Abstract

Logistics is one of the sectors that is evolving in parallel with Industry 4.0, which refers to the integration of new technologies, information, and agents, with the common goal of improving the efficiency and responsiveness of a logistics management system. The warehouse is an essential link in logistics management, a factor of competitiveness, and a link between the partners of the entire logistics chain. It has become essential to manage warehouses effectively and to allocate their resources efficiently. The digitalization of warehouses is currently one of the research topics of Logistics 4.0. This work presents a methodology of the digital transition of warehouse management, which consists of four main steps: the diagnosis of a warehouse to identify the different processes, the degree of involvement of the employees, a calculation of the degree of maturity to identify the new technology and means of data transfer, and the associated software for the collection of information and the methods of data processing. This digital transition methodology was applied to an industrial company. The results obtained allowed for the improvement of all the indicators measuring the performance of the warehouse on economic, social, and environmental levels.

1. Introduction

For several years now, consumer habits have been constantly evolving, which means that the supply chain has had to adapt. From inventory to order returns management, the warehouse and its logistics are now taking on a 4.0 dimension. The warehouse is no longer considered as a simple storage area; it is now at the heart of the information system and corporate strategy, so it requires an adequate and efficient management of its flow. A warehouse allows for the safe storage of goods. In order to support this role, strategic choices must be made regarding the handling of equipment, the type of pallet racking to be used, and the configuration of the space.

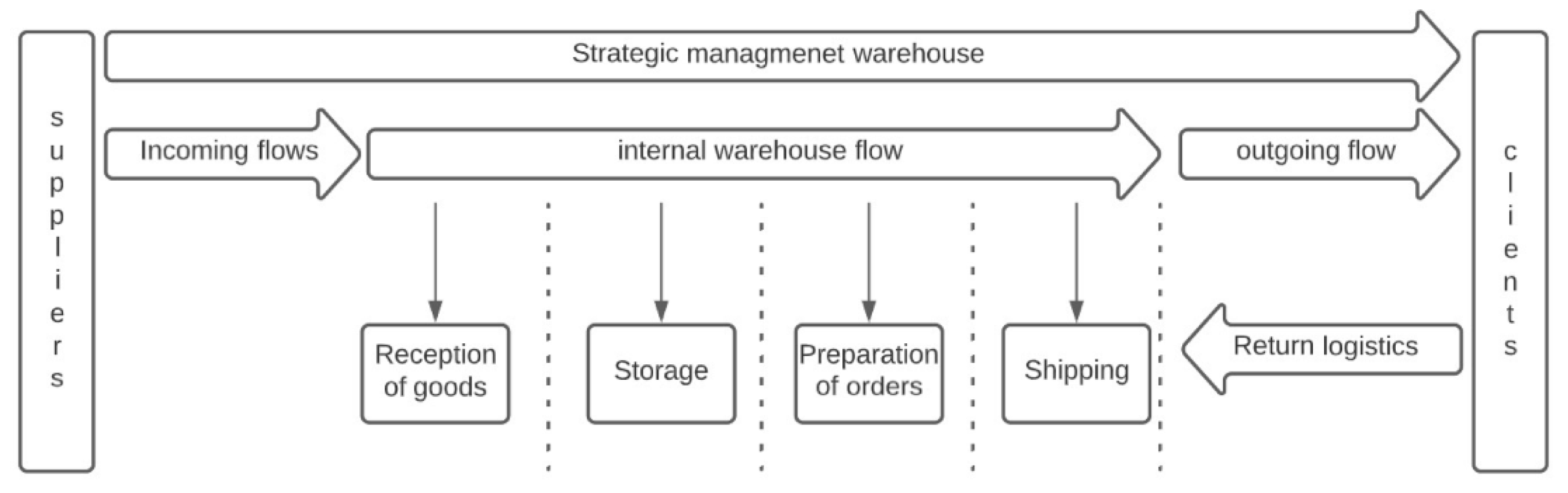

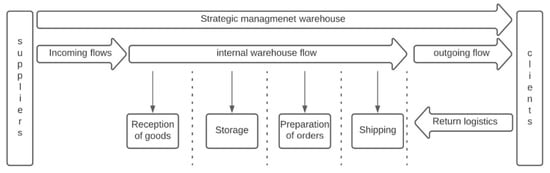

The warehouse is a strategic place that must meet the needs of a structure while satisfying the triad of quality–cost and sustainable development. A warehouse performs the basic functions of receiving, storage, order preparation, and shipping [1,2].

The volatile demand from customers to search for and purchase items at any time has disrupted the entire supply chain from supplier to customer. Manufacturers, distributors, and warehouses are struggling to meet their needs. B2B companies are suffering from the full impact of the digital revolution, as they need to produce, store, and ship items faster and with extreme precision. The “everything now” mentality has spread to all industries, where decision-makers need to secure their bottom line and achieve a strong return on investment, while improving customer satisfaction [3]. The requirements are also numerous: multiplication of references and partners, preparation of heterogeneous pallets in weight and volume, reliable and fast shipments of single products, the arrival of multi-channel, and synergies between physical and digital points of sale that further complicate logistics tasks; hence, there is the need to introduce these new technologies [4].

The answer to these logistical constraints mentioned in the previous paragraph comes thanks to the emergence and consolidation of new technologies, which constitute an important technological revolution that will ensure responsiveness, agility, and customer satisfaction. These new technologies also promote economic, social, and environmental performance [5]. Many 4.0 solutions are proposed on the current market, and, as a consequence, logistics systems are gaining in flexibility and agility. The gradual transition to Supply Chain 4.0 is making the promise of a more flexible and autonomous organization a reality for companies seeking productivity [6], thus meeting the needs of end customers. As a result, the competitiveness of territories goes hand in hand with the growth of technologies. As a result, the competitiveness of territories goes hand in hand with the growth of technologies. This digital transformation allows for a reduction in costs, delays, and traceability and contributes to the competitiveness of the warehouse [7]. A new challenge is added to the digital warehouse, which is to meet the requirements of sustainable development [8]. Faced with the current challenges of sustainable development, traceability, profitability, customer satisfaction, and last-mile deliveries, the objective of this article is to present a classic transformation approach to a connected, high-performance warehouse of the future.

In the literature, I have found that the true impact of these technologies on the supply chain in general, and on the warehouse specifically, is still unclear. Some of the constraints to making a digital transition to a warehouse of the future are cited: complexity of systems, financial investment, lack of skills, insufficient knowledge of these technologies, high degree of IT requirements, security, confidentiality [9], and carbon footprint. The number of warehouses is more and more important, as they are implanted into the territories next to cities; they contribute to economic development, certainly, but their spaces, which occupy thousands of hectares, are used to the detriment of green space for storage and parking roads and are full of implanted activities. With this work, I contribute by providing an effective methodology for the digital transition of a logistics warehouse.

Therefore, my research will be divided into three parts: first, I present a literature review of the scientific research related to the digital supply chain, its advantages, and the impact of digitalization; then, I propose a methodology with different steps to implement the new technologies and design a warehouse of the future in the context of sustainable development. In the third part, I propose a case study of a food company.

2. Analysis of the Literature Review

State of the Art

The warehouse plays an essential role in a company, as it is the intermediary between all stakeholders, ensuring the storage of raw materials, storing finished goods, expediting order picking, and delivering products to their final destination.

Warehouses perform the basic functions of receiving, storage, order picking, and shipping [10]. Some are more complex and also perform distribution and value-added activities.

