A Comprehensive Review on Construction Applications and Life Cycle Sustainability of Natural Fiber Biocomposites

Abstract

1. Introduction

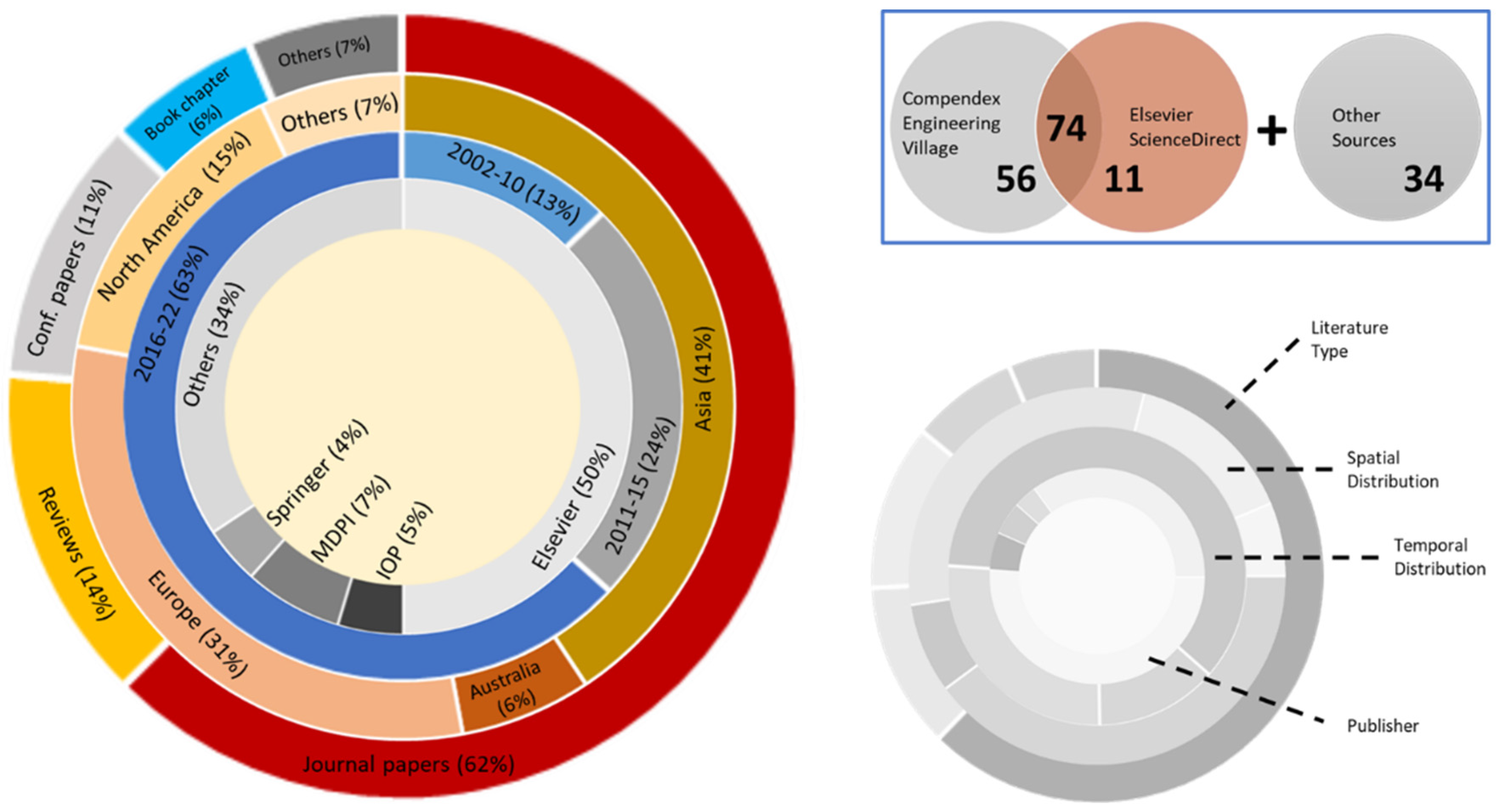

2. Methodology

3. Biocomposites

3.1. Natural Fibers for Biocomposites

3.2. Rise in Research and Industrial Applications

- Sound absorbers for noise control [49]

- Mats, gardening articles, and storage cabinets [47]

- Biomedical and optical applications [53]

- Marine application (limited) [57]

4. Biocomposites as Construction Materials

4.1. Field Applications

4.2. Natural Fibers as Reinforcement

4.3. External Strengthening Agent

4.4. Internally Filled FRP Tubes

4.5. Bio-Based Sandwich Panels

4.6. Insulation and other Applications

| Author (Year) | Region | Material Combination | Objectives | Findings | Weakness/Recommendation |

|---|---|---|---|---|---|

| Ibraheem et al. (2011) [23] | Malaysia | Insulation boards (kenaf) | Development of green insulation boards using polyurethane with kenaf fibers | 50% kenaf fiber content was optimum (out of 40%, 50% & 60%) Thermal conductivity reduced with an increase in fiber content The NaOH treatment of kenaf fibers increased the mechanical properties. | The use of optimum content and proper treatment of fibers keeping in account the porosity and bonding of fibers can help produce high-quality insulation products. |

| Korjenic et al. (2016) [46] | Austria | Plant-based building facades (flax, hemp & jute) | Present results regarding insulation material based on natural fibers | Optimal mix of materials out of all combinations provided thermal performance comparable to market materials | Recommended due to their thermal performance and smaller PEI (primary energy input) compared to glass fibers. |

| Brzyski et al. (2017) [148] | Poland | Hemp Flax composite material | Study various combinations of flax-hemp composites foe low energy buildings | Composites showed low strength, low density, low thermal conductivity and high absorptivity. | Recommended as insulation/filler or for external wall construction |

| Costantine et al. (2018) [149] | France | Hemp lime concrete for insulation | Assess the performance of the building in terms of thermal insulation | Reasonable thermal comfort (some high relative humidity areas) | Limitations in terms of site implementation of hemp concrete as compared to other materials |

| Garikapati et al. (2020) [68] | Canada | Flax lime concrete/beams with jute fabric mesh | Study flax shives mixed with a lime-based binder work as a construction material | Jute fabric was effective in crack control | Recommended for infilling masonry blocks and for filling wall cavities as insulation |

4.7. Key Concerns and Challenges

5. Life Cycle Sustainability of Biocomposites

5.1. Environmental Performance

5.2. Economic Performance

5.3. Environmental and Economic Benefits

- Their production processes are less energy-intensive, and their lighter nature (in weight) helps their transportation. The low weight also helps automobile manufacture due to fuel efficiency [44]. The transport distance of raw materials is a critical factor. For example, the fibers imported from other countries can cost even more and produce more emissions than the locally available synthetic fibers.

- Compared to glass or carbon, natural fibers like hemp, sisal and flax have less health implications for industry workers. They also reduce the burden on the manufacturing equipment due to decreased abrasion.

5.4. Research Gaps and Future Needs

- Natural fiber-based biocomposites have a wide range of encouraging construction applications and bright sustainability prospects. Biocomposites’ projected environmental benefits are based on limited studies. Therefore, detailed lifecycle-based assessments of biocomposites as building materials should be conducted to establish them in the world’s construction market.

- Biocomposites’ economic and social lifecycle impacts have been investigated less than their environmental aspects, as indicated by the low number of records on research databases. More studies on life cycle costing (LCC) and social life cycle assessment (sLCA) can enhance the current body of knowledge on biocomposites’ sustainability.

- Introducing an innovative material in a well-established construction industry is daunting. Both mechanical properties and the life cycle sustainability aspects must be incorporated in decision and policy-making. This process necessitates a decision support framework that can incorporate complex criteria and rank the biocomposites against synthetic composites under various scenarios.

6. Conclusions

- The research and development in biocomposites have received an exponential boost in the last five years due to their sustainability potential, specifically in the construction sector. Biocomposites primarily use natural fibers from plant sources (lignocellulosic fibers) like flax, hemp, jute, and kenaf. Their field applications include biocomposite bridges in the Netherlands and widely used hempcrete, which have paved the way for more bio-based structures.

- The most common application is using natural fiber as reinforcement in concrete. The current literature indicates that the compressive strength of natural fiber reinforced cementitious composites/concrete tends to be lower or comparable with concrete having no fibers. The decline in strength occurs due to fibers’ low density and softer nature. However, the natural fibers addition results in enhanced post-cracking behavior, flexural strength, and impact resistance. Moreover, natural fibers also provide internal curing and reduce the early shrinkage for high-performance concretes. The challenges in its use are a selection of optimum fiber content, mix design, suitable fiber length, and the surface treatment method.

- The strength enhancement using natural FRPs for structural strengthening often lies below the synthetic composites; nevertheless, the strengthening effect is substantially higher than the un-strengthened specimens. Moreover, the natural FRPs also show higher ductility and energy absorption than carbon and glass FRP. The strengthening effect also depends on the number of FRP layers, fabrication, and direction of fibers. The concern related to natural FRPs is their long-term durability which must be addressed for longer service life.

- Natural fiber biocomposites have shown significant results as non-load-bearing members like insulation, boards, sound absorbers, facades and foamed sandwich panels (which can also be load-bearing). Biocomposite insulations provide thermal performance and comfort comparable to market materials. The applications like bio-based panels and natural FRP tubular members need more exploration in terms of fibers, as current studies mainly cover flax fibers.

- Biocomposites promise to be economical and environmentally friendly construction materials because of their natural origin; however, evaluating their life cycle assessment and cost is vital to have a broader picture of their prospects. The available studies along with the economic and energy footprint data validate their benefits to some extent. However, the current literature is deficient in life cycle studies of biocomposites, particularly as a construction material. Moreover, there are environmental impact categories where biocomposites underperform compared to synthetic composites. Therefore, it is necessary to have more lifecycle-based case studies for various scenarios. A life-cycle decision support tool can present a comprehensive package to planners, designers, and other construction stakeholders to select and rank biocomposites for different applications and regions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Department of Economic and Social Affairs of United Nations. World Population Prospects 2019; United Nations, Ed.; United Nations: New York, NY, USA, 2019; ISBN 9789211483161. [Google Scholar]

- Statista. Global Construction Industry Spending 2014–2019, with Forecasts up Until 2035 Published by Raynor de Best, 15 February 2021. The Construction Industry Grew to a Spending Value of Close to 12 Trillion, U.S. Dollars before the Coronavirus Pandemic, and Is Expecte. Available online: https://www.statista.com/statistics/788128/construction-spending-worldwide/ (accessed on 16 April 2021).

