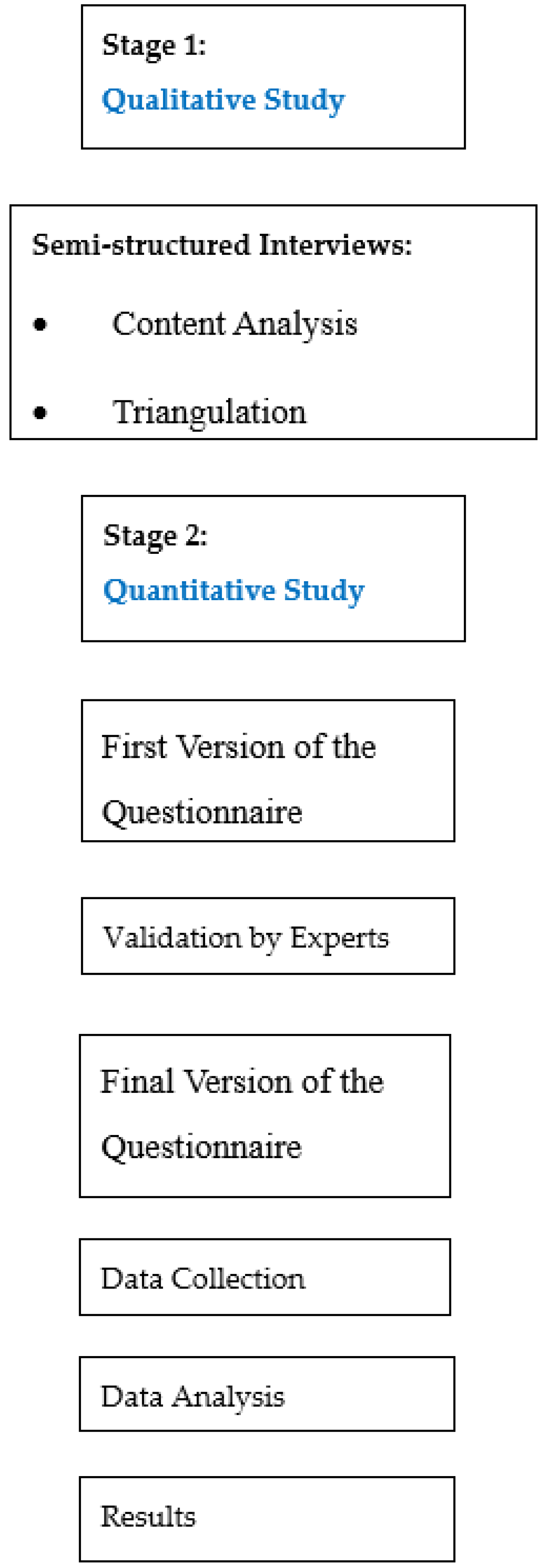

3. Methodology

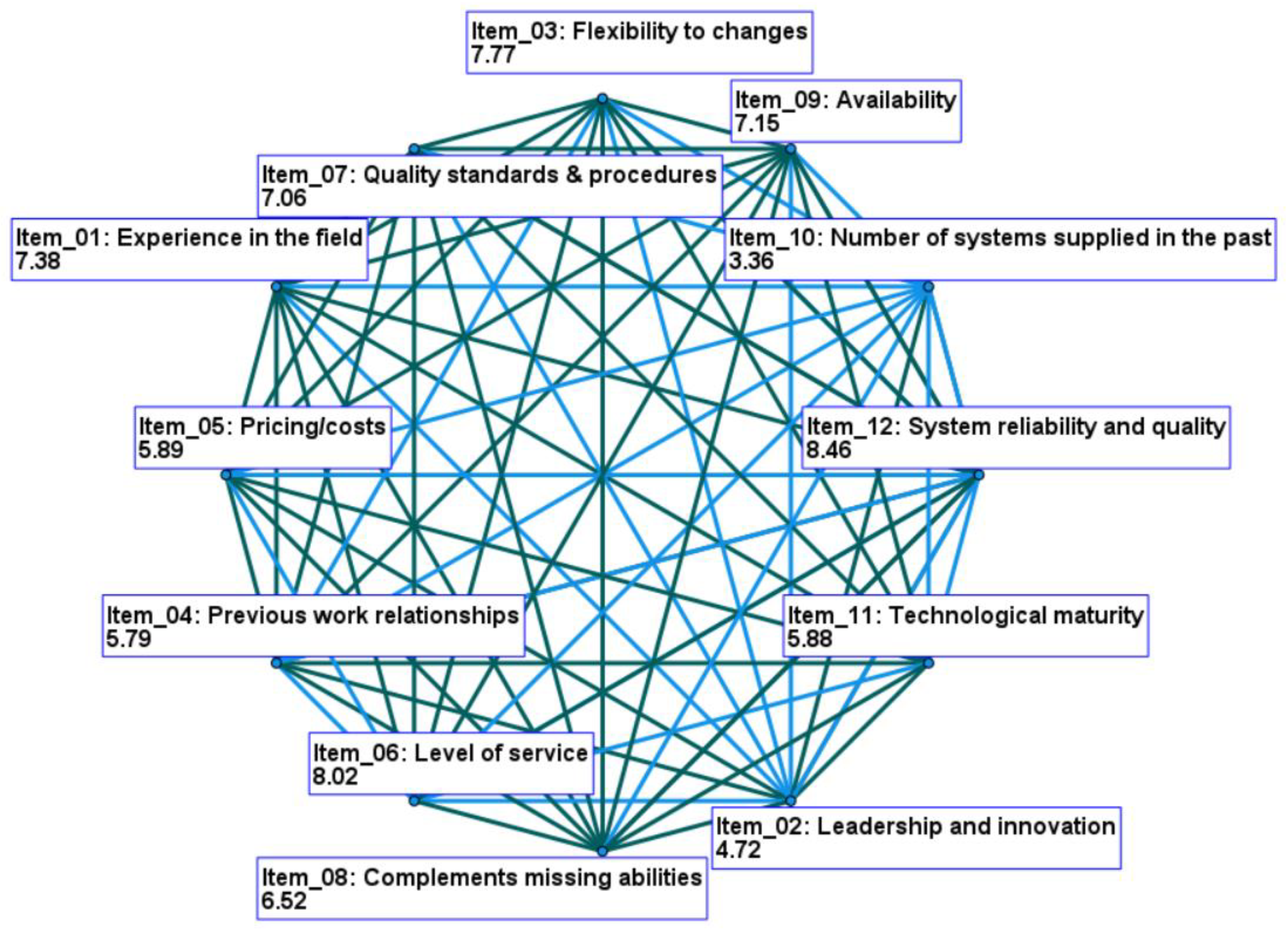

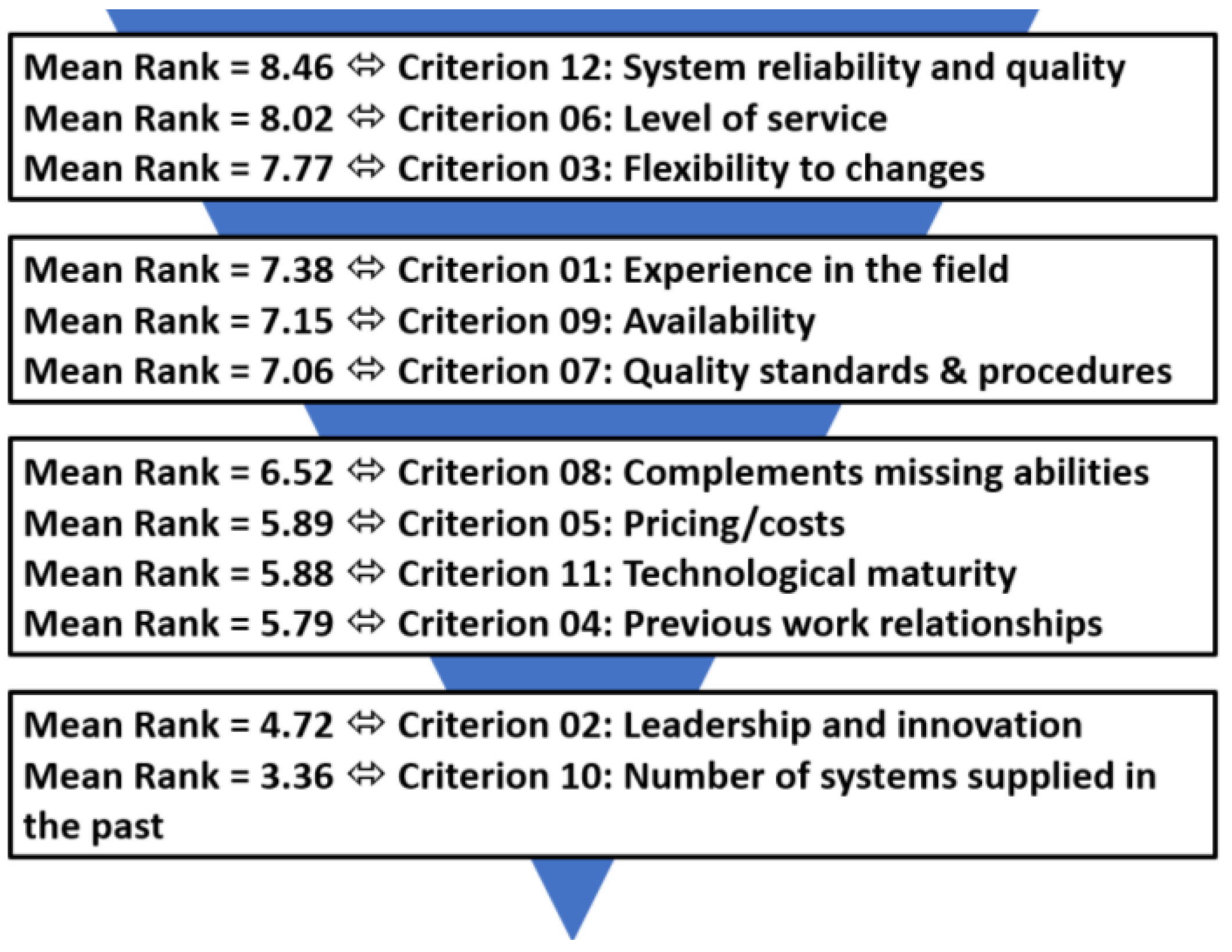

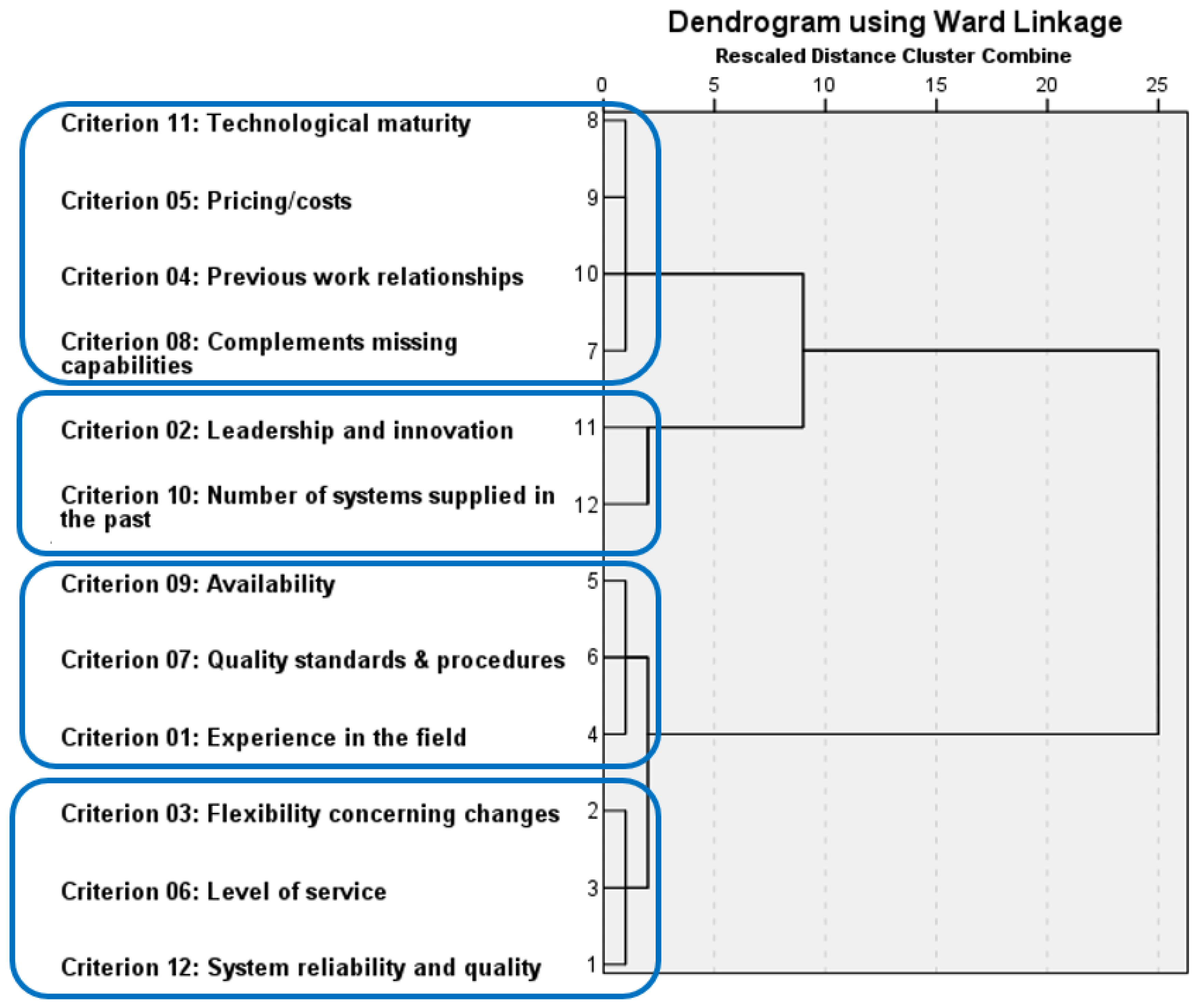

