Zero Waste Systems: Barriers and Measures to Recycling of Construction and Demolition Waste

Abstract

:1. Introduction

1.1. Household Waste Recycling in Costa Rica

1.2. Construction Sector and the Environment

1.3. Construction and Demolition Waste Recycling

2. Materials and Methods

3. Results and Discussion

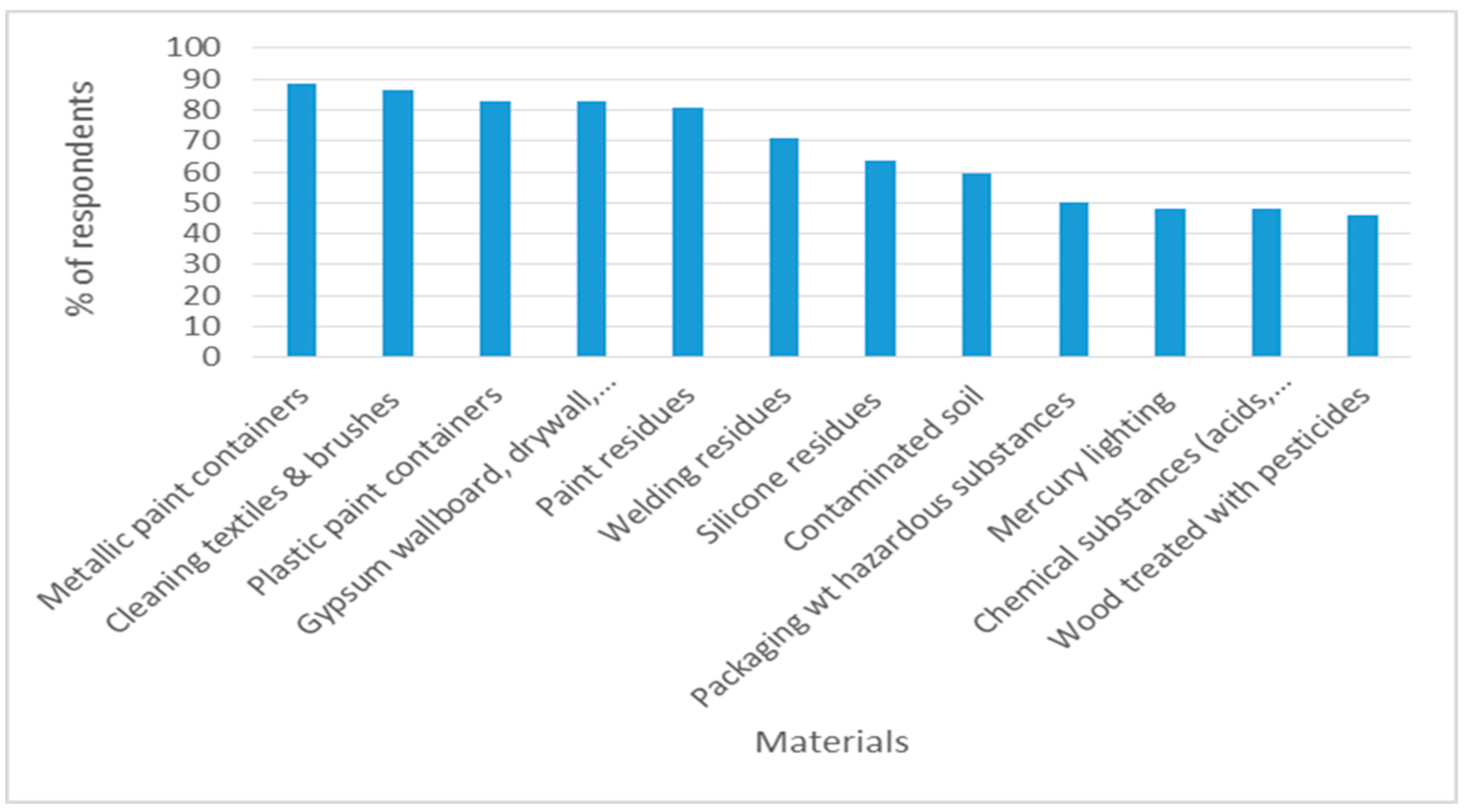

3.1. Construction Companies

3.2. Cement Producing Companies

3.3. Waste Management Companies

3.3.1. Concrete Managers

3.3.2. Wood Managers

3.3.3. Metal Managers

3.3.4. Packaging Materials

3.3.5. Material Transformation Facilities

3.3.6. Distributors of Construction Materials

3.3.7. Governmental Office

3.4. Materials Reused and/or Recycled in Costa Rica

3.5. Barriers Found for C&DW Recycling in Costa Rican

3.5.1. Technical Barriers

3.5.2. Financial Barriers

3.5.3. Environmental Barriers

3.5.4. Social

3.5.5. Legal

3.6. Measures Proposed for the Valorization of C&DW

3.6.1. Technical

- Conduct further research to demonstrate that recycled aggregates can be used for other purposes than structural or road projects.

- Train engineers and architects on alternatives for the use of concrete waste.

- Raise awareness among construction companies and managers so that they do not discard painted concrete, since cement producers can recycle it.

- Encourage partnerships between construction companies, managers, and processors of C&DW.

- Promote access to information or participation in international fairs to gain new insights in technology, innovation, and equipment for the transformation of C&DW.

3.6.2. Financial

- Create a market for recycled materials within the construction sector.

- Promote the environmental and economic benefits of using recycled materials in construction companies.

- Develop incentives, exemptions, or environmental certificates, for those companies with proper management of C&DW.

- Train managing SMEs on circularity and its important role in the market.

- Request the banking sector (public and private) open more accessible green credits for proper C/DW management.

- Promote the transformation and national commercialization of C&DW, through financial facilities for the acquisition of required equipment and infrastructure.

- Ensure cement producing companies are aware of the environmental impact of their packaging and their extended responsibility as producers.

3.6.3. Environmental

- Create alliances with other companies in order to exchange waste materials that can be reused.

- Incentivize research on the transformation of C&DW into new products.

