Numerical Analysis of a TEG and mPCM Enhancement System for BIPVs Using CFD

Abstract

1. Introduction

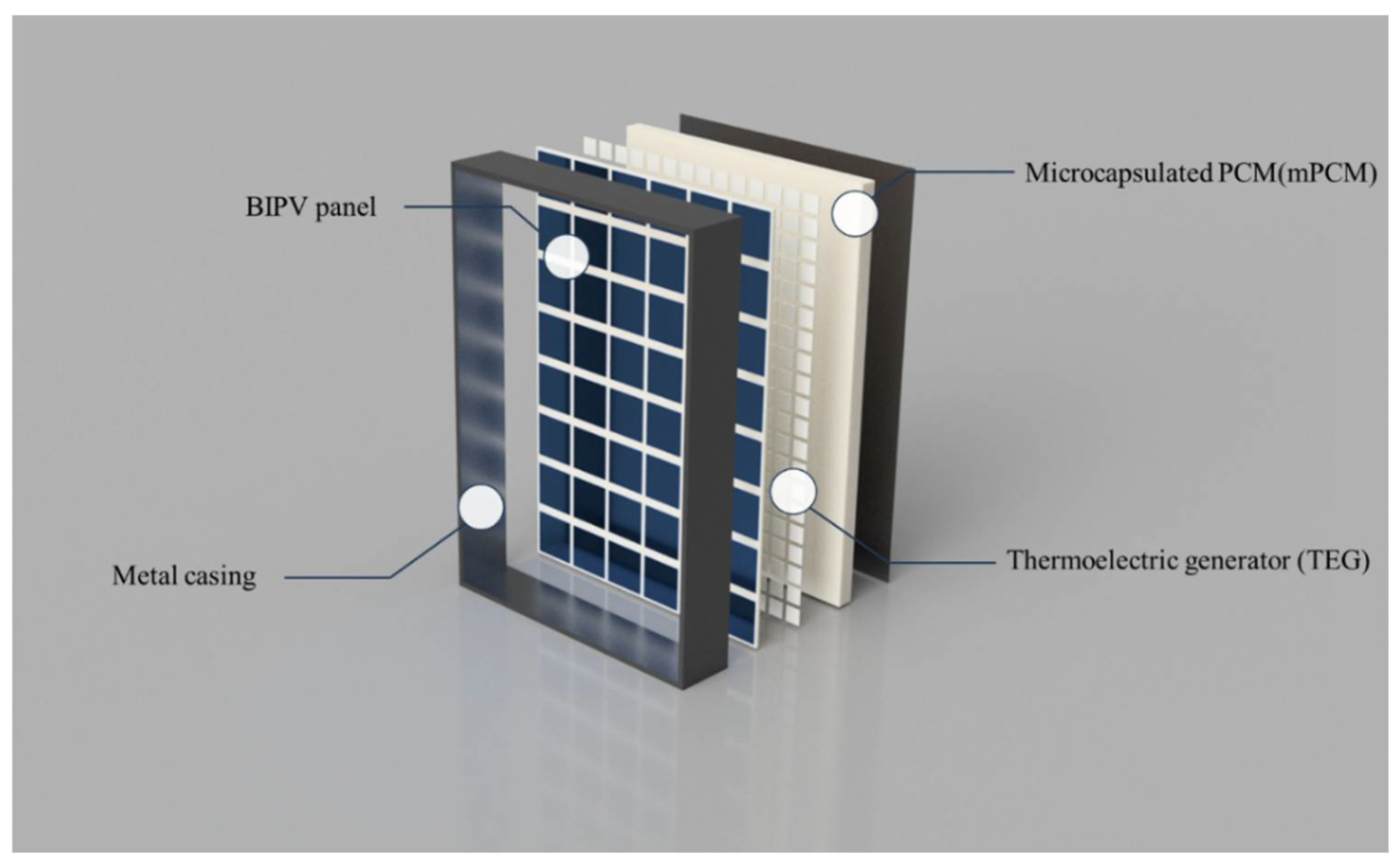

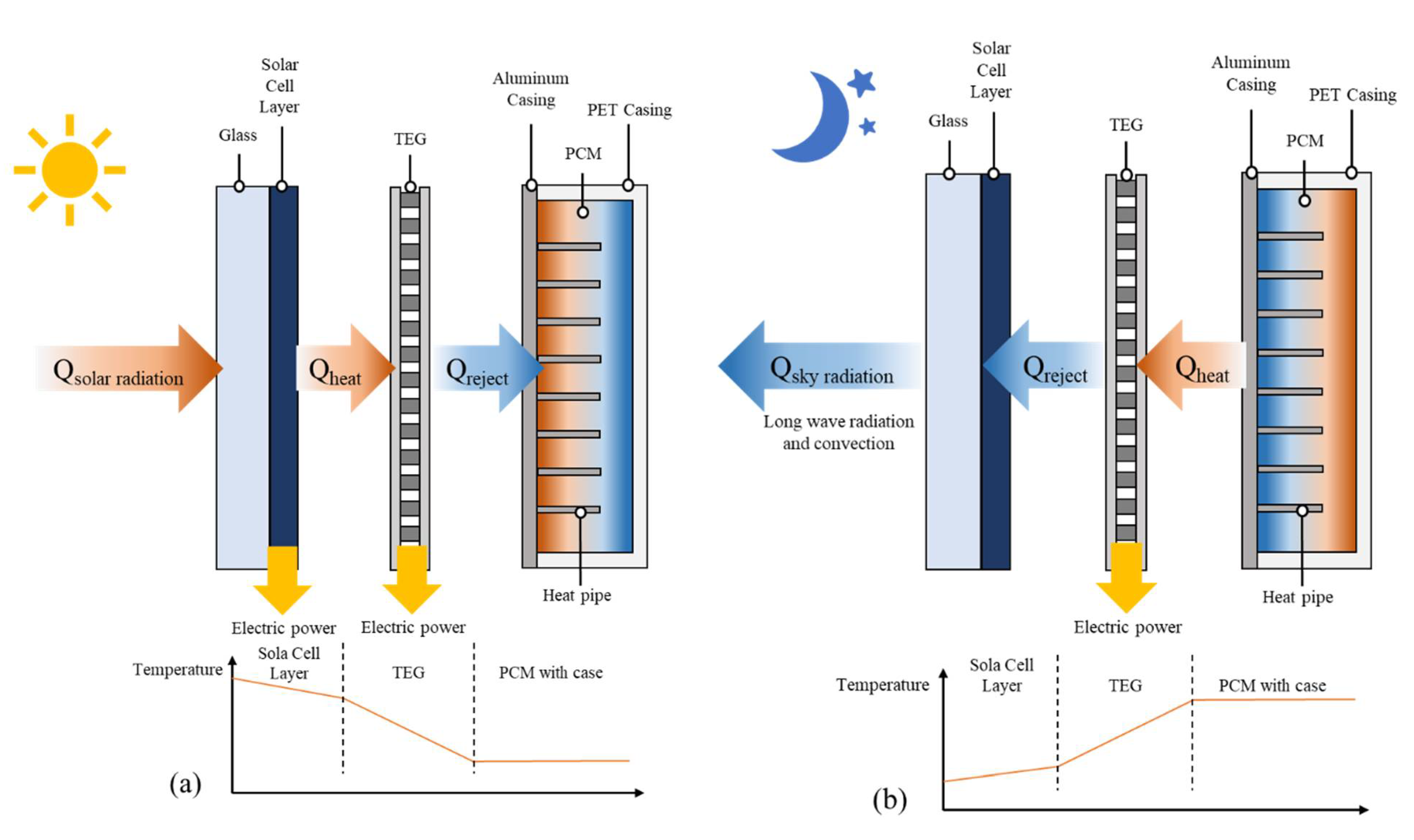

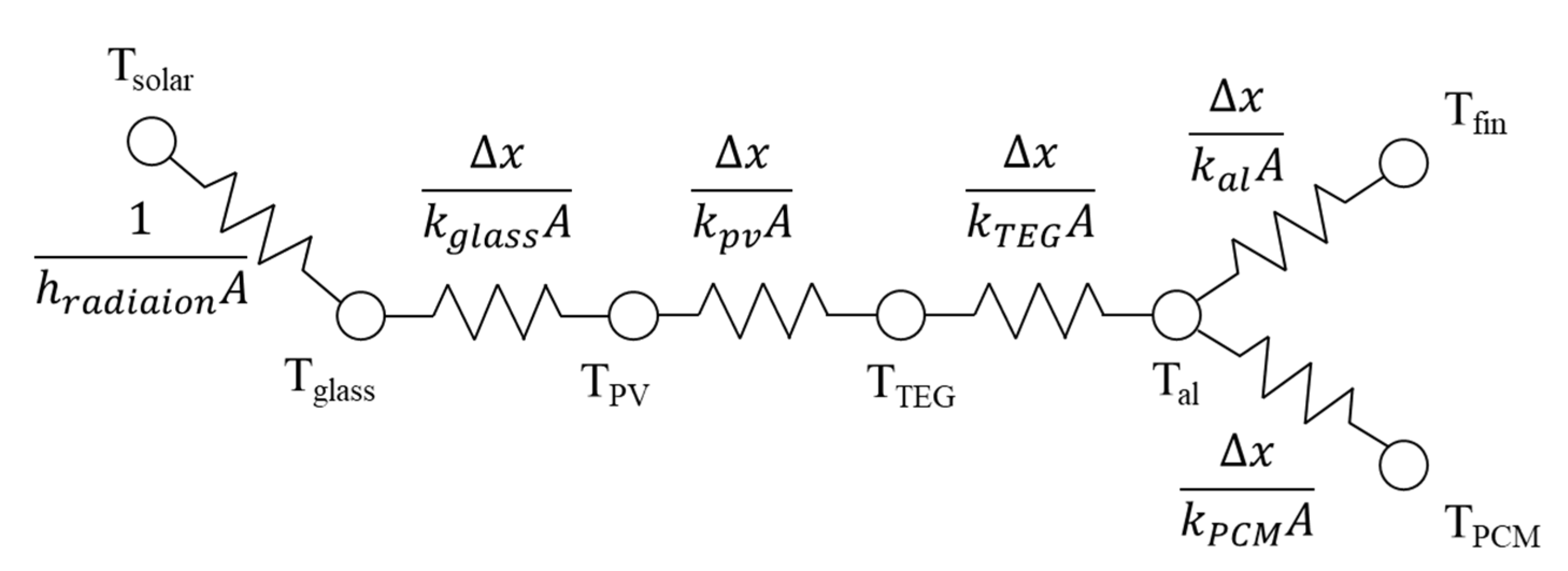

2. System Overview

2.1. Building-Integrated Photovoltaic with TEG and PCM (BIPV–TEG–PCM)

2.2. Microencapsulated Phase Change Material (mPCM)

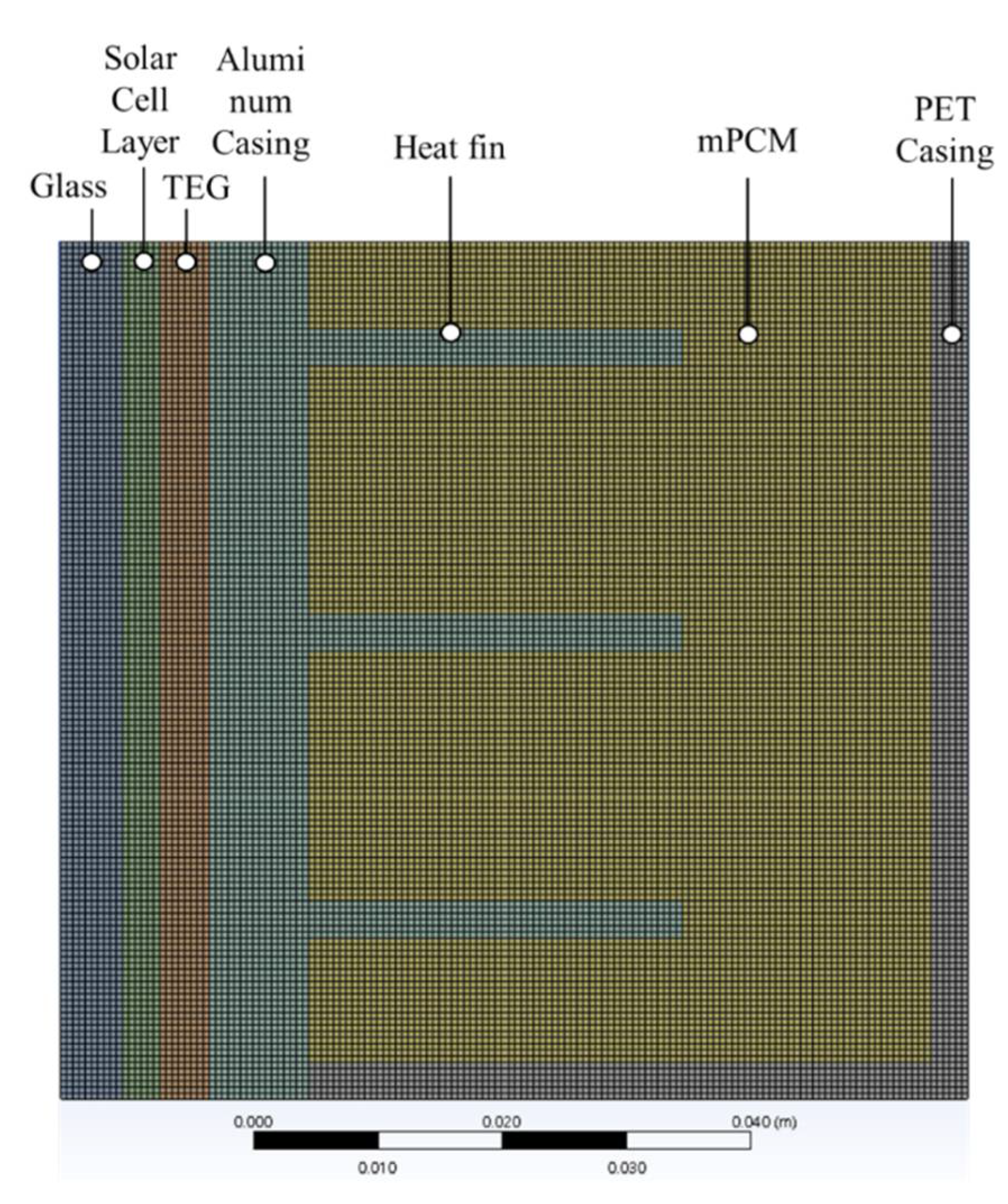

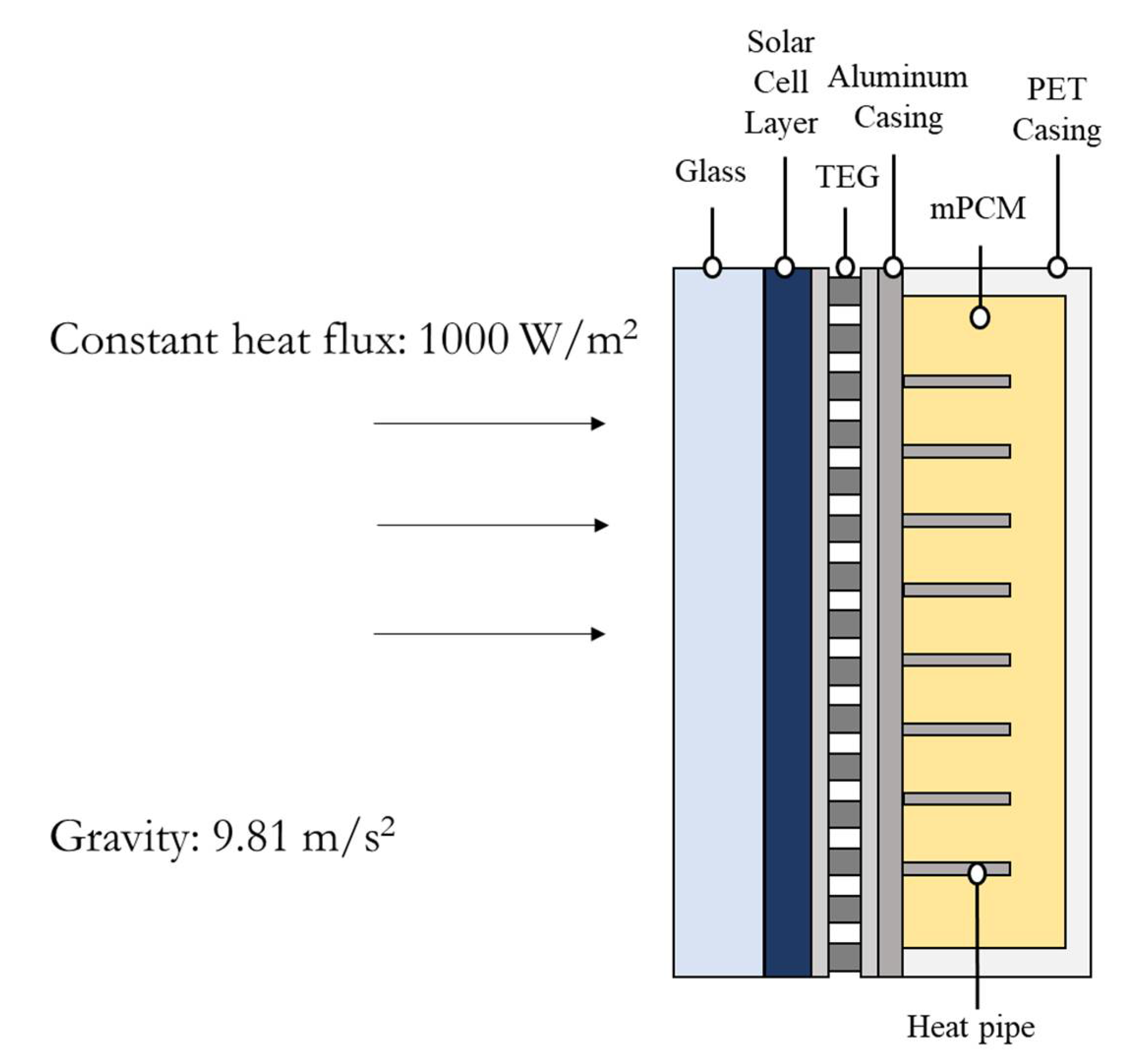

3. Numerical Analysis Method

4. Results and Discussion

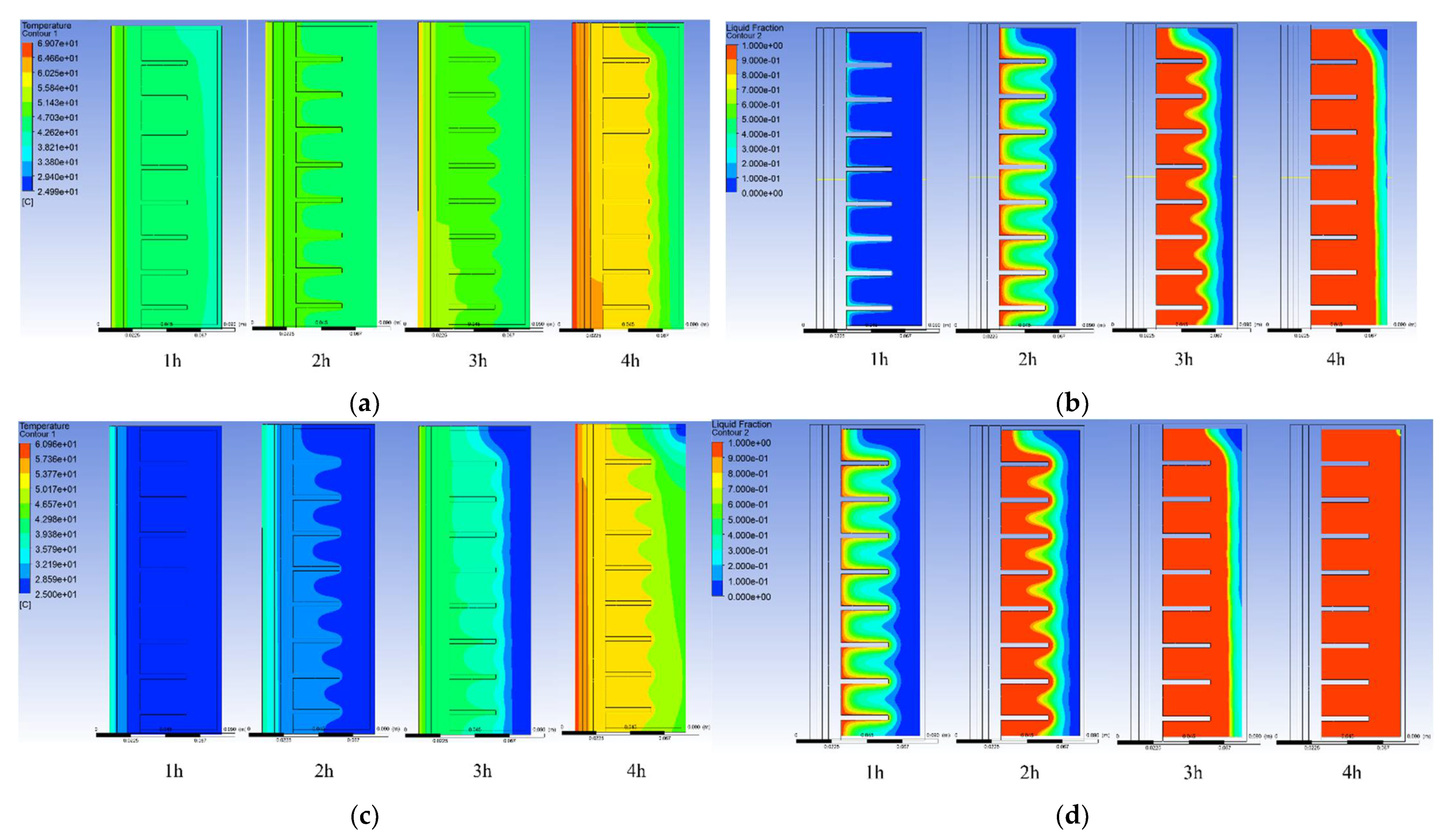

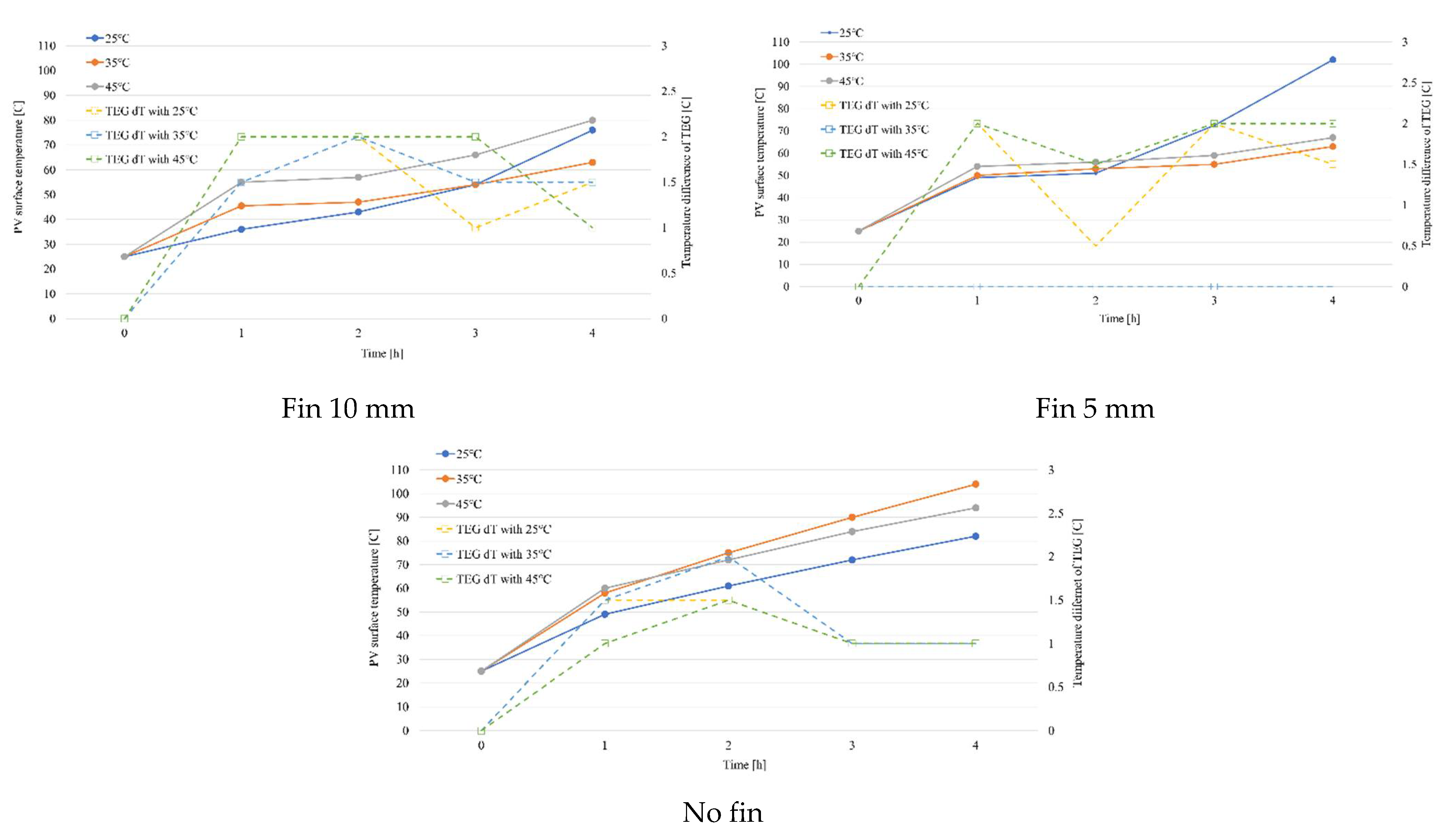

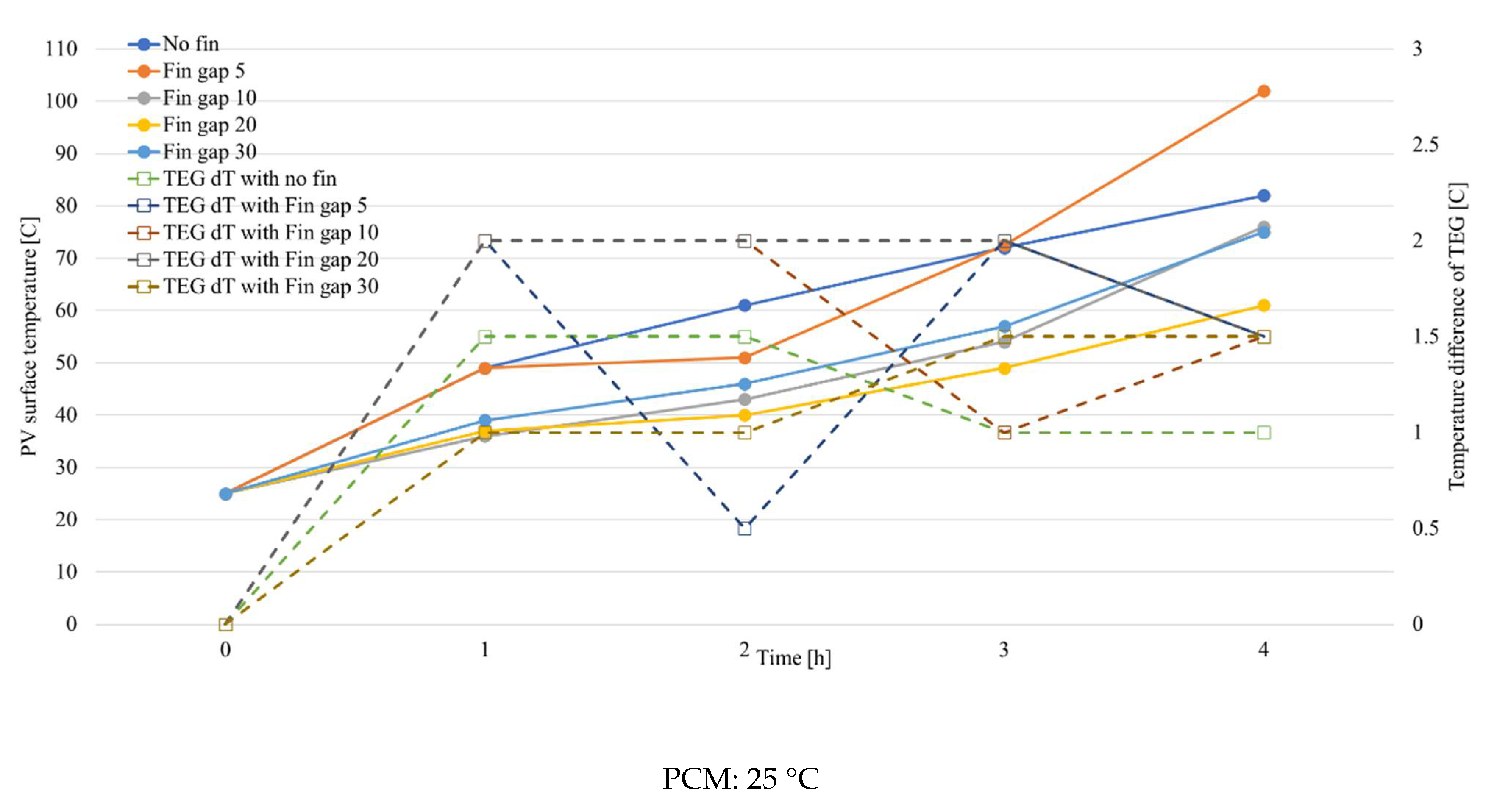

4.1. Effects of PCM Melting Temperature

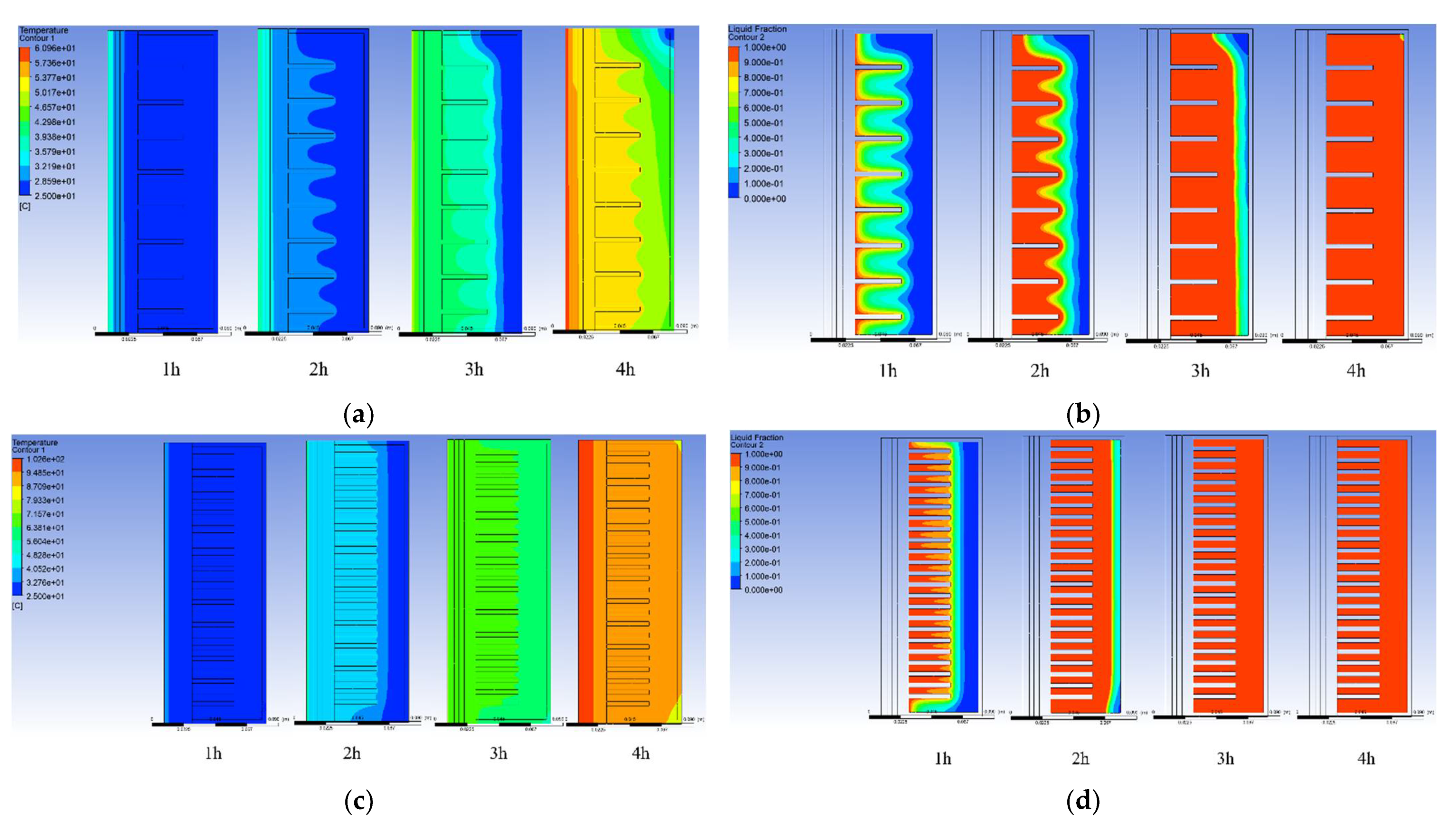

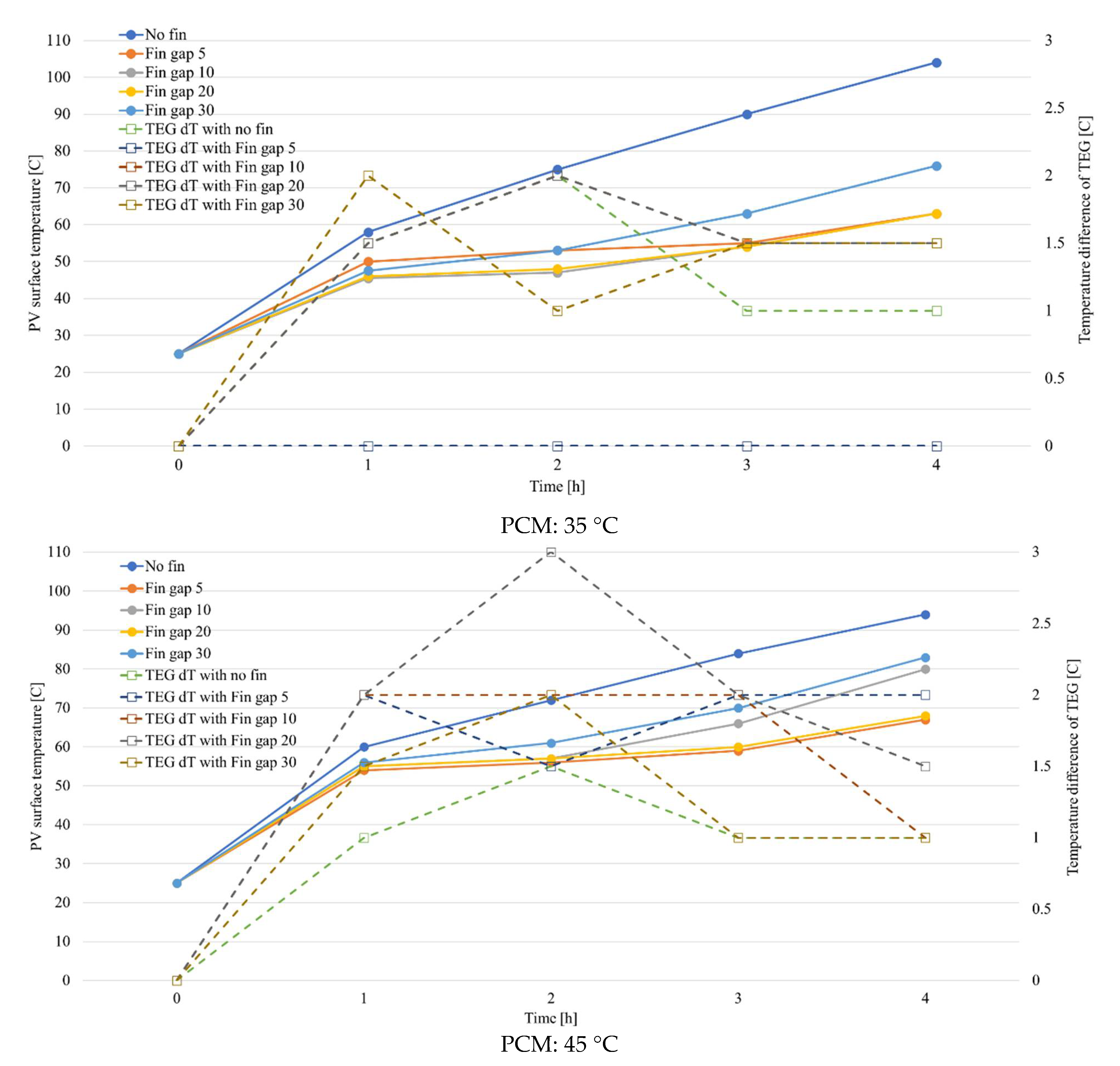

