Energy Simulation and Parametric Analysis of Water Cooled Thermal Photovoltaic Systems: Energy and Exergy Analysis of Photovoltaic Systems

Abstract

1. Introduction

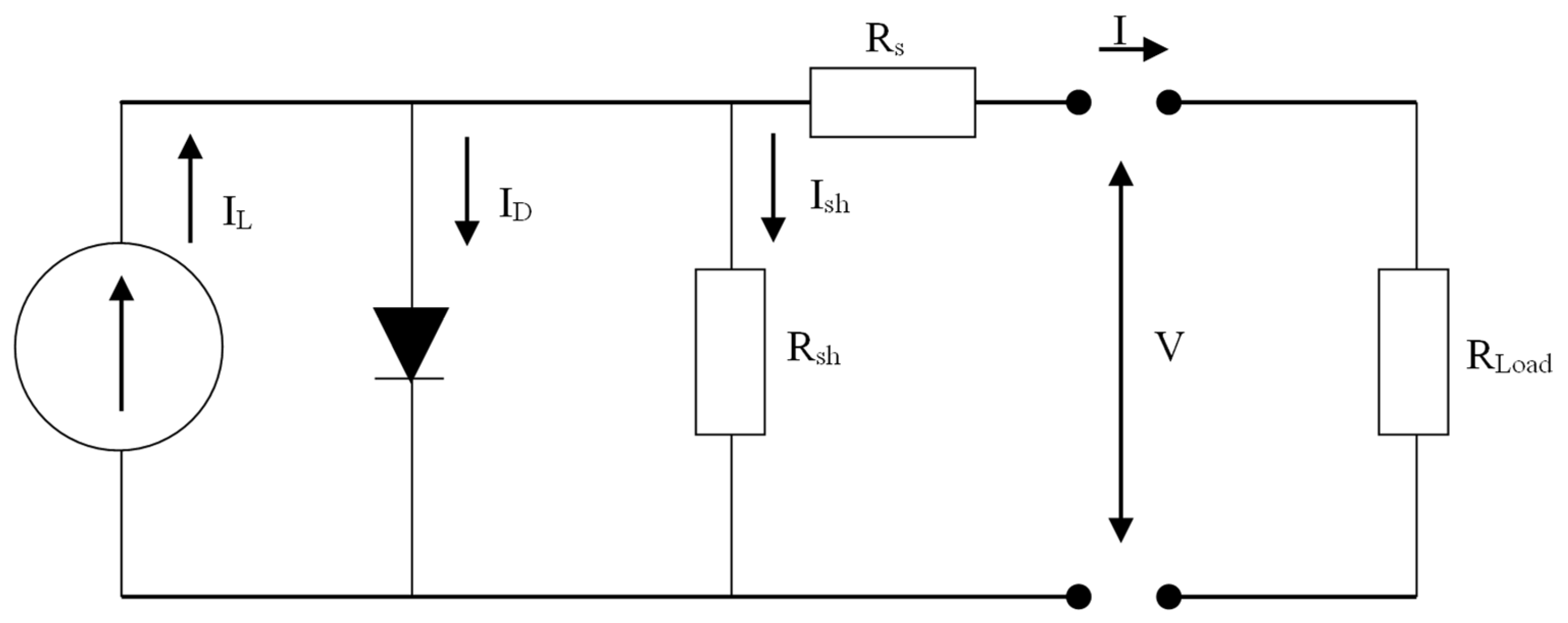

2. Photovoltaic System Modeling

2.1. Electrical Modeling

2.2. Energy Efficiency

2.3. Exergy Efficiency

2.4. PV/T Simulation

2.5. Economic Analysis

3. Results and Discussion