- Create a seal and/or product certification for recycled construction materials.

- Raise awareness, through talks or training, to cement producers and distributors, regarding Extended Producer Responsibility toward their packaging materials.

- Comply with legislation regarding the management of wood and cement packaging materials.

3.6.4. Social

- Create a permanent dialogue platform among actors in the value chain, which facilitates coordination, training, technical assistance, and exchange of experiences.

- Create awareness on clients, designers, and constructors on the uses of recycled materials in projects, where quality can be guaranteed.

- Incorporate topics associated to sustainable construction, where the integration of recycled materials is considered, into university curricula.

- Encourage universities and research centers to investigate the technical characteristics of recycled C&DW.

- Ensure construction companies are aware of the importance of separating their waste for its recovery and recycling.

- Promote, through construction unions (e.g., Construction Chambers, Federation of Engineers, and alike), the use of recycled materials that meet the quality criteria established by such entities.

- Develop a strategy involving all the actors from the sector in searching for solutions to C&DW.

3.6.5. Legal

- Develop specific regulations for the proper management of C&DW.

- Enforce existing regulations in relation to C&DW current practices.

- Ensure information is available from regulatory entities regarding the procedures that construction companies must follow in relation to C&DW.

- Update the legal requirements to be more flexible for the collection and processing of waste materials.

- Propose the inclusion of the informal collection sector into the simplified Tax Regime and eliminate the obligation to pay taxes when the transaction is lower than a threshold.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tseng, M.L.; Chiu, A.S.F.; Liu, G.; Jantaralolica, J. Circular Economy enables sustainable consumption and production in multilevel supply chain system. Resour. Conserv. Recycl. 2020, 154, 104601. [Google Scholar] [CrossRef]

- Abarca-Guerrero, L.; Maas, G.; Hogland, W. Solid waste management challenges for cities in developing countries. Waste Manag. J. 2013, 33, 220–232. [Google Scholar] [CrossRef]

- Lansink, A. Challenging Changes: Connecting Waste Hierarchy and Circular Economy; LEA: Hague, The Netherlands, 2017; pp. 23–26. [Google Scholar]

- Zero Waste International Alliance (ZWIA). 2018. Available online: https://zwia.org/zero-waste-definition/ (accessed on 2 August 2022).