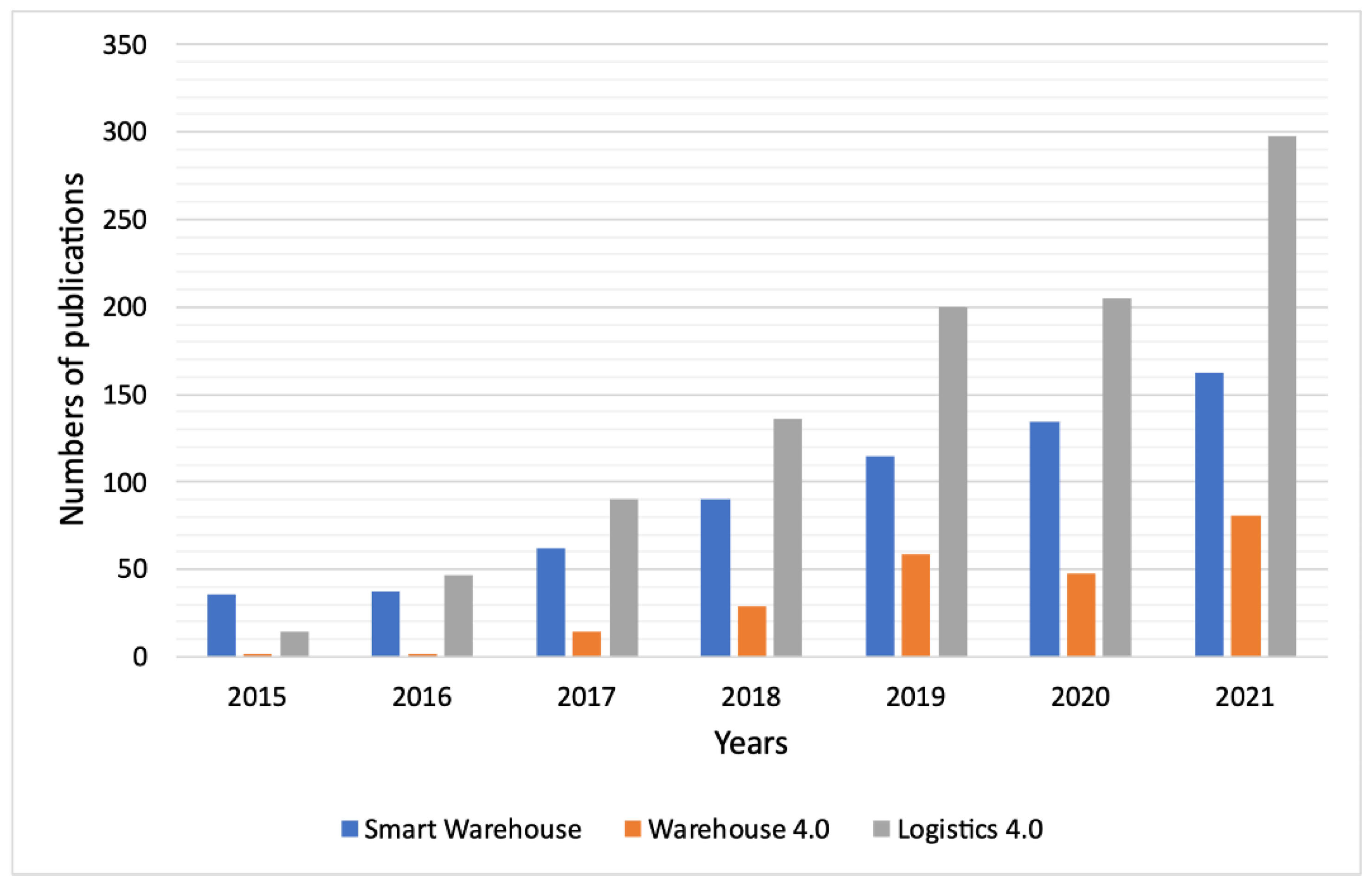

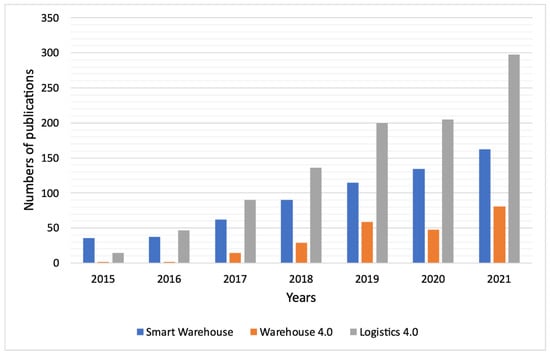

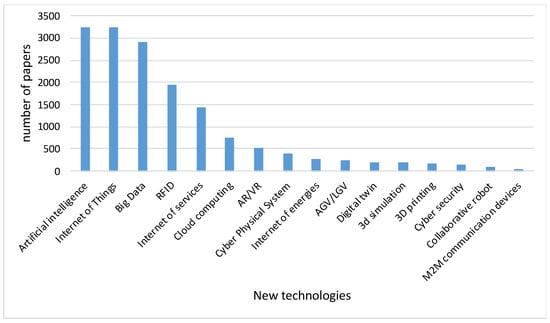

To cover relevant and recent publications on Warehouse 4.0, I used two scientific search platforms, Scopus and Google Scholar, and two keywords, “Smart Warehouse” and “Warehouse 4.0”. Figure 1 represents the number of publications in which the terms “Smart Warehouse”, “Warehouse 4.0”, and “Logistics 4.0” appeared, based on Scopus.

Figure 1.

Number of publications where ‘‘Smart Warehouse’’, ‘‘Warehouse 4.0’’, and ‘‘Logistics 4.0’’ appeared, from 2015 to 2021.

From the graph, it can be seen that this new concept is an industrial trend that is increasingly attracting the attention of researchers and even companies looking to optimize their management and strengthen their competitiveness in the market. The new technologies used in Warehouse 4.0, which I will mention later, offer solutions to major problems such as: traceability, processing and analysis of massive data, choosing the right decisions, security, order forecasting, etc. [9], which explains the convergence of companies towards this technological option.

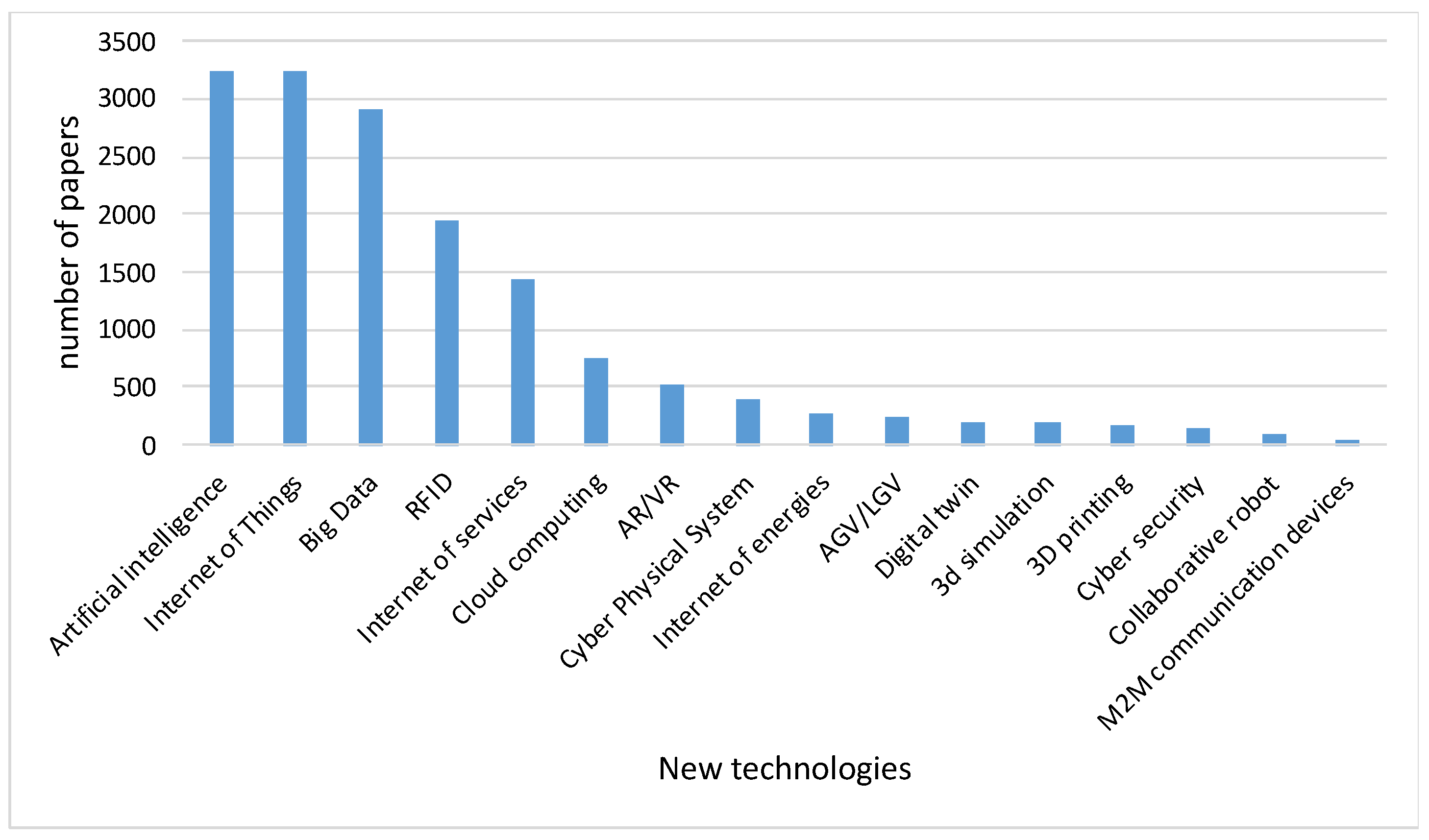

In order to determine the most important technologies for a warehouse and for logistics in general, I performed a more specific search, associating the term “Warehouse 4.0” or “Logistics 4.0” with the name of the technology and extracting the number of publications where both keywords are mentioned; thus, I obtained the results represented in Figure 2.

Figure 2.

Number of publications for each technology used in logistics from 2015 to 2021.

According to this bibliographic research, a Warehouse Management System (WMS), Big Data, Artificial Intelligence (AI), the Internet of Things (IoT), Radio-Identification (RFID), Machine-to-Machine Communication, and Cloud Computing are the most used technologies by a warehouse. This result can be explained by the need for the collection of information from the various stakeholders in the supply chain by the IoT, Big Data, and processing methods using artificial intelligence.

The concept of the warehouse of the future is addressed by [11]. The authors focused in particular on the strategic planning of the warehouse of the future. The transition of logistics centers has changed with the emergence of the Industry 4.0 era [10]. These technologies are used in logistics operations by practitioners and academics in engineering and operations management to increase performance [12]. The warehouse can integrate 5G technology to schedule and route vehicles [13]. The use of real-time location systems in warehouse management can increase the efficiency and safety of forklift placement, tracking, and order processing [14]. These technologies can manage information on demand and locate the customer to expedite product delivery. In Table 1, we present the main technologies used and their impact on the different activities of the warehouse. These technologies allow the transformation of a traditional warehouse into a digitalized warehouse.

Table 1.

Definition of 4.0 technologies and their uses in the warehouse.