- Ferrer, A.L.C.; Thomé, A.M.T.; Scavarda, A.J. Sustainable urban infrastructure: A review. Resour. Conserv. Recycl. 2018, 128, 360–372. [Google Scholar] [CrossRef]

- Thomé, A.M.T.; Ceryno, P.S.; Scavarda, A.; Remmen, A. Sustainable infrastructure: A review and a research agenda. J. Environ. Manag. 2016, 184, 143–156. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.; Yadav, N.K. A Review on Comparison of Ancient and Modern Construction Materials in Civil Engineering. Int. J. Res. Appl. Sci. Eng. Technol. 2016, 4, 254–256. [Google Scholar]

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282. [Google Scholar] [CrossRef]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- Chang, Y.; Ries, R.J.; Wang, Y. The quantification of the embodied impacts of construction projects on energy, environment, and society based on I-O LCA. Energy Policy 2011, 39, 6321–6330. [Google Scholar] [CrossRef]

- Asadollahfardi, G.; Asadi, M.; Karimi, S. Life-Cycle Assessment of Construction in a Developing Country. Environ. Qual. Manag. 2015, 24, 11–21. [Google Scholar] [CrossRef]

- Khan, R.; Jabbar, A.; Ahmad, I.; Khan, W.; Khan, A.N.; Mirza, J. Reduction in environmental problems using rice-husk ash in concrete. Constr. Build. Mater. 2012, 39, 6321–6330. [Google Scholar] [CrossRef]

- Dahlbo, H.; Bachér, J.; Lähtinen, K.; Jouttijärvi, T.; Suoheimo, P.; Mattila, T.; Sironen, S.; Myllymaa, T.; Saramäki, K. Construction and demolition waste management—A holistic evaluation of environmental performance. J. Clean. Prod. 2015, 107, 333–341. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, V.H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater. 2011, 25, 575–581. [Google Scholar] [CrossRef]

- Tian, H.; Zhang, Y.X.; Yang, C.; Ding, Y. Recent advances in experimental studies of the mechanical behaviour of natural fibre-reinforced cementitious composites. Struct. Concr. 2016, 17, 564–575. [Google Scholar] [CrossRef]

- Ahmad, J.; Arbili, M.M.; Majdi, A.; Althoey, F.; Deifalla, A.F.; Rahmawati, C. Performance of concrete reinforced with jute fibers (natural fibers): A review. J. Eng. Fibers Fabr. 2022, 17, 15589250221121871. [Google Scholar] [CrossRef]

- Wang, B.; Bachtiar, E.V.; Yan, L.; Kasal, B.; Fiore, V. Flax, Basalt, E-Glass FRP and Their Hybrid FRP Strengthened Wood Beams: An Experimental Study. Polymers 2019, 11, 1255. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Chouw, N. Experimental study of flax FRP tube encased coir fibre reinforced concrete composite column. Constr. Build. Mater. 2013, 40, 1118–1127. [Google Scholar] [CrossRef]

- CoDyre, L.; Fam, A. Axial Strength of Sandwich Panels of Different Lengths with Natural Flax-Fiber Composite Skins and Different Foam-Core Densities. J. Compos. Constr. 2017, 21, 04017042. [Google Scholar] [CrossRef]

- Spierling, S.; Knüpffer, E.; Behnsen, H.; Mudersbach, M.; Krieg, H.; Springer, S.; Albrecht, S.; Herrmann, C.; Endres, H.-J. Bio-based plastics—A review of environmental, social and economic impact assessments. J. Clean. Prod. 2018, 185, 476–491. [Google Scholar] [CrossRef]

- Coutts, R.S.P. A review of Australian research into natural fibre cement composites. Cem. Concr. Compos. 2005, 27, 518–526. [Google Scholar] [CrossRef]

- Ibraheem, S.A.; Ali, A.; Khalina, A. Development of Green Insulation Boards from Kenaf Fibres and Polyurethane. Polym.-Plast. Technol. Eng. 2011, 50, 613–621. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. Effect of Sheep Wool Fibers on Thermal Insulation and Mechanical Properties of Cement-Based Composites. J. Nat. Fibers 2019, 17, 1532–1543. [Google Scholar] [CrossRef]

- Alyousef, R.; Alabduljabbar, H.; Mohammadhosseini, H.; Mohamed, A.M.; Siddika, A.; Alrshoudi, F.; Alaskar, A. Utilization of sheep wool as potential fibrous materials in the production of concrete composites. J. Build. Eng. 2020, 30, 101216. [Google Scholar] [CrossRef]

- Vilaplana, F.; Strömberg, E.; Karlsson, S. Environmental and resource aspects of sustainable biocomposites. Polym. Degrad. Stab. 2010, 95, 2147–2161. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; Lawrence, T., Ed.; Taylor & Francis: Abingdon upon Thames, UK, 2005; ISBN 9780203508206. [Google Scholar]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Aditya, P.; Kishore, K.; Prasad, D. Characterization of Natural Fiber Reinforced Composites. Int. J. Eng. Appl. Sci. 2017, 4, 26–32. [Google Scholar]

- Averous, L.; Boquillon, N. Biocomposites based on plasticized starch: Thermal and mechanical behaviours. Carbohydr. Polym. 2004, 56, 111–122. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A Review of Natural Fibers Used in Biocomposites: Plant, Animal and Regenerated Cellulose Fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Wedin, R. Chemistry on a High-Carb Diet; American Chemical Society: Washington, DC, USA, 2004; pp. 23–27. [Google Scholar]

- Shanks, R.A.; Hodzic, A.; Wong, S. Thermoplastic biopolyester natural fiber composites. J. Appl. Polym. Sci. 2004, 91, 2114–2121. [Google Scholar] [CrossRef]

- Pandey, J.; Nagarajan, V.; Mohanty, A.K.; Misra, M. Commercial potential and competitiveness of natural fiber composites. In Biocomposites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 1–15. [Google Scholar]

- Lalit, R.; Mayank, P.; Ankur, K. Natural Fibers and Biopolymers Characterization: A Future Potential Composite Material. J. Mech. Eng. 2018, 68, 33–50. [Google Scholar] [CrossRef]

- Neto, J.S.S.; de Queiroz, H.F.M.; Aguiar, R.A.A.; Banea, M.D. A Review on the Thermal Characterisation of Natural and Hybrid Fiber Composites. Polymers 2021, 13, 4425. [Google Scholar] [CrossRef]

- Townsend, T. 1B—World natural fibre production and employment. In Handbook of Natural Fibres; Kozłowski, R.M., Mackiewicz-Talarczyk, M., Eds.; The Textile Institute Book Series; Elsevier WP Woodhead Publishing: Duxford, UK; Cambridge, UK; Kidlington, UK, 2020; pp. 15–36. ISBN 978-0-12-818398-4. [Google Scholar]

- Van Dam, J.E.G. Environmental Benefits of Natural Fibre Production and Use. In Proceedings of the Symposium on Natural Fibres. 2020. Available online: https://www.fao.org/3/i0709e/i0709e03.pdf (accessed on 15 July 2021).

- Campilho, R.D.S.G. Recent innovations in biocomposite products. In Biocomposites for High-Performance Applications: Current Barriers and Future Needs Towards Industrial Development; Elsevier: Amsterdam, The Netherlands, 2017; ISBN 9780081007945. [Google Scholar]

- Guo, Y.; Deng, Y. Recycling of Flax Fiber Towards Developing Biocomposites for Automotive Application From a Life Cycle Assessment Perspective. In Reference Module in Materials Science and Materials Engineering; Elsevier: Hoboken, NJ, USA, 2019. [Google Scholar] [CrossRef]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X.-H. Review of the applications of biocomposites in the automotive industry. Polym. Compos. 2016, 38, 2553–2569. [Google Scholar] [CrossRef]

- Khalfallah, M.; Abbès, B.; Abbès, F.; Guo, Y.; Marcel, V.; Duval, A.; Vanfleteren, F.; Rousseau, F. Innovative flax tapes reinforced Acrodur biocomposites: A new alternative for automotive applications. Mater. Des. 2014, 64, 116–126. [Google Scholar] [CrossRef]

- Roy, P.; Tadele, D.; Defersha, F.; Misra, M.; Mohanty, A.K. Environmental and economic prospects of biomaterials in the automotive industry. Clean Technol. Environ. Policy 2019, 21, 1535–1548. [Google Scholar] [CrossRef]

- Guadagnuolo, M.; Faella, G. Simplified Design of Masonry Ring-Beams Reinforced by Flax Fibers for Existing Buildings Retrofitting. Buildings 2020, 10, 12. [Google Scholar] [CrossRef]

- Korjenic, A.; Zach, J.; Hroudová, J. The use of insulating materials based on natural fibers in combination with plant facades in building constructions. Energy Build. 2016, 116, 45–58. [Google Scholar] [CrossRef]

- Bharath, K.N.; Basavarajappa, S. Applications of biocomposite materials based on natural fibers from renewable resources: A review. Sci. Eng. Compos. Mater. 2016, 23, 123–133. [Google Scholar] [CrossRef]

- Grozdanov, A.; Jordanov, I.; Errico, M.; Gentile, G.; Avella, M. Biocomposites Based on Natural Fibers and Polymer Matrix—From Theory to Industrial Products. In Green Biorenewable Biocomposites; Apple Academic Press: Palm Bay, FL, USA, 2015. [Google Scholar]