4.2. Effects of Heat Fin Interval

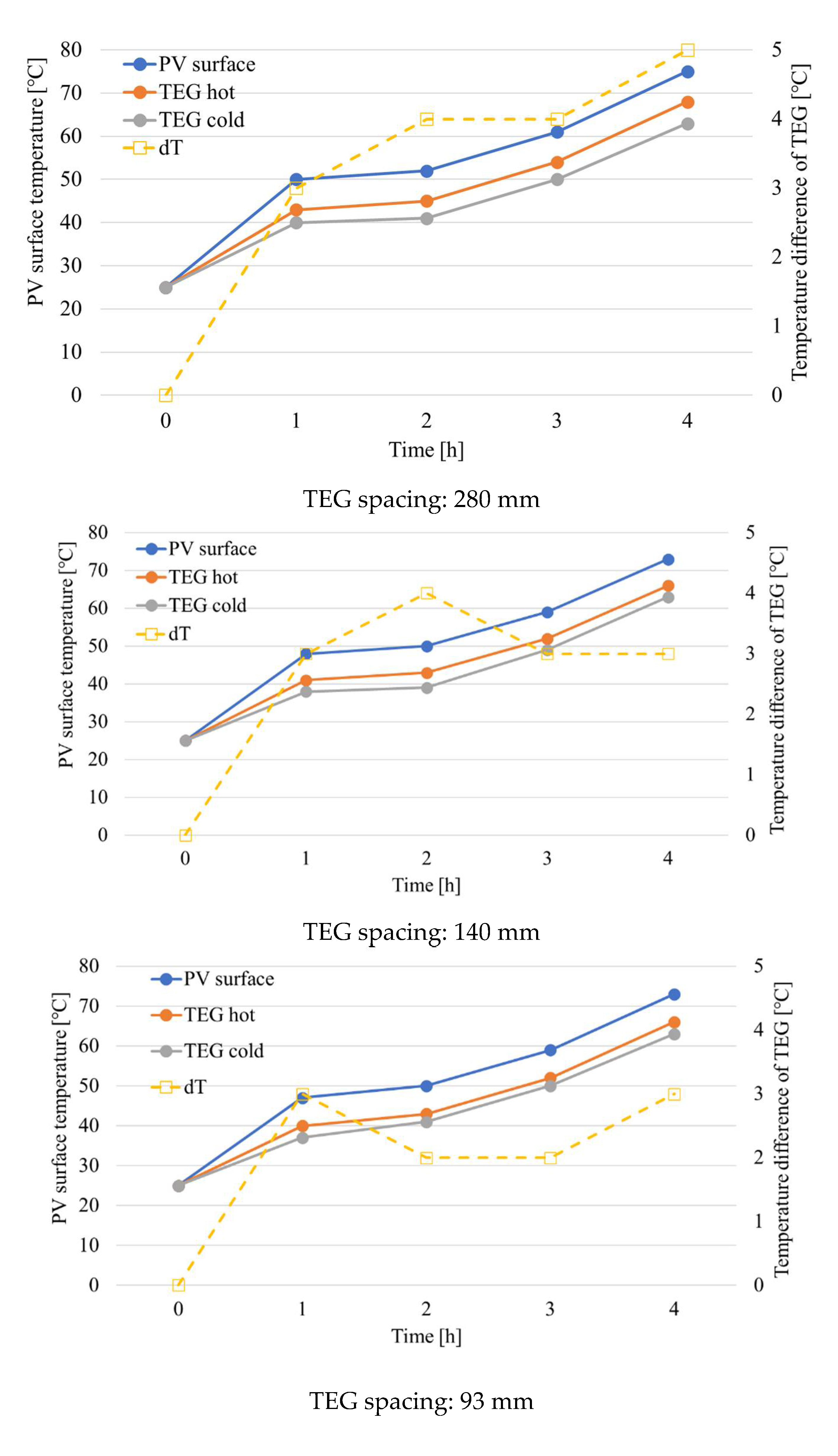

4.3. Arrangement of Thermoelectric Generator (TEG)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ng, E. Designing High-Density Cities for Social & Environmental Sustainability; Routledge: London, UK, 2009. [Google Scholar]

- United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction: Towards a Zero-emission, Efficient and Resilient Buildings and Construction Sector. Nairobi. 2020. Available online: https://globalabc.org/sites/default/files/inline-files/2020%20Buildings%20GSR_FULL%20REPORT.pdf (accessed on 2 November 2022).

- Koyunbaba, B.K.; Yilmaz, Z.; Ulgen, K. An Approach for Energy Modeling of a Building Integrated Photovoltaic (BIPV) Trombe Wall System. Energy Build. 2013, 67, 680–688. [Google Scholar] [CrossRef]