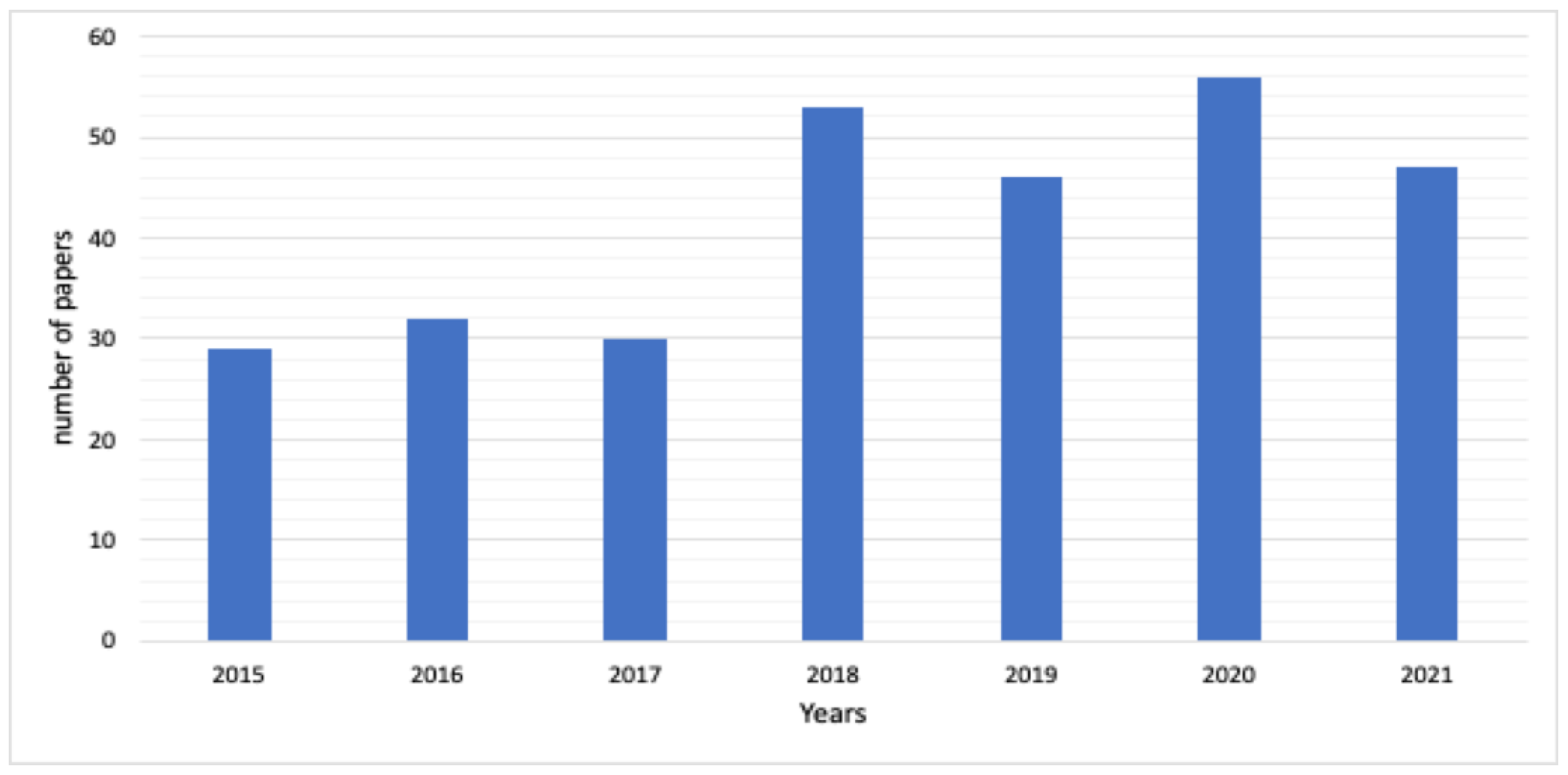

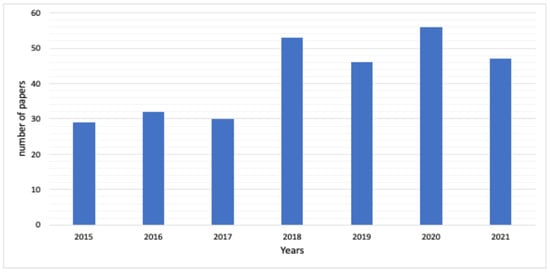

A lot of research has focused on the new 4.0 technologies, but few articles object to the impact of new technologies on sustainable development, which is justified by the number of publications that appeared between 2015–2021, as shown in Figure 3.

Figure 3.

Number of publications on warehouses and their link to sustainability from 2015 to 2021.

Regarding sustainable development and logistics, in 1987, the Brundtland Report, drawn up by the United Nations Commission on Environment and Development, defined Sustainable Development (SD) as “development that meets our needs without compromising the ability of future generations to meet their own needs”. Since then, the concept of SD has been progressively adopted around the world. For companies, SD implies that they develop based on three pillars: environmental, social, and economic; this is called corporate social responsibility (CSR).

The concept of sustainable development was born around the 1970s. According to Linton et al. (2007), sustainable development concerns many disciplines such as earth and environmental sciences, medicine, material sciences, agriculture, biology, economics, social sciences, and management sciences such as industrial logistics [33].

There are several definitions of CSR in the literature. The European Commission defines the concept of CSR as “the voluntary integration by companies of social and environmental concerns into their business operations and their interaction with their stakeholders” (European Commission, 2001) [34], as shown in Table 2.

Table 2.

Contributions of sustainable development in logistics.

A digitalized warehouse must be able to meet the needs of customers, improve performance by using the fourth revolution technologies, and take into account the requirements of sustainable development from social, economic, and environmental points of view. Table 3 summarizes the main positive sustainable impacts of digital technologies in a warehouse context [40].

Table 3.

The main positive sustainable impacts of digital technologies in a warehouse context.

3. Methodology

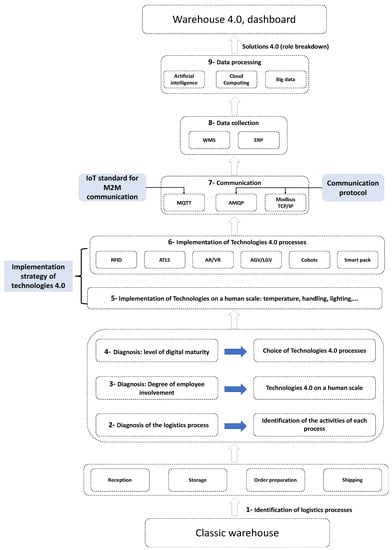

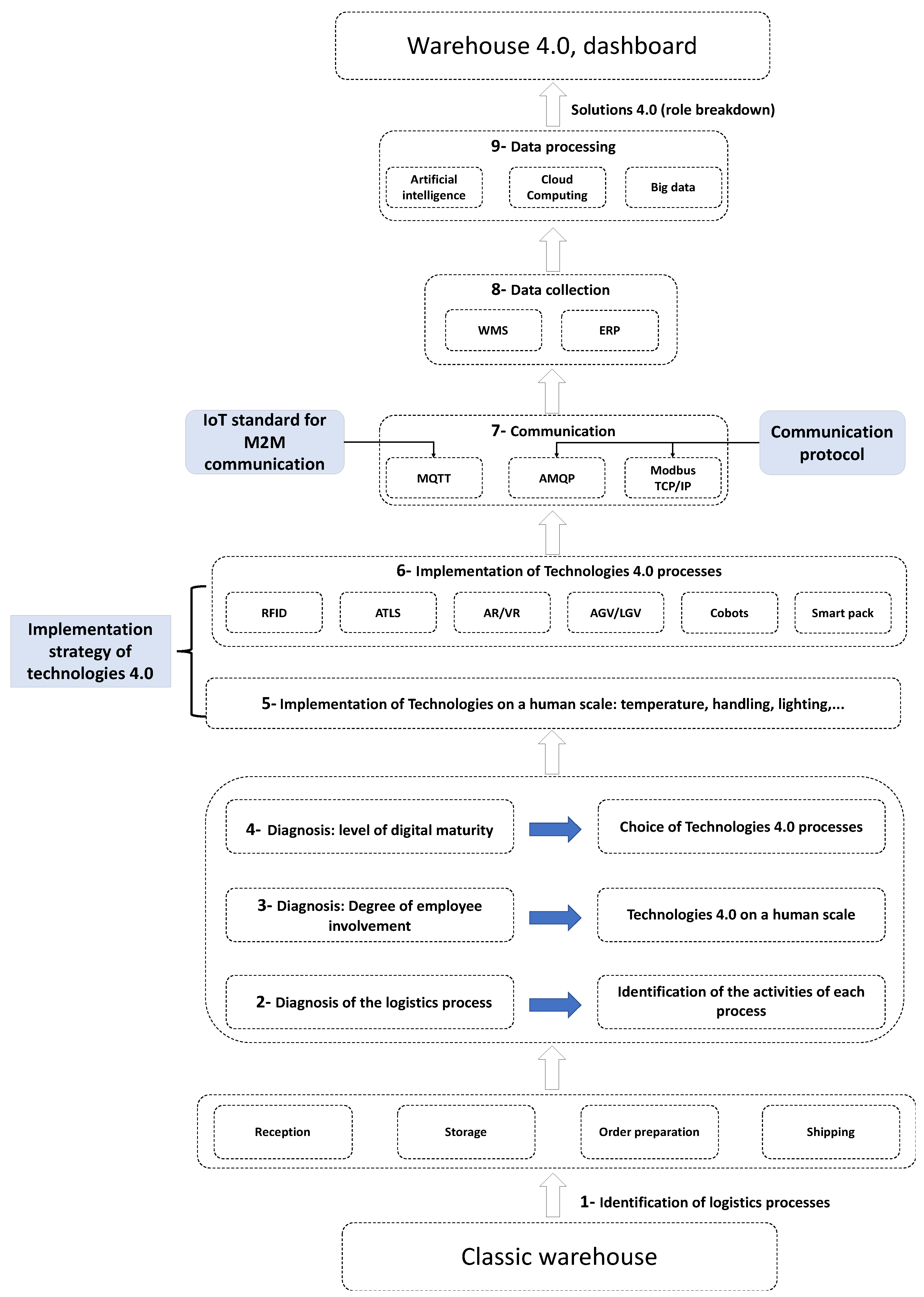

The present research work consists of carrying out a digital transformation of a warehouse within the framework of sustainable development. This research problem is part of the digitalization of a warehouse. What is the transition from a traditional warehouse to a 4.0 warehouse? How to automate the activities of a warehouse to have a connected warehouse? The objective of this work is a method that will facilitate the tasks of a company to operate in their warehouse and will present a decision support tool for principals in logistics to achieve a digital transformation of their warehouse. To answer this problem, the research methodology of this work is in Figure 4.

