Thermal and Thermal-Oxidative Molecular Degradation of Polystyrene and Acrylonitrile Butadiene Styrene during 3D Printing Starting from Filaments and Pellets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

Filament Fabrication

2.3. Characterization

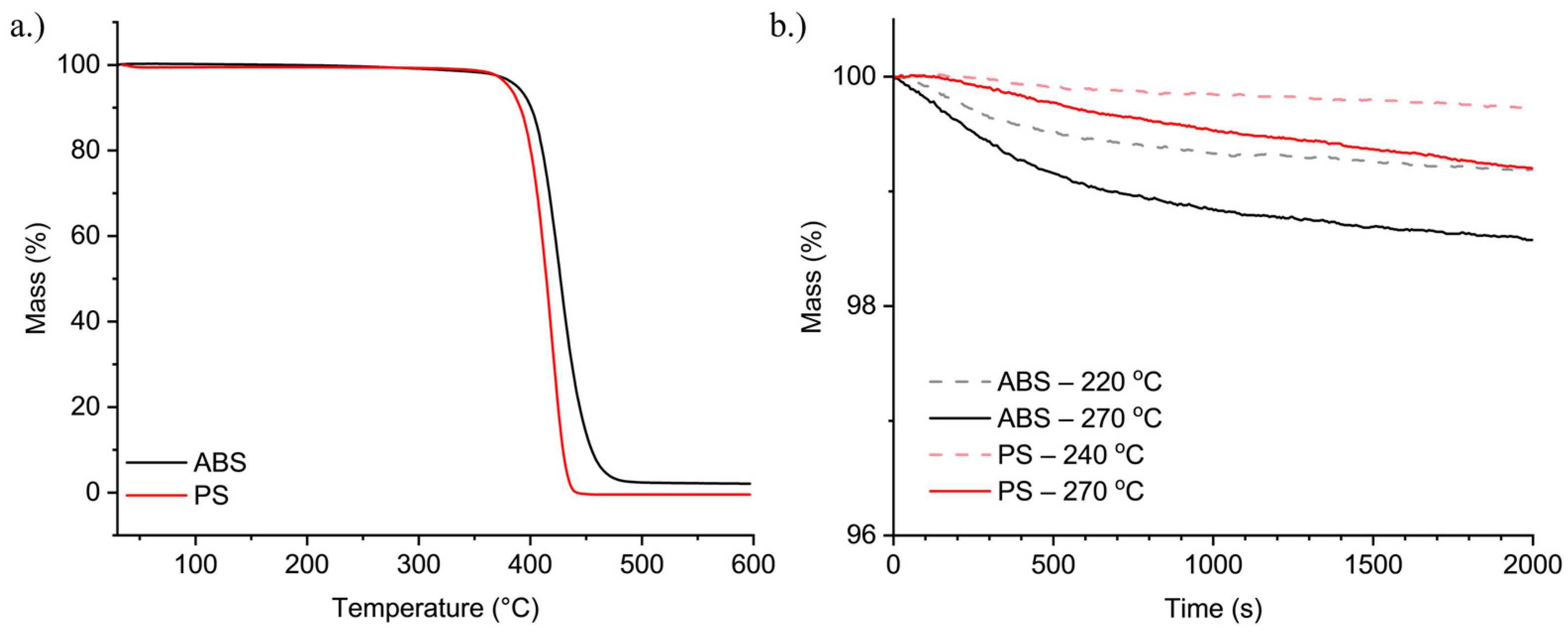

2.3.1. Thermal Stability of Raw Materials

2.3.2. Degradation Analysis

Linear Viscoelastic Properties

Size-Exclusion Chromatography

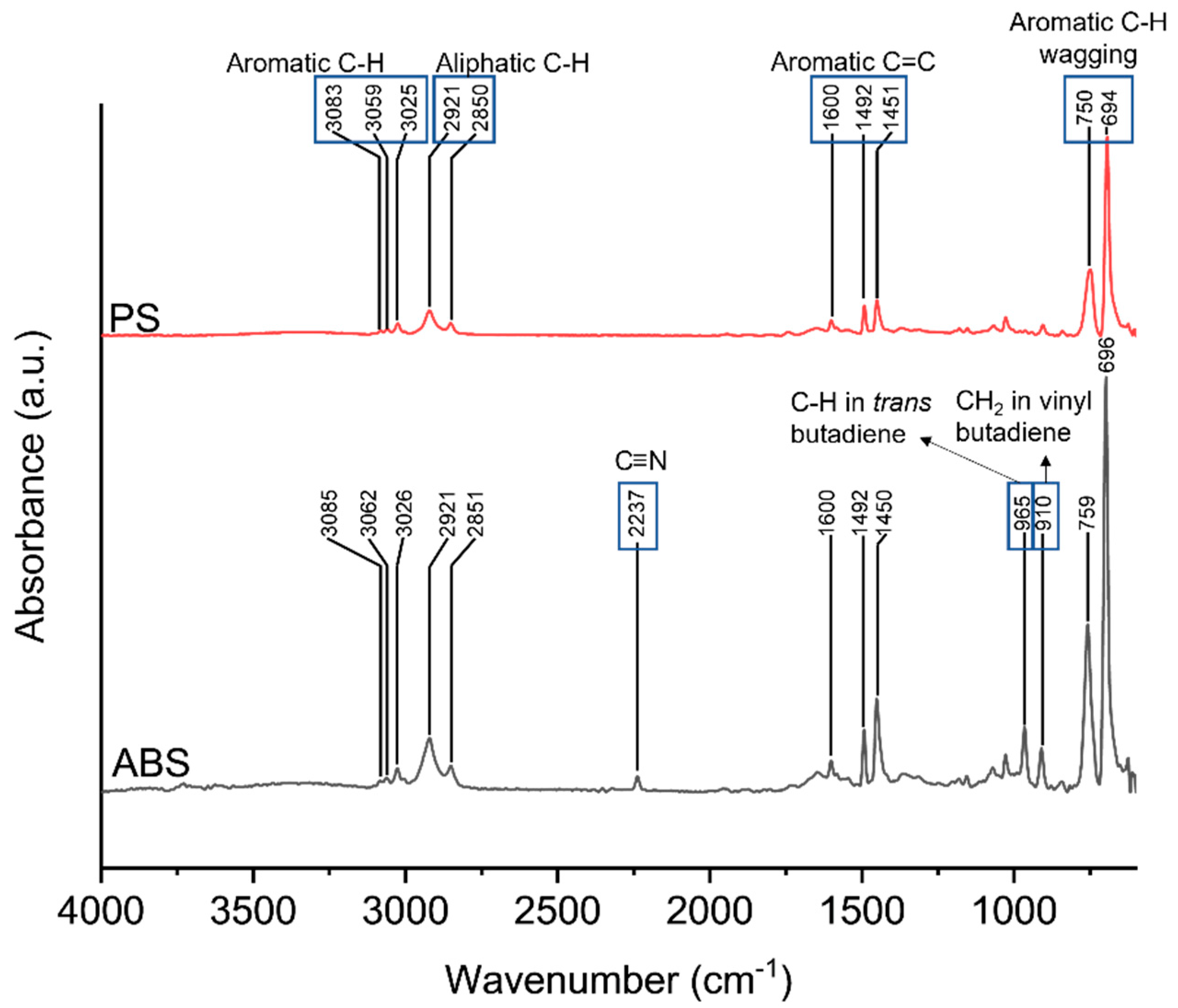

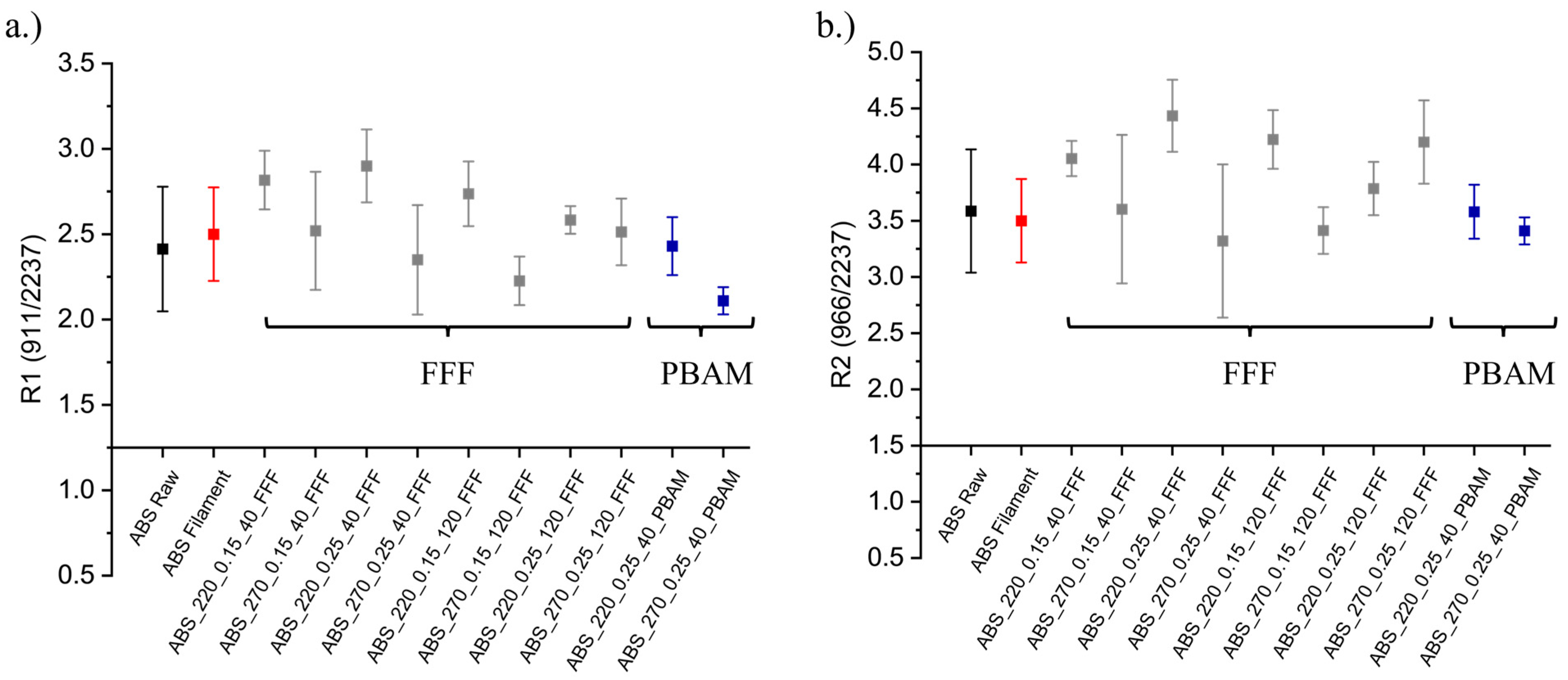

Fourier-Transform Infrared Spectroscopy

2.3.3. Color Variations, Mechanical Properties and Morphology

Yellowness Index

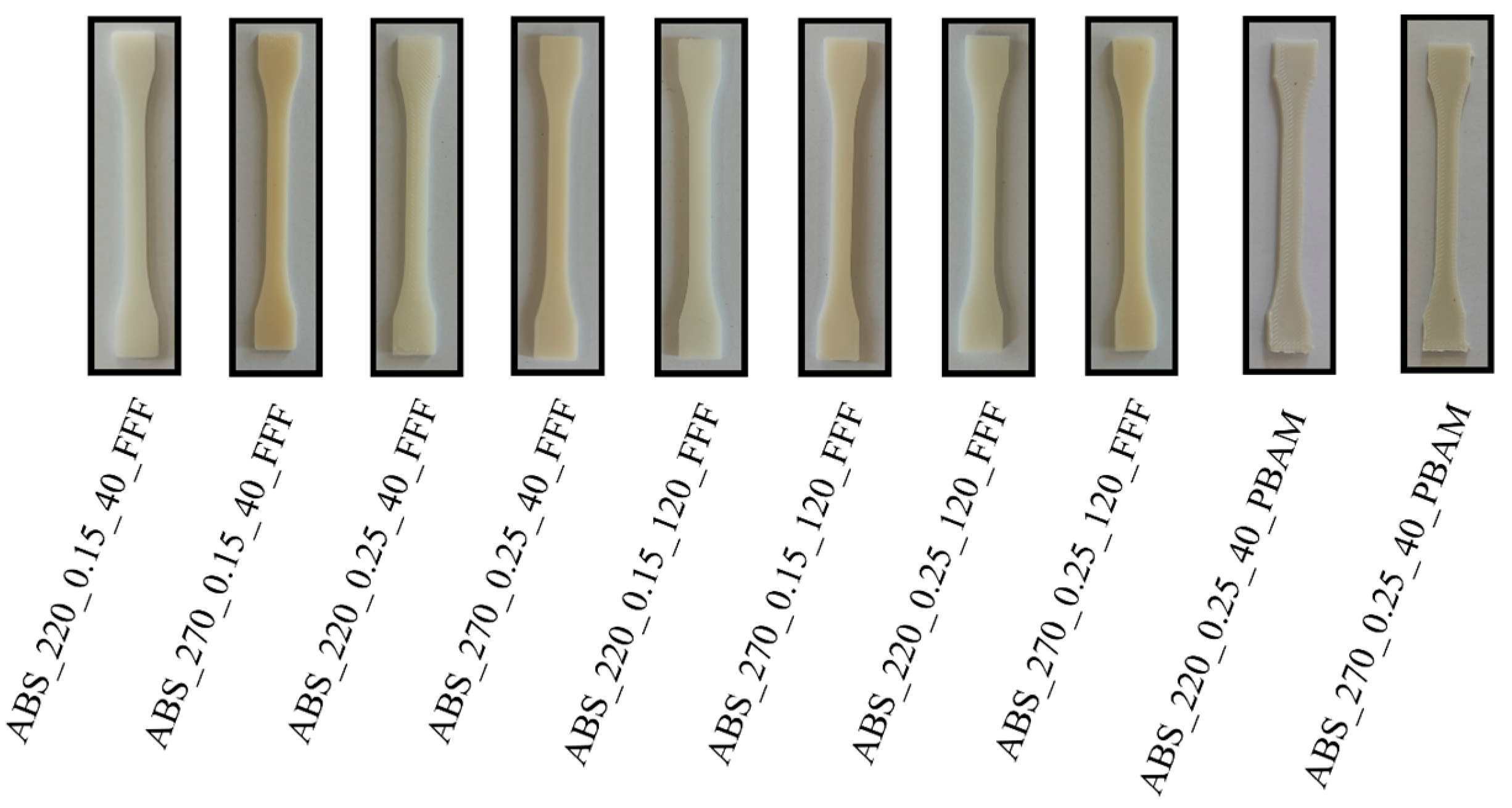

Tensile Tests

Morphological Analysis

2.3.4. Statistical Analysis

3. Results

3.1. Conventional Thermal Stability of Feedstock Materials

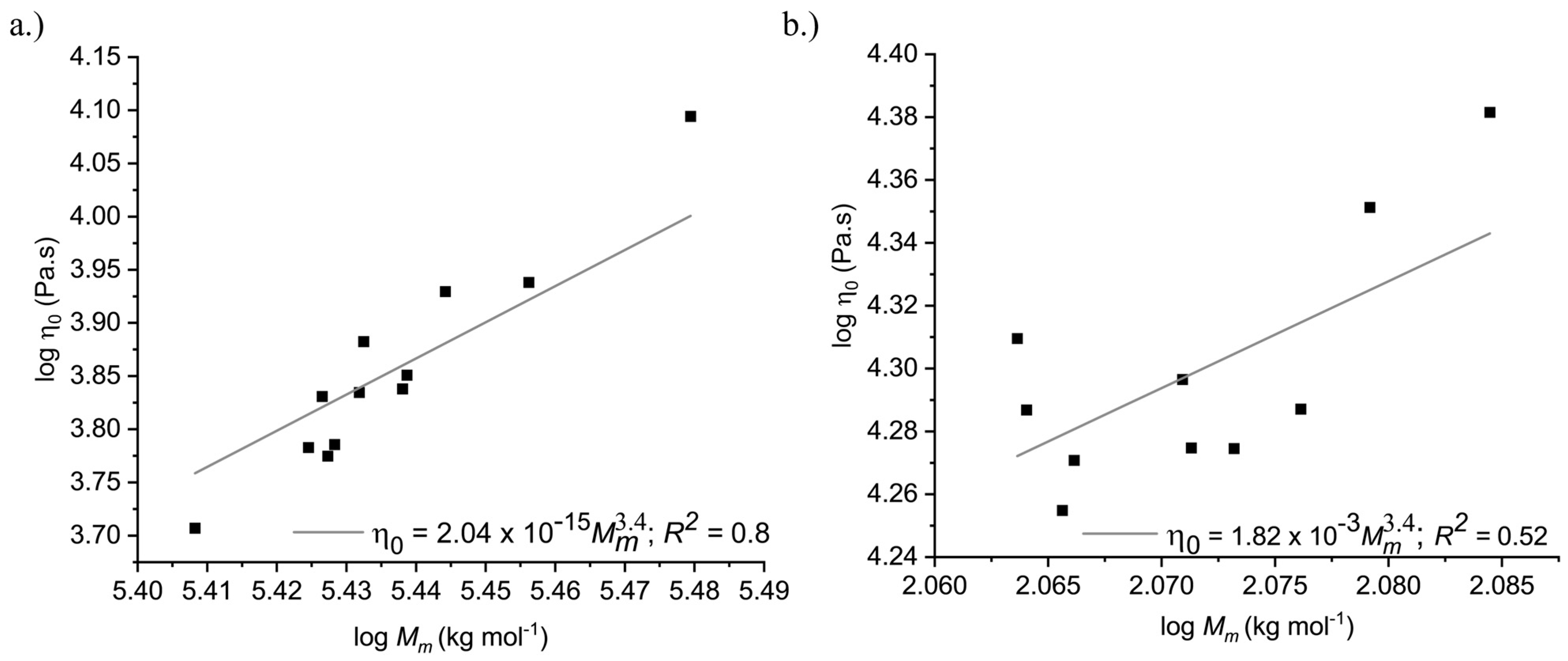

3.2. Detailed Rheological, Size Exclusion Chromatography and Fourier Transfer Infrared Spectroscopy Analysis for Stability under Processing Conditions

