Effect of PdNiBi Metal Content: Cost Reduction in Alkaline Direct Ethanol Fuel Cells

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

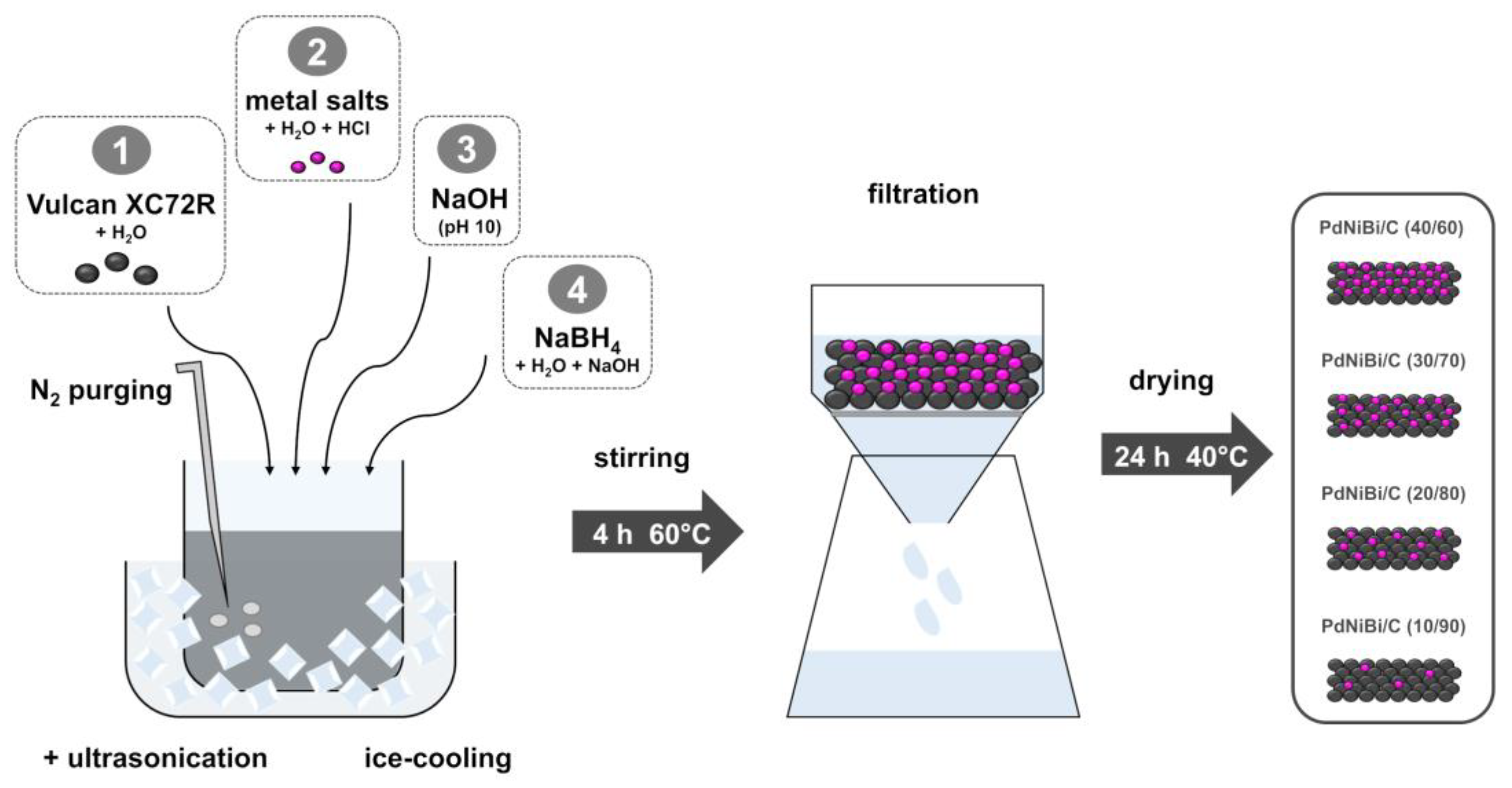

2.2. Catalyst Synthesis

2.3. Physicochemical Characterization

2.4. Electrochemical Characterization

2.5. Cell Performance Measurement

3. Results and Discussion

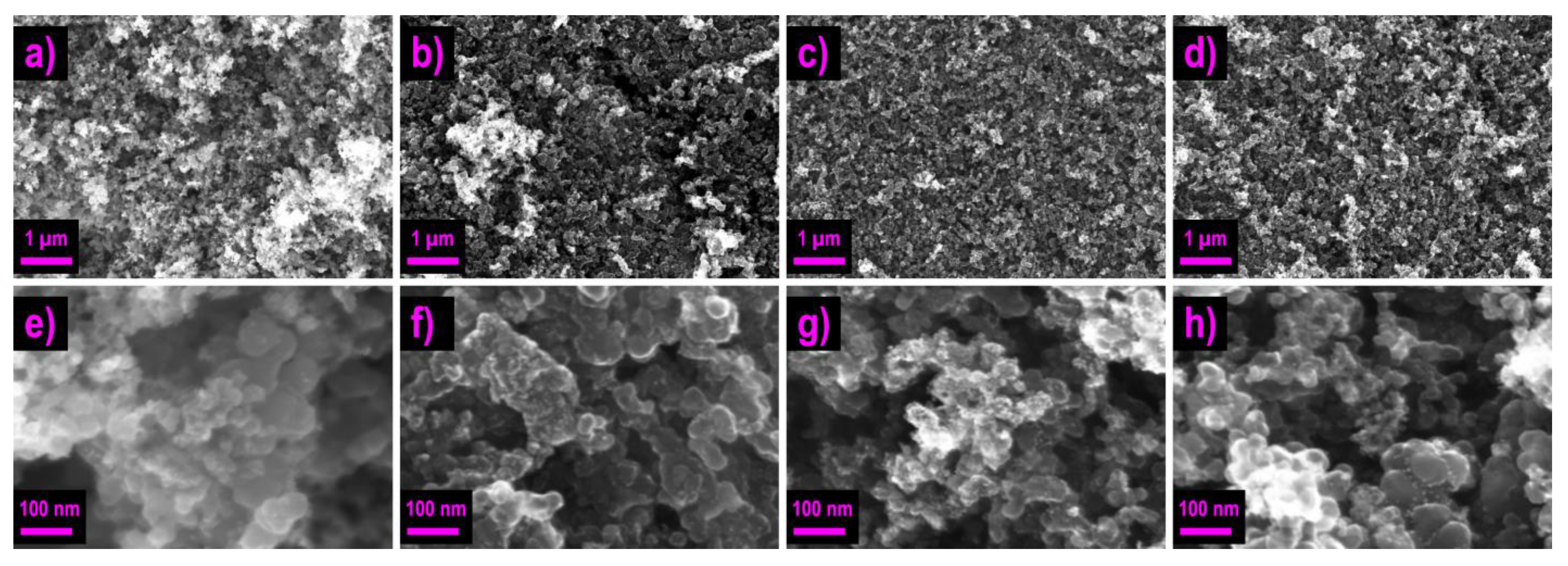

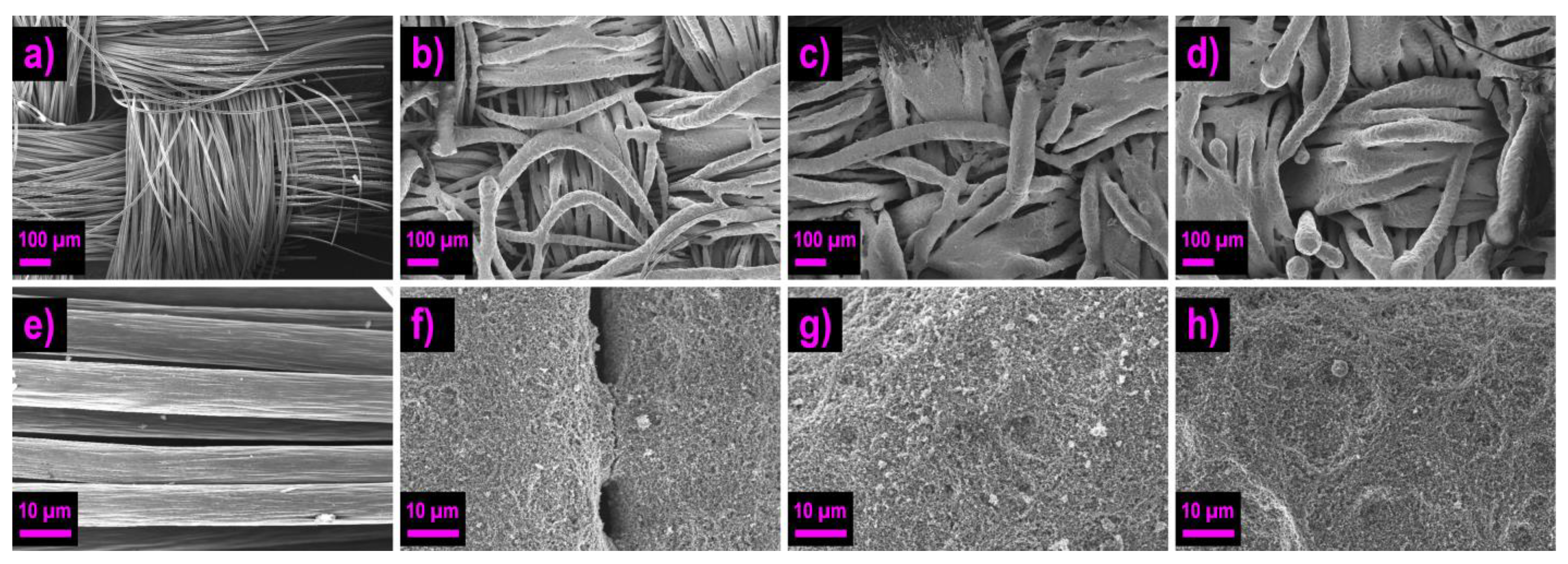

3.1. Physicochemical Characterization

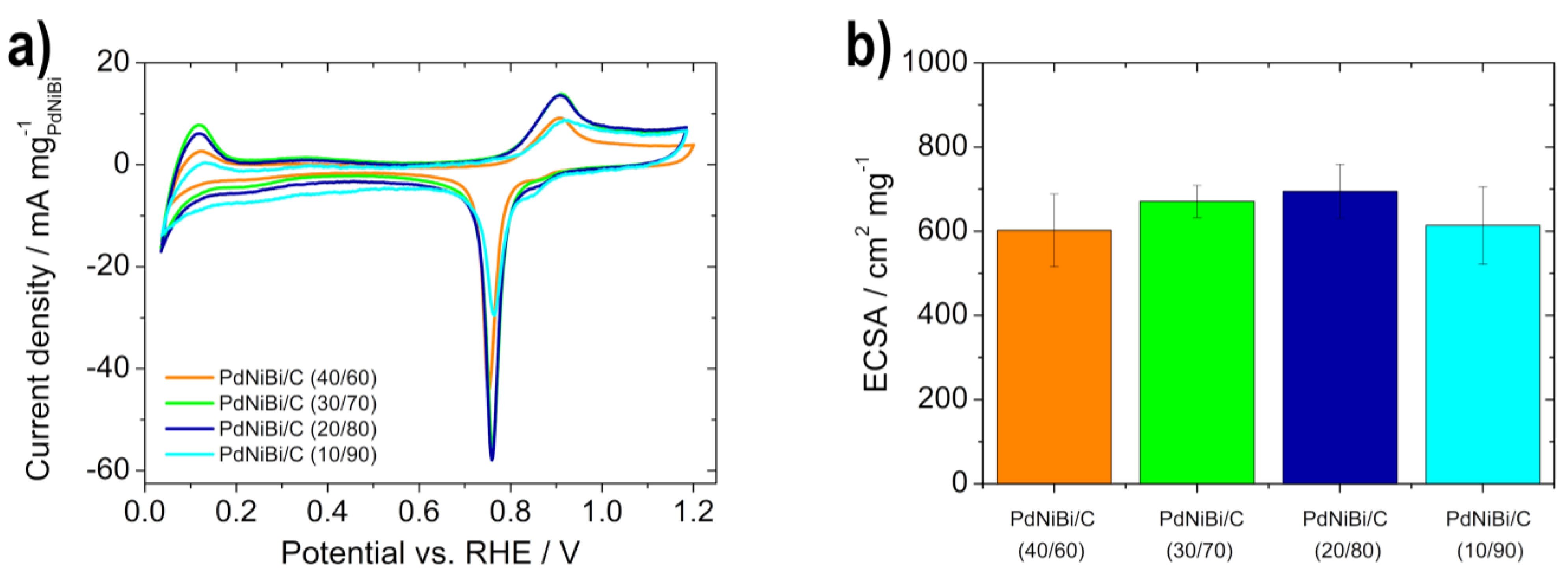

3.2. Electrochemical Characterization

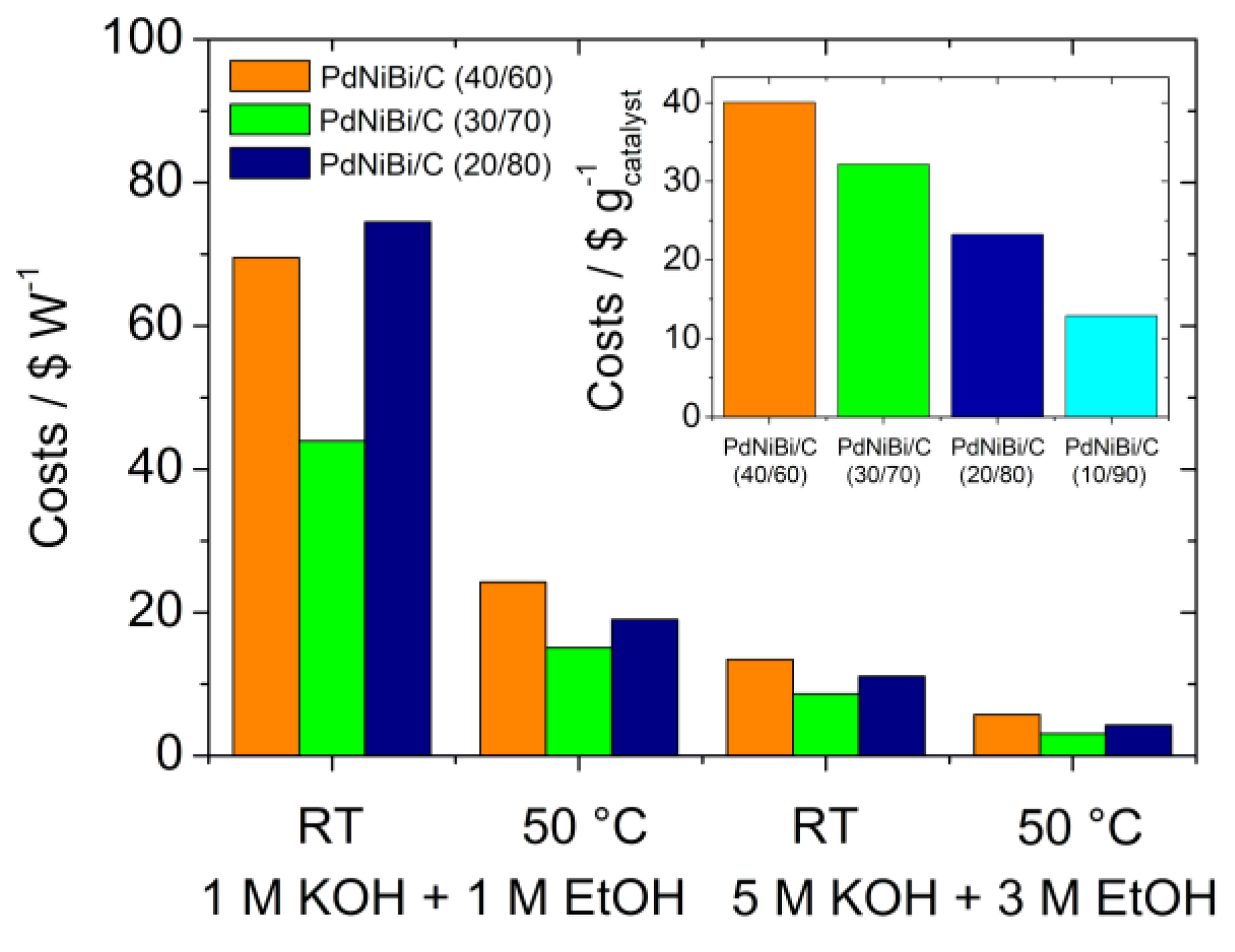

3.3. Cell Performance Measurement and Cost Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, T.S.; Li, Y.S.; Shen, S.Y. Anion-Exchange Membrane Direct Ethanol Fuel Cells: Status and Perspective. Front. Energy Power Eng. China 2010, 4, 443–458. [Google Scholar] [CrossRef]