- Yılmaz, N.; Powell, N. Biocomposite Structures as Sound Absorber Materials. In Green Biorenewable Biocomposites; Apple Academic Press: Palm Bay, FL, USA, 2015. [Google Scholar] [CrossRef]

- Sirviö, J.A.; Kolehmainen, A.; Liimatainen, H.; Niinimäki, J.; Hormi, O.E. Biocomposite cellulose-alginate films: Promising packaging materials. Food Chem. 2014, 151, 343–351. [Google Scholar] [CrossRef]

- Marra, A.; Silvestre, C.; Duraccio, D.; Cimmino, S. Polylactic acid/zinc oxide biocomposite films for food packaging application. Int. J. Biol. Macromol. 2016, 88, 254–262. [Google Scholar] [CrossRef]

- Narayanan, M.; Loganathan, S.; Valapa, R.B.; Thomas, S.; Varghese, T. UV protective poly(lactic acid)/rosin films for sustainable packaging. Int. J. Biol. Macromol. 2017, 99, 37–45. [Google Scholar] [CrossRef]

- Annamalai, P.; Depan, D. Nano-Cellulose Reinforced Chitosan Nanocomposites For Packaging and Biomedical Applications. In Green Biorenewable Biocomposites; Apple Academic Press: Palm Bay, FL, USA, 2015. [Google Scholar]

- Fouly, A.; Ibrahim, A.; Sherif, E.-S.; FathEl-Bab, A.; Badran, A. Effect of Low Hydroxyapatite Loading Fraction on the Mechanical and Tribological Characteristics of Poly(Methyl Methacrylate) Nanocomposites for Dentures. Polymers 2021, 13, 857. [Google Scholar] [CrossRef]

- Fouly, A.; Alnaser, I.A.; Assaifan, A.K.; Abdo, H.S. Evaluating the Performance of 3D-Printed PLA Reinforced with Date Pit Particles for Its Suitability as an Acetabular Liner in Artificial Hip Joints. Polymers 2022, 14, 3321. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Zuhri, M.Y.M.; Norrrahim, M.N.F.; Misenan, M.S.M.; Jenol, M.A.; Samsudin, S.A.; Nurazzi, N.M.; Asyraf, M.R.M.; Supian, A.B.M.; Bangar, S.P.; et al. Natural Fiber-Reinforced Polycaprolactone Green and Hybrid Biocomposites for Various Advanced Applications. Polymers 2022, 14, 182. [Google Scholar] [CrossRef] [PubMed]

- Reddy, T.R.K.; Kim, H.-J.; Park, J.-W. Renewable Biocomposite Properties and their Applications. In Composites from Renewable and Sustainable Materials; IntechOpen: London, UK, 2016. [Google Scholar]

- Gorz, A. Ecologica; Editoriale Jaca Book: Milano, Italy, 2009; Volume 867, ISBN 8816408677. [Google Scholar]

- Drury, J. Hemp Hits New High as Building Material on Dutch Bridge. Available online: https://www.reuters.com/article/us-netherlands-biobridge-idUSKBN1522HG (accessed on 12 December 2020).

- Mathijsen, D. Innovative bio-composite bicycle swing bridge “Ritsumasyl” in the Netherlands shows why the industry should embrace bio-based composites. Reinf. Plast. 2020, 64, 212–217. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. A comprehensive review on the use of hemp in concrete. Constr. Build. Mater. 2022, 341. [Google Scholar] [CrossRef]

- Sáez-Pérez, M.; Brümmer, M.; Durán-Suárez, J. A review of the factors affecting the properties and performance of hemp aggregate concretes. J. Build. Eng. 2020, 31, 101323. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.R.; Singh, L.P. A review of the properties of hemp concrete for green building applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Fernandez, J.E. Flax fiber reinforced concrete—A natural fiber biocomposite for sustainable building materials. In High Performance Structures and Materials; WIT Press: Southampton, UK, 2002. [Google Scholar]

- Page, J.; Khadraoui, F.; Boutouil, M.; Gomina, M. Multi-physical properties of a structural concrete incorporating short flax fibers. Constr. Build. Mater. 2017, 140, 344–353. [Google Scholar] [CrossRef]

- Kouta, N.; Saliba, J.; Saiyouri, N. Fracture behavior of flax fibers reinforced earth concrete. Eng. Fract. Mech. 2020, 241, 107378. [Google Scholar] [CrossRef]

- Benmahiddine, F.; Cherif, R.; Bennai, F.; Belarbi, R.; Tahakourt, A.; Abahri, K. Effect of flax shives content and size on the hygrothermal and mechanical properties of flax concrete. Constr. Build. Mater. 2020, 262, 120077. [Google Scholar] [CrossRef]

- Garikapati, K.P.; Sadeghian, P. Mechanical behavior of flax-lime concrete blocks made of waste flax shives and lime binder reinforced with jute fabric. J. Build. Eng. 2020, 29, 101187. [Google Scholar] [CrossRef]

- Rahimi, M.; Hisseine, O.A.; Tagnit-Hamou, A. Effectiveness of treated flax fibers in improving the early age behavior of high-performance concrete. J. Build. Eng. 2021, 45, 103448. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Wang, L. Properties of hemp fibre reinforced concrete composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 497–505. [Google Scholar] [CrossRef]

- de Bruijn, P.B.; Jeppsson, K.-H.; Sandin, K.; Nilsson, C. Mechanical properties of lime–hemp concrete containing shives and fibres. Biosyst. Eng. 2009, 103, 474–479. [Google Scholar] [CrossRef]

- Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concretes. Constr. Build. Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Awwad, E.; Mabsout, M.; Hamad, B.; Farran, M.T.; Khatib, H. Studies on fiber-reinforced concrete using industrial hemp fibers. Constr. Build. Mater. 2012, 35, 710–717. [Google Scholar] [CrossRef]

- Awwad, E.; Choueiter, D.; Khatib, H. Concrete masonry blocks reinforced with local industrial hemp fibers and hurds. In Proceedings of the 3rd International Conference on Sustainable Construction Materials and Technologies, Kyoto, Japan, 18–21 August 2013. [Google Scholar]

- Merta, I.; Tschegg, E. Fracture energy of natural fibre reinforced concrete. Constr. Build. Mater. 2013, 40, 991–997. [Google Scholar] [CrossRef]

- Walker, R.; Pavia, S.; Mitchell, R. Mechanical properties and durability of hemp-lime concretes. Constr. Build. Mater. 2014, 61, 340–348. [Google Scholar] [CrossRef]

- Zhou, X.M.; Madanipour, R.; Ghaffar, S. Impact Properties of Hemp Fibre Reinforced Cementitious Composites. Key Eng. Mater. 2016, 711, 163–170. [Google Scholar] [CrossRef]

- Barbuta, M.; Serbanoiu, A.A.; Teodorescu, R.; Rosca, B.; Mitroi, R.; Bejan, G. Characterization of polymer concrete with natural fibers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 246, 012033. [Google Scholar] [CrossRef]

- Grubeša, I.N.; Marković, B.; Gojević, A.; Brdarić, J. Effect of hemp fibers on fire resistance of concrete. Constr. Build. Mater. 2018, 184, 473–484. [Google Scholar] [CrossRef]

- Wong, K.; Zahi, S.; Low, K.; Lim, C. Fracture characterisation of short bamboo fibre reinforced polyester composites. Mater. Des. 2010, 31, 4147–4154. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, Z.; Chen, G.W. Experimental research on bamboo fiber reinforced concrete. Appl. Mech. Mater. 2013, 357, 1045–1048. [Google Scholar] [CrossRef]

- Ahmed, S.; Raza, A.; Gupta, H. Mechanical Properties of Bamboo Fibre Reinforced Concrete. In Proceedings of the 2nd International Conference on Research in Science, Engineering and Technology, Dubai, United Arab Emirates, 21–22 March 2014. [Google Scholar] [CrossRef]

- Agarwal, A.; Nanda, B.; Maity, D. Experimental investigation on chemically treated bamboo reinforced concrete beams and columns. Constr. Build. Mater. 2014, 71, 610–617. [Google Scholar] [CrossRef]

- Moroz, J.; Lissel, S.; Hagel, M. Performance of bamboo reinforced concrete masonry shear walls. Constr. Build. Mater. 2014, 61, 125–137. [Google Scholar] [CrossRef]

- Goh, L.D.; Zulkornain, A.S. Influence of bamboo in concrete and beam applications. J. Phys. Conf. Ser. 2019, 1349, 012127. [Google Scholar] [CrossRef]

- Sridhar, J.; Gobinath, R.; Kırgız, M.S. Comparative study for efficacy of chemically treated jute fiber and bamboo fiber on the properties of reinforced concrete beams. J. Nat. Fibers 2022, 19, 1–11. [Google Scholar] [CrossRef]

- Dhandhania, V.; Sawant, S. Coir Fiber Reinforced Concrete. J. Text. Sci. Eng. 2014, 4, 5. [Google Scholar]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, M.; Alyousef, R.; et al. Effect of coconut fiber length and content on properties of high strength concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 2020, 244, 118382. [Google Scholar] [CrossRef]

- Elsaid, A.; Dawood, M.; Seracino, R.; Bobko, C. Mechanical properties of kenaf fiber reinforced concrete. Constr. Build. Mater. 2011, 25, 1991–2001. [Google Scholar] [CrossRef]

- Mohsin, S.M.; Baarimah, A.O.; Jokhio, G.A. Effect of kenaf fiber in reinforced concrete slab. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 342, p. 012104. [Google Scholar]

- Baarimah, A.O.; Syed Mohsin, S.M. Mechanical properties of steel/kenaf (hybrid) fibers added into concrete mixtures. IOP Conf. Ser. Mater. Sci. Eng. 2018, 342, 012075. [Google Scholar] [CrossRef]

- Muda, Z.C.; Mohd Kamal, N.L.; Syamsir, A.; Sheng, C.Y.; Beddu, S.; Mustapha, K.N.; Thiruchelvam, S.; Usman, F.; Alam, M.A.; Birima, A.H.; et al. Impact Resistance Performance of Kenaf Fibre Reinforced Concrete. IOP Conf. Ser. Earth Environ. Sci. 2016, 32, 012019. [Google Scholar] [CrossRef]