- Darkwa, J.; Calautit, J.; Du, D.; Kokogianakis, G. A Numerical and Experimental Analysis of an Integrated TEG-PCM Power Enhancement System for Photovoltaic Cells. Appl. Energy 2019, 248, 688–701. [Google Scholar] [CrossRef]

- Bayrak, F.; Oztop, H.F.; Selimefendigil, F. Experimental Study for the Application of Different Cooling Techniques in Photovoltaic (PV) Panels. Energy Convers. Manag. 2020, 212, 112789. [Google Scholar] [CrossRef]

- Kaiser, A.S.; Zamora, B.; Mazón, R.; García, J.R.; Vera, F. Experimental Study of Cooling BIPV Modules by Forced Convection in the Air Channel. Appl. Energy 2014, 135, 88–97. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, S.H.; Kang, J.G.; Kim, J.T. Experimental Performance of Heating System with Buildingintegrated PVT (BIPVT) Collector. Energy Procedia 2014, 48, 1374–1384. [Google Scholar] [CrossRef]

- Al-najjar, H.M.T.; Mahdi, J.M.; Bokov, D.O.; Ben Khedher, N.; Alshammari, N.K.; Jade, M.; Opulencia, C.; Fagiry, M.A.; Yaïci, W.; Talebizadehsardari, P. Improving the Melting Duration of a PV/PCM System Integrated with Different Metal Foam Configurations for Thermal Energy Management. Nanomaterials 2022, 12, 423. [Google Scholar] [CrossRef] [PubMed]

- Akshayveer; Kumar, A.; Singh, A.P.; Singh, O.P. Effect of Novel PCM Encapsulation Designs on Electrical and Thermal Performance of a Hybrid Photovoltaic Solar Panel. Sol. Energy 2020, 205, 320–333. [Google Scholar] [CrossRef]