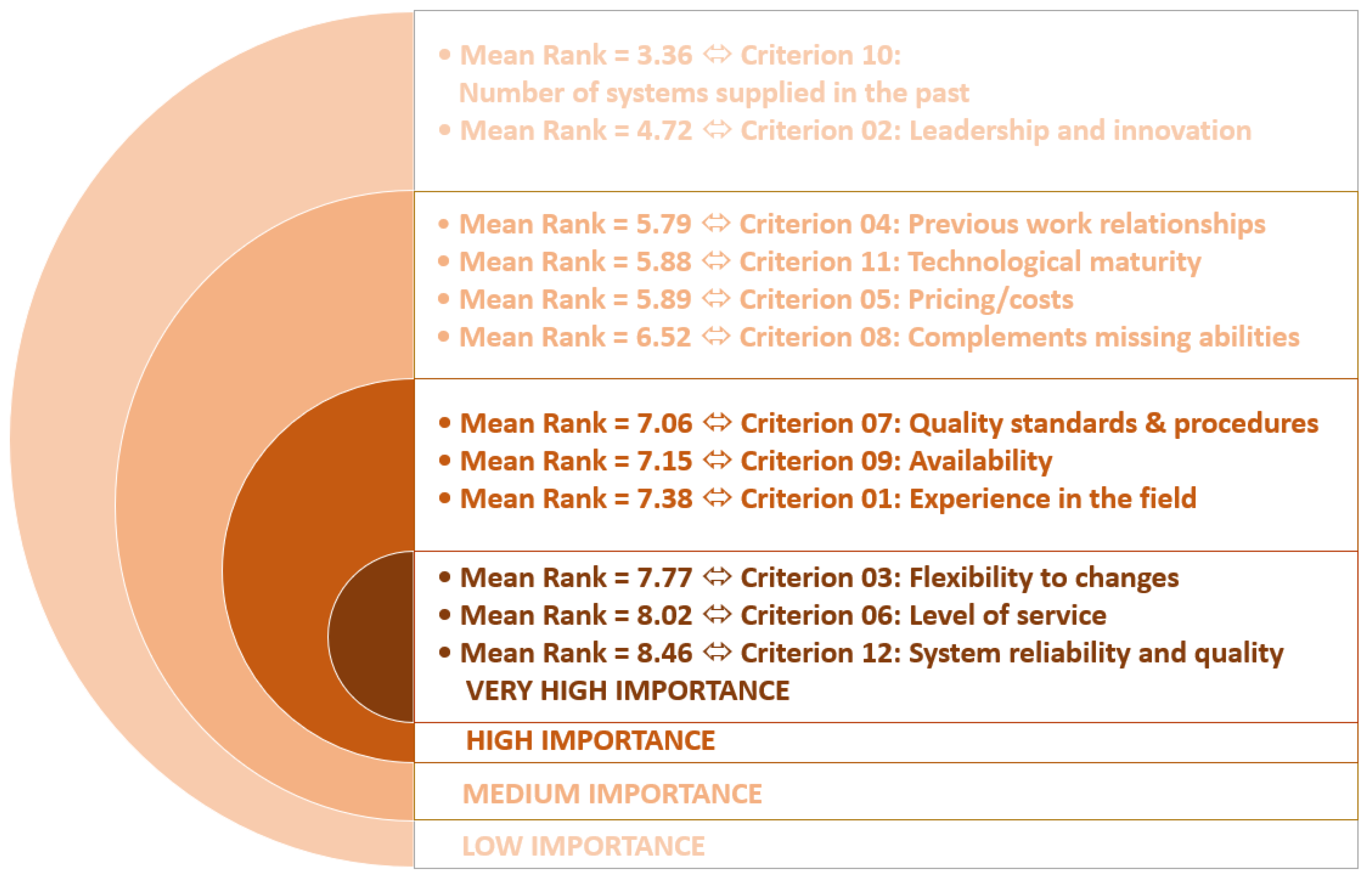

- Criterion 01: Experience in the field;

- Criterion 02: Leadership and innovation;

- Criterion 03: Flexibility to changes;

- Criterion 04: Previous work relationships;

- Criterion 05: Pricing/costs;

- Criterion 06: Level of service;

- Criterion 07: Quality standards and procedures;

- Criterion 08: Complements missing abilities;

- Criterion 09: Availability;

- Criterion 10: Number of systems supplied in the past;

- Criterion 11: Technological maturity;

- Criterion 12: System reliability and quality.