- Mahzabin, M.S.; Jee Hock, L.; Siong Kang, L.; Nikbakht Jarghouyeh, E. Behaviour of kenaf fibre reinforced composite. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 513. [Google Scholar]

- Zhou, C.; Cai, L.; Chen, Z.; Li, J. Effect of kenaf fiber on mechanical properties of high-strength cement composites. Constr. Build. Mater. 2020, 263, 121007. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, N.; Liao, Y.; Pan, Z.; Liu, Y.; Zhou, L.; Liu, Z.; Jiang, Z. Enhanced flexural performance of epoxy polymer concrete with short natural fibers. Sci. China Technol. Sci. 2018, 61, 1107–1113. [Google Scholar] [CrossRef]

- Prasannan, D.; Nivin, S.; Kumar, R.R.; Giridharan, S.; Elavivekan, M. Comparative Study of Banana and Sisal Fibre Reinforced Concrete With Conventional Concrete. Int. J. Pure Appl. Math. 2018, 118, 1757–1765. [Google Scholar]

- Frazão, C.; Barros, J.; Filho, R.T.; Ferreira, S.; Gonçalves, D. Development of sandwich panels combining Sisal Fiber-Cement Composites and Fiber-Reinforced Lightweight Concrete. Cem. Concr. Compos. 2018, 86, 206–223. [Google Scholar] [CrossRef]

- Okeola, A.A.; Abuodha, S.O.; Mwero, J. Experimental Investigation of the Physical and Mechanical Properties of Sisal Fiber-Reinforced Concrete. Fibers 2018, 6, 53. [Google Scholar] [CrossRef]

- Mouli, K.C.; Pannirselvam, N.; Anitha, V.; Kumar, D.V.; Rao, S.V. Strength studies on banana fibre concrete with metakaolin. Int. J. Civ. Eng. Technol. 2019, 10, 684–689. [Google Scholar]

- Zakaria, M.; Ahmed, M.; Hoque, M.; Islam, S. Scope of using jute fiber for the reinforcement of concrete material. Text. Cloth. Sustain. 2016, 2, 123. [Google Scholar] [CrossRef]

- Zia, A.; Ali, M. Behavior of fiber reinforced concrete for controlling the rate of cracking in canal-lining. Constr. Build. Mater. 2017, 155, 726–739. [Google Scholar] [CrossRef]

- Akasaka, H.; Ozawa, M.; Parajuli, S.S.; Sugino, Y.; Akutsu, Y.; Murakami, M. Preventive Effect on Fire Spalling of High-Strength Concrete With Jute Fibre in Ring-Restraint Specimen. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 431. [Google Scholar] [CrossRef]

- Dayananda, N.; Gowda, B.S.K.; Prasad, G.L.E. A Study on Compressive Strength Attributes of Jute Fiber Reinforced Cement Concrete Composites. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376, 012069. [Google Scholar] [CrossRef]

- Kundu, S.P.; Chakraborty, S.; Chakraborty, S. Effectiveness of the surface modified jute fibre as fibre reinforcement in controlling the physical and mechanical properties of concrete paver blocks. Constr. Build. Mater. 2018, 191, 554–563. [Google Scholar] [CrossRef]

- Islam, M.S.; Ahmed, S.J. Influence of jute fiber on concrete properties. Constr. Build. Mater. 2018, 189, 768–776. [Google Scholar] [CrossRef]

- Zhang, T.; Yin, Y.; Gong, Y.; Wang, L. Mechanical properties of jute fiber-reinforced high-strength concrete. Struct. Concr. 2019, 21, 703–712. [Google Scholar] [CrossRef]

- Ahmed, S.; Ali, M. Improvement in Impact Resistance of GFRP Rebars Reinforced Concrete Wall Panels Using Jute Fibres. In Proceedings of the 11th International Civil Engineering, Karachi, Pakistan, 13–14 March 2020. [Google Scholar]

- Zhang, D.; Tan, K.H.; Dasari, A.; Weng, Y. Effect of natural fibers on thermal spalling resistance of ultra-high performance concrete. Cem. Concr. Compos. 2020, 109, 103512. [Google Scholar] [CrossRef]

- Khaleel, S.; Madhavi, K.; Basutkar, S. Mechanical characteristics of brick masonry using natural fiber composites. Mater. Today Proc. 2020, 46, 4817–4824. [Google Scholar] [CrossRef]

- Irawan, T.; Saloma; Idris, Y. Mechanical Properties of Foamed Concrete with Additional Pineapple Fiber and Polypropylene Fiber. J. Phys. Conf. Ser. 2019, 1198, 082018. [Google Scholar] [CrossRef]

- Esper, C.D.H.; Canseco, H.A.R. Influence of Alkali Treatment and Fiber Content on Mechanical Properties of Pineapple Leaf Fiber (PALF)-Reinforced Cement-Based Composites via Full Factorial Design. Mater. Sci. Forum 2020, 1005, 65–75. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Lee, G.-W.; Choi, Y.-C. Effect of abaca natural fiber on the setting behavior and autogenous shrinkage of cement composite. J. Build. Eng. 2022, 56, 104719. [Google Scholar] [CrossRef]

- Voutetaki, M.E.; Naoum, M.C.; Papadopoulos, N.A.; Chalioris, C.E. Cracking Diagnosis in Fiber-Reinforced Concrete with Synthetic Fibers Using Piezoelectric Transducers. Fibers 2022, 10, 5. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials. I. hemp fibres. J. Mater. Sci. 2006, 41, 2483–2496. [Google Scholar] [CrossRef]

- Hu, B.; Dweib, M.; Wool, R.P.; Shenton, H.W. Bio-Based Composite Roof for Residential Construction. J. Arch. Eng. 2007, 13, 136–143. [Google Scholar] [CrossRef]

- Takasaki, K.; Jirawattanasomkul, T.; Zhang, D.; Ueda, T. Experimental study on shear behavior of RC beams jacketed by flax fiber sheet. Proc. Japan Concr. Inst. 2014, 36, 1189–1194. [Google Scholar]

- Yan, L.; Su, S.; Chouw, N. Microstructure, flexural properties and durability of coir fibre reinforced concrete beams externally strengthened with flax FRP composites. Compos. Part B Eng. 2015, 80, 343–354. [Google Scholar] [CrossRef]

- Huang, L.; Yan, B.; Yan, L.; Xu, Q.; Tan, H.; Kasal, B. Reinforced concrete beams strengthened with externally bonded natural flax FRP plates. Compos. Part B Eng. 2016, 91, 569–578. [Google Scholar] [CrossRef]

- Di Luccio, G.; Michel, L.; Ferrier, E.; Martinelli, E. Seismic retrofitting of RC walls externally strengthened by flax–FRP strips. Compos. Part B Eng. 2017, 127, 133–149. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. Experimental and theoretical studies of flax FRP strengthened coconut fibre reinforced concrete slabs under impact loadings. Constr. Build. Mater. 2018, 171, 546–557. [Google Scholar] [CrossRef]

- Chen, C.; Yang, Y.; Zhou, Y.; Xue, C.; Chen, X.; Wu, H.; Sui, L.; Li, X. Comparative analysis of natural fiber reinforced polymer and carbon fiber reinforced polymer in strengthening of reinforced concrete beams. J. Clean. Prod. 2020, 263, 121572. [Google Scholar] [CrossRef]

- Siriluk, S.; Hussain, Q.; Rattanapitikon, W.; Pimanmas, A. Shear Strengthening of Reinforced Concrete Beams with HFRP Composite. Mater. Sci. Forum 2016, 860, 152–155. [Google Scholar] [CrossRef]

- Ghalieh, L.; Awwad, E.; Saad, G.; Khatib, H.; Mabsout, M. Concrete Columns Wrapped with Hemp Fiber Reinforced Polymer—An Experimental Study. Procedia Eng. 2017, 200, 440–447. [Google Scholar] [CrossRef]

- Bitar, R.; Saad, G.; Awwad, E.; El Khatib, H.; Mabsout, M. Strengthening unreinforced masonry walls using natural hemp fibers. J. Build. Eng. 2020, 30, 101253. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.J. Strengthening of RC beams in flexure using natural jute fibre textile reinforced composite system and its comparative study with CFRP and GFRP strengthening systems. Int. J. Sustain. Built Environ. 2013, 2, 41–55. [Google Scholar] [CrossRef]

- Hafizah, N.A.K.; Bhutta, M.A.R.; Jamaludin, M.Y.; Warid, M.H.; Ismail, M.; Rahman, M.S.; Yunus, I.; Azman, M. Kenaf Fiber Reinforced Polymer Composites for Strengthening RC Beams. J. Adv. Concr. Technol. 2014, 12, 167–177. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.J. Flexural strengthening of RC beams using natural sisal and artificial carbon and glass fabric reinforced composite system. Sustain. Cities Soc. 2014, 10, 195–206. [Google Scholar] [CrossRef]

- Sen, T.; Paul, A. Confining concrete with sisal and jute FRP as alternatives for CFRP and GFRP. Int. J. Sustain. Built Environ. 2015, 4, 248–264. [Google Scholar] [CrossRef]

- Tan, H.; Yan, L.; Huang, L.; Wang, Y.; Li, H.; Chen, J.-Y. Behavior of sisal fiber concrete cylinders externally wrapped with jute FRP. Polym. Compos. 2015, 38, 1910–1917. [Google Scholar] [CrossRef]

- Alam, A.; Al Riyami, K. Shear strengthening of reinforced concrete beam using natural fibre reinforced polymer laminates. Constr. Build. Mater. 2018, 162, 683–696. [Google Scholar] [CrossRef]

- Omar, Z.; Sugiman, S.; Yussof, M.M.; Ahmad, H. The effects of woven fabric Kenaf FRP plates flexural strengthened on plain concrete beam under a four-point bending test. Case Stud. Constr. Mater. 2022, 17, e01503. [Google Scholar] [CrossRef]