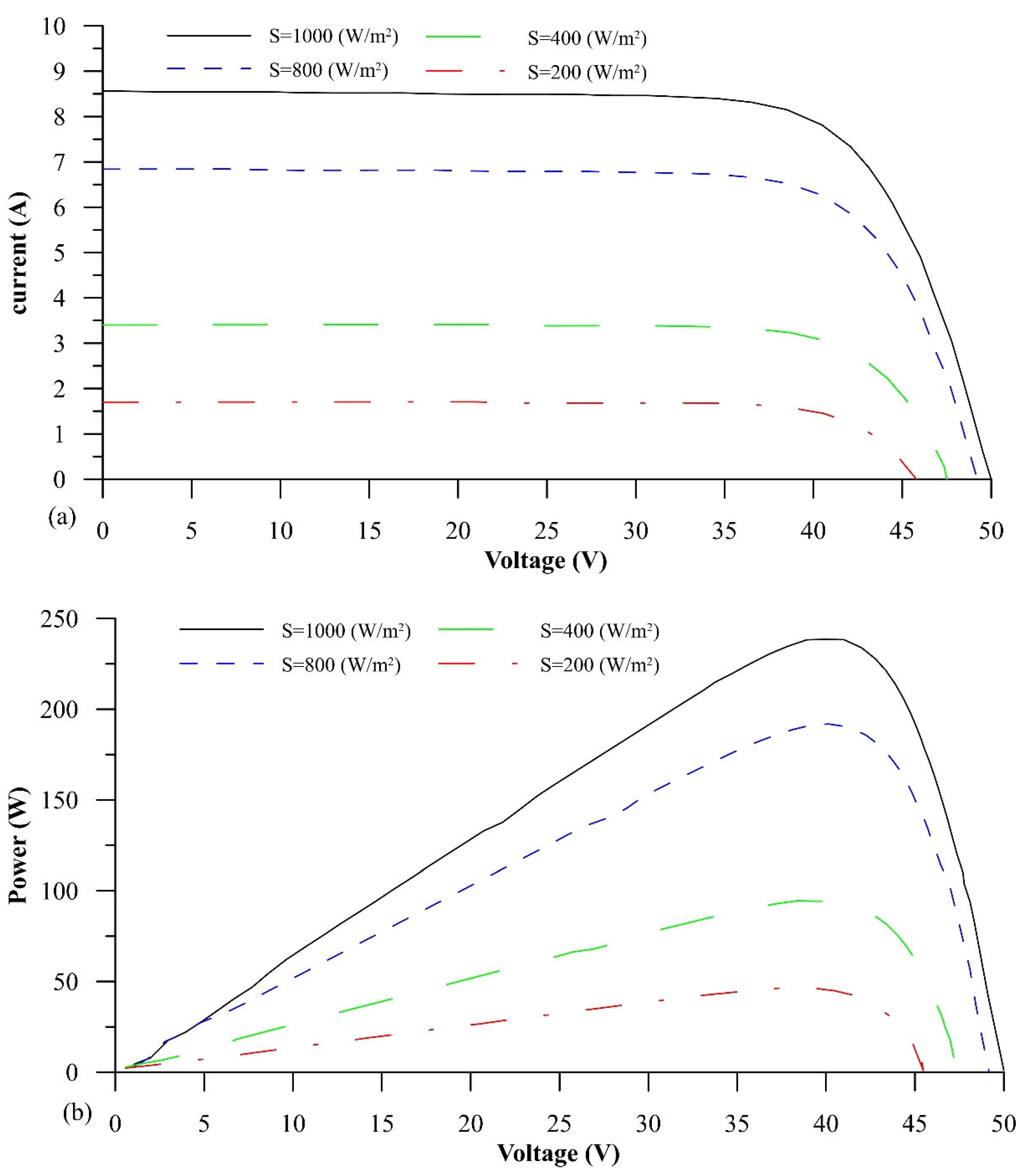

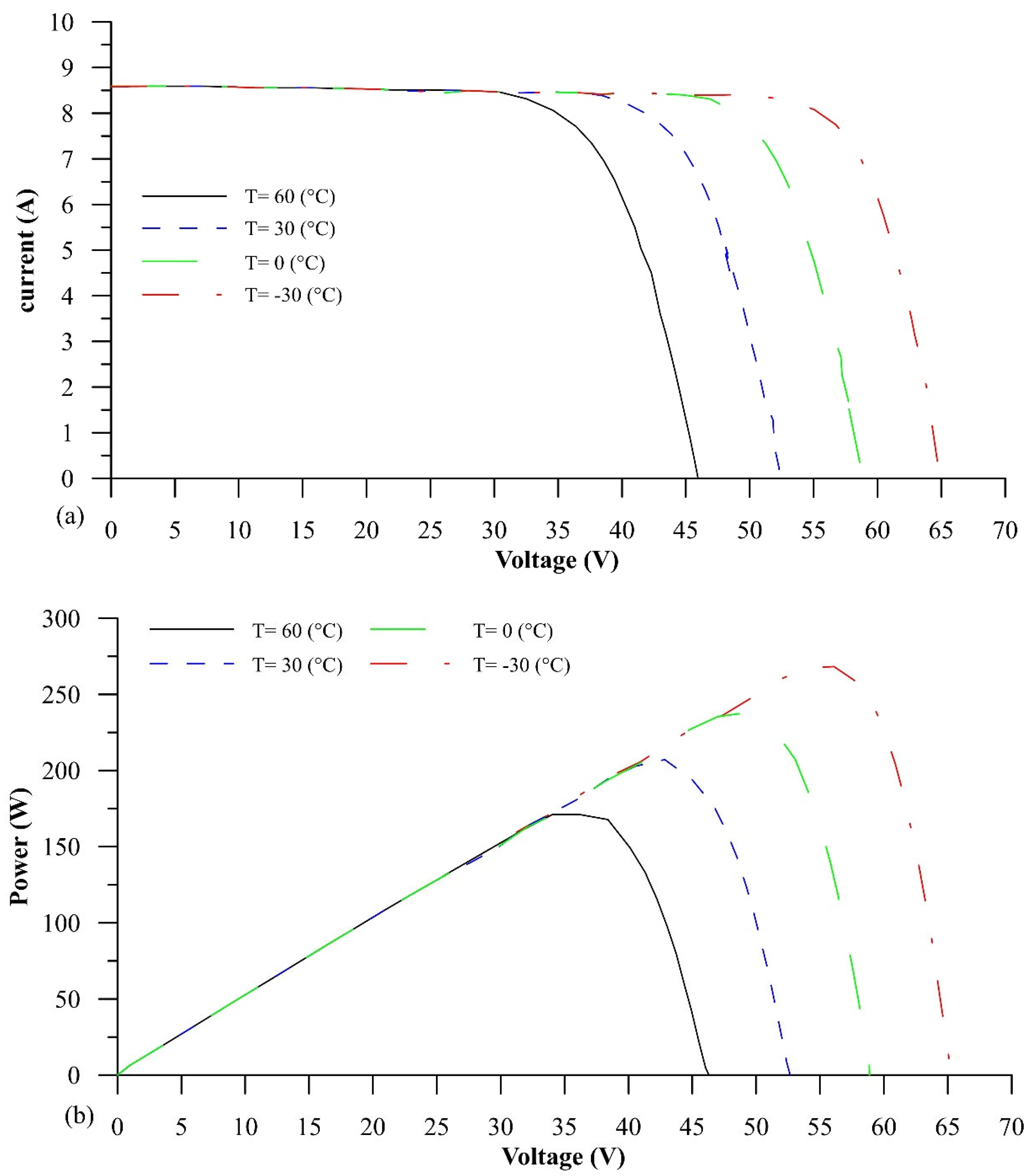

3.1. Extraction of Specified Curves

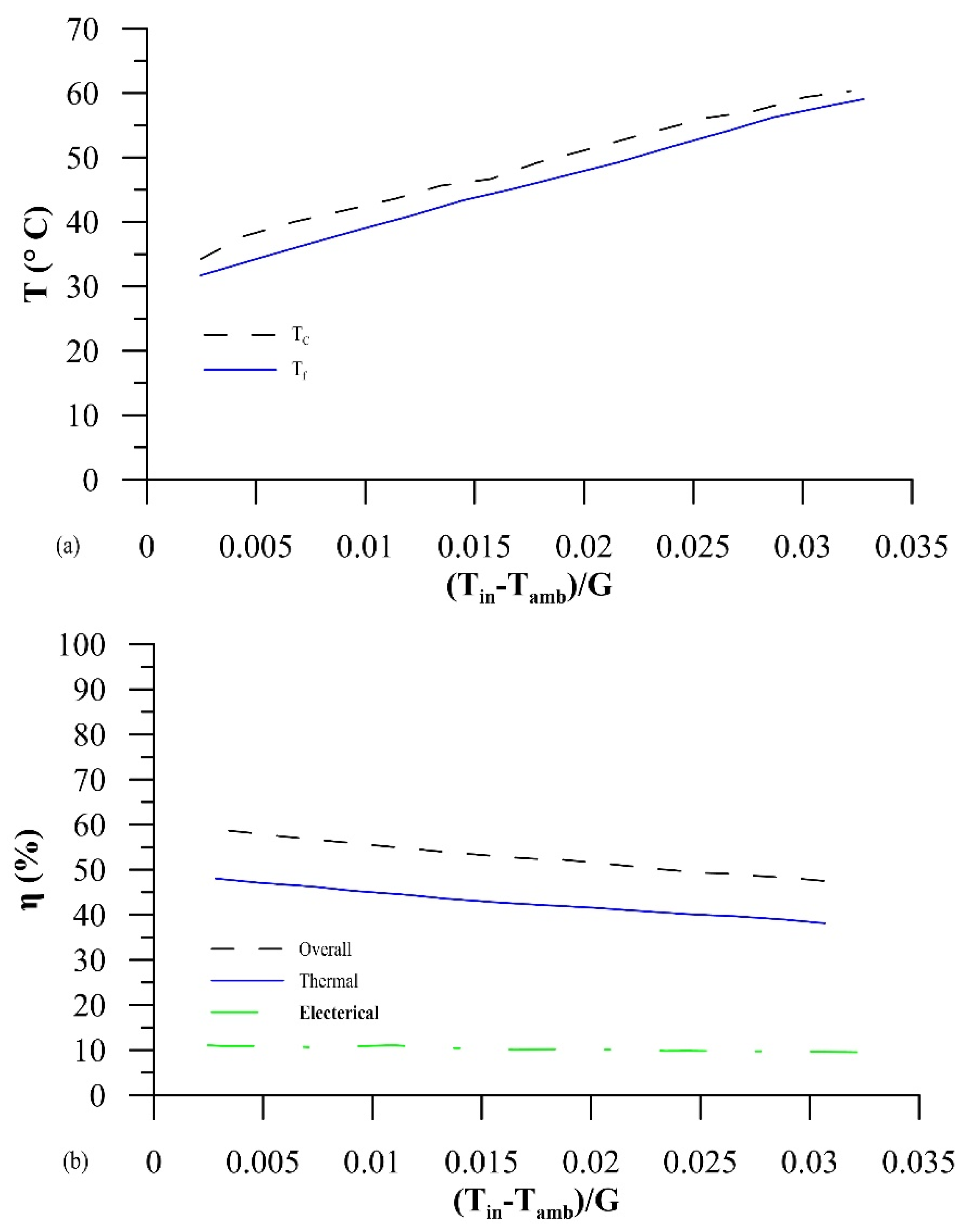

3.2. Parametric Analysis of the PV/T System and a Discussion of the Results

4. Conclusions

- The average energy efficiency of this panel during the day is 15.29 percent. The greatest instantaneous return value of 12.95 percent and the minimum value of 10.88 percent were calculated during the experiment.

- This panel’s average exergy efficiency throughout the day is 17.23 percent. Only around 14.5 percent of the energy absorbed from the sun is turned into useable energy, with the remainder being irreversibly wasted, illustrating the inefficiency of the energy conversion process in this panel.

- Because increasing the intensity of sunlight and decreasing the temperature are the most essential aspects in improving electrical power and efficiency, the optimal working conditions for this solar panel are those with the highest intensity of radiation and the lowest temperature.

- Because increasing the temperature during the day has a negative impact on energy efficiency and output power, cooling these panels can be regarded as a technique to improve efficiency.