Statistical Analyses

4. Results

5. Discussion

6. Summary

Study Limitations and Recommendations for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Laryea, S.; Lubbock, A. Tender pricing environment of subcontractors in the United Kingdom. J. Constr. Eng. Manag. 2014, 140, 04013029. [Google Scholar] [CrossRef]

- Choudhry, R.; Hinze, J.; Arshad, M.; Gabriel, H. Subcontracting practices in the construction industry of Pakistan. J. Constr. Eng. Manag. 2010, 138, 1353–1359. [Google Scholar] [CrossRef]

- Ulubeyli, S.; Manisali, E.; Kazaz, A. Subcontractor selection practices in international construction projects. J. Civ. Eng. Manag. 2010, 16, 47–56. [Google Scholar] [CrossRef]

- Vo, K.D.; Pham, C.P.; Phan, P.T.; Vu, N.B.; Duong, M.T.H.; Le, L.P.; Nguyen, Q.L.H.T.T. Critical factors of subcontractor evaluation and selection: A case study in Vietnam. J. Asian Finance Econ. Bus. 2021, 8, 297–305. [Google Scholar] [CrossRef]

- Mbachu, J. Conceptual framework for the assessment of subcontractors’ eligibility and performance in the construction industry. Constr. Manag. Econ. 2008, 26, 471–484. [Google Scholar] [CrossRef]

- Project Management Institute. A Guide to the Project Management Body of Knowledge (PMBOK Guide), 7th ed.; Project Management Institute: Newtown Square, PA, USA, 2021. [Google Scholar]

- Shtub, A.; Cohen, Y. Introduction to Industrial Engineering; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Andersen, P.H. Organizing international technological collaboration in subcontractor relationships: An investigation of the knowledge-stickiness problem. Res. Policy 1999, 28, 625–642. [Google Scholar] [CrossRef]

- Polat, G.; Kaplan, B.; Bingol, B.N. Subcontractor selection using genetic algorithm. Procedia Eng. 2015, 123, 432–440. [Google Scholar] [CrossRef]

- Ng, S.T.; Tang, Z.; Palaneeswaran, E. Factors contributing to the success of equipment-intensive subcontractors in construction. Int. J. Proj. Manag. 2009, 27, 736–744. [Google Scholar] [CrossRef]

- Arslan, G.; Kivrak, S.; Birgonul, M.T.; Dikmen, I. Improving sub-contractor selection process in construction projects: Web-based subcontractor evaluation system (WEBSES). Autom. Constr. 2008, 17, 480–488. [Google Scholar] [CrossRef]

- Hartmann, A.; Ling, F.Y.Y.; Tan, J.S.H. Relative importance of subcontractor selection criteria: Evidence from Singapore. J. Constr. Eng. Manag. 2009, 135, 826–832. [Google Scholar] [CrossRef]

- Hartmann, A.; Caerteling, J. Subcontractor procurement in construction: The interplay of price and trust. Int. J. Supply Chain Manag. 2010, 15, 354–362. [Google Scholar] [CrossRef]

- Shash, A.A. Bidding practices of subcontractors in Colorado. J. Constr. Eng. Manag. 1998, 124, 219–225. [Google Scholar] [CrossRef]

- Williams, P.; Cooke, B. Construction Planning, Programming and Control; Wiley: Blackwell, UK, 2009. [Google Scholar]

- Luu, D.T.; Sher, W. Construction tender subcontract selection using case-based reasoning. Aust. J. Constr. Econ. Build. 2006, 6, 31–43. [Google Scholar] [CrossRef]

- Pishdad-Bozorgi, P.; Yoon, J.H. Transformational approach to subcontractor selection using blockchain-enabled smart contract as trust enhancing technology. Autom. Constr. 2022, 142, 1–14. [Google Scholar] [CrossRef]

- Tserng, H.P.; Lin, P.H. An accelerated subcontracting and procuring model for construction projects. Autom. Constr. 2002, 11, 105–125. [Google Scholar] [CrossRef]

- Atkinson, R. Project management: Cost, time and quality, two best guesses and a phenomenon, its time to accept other success criteria. Int. J. Proj. Manag. 1999, 17, 337–342. [Google Scholar] [CrossRef]

- Badewi, A. Project management, benefits management and program management. In Strategic Project Management: Contemporary Issues and Strategies for Developing Economies; Barclay, C., Osei-Bryson, K.-M., Eds.; CRC Press: Boca Raton, Florida, 2015; pp. 85–104. [Google Scholar]

- Blaskovics, B. The impact of personal attributes of project managers working in ICT sector on achieving project success. Ph.D. Thesis, Corvinus University of Budapest, Budapest, Hungary, 2014. [Google Scholar]

- Bryde, D.J.; Robinson, L. Client versus contractor perspectives on project success criteria. Int. J. Proj. Manag. 2005, 23, 622–629. [Google Scholar] [CrossRef]