3.3. Analysis of Variations in Color, Mechanical Properties and Morphology

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Volpato, N.; Kretschek, D.; Foggiatto, J.A.; Gomez da Silva Cruz, C.M. Experimental analysis of an extrusion system for additive manufacturing based on polymer pellets. Int. J. Adv. Manuf. Technol. 2015, 81, 1519–1531. [Google Scholar] [CrossRef]

- La Gala, A.; Fiorio, R.; Erkoç, M.; Cardon, L.; D’hooge, D.R. Theoretical evaluation of the melting efficiency for the single-screw micro-extrusion process: The case of 3D printing of abs. Processes 2020, 8, 1522. [Google Scholar] [CrossRef]

- Moreno Nieto, D.; Casal López, V.; Molina, S.I. Large-format polymeric pellet-based additive manufacturing for the naval industry. Addit. Manuf. 2018, 23, 79–85. [Google Scholar] [CrossRef]

- Wang, S.; Daelemans, L.; D’hooge, D.R.; Couck, L.; Van Den Broeck, W.; Cornillie, P.; Gou, M.; De Clerck, K.; Cardon, L. Lifting the quality of fused filament fabrication of polylactic acid based composites. Compos. Part B Eng. 2021, 210, 108613. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Van Waeleghem, T.; Marchesini, F.H.; Cardon, L.; D’hooge, D.R. Melt exit flow modelling and experimental validation for fused filament fabrication: From Newtonian to non-Newtonian effects. J. Manuf. Process. 2022, 77, 138–150. [Google Scholar] [CrossRef]

- La Gala, A.; Fiorio, R.; Ceretti, D.V.A.; Erkoç, M.; Cardon, L.; D’hooge, D.R. A Combined Experimental and Modeling Study for Pellet-Fed Extrusion-Based Additive Manufacturing to Evaluate the Impact of the Melting Efficiency. Materials 2021, 14, 5566. [Google Scholar] [CrossRef]

- Vilaplana, F.; Karlsson, S.; Ribes-Greus, A. Changes in the microstructure and morphology of high-impact polystyrene subjected to multiple processing and thermo-oxidative degradation. Eur. Polym. J. 2007, 43, 4371–4381. [Google Scholar] [CrossRef]

- De Keer, L.; Van Steenberge, P.H.M.; Reyniers, M.; Marin, G.B.; Hungenberg, K.; Seda, L.; D’hooge, D.R. A complete understanding of the reaction kinetics for the industrial production process of expandable polystyrene. AIChE J. 2017, 63, 2043–2059. [Google Scholar] [CrossRef]

- Peterson, A.M. Review of acrylonitrile butadiene styrene in fused filament fabrication: A plastics engineering-focused perspective. Addit. Manuf. 2019, 27, 363–371. [Google Scholar] [CrossRef]

- Moore, J.D. Acrylonitrile-butadiene-styrene (ABS)—A review. Composites 1973, 4, 118–130. [Google Scholar] [CrossRef]

- Dey, A.; Eagle, I.N.R.; Yodo, N. A review on filament materials for fused filament fabrication. J. Manuf. Mater. Process. 2021, 5, 69. [Google Scholar] [CrossRef]

- Akintola, T.M.; Tran, P.; Sweat, R.D.; Dickens, T. Thermomechanical multifunctionality in 3d-printed polystyrene-boron nitride nanotubes (Bnnt) composites. J. Compos. Sci. 2021, 5, 61. [Google Scholar] [CrossRef]