- An, L.; Zhao, T.S.; Li, Y.S. Carbon-Neutral Sustainable Energy Technology: Direct Ethanol Fuel Cells. Renew. Sustain. Energy Rev. 2015, 50, 1462–1468. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The Role of Renewable Energy in the Global Energy Transformation. Energy Strateg. Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Shindell, D.; Smith, C.J. Climate and Air-Quality Benefits of a Realistic Phase-out of Fossil Fuels. Nature 2019, 573, 408–411. [Google Scholar] [CrossRef] [PubMed]

- Wolf, S.; Roschger, M.; Genorio, B.; Kolar, M.; Garstenauer, D.; Bitschnau, B.; Hacker, V. Ag-MnxOy on Graphene Oxide Derivatives as Oxygen Reduction Reaction Catalyst in Alkaline Direct Ethanol Fuel Cells. Catalysts 2022, 12, 780. [Google Scholar] [CrossRef]

- Yu, E.H.; Wang, X.; Krewer, U.; Li, L.; Scott, K. Direct Oxidation Alkaline Fuel Cells: From Materials to Systems. Energy Environ. Sci. 2012, 5, 5668–5680. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, F.F.; Yang, Y.Y.; Cai, W. Bin. Carbon Supported Pd-Ni-P Nanoalloy as an Efficient Catalyst for Ethanol Electro-Oxidation in Alkaline Media. J. Power Sources 2013, 243, 369–373. [Google Scholar] [CrossRef]

- Wu, Q.; Jiang, L.; Qi, L.; Yuan, L.; Wang, E.; Sun, G. Electrocatalytic Activity and Stability of Ag-MnOx/C Composites toward Oxygen Reduction Reaction in Alkaline Solution. Electrochim. Acta 2014, 123, 167–175. [Google Scholar] [CrossRef]

- Neto, A.O.; Tusi, M.M.; De Oliveira Polanco, N.S.; Da Silva, S.G.; Coelho Dos Santos, M.; Spinacé, E.V. PdBi/C Electrocatalysts for Ethanol Electro-Oxidation in Alkaline Medium. Int. J. Hydrogen Energy 2011, 36, 10522–10526. [Google Scholar] [CrossRef]

- Roschger, M.; Wolf, S.; Mayer, K.; Singer, M.; Hacker, V. Alkaline Direct Ethanol Fuel Cell: Effect of the Anode Flow Field Design and the Setup Parameters on Performance. Energies 2022, 15, 7234. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of Renewable Energy Sources in Environmental Protection: A Review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Muktham, R.; Bhargava, K.S.; Bankupalli, S.; Ball, A. A Review on 1st and 2nd Generation Bioethanol Production-Recent Progress. J. Sustain. Bioenergy Syst. 2016, 6, 72–92. [Google Scholar] [CrossRef]

- Shen, S.Y.; Zhao, T.S.; Wu, Q.X. Product Analysis of the Ethanol Oxidation Reaction on Palladium-Based Catalysts in an Anion-Exchange Membrane Fuel Cell Environment. Int. J. Hydrogen Energy 2012, 37, 575–582. [Google Scholar] [CrossRef]