- Cheraghi, S.H.; Dadashzadeh, M.; Subramanian, M. Critical Success Factors for Supplier Selection: An Update. J. Appl. Bus. Res. 2004, 20, 91–108. [Google Scholar] [CrossRef][Green Version]

- Choudhary, D.; Shankar, R. Joint decision of procurement lot-size, supplier selection, and carrier selection. J. Purch. Supply Manag. 2013, 19, 16–26. [Google Scholar] [CrossRef]

- De Wit, A. Measurement of project success. Int. J. Proj. Manag. 1988, 6, 164–170. [Google Scholar] [CrossRef]

- Dvir, D.; Lipovetsky, S.; Shenhar, A.; Tishler, A. In search of project classification: A non-universal approach to project success factors. Res. Policy 1998, 27, 915–935. [Google Scholar] [CrossRef]

- Giunipero, L.C.; Hooker, R.E.; Joseph-Matthews, S.; Yoon, T.E.; Brudvig, S. A decade of SCM literature: Past, present and future implications. J. Supply Chain Manag. 2008, 44, 66–86. [Google Scholar] [CrossRef]

- Handfield, R.B.; Cousins, P.D.; Lawson, B.; Petersen, K.J. How can supply management really improve performance? A knowledge-based model of alignment capabilities. J. Supply Chain Manag. 2015, 51, 3–17. [Google Scholar] [CrossRef]

- Ika, L.A. Project success as a topic in project management journals. Proj. Manag. J. 2009, 40, 6–19. [Google Scholar] [CrossRef]

- Kakwezi, P.; Nyeko, S. Procurement processes and performance: Efficiency and effectiveness of the procurement function. Int. J. Soc. Sci. Manag. Entrep. 2019, 3, 172–182. [Google Scholar]

- Muller, R.; Turner, R. The influence of project managers on project success criteria and project success by type of project. Eur. Manag. J. 2007, 25, 298–309. [Google Scholar] [CrossRef]

- Nair, A.; Jayaram, J.; Das, A. Strategic purchasing participation, supplier selection, supplier evaluation and purchasing performance. Int. J. Prod. Res. 2015, 53, 6263–6278. [Google Scholar] [CrossRef]

- Paasio, P. The process of selecting subcontractors, Case Laitex Oy. Master’s Thesis, Saimaa University of Applied Sciences, Lappeenranta, Finland, 2011. [Google Scholar]

- Rose, K.H. A guide to the Project Management Body of Knowledge, 5th ed.; Project Management Institute: Pennsylvania, PA, USA, 2013; Volume 44. [Google Scholar]

- van Weele, A.J. Purchasing and Supply Chain Management: Analysis, Strategy, Planning and Practice; Cengage Learning: London, UK, 2010. [Google Scholar]

- Zwikael, O.; Globerson, S.; Shtub, A. Project Management: Planning, Execution and Control; Oyunon (Probook): Tel Aviv, Israel, 2009. [Google Scholar]

- Stadnicka, D.; Ratnayake, R.M.C. Development of a rule base and algorithm for a quotation preparation process: A case study with a VSM approach. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2015; pp. 1100–1106. [Google Scholar] [CrossRef]

- Hinze, J.; Tracey, A. The contractor-subcontractor relationship: The subcontractor’s view. J. Constr. Eng. Manag. 1994, 120, 274–287. [Google Scholar] [CrossRef]

- Manu, E.; Ankrah, N.; Chinyio, E.; Proverbs, D. Trust influencing factors in main contractor and subcontractor relationships during projects. Int. J. Proj. Manag. 2015, 33, 1495–1508. [Google Scholar] [CrossRef]

- Akal, A.Y. What are the readability issues in sub-contracting’s tender documents? Buildings 2022, 12, 839. [Google Scholar] [CrossRef]

- ICCPM. Complex project manager competency, standards version 4.1 (August 2012); The International Centre for Complex Project Management: Deakin West, ACT, Australia, 2012. [Google Scholar]

- Bosch-Rekveldt, M.; Jongkind, Y.; Mooi, H.; Bakker, H.; Verbraeck, A. Grasping project complexity in large engineering projects: The TOE (Technical, Organizational and Environmental) framework. Int. J. Proj. Manag. 2011, 29, 728–739. [Google Scholar] [CrossRef]

- He, Q.H.; Luo, L.; Hu, Y.; Chan, A.P.C. Measuring the complexity of mega construction projects in China-A fuzzy analytic network process analysis. Int. J. Proj. Manag. 2015, 33, 549–563. [Google Scholar] [CrossRef]

- Floricel, S.; Michela, J.L.; Piperca, S. Complexity, uncertainty-reduction strategies, and project performance. Int. J. Proj. Manag. 2016, 34, 1360–1383. [Google Scholar] [CrossRef]

- Muller, R.; Geraldi, J.; Turner, J.R. Relationships between leadership and success in different types of project complexities. IEEE Trans. Eng. Manag. 2012, 59, 77–90. [Google Scholar] [CrossRef]