However, the integration of digitalization in the supply chain is not easy because of many challenges in terms of lack of framework or guide for the adoption of digitalization in the supply chain and the resistance of the staff, the lack of information sharing between the actors of the supply chain, and the cost that can generate this digital transition in terms of technology purchase, training of staff, experts who accompany the companies, etc.

All these constraints can obstruct the supply chain managers in their deployment of digital technologies. To answer this challenge, I will propose a simple and realistic methodology that can be used by companies that want to integrate these new technologies into their logistics processes.

The integration of these technologies must be based on the requirements of the SD that Morocco has invested in, in order to manage natural resources and improve the living environment of its population.

3.1. Steps to Implement 4.0 Technologies in a Warehouse

The digitalization of a warehouse or the transition from a traditional warehouse to Warehouse 4.0 is a major project that requires the strong mobilization of internal resources and the strong support of an expert company that will ensure the good management of the project. The increased consideration of the environment should, however, allow a company to increase its revenue, satisfy its customers, and build a new competitive advantage [55].

The mapping brings together all the activities to describe the approach, following the transfer from a traditional warehouse to Warehouse 4.0, as shown in Figure 4.

This methodology consists of first mapping all the activities to describe the approach to follow for a transfer of a warehouse, which consists of all the related processes and activities, the diagnosis of the measurement of the degree of maturity, the degree of resistance of the employees to the project of digital transition, and the choice of the various technologies and means of data transmission. The digitalization of a warehouse or the transition from a traditional warehouse to Warehouse 4.0 is a major project that requires the strong mobilization of internal resources and the strong support of an expert company that will ensure the good management of the project.

Figure 4.

Warehouse digitization step.

Figure 4.

Warehouse digitization step.

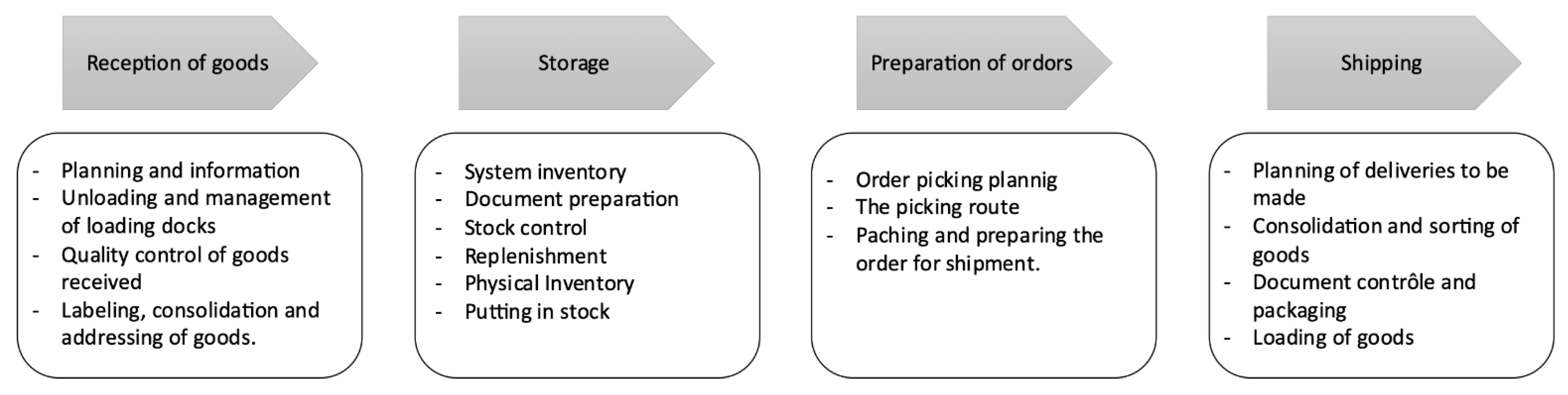

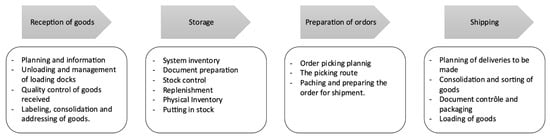

3.2. Identification of Warehouse Logistics’ Processes

Generally, warehousing is divided into 4 basic processes: receiving goods from suppliers, storage, order picking and shipping to the customer. Each process is composed of several functions and subfunctions that describe its activities, as shown in Figure 5.

Figure 5.

Warehouse process.

Saving time and increasing productivity and efficiency, to improve warehouse management, is nowadays a key factor for companies in their race for performance. To increase the level of service and the number of goods stored and to satisfy the needs of customers, it is necessary for a company to manage its stock well. Good warehouse management means knowing the strengths and weaknesses in order to improve them. To do this, I offer a digital maturity diagnosis.

The concept of the “Maturity Model” allows a logistician to describe the level of evolution in the digitalization of their company. It consists of positioning oneself and detecting the problems within the company and setting a roadmap for its evolutionary capacities, while assisting its employees. In addition, the final phase of my model, which is intelligent automation, corresponds to the moment when warehouses will be able to perform predictive operations.

The extensive scientific literature has shown several approaches to measure the level of maturity or readiness to implement Industry 4.0 in a company (Table 4). The common objective is to assess the maturity level of the company’s processes and to provide an indication of the actions needed to increase this level.

Table 4.

Maturity models found in the literature [56].

Some of these models are called “readiness”, such as the Singapore model [57] and “DREAMY” [58], but none of these can assess the readiness for Industry 4.0 implementation. According to [59], these models do not differentiate between readiness and maturity.

Based on this work, I propose maturity levels adapted to my case study for the evaluation of the existing situation in a warehouse. I have proposed four levels in the form of percentages to measure the initial state of the technologies. The four levels of maturity are defined in Section 3.3.

3.3. Diagnostic 4.0 Digital Maturity

It is important to analyze the situation of the company, to establish an inventory of strengths and weaknesses of the company, so the diagnosis of the digital maturity takes into account the reality of the company, its strategy, and its needs.

With the objective of integrating these new technologies, it is first necessary to carry out a 4.0 diagnosis for each process of the warehouse, to be able to position the company on a scale of maturity concerning Warehouse 4.0. For this purpose, a questionnaire has been established on all the activities of a warehouse. Each element has 4 levels of maturity, where level 1 reflects the total absence of new technologies, and level 4 represents the application of 4.0 technologies.

- -

- Level 1: 4.0 technologies not used (traditional management mode);

- -

- Level 2: 4.0 technologies used and not mastered (ERP and WMS);

- -

- Level 3: 4.0 technologies occasionally used and mastered;

- -

- Level 4: 4.0 technologies used and mastered (existing tools such as RFID, AR, IoT, AI, Power BI, stacker crane, cyber security, etc.)

The maturity level (MD) of each dimension results from the calculation of the weighted average of all the elemental deadlines (MDIi) in its associated dimension. The weighting factor (gDIi) is equal to the importance rating in the company. The maturity level is calculated using the following formula [60]:

where

M: maturity;

D: dimension;

I: item;

g: weighting factor;

n: number of maturity.

The results are represented in Table 5.

Table 5.

The weighting factor and weighted average of the current status and target state.