- Maulana, M.; Sugiman, S.; Ahmad, H.; Mohd Jaini, Z.; Mansor, H. XFEM Modelling and Experimental Observations of Foam Concrete Beam Externally-Bonded with KFRP Sheet. Lat. Am. J. Solids Struct. 2022, 19, 460. [Google Scholar] [CrossRef]

- Chin, S.C.; Moh, J.N.S.; Doh, S.I.; Yahaya, F.M.; Gimbun, J. Strengthening of Reinforced Concrete Beams Using Bamboo Fiber/Epoxy Composite Plates in Flexure. Key Eng. Mater. 2019, 821, 465–471. [Google Scholar] [CrossRef]

- Tshai, K.Y.; Kong, I. 12-Advancement in flame retardancy of natural fibre reinforced composites with macro to nanoscale particulates additives. In Woodhead Publishing Series in Composites Science and Engineering; Goh, K.L., Aswathy, M.K., De Silva, R.T., Thomas, S., Eds.; Woodhead Publishing: Sawston, UK, 2020; pp. 311–342. [Google Scholar]

- Yan, B.; Huang, L.; Yan, L.; Gao, C.; Kasal, B. Behavior of flax FRP tube encased recycled aggregate concrete with clay brick aggregate. Constr. Build. Mater. 2017, 136, 265–276. [Google Scholar] [CrossRef]

- Huang, L.; Chen, L.; Yan, L.; Kasal, B.; Jiang, Y.; Liu, C. Behavior of polyester FRP tube encased recycled aggregate concrete with recycled clay brick aggregate: Size and slenderness ratio effects. Constr. Build. Mater. 2017, 154, 123–136. [Google Scholar] [CrossRef]

- Gao, C.; Fu, Q.; Huang, L.; Yan, L.; Gu, G. Jute Fiber-Reinforced Polymer Tube-Confined Sisal Fiber-Reinforced Recycled Aggregate Concrete Waste. Polymers 2022, 14, 1260. [Google Scholar] [CrossRef]

- Betts, D.; Sadeghian, P.; Fam, A. Structural behaviour of sandwich panels constructed of foam cores and flax FRP facings. In Proceedings of the 6th International Conference on Engineering Mechanics and Materials, Vancouver, BC, Canada, 31 May–3 June 2017. [Google Scholar]

- Codyre, L.; Mak, K.; Fam, A. Flexural and axial behaviour of sandwich panels with bio-based flax fibre-reinforced polymer skins and various foam core densities. J. Sandw. Struct. Mater. 2016, 20, 595–616. [Google Scholar] [CrossRef]

- Firouzsalari, S.E.; Dizhur, D.; Jayaraman, K.; Ingham, J.M. Bending behaviour of flax fabric-reinforced epoxy pipes. Compos. Part A Appl. Sci. Manuf. 2020, 140, 106179. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J. Can flax replace E-glass in structural composites? A small wind turbine blade case study. Compos. Part B Eng. 2013, 52, 172–181. [Google Scholar] [CrossRef]

- Markiewicz, E.; Borysiak, S.; Paukszta, D. Polypropylene-lignocellulosic material composites as promising sound absorbing materials. Polimery 2009, 54, 430–435. [Google Scholar] [CrossRef]

- Khalina, A.; Zainudin, E.; Faizal, A.R.M.; Jalaluddin, H.; Umar, A.; Syuhada, W. Development of Biocomposite Wall Cladding from Kenaf Fibre by Extrusion Molding Process. Key Eng. Mater. 2011, 471–472, 239–244. [Google Scholar] [CrossRef]

- Panigrahi, S.; Rana, A.; Kushwaha, R.L.; Panigrahy, B.S. Biodegradable Green Composite Boards for Industrial Application; SAE Technical Paper 2008-01-2625; SAE International: Warrandale, PA, USA, 2008. [Google Scholar] [CrossRef]

- Kremensas, A.; Kairytė, A.; Vaitkus, S.; Vėjelis, S.; Balčiūnas, G. Mechanical Performance of Biodegradable Thermoplastic Polymer-Based Biocomposite Boards from Hemp Shivs and Corn Starch for the Building Industry. Materials 2019, 12, 845. [Google Scholar] [CrossRef] [PubMed]

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite Materials Based on Hemp and Flax for Low-Energy Buildings. Materials 2017, 10, 510. [Google Scholar] [CrossRef] [PubMed]

- Costantine, G.; Maalouf, C.; Moussa, T.; Polidori, G. Experimental and numerical investigations of thermal performance of a Hemp Lime external building insulation. Build. Environ. 2018, 131, 140–153. [Google Scholar] [CrossRef]

- Corona, A.; Madsen, B.; Hauschild, M.Z.; Birkved, M. Natural fibre selection for composite eco-design. CIRP Ann. 2016, 65, 13–16. [Google Scholar] [CrossRef]

- Correa, J.P.; Montalvo-Navarrete, J.M.; Hidalgo-Salazar, M.A. Carbon footprint considerations for biocomposite materials for sustainable products: A review. J. Clean. Prod. 2018, 208, 785–794. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management. Life Cycle Assessment. Principles and Framework. International Organisation for Standardisation: Geneva, Switzerland, 2006.

- BS ISO 15686-5:2017; Buildings and Constructed Assets—Service Life Planning Part 5: Life-Cycle Costing. International Organisation for Standardisation: Geneva, Switzerland, 2017.

- de Beus, N.; Carus, M.; Barth, M. Carbon Footprint and Sustainability of Different Natural Fibres for Biocomposites and Insulation Material. 2019. Available online: http://eiha.org/media/2019/03/19-03-13-Study-Natural-Fibre-Sustainability-Carbon-Footprint.pdf (accessed on 15 June 2021).

- Dissanayake, N.P.J.; Summerscales, J.; Grove, S.M.; Singh, M.M. Energy Use in the Production of Flax Fiber for the Reinforcement of Composites. J. Nat. Fibers 2009, 6, 331–346. [Google Scholar] [CrossRef]

- Korol, J.; Burchart-Korol, D.; Pichlak, M. Expansion of environmental impact assessment for eco-efficiency evaluation of biocomposites for industrial application. J. Clean. Prod. 2016, 113, 144–152. [Google Scholar] [CrossRef]

- Bhardwaj, S.; Engg, C.S.O.B. Natural Fibre Composites- An Opportunity for Farmers. Int. J. Pure Appl. Biosci. 2017, 5, 509–514. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Korol, J.; Hejna, A.; Burchart-Korol, D.; Chmielnicki, B.; Wypiór, K. Water Footprint Assessment of Selected Polymers, Polymer Blends, Composites, and Biocomposites for Industrial Application. Polymers 2019, 11, 1791. [Google Scholar] [CrossRef]

- Sathishkumar, S.; Naveen, T.K.; Jeevarathinam, A.; Karthik, V.; Dhandapani, N.V. Thermal Conductivity of Natural Fiber Reinforced Plastics. 2018, Volume 118, No. 20. pp. 43–51. Available online: http://www.ijpam.eu (accessed on 19 September 2022).

- Batouli, S.M.; Zhu, Y. Comparative Life-Cycle Assessment Study of Kenaf Fiber-Based and Glass Fiber-Based Structural Insulation Panels. In Proceedings of the International Conference on Construction and Real Estate Management 2013, ICCREM, Karlsruhe, Germany, 10–11 October 2013; pp. 377–388. [Google Scholar] [CrossRef]

- Zea Escamilla, E.; Wallbaum, H. Environmental Savings from the use of Vegetable Fibres as Concrete Reinforcement. In Proceedings of the Modern Methods and Advances in Structural Engineering and Construction, Zurich, Switzerland, 21–26 June 2011; ISBN 978-981-08-7920-4. [Google Scholar]

- Arrigoni, A.; Pelosato, R.; Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Díaz, A.V.; López, A.F.; Bugallo, P.M.B. Analysis of Biowaste-Based Materials in the Construction Sector: Evaluation of Thermal Behaviour and Life Cycle Assessment (LCA). Waste Biomass Valorization 2022, 13, 4983–5004. [Google Scholar] [CrossRef]

- Le Duigou, A.; Baley, C. Coupled micromechanical analysis and life cycle assessment as an integrated tool for natural fibre composites development. J. Clean. Prod. 2014, 83, 61–69. [Google Scholar] [CrossRef]

- Merta, I.; Mladenovič, A.; Turk, J.; Šajna, A.; Pranjić, A.M. Life Cycle Assessment of Natural Fibre Reinforced Cementitious Composites. Key Eng. Mater. 2018, 761, 204–209. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Ismail, M.; Rahmat, A.R. A cradle-to-gate based life cycle impact assessment comparing the KBF w EFB hybrid reinforced poly hydroxybutyrate biocomposite and common petroleum-based composites as building materials. Environ. Impact Assess. Rev. 2018, 70, 11–21. [Google Scholar] [CrossRef]

- Xu, X.; Jayaraman, K.; Morin, C.; Pecqueux, N. Life cycle assessment of wood-fibre-reinforced polypropylene composites. J. Mater. Process. Technol. 2008, 198, 168–177. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E.; Drzal, L.T.; Misra, M. Life Cycle Assessment of Kenaf Fiber Reinforced Biocomposite. J. Biobased Mater. Bioenergy 2008, 2, 85–93. [Google Scholar] [CrossRef]

- Akhshik, M.; Panthapulakkal, S.; Tjong, J.; Sain, M. Life cycle assessment and cost analysis of hybrid fiber-reinforced engine beauty cover in comparison with glass fiber-reinforced counterpart. Environ. Impact Assess. Rev. 2017, 65, 111–117. [Google Scholar] [CrossRef]

- Haylock, R.; Rosentrater, K.A. Cradle-to-Grave Life Cycle Assessment and Techno-Economic Analysis of Polylactic Acid Composites with Traditional and Bio-Based Fillers. J. Polym. Environ. 2017, 26, 1484–1503. [Google Scholar] [CrossRef]