- Awasthi, A.K.; Cheela, V.R.S.; D’Adamo, I.; Iacovidou, E.; Islam, M.R.; Johnson, M.; Miller, T.R.; Parajuly, K.; Parchomenko, A.; Radhakrishan, L.; et al. Zero waste approach towards a sustainable waste management. Resour. Environ. Sustain. 2021, 3, 100014. [Google Scholar] [CrossRef]

- European Environmental Bureau (EEB); Eunomia. Recycling—Who Really Leads the World? Identifying the World’s Best Municipal Waste Recyclers. Available online: https://eeb.org/wp-content/uploads/2019/06/Recycling_who-really-leads-the-world-REPORT.pdf (accessed on 11 August 2022).

- Inter-America Development Bank (IADB). Solid Waste Management in Latin America and the Caribbean. August 2015. Available online: https://publications.iadb.org/en/solid-waste-management-latin-america-and-caribbean (accessed on 11 August 2022).

- Ministerio de Salud; Ministerio de Ambiente y Energía. Línea Base del Plan Nacional de Residuos Marinos 2021–2030. 2021. Available online: https://minae.go.cr/noticias-minae/documentos/259-plan-nacional-de-residuos-marinos-2021-2030 (accessed on 11 August 2022).

- Rodriguez Leandro, R. Retos y Oportunidades para la Valorización de Residuos Sólidos en Costa Rica. Licentiate Thesis, Instituto Tecnologico de Costa Rica, Cartago, Costa Rica, 2020. Available online: https://repositoriotec.tec.ac.cr/bitstream/handle/2238/11464/TFG_Rosibel_Rodr%c3%adguez_Leandro.pdf?sequence=1&isAllowed=y (accessed on 4 August 2022).

- Abarca-Guerrero, L.; Lobo-Ugalde, S. Análisis de Mercado de los Residuos Sólidos Ordinarios, sus Subproductos y Evaluación del Costo-Beneficio de las Tecnologías Disponibles en Residuos Valorizables que Pueden Dar una Oportunidad de Negocio; Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Bonn, Germany, 2020; Available online: https://girs.arkkosoftqa.com/GEI/Tecnologias%20y%20subproductos/2.%20Impactos%20y%20An%C3%A1lisis%20Costo%20Beneficio%20de%20tecnologias.pdf (accessed on 11 August 2022).

- Reid, J.M.; El-Gamil-Hassan, K.; Al-Kuwari, M.S. Improving the management of construction waste in Qatar. Waste Resour. Manag. 2016, 169, 21–29. [Google Scholar] [CrossRef]

- Abarca-Guerrero, L.; Maas, G.; van Twillert, H. Barriers and Motivations for Construction Waste Reduction Practices in Costa Rica. Resources 2017, 6, 69. [Google Scholar] [CrossRef] [Green Version]

- Negash, Y.T.; Hassan, A.M.; Tseng, M.-L.; Wu, K.-J.; Ali, M.H. Sustainable construction and demolition waste management in Somaliland: Regulatory barriers lead to technical and environmental barriers. J. Clean. Prod. 2021, 297, 126717. [Google Scholar] [CrossRef]

- Karji, A.; Namian, M.; Tafazzoli, M. identifying the key barriers to promote sustainable construction in the United States: A principal component analysis. Sustainability 2020, 12, 5088. [Google Scholar] [CrossRef]

- Ngowi, A. Challenges facing construction industries in developing countries. Build. Res. Inf. 2002, 30, 149–151. [Google Scholar]

- Gangolells, M.; Casals, M.; Forcada, N.; Macarulla, M. Analysis of the implementation of effective waste management practices in construction projects and sites. Resour. Conserv. Recycl. 2014, 93, 99–111. [Google Scholar] [CrossRef] [Green Version]

- Al-Otaibi, A.; Bowan, P.A.; Abdel daiem, M.M.; Said, N.; Ebohon, J.O.; Alabdullatief, A.; Al-Enazi, E.; Watts, G. Identifying the Barriers to Sustainable Management of Construction and Demolition Waste in Developed and Developing Countries. Sustainability 2022, 14, 7532. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Bossink, B.A.G.; Brouwers, H.J.H. Construction waste: Quantification and source evaluation. J. Constr. Eng. Manag. 1996, 122, 55–60. [Google Scholar] [CrossRef] [Green Version]

- Hong Kong Environmental Protection Department. Statistics Data. Available online: https://www.epd.gov.hk/epd/english/top.html (accessed on 18 September 2019).

