Slope Stability Analysis for the Phosphogypsum Stockpiles: A Case Study for the Sustainable Management of the Phosphogypsum Stacks in Aqaba Jordan

Abstract

1. Introduction

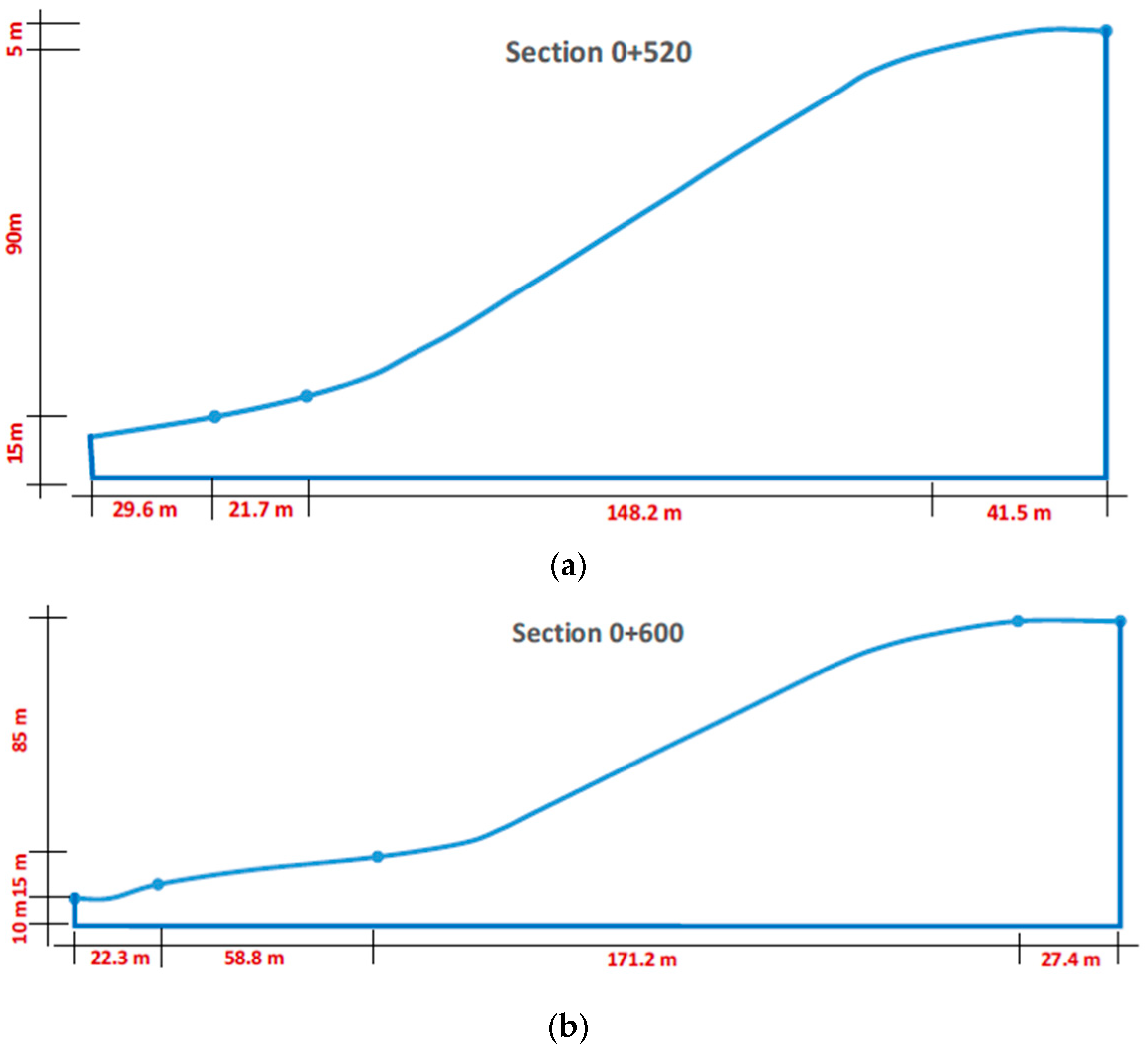

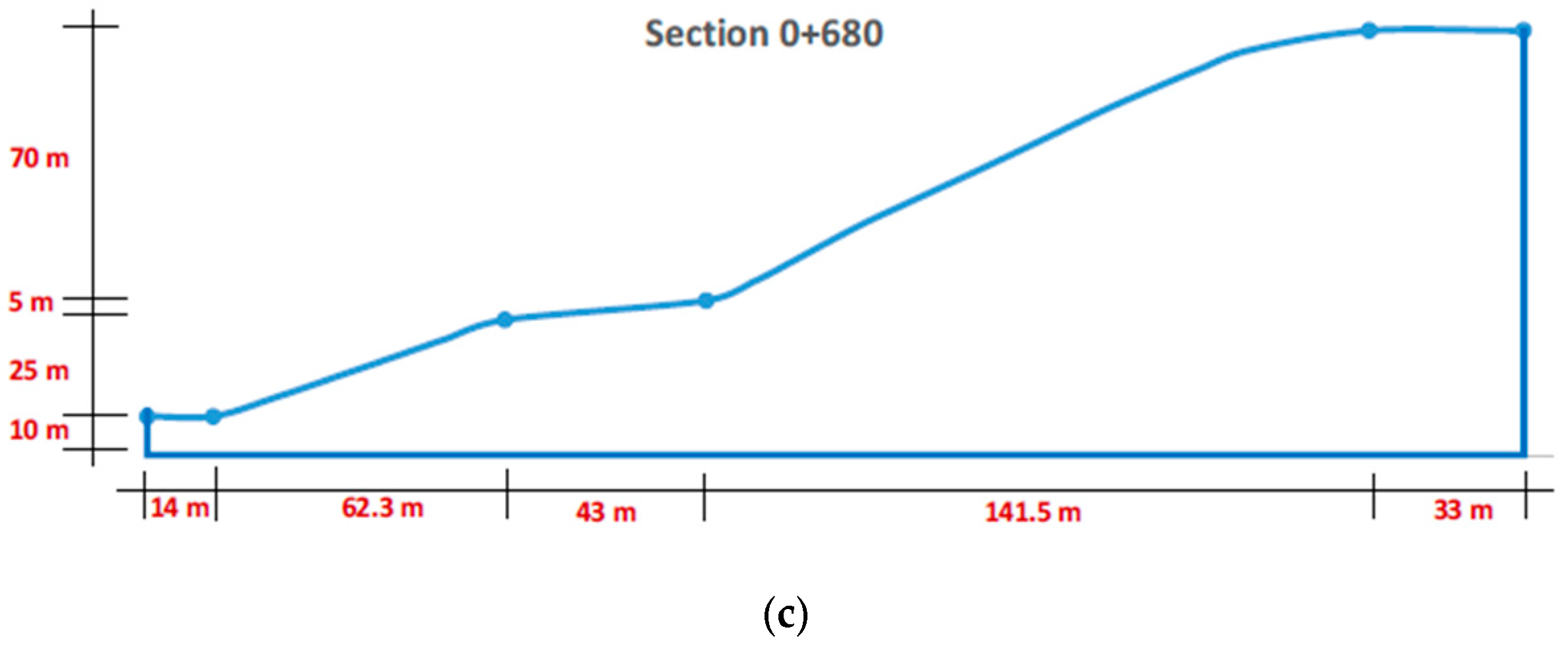

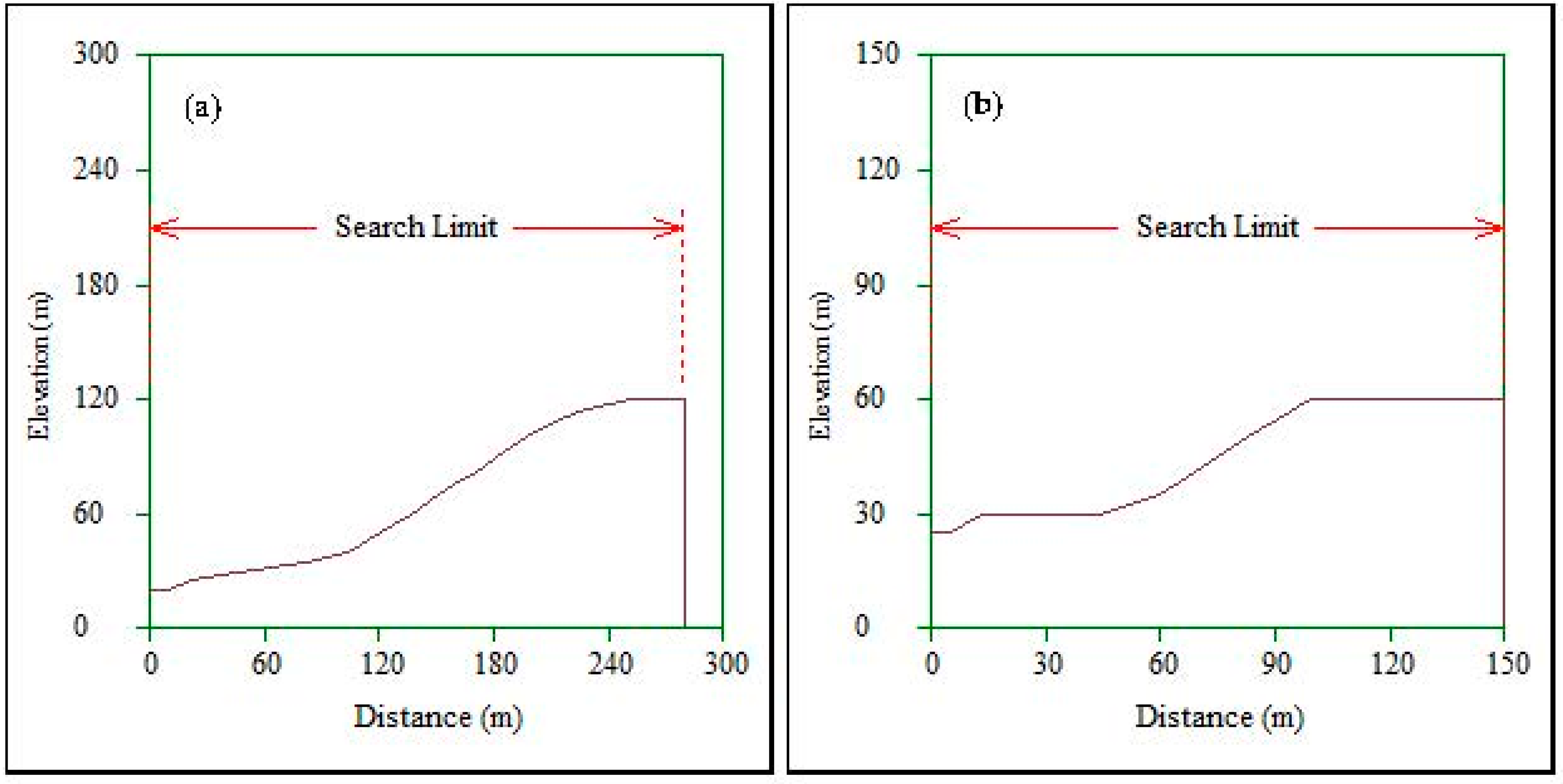

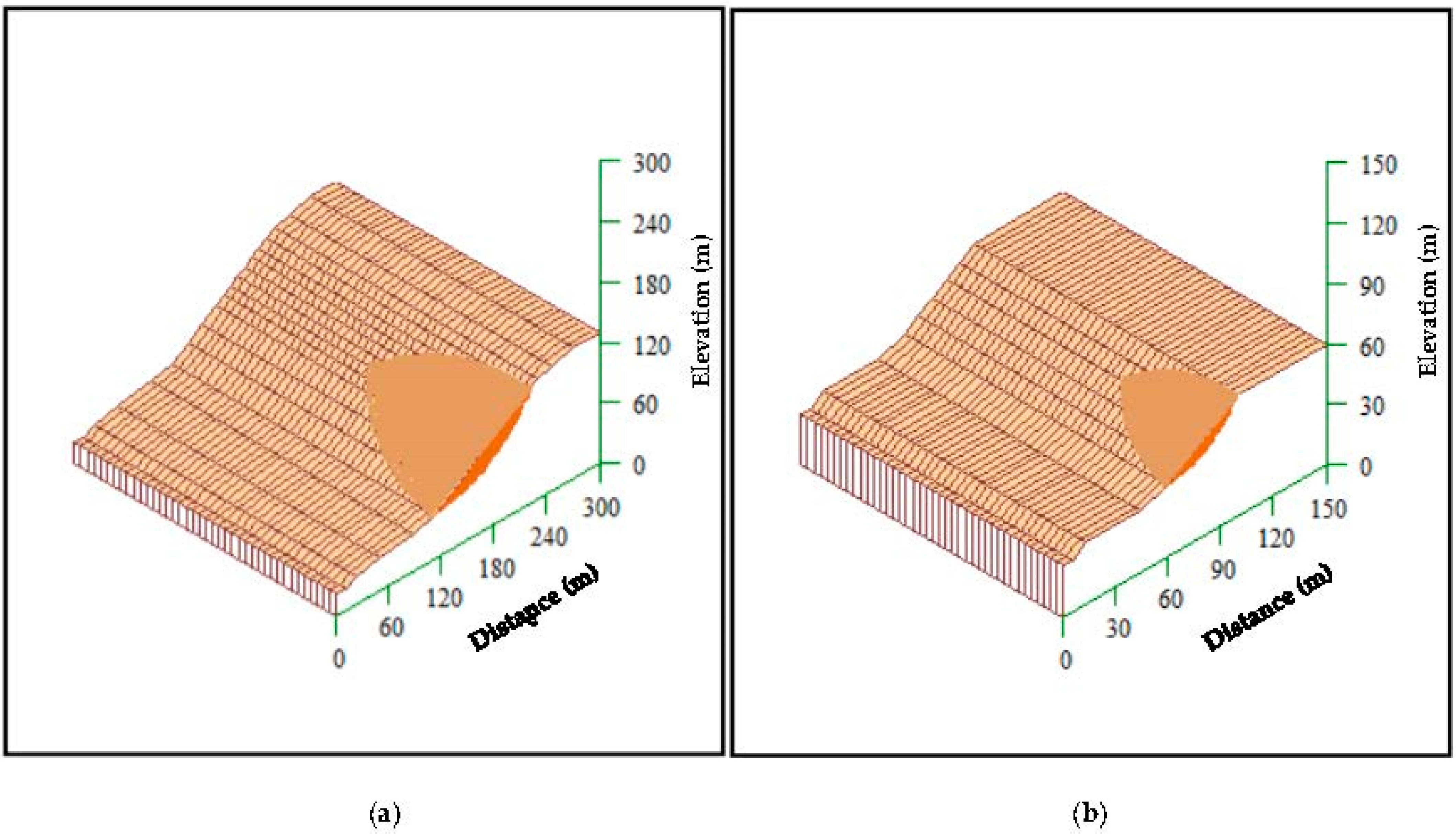

2. Geometric Configuration

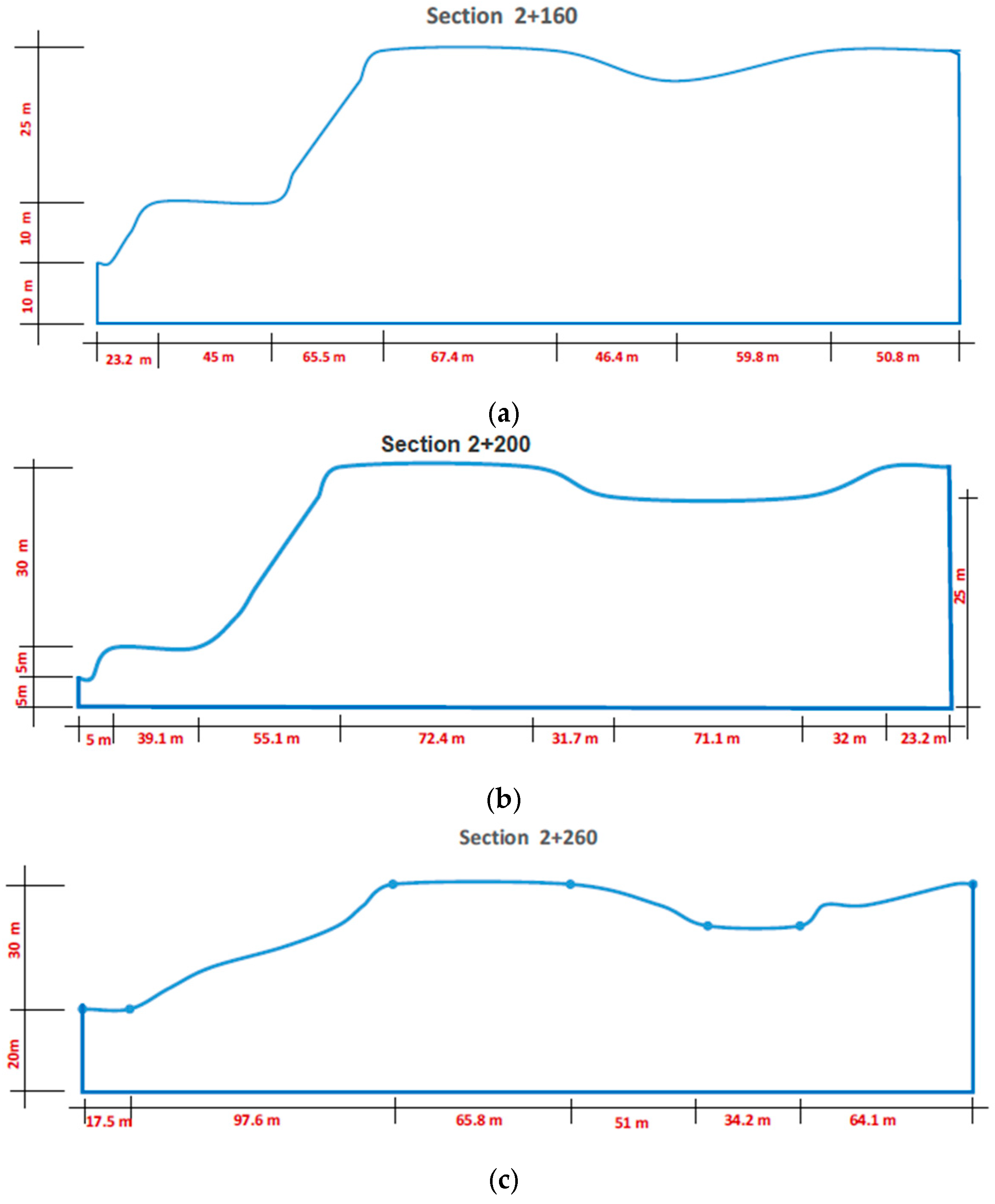

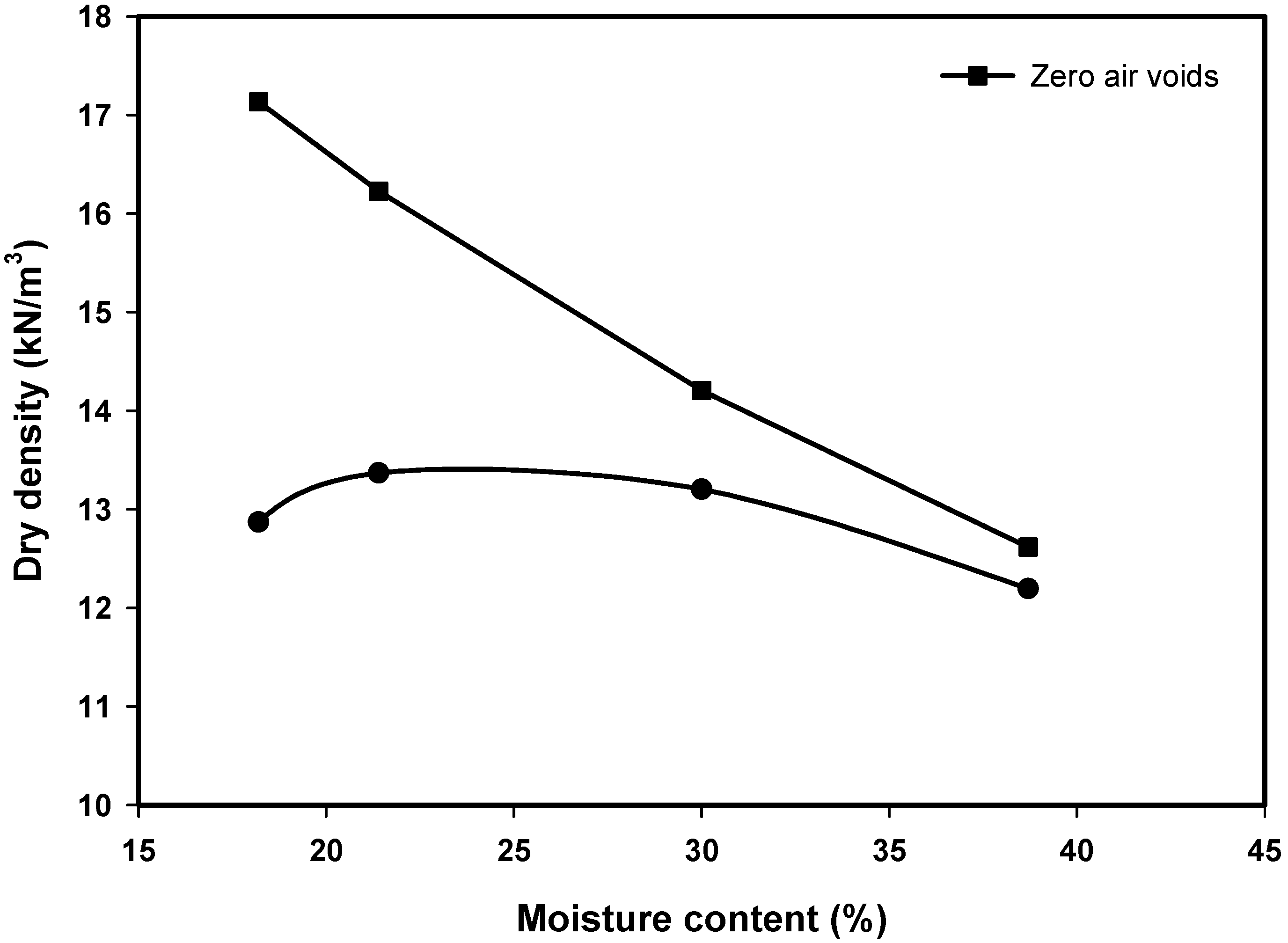

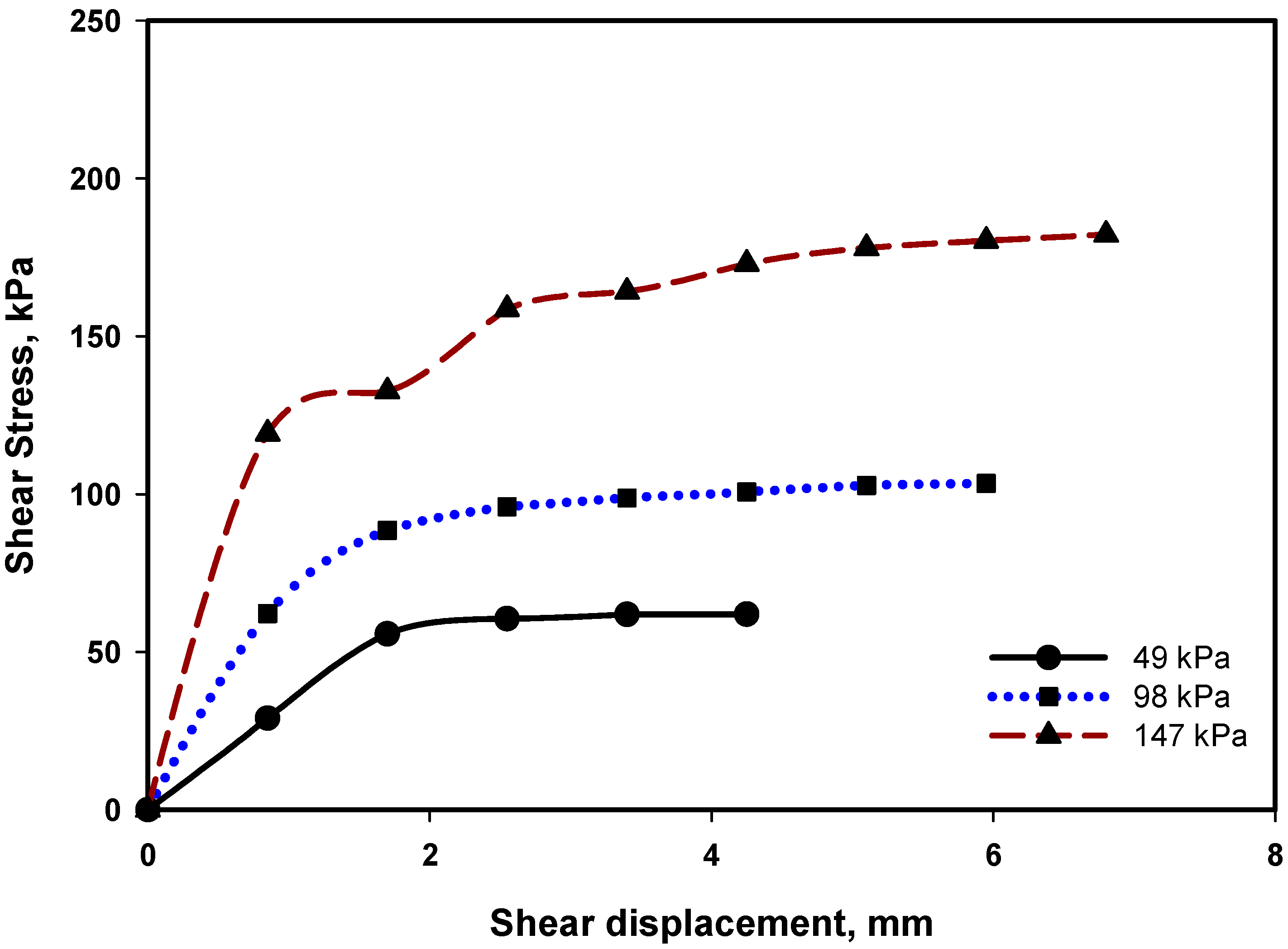

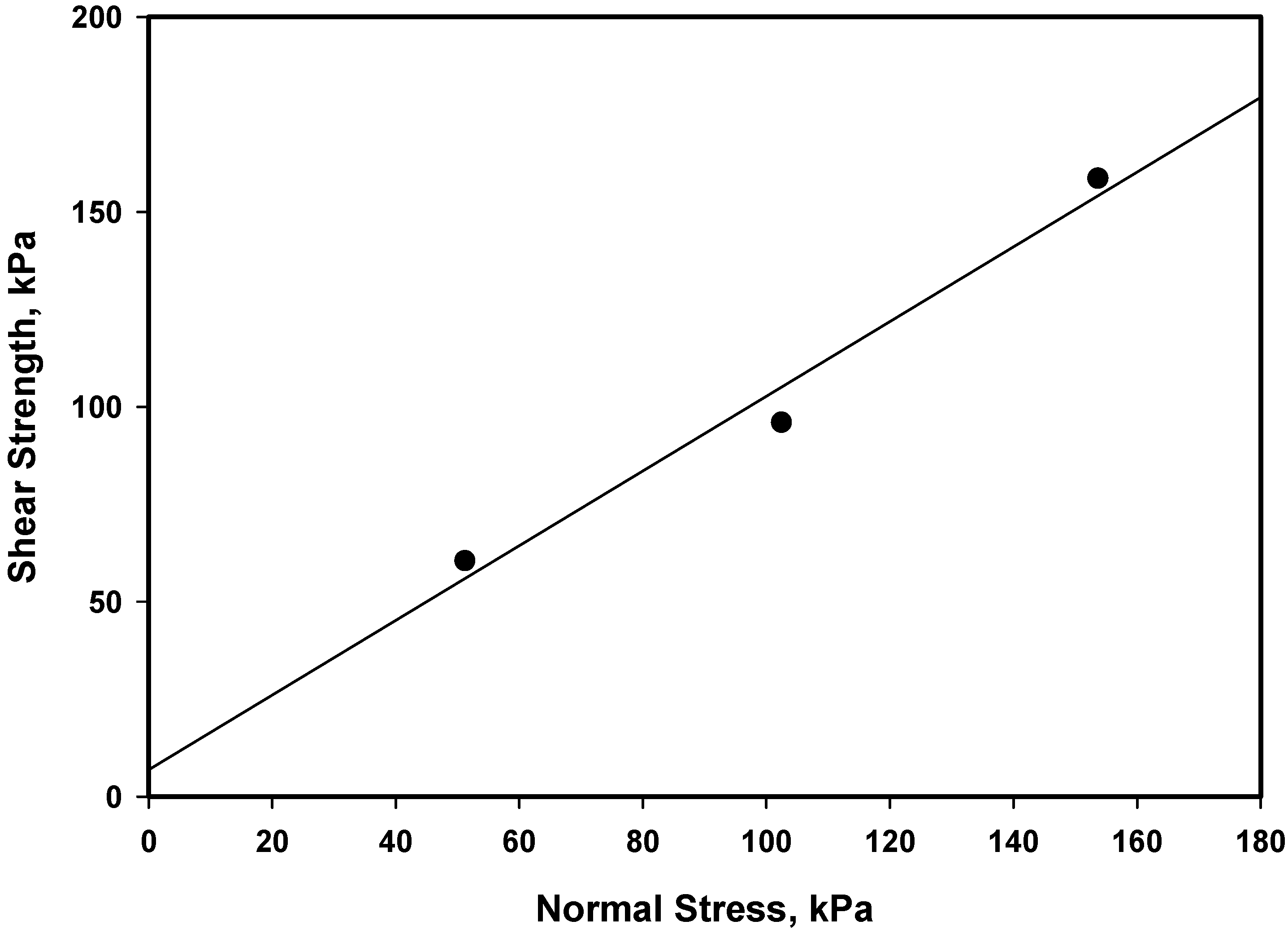