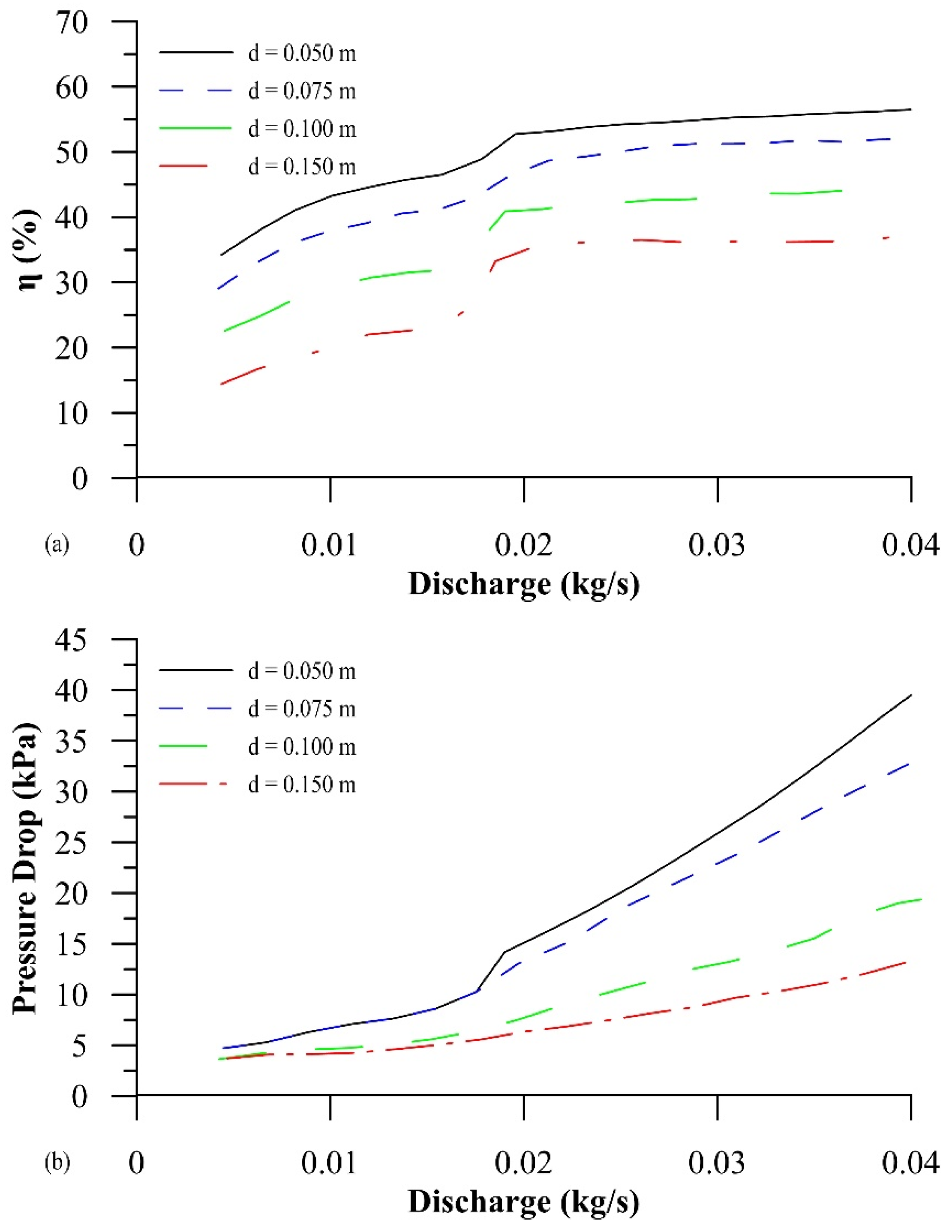

- A thermal photovoltaic system with a sheet and spiral tube layout has been simulated and parametrically analyzed. The configuration of sheet and helical tubes for the PV/T system of cold water was simulated using a numerical model. As a result of the construction of a MATLAB code, the proposed model with an RMSE = 0.94 is in a good agreement with the experimental data. According to the data, the modeled sample has a thermal efficiency of 43 to 52 percent and an electrical efficiency of 11.5 percent. Parametric analysis was used to assess the state of performance parameters based on control and independent parameters. Changes in overall efficiency and pressure drop are explored in general by adjusting the fluid flow parameters, pipe distance, and pipe diameter. The results show that raising the flow, decreasing the distance between the pipes, and decreasing the pipe diameter all result in an increase in total efficiency. While the pressure drop increases with increasing flow, so does the distance between the pipes and the diameter of the pipes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maleki, A.; Haghighi, A.; El Haj Assad, M.; Mahariq, I.; Alhuyi Nazari, M. A Review on the Approaches Employed for Cooling PV Cells. Sol. Energy 2020, 209, 170–185. [Google Scholar] [CrossRef]

- Karimi, G.; Moradi, Y. Buffer Insertion for Delay Minimization in RLC Interconnects Using Cuckoo Optimization Algorithm. Analog Integrated Circuits and Signal Processing 2019, 99, 111–121. [Google Scholar] [CrossRef]