- Duan, J. A Novel Heat Sink for Cooling Concentrator Photovoltaic System Using PCM-Porous System. Appl. Therm. Eng. 2021, 186, 116522. [Google Scholar] [CrossRef]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Optimization of Finned Solar Photovoltaic Phase Change Material (Finned Pv Pcm) System. Int. J. Therm. Sci. 2018, 130, 313–322. [Google Scholar] [CrossRef]

- Huang, M.J.; Eames, P.C.; Norton, B.; Hewitt, N.J. Natural Convection in an Internally Finned Phase Change Material Heat Sink for the Thermal Management of Photovoltaics. Sol. Energy Mater. Sol. Cells 2011, 95, 1598–1603. [Google Scholar] [CrossRef]

- Hasan, A.; Sarwar, J.; Alnoman, H.; Abdelbaqi, S. Yearly Energy Performance of a Photovoltaic-Phase Change Material (PV-PCM) System in Hot Climate. Sol. Energy 2017, 146, 417–429. [Google Scholar] [CrossRef]

- Sharma, S.; Tahir, A.; Reddy, K.S.; Mallick, T.K. Performance Enhancement of a Building-Integrated Concentrating Photovoltaic System Using Phase Change Material. Sol. Energy Mater. Sol. Cells 2016, 149, 29–39. [Google Scholar] [CrossRef]

- Stropnik, R.; Stritih, U. Increasing the Efficiency of PV Panel with the Use of PCM. Renew. Energy 2016, 97, 671–679. [Google Scholar] [CrossRef]

- Ong, K.S.; Naghavi, M.S.; Lim, C. Thermal and Electrical Performance of a Hybrid Design of a Solar-Thermoelectric System. Energy Convers. Manag. 2017, 133, 31–40. [Google Scholar] [CrossRef]

- Yin, E.; Li, Q.; Xuan, Y. Thermal Resistance Analysis and Optimization of Photovoltaic-Thermoelectric Hybrid System. Energy Convers. Manag. 2017, 143, 188–202. [Google Scholar] [CrossRef]

- Lin, J.; Liao, T.; Lin, B. Performance Analysis and Load Matching of a Photovoltaic-Thermoelectric Hybrid System. Energy Convers. Manag. 2015, 105, 891–899. [Google Scholar] [CrossRef]

- Makki, A. Innovative Heat Pipe-Based Photovoltaic/Thermoelectric (PV/TEG) Generation System. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2017. [Google Scholar]

- Cotfas, D.T.; Cotfas, P.A.; Machidon, O.M.; Ciobanu, D. Investigation of the Photovoltaic Cell/ Thermoelectric Element Hybrid System Performance. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 012037. [Google Scholar] [CrossRef]