- An, L.; Zhao, T.S. Transport Phenomena in Alkaline Direct Ethanol Fuel Cells for Sustainable Energy Production. J. Power Sources 2017, 341, 199–211. [Google Scholar] [CrossRef]

- Antolini, E. Catalysts for Direct Ethanol Fuel Cells. J. Power Sources 2007, 170, 1–12. [Google Scholar] [CrossRef]

- Zhang, Z.; Xin, L.; Sun, K.; Li, W. Pd-Ni Electrocatalysts for Efficient Ethanol Oxidation Reaction in Alkaline Electrolyte. Int. J. Hydrogen Energy 2011, 36, 12686–12697. [Google Scholar] [CrossRef]

- Shen, S.Y.; Zhao, T.S.; Xu, J.B.; Li, Y.S. Synthesis of PdNi Catalysts for the Oxidation of Ethanol in Alkaline Direct Ethanol Fuel Cells. J. Power Sources 2010, 195, 1001–1006. [Google Scholar] [CrossRef]

- Bilgen, S. Structure and Environmental Impact of Global Energy Consumption. Renew. Sustain. Energy Rev. 2014, 38, 890–902. [Google Scholar] [CrossRef]

- Kamarudin, M.Z.F.; Kamarudin, S.K.; Masdar, M.S.; Daud, W.R.W. Review: Direct Ethanol Fuel Cells. Int. J. Hydrogen Energy 2013, 38, 9438–9453. [Google Scholar] [CrossRef]

- Ma, L.; Chu, D.; Chen, R. Comparison of Ethanol Electro-Oxidation on Pt/C and Pd/C Catalysts in Alkaline Media. Int. J. Hydrogen Energy 2012, 37, 11185–11194. [Google Scholar] [CrossRef]

- Geraldes, A.N.; Da Silva, D.F.; Pino, E.S.; Da Silva, J.C.M.; De Souza, R.F.B.; Hammer, P.; Spinacé, E.V.; Neto, A.O.; Linardi, M.; Dos Santos, M.C. Ethanol Electro-Oxidation in an Alkaline Medium Using Pd/C, Au/C and PdAu/C Electrocatalysts Prepared by Electron Beam Irradiation. Electrochim. Acta 2013, 111, 455–465. [Google Scholar] [CrossRef]

- Wang, L.; Lavacchi, A.; Bevilacqua, M.; Bellini, M.; Fornasiero, P.; Filippi, J.; Innocenti, M.; Marchionni, A.; Miller, H.A.; Vizza, F. Energy Efficiency of Alkaline Direct Ethanol Fuel Cells Employing Nanostructured Palladium Electrocatalysts. Chem. Cat. Chem. 2015, 7, 2214–2221. [Google Scholar] [CrossRef]

- Lafforgue, C.; Maillard, F.; Martin, V.; Dubau, L.; Chatenet, M. Degradation of Carbon-Supported Platinum-Group-Metal Electrocatalysts in Alkaline Media Studied by in Situ Fourier Transform Infrared Spectroscopy and Identical-Location Transmission Electron Microscopy. ACS Catal. 2019, 9, 5613–5622. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, H.; Li, X.; Xia, F.; Liu, Y.; Xu, X.; Gao, J.; Xing, F. One-Step Synthesis of Palladium-Gold-Silver Ternary Nanoparticles Supported on Reduced Graphene Oxide for the Electrooxidation of Methanol and Ethanol. Electrochim. Acta 2015, 172, 42–51. [Google Scholar] [CrossRef]

- Cai, J.; Huang, Y.; Guo, Y. Bi-Modified Pd/C Catalyst via Irreversible Adsorption and Its Catalytic Activity for Ethanol Oxidation in Alkaline Medium. Electrochim. Acta 2013, 99, 22–29. [Google Scholar] [CrossRef]

- Tan, J.L.; De Jesus, A.M.; Chua, S.L.; Sanetuntikul, J.; Shanmugam, S.; Tongol, B.J.V.; Kim, H. Preparation and Characterization of Palladium-Nickel on Graphene Oxide Support as Anode Catalyst for Alkaline Direct Ethanol Fuel Cell. Appl. Catal. A Gen. 2017, 531, 29–35. [Google Scholar] [CrossRef]

- Su, P.C.; Chen, H.S.; Chen, T.Y.; Liu, C.W.; Lee, C.H.; Lee, J.F.; Chan, T.S.; Wang, K.W. Enhancement of Electrochemical Properties of Pd/C Catalysts toward Ethanol Oxidation Reaction in Alkaline Solution through Ni and Au Alloying. Int. J. Hydrogen Energy 2013, 38, 4474–4482. [Google Scholar] [CrossRef]

- Ma, L.; He, H.; Hsu, A.; Chen, R. PdRu/C Catalysts for Ethanol Oxidation in Anion-Exchange Membrane Direct Ethanol Fuel Cells. J. Power Sources 2013, 241, 696–702. [Google Scholar] [CrossRef]