- Lawson, N.; Douglas, I. Recycling construction and demolition waste—A UK perspective. Environ. Manag. Health 2001, 12, 146–157. [Google Scholar] [CrossRef]

- Kartam, N.; Al-Mutairi, N.; Al-Ghusain, I.; Al-Humoud, J. Environmental management of construction and demolition waste in Kuwait. Waste Manag. 2004, 24, 1049–1059. [Google Scholar] [CrossRef]

- Apotheker, S. Construction and demolition debris-The invisible waste stream. Resour. Recycl. 1990, 9, 66–74. [Google Scholar]

- Peng, C.L.; Grosskopt, K.R.; Kibert, C.J. Construction waste management and recycling strategies in the United States. In Proceedings of the First Conference of CIB TG 16 on Sustainable Construction, Tampa, FL, USA, 6–9 November 1994; pp. 689–696. [Google Scholar]

- Brooks, K.A.; Adams, C.; Demsetz, L.A. Germany’s Construction and Demolition Debris Recycling Infrastructure: What Lessons Does It Have for the US? In Proceedings of the First Conference of CIB TG 16 on Sustainable Construction, Tampa, FL, USA, 6–9 November 1994; pp. 647–656. [Google Scholar]

- Heino, E. Recycling of Construction Waste. In Proceedings of the First Conference of CIB TG 16 on Sustainable Construction, Tampa, FL, USA, 6–9 November 1994; pp. 565–572. [Google Scholar]

- Kennedy, C.; Cuddihy, J.; Engel-Yan, J. The changing metabolism of cities. J. Ind. Ecol. 2007, 11, 43–59. [Google Scholar] [CrossRef]

- Llatas, C. A model for quantifying construction waste in projects according to the European waste list. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef]

- Rosales-Calvo, S.; Abarca-Guerrero, L.; Leandro-Hernandez, A.G.; Angulo-Varela, J.P. Construction waste and potential environmental impacts. Tecnol. Marcha 2022, 35, 95–103. [Google Scholar]

- Del Río Merino, M.; Izquierdo, P.; Weis, I. Sustainable construction: Construction and demolition waste reconsidered. Waste Manag. Res. 2010, 28, 118–129. [Google Scholar] [CrossRef] [Green Version]

- Bakshan, A.; Srour, I.; Chehab, G.; El-Fadel, M. A field based methodology for estimating waste generation rates at various stages of construction projects. Resour. Conserv. Recycl. 2015, 100, 70–80. [Google Scholar] [CrossRef]

- Bergsdal, H.; Bohne, R.E.; Brattebø, H. Projection of construction and demolition waste in Norway. J. Ind. Ecol 2007, 11, 3. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S.H. Estimation of construction waste generation and management in Thailand. Waste Manag. 2009, 29, 731–738. [Google Scholar] [CrossRef]

- MartínezLage, I.; Martínez, F.; Herrero, C.V.; Ordóñez, J.L.P. Estimation of the annual production and composition of C&D Debris in Galicia (Spain). Waste Manag. 2010, 30, 636–645. [Google Scholar]

- Sandler, K. Analyzing what’s recyclable in C&D debris. Biocycle 2003, 44, 51–54. [Google Scholar]

- Zhao, W.; Leeftink, R.B.; Rotter, V.S. Evaluation of the economic feasibility for the recycling of construction and demolition waste in China-the case of Chongqing. Resour. Conserv. Recycl. 2010, 54, 377–389. [Google Scholar] [CrossRef]

- Cochran, K.; Townsend, T.; Reinhart, D.; Heck, H. Estimation of regional building-related C&D debris generation and composition: Case study for Florida, US. Waste Manag. 2007, 27, 921–931. [Google Scholar]

- Begum, R.A.; Siwar, C.; Pereira, J.J.; Jaafar, A.H. A benefit-cost analysis on the economic feasibility of construction waste minimisation: The case of Malaysia. Resour. Conserv. Recycl. 2006, 48, 86–98. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Characterization of Building-Related Construction and Demolition Debris in the United States; Report No. EPA530-R-98-010; United States Environmental Protection Agency: Washington, DC, USA, 1998. Available online: https://www.epa.gov/sites/production/files/2016-03/documents/charact_bulding_related_cd.pdf (accessed on 15 August 2022).