3. Material Properties

4. Methods of Analysis

5. Previous Seismicity Studies

6. Result and Discussion

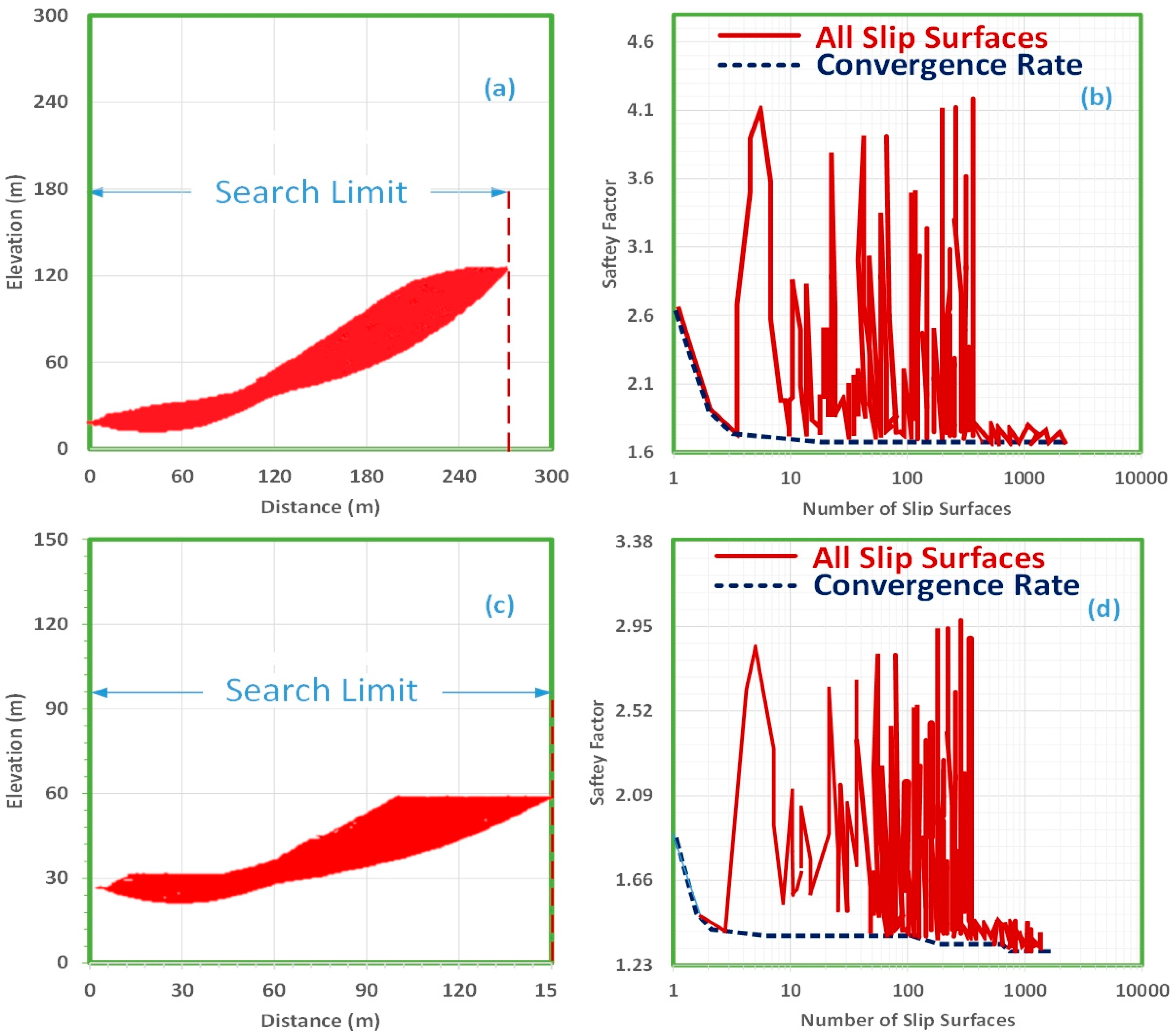

6.1. Stability Analysis Using Limiting Equilibrium Method

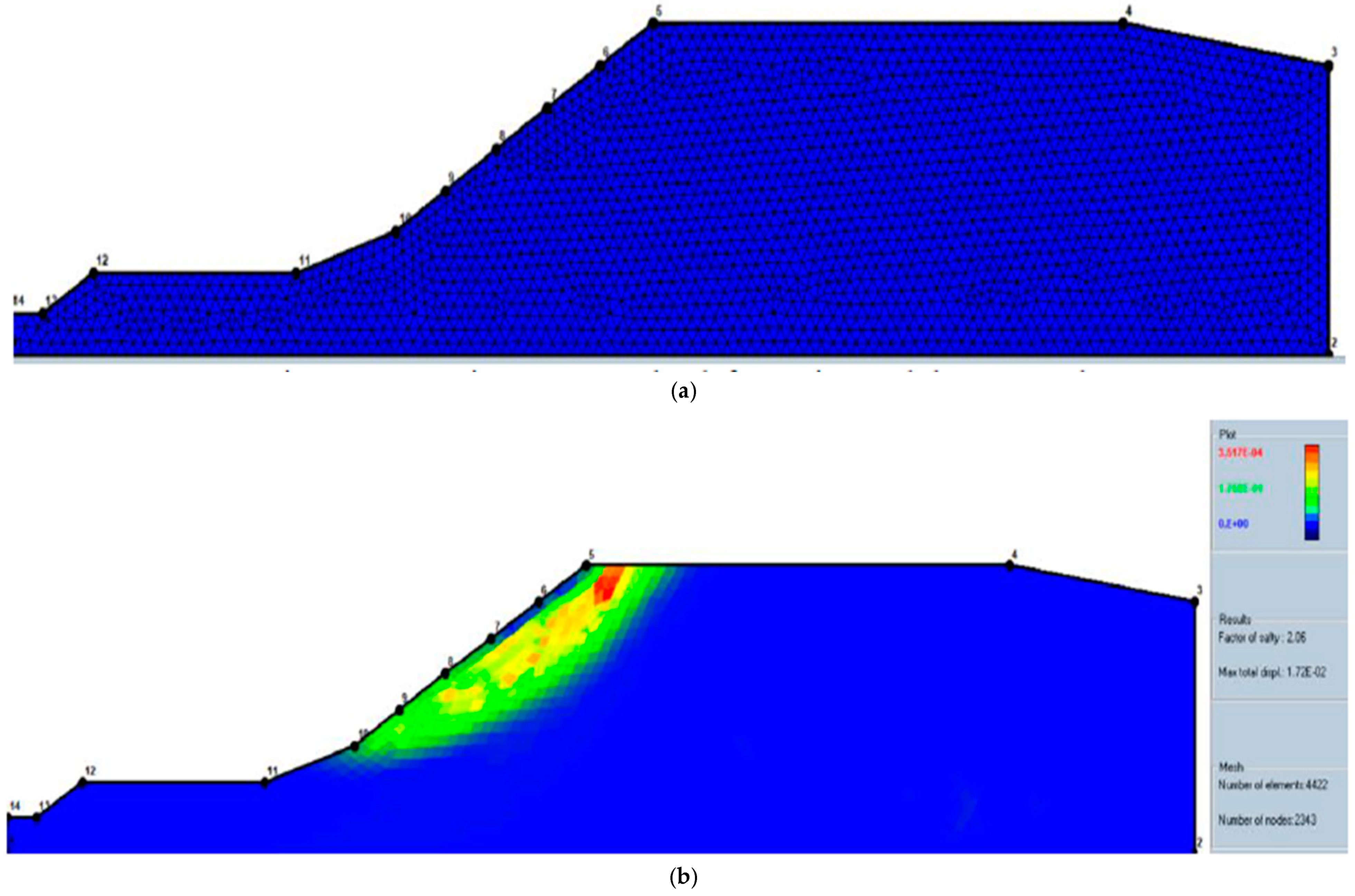

6.2. Stability Analysis Using Finite Element Method

7. Conclusions

- The Jordanian phosphogypsum is mainly composed of sands and fine-grain material, the plasticity characterization showed that the material is a low-plastic material, and its chemical composition is primarily made up of approximately 87% calcium sulfate (CaSO4).