- Molajou, A.; Pouladi, P.; Afshar, A. Incorporating Social System into Water-Food-Energy Nexus. Water Resour. Manag. 2021, 35, 4561–4580. [Google Scholar] [CrossRef]

- Khenfer, N.; Dokkar, B.; Messaoudi, M.T. Overall Efficiency Improvement of Photovoltaic-Thermal Air Collector: Numerical and Experimental Investigation in the Desert Climate of Ouargla Region. Int. J. Energy Environ. Eng. 2020, 11, 497–516. [Google Scholar] [CrossRef]

- Molajou, A.; Afshar, A.; Khosravi, M.; Soleimanian, E.; Vahabzadeh, M.; Variani, H.A. A New Paradigm of Water, Food, and Energy Nexus. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, S.; Tiwari, G.N.; Al-Helal, I.M. Performance Analysis of Photovoltaic-Thermal (PVT) Mixed Mode Greenhouse Solar Dryer. Sol. Energy 2016, 133, 421–428. [Google Scholar] [CrossRef]

- Abdulrazzaq, A.K.; Plesz, B.; Bognár, G. A Novel Method for Thermal Modelling of Photovoltaic Modules/Cells under Varying Environmental Conditions. Energies 2020, 13, 3318. [Google Scholar] [CrossRef]

- Wahab, A.; Khan, M.A.Z.; Hassan, A. Impact of Graphene Nanofluid and Phase Change Material on Hybrid Photovoltaic Thermal System: Exergy Analysis. J. Clean. Prod. 2020, 277, 123370. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ahmadi, M.A.; Feidt, M. Optimisation Des Performances d’un Cycle de Brayton Irréversible Solarisé à Compressions et Détentes Multiples Sur La Base d’un Algorithme Génétique Multi-Objectif. Oil Gas Sci. Technol. 2016, 71, 2014028. [Google Scholar] [CrossRef]

- Ren, X.; Li, J.; Gao, D.; Wu, L.; Pei, G. Analysis of a Novel Photovoltaic/Thermal System Using InGaN/GaN MQWs Cells in High Temperature Applications. Renew. Energy 2021, 168, 11–20. [Google Scholar] [CrossRef]

- Ruzzenenti, F.; Bravi, M.; Tempesti, D.; Salvatici, E.; Manfrida, G.; Basosi, R. Evaluation of the Environmental Sustainability of a Micro CHP System Fueled by Low-Temperature Geothermal and Solar Energy. Energy Convers. Manag. 2014, 78, 611–616. [Google Scholar] [CrossRef]

- Calise, F.; D’Accadia, M.D.; Vicidomini, M.; Scarpellino, M. Design and Simulation of a Prototype of a Small-Scale Solar CHP System Based on Evacuated Flat-Plate Solar Collectors and Organic Rankine Cycle. Energy Convers. Manag. 2015, 90, 347–363. [Google Scholar] [CrossRef]

- Hanifi, K.; Javaherdeh, K.; Yari, M. Exergy and Exergoeconomic Analysis and Optimization of the Cogeneration Cycle under Solar Radiation Dynamic Model Using Genetic Algorithm. In Green Energy and Technology; Springer: Cham, Switzerland, 2018; pp. 1139–1160. [Google Scholar]

- Style, R.W.; Peppin, S.S.L.; Cocks, A.C.F.; Wettlaufer, J.S. Ice-Lens Formation and Geometrical Supercooling in Soils and Other Colloidal Materials. Phys. Rev. E-Stat. Nonlinear Soft Matter Phys. 2011, 84, 041402. [Google Scholar] [CrossRef] [PubMed]

- Salek, F.; Rahnama, M.; Eshghi, H.; Babaie, M.; Naserian, M.M. Investigation of Solar-Driven Hydroxy Gas Production System Performance Integrated with Photovoltaic Panels with Single-Axis Tracking System. Renew. Energy Res. Appl. 2022, 3, 31–40. [Google Scholar]

- Eshghi, H.; Kahani, M.; Zamen, M. Cooling of Photovoltaic Panel Equipped with Single Circular Heat Pipe: An Experimental Study. Renew. Energy Res. Appl. 2022. [Google Scholar] [CrossRef]

- Bayrak, F.; Oztop, H.F.; Selimefendigil, F. Effects of Different Fin Parameters on Temperature and Efficiency for Cooling of Photovoltaic Panels under Natural Convection. Sol. Energy 2019, 188, 484–494. [Google Scholar] [CrossRef]