- Bakchan, A.; Faust, K.M. Construction waste generation estimates of institutional building projects: Leveraging waste hauling tickets. Waste Manag. 2019, 87, 301–312. [Google Scholar] [CrossRef]

- European Commission. Service Contract on Management of Construction and Demolition Waste-SR1, Final Report Task 2. 2011. Available online: https://environment.ec.europa.eu/system/files/2020-12/2011_CDW_Report_0.pdf (accessed on 1 August 2022).

- Nakajima, S.; Russell, M. Barriers for Deconstruction and Reuse/Recycling of Construction Materials; International Council for Research and Innovation in Building and Construction: Ottawa, ON, Canada, 2014; Available online: https://www.researchgate.net/publication/264671518_Barriers_for_Deconstruction_and_ReuseRecycling_of_Construction_Materials_in_Norway (accessed on 1 August 2022).

- Laredo dos Reis, J.; Cardoso, J.; Ferreira, P. Mechanical Properties of Recycled Kraft Paper Residue Polyester Composites. Mater. Res. 2014, 17, 888–892. [Google Scholar] [CrossRef] [Green Version]

- Crawford, R.H.; Mathur, D.; Gerritsen, R. Barriers to improving the environmental performance of construction waste management in remote communities. Procedia Eng. 2017, 196, 830–837. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S. Prioritizing barriers to green manufacturing: Environmental, social and economic perspectives, variety management in manufacturing. Procedia CIRP 2014, 17, 559–564. [Google Scholar] [CrossRef] [Green Version]

- Veleva, V.; Bodking, G.; Todorova, S. The need for better measurement and employee engagement to advance a circular economy: Lessons from Biogen’s “ZeroWaste”. J. Clean. Prod. 2017, 154, 517–529. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Ritala, P.; Mäkinen, S.J. Exploring institutional drivers and barriers of the circular economy: A cross-regional comparison of China, the US, and Europe. Resour. Conserv. Recycl. 2018, 135, 70–82. [Google Scholar] [CrossRef]

- Yuan, H.; Shen, L.; Wang, J. Major obstacles to improving the performance of waste management in China’s construction industry. Facilitie 2011, 29, 224–242. [Google Scholar] [CrossRef]

- Kuijsters, A. Environmental Response of the Chilean Building Sector. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2004. [Google Scholar]

- Dumlao-Tan, M.L.; Halog, A. Chapter 2. Moving Toward a Circular Economy in SolidWaste Management. In Advances in Solid and Hazardous Waste Management: Concepts and Practices, 1st ed.; Goel, S., Ed.; Springer International Publishing: New York, NY, USA, 2017; pp. 29–48. [Google Scholar]

- Singh, J.; Ordonez, I. Resource recovery from post-consumer waste: Important lessons for the upcoming circular economy. J. Clean. Prod. 2016, 134, 342–353. [Google Scholar] [CrossRef]

- Lee, J.; Pedersen, A.B.; Thomsen, M. Are the resource strategies for sustainable development sustainable? Downside of a zero waste society with circular resource flows. Environ. Technol. Innov. 2014, 1, 46–54. [Google Scholar] [CrossRef]

- Hossain, M.U.; Wu, Z.; Poon, C.S. Comparative environmental evaluation of construction waste management through different waste sorting systems in Hong Kong. Waste Manag. 2017, 69, 325–335. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Developing strategies for managing construction and demolition wastes in Malaysia based on the concept of circular economy. J. Mater. Cycles Waste Manag. 2016, 19, 1144–1154. [Google Scholar] [CrossRef]

- Li, J.; Yu, K. A study on legislative and policy tools for promoting the circular economic model for waste management in China. J. Mater. Cycles Waste Manag. 2011, 13, 103–112. [Google Scholar] [CrossRef]

- Ritzén, S.; Sandström, G.Ö. Barriers to the circular economy—Integration of perspectives and domains. Procedia CIRP 2017, 64, 7–12. [Google Scholar] [CrossRef]