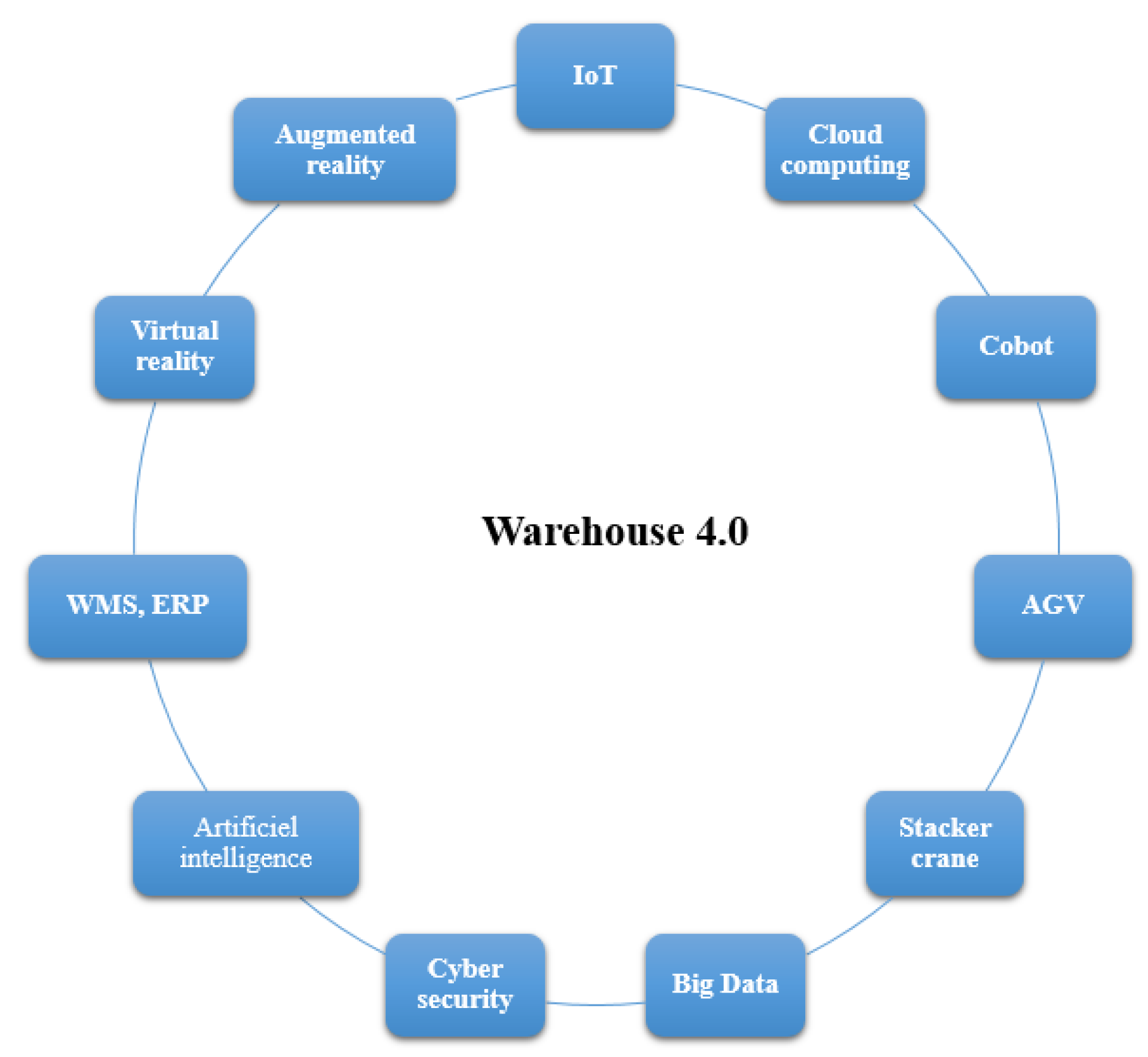

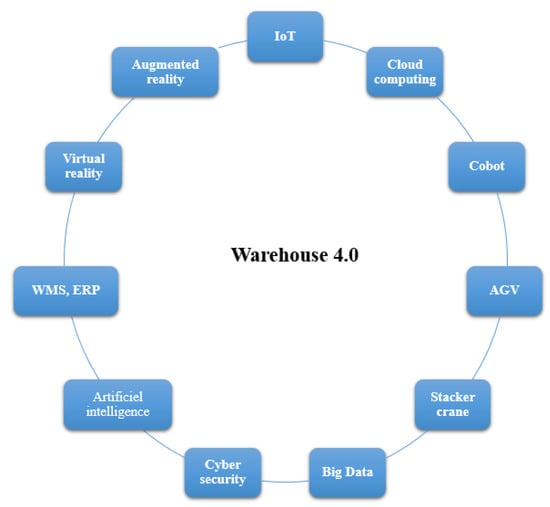

3.4. New Warehouse Technologies

The technologies deployed in Warehouse 4.0 generally allow for the circulation of goods, flexibility and reactivity in order to handle more flows, and improvement of the situation of employees and the working environment [61]. It is impossible to dissociate the digital transformation processes from the technologies that are at the heart of Industry 4.0. To contextualize, I review the main technologies related to digital transformation in warehouse management [40]; these are changing the way a warehouse is managed, as shown in Figure 6. This figure shows the main Industry 4.0 technologies most often used in a warehouse, as cited in the literature review (see Section 2.1)

Figure 6.

Warehouse 4.0 technologies.

4. Case Study

4.1. Company Presentation

In an effort to validate my research on the digital transition to Warehouse 4.0, I integrated new Industry 4.0 technologies. My case study is an international food and beverage manufacturing company. This company agreed to engage in this exercise by providing me with the space, time, and data on the production and logistics activities of its warehouse.

The technologies deployed in Warehouse 4.0 generally allow a beverage distribution company to run 60 products, with 12 flavors and five different volumes for each product (2 l, 1.5 l, 0.5 l, and 33 cl). The average amount of production per day is 400,000 units, which reaches 500,000 products per day in the peak seasons. These products are stored in a warehouse (which is the case study) and shipped to customers.

In order to stand out from its competitors, the company wishes to improve and develop the performance of its warehouse by integrating new technologies to improve its reactivity, avoid stockouts, and accurately forecast the flow of products (order and production), while improving its environmental and societal performance. The integration process begins with various identification diagnoses (process, degree of maturity, cause of resistance to change, and technological needs). Following these diagnoses, an action plan is developed for a better digital transition.

4.2. Issues

My case study is a company that seeks to improve its warehouse management by integrating the 4.0 technologies necessary to achieve its performance. Currently, the company’s warehouse relies on a labor force and faces the improvement and optimization of its warehousing processes, through the implementation of technologies to solve problems such as: control of supply to avoid stock shortage, mislocation of lots, optimization of warehouse space, delayed deliveries responsiveness, flexibility, high demand for certain seasons, etc. In order to measure the evolution of the performance, I will establish indicators.

4.3. Diagnostique Multidimensionnel

In order to proceed to the identification of the processes of a logistics warehouse, I started by carrying out, with the help of a diagnosis, an analysis of the existing functioning: which tasks the operators carry out, the time of each task (to evaluate the productivity), the management of the stock, the difficulties, the condition of work, etc.

In parallel, I also evaluated the expectations and fears of the employees that were necessary to succeed in this digital transition project; thirdly, I calculated the degree of digital maturity in order to establish an action plan.

A questionnaire is used in order to calculate the degree of digital maturity and to propose new technologies.

Identifying Process

Before implementing new technologies in the logistics processes of a warehouse, it is necessary to understand what they are and how they work. This allows for an idea of what exists and what can be done to improve things.

Following an established questionnaire, I identified the different processes of the warehouse and the different related activities of the warehouse.

Logistics flows and processes refer to the activities that are carried out successively throughout the life cycle of a product, from its reception to its distribution. This is also referred to as the “value chain” or “activity chain”. These activities include the physical movement of finished products (handling, storage, and shipping) and the flow of information. The processes and activities identified are shown in Figure 7.

Figure 7.

The processes and different activities of the warehouse.

4.4. Relationship between the Most Used 4.0 Technologies in a Warehouse and the Different Functions of Each Process

Warehouse 4.0 takes as a starting point the digitalization, in other words, the integration of 4.0 technologies in the warehouse process. This new trend aims to use technologies such as AI, BD, and cobots; the question is about the effectiveness and usefulness of these technologies for the different stages of storage. To do this, Table 6 summarizes the relationship between the most used 4.0 technologies in a warehouse and the different functions of each process. This result represents a decision aid for the company to choose the technology or technologies suitable for each process. This detailed bibliographic study on the relationship of 4.0 technologies, with the different processes of the warehouse as well as the sustainable contribution of 4.0 technologies in the supply chain, has been presented [61].

Table 6.

The contribution of technology to the warehouse process.