- Zhu, F.; Wang, M.; He, Y.; Ma, G.; Zhang, Z.; Wang, X. A Comparative Study of Elemental Additives (Ni, Co and Ag) on Electrocatalytic Activity Improvement of PdSn-Based Catalysts for Ethanol and Formic Acid Electro-Oxidation. Electrochim. Acta 2014, 148, 291–301. [Google Scholar] [CrossRef]

- Guo, J.; Chen, R.; Zhu, F.C.; Sun, S.G.; Villullas, H.M. New Understandings of Ethanol Oxidation Reaction Mechanism on Pd/C and Pd2Ru/C Catalysts in Alkaline Direct Ethanol Fuel Cells. Appl. Catal. B Environ. 2018, 224, 602–611. [Google Scholar] [CrossRef]

- Sekol, R.C.; Carmo, M.; Kumar, G.; Gittleson, F.; Doubek, G.; Sun, K.; Schroers, J.; Taylor, A.D. Pd-Ni-Cu-P Metallic Glass Nanowires for Methanol and Ethanol Oxidation in Alkaline Media. Int. J. Hydrogen Energy 2013, 38, 11248–11255. [Google Scholar] [CrossRef]

- Tusi, M.M.; Polanco, N.S.O.; Da Silva, S.G.; Spinacé, E.V.; Neto, A.O. The High Activity of PtBi/C Electrocatalysts for Ethanol Electro-Oxidation in Alkaline Medium. Electrochem. Commun. 2011, 13, 143–146. [Google Scholar] [CrossRef]

- Cermenek, B.; Ranninger, J.; Feketeföldi, B.; Letofsky-Papst, I.; Kienzl, N.; Bitschnau, B.; Hacker, V. Novel Highly Active Carbon Supported Ternary PdNiBi Nanoparticles as Anode Catalyst for the Alkaline Direct Ethanol Fuel Cell. Nano Res. 2019, 12, 683–693. [Google Scholar] [CrossRef]

- Cermenek, B.; Genorio, B.; Winter, T.; Wolf, S.; Connell, J.G.; Roschger, M.; Letofsky-Papst, I.; Kienzl, N.; Bitschnau, B.; Hacker, V. Alkaline Ethanol Oxidation Reaction on Carbon Supported Ternary PdNiBi Nanocatalyst Using Modified Instant Reduction Synthesis Method. Electrocatalysis 2020, 11, 203–214. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Ye, S. Recent Advances in Activity and Durability Enhancement of Pt/C Catalytic Cathode in PEMFC. Part I. Physico-Chemical and Electronic Interaction between Pt and Carbon Support, and Activity Enhancement of Pt/C Catalyst. J. Power Sources 2007, 172, 133–144. [Google Scholar] [CrossRef]

- Kim, M.; Park, J.N.; Kim, H.; Song, S.; Lee, W.H. The Preparation of Pt/C Catalysts Using Various Carbon Materials for the Cathode of PEMFC. J. Power Sources 2006, 163, 93–97. [Google Scholar] [CrossRef]

- Tang, S.; Sun, G.; Qi, J.; Sun, S.; Guo, J.; Xin, Q.; Haarberg, G.M. Review of New Carbon Materials as Catalyst Supports in Direct Alcohol Fuel Cells. Chinese J. Catal. 2010, 31, 12–17. [Google Scholar] [CrossRef]

- Lobato, J.; Cañizares, P.; Ubeda, D.; Pinar, F.J.; Rodrigo, M.A. Testing PtRu/CNF Catalysts for a High Temperature Polybenzimidazole-Based Direct Ethanol Fuel Cell. Effect of Metal Content. Appl. Catal. B Environ. 2011, 106, 174–180. [Google Scholar] [CrossRef]

- Darab, M.; Barnett, A.O.; Lindbergh, G.; Thomassen, M.S.; Sunde, S. The Influence of Catalyst Layer Thickness on the Performance and Degradation of PEM Fuel Cell Cathodes with Constant Catalyst Loading. Electrochim. Acta 2017, 232, 505–516. [Google Scholar] [CrossRef]

- Yong, Y.W.; Azam, A.M.I.N.; Masdar, M.S.; Zainoodin, A.M.; Kamarudin, S.K. Anode Structure with Double-Catalyst Layers for Improving the Direct Ethanol Fuel Cell Performance. Int. J. Hydrogen Energy 2020, 45, 22302–22314. [Google Scholar] [CrossRef]

- Ekdharmasuit, P.; Therdthianwong, A.; Therdthianwong, S. Anode Structure Design for Generating High Stable Power Output for Direct Ethanol Fuel Cells. Fuel 2013, 113, 69–76. [Google Scholar] [CrossRef]

- Abdullah, S.; Kamarudin, S.K.; Hasran, U.A.; Masdar, M.S.; Daud, W.R.W. Electrochemical Kinetic and Mass Transfer Model for Direct Ethanol Alkaline Fuel Cell (DEAFC). J. Power Sources 2016, 320, 111–119. [Google Scholar] [CrossRef]