- Abba, A.H.; Noor, Z.Z.; Yusuf, R.O.; Din, M.F.M.D.; Hassan, M.A.A. Assessing environmental impacts of municipal solid waste of Johor by analytical hierarchy process. Resour. Conserv. Recycl. 2014, 73, 188–196. [Google Scholar] [CrossRef]

- Osmani, M.; Villoria-Sáez, P. Current and emerging construction waste management status, trends and approaches. In Waste, 2nd ed.; Letcher, T.M., Vallero, D.A., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 365–380. [Google Scholar]

- Yong, D. Plant location selection based on fuzzy TOPSIS. Int. J. Adv. Manuf. Technol. 2006, 28, 839–844. [Google Scholar] [CrossRef]

- Teo, M.M.M.; Loosemore, M. A theory of waste behavior in the construction industry. Constr. Manag. Econ. 2001, 19, 741–751. [Google Scholar] [CrossRef]

| Financial | Low (international) prices of recycled materials, operation, and investments costs are not covered |

| Limited market, few companies determine the price and buy materials | |

| High direct costs: taxes, social charges, electricity price, high transportation costs | |

| Recycling sector has difficulties accessing credit due to guarantees needed, equipment is not allowed as collateral, high interest rates | |

| Lack of measures to consider the base recyclers (waste pickers) when the landfills are closed | |

| High costs and complicated processes to formalize recycling related businesses | |

| Infrastructure and equipment are expensive | |

| Institutional/normative | Lack of financial incentives for the activity |

| Excessive requirements (permits), complex and slow registration processes | |

| Government not supporting procurement of products with recycled material | |

| Lack of support to the recycling sector from decision makers | |

| Unfair competition by non-formalized companies, which operate with lower costs | |

| Formal companies can no longer buy material from waste pickers | |

| Most municipalities do not collect waste separately, as a result much material goes to final disposal sites | |

| Socio-cultural | Poor separation by households of recyclable materials, especially plastic |

| Little recognition of grassroots recyclers (waste pickers) and their work by the municipalities and citizens | |

| Different stakeholders in the recycling value chain do not understand the needs of each other | |

| Lack of recognition of the good initiatives and investments made in the solid waste sector | |

| Technological | No technical support from knowledge organizations for the transformation of materials. The recyclers learn by doing |

| Companies lack knowledge on modern machinery and technologies to improve and increase production processes | |

| Workers at recycling related businesses with low skills | |

| There are no detailed statistics on available materials, real savings, or ecological footprint due to recycling | |

| Materials cannot be transformed in the country |

| Country | C&D Waste (% by Weight) | Reference |

|---|---|---|

| Netherlands | 26 | [19] |

| Hong Kong | 44 | [20] |

| England and Wales | 42.2 | [21] |

| Kuwait | 15–30 | [22] |

| USA | 20–29 | [19,23,24] |

| Australia | 20–30 | [25] |

| Germany | 19 | [25] |

| Finland | 13–15 | [26] |

| Japan/Tokyo | 57 | [27] |

| Worldwide | 13–35 | [19,28] |

| Type of Construction | Place | Composition (%) | Reference | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Concrete | Masonry (Concrete Blocks, Bricks, and Concrete Residues) | Wood | Gypsum and Plaster | Metals | Roofing Materials | Plastic | Paper/ Cardboard | |||

| Residential and non-residential | Lebanon | 23.00 | 17.44 | 11.50 | - | 3.30 | - | - | - | [31] |

| Norway | 45.80 | 13.67 | 6.25 | 1.32 | - | 4.50 | [32] | |||

| Thailand | 46.00 | 14.00 | 6.00 | 1.00 | 2.00 | 5.00 | [33] | |||

| Spain | 29.30 | - | 5.40 | 3.60 | 8.80 | - | 3.80 | 3.40 | [34] | |

| USA | 40.00–50.00 | 1.00–5.00 | 20.00–30.00 | 5.00–15.00 | 1.00–5.00 | 1.00–10.00 | 1.00–5.00 | - | [35] | |

| Chongqing, China | 14.00 | 23.00–29.00 | 15.00 | - | 2.50 | - | - | 4.00 | [36] | |

| Non-residential (general) | Florida, USA | [37] | ||||||||

| Non-residential (Institutional) | Malaysia | 65.80 | 1.60 | 5.00 | - | 1.00 | 0.20 | 0.05 | [38] | |