- Sevastaki, M.; Suchea, M.P.; Kenanakis, G. 3D Printed Fully Recycled Tio2-Polystyrene Nanocomposite Photocatalysts for Use Against Drug Residues. Nanomaterials 2020, 10, 2144. [Google Scholar] [CrossRef]

- Hinsken, H.; Moss, S.; Pauquet, J.; Zweifela, H. Degradation of Polyolefins during Melt Processing. Polym. Degrad. Stab. 1991, 34, 279–293. [Google Scholar] [CrossRef]

- Colin, X.; Verdu, J. Polymer degradation during processing. Comptes Rendus Chim. 2006, 9, 1380–1395. [Google Scholar] [CrossRef]

- Capone, C.; Di Landro, L.; Inzoli, F.; Penco, M.; Sartore, L. Thermal and mechanical degradation during polymer extrusion processing. Polym. Eng. Sci. 2007, 47, 1813–1819. [Google Scholar] [CrossRef]

- Gol’dberg, V.M.; Zaikov, G.E. Kinetics of mechanical degradation in melts under model conditions and during processing of polymers-A review. Polym. Degrad. Stab. 1987, 19, 221–250. [Google Scholar] [CrossRef]

- Whitlock, L.R.; Porter, R.S. The source of degradation during extrusion of polystyrene. J. Appl. Polym. Sci. 1973, 17, 2761–2770. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S. The effect of process and structural parameters on the stability, thermo-mechanical and thermal degradation of polymers with hydrocarbon skeleton containing PE, PP, PS, PVC, NR, PBR and SBR. J. Therm. Anal. Calorim. 2021, 143, 2867–2882. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, 1–27. [Google Scholar] [CrossRef] [PubMed]

- Schweighuber, A.; Felgel-Farnholz, A.; Bögl, T.; Fischer, J.; Buchberger, W. Investigations on the influence of multiple extrusion on the degradation of polyolefins. Polym. Degrad. Stab. 2021, 192, 109689. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Lee, D.; Lee, Y.; Lee, K.; Ko, Y.; Kim, N. Development and Evaluation of a Distributed Recycling System for Making Filaments Reused in Three-Dimensional Printers. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 021007. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef] [Green Version]

- Hawkins, W.L. Polymer Degradation and Stabilization; Polymers Properties and Applications; Springer: Berlin/Heidelberg, Germany, 1984; ISBN 978-3-642-69378-6. [Google Scholar]

- Badia, J.D.; Gil-Castell, Ó.; Teruel-Juanes, R.; Ribes-Greus, A. Recycling of Polylactide. Encycl. Renew. Sustain. Mater. 2020, 2, 282–295. [Google Scholar] [CrossRef]

- Gijsman, P. Review on the thermo-oxidative degradation of polymers during processing and in service. E-Polymers 2008, 8, 1–34. [Google Scholar] [CrossRef]

- La Gala, A.; Ceretti, D.V.A.; Fiorio, R.; Cardon, L.; D’hooge, D.R. Comparing pellet- and filament-based additive manufacturing with conventional processing for ABS and PLA parts. J. Appl. Polym. Sci. 2022, 139, e53089. [Google Scholar] [CrossRef]

- Gradwohl, M.; Chai, F.; Payen, J.; Guerreschi, P.; Marchetti, P.; Blanchemain, N. Effects of two melt extrusion based additive manufacturing technologies and common sterilization methods on the properties of a medical grade PLGA copolymer. Polymers 2021, 13, 572. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, E.; Ceretti, D.A.; Wang, S.; Jiang, Y.; Zhang, J.; D’hooge, D.R.; Cardon, L. Fused filament fabrication of copolyesters by understanding the balance of inter- and intra-layer welding. Plast. Rubber Compos. 2022, 51, 126–132. [Google Scholar] [CrossRef]

- Jagenteufel, R.; Hofstaetter, T.; Kamleitner, F.; Pedersen, D.B.; Tosello, G.; Hansen, H.N. Rheology of high melt strength polypropylene for additive manufacturing. Adv. Mater. Lett. 2017, 8, 712–716. [Google Scholar] [CrossRef] [Green Version]

- Chu, J.S.; Koay, S.C.; Chan, M.Y.; Choo, H.L.; Ong, T.K. Recycled plastic filament made from post-consumer expanded polystyrene and polypropylene for fused filamant fabrication. Polym. Eng. Sci. 2022, 62, 3786–3795. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Crittenden, K.; Weiss, L.; Bardaweel, H. Recycle of waste tire rubber in a 3D printed composite with enhanced damping properties. J. Clean. Prod. 2022, 368, 133085. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Esposito Corcione, C. Sustainable Polymer Composites Manufacturing through 3D Printing Technologies by Using Recycled Polymer and Filler. Polymers 2022, 14, 3756. [Google Scholar] [CrossRef]

- Madhu, N.R.; Erfani, H.; Jadoun, S.; Amir, M.; Thiagarajan, Y.; Chauhan, N.P.S. Fused deposition modelling approach using 3D printing and recycled industrial materials for a sustainable environment: A review. Int. J. Adv. Manuf. Technol. 2022, 122, 2125–2138. [Google Scholar] [CrossRef]

- Gomes, T.E.; Cadete, M.S.; Dias-de-Oliveira, J.; Neto, V. Controlling the properties of parts 3D printed from recycled thermoplastics: A review of current practices. Polym. Degrad. Stab. 2022, 196, 109850. [Google Scholar] [CrossRef]