- Two sections were singled out as the most critical sections namely the South-West and the East. Furthermore, for each section, three critical piles were selected for analysis and verification.

- Both the limit equilibrium approach (LEM) and Finite element method (FEM) analysis performed in 2-D and 3-D systems, indicate that the slopes are stable under all loading conditions (Static and Seismic loading), for all sections.

- The critical pile in the South-West section was 0 + 600 with the steepest slope with a minimum factor of safety in the static condition of 1.695 and in the seismic condition of 1.076, which indicates the stability of the pile.

- Similarly, the critical section in the East pile (2 + 200) has a minimum factor of safety of 1.896 in static conditions and 1.072 in seismic conditions.

8. Study Limitations and Future Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chernysh, Y.; Yakhnenko, O.; Chubur, V.; Roubík, H. Phosphogypsum Recycling: A Review of Environmental Issues, Current Trends, and Prospects. Appl. Sci. 2021, 11, 1575. [Google Scholar] [CrossRef]

- Outbakat, M.B.; El Mejahed, K.; El Gharous, M.; El Omari, K.; Beniaich, A. Effect of Phosphogypsum on Soil Physical Properties in Moroccan Salt-Affected Soils. Sustainability 2022, 14, 13087. [Google Scholar] [CrossRef]

- Cichy, B.; Kraszewski, C.; Rafalski, L. Geotechnical Properties of Phosphogypsum and Its Use in Road Engineering. In Proceedings of the China-Europe Conference on Geotechnical Engineering, Vienna, Austria, 13–16 August 2018; Springer: Cham, Switzerland, 2018; pp. 1664–1667. [Google Scholar]

- Mesić, M.; Brezinščak, L.; Zgorelec, Ž.; Perčin, A.; Šestak, I.; Bilandžija, D.; Trdenić, M.; Lisac, H. The application of phosphogypsum in agriculture. Agric. Conspec. Sci. 2016, 81, 7–13. [Google Scholar]

- Abdel-Fattah, M.K.; El-Naka, E.S.A. Empirical approach of leaching curves for determining the efficiency of reclaiming saline-sodic soils in Sahl El-Tina, Sinai, Egypt. Int. J. Plant Soil Sci. 2015, 8, 13–15. [Google Scholar] [CrossRef] [PubMed]