| Portland, Oregon, USA | - | - | 20,50 | - | - | - | - | 19.30 | [39] | |

| Total intervals | 14.00–65.80 | 1.00–46.00 | 5.00–30.00 | 3.60–15.00 | 1.00–8.80 | 0.20–10.00 | 0.05–5.00 | 0.05–19.30 | ||

| Unknown | Texas, USA | 48.50 | 40.70 | - | 2.10 | - | 0.30 | 1.20 | [40] | |

| Material | Location | Barrier | Source |

|---|---|---|---|

| Concrete | European Union (EU) | Research deficiencies about alternatives for concrete recycling except for road works | [41] |

| Concrete | EU | Separation at source inadequate, reducing the quality of the waste material for recycling | [41] |

| Concrete | EU | Design of buildings do not consider the end of life of the building | [41] |

| Concrete | EU | Green building systems of some European countries (e.g., German Sustainable Building Certificate, HQE-Haute Qualité Environnementale in France, BREEAM-BRE Environmental Assessment Method in the UK), do not integrate in their rating charts the re-use of concrete elements and the use of structural concrete made of recycled aggregates | [41] |

| Concrete | Canada | Residual contaminants reduce aggregate compressive strength by about 25% | [42] |

| Concrete | Canada | Source separation of materials is difficult | [42] |

| Concrete | Canada | It is not cost effective to deconstruct and reuse concrete | [42] |

| Wood | Canada | Inadequate management of on-site grading, particularly in the case of preserved wood products | [42] |

| Wood | Canada | Lack of knowledge on treatments options enabling the reuse and recycling of preserved wood | [42] |

| Wood | Canada | Absence of infrastructure for the collection, transport, storage, and preparation of preserved or untreated wood | [42] |

| Steel | Canada | Complications of reusing building components in “as is” condition | [42] |

| Wood | Norway | The barrier is related to form, strength, and contaminations | [42] |

| Concrete | Norway | Removal of paint in concrete is costly therefore it is sent to special disposal sites | [42] |

| Concrete | Norway | Construction companies might not have the equipment to separate concrete from the reinforcing bars | [42] |

| Concrete | Norway | New road projects consider recycled concrete to be of low quality, despite evidence showing the contrary | [42] |

| Kraft paper packaging | N.I. | Bags impregnated with cement causes conventional paper recycling to be impossible | [43] |

| Material | Location | Barrier | Source |

|---|---|---|---|

| Concrete | European Union | Funding problems for research on alternatives to optimize existing options for recycling | [41] |

| Concrete | Canada | Recycled aggregates are considered of low quality, therefore it should have a lower price | [41] |

| General | N.I. | Lack of funding to implement circular economy in C&DW management | [41] |

| General | N.I. | Construction costs do not reflect environmental costs | [42] |

| General | N.I. | Lack of time for C&DW separation | [42] |

| General | N.I. | Absence of contractual requirements for the reuse and recycling of materials | [42] |

| General | N.I. | Reluctance to segregate for recycling and re-using materials with a low economic value or difficult to reuse | [42] |

| General | N.I. | Perspective that C&DW management are not cost-effective | [42] |

| Wood | Canada | Infrastructure for timber recycling is considered costly | [42] |

| Concrete | Japan | It is more costly and energy-intensive to produce aggregates from recycled concrete than from virgin raw materials | [42] |

| Concrete | Norway | The cost of virgin gravel can be cheaper than recycled aggregate when the transportation and storage costs are added | [42] |

| Concrete | USA | Recycling plants are not always available near demolition sites and sometimes charge a fee to process the demolition waste; it is cheaper to transport waste to the landfills | [42] |

| General | N.I. | Priority is given to economic benefits and not to environmental aspects | [42] |

| General | N.I. | Lack of financial incentives for reduction or recycling of C&DW | [42] |

| Material | Location | Barrier | Source |

|---|---|---|---|

| General | N.I. | Attitude of constructors toward C&DW | [44,45,46] |

| General | N.I. | User preference for new over reused or recycled materials | [45,47] |