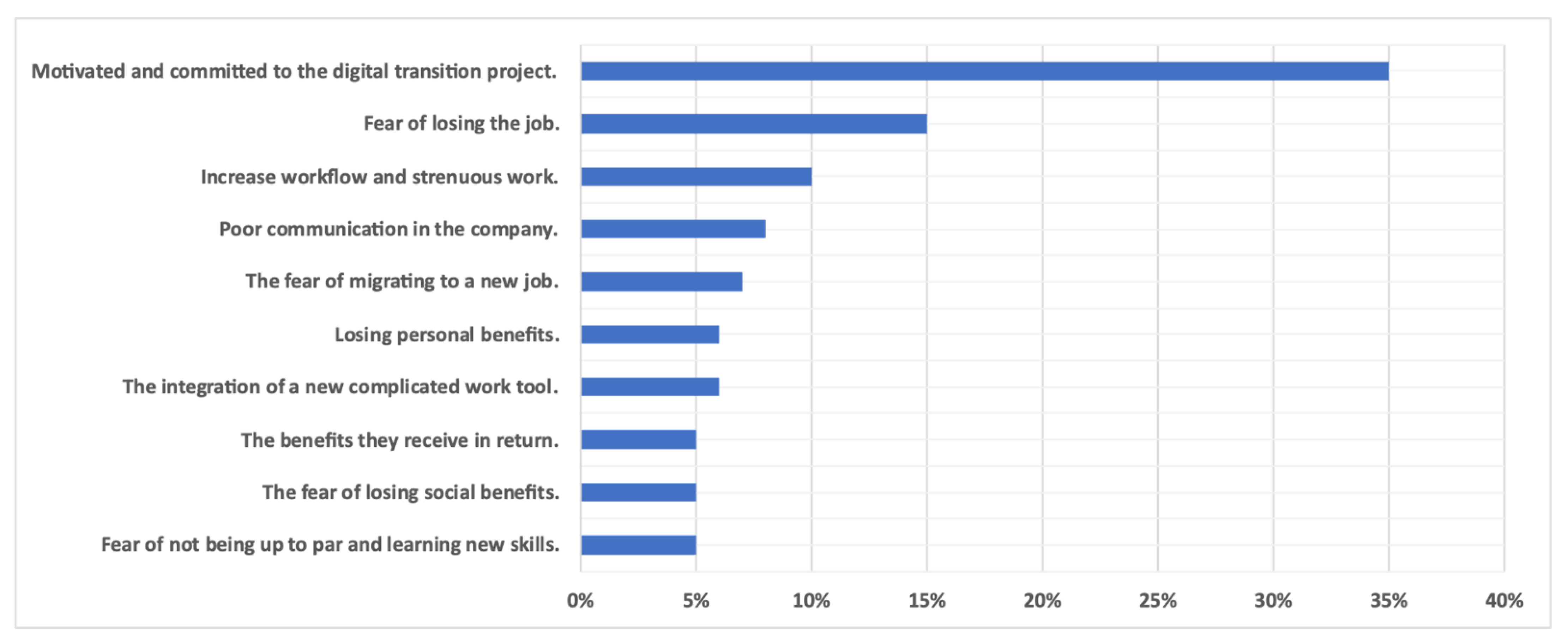

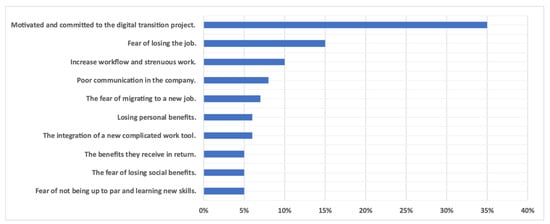

4.5. Risk of Digital Transformation and Solutions Provided by New Technologies

During the process of implementing 4.0 technologies, change managers may be confronted with resistance from employees. It will also be necessary to involve a certain number of stakeholders, so the implementation of this novelty is accepted as easily as possible. The most important challenge during the digital transition has been organizational rather than technological. Before introducing these new technologies, I prepared and made employees aware, a few months in advance, of the changes that would occur. The people-centered approach significantly reduced the resistance to change from employees that I encountered during this process. A diagnosis was carried out at the level of employees, with 100 people out of the 300 employees, to discover their expectations of this digital transition project. The diagnosis conducted includes the following elements [62]:

- -

- Sustainable practices and actions;

- -

- Obstacles and brakes to digitalization.

These are the different key individual or collective factors leading to resistance to change. Among the reasons for resistance, as presented in Figure 8, I cite:

Figure 8.

Main reasons for resistance to change.

- -

- Integration of a new and complicated work tool;

- -

- Fear of losing work;

- -

- Fear of not being up to the task and of acquiring new skills;

- -

- Poor communication from management and within the company;

- -

- Increased workflow and strenuous work;

- -

- Loss of personal benefits;

- -

- Fear of losing social benefits;

- -

- Fear of migrating to a new job;

- -

- Motivation and commitment to the digital transition project;

- -

- Benefits received in return.

Before tackling a digital transition in a company, it is interesting to improve the human factor, to prepare them for the changes. Several authors have worked on this theme such as [63,64]; for this case, I have made a diagnosis that has the objective of learning the opinions of employees about this digitalization project for the warehouse.

In the questionnaire, the majority of employees declared that they were afraid to adhere to the digital transition project, which pushes the company to act and to establish communication links. The latter is one of the essential elements for the digital transition.

Communication has helped to share ideas and to encourage reflection on new ideas for the project, and it has allowed employees to have a better understanding of the project, so that they can adhere to it. This action explained the need for change by the company and identified the benefits for the individual and the whole company. Internal or external training is deemed necessary to help employees improve their digitalization skills and to motivate them to succeed in this project. In this way, the company acquires the human resources needed to overcome the obstacles of digital transformation. To remedy the majority of employees’ fears, the company has prioritized the implementation of human-dimension technologies to improve the working conditions. This is reflected in two actions:

- -

- The technologies developed have made it possible to improve the working conditions on the premises that is becoming connected. They provide optimal security. They manage spaces, obtain accurate data, and are able to make strategic decisions about the use of the work environment. They are intelligent tools for space management, which modify the light according to the time of day and the brightness for the maximum comfort and a reduction in energy consumption, program the temperature of the room according to its occupation and according to the seasons (heating, air conditioning, etc.), and to optimize the air diffusion according to the number of people present in the warehouse.

- -

- The availability of highly advanced handling technologies to eliminate tedious work such as stacker cranes, cobots, etc.

These applications aim to obtain a better management of the premises and also to have a positive influence on the working conditions, to reduce painful work, and to optimize the locations, the well-being, and the motivation of the employees.

4.6. Process Maturity Diagnostics

To do this, I follow the methodology developed earlier in Figure 4 to integrate 4.0 solutions. This step is based on a diagnosis using a questionnaire to calculate the degree of maturity of the different processes of the reception of the product to be bottled, the storage of the products in the warehouse, and then the preparation of orders and shipping, as shown in Table 7.

Table 7.

Diagnostic questionnaire for the warehouse.

The diagnosis that I propose has as objective: to discover the existing as new technology and to propose a digitalization of the warehouse for a company. I have elaborated the questionnaire according to four axes; with this questionnaire (Table 6), it is possible to evaluate the overall maturity of the company for the choice of new technologies.

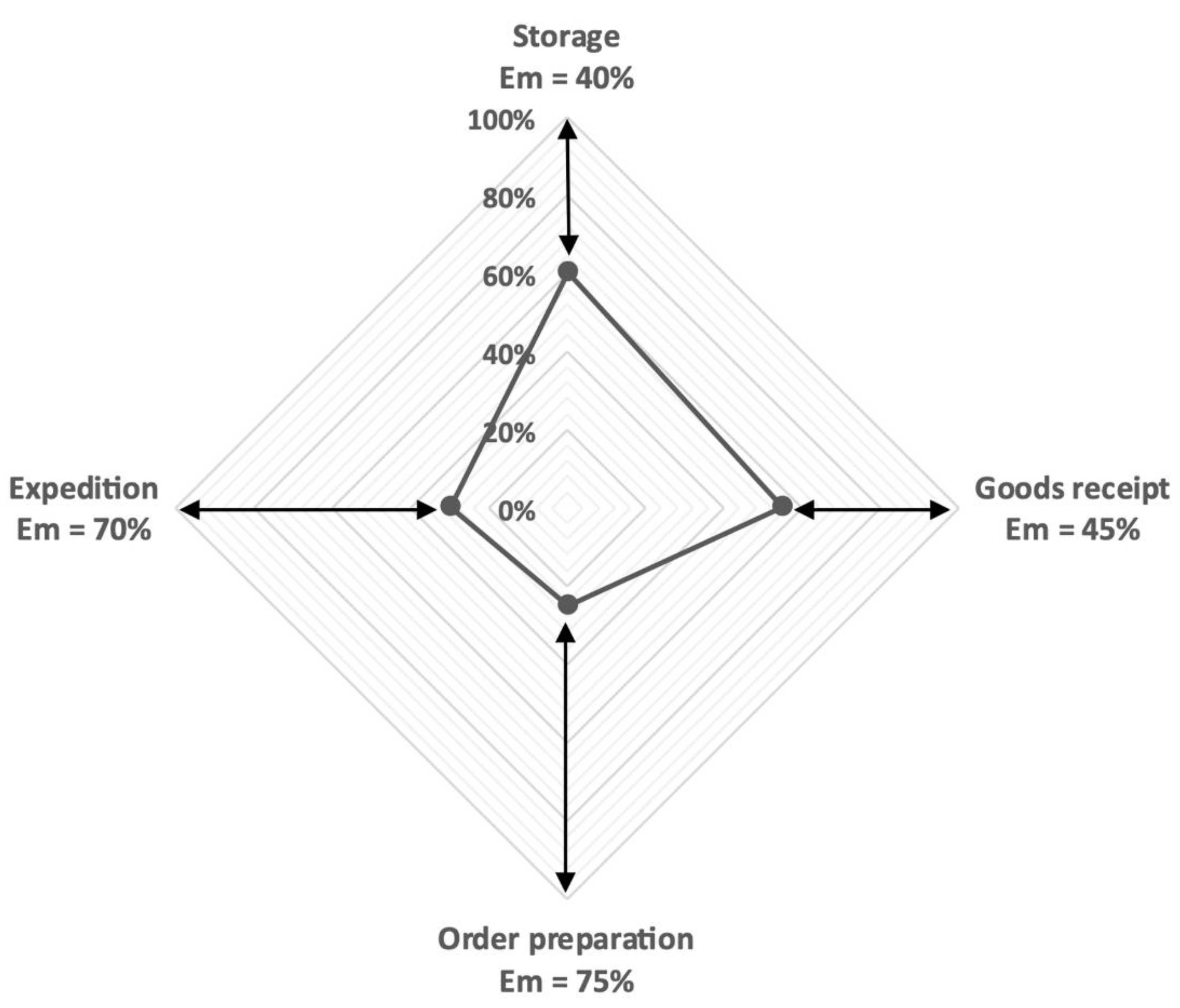

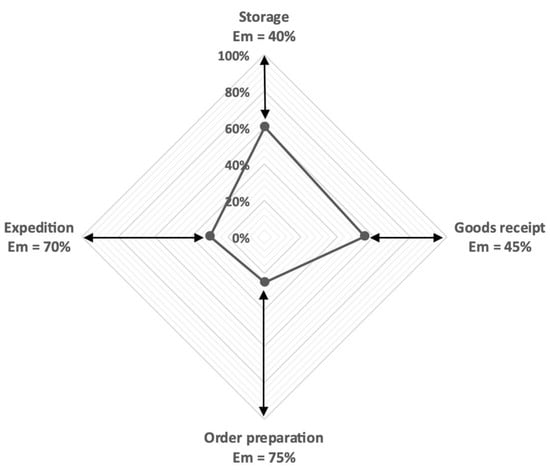

I present, in Figure 9, the result of the calculation of the current degree of maturity obtained by the diagnosis carried out using Equation (1). Following this diagnosis, an action plan is initiated.