- Enamorado, S.; Abril, J.M.; Mas, J.L.; Periáñez, R.; Polvillo, O.; Delgado, A.; Quintero, J.M. Transfer of Cd, Pb, Ra and U from Phosphogypsum Amended Soils to Tomato Plants. Water Air Soil Pollut. 2009, 203, 65–77. [Google Scholar] [CrossRef]

- Abril, J.-M.; García-Tenorio, R.; Enamorado, S.M.; Hurtado, M.D.; Andreu, L.; Delgado, A. The cumulative effect of three decades of phosphogypsum amendments in reclaimed marsh soils from SW Spain: 226Ra, 238U and Cd contents in soils and tomato fruit. Sci. Total Environ. 2008, 403, 80–88. [Google Scholar] [CrossRef]

- Saadaoui, E.; Ghazel, N.; Ben Romdhane, C.; Massoudi, N. Phosphogypsum: Potential uses and problems—A review. Int. J. Environ. Stud. 2017, 74, 558–567. [Google Scholar] [CrossRef]

- Islam, G.S.; Chowdhury, F.H.; Raihan, M.T.; Amit, S.K.S.; Islam, M.R. Effect of Phosphogypsum on the Properties of Portland Cement. Procedia Eng. 2017, 171, 744–751. [Google Scholar] [CrossRef]

- Gascó, C.; Alvarez, A.; Navarro, N.; Yagüe, L.; Tayibi, H.; López Gómez, F.A.; Antonio, F.; López-Delgado, A.; Alguacil, F.J. Advantages and disadvantages of using phosphogypsum as building material. In Proceedings of the 1st Spanish National Conference on Advances in Materials Recycling and Eco-Energy, Madrid, Spain, 12–13 November 2009. [Google Scholar]

- Ajam, L.; Ben Ouezdou, M.; Felfoul, H.S.; El Mensi, R. Characterization of the Tunisian phosphogypsum and its valorization in clay bricks. Constr. Build. Mater. 2009, 23, 3240–3247. [Google Scholar] [CrossRef]

- López, F.A.; Gázquez, M.; Alguacil, F.J.; Bolívar, J.P.; García-Díaz, I.; López-Coto, I. Microencapsulation of phosphogypsum into a sulfur polymer matrix: Physico-chemical and radiological characterization. J. Hazard. Mater. 2011, 192, 234–245. [Google Scholar] [CrossRef]

- Amrani, M.; Taha, Y.; Kchikach, A.; Benzaazoua, M.; Hakkou, R. Phosphogypsum recycling: New horizons for a more sustainable road material application. J. Build. Eng. 2020, 30, 101267. [Google Scholar] [CrossRef]

- Silva, M.V.; de Rezende, L.R.; dos Anjos Mascarenha, M.M.; de Oliveira, R.B. Phosphogypsum, tropical soil and cement mixtures for asphalt pavements under wet and dry environmental conditions. Resour. Conserv. Recycl. 2019, 144, 123–136. [Google Scholar] [CrossRef]

- Rutherford, M.J.; Dudas, P.M.; Samek, R.A. Environmental impacts of phosphogypsum. Sci. Total Environ. 1994, 149, 1–38. [Google Scholar] [CrossRef]

- Lysandrou, M.; Pashalidis, I. Uranium chemistry in stack solutions and leachates of phosphogypsum disposed at a coastal area in Cyprus. J. Environ. Radioact. 2008, 99, 359–366. [Google Scholar] [CrossRef]

- Al-Hwaiti, M.S.; Al-Khashman, O.A. Potentially Utilizations of Jordan Phosphogypsum: A Review. Int. J. Curr. Res. 2019, 11, 3258–3262. [Google Scholar]

- Tayibi, H.; Choura, M.; López, F.A.; Alguacil, F.J.; López-Delgado, A. Environmental impact and management of phosphogypsum. J. Environ. Manag. 2009, 90, 2377–2386. [Google Scholar] [CrossRef]

- Al-Hwaiti, M.; Ranville, J.; Ross, P. Bioavailability and mobility of trace metals in phosphogypsum from Aqaba and Eshidiya, Jordan. Geochemistry 2010, 70, 283–291. [Google Scholar] [CrossRef]

- Yeh, H.-F.; Huang, T.-T.; Lee, J.-W. Effect of Unimodal and Bimodal Soil Hydraulic Properties on Slope Stability Analysis. Water 2021, 13, 1674. [Google Scholar] [CrossRef]

- Paige-Green, P.; Gerber, S. An evaluation of the use of by-product phosphogypsum as a pavement material for roads. In Proceedings of the South African Transport Conference “Action in Transport for the New Millennium”, Pretoria, South Africa, 17–20 July 2000. [Google Scholar]

- Havanagi, V.; Sinha, A.K.; Parvathi, G.S. Characterization of Phosphogypsum waste for Road construction. In Proceedings of the Indian Geotechnical Conference, Bengaluru, India, 13–15 December 2018; pp. 13–15. [Google Scholar]

- IAEA. Radiation Protection and Management of NORM Residues in the Phosphate Industry. Safety Reports Series. No. 78. 2013. Available online: http://www-pub.iaea.org/MTCD/Publications/PDF/Pub1582_web.pdf (accessed on 25 June 2020).

- Janbu, N. Application of composite slip surface for stability analysis. In Proceedings of the European Conference on Stability of Earth Slopes, Stockholm, Sweden, 24–25 September 1954. [Google Scholar]

- Janbu, N. Slope stability computations. In Embankment Dam Engineering (Casagrande Memorial Volume); Hirschfield, E., Poulos, S., Eds.; John Wiley: New York, NY, USA, 1973. [Google Scholar]

- Husein Malkawi, A.I.; Fahmi, K.J. Locally derived earthquake ground motion attenuation relations for Jordan and conterminous areas. Q. J. Eng. Geol. 1996, 29, 309–319. [Google Scholar] [CrossRef]

- Jiménez, M.J. “Jordan Seismic Hazard Mapping” Final Report 20.07.2004; Institute of Earth Sciences “Jaume Almera” prepared for the Jordan Atomic Energy Commission (JAEC); Institute of Earth Sciences “Jaume Almera”: Barcelona, Spain, 2004. [Google Scholar]

- Ambraseys, N.N.; Simpson, K.A.; Bommer, J.J. Prediction of horizontal response spectra in Europe. Earthq. Eng. Struct. Dyn. 1996, 25, 371–400. [Google Scholar] [CrossRef]

- Malkawi, A.I.H.; Hassan, W.F.; Sarma, S.K. Global Search Method for Locating General Slip Surface Using Monte Carlo Techniques. J. Geotech. Geoenviron. Eng. 2001, 127, 688–698. [Google Scholar] [CrossRef]