- Rodriguez, L.J.; Orrego, C.E.; Ribeiro, I.; Peças, P. Life-Cycle Assessment and Life-Cycle Cost study of Banana (Musa sapientum) fiber Biocomposite materials. Procedia CIRP 2018, 69, 585–590. [Google Scholar] [CrossRef]

- Beigbeder, J.; Soccalingame, L.; Perrin, D.; Bénézet, J.-C.; Bergeret, A. How to manage biocomposites wastes end of life? A life cycle assessment approach (LCA) focused on polypropylene (PP)/wood flour and polylactic acid (PLA)/flax fibres biocomposites. Waste Manag. 2018, 83, 184–193. [Google Scholar] [CrossRef] [PubMed]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

| Natural Fiber | Production (Metric Tons) | Main Producers |

|---|---|---|

| Cotton | 26,120,000 | China, USA, India, Pakistan |

| Kapok | 96,000 | Indonesia |

| Jute, kenaf and allied fibers | 2,500,000 | India, Bangladesh, China, Thailand |

| Flax | 310,000 | China, France, Belgium, Belarus, Ukraine |

| Hemp | 70,000 | China |

| Ramie | - | China |

| Abaca | 83,000 | Philippines, Ecuador |

| Sisal, henequen & allied fibers | 210,000 | Brazil, China, Tanzania, Kenya |

| Coir | 970,000 | India, Sri Lanka |

| Author (Year) | Region | Material Combination | Objectives | Findings | Weakness/Recommendation |

|---|---|---|---|---|---|

| Flax | |||||

| Fernandez (2002) [64] | USA | Flax fiber reinforced concrete | Promote the use of flax fiber as a sustainable material | Enhanced strength and toughness | Recommended for shear strengthening for potential material savings |

| Page et al. (2017) [65] | France | Flax fiber reinforced concrete | Improvement of fresh state implementation conditions. Improve the mechanical properties in the hardened state | Compressive strength decreased with an increase in fiber content but flexural capacity was enhanced | Reduction in concrete workability due to fibers and increased air content. |

| Kouta et al. (2020) [66] | France | Flax fiber reinforced earth concrete | Investigate fracture behavior of flax fiber in earth concrete | Flax fibers augmented the fracture properties of earth concrete (increased with % and length of fibers) and provided ductility (by crack bridging) | Can be used as a sustainable option for earthen concrete but need more exploration in terms of damage mechanism. |

| Benmahiddine et al. (2020) [67] | France | Flax shive reinforced concrete | Investigate the potential of flax concrete towards sustainable construction | Flax concrete having 14.5% bulk concrete provided the maximum strength. The strength values were lower as compared to conventional concrete (and decreased with more flax content) | Recommended by authors to be used as insulation/filling materials |

| Garikapati and Sadeghian (2020) [68] | Canada | Flax-lime concrete blocks with jute reinforcement | Study flax shives with lime-based binder as a construction material with jute mesh | Enhanced energy absorption and bending capacity using jute mesh | Recommended as masonry blocks and insulation in wall cavities |

| Rahimi et al. (2022) [69] | Canada | Treated flax fibers in high-performance concrete | Comparing treated flax fiber with light weight aggregates and admixtures for controlling shrinkage of high-performance concrete | 12% increase in compressive strength by flax fiber Flax fibers caused 23–26% reduction in shrinkage while improving the energy absorption capacity of concrete | Treated flax fiber recommended for better volumetric stability of high-performance concrete |

| Hemp | |||||

| Li et al. (2006) [70] | Australia | Hemp fiber reinforced concrete | Experimental investigation for mechanical properties of hemp fiber concrete | Fiber content is crucial in mechanical performance Compressive strength reduces by adding fibers in comparison to conventional concrete The wet mix shows better flexural performance as compared to the dry mix | Recommended for pavements |

| Brujin et al. (2009) [71] | Sweden | Hemp-lime concrete | Feasibility study of hemp lime concrete as a load-bearing member | Low compressive strengths and young modulus | Not suitable for load-bearing application |

| Arnaud and Gourlay (2012) [72] | France | Hemp fiber reinforced concrete | Study the impact of various mix design factors on hemp concrete | Hemp concrete’s properties depend on curing conditions, age, binder type/content and hemp characteristics | Care to be exercised during mix design |

| Awwad et al. (2012) [73] | Lebanon | Hemp fiber reinforced concrete | Investigate the mechanical and thermal properties of hemp fiber concrete | Fibers addition resulted in coarse aggregate reduction No impact on tensile strength and increased ductility Reduction in thermal conductivity and modulus of elasticity | Hemp fibers reduced the compressive strength by about 25% (0.75–1% fibers); therefore, recommended for non-structural applications |

| Awwad et al. (2013) [74] | Lebanon | Hemp concrete masonry blocks (untreated hemp and hurds) | Investigating the behavior of hemp fibers masonry blocks Reducing the aggregates and density of blocks while enhancing thermal and acoustic properties | Compressive strength decreased with an increase in hemp fiber content About 20% decrease in thermal conductivity | Fulfils minimum strength requirement for non-load bearing members |

| Merta and Tschegg (2013) [75] | Austria | Natural fibers in concrete | Study the influence of fibers on energy absorption capacity of concrete | 70%, 2% and 5% increase in fracture energy using hemp, straw and grass fibers respectively in comparison to unreinforced concrete | 4%, 7% and 8% decline in split tensile strength with hemp, straw and grass, respectively |

| Walker et al. (2014) [76] | Ireland | Hemp-lime concrete | Evaluate the post-exposure performance of hemp-lime concrete against sodium chloride | Resistance to biodeterioration (hemp concrete) | Recommended as a sustainable material |

| Zhou et al. (2016) [77] | London, UK | Hemp fiber reinforced concrete panels | Investigate the impact resistance with other mechanical properties | Low compressive strength but high split tensile strength with longer fibers (20 mm) as compared to short (10 mm) Better impact resistance, low crack propagation, and high energy absorption with longer fibers (20 mm) | No comparison with unreinforced concrete It can be used for structures subjected to impact loading with careful selection of fiber length and content |

| Barbuta et al. (2017) [78] | Romania | Natural fibers in polymer concrete with fly ash | Analyze the behavior of hemp/wool on the mechanical properties of polymer concrete | Decline in compressive strength but increase in tensile strength (for wool only) Greater flexural strength with hemp fibers in comparison to wool Increase in fiber dosage decreased the density | Suggested for eco-friendly concrete with enhanced thermal performance |

| Grubesa et al. (2018) [79] | Croatia | Hemp fiber reinforced concrete | Study the influence of fiber treatment on their properties at ambient temperature and fire resistance of hemp concrete | Hemp fibers did not impact the fire resistance of concrete. Crack propagation was reduced at elevated temperature (400 °C) | Not useful for fire resistance under very high temperatures but useful for enhancing fire resistance at moderately high temperatures |

| Bamboo | |||||

| Wong et al. (2010) [80] | Malaysia | Fiber reinforced polyester concrete | Point out the optimum volume fraction % and fiber length for improved impact resistance | 16.6 times higher toughness was achieved using optimum content under study (50% fiber volume fraction and 10 mm fiber length | Durability for outdoor applications may be a drawback that can be explored and improved |

| Zhang et al. (2013) [81] | Shanghai, China | Bamboo fiber reinforced concrete | Study the mechanical performance of bamboo fiber concrete | Positive impact on split tensile strength but adverse impact on compressive strength | Maybe used for controlling initial micro-cracking. |

| Ahmad et al. (2014) [82] | Bamboo reinforced concrete beam (fibers) | Study the effect of bamboo fiber on mechanical properties of concrete | No influence on 28 days strength but high 50-day strength Increased flexural strength and modulus of elasticity | Recommended for low-cost buildings | |

| Agarwal et al. (2014) [83] | India | Bamboo reinforced beam and column | Improve the bond strength at the interface of bamboo fiber concrete and other mechanical properties | Bonding strength of treated bamboo depends on the adhesive used Untreated bamboo does not impact strength Treated bamboo (8%) provides the same strength as steel (0.89%) Flexural load capacity increased by 29% by 1.49% treated bamboo | Suggested as potential substitute reinforcement |

| Moroz et al. (2014) [84] | Canada | Bamboo reinforced concrete masonry shear walls | Compare bamboo to steel as a replacement in shear walls | Increased shear capacity and ductility vs. unreinforced masonry Reasonably closer behavior to steel reinforcement | Waterproofing of bamboo reinforcement is required Long-term properties investigation and cost analysis should be done |

| Goh and Zulkornain (2019) [85] | Malaysia | Bamboo fiber reinforced concrete | Investigate the influence of various fiber fractions on the compressive strength of concrete | Improved compressive strength was achieved with 0.5% fibers (optimum) Beams with only bamboo fiber had lower strengths as compared to control concrete | Suggested by authors for either non-structural applications or in flexure with supporting shear strengthening |

| Sridhar et al. (2022) [86] | Turkey | Treated jute and bamboo fiber in reinforced concrete | Comparison of the effectiveness of chemically treated jute and bamboo fiber on reinforced concrete’s mechanical properties | Optimal dosage was 1.5% and 2% for bamboo and jute, respectively Improved compressive and flexural strengths by both fibers (17–31%) Scanning electron microscopy showed good bonding between fiber and matrix | Treated bamboo recommended for concrete flexural capacity enhancement |

| Coconut (coir) | |||||

| Dhandhania and Sawant (2014) [87] | India | Coir fiber reinforced concrete | Study coconut fiber as replacement reinforcement for roofs | Reasonable strength enhancement No corrosion and cooling ability due to low thermal conductivity | Can be used to avoid corrosion |

| Ahmad et al. (2020) [88] | Pakistan | Coconut fiber reinforced high-strength concrete | Explore the use of coconut fibers in high-strength concrete to optimize the fiber’s aspects | Increased compressive, flexural and tensile strengths Enhanced energy absorption in comparison to high-strength concrete | Best performance with 1.5% fiber content (by cement mass) at 50 mm length |