Figure 9.

Warehouse digital maturity gap (Em).

The company has certain technologies such as ERP, management software, etc. According to Figure 9, it can be seen that the average digital maturity is less than 50%. The difficulties are mainly at the level of order preparation and shipping; hence, there is the need for an effort to be made by the company. Ie present, in Table 8, the problems identified for each process, their impact on the process, and the proposed solutions.

Table 8.

Detected warehouse problems and associated technologies.

4.7. New Warehouse Design

Warehouses are important elements of the logistics industry, as their operational efficiency determines the operational efficiency of logistics [65]. The transition to Warehouse 4.0 not only solved the problems related to management but also guaranteed real-time warehouse control, eliminating unnecessary and repetitive tasks, reducing the number of accidents, and ensuring a response to customer requirements, by using the following technologies:

- -

- Connectivity 4.0 technology: IOT, augmented reality, RFID, and barcodes;

- -

- Data collection: WMS and ERP;

- -

- Data processing: AI.

In conclusion, this work presents a clear methodology to achieve the digital transformation of a warehouse by using the framework of sustainable development. The objective of this work in the form of the methodology presented in Figure 4 can facilitate the digital transition of the warehouse. This structured approach, composed of different steps, can be considered as a decision-support tool for logistics principals to implement the new technologies of Industry 4.0 in their warehouses.

Performance Indicators for the Digital Warehouse

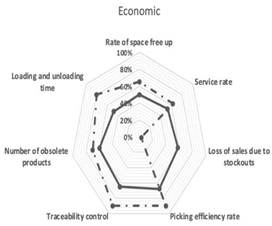

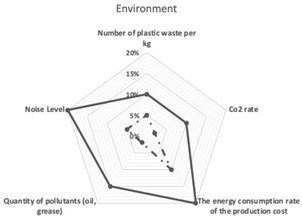

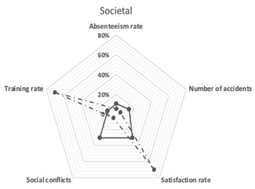

The notion of performance has always been placed in an economic and financial perspective, where shareholder satisfaction was privileged. However, more and more research is associating other non-financial indicators with financial indicators. In fact, the objective is to conceive a multidimensional evaluation where the interests of all actors are now integrated for decision-makers and employees. Indeed, the impact of logical sustainable development is increasingly felt within companies. According to this strategy, companies must then reflect on the practice of economic, environmental, and social/societal indicators [66].

I address the problem of managing logistics activities in a warehouse within the framework of a corporate social responsibility (CSR) approach. I propose an integrated approach that allows to operationalize the evaluation of the performance according to economic, environmental, and social dimensions. The role of the indicators established is to inform managers and executives about the social and environmental impacts of the company’s activities on the one hand and about the quality of relations between the company and its stakeholders on the other hand. They are interested in a new form of performance, environmental or social, which can ultimately have significant impacts on the financial performance of the company [67].

For the monitoring of the different activities, indicators are established to measure the overall economic and financial sustainability, environmental, and societal indicators (see Table 9).

Table 9.

CSR Performance Indicators.

5. Evaluation of the Results Obtained and Discussion

The digital transition of warehouses, which takes into account sustainable development issues, has a very positive impact on warehouse performance.

The company prioritized some technologies to be implemented over others, starting with technologies that improve the well-being of employees. This was a very intelligent choice, to motivate and support the stakeholders to succeed in the company’s digital transition project. Secondly, technologies were implemented to improve process activities: software such as WMS to make processes more flexible and shorten delivery times, artificial intelligence to help with data analysis, the IoT to create a transparent and connected warehouse, and stacker cranes to make better use of warehouse space.

The before and after results measured by the three sustainability indicators are presented in Table 10.

Table 10.

Results obtained.

6. Conclusions

The digitalization of warehouse operations through these new solutions is the most effective strategy to eliminate mistakes and optimize the performance of the warehouse. Industry 4.0 proposes ambitious solutions to meet the market requirements. This work has focused on Warehouse 4.0, explaining the usefulness of new technologies in the warehousing process. The methodology showed how to transfer a conventional warehouse to Warehouse 4.0, making it more efficient.

Through the case study and a diagnostic measurement of the degree of maturity in 4.0 technology, the choice of appropriate technologies has shown that these new tools allow a company to optimize the management of its warehouse at the level of each process and eliminate the related problems, which is justified by the difference between the calculation of the degree of maturity before and after the integration of technologies. This digital transition is presented from a sustainable development perspective. In this sense, the three dimensions (economic, environmental, and social) are taken into account from the start, which has facilitated the success of this project, in particular the clear improvement of the indicators.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Conflicts of Interest

The author declares no conflict of interest.

References

- Edouard, A.; Lamouri, S.; Fortineau, V.; Sallez, Y.; Berger, A. Utilisation des approches de l’industrie 4.0 et de l’internet physique pour le deploiement d’entrepots urbains. In Proceedings of the 13ème Conference Internationale de Modelisation, Optimisation et Simulation (MOSIM2020), Agadir, Morocco, 12–14 November 2020. [Google Scholar]

- Mourdi, K. Farm Storage Management: Mapping, Modeling and Optimization; Laval University: Québec, QC, Canada, 2021; p. 130. [Google Scholar]

- Warehouse Vision Study; Zebra Technologies: Lincolnshire, IL, USA, 2019.

- Warehouse 4.0, the End of a Standard? CBRE: Paris, France, 2017.

- Rakyta, M.; Bubenik, P.; Binasova, V.; Micieta, B.; Staffenova, K. Advanced Logistics Strategy of a Company to Create Sustainable Development in the Industrial Area. Sustainability 2022, 14, 12659. [Google Scholar] [CrossRef]

- Derrouiche, R.; Lamouri, S. Numéro spécial: «Supply Chain 4.0». Logistique Manag. 2020, 28, 1–3. [Google Scholar] [CrossRef]

- Djahara, R.; Sahnoun, M.; Bettayeb, B. Le parc logistique du futur, un acteur d’un développement. In Proceedings of the 27ème Colloque des Sciences de la Conception et de L’innovation (eCONFERE’20), Paris, France, 2 July 2020. [Google Scholar]

- Rogetzer, P.; Nowak, T.; Jammernegg, W.; Wakolbinger, T. Impact de la numérisation sur les chaînes d’approvisionnement durables. In Dans Chancen und Grenzen der Nachhaltigkeitstransformation; Springer Gabler: Wiesbaden, Germany, 2019; pp. 131–144. [Google Scholar]

- Martins, F.D.C.; Simon, A.T.; de Campos, R.S. Supply Chain 4.0 challenges. Gest. Produção 2020, 27, 5427. [Google Scholar] [CrossRef]

- Yavas, V.; Ozkan-Ozen, Y.D. Logistics centers in the new industrial era: A proposed framework for logistics center 4.0. Transp. Res. Part E Logist. Transp. Rev. 2020, 135, 101864. [Google Scholar] [CrossRef]

- Kucharavy, D.; Damand, D.; Chehbi-Gamoura, S.; Barth, M.; Mornay, S. Entrepôt du futur: Le concept de cartographie de contradictions. Logistique Manag. 2019, 28, 48–56. [Google Scholar] [CrossRef]

- Dusadeerungsikul, P.O.; Nof, S.Y. A Cyber Collaborative Protocol for Real-Time Communication and Control in Human-Robot-Sensor Work. Int. J. Comput. Commun. CONTROL 2021, 16. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control 2021, 32, 775–788. [Google Scholar] [CrossRef]

- Halawa, F.; Dauod, H.; Lee, I.G.; Li, Y.; Yoon, S.W.; Chung, S.H. Introduction of a real time location system to enhance the warehouse safety and operational efficiency. Int. J. Prod. Econ. 2020, 224. [Google Scholar] [CrossRef]

- Hamet, P.; Tremblay, J. Artificial intelligence in medicine. Metabolism 2017, 69, S36–S40. [Google Scholar] [CrossRef]

- Silva, N.; Barros, J.; Santos, M.Y.; Costa, C.; Cortez, P.; Carvalho, M.S.; Gonçalves, J.N.C. Advancing Logistics 4.0 with the Implementation of a Big Data Warehouse: A Demonstration Case for the Automotive Industry. Electronics 2021, 10, 2221. [Google Scholar] [CrossRef]

- Radu, L.-D. Green Cloud Computing: A Literature Survey. Symmetry 2017, 9, 295. [Google Scholar] [CrossRef]

- Durand, D.; Gnimpieba Zanfack, D.R.; Sidi Moh, A.N.; Fortin, J. Internet des objets et interopérabilité des flux logistiques: État de l’art et perspectives. In Proceedings of the 10èmes Journées Francophones Mobilité et Ubiquité, Sophia Antipolis, France, 5–6 June 2014. [Google Scholar]

- Kremer, S.; Mé, L.; Rémy, D.; Roca, V. Défis Actuels et Axes de Recherche à l’Inria; Inria Livre Blanc: Rennes, France, 2019. [Google Scholar]

- von Solms, R.; van Niekerk, J. From information security to cyber security. Comput. Secur. 2013, 38, 97–102. [Google Scholar] [CrossRef]

- Seemma, P.S.; Nandhini, S.; Sowmiya, M.M. Overview of Cyber Security. Overview of Cyber Security. Int. J. Adv. Res. Comput. Commun. Eng. 2018, 7, 125–128. [Google Scholar] [CrossRef]

- Mikkola, A. Improving Supply Chain and Logistics and Reducing Costs by Design and Improvement of Packaging with the Help of Lean and DFL; nylio pisto, University of Vaasa: Vaasa, Finland, 2021. [Google Scholar]