- James, D.D.; Pickup, P.G. Effects of Crossover on Product Yields Measured for Direct Ethanol Fuel Cells. Electrochim. Acta 2010, 55, 3824–3829. [Google Scholar] [CrossRef]

- Sundar Pethaiah, S.; Arunkumar, J.; Ramos, M.; Al-Jumaily, A.; Manivannan, N. The Impact of Anode Design on Fuel Crossover of Direct Ethanol Fuel Cell. Bull. Mater. Sci 2016, 39, 273–278. [Google Scholar] [CrossRef]

- Alzate, V.; Fatih, K.; Wang, H. Effect of Operating Parameters and Anode Diffusion Layer on the Direct Ethanol Fuel Cell Performance. J. Power Sources 2011, 196, 10625–10631. [Google Scholar] [CrossRef]

- Moreno-Jiménez, D.A.; Pacheco-Catalán, D.E.; Ordóñez, L.C. Influence of MEA Catalytic Layer Location and Air Supply on Open-CathodeDirect Ethanol Fuel Cell Performance. Int. J. Electrochem. Sci. 2015, 10, 8808–8822. [Google Scholar]

- Song, S.; Wang, G.; Zhou, W.; Zhao, X.; Sun, G.; Xin, Q.; Kontou, S.; Tsiakaras, P. The Effect of the MEA Preparation Procedure on Both Ethanol Crossover and DEFC Performance. J. Power Sources 2005, 140, 103–110. [Google Scholar] [CrossRef]

- Mayrhofer, K.J.J.; Strmcnik, D.; Blizanac, B.B.; Stamenkovic, V.; Arenz, M.; Markovic, N.M. Measurement of Oxygen Reduction Activities via the Rotating Disc Electrode Method: From Pt Model Surfaces to Carbon-Supported High Surface Area Catalysts. Electrochim. Acta 2008, 53, 3181–3188. [Google Scholar] [CrossRef]

- Grandi, M.; Mayer, K.; Gatalo, M.; Kapun, G.; Ruiz-Zepeda, F.; Marius, B.; Gaberšček, M.; Hacker, V. The Influence Catalyst Layer Thickness on Resistance Contributions of PEMFC Determined by Electrochemical Impedance Spectroscopy. Energies 2021, 14, 7299. [Google Scholar] [CrossRef]

- Casella, I.G.; Contursi, M. Characterization of Bismuth Adatom-Modified Palladium Electrodes. The Electrocatalytic Oxidation of Aliphatic Aldehydes in Alkaline Solutions. Electrochim. Acta 2006, 52, 649–657. [Google Scholar] [CrossRef]

- Simões, M.; Baranton, S.; Coutanceau, C. Influence of Bismuth on the Structure and Activity of Pt and Pd Nanocatalysts for the Direct Electrooxidation of NaBH4. Electrochim. Acta 2010, 56, 580–591. [Google Scholar] [CrossRef]

- Singh, R.N.; Singh, A.; Anindita. Electrocatalytic Activity of Binary and Ternary Composite Films of Pd, MWCNT, and Ni for Ethanol Electro-Oxidation in Alkaline Solutions. Carbon N.Y. 2009, 47, 271–278. [Google Scholar] [CrossRef]

- Jongsomjit, S.; Prapainainar, P.; Sombatmankhong, K. Synthesis and Characterisation of Pd-Ni-Sn Electrocatalyst for Use in Direct Ethanol Fuel Cells. Solid State Ionics 2016, 288, 147–153. [Google Scholar] [CrossRef]

- Liang, Z.X.; Zhao, T.S.; Xu, J.B.; Zhu, L.D. Mechanism Study of the Ethanol Oxidation Reaction on Palladium in Alkaline Media. Electrochim. Acta 2009, 54, 2203–2208. [Google Scholar] [CrossRef]

- Hofstead-Duffy, A.M.; Chen, D.J.; Sun, S.G.; Tong, Y.J. Origin of the Current Peak of Negative Scan in the Cyclic Voltammetry of Methanol Electro-Oxidation on Pt-Based Electrocatalysts: A Revisit to the Current Ratio Criterion. J. Mater. Chem. 2012, 22, 5205–5208. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, X.; Schechter, J.M.; Yang, Y. Revisiting the Oxidation Peak in the Cathodic Scan of the Cyclic Voltammogram of Alcohol Oxidation on Noble Metal Electrodes. RSC Adv. 2016, 6, 5384–5390. [Google Scholar] [CrossRef]

| Catalysts | Measured | Calculated | ||||||

|---|---|---|---|---|---|---|---|---|

| Pd | Ni | Bi | Totalmetal | Pd | Ni | Bi | Totalmetal | |

| PdNiBi/C (40/60) | 33.7 | 2.2 | 4.7 | 40.6 | 33.9 | 2.2 | 3.9 | 40 |

| PdNiBi/C (30/70) | 27.0 | 1.8 | 3.4 | 32.2 | 25.4 | 1.7 | 2.9 | 30 |

| PdNiBi/C (20/80) | 17.4 | 1.2 | 2.6 | 21.2 | 16.9 | 1.1 | 2.0 | 20 |

| PdNiBi/C (10/90) | 8.6 | 0.5 | 1.3 | 10.4 | 8.5 | 0.5 | 1.0 | 10 |

| Catalyst | ECSA/cm2 mg−1 | Eonseta/V vs. RHE | jfb/A mg−1 | jbb/A mg−1 | Qfc/C mg−1 | Qbc/C mg−1 | jdd/% |