- Husein Malkawi, A.I.; Hassan, W.F.; Sarma, S.K. An efficient search method for locating circular slip surface using Monte Carlo Technique. Can. Geotech. J. 2001, 38, 1081–1089. [Google Scholar] [CrossRef]

- Husein Malkawi, A.I.; Hassan, W.F. SAS-MCT 4.0, Stability Analysis of Slopes Using Monte Carlo Technique. A Software for 2-D and 3-D Slope Stability Analysis with Dynamic Effect, including Non-Circular Slip Surface. Windows Version. 2005. [Google Scholar]

- Duncan, J.M.; Wright, S.G.; Brandon, T.L. Soil Strength and Slope Stability, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Stark, T.D.; Ruffing, D.G. Selecting Minimum Factor of Safety for 3D Slope Stability Analyses. In Proceedings of the Geo-Risk 2017 Conference, Denver, CO, USA, 4–7 June 2017. Geotechnical Special Publication. [Google Scholar]

- Husein Malkawi, A.I.; Belakhdar, K. SAS-FEM 5.0, Stability Analysis of Slopes Using Finite Element Method. A Software for Slope Stability Analysis with Dynamic effect, Windows Version. 2008. [Google Scholar]

| Analysis | Unit | Results |

|---|---|---|

| P2O5 | % | 1.87 |

| SO3 | % | 51.22 |

| SiO2 | % | 9.14 |

| Al2O3 | % | 0.26 |

| Fe2O3 | % | 0.15 |

| K2O | % | 0.02 |

| Na2O | % | 0.42 |

| F | % | 0.79 |

| Calcium Oxide | % | 35.56 |

| Dry solids at 60 C | % | 96 |

| Dry solids at 250 C | % | 80.52 |

| CI | PPm | 94 |

| PH (1% Solution) | 3.340 |

| Condition | Minimum | |

|---|---|---|

| 1 | For general slope stability analysis of permanent cut, fill.. etc. | 1.25 to 1.5 |

| 2 | With earthquake loading in addition (Pseudo-static) | 1.0 |

| Soil Strength Uncertainty | Imminent Threat to Human Life | Potential for Major Construction or Environmental Impact | Recommended Minimum 2-D FS | Minimum 3-D FS |

|---|---|---|---|---|

| Small | Low | Low | 1.3 | 1.4 |

| Small | High | High | 1.5 | 1.7 |

| Small | Low | High | 1.3 | 1.5 |

| Small | High | Low | 1.5 | 1.7 |

| Large | Low | Low | 1.5 | 1.7 |

| Large | High | High | 2.0 | 2.3 |

| Large | Low | High | 1.5 | 1.7 |

| Large | High | Low | 2.0 | 2.3 |

| Condition | Factor of Safety | |||||||

|---|---|---|---|---|---|---|---|---|

| Limit Equilibrium Methods (LEA) | Circular | Non-Circular | Minimum Required Factor of Safety | |||||

| Static | Dynamic | Static | Dynamic | |||||

| 2-D | 3-D | 2-D | 3-D | 2-D | 2-D | |||

| Present Level (Static) | Ordinary Method | 1.7 | - | - | - | - | - | 1.25 to 1.5 |

| Bishop | 1.814 | 1.803 | - | - | - | - | ||

| Janbu | 1.695 | 1.773 | - | - | 1.82 | - | ||

| With Earthquick Loading (Pseudo-static) | Ordinary Method | - | - | 1.408 * 1.30 ** | - | - | - | 1.00 |

| Bishop | - | - | 1.399 * 1.247 ** | 1.203 * 1.027 ** | - | - | ||

| Janbu | - | - | 1.297 * 1.152 ** | 1.252 * 1.076 ** | - | 1.372 * 1.228 ** | ||

| Condition | Factor of Safety | |||||||

|---|---|---|---|---|---|---|---|---|

| Limit Equilibrium Methods (LEA) | Circular | Non-Circular | Minimum Required Factor of Safety | |||||

| Static | Dynamic | Static | Dynamic | |||||

| 2-D | 3-D | 2-D | 3-D | 2-D | 2-D | |||

| Present Level (Static) | Ordinary Method | 1.905 | - | - | - | - | - | 1.25 to 1.5 |

| Bishop | 2.027 | 2.073 | - | - | - | - | ||

| Janbu | 1.896 | 2.018 | - | - | 2.119 | - | ||

| With Earthquick Loading (Pseudo-static) | Ordinary Method | - | - | 1.567 * 1.444 ** | - | - | - | 1.00 |

| Bishop | - | - | 1.567 * 1.40 ** | 1.246 * 1.035 ** | - | - | ||

| Janbu | - | - | 1.452 * 1.291 ** | 1.292 * 1.072 ** | - | 1.52 * 1.44 ** | ||

| Pile ID | Finite Element Method (FEM), (Static Analysis) | |||

|---|---|---|---|---|

| The Minimum Required Factor of Saftey Is 1.25 to 1.5 | ||||

| Factor of Safety | Number of Nodes | Number of LST Element | Max Displacement, (m) | |

| 0 + 520 | 1.84 | 2300 | 4372 | 0.211 |

| 0 + 600 | 1.82 | 2181 | 4125 | 0.173 |

| 0 + 680 | 2.12 | 2515 | 4778 | 0.246 |

| 2 + 160 | 2.18 | 1781 | 3347 | 0.0204 |

| 2 + 200 | 2.06 | 2343 | 4422 | 0.0172 |

| 2 + 260 | 3.3 | 2189 | 4154 | 0.0268 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Husein Malkawi, D.A.; Husein Malkawi, A.I.; Bani-Hani, K.A. Slope Stability Analysis for the Phosphogypsum Stockpiles: A Case Study for the Sustainable Management of the Phosphogypsum Stacks in Aqaba Jordan. Sustainability 2022, 14, 15763. https://doi.org/10.3390/su142315763

Husein Malkawi DA, Husein Malkawi AI, Bani-Hani KA. Slope Stability Analysis for the Phosphogypsum Stockpiles: A Case Study for the Sustainable Management of the Phosphogypsum Stacks in Aqaba Jordan. Sustainability. 2022; 14(23):15763. https://doi.org/10.3390/su142315763

Chicago/Turabian StyleHusein Malkawi, Dima A., Abdallah I. Husein Malkawi, and Khaldoon A. Bani-Hani. 2022. "Slope Stability Analysis for the Phosphogypsum Stockpiles: A Case Study for the Sustainable Management of the Phosphogypsum Stacks in Aqaba Jordan" Sustainability 14, no. 23: 15763. https://doi.org/10.3390/su142315763

APA StyleHusein Malkawi, D. A., Husein Malkawi, A. I., & Bani-Hani, K. A. (2022). Slope Stability Analysis for the Phosphogypsum Stockpiles: A Case Study for the Sustainable Management of the Phosphogypsum Stacks in Aqaba Jordan. Sustainability, 14(23), 15763. https://doi.org/10.3390/su142315763