| General | N.I. | Construction industry culture | [44] |

| General | N.I. | Lack of a well-developed C&DW recycling market | [42,48] |

| General | N.I. | Low customer demand for sustainable buildings | [49] |

| General | N.I. | Difficulty to modify labor practices | [48] |

| General | N.I. | Belief that efforts will not be sufficient to eliminate C&DW completely | [12] |

| Material | Location | Barrier | Source |

|---|---|---|---|

| Concrete | European Union | Deficiencies in the planning, design, renovation, and deconstruction processes hinder the “zero discharge” target | [41] |

| General | N.I. | Inefficient processes of dismantling, classification, transport, and recovery of C&DW | [42,44,50] |

| General | N.I. | C&DW reduction does not receive sufficient attention in construction planning and design | [49,50] |

| General | N.I. | Limited use of recyclable materials in construction | [50] |

| General | N.I. | Unfriendly methods in the construction and demolition processes | [46,47,51,52] |

| General | N.I. | Landfilling is preferred due to the lack of incentives for other treatments | [47,53,54] |

| General | N.I. | Lack of Extended Producer Responsibility for construction materials | [55,56] |

| General | N.I. | Complexity for the transformation of the sector into a circular economy model of production and consumption | [45,46,56] |

| General | N.I. | Lack of knowledge and awareness related to the management of C&DW | [44,47,56] |

| General | N.I. | No benefits for sorting packaging materials | [44] |

| General | N.I. | Lack of integration of sustainable C&DW management | [56] |

| General | N.I. | Uncertainty in moving toward circular economy in C&DW management | [45,56] |

| General | N.I. | Lack of certainty on the status of the C&DW | [42,44] |

| Material | Location | Barrier | Source |

|---|---|---|---|

| Concrete | European Union | Insufficient regulation support prohibiting the disposal of C&DW in dumps or landfills, so there is less encouragement to recycle it | [41] |

| Concrete | European Union | Deficiencies in certifications demonstrating that recycled concrete complies with standards and can meet the same properties as virgin materials | [41] |

| General | N.I. | Inadequate regulations and enforcement for C&DW | [47,48,55,57,58] |

| General | N.I. | Lack of clear C&DW national goals, objectives, and vision | [46,54,59] |

| General | N.I. | Lack of standardized reporting and accessible data on C&DW reduction | [12,46] |

| General | N.I. | Contractors lacking economic penalizing methods for C&DW management | [48] |

| General | N.I. | Lack of coordination among stakeholders of construction sector | [49] |

| General | N.I. | Inconsistencies between different governmental institutions | [49] |

| General | N.I. | Absence of industry standards or performance standards for C&WM | [60] |

| General | N.I. | Individual responsibilities in terms of waste management are poorly defined | [60] |

| General | N.I. | Lack of enforcement of construction and waste management policies and plans | [48] |

| Wood | Japan | The recycling policy is not complied with, as the preference is to use wood as an energy resource rather than to recycle | [42] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abarca-Guerrero, L.; Lobo-Ugalde, S.; Méndez-Carpio, N.; Rodríguez-Leandro, R.; Rudin-Vega, V. Zero Waste Systems: Barriers and Measures to Recycling of Construction and Demolition Waste. Sustainability 2022, 14, 15265. https://doi.org/10.3390/su142215265

Abarca-Guerrero L, Lobo-Ugalde S, Méndez-Carpio N, Rodríguez-Leandro R, Rudin-Vega V. Zero Waste Systems: Barriers and Measures to Recycling of Construction and Demolition Waste. Sustainability. 2022; 14(22):15265. https://doi.org/10.3390/su142215265

Chicago/Turabian StyleAbarca-Guerrero, Lilliana, Susi Lobo-Ugalde, Nicole Méndez-Carpio, Rosibel Rodríguez-Leandro, and Victoria Rudin-Vega. 2022. "Zero Waste Systems: Barriers and Measures to Recycling of Construction and Demolition Waste" Sustainability 14, no. 22: 15265. https://doi.org/10.3390/su142215265

APA StyleAbarca-Guerrero, L., Lobo-Ugalde, S., Méndez-Carpio, N., Rodríguez-Leandro, R., & Rudin-Vega, V. (2022). Zero Waste Systems: Barriers and Measures to Recycling of Construction and Demolition Waste. Sustainability, 14(22), 15265. https://doi.org/10.3390/su142215265