|---|---|---|---|---|---|---|---|

| PdNiBi/C (40/60) | 602 ± 87.0 | 0.20 ± 0.01 | 2.42 ± 0.13 | 1.84 ± 0.38 | 88.2 ± 9.18 | 25.3 ± 3.24 | 75.8 ± 9.8 |

| PdNiBi/C (30/70) | 671 ± 38.3 | 0.20 ± 0.02 | 3.00 ± 0.14 | 3.05 ± 0.45 | 83.2 ± 4.18 | 36.8 ± 3.94 | 78.9 ± 5.1 |

| PdNiBi/C (20/80) | 695 ± 64.3 | 0.24 ± 0.01 | 3.72 ± 0.33 | 3.70 ± 0.74 | 94.8 ± 3.25 | 43.2 ± 6.95 | 85.7 ± 3.2 |

| PdNiBi/C (10/90) | 614 ± 92.1 | 0.30 ± 0.02 | 3.67 ± 0.79 | 3.69 ± 1.02 | 78.5 ± 18.1 | 46.9 ± 10.0 | 97.1 ± 1.8 |

| Catalyst a | Scan Rate/mV s−1 | Electrolyte + EtOH Concentration | Eonset/V vs. RE b | jf/mA mg−1 | jb/mA mg−1 | Ref. |

|---|---|---|---|---|---|---|

| comm. Pd/C | 10 | 1 M NaOH + 1 M EtOH | - | ~1400 | ~1900 | [20] |

| Pd2Ni1/C | 50 | 1 M NaOH + 1 M EtOH | −0.758 vs. Hg/HgO | 2956.6 | ~3400 | [16] |

| PdBi/C | 50 | 1 M KOH + 1 M EtOH | −0.75 vs. Hg/HgO | 5667 | - | [25] |

| PdNiP/C | 50 | 0.5 M NaOH + 1 M EtOH | −0.61 vs. SCE | 2533 | ~2400 | [7] |

| Pd2Sn2Ni1/C | 50 | 1 M KOH + 1 M EtOH | −0.50 vs. Hg/HgO | 463 | ~350 | [29] |

| Pd20%Ni10%Sn10%/CB | 50 | 1 M KOH + 1 M EtOH | −0.564 vs. Ag/AgCl | 2151 | - | [53] |

| PdNiBi/C (30/70) * | 10 | 1 M KOH + 1 M EtOH | 0.20 vs. RHE | 3000 | 3050 | This study |

| PdNiBi/C (20/80) * | 10 | 1 M KOH + 1 M EtOH | 0.24 vs. RHE | 3720 | 3700 | This study |

| PdNiBi/C (10/90) * | 10 | 1 M KOH + 1 M EtOH | 0.30 vs. RHE | 3670 | 3690 | This study |

| Catalyst | Open Circuit Voltage/V | Pmax/mW mg−1PdNiBi | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 M KOH + 1 M EtOH | 5 M KOH + 3 M EtOH | 1 M KOH + 1 M EtOH | 5 M KOH + 3 M EtOH | |||||

| RT | 50 °C | RT | 50 °C | RT | 50 °C | RT | 50 °C | |

| PdNiBi/C (40/60) | 0.92 | 0.93 | 0.96 | 1.05 | 1.43 | 4.14 | 7.46 | 17.5 |

| PdNiBi/C (30/70) | 0.87 | 0.93 | 0.93 | 1.05 | 2.44 | 7.11 | 12.4 | 34.8 |

| PdNiBi/C (20/80) | 0.87 | 0.95 | 0.98 | 1.08 | 1.56 | 6.11 | 10.5 | 27.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roschger, M.; Wolf, S.; Genorio, B.; Hacker, V. Effect of PdNiBi Metal Content: Cost Reduction in Alkaline Direct Ethanol Fuel Cells. Sustainability 2022, 14, 15485. https://doi.org/10.3390/su142215485

Roschger M, Wolf S, Genorio B, Hacker V. Effect of PdNiBi Metal Content: Cost Reduction in Alkaline Direct Ethanol Fuel Cells. Sustainability. 2022; 14(22):15485. https://doi.org/10.3390/su142215485

Chicago/Turabian StyleRoschger, Michaela, Sigrid Wolf, Boštjan Genorio, and Viktor Hacker. 2022. "Effect of PdNiBi Metal Content: Cost Reduction in Alkaline Direct Ethanol Fuel Cells" Sustainability 14, no. 22: 15485. https://doi.org/10.3390/su142215485

APA StyleRoschger, M., Wolf, S., Genorio, B., & Hacker, V. (2022). Effect of PdNiBi Metal Content: Cost Reduction in Alkaline Direct Ethanol Fuel Cells. Sustainability, 14(22), 15485. https://doi.org/10.3390/su142215485