| Khan et al. (2020) [89] | Pakistan | Coconut fiber reinforced silica fume modified concrete | Optimizing thickness design of concrete road | Increased compressive, split tensile strengths, energy absorption and modulus of elasticity for coconut reinforced concrete versus plain concrete at 15% silica fume. | Recommended for concrete pavement use |

| Kenaf | |||||

| Elsaid et al. (2011) [90] | USA | kenaf fiber reinforced concrete | Characterize the mechanical properties of kenaf fiber reinforced concrete | Similar or lower strength than plain concrete Increased ductility and energy absorption | More water is required for suitable workability Suggested for impact-resistant applications |

| Mohsin et al. (2018) [91] | Malaysia | kenaf concrete slab | Study the behavior of kenaf fiber concrete slabs and improvement in shear capacity | Increased flexural strength, reduced crack propagation and improved ductility | No regain of shear capacity (lost due to decreased thickness) by adding fibers |

| Baarimah and Mohsin (2018) [92] | Malaysia | kenaf fiber concrete/hybrid (steel/kenaf) | Evaluate behavior of kenaf fiber or hybrid (kenaf-steel) fiber reinforced concrete | Increased mechanical properties with steel fibers Compressive strength improved with high % of steel with kenaf fibers (hybrid) Flexural strength was improved with even low steel hybrid mix Failure patterns changed from brittle to ductile | Hybrid combination of kenaf-steel can be applied for flexural applications |

| Muda et al. (2019) [93] | Malaysia | kenaf fiber mesh reinforced concrete | Investigate the impact resistance relationship with kenaf mesh reinforcement | Enhanced first crack and ultimate resistance with kenaf fiber mesh as compared to control specimen. Increased impact resistance with kenaf mesh having a higher diameter for the same thickness of slab | |

| Mahzabin et al. [94] | Malaysia | Kenaf fiber reinforced concrete | Compare kenaf fiber composite concrete with normal concrete in terms of mechanical properties | Equal or slightly low compressive strength, lower density, low slump and higher absorption than normal concrete Improved split tensile strength and flexural capacity | |

| Zhou et al. (2020) [95] | China | Kenaf reinforced high-strength concrete | Investigating the effect of natural fiber on high-strength concrete | Decreased compressive strength (12.2–46.2%) Increased flexural strength (30–67%) | The optimum fiber content was 1% |

| Sisal/Banana/Ramie | |||||

| Hu et al. (2018) [96] | Guangzhou, China | Fiber reinforced epoxy polymer concrete | Study the flexural behavior using sisal or ramie fibers | 0.36% fibers caused 25.3% and 10.4% increase in flexural strength using ramie and sisal fiber, respectively without compromise on compressive strength Higher fiber % resulted in decreased strength | Suggested for highway pavements and bridges as they are subjected to both compressive and bending loads |

| Prasannan et al. (2018) [97] | India | Fiber reinforced concrete | Study the effect of sisal and banana fibers on concrete properties | Minor improvements in compressive and split tensile strength Substantial increase in the flexural strength | Recommended for flexural applications where depth needs to be reduced |

| Frazao et al. (2018) [98] | Portugal | Sisal fiber cement composite reinforced lightweight concrete | Experimentally investigate the mechanical behavior of the composite reinforced concrete | Improved modulus of elasticity and tensile strength Reduced compressive strength, workability and more water absorption | Recommended for applications needing ductility |

| Okeoloa et al. (2018) [99] | Kenya | Sisal fiber reinforced concrete | Investigating the mechanical properties at different % of sisal | Increased split tensile strength and modulus of elasticity Decreased compressive strength, water absorption and workability | 1% sisal as optimum out of 0.5–2.0% |

| Mouli et al. (2019) [100] | India | Metakaolin and banana reinforced concrete | Explore the effect of banana fibers on concrete properties | Increase in compressive strength and tensile strength in comparison to plain concrete, along with greater cracking resistance | Fiber content beyond optimum may cause a negative impact on mechanical properties |

| Jute | |||||

| Zakaria et al. (2017) [101] | Bangladesh | Jute fiber reinforced concrete | Evaluate the strength improvement in concrete using jute fibers | Increased compressive, flexural and tensile strength with 0.1% & 0.25% volume content and 10 mm & 15 mm fiber length Jute yarn was found to be more suitable for concrete than jute fiber | Jute yarn was recommended for concrete due to renewability, low cost and strength improvement |

| Zia and Ali (2017) [102] | Pakistan | Fiber reinforced canal lining | Study behavior of jute fiber reinforced concrete in crack control of canal-lining | Jute fiber concrete showed 61% decreased slump, 31% compressive strength drop but 87% enhanced absorbed energy and better tensile strength than plain concrete lining | Suggested to use for controlling the cracking rate in canal lining |

| Akasaka et al. (2018) [103] | Japan | Fiber reinforced concrete (ring restrained specimen) | Experimentally observe the effect of incorporating jute for reducing high-strength concrete spalling | Negligible spalling with jute fibers. | Can be used in combination with ring restraint for control of spalling |

| Dayananda et al. (2018) [104] | India | Jute fiber reinforced concrete | Investigate the effect of raw jute on the compressive strength of concrete | Improved compressive strength as compared to control concrete Optimum fiber content was 0.4% after which strength and workability reduced | It’s important to find the optimum dosage of fibers |

| Kundu et al. (2018) [105] | India | Jute fiber concrete paver blocks | Study jute fibers for improvement of strength and flexibility of concrete paver blocks | Surface modified (using SBR latex and tannin) jute fibers increased compressive strength, flexural strength and flexural toughness by 30%, 49% and 166%, respectively. | It is recommended as a paver material as it enhances mechanical performance and can potentially reduce life cycle cost as It extends the service life |

| Islam and Ahmad (2018) [106] | Saudi Arabia | Jute fiber reinforced concrete | Evaluate the impact of different dosages of jute fibers on fresh and hardened properties of concrete. Also, studying the effect of fiber length and volume | Increase in fiber content caused decrease in slump Mixed influence on compressive strength depending on fiber content, type and size Flexural strength was reduced but the number of cracks/crack widths was lowered | Care to be exercised during mix design with fiber size and proportion |

| Zhang et al. (2019) [107] | China | Jute fiber reinforced high strength concrete | Explore effect of the water–cement ratio, jute fiber length, and jute fiber content on the high-strength concrete properties | Improved mechanical properties with optimum features (fiber content = 3 kg/m3, fiber length = 16 mm and W/C = 0.3) | Need for exploring the acidity and alkalinity of natural fibers and cement |

| Ahmad and Ali (2020) [108] | Pakistan | Reinforced (Steel/GFRP) concrete walls with jute fibers | Augment the impact resistance of reinforced concrete walls | Jute reinforced concrete showed better toughness as compared to plain concrete. The GFRP and jute concrete combination was found to be the best. | Jute fibers recommended as sustainable material keeping in view the optimum fiber length, content and mix design |

| Zhang et al. (2020) [109] | Singapore | Fiber reinforced ultra-high performance concrete | Study high-temperature behavior of ultra-high performance concrete with jute fibers | More jute fiber is required to counter the thermal spalling compared to synthetic fibers. Weathering effects did not have any significant impact on the basic mechanical properties. | |

| Khaleel et al. (2021) [110] | India | Jute reinforced masonry bricks | Investigation of mechanical properties (fiber reinforced vs. textile reinforced) | Higher effectiveness of fiber reinforcement against textile reinforced. Enhanced energy absorption capacity | Can be utilized in earthquake zones |

| Pineapple | |||||

| Irawan and Idris (2019) [111] | Indonesia | Fiber reinforced foamed concrete | Investigate behavior of foamed concrete with the addition of pineapple and polypropylene fiber | The compressive and flexural strengths both increased with the increase in fiber content with 0.4% polypropylene fiber (of total volume) with 12 mm length gave the maximum strengths. The fibers also reduced the microcracking of the concrete | The authors suggested using pineapple & polypropylene fibers for non-structural and structural concrete elements |

| Esper and Canseco (2020) [112] | Philippines | Pineapple fiber reinforced concrete | Study the effect of pineapple leaf fiber on concrete properties | Due to hydrophilic nature, treatment is required for addition of fibers into a cementitious material. The highest tensile strength (parallel to surface) and flexural strength were observed for 1% fiber content (w/w cement) out of 1.4 and 7% with 4% NaOH treatment | Pineapple fiber can be used as a low-cost and renewable source with special attention to optimum content and fiber treatment |

| Author (Year) | Region | Material Combination | Objective(s) | Findings | Weakness/Recommendation |

|---|---|---|---|---|---|

| Flax | |||||

| Takasaki et al. (2014) [118] | Japan | Reinforced concrete beams strengthened by Flax fiber sheets | Study the shear strengthening effect of Flax fabric | 22–72% improvement in shear strength of the beam Higher number of layers provided higher strengths | The direction of fiber in applied sheets influences the strengthening effect (WEFT direction better than WARP) |

| Yan et al. (2015) [119] | Germany | Concrete beams with coir (coconut) fibers and FFRP wrapping | Investigate the effectiveness of FFRP wrapping for concrete beams | Increased mechanical properties (flexural strength, deflection and ultimate load) More strengthening with more layers of wrapping Coir fibers augmented the lateral load capacity and fracture energy | FFRP can be used for strengthening of structures with an adequate intervention for ensured durability. |

| Huang et al. (2016) [120] | China | Concrete beams with external FFRP plates | Study flexural performance of FFRP strengthened concrete beams | Increased load-bearing capacity, deflection, ductility and energy absorption with FFRP strengthening Comparable load-bearing capacity to CFRP and GFRP | Lower tensile strength and modulus compared to CFRP and GFRP |

| Luccio et al. (2017) [121] | France | Reinforced concrete walls strengthened by flax FRP strips | Assess the feasibility of strengthening RC walls using flax FRP | Up to 150% strength enhancement and 30% increase in ductility were observed due to FFRP comparable to carbon FRP strips. | Authors recommended using FFRP for seismic retrofitting due to high displacement capacities with a suggestion for further experimental explorations. |