- Fiorio, R.; D’hooge, D.R.; Ragaert, K.; Cardon, L. A statistical analysis on the effect of antioxidants on the thermal-oxidative stability of commercial massand emulsion-polymerized ABS. Polymers 2018, 11, 25. [Google Scholar] [CrossRef]

- Adeniyi, J.B.; Kolawole, E.G. Thermal and photo-degradation of unstabilized ABS. Eur. Polym. J. 1984, 20, 43–47. [Google Scholar] [CrossRef]

- Santos, R.M.; Botelho, G.L.; Machado, A.V. Artificial and natural weathering of ABS. J. Appl. Polym. Sci. 2010, 116, 2005–2014. [Google Scholar] [CrossRef]

- Zhu, X. Effects of acids on thermal and thermooxidative degradation of polystyrene. Polym. Degrad. Stab. 1997, 57, 163–173. [Google Scholar] [CrossRef]

- ASTM Standard Practice for Calculating Yellowness and Whiteness Indices from Instrumentally Measured Color Coordinates. Annu. B ASTM Stand. 2015, 6, 1–6. [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 5th ed.John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Spoerk, M.; Arbeiter, F.; Raguž, I.; Holzer, C.; Gonzalez-Gutierrez, J. Mechanical recyclability of polypropylene composites produced by material extrusion-based additive manufacturing. Polymers 2019, 11, 1318. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adeniyi, J.B. Clarification a N D Discussion of Chemical Photo-Oxidative Degradation of Abs. Eur. Polym. J. 1984, 20, 291–299. [Google Scholar] [CrossRef]

- Cameron, G.G.; Kerr, G.P. Thermal degradation of polystyrene-I. Chain scission at low temperatures. Eur. Polym. J. 1968, 4, 709–717. [Google Scholar] [CrossRef]

- Guyot, A. Recent developments in the thermal degradation of polystyrene—A review. Polym. Degrad. Stab. 1986, 15, 219–235. [Google Scholar] [CrossRef]

- Münstedt, H. Rheology of rubber-modified polymer melts. Polym. Eng. Sci. 1981, 21, 259–270. [Google Scholar] [CrossRef]

- Aoki, Y. Rheological properties of abs polymer melts having a good dispersion of rubber particles. J. Nonnewton. Fluid Mech. 1986, 22, 91–99. [Google Scholar] [CrossRef]

- Bertin, M.-P.; Marin, G.; Montfort, J.-P. Viscoelastic properties of acrylonitrile-butadiene-styrene (ABS) polymers in the molten state. Polym. Eng. Sci. 1995, 35, 1394–1406. [Google Scholar] [CrossRef]

- Ceretti, D.V.A.; Fiorio, R.; Van Waeleghem, T.; Desmet, A.; Florizoone, B.; Cardon, L.; D’hooge, D.R. Exploiting mono- and hybrid nanocomposite materials for fused filament fabrication with acrylonitrile butadiene styrene as polymer matrix. J. Appl. Polym. Sci. 2022, 139, e52922. [Google Scholar] [CrossRef]

- Lertwimolnun, W.; Vergnes, B. Influence of compatibilizer and processing conditions on the dispersion of nanoclay in a polypropylene matrix. Polymer 2005, 46, 3462–3471. [Google Scholar] [CrossRef]

- Karahaliou, E.-K.; Tarantili, P.A. Stability of ABS compounds subjected to repeated cycles of extrusion processing. Polym. Eng. Sci. 2009, 49, 2269–2275. [Google Scholar] [CrossRef]

- Berzin, F.; Vergnes, B.; Delamare, L. Rheological behavior of controlled-rheology polypropylenes obtained by peroxide-promoted degradation during extrusion: Comparison between homopolymer and copolymer. J. Appl. Polym. Sci. 2001, 80, 1243–1252. [Google Scholar] [CrossRef]

- Filippone, G.; Carroccio, S.C.; Mendichi, R.; Gioiella, L.; Dintcheva, N.T.; Gambarotti, C. Time-resolved rheology as a tool to monitor the progress of polymer degradation in the melt state—Part I: Thermal and thermo-oxidative degradation of polyamide 11. Polymer 2015, 72, 134–141. [Google Scholar] [CrossRef]

- Tzoganakis, C.; Hamielec, A.E.; Tang, Y.; Vlachopoulos, J. Controlled degradation of polypropylene: A comprehensive experimental and theoretical investigation. Polym. Plast. Technol. Eng. 1989, 28, 319–350. [Google Scholar] [CrossRef]

- Dealy, J.M.; Larson, R.G. Structure and Rheology of Molten Polymers; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2006; ISBN 978-3-446-21771-3. [Google Scholar]

- Signoret, C.; Caro-Bretelle, A.S.; Lopez-Cuesta, J.M.; Ienny, P.; Perrin, D. MIR spectral characterization of plastic to enable discrimination in an industrial recycling context: I. Specific case of styrenic polymers. Waste Manag. 2019, 95, 513–525. [Google Scholar] [CrossRef] [Green Version]

- Saviello, D.; Pouyet, E.; Toniolo, L.; Cotte, M.; Nevin, A. Synchrotron-based FTIR microspectroscopy for the mapping of photo-oxidation and additives in acrylonitrile-butadiene-styrene model samples and historical objects. Anal. Chim. Acta 2014, 843, 59–72. [Google Scholar] [CrossRef]

- Salari, D.; Ranjbar, H. Study on the Recycling of ABS Resins: Simulation of Reprocessing and Thermo-oxidation. Iran. Polym. J. 2008, 17, 599–610. [Google Scholar]