- Nguyen, T.S.; Mohamed, S.; Mostafa, S. Project stakeholder’s engagement and performance: A comparison between complex and non-complex projects using SEM. Built Environ. Proj. Asset Manag. 2021, 11, 804–818. [Google Scholar] [CrossRef]

- Sharon, A.; Dori, D. A project–product model–based approach to planning work breakdown structures of complex system projects. IEEE Syst. J. 2015, 9, 366–376. [Google Scholar] [CrossRef]

- SEBoK Editorial Board. The Guide to the Systems Engineering Body of Knowledge (SEBoK), v. 2.6; Trustees of the Stevens Institute of Technology: Hoboken, NJ, USA, 2022. [Google Scholar]

- Rouse, W.B. Complex engineered, organizational and natural systems: Issues underlying the complexity of systems and fundamental research needed to address these issues. Syst. Eng. 2007, 10, 260–271. [Google Scholar] [CrossRef]

- Sheard, S.A.; Mostashari, A. Principles of complex systems for systems engineering. Syst. Eng. 2009, 12, 295–311. [Google Scholar] [CrossRef]

- IBM SPSS, Version 27.0; IBM SPSS Statistics for Windows; IBM Corp: Armonk, NY, USA, 2020.

- Desaria, T.; Rajiv, B.; Bhavsar, J. Methodology for ranking of factors affecting selection of subcontractor for construction contractors of Gujarat. Int. J. Eng. Trends Technol. 2016, 32, 19–25. [Google Scholar] [CrossRef]

- El-Khalek, H.; Aziz, R.; Morgan, E. Identification of construction subcontractor prequalification evaluation criteria and their impact on project success. Alex. Eng. J. 2019, 58, 217–223. [Google Scholar] [CrossRef]

- Lewis, M.A.; Roehrich, J.K. Contracts, relationships and integration: Towards a model of the procurement of complex performance. Int. J. Procure. Manag. 2009, 2, 125–142. [Google Scholar] [CrossRef]

- Koçak, S.; Kazaz, A.; Ulubeyli, S. Subcontractor selection with additive ratio assessment method. J. Constr. Eng. Manag. Innov. 2018, 1, 18–32. [Google Scholar] [CrossRef]

- Nguyen, D.T.; Duong, Q.B.; Zamai, E.; Shahzad, M.K. Fault diagnosis for the complex manufacturing system. Proc. Inst. Mech. Eng. Part O: J. Risk Reliab. 2016, 230, 178–194. [Google Scholar] [CrossRef]

- Lee, H. Development of real-time sketch-based on-the-spot process modeling and analysis system. J. Manuf. Syst. 2020, 54, 215–226. [Google Scholar] [CrossRef]

- Souza, M.L.H.; da Costa, C.A.; Ramos, G.O.; Rosa, R. A survey on decision-making based on system reliability in the context of Industry 4.0. J. Manuf. Syst. 2020, 56, 133–156. [Google Scholar] [CrossRef]

| Criterion 01: Experience in the Field | Criterion 02: Leadership and Innovation | ||

| Mean Rank | 7.38 | Mean Rank | 4.72 |

| M(SD) | 8.45 (1.27) | M(SD) | 7.37 (1.52) |

| Treat as Ordinal: | Treat as Ordinal: | ||

| Type of Distribution | Binomial | Type of Distribution | Binomial |

| Fit Statistics | *** | Fit Statistics | |

| Parameters | n = 10; prob = 0.84 | Parameters | n = 11; prob = 0.67 |

| Treat as Continuous: | Treat as Continuous: | ||

| Type of Distribution | Triangular | Type of Distribution | Triangular |

| Fit Statistics | A = −2.24 ***; K = 0.34 *** | Fit Statistics | A = 0.61 ***; K = 0.20 *** |

| Parameters | max = 10; min = 4; mode = 10 | Parameters | max = 10; min = 4 mode = 8.11 |

| Criterion 03: Flexibility Concerning Changes | Criterion 04: Previous Work Relationships | ||

| Mean Rank | 7.77 | Mean Rank | 5.79 |

| M(SD) | 8.57 (1.25) | M(SD) | 7.68 (1.86) |

| Treat as Ordinal: | Treat as Ordinal: | ||

| Type of Distribution | Binomial | Type of Distribution | Poisson |

| Fit Statistics | *** | Fit Statistics | *** |

| Parameters | n = 10; prob = 0.86 | Parameters | Mean = 7.68 |

| Treat as Continuous: | Treat as Continuous: | ||

| Type of Distribution | Triangular | Type of Distribution | Triangular |

| Fit Statistics | A = −8.43 ***; K = 0.25 *** | Fit Statistics | A = −2.34 ***; K = 0.29 *** |