- Said, Z.; Arora, S.; Bellos, E. A Review on Performance and Environmental Effects of Conventional and Nanofluid-Based Thermal Photovoltaics. Renew. Sustain. Energy Rev. 2018, 94, 302–316. [Google Scholar] [CrossRef]

- Huang, M.; Wang, Y.; Li, M.; Keovisar, V.; Li, X.; Kong, D.; Yu, Q. Comparative Study on Energy and Exergy Properties of Solar Photovoltaic/Thermal Air Collector Based on Amorphous Silicon Cells. Appl. Therm. Eng. 2021, 185, 116376. [Google Scholar] [CrossRef]

- Rashidi, M.M.; Mahariq, I.; Murshid, N.; Mahian, O.; Alhuyi Nazari, M. Applying Wind Energy as a Clean Source for Reverse Osmosis Desalination: A Comprehensive Review. Alex. Eng. J. 2022, 61, 12977–12989. [Google Scholar] [CrossRef]

- Bandaru, S.H.; Becerra, V.; Khanna, S.; Radulovic, J.; Hutchinson, D.; Khusainov, R. A Review of Photovoltaic Thermal (Pvt) Technology for Residential Applications: Performance Indicators, Progress, and Opportunities. Energies 2021, 14, 3853. [Google Scholar] [CrossRef]

- Mohammadnezami, M.H.; Ehyaei, M.A.; Rosen, M.A.; Ahmadi, M.H. Meeting the Electrical Energy Needs of a Residential Building with a Wind-Photovoltaic Hybrid System. Sustainability 2015, 7, 2554–2569. [Google Scholar] [CrossRef]

- Rajaee, F.; Rad, M.A.V.; Kasaeian, A.; Mahian, O.; Yan, W.M. Experimental Analysis of a Photovoltaic/Thermoelectric Generator Using Cobalt Oxide Nanofluid and Phase Change Material Heat Sink. Energy Convers. Manag. 2020, 212, 112780. [Google Scholar] [CrossRef]

- Mousavi Baygi, S.R.; Sadrameli, S.M. Thermal Management of Photovoltaic Solar Cells Using Polyethylene Glycol1000 (PEG1000) as a Phase Change Material. Therm. Sci. Eng. Prog. 2018, 5, 405–411. [Google Scholar] [CrossRef]

- Firoozzadeh, M.; Shiravi, A.H.; Lotfi, M.; Aidarova, S.; Sharipova, A. Optimum Concentration of Carbon Black Aqueous Nanofluid as Coolant of Photovoltaic Modules: A Case Study. Energy 2021, 225, 120219. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Turan, A.; Abeykoon, C. Energy and Exergy Efficiencies Enhancement Analysis of Integrated Photovoltaic-Based Energy Systems. J. Energy Storage 2019, 26, 101029. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Y.; Ding, Y.; Cai, B.; Yang, J. Numerical Analysis on the Performance of High Concentration Photovoltaic Systems Under the Nonuniform Energy Flow Density. Front. Energy Res. 2021, 9, 705801. [Google Scholar] [CrossRef]

- Bamisile, O.; Huang, Q.; Dagbasi, M.; Adebayo, V.; Okonkwo, E.C.; Ayambire, P.; Al-Ansari, T.; Ratlamwala, T.A.H. Thermo-Environ Study of a Concentrated Photovoltaic Thermal System Integrated with Kalina Cycle for Multigeneration and Hydrogen Production. Int. J. Hydrogen Energy 2020, 45, 26716–26732. [Google Scholar] [CrossRef]

- Gupta, N.; Tiwari, A.; Tiwari, G.N. Exergy Analysis of Building Integrated Semitransparent Photovoltaic Thermal (BiSPVT) System. Eng. Sci. Technol. Int. J. 2017, 20, 41–50. [Google Scholar] [CrossRef]

- Valizadeh, M.; Sarhaddi, F. Mahdavi Adeli Exergy Performance Assessment of a Linear Parabolic Trough Photovoltaic Thermal Collector. Renew. Energy 2019, 138, 1028–1041. [Google Scholar] [CrossRef]