| Wang and Chow (2018) [122] | New Zealand | Concrete slabs with coconut fibers strengthened with flax fiber reinforced polymer (FFRP) | Evaluate the impact resistance of the FFRP wrapping and finding the more effective configuration | Better impact resistance, improved structural integrity under impact loading and more energy absorption capacity for slabs having fibers and FFRP wrap | Can be used for pavements or other structures having impact loads |

| Wang et al. (2019) [18] | Germany | Wooden beams externally strengthened using flax FRP | Compare Flax, Basalt and Glass FRP as external flexural strengthening agent | Flax FRP exhibited higher flexural load capacity than basalt and comparable with glass FRP The capacity increased for hybrid layer and a greater number of layers but the failure modes changed to debonding | Can be used for beam strengthening but cost provisions (in comparison to deep beam) and optimum number of layers must be used |

| Guadagnuolo and Faella (2020) [45] | Italy | Masonry beams strengthened with flax fiber fabric for seismic strengthening | Assess the retrofitting efficiency of masonry ring-beams with flax fabric for existing buildings | Enhanced seismic performance, increased resisting moments and deformation capacities compatible with adjoining masonry walls | Recommended for monumental buildings |

| Chen et al. (2020) [123] | China | Reinforced concrete beams strengthened by Natural FRP | Investigate the feasibility of natural FRP as replacement of synthetic FRP in structural strengthening upgrades | Significant (41%) increase in load-carrying capacity of RC beams (better than CFRP) and 20–40% cost efficiency Flax (particularly unidirectional) FRP achieved the best strengthening effect and cost-efficiency | Long term durability still unknown.Lower effective bond length of jute (more vulnerable to debonding) |

| Hemp | |||||

| Siriluk et al. (2016) [124] | Thailand | Reinforced concrete beam with HFRP (shear strengthening) | Investigate the shear strengthening effect of HFRP | Increased shear capacity Better strength with uni-directional weaved wrap as compared to matte weaving | HFRP costs are significantly lower than CFRP and GFRP |

| Ghalieh et al. (2017) [125] | Lebanon | Concrete columns with hemp fiber reinforced polymer (HFRP) confinement | Study HFRP efficacy for column strengthening along with factors like number of layers and column slenderness ratio | Increased compressive strength, ductility and energy absorption capacities.More capacity enhancement with a greater number of wraps | Ultimate stress impacted by the column’s slenderness ratio |

| Bitar et al. (2020) [126] | Lebanon | Unreinforced masonry walls externally strengthened by hemp fiber fabric | Investigate the effect of hemp fabric in enhancing flexural capacity | Substantial increase in flexural capacity using hemp fabric (up to 500%) along with enhanced deflectionshemp fiber rupture governed the majority of failure modes | Going beyond the optimum reinforcement ratio (2% in this case) may result in a loss of ductility |

| Kenaf/Jute/Sisal | |||||

| Sen and Reddy (2013) [127] | India | Reinforced concrete beams strengthened with jute composites | Study jute fibers for structural retrofitting of beams | Approx. 60% increase in the load-carrying capacity of beams (full wrap) 25% strength enhancement with strip wrappingHigh deformability index as compared to CFRP and GFRP | Jute FRP recommended for structural strengthening |

| Hafizah et al. (2014) [128] | Malaysia | Reinforced concrete beam with kenaf composites | Study of kenaf fiber application for strengthening of beams (flexural strength, deflections etc.) | More fiber content resulted in higher strength of kenaf composites Enhanced flexural strength (40%), deflection (24%) and stiffness | Need to investigate long-term durability |

| Sen and Reddy (2014) [129] | India | Reinforced concrete beams strengthened with sisal composites | Investigate the structural strengthening characteristics of sisal composites | Heat treatment increased the flexural and tensile strength of sisal FRP About 110% and 65% strengthening was achieved using full and strip sisal wrapping, respectively | Sisal composites also provide an edge in terms of life cycle environmental impacts |

| Sen and Paul (2015) [130] | India | Concrete cylinders confined with natural FRP | Evaluate the confinement strength/modulus parameters of fully and strip-wrapped concrete cylinders by natural jute and sisal fabrics | Approx. 65% and 50% strength increment using sisal and jute FRPs, respectively | Lower strengthening in comparison to GFRP and CFRP but more sustainable |

| Tan et al. (2017) [131] | China | Jute FRP confined sisal fiber concrete cylinders | Experimentally study the compressive behavior of jute polymer confined sisal fiber concrete | Jute FRP enhanced the compressive strength of plain and sisal fiber concrete with more increase with sisal fibers 18%, 35% and 58% increase with 1, 3 and 5 layers, respectively Sisal fiber increased the fiber efficiency but not the ultimate strain. More layers increased the ductility | Suggested further studies on axial/flexural strengthening of concrete and masonry. Durability needs to be examined |

| Alam and Riyami (2018) [132] | Malaysia | Reinforced concrete beams with natural composite plates (shear strengthening) | Produce high-strength composite plates with treated/untreated kenaf, jute and jute rope for shear strengthening of beams | The maximum natural fiber content for fabrication was 45% 35%, 36% & 34% higher shear strengths for beams strengthened with untreated kenaf, jute and jute rope plates, respectively 10%, 23% & 31% higher shear strengths for beams strengthened with treated fiber plates | Important to investigate the optimum fiber content with each composite for better structural performance |

| Omar et al. (2022) [133] | Malaysia | Plain concrete beam strengthened by kenaf FRP plates | Optimization of varying kenaf FRP plates for flexural strengthening of beams | Increased flexural strength and deformability by all 4 variants of kenaf FRP Main failure mode in plate rupture utilizing the full strength | Thicker kenaf FRP plates provide the best performance. |

| Maulana et al. (2022) [134] | Malaysia | Foam concrete beam strengthened by kenaf FRP sheet | Experimental investigation of strengthened beam behavior and strength prediction | Increased lengths of the sheet provided higher flexural capacities More layers of KFRP reduced the ultimate displacement Finite element modelling resulted in models with average 10% discrepancies with experiments | The major failure mode was shear failure, and only the specimen with the longest FRP sheet failed in rupture |

| Bamboo | |||||

| Chin et al. (2019) [135] | Malaysia | Reinforced concrete beams strengthened with bamboo fiber composite plate | Test the effectiveness of the plates as external strengthening material in flexure | 10–12% increase in flexural strength as compared to un-strengthened beam and diversion of cracks from vertical to diagonal at the end of plates | Recommended for flexural strengthening of RC beams |

| Author (Year) | Region | Material Combination | Objectives | Findings | Weakness/Recommendation |

|---|---|---|---|---|---|

| Yan and Chouw (2013) [19] | New Zealand | Flax FRP tube filled with coir reinforced concrete | Investigate the efficacy of coir as concrete reinforcement and flax FRP as confinement material | Improved axial compressive strength and ductility with FFRP confinement for both plain and coir reinforced concrete. (also, with increased tube thickness) Significant enhancement in ultimate lateral load and mid-span deflection using FFRP tube. | FFRP-CFRC composite columns have the potential to be used as axial/flexural structural members |

| Yan et al. (2017) [137] | China | Flax FRP tube filled with masonry recycled aggregate concrete (partial replacement) | Investigate the compressive behavior of the hybrid material | FFRP tube enhanced the strength of recycled aggregate concrete with more strength enhancement for higher concrete strength | |

| Huang et al. (2017) [138] | China | Flax FRP tube filled with recycled aggregate concrete containing clay brick aggregate | Investigate the compressive behavior of the hybrid material | FFRP tube confinement significantly increased both strength and ductility of the confined cylinders | |

| Gao et al. (2022) [139] | China | Sisal fibers in recycled aggregate concrete confined by jute FRP tube | Study the compressive behavior of sisal fiber recycled aggregate concrete in jute FRP tube | Increased compressive strength and ultimate strain provided by jute FRP Bridging effect and slow lateral dilation provided by sisal fibers | Fiber orientation in recycled aggregate concrete plays an important role in ultimate compressive strength and strain |

| Author (Year) | Region | Material Combination | Objectives | Findings | Weakness/Recommendation |

|---|---|---|---|---|---|

| Hu et al. (2007) [117] | USA | Bio-based skin for sandwich panels | Structural design and performance evaluation of the sandwich roof | Wrapping the bio-based skins provided better performance than the stacked layers. The model satisfied the deflection criteria. | Recommended investigating the creep, thermal analysis and inflammability further |

| CoDyre and Fam (2017) [20] | Canada | Foam-core panels with flax composite skins | Investigate axial compressive behavior of the sandwich panels with flax composite skins | Flax FRP sandwich specimens exhibited about one-third of the strength given by sandwich specimens with glass FRP skin Longer panels failed due to global buckling at peak load; whereas’ shorter panels had localized failures | Design can be optimized according to the usage requirements |

| Betts et al. (2017) [140] | Canada | Sandwich Panels having foam cores and Flax FRP facings | Investigate failure mechanisms of sandwich foamed panels with FFRP facings | Flax FRP facings were found suitable for sandwich panels (having polyisocyanurate foams) | The failure mechanisms depend on the facing thickness |

| CoDyre et al. (2018) [141] | Canada | Foam-core panels with flax composite skins | Investigate axial & flexural behavior of the sandwich panels with flax composite skins | Three-layered flax reinforced skin (only 17% thicker than one glass FRP provided equivalent flexural and axial strengths at all three core densities with slight deviations The enhancement in axial & flexural strength was more for specimens with FFRP skins as compared to specimens with GFRP | FFRP skins can be used to replace GFRP with a higher number of layers. Cost analysis needs to be done |

| Fiber | Major Chemical Components | Physical/Mechanical Properties | Economy | Env. Properties | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cellulose (%) | Hemi-cellulose (%) | Lignin (%) | Density (g/cm3) | Diameter (μm) | Length (mm) | Tensile Strength (MPa) | Young’s Modulus (GPA) | Elongation at Break (%) | Moisture Content (%) | Thermal conductivity (W/Mk) | Price (US$/ton) | Embodied Energy (GJ