| Parameters | max = 10; min = 5; mode = 10 | Parameters | max = 10; min = 1; mode = 10 |

| Criterion 05: Pricing/Costs | Criterion 06: Level of Service | ||

| Mean Rank | 5.89 | Mean Rank | 8.02 |

| M(SD) | 7.86 (1.50) | M(SD) | 8.55 (1.34) |

| Treat as Ordinal: | Treat as Ordinal: | ||

| Type of Distribution | Binomial | Type of Distribution | Binomial |

| Fit Statistics | Fit Statistics | *** | |

| Parameters | n = 11; prob = 0.71 | Parameters | n = 11; prob = 0.78 |

| Treat as Continuous: | Treat as Continuous: | ||

| Type of Distribution | Triangular | Type of Distribution | Triangular |

| Fit Statistics | A = −2.33 ***; K = 0.14 *** | Fit Statistics | A = −6.98 ***; K = 0.33 *** |

| Parameters | max = 10; min = 4; mode = 9.57 | Parameters | max = 10; min = 4; mode = 10 |

| Criterion 07: Quality Standards and Procedures | Criterion 08: Complements Missing Capabilities | ||

| Mean Rank | 7.06 | Mean Rank | 6.52 |

| M(SD) | 8.25 (1.45) | M(SD) | 8.09 (1.47) |

| Treat as Ordinal: | Treat as Ordinal: | ||

| Type of Distribution | Binomial | Type of Distribution | Binomial |

| Fit Statistics | Fit Statistics | ||

| Parameters | n = 11; prob = 0.75 | Parameters | n = 11; prob = 0.74 |

| Treat as Continuous: | Treat as Continuous: | ||

| Type of Distribution | Triangular | Type of Distribution | Triangular |

| Fit Statistics | A = −7.64 ***; K = 0.25 *** | Fit Statistics | A = −4.57 ***; K = 0.18 *** |

| Parameters | max = 10; min = 4; mode = 10 | Parameters | max = 10; min = 4; mode = 10 |

| Criterion 09: Availability | Criterion 10: Number of Systems Supplied in the Past | ||

| Mean Rank | 7.15 | Mean Rank | 3.36 |

| M(SD) | 8.37 (1.30) | M(SD) | 6.54 (1.97) |

| Treat as Ordinal: | Treat as Ordinal: | ||

| Type of Distribution | Binomial | Type of Distribution | Binomial |

| Fit Statistics | Fit Statistics | ||

| Parameters | n = 10; prob = 0.84 | Parameters | n = 16; prob = 0.41 |

| Treat as Continuous: | Treat as Continuous: | ||

| Type of Distribution | Triangular | Type of Distribution | Triangular |

| Fit Statistics | A = −7.15 ***; K = 0.18 *** | Fit Statistics | A = 1.90 ***; K = 0.21 *** |

| Parameters | max = 10; min = 5; mode = 10 | Parameters | max = 10; min = 2; mode = 7.62 |

| Criterion 11. Technological Maturity | Criterion 12. System Reliability and Quality | ||

| Mean Rank | 5.88 | Mean Rank | 8.46 |

| M(SD) | 7.91 (1.31) | M(SD) | 8.82 (1.00) |

| Treat as Ordinal: | Treat as Ordinal: | ||

| Type of Distribution | Binomial | Type of Distribution | Binomial |

| Fit Statistics | ** | Fit Statistics | |

| Parameters | n = 10; prob = 0.79 | Parameters | n = 10; prob = 0.88 |

| Treat as Continuous: | Treat as Continuous: | ||

| Type of Distribution | Weibull | Type of Distribution | Triangular |

| Fit Statistics | A = 3.60 **; K = 0.24 ** | Fit Statistics | A = −7.94 ***; K = 0.30 *** |

| Parameters | b = 8.40; b = 8.16; c = 0.00 | Parameters | max = 10; min = 5; mode = 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fridkin, S.; Kordova, S. Examining Criteria for Choosing Subcontractors for Complex and Multi-Systems Projects. Sustainability 2022, 14, 14988. https://doi.org/10.3390/su142214988

Fridkin S, Kordova S. Examining Criteria for Choosing Subcontractors for Complex and Multi-Systems Projects. Sustainability. 2022; 14(22):14988. https://doi.org/10.3390/su142214988

Chicago/Turabian StyleFridkin, Shimon, and Sigal Kordova. 2022. "Examining Criteria for Choosing Subcontractors for Complex and Multi-Systems Projects" Sustainability 14, no. 22: 14988. https://doi.org/10.3390/su142214988

APA StyleFridkin, S., & Kordova, S. (2022). Examining Criteria for Choosing Subcontractors for Complex and Multi-Systems Projects. Sustainability, 14(22), 14988. https://doi.org/10.3390/su142214988