- Desrousseaux, C.; Cueff, R.; Aumeran, C.; Garrait, G.; Mailhot-Jensen, B.; Traoré, O.; Sautou, V. Fabrication of acrylonitrile-butadiene-styrene nanostructures with anodic alumina oxide templates, characterization and biofilm development test for Staphylococcus epidermidis. PLoS ONE 2015, 10, e0135632. [Google Scholar] [CrossRef] [PubMed]

- Moss, S.; Zweifel, H. Degradation and stabilization of high density polyethylene during multiple extrusions. Polym. Degrad. Stab. 1989, 25, 217–245. [Google Scholar] [CrossRef]

- Samper, M.D.; Garcia-Sanoguera, D.; Parres, F.; López, J. Recycling of expanded polystyrene from packaging. Prog. Rubber Plast. Recycl. Technol. 2010, 26, 83–92. [Google Scholar] [CrossRef]

- McNeill, I.C.; Razumovskii, L.P.; Gol’dberg, V.M.; Zaikov, G.E. The thermo-oxidative degradation of polystyrene. Polym. Degrad. Stab. 1994, 45, 47–55. [Google Scholar] [CrossRef]

- D’Esposito, L.; Koenig, J.L. A comparison of the thermal and mechanical degradation of glassy polystyrene by Fourier transform infrared spectroscopy. Polym. Eng. Sci. 1979, 19, 162–165. [Google Scholar] [CrossRef]

- Achtioui, T.; Lacoste, C.; Le Baillif, M.; Erre, D. Prediction of the yellowing of styrene-stat-Acrylonitrile and acrylonitrile-butadiene-styrene during processing in an internal mixer. J. Polym. Eng. 2018, 38, 983–993. [Google Scholar] [CrossRef]

- Coogan, T.J.; Kazmer, D.O. Modeling of interlayer contact and contact pressure during fused filament fabrication. J. Rheol. 2019, 63, 655–672. [Google Scholar] [CrossRef]

| Material | Temperature Profile (°C) | Screw Speed (rpm) | Spooling Speed (m min−1) | |||

|---|---|---|---|---|---|---|

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | |||

| ABS | 145 | 185 | 205 | 210 | 27 | 5.0 |

| PS | 215 | 220 | 225 | 230 | 13 | 2.2 |

| Material | Run | Sample | Nozzle Temperature (°C) | Layer Thickness (mm) | Print Velocity (mm s−1) |

|---|---|---|---|---|---|

| ABS | 1 | ABS_220_0.15_40_FFF | 220 | 0.15 | 40 |

| 2 | ABS_270_0.15_40_FFF | 270 | 0.15 | 40 | |

| 3 | ABS_220_0.25_40_FFF | 220 | 0.25 | 40 | |

| 4 | ABS_270_0.25_40_FFF | 270 | 0.25 | 40 | |

| 5 | ABS_220_0.15_120_FFF | 220 | 0.15 | 120 | |

| 6 | ABS_270_0.15_120_FFF | 270 | 0.15 | 120 | |

| 7 | ABS_220_0.25_120_FFF | 220 | 0.25 | 120 | |

| 8 | ABS_270_0.25_120_FFF | 270 | 0.25 | 120 | |

| PS | 9 | PS_240_0.15_40_FFF | 240 | 0.15 | 40 |

| 10 | PS_270_0.15_40_FFF | 270 | 0.15 | 40 | |

| 11 | PS_240_0.25_40_FFF | 240 | 0.25 | 40 | |

| 12 | PS_270_0.25_40_FFF | 270 | 0.25 | 40 | |

| 13 | PS_240_0.15_120_FFF | 240 | 0.15 | 120 | |

| 14 | PS_270_0.15_120_FFF | 270 | 0.15 | 120 | |

| 15 | PS_240_0.25_120_FFF | 240 | 0.25 | 120 | |

| 16 | PS_270_0.25_120_FFF | 270 | 0.25 | 120 |

| Material | Sample | Temperature Profile (°C) | Screw Speed (rpm) | ||

|---|---|---|---|---|---|

| Zone 1 | Zone 2 | Zone 3 | |||

| ABS | ABS_220_0.25_40_PBAM | 220 | 220 | 220 | 0.8 |

| ABS_270_0.25_40_PBAM | 220 | 270 | 270 | 0.8 | |

| PS | PS_240_0.25_40_PBAM | 220 | 240 | 240 | 0.1 |

| PS_270_0.25_40_PBAM | 220 | 270 | 270 | 0.1 | |

| Processing Technique | Entry | Sample | σ0 (Pa) | η0 (Pa·s) | λ (s) | a (−) | n (−) |