- Siddiqui, O.; Dincer, I. A New Solar Energy System for Ammonia Production and Utilization in Fuel Cells. Energy Convers. Manag. 2020, 208, 112590. [Google Scholar] [CrossRef]

- Alobaid, M.; Hughes, B.; O’Connor, D.; Calautit, J.; Heyes, A. Improving Thermal and Electrical Efficiency in Photovoltaic Thermal Systems for Sustainable Cooling System Integration. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 305–322. [Google Scholar] [CrossRef]

- Seyedmahmoudian, M.; Mekhilef, S.; Rahmani, R.; Yusof, R.; Renani, E.T. Analytical Modeling of Partially Shaded Photovoltaic Systems. Energies 2013, 6, 128–144. [Google Scholar] [CrossRef]

- Nurwidiana, N.; Sopha, B.M.; Widyaparaga, A. Modelling Photovoltaic System Adoption for Households: A Systematic Literature Review. Evergreen 2021, 8, 69–81. [Google Scholar] [CrossRef]

- Rosa-Clot, M.; Tina, G.M. Submerged and Floating Photovoltaic Systems: Modelling, Design and Case Studies; Academic Press: Cambridge, MA, USA, 2017; ISBN 9780128123232. [Google Scholar]

| Parameter | Value |

|---|---|

| Ambient temperature (T) | 25 °C |

| Solar radiation (S) | 1000 W/m2 |

| Wind speed (Vw) | 1.5 m/s |

| Inlet water temperature (Tin) | 30–40 °C |

| Collector area (A) | 1.5 m2 |

| Diameter of pipe (d) | 0.0075 m |

| Item | Assumption |

|---|---|

| Helical Tube | 250 ($/m2) |

| Photovoltaic Panel | 10,000 ($/kW) |

| Inverter | 1200 ($/kW) |

| Battery | 120 ($/kW) |

| Source | Equipment | Power Cost |

|---|---|---|

| Open flow (T = 30 °C) | ||

| Solar | Conventional tube | 1.074 |

| Gas | Boiler | 0.024 |

| Gas & Solar | Conventional tube & Boiler | 0.820 |

| Solar | Helical tube | 0.346 |

| Gas & Solar | Helical tube & Boiler | 0.185 |

| Close flow (T = 60 °C) | ||

| Solar | Helical tube | 0.345 |

| Gas | Boiler | 0.023 |

| Gas & Solar | Helical tube & Boiler | 0.184 |

| Solar Pump | ||

| Solar | Photovoltaic System | 0.44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Candra, O.; Kumar, N.B.; Dwijendra, N.K.A.; Patra, I.; Majdi, A.; Rahardja, U.; Kosov, M.; Guerrero, J.W.G.; Sivaraman, R. Energy Simulation and Parametric Analysis of Water Cooled Thermal Photovoltaic Systems: Energy and Exergy Analysis of Photovoltaic Systems. Sustainability 2022, 14, 15074. https://doi.org/10.3390/su142215074

Candra O, Kumar NB, Dwijendra NKA, Patra I, Majdi A, Rahardja U, Kosov M, Guerrero JWG, Sivaraman R. Energy Simulation and Parametric Analysis of Water Cooled Thermal Photovoltaic Systems: Energy and Exergy Analysis of Photovoltaic Systems. Sustainability. 2022; 14(22):15074. https://doi.org/10.3390/su142215074

Chicago/Turabian StyleCandra, Oriza, Narukullapati Bharath Kumar, Ngakan Ketut Acwin Dwijendra, Indrajit Patra, Ali Majdi, Untung Rahardja, Mikhail Kosov, John William Grimaldo Guerrero, and Ramaswamy Sivaraman. 2022. "Energy Simulation and Parametric Analysis of Water Cooled Thermal Photovoltaic Systems: Energy and Exergy Analysis of Photovoltaic Systems" Sustainability 14, no. 22: 15074. https://doi.org/10.3390/su142215074

APA StyleCandra, O., Kumar, N. B., Dwijendra, N. K. A., Patra, I., Majdi, A., Rahardja, U., Kosov, M., Guerrero, J. W. G., & Sivaraman, R. (2022). Energy Simulation and Parametric Analysis of Water Cooled Thermal Photovoltaic Systems: Energy and Exergy Analysis of Photovoltaic Systems. Sustainability, 14(22), 15074. https://doi.org/10.3390/su142215074