- Wu, B.; Chi, X.; Zhao, C.; Zhang, W.; Lu, Y.; Jiang, D. Dynamic Path Planning for Forklift AGV Based on Smoothing A* and Improved DWA Hybrid Algorithm. Sensors 2022, 22, 7079. [Google Scholar] [CrossRef] [PubMed]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Akella, P.; Peshkin, M.; Colgate, E.; Wannasuphoprasit, W.; Nagesh, N.; Wells, J.; Holland, S.; Pearson, T.; Peacock, B. Cobots for the automobile assembly line. In Proceedings of the 1999 IEEE International Conference on Robotics and Automation (Cat. No.99CH36288C), Detroit, MI, USA, 10–15 February 1999; pp. 728–733. [Google Scholar] [CrossRef]

- Sah, B.; Gupta, R.; Bani-Hani, D. Analysis of barriers to implement drone logistics. Int. J. Logist. Res. Appl. 2020, 24, 531–550. [Google Scholar] [CrossRef]

- Claverie, B.; Le Blanc, B.; Fouillat, P. La cobotique. Commun. Organ. 2013, 44, 203–214. [Google Scholar] [CrossRef]

- Bottani, E.; Vignali, G. Augmented reality technology in the manufacturing industry: A review of the last decade. IISE Trans. 2019, 51, 284–310. [Google Scholar] [CrossRef]

- Boulos, M.N.K.; Berry, G. Real-time locating systems (RTLS) in healthcare: A condensed primer. Int. J. Health Geogr. 2012, 11, 25. [Google Scholar] [CrossRef]

- Chen, S.; Brahma, S.; Mackay, J.; Cao, C.; Aliakbarian, B. The role of smart packaging system in food supply chain. J. Food Sci. 2020, 85, 517–525. [Google Scholar] [CrossRef]

- Zhu, X.; Mukhopadhyay, S.K.; Kurata, H. A review of RFID technology and its managerial applications in different industries. J. Eng. Technol. Manag. 2012, 29, 152–167. [Google Scholar] [CrossRef]

- Bouh, M.A. Sélection des Équipements de Manutention et D’entreposage; Polytechnique Montréal, Montréal University: Montreal, QC, Canada, 2017. [Google Scholar]

- Gupta, S.; Prathipati, B.; Dangayach, G.S.; Rao, P.N.; Jagtap, S. Development of a Structural Model for the Adoption of Industry 4.0 Enabled Sustainable Operations for Operational Excellence. Sustainability 2022, 14, 11103. [Google Scholar] [CrossRef]

- Chardine-Baumann, E.; Botta-Genoulaz, V. Prise en considération des problématiques des chaînes logistiques durables dans les référentiels d’évaluation de performance. Logistique Manag. 2009, 17, 31–41. [Google Scholar] [CrossRef]

- Kayikci, Y. Sustainability impact of digitization in logistics. Procedia Manuf. 2018, 21, 782–789. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Évaluer les défis des initiatives de l’industrie 4.0 pour la durabilité de la chaîne d’approvisionnement dans les économies émergentes. Process Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Bhat, R.; Jõudu, I. Emerging issues and challenges in agri-food supply chain. In Sustainable Food Supply Chains; University of Bologna: Bologna, Italy, 2019; pp. 23–37. [Google Scholar] [CrossRef]

- Ait-Daoud, S. Le management Responsable des Technologies de l’Information (MRTI): Entre Approches Éthique et Institutionnelle. Ph.D. Thesis, Montpellier 2, Montpellier, France, 2012. [Google Scholar]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2018, 57, 2117–2135. [Google Scholar] [CrossRef]

- Bennouri, J.; Ouariti, O.P.Z. L’étude de l’impact des innovations technologiques digitales sur la performance durable d’une chaîne logistique: Cas du secteur halio-industriel. In Proceedings of the 13ème Conference Internationale De Modelisation, Optimisation et Simulation (MOSIM2020), Agadir, Morocco, 12–14 November 2020. [Google Scholar]

- Swan, M. Blockchain: Blueprint for a New Economy; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2015. [Google Scholar]

- Chapron, G. The environment needs cryptogovernance. Nature 2017, 545, 403–405. [Google Scholar] [CrossRef]

- Bhat, R. (Ed.) Sustainability Challenges in the Agrofood Sector; John Wiley & Sons: Bogor, Indonisia, 2017. [Google Scholar]

- Davidsson, P.; Hajinasab, B.; Holmgren, J.; Jevinger; Persson, J. A. The Fourth Wave of Digitalization and Public Transport: Opportunities and Challenges. Sustainability 2016, 8, 1248. [Google Scholar] [CrossRef]

- Dossou, P.-E. Impact of Sustainability on the supply chain 4.0 performance. Procedia Manuf. 2018, 17, 452–459. [Google Scholar] [CrossRef]

- de Man, J.C.; Strandhagen, J.O. An Industry 4.0 research agenda for sustainable business models. Procedia CIRP 2017, 63, 721–726. [Google Scholar] [CrossRef]

- Mercier-Laurent, E. Intelligence articielle 4.0 pour l’Industrie 4.0. In Bulletin de la Société Informatique de France; SIF: Paris, Farnce, 2020; pp. 127–137. [Google Scholar]

- Pale, T. La Robotique Collaborative. Promouvoir un Outil de Développement en Jugulant la Faiblesse des Infrastructures Physiques en Afrique. Communication, Technologies et DéVeloppement, 2020. Available online: https://journals.openedition.org/ctd/pdf/2628 (accessed on 28 March 2021).

- Li, J.; Tao, F.; Cheng, Y.; Zhao, L. Big data in product lifecycle management. Int. J. Adv. Manuf. Technol. 2015, 81, 667–684. [Google Scholar] [CrossRef]

- Ngai EW, T.; Peng, S.; Alexander, P.; Moon, K.K. Decision support and intelligent systems in the textile and apparel supply chain: An academic review of research articles. Expert Syst. Appl. 2014, 41, 81–91. [Google Scholar] [CrossRef]

- Kellens, K.; Mertens, R.; Paraskevas, D.; Dewulf, W.; Duflou, J.R. Environmental Impact of Additive Manufacturing Processes: Does AM contribute to a more sustainable way of part manufacturing? Procedia CIRP 2017, 61, 582–587. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic implications of 3D printing: Market structure models in light of additive manufacturing revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Ben-Ner, A.; Siemsen, E. Decentralization and localization of production: The organizational and economic consequences of additive manufacturing (3D printing). Calif. Manag. Rev. 2017, 59, 5–23. [Google Scholar] [CrossRef]

- Hoummady, M.; Lemercier, P.; Boisard, A.S. Evolutions de la Logistique à L’horizon 2025: Enjeux et Impacts du Big Data, de L’Intelligence Artificielle et de la Robotisation, 2015. Available online: https://hal-brgm.archives-ouvertes.fr/hal-01860451/document (accessed on 29 March 2021).

- Rodić, I. Responsabilité Sociale des Entreprises—Le déVeloppement D’un Cadre Européen; European Institute, Geneve Universtiy: Geneve, Switzerland, 2017. [Google Scholar]

- Pacchini AP, T.; Lucato, W.C.; Facchini, F.; Mummolo, G. The degree of readiness for the implementation of Industry 4.0. Comput. Ind. 2019, 113, 103125. [Google Scholar] [CrossRef]

- Lin, T.C.; Wang, K.J.; Sheng, M.L. To assess smart manufacturing readiness by maturity model: A case study on Taiwan enterprises. Int. J. Comput. Integr. Manuf. 2020, 33, 102–115. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Schumacher, A.; Erol, S.; Sihn, W. A Maturity Model for Assessing Industry 4.0 Readiness and Maturity of Manufacturing Enterprises, 2016. Available online: https://publik.tuwien.ac.at/files/publik_255446.pdf (accessed on 8 April 2021).

- Hassani, A. Industry 4.0 and Key Project Success Factors; Quebec University: Quebec, QC, Canada, 2020. [Google Scholar]

- El Kihel, Y.; El Kihel, A.; Bouyahrouzi, E.M. Contribution of Maintenance 4.0 in Sustainable Development with an Industrial Case Study. Sustainability 2022, 14, 11090. [Google Scholar] [CrossRef]

- Mhaezi, H. Sustainable Supply Chain in Morocco: State of Play, Motivations and Obstacles, Casablanca, Morocco, 2016. Available online: https://revues.imist.ma/index.php/MLS/article/view/6812/4084 (accessed on 8 April 2021).

- Foshay, N.; Mukherjee, A.; Taylor, A. Does data warehouse end user metadata add value? Commun. ACM 2007, 50, 70–77. [Google Scholar] [CrossRef]

- Desmet, P.; Fokkinga, S. Beyond Maslow’s pyramid: Introducing a typology of thirteen basic needs for human-centered design. Multimodal Technol. Interact. 2020, 4, 38. [Google Scholar] [CrossRef]

- Hong-Ying, S. The application of barcode technology in logistics and warehouse management. In Proceedings of the 2009 First International Workshop on Education Technology and Computer Science, Wuhan, China, 7–8 March 2009; Volume 3, pp. 732–735. [Google Scholar]

- Tadesse, M.D.; Kine, H.Z.; Gebresenbet, G.; Tavasszy, L.; Ljungberg, D. Key Logistics Performance Indicators in Low-Income Countries: The Case of the Import–Export Chain in Ethiopia. Sustainability 2022, 14, 12204. [Google Scholar] [CrossRef]

- Preston, L.E.; O’bannon, D.P. The corporate social-financial performance relationship: A typology and analysis. Bus. Soc. 1997, 36, 419–429. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).