|---|---|---|---|---|---|---|---|

| - | 1 | ABS Raw | 2797 | 24,073 | 0.55 | 0.35 | 0.32 |

| SSE | 2 | ABS Filament | 2516 | 22,452 | 0.63 | 0.37 | 0.35 |

| SSE + FFF | 3 | ABS_220_0.15_40_FFF | 2824 | 17,983 | 0.43 | 0.41 | 0.34 |

| 4 | ABS_270_0.15_40_FFF | 3130 | 19,369 | 0.45 | 0.40 | 0.34 | |

| 5 | ABS_220_0.25_40_FFF | 2979 | 18,654 | 0.46 | 0.42 | 0.34 | |

| 6 | ABS_270_0.25_40_FFF | 2905 | 18,817 | 0.44 | 0.40 | 0.33 | |

| 7 | ABS_220_0.15_120_FFF | 3073 | 18,826 | 0.49 | 0.41 | 0.35 | |

| 8 | ABS_270_0.15_120_FFF | 2758 | 19,793 | 0.55 | 0.39 | 0.36 | |

| 9 | ABS_220_0.25_120_FFF | 3046 | 19,356 | 0.49 | 0.40 | 0.34 | |

| 10 | ABS_270_0.25_120_FFF | 2836 | 20,397 | 0.51 | 0.39 | 0.34 | |

| PBAM | 11 | ABS_220_0.25_40_PBAM | 2139 | 32,862 | 0.78 | 0.34 | 0.33 |

| 12 | ABS_270_0.25_40_PBAM | 2369 | 43,684 | 1.45 | 0.32 | 0.34 | |

| - | 13 | PS Raw | - | 12,423 | 0.23 | 0.56 | 0.21 |

| SSE | 14 | PS Filament | - | 8530 | 0.18 | 0.57 | 0.24 |

| SSE + FFF | 15 | PS_240_0.15_40_FFF | - | 6833 | 0.14 | 0.58 | 0.24 |

| 16 | PS_270_0.15_40_FFF | - | 5093 | 0.11 | 0.59 | 0.24 | |

| 17 | PS_240_0.25_40_FFF | - | 6885 | 0.15 | 0.58 | 0.24 | |

| 18 | PS_270_0.25_40_FFF | - | 5953 | 0.13 | 0.56 | 0.23 | |

| 19 | PS_240_0.15_120_FFF | - | 7094 | 0.16 | 0.58 | 0.25 | |

| 20 | PS_270_0.15_120_FFF | - | 6105 | 0.14 | 0.57 | 0.25 | |

| 21 | PS_240_0.25_120_FFF | - | 7628 | 0.19 | 0.58 | 0.26 | |

| 22 | PS_270_0.25_120_FFF | - | 6064 | 0.15 | 0.60 | 0.25 | |

| PBAM | 23 | PS_240_0.25_40_PBAM | - | 8671 | 0.21 | 0.58 | 0.26 |

| 24 | PS_270_0.25_40_PBAM | - | 6773 | 0.26 | 0.65 | 0.31 |

| Sample—ABS | Mm (kg mol−1) | Đ | Sample—PS | Mm (kg mol−1) | Đ |

|---|---|---|---|---|---|

| ABS Raw | 121.5 | 1.36 | PS Raw | 301.6 | 2.19 |

| ABS Filament | 120.0 | 2.16 | PS Filament | 278.1 | 2.26 |

| ABS_220_0.15_40_FFF | 116.3 | 2.04 | PS_240_0.15_40_FFF | 270.3 | 2.16 |

| ABS_270_0.15_40_FFF | 119.2 | 2.00 | PS_270_0.15_40_FFF | 256.1 | 2.35 |

| ABS_220_0.25_40_FFF | 116.4 | 2.07 | PS_240_0.25_40_FFF | 274.2 | 2.06 |

| ABS_270_0.25_40_FFF | 118.4 | 2.06 | PS_270_0.25_40_FFF | 267.5 | 2.72 |

| ABS_220_0.15_120_FFF | 117.8 | 2.05 | PS_240_0.15_120_FFF | 274.6 | 2.22 |

| ABS_270_0.15_120_FFF | 117.7 | 1.98 | PS_270_0.15_120_FFF | 268.1 | 2.21 |

| ABS_220_0.25_120_FFF | 115.9 | 2.12 | PS_240_0.25_120_FFF | 270.7 | 2.19 |

| ABS_270_0.25_120_FFF | 115.8 | 2.12 | PS_270_0.25_120_FFF | 265.8 | 2.14 |

| ABS_220_0.25_40_PBAM | 116.5 | 2.04 | PS_240_0.25_40_PBAM | 285.9 | 2.22 |

| ABS_270_0.25_40_PBAM | 117.3 | 2.68 | PS_270_0.25_40_PBAM | 267.0 | 2.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ceretti, D.V.A.; Marien, Y.W.; Edeleva, M.; La Gala, A.; Cardon, L.; D’hooge, D.R. Thermal and Thermal-Oxidative Molecular Degradation of Polystyrene and Acrylonitrile Butadiene Styrene during 3D Printing Starting from Filaments and Pellets. Sustainability 2022, 14, 15488. https://doi.org/10.3390/su142315488

Ceretti DVA, Marien YW, Edeleva M, La Gala A, Cardon L, D’hooge DR. Thermal and Thermal-Oxidative Molecular Degradation of Polystyrene and Acrylonitrile Butadiene Styrene during 3D Printing Starting from Filaments and Pellets. Sustainability. 2022; 14(23):15488. https://doi.org/10.3390/su142315488

Chicago/Turabian StyleCeretti, Daniel V. A., Yoshi W. Marien, Mariya Edeleva, Andrea La Gala, Ludwig Cardon, and Dagmar R. D’hooge. 2022. "Thermal and Thermal-Oxidative Molecular Degradation of Polystyrene and Acrylonitrile Butadiene Styrene during 3D Printing Starting from Filaments and Pellets" Sustainability 14, no. 23: 15488. https://doi.org/10.3390/su142315488

APA StyleCeretti, D. V. A., Marien, Y. W., Edeleva, M., La Gala, A., Cardon, L., & D’hooge, D. R. (2022). Thermal and Thermal-Oxidative Molecular Degradation of Polystyrene and Acrylonitrile Butadiene Styrene during 3D Printing Starting from Filaments and Pellets. Sustainability, 14(23), 15488. https://doi.org/10.3390/su142315488