- Yin, E.; Li, Q.; Li, D.; Xuan, Y. Experimental Investigation on Effects of Thermal Resistances on a Photovoltaic-Thermoelectric System Integrated with Phase Change Materials. Energy 2019, 169, 172–185. [Google Scholar] [CrossRef]

- Motiei, P.; Yaghoubi, M.; GoshtasbiRad, E. Transient Simulation of a Hybrid Photovoltaic-Thermoelectric System Using a Phase Change Material. Sustain. Energy Technol. Assessments 2019, 34, 200–213. [Google Scholar] [CrossRef]

- Naderi, M.; Ziapour, B.M.; Gendeshmin, M.Y. Improvement of Photocells by the Integration of Phase Change Materials and Thermoelectric Generators (PV-PCM-TEG) and Study on the Ability to Generate Electricity around the Clock. J. Energy Storage 2021, 36, 102384. [Google Scholar] [CrossRef]

- Ko, J.; Jeong, J.W. Annual Performance Evaluation of Thermoelectric Generator-Assisted Building-Integrated Photovoltaic System with Phase Change Material. Renew. Sustain. Energy Rev. 2021, 145, 111085. [Google Scholar] [CrossRef]

- Virgone, J.; Roux, J. Energetic Efficiency of Room Wall Containing PCM Wallboard: A Full-Scale Experimental Investigation. Energy Build. 2008, 40, 148–156. [Google Scholar] [CrossRef]

- Ansuini, R.; Larghetti, R.; Giretti, A.; Lemma, M. Radiant Floors Integrated with PCM for Indoor Temperature Control. Energy Build. 2011, 43, 3019–3026. [Google Scholar] [CrossRef]

- Osterman, E.; Tyagi, V.V.; Butala, V.; Rahim, N.A.; Stritih, U. Review of PCM Based Cooling Technologies for Buildings. Energy Build. 2012, 49, 37–49. [Google Scholar] [CrossRef]

- Karthick, A.; Kalidasa Murugavel, K.; Ghosh, A.; Sudhakar, K.; Ramanan, P. Investigation of a Binary Eutectic Mixture of Phase Change Material for Building Integrated Photovoltaic (BIPV) System. Sol. Energy Mater. Sol. Cells 2020, 207, 110360. [Google Scholar] [CrossRef]

- Byon, Y.S.; Jeong, J.W. Phase Change Material-Integrated Thermoelectric Energy Harvesting Block as an Independent Power Source for Sensors in Buildings. Renew. Sustain. Energy Rev. 2020, 128, 109921. [Google Scholar] [CrossRef]

- Huang, X.; Zhu, C.; Lin, Y.; Fang, G. Thermal Properties and Applications of Microencapsulated PCM for Thermal Energy Storage: A Review. Appl. Therm. Eng. 2019, 147, 841–855. [Google Scholar] [CrossRef]

- Chai, L.; Wang, X.; Wu, D. Development of Bifunctional Microencapsulated Phase Change Materials with Crystalline Titanium Dioxide Shell for Latent-Heat Storage and Photocatalytic Effectiveness. Appl. Energy 2015, 138, 661–674. [Google Scholar] [CrossRef]

- Diarce, G.; Campos-Celador, Á.; Martin, K.; Urresti, A.; García-Romero, A.; Sala, J.M. A Comparative Study of the CFD Modeling of a Ventilated Active Façade Including Phase Change Materials. Appl. Energy 2014, 126, 307–317. [Google Scholar] [CrossRef]

- Darzi, A.A.R.; Moosania, S.M.; Tan, F.L.; Farhadi, M. Numerical Investigation of Free-Cooling System Using Plate Type PCM Storage. Int. Commun. Heat Mass Transf. 2013, 48, 155–163. [Google Scholar] [CrossRef]

- Liu, X.D.; Park, Y.H. Structure and Transport Properties of (Bi1-XSbx)2Te3 Thermoelectric Materials Prepared by Mechanical Alloying and Pulse Discharge Sintering. Mater. Trans. 2002, 43, 681–687. [Google Scholar] [CrossRef][Green Version]

- Niu, X.; Yu, J.; Wang, S. Experimental Study on Low-Temperature Waste Heat Thermoelectric Generator. J. Power Sources 2009, 188, 621–626. [Google Scholar] [CrossRef]

- Kazemian, A.; Salari, A.; Ma, T. A Year-Round Study of a Photovoltaic Thermal System Integrated with Phase Change Material in Shanghai Using Transient Model. Energy Convers. Manag. 2020, 210, 112657. [Google Scholar] [CrossRef]

- Lim, H.; Kang, Y.K.; Jeong, J.W. Thermoelectric Radiant Cooling Panel Design: Numerical Simulation and Experimental Validation. Appl. Therm. Eng. 2018, 144, 248–261. [Google Scholar] [CrossRef]

| Description | Value |

|---|---|

| Phase change temperature [°C] | 25, 35, 45 |

| Latent heat capacity [J/kg] | 192,660 |

| Specific heat capacity [J/kg] | 1970 |

| ] | 946.4 |

| Thermal conductivity [W/mK] | 0.749 |

| Particle size [μm] | 10 |

| Material | Density [kg/m3] | Specific Heat [J/kgK] | Thermal Conductivity [W/mK] | Thickness [mm] |

|---|---|---|---|---|

| Glass | 2200 | 830 | 0.76 | 5 |

| PV | 2230 | 700 | 148 | 3 |

| Aluminum | 2719 | 871 | 202.4 | 8 |

| PET | 1500 | 1200 | 0.2 | 3 |

| TEG | 7670 | 198 | 1.61 | 4 |

| Heat fin | 2719 | 871 | 202.4 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, Y.-K.; Joung, J.; Kim, M.; Lee, H.-H.; Jeong, J.-W. Numerical Analysis of a TEG and mPCM Enhancement System for BIPVs Using CFD. Sustainability 2022, 14, 15559. https://doi.org/10.3390/su142315559

Kang Y-K, Joung J, Kim M, Lee H-H, Jeong J-W. Numerical Analysis of a TEG and mPCM Enhancement System for BIPVs Using CFD. Sustainability. 2022; 14(23):15559. https://doi.org/10.3390/su142315559

Chicago/Turabian StyleKang, Yong-Kwon, Jaewon Joung, Minseong Kim, Hyun-Hwa Lee, and Jae-Weon Jeong. 2022. "Numerical Analysis of a TEG and mPCM Enhancement System for BIPVs Using CFD" Sustainability 14, no. 23: 15559. https://doi.org/10.3390/su142315559

APA StyleKang, Y.-K., Joung, J., Kim, M., Lee, H.-H., & Jeong, J.-W. (2022). Numerical Analysis of a TEG and mPCM Enhancement System for BIPVs Using CFD. Sustainability, 14(23), 15559. https://doi.org/10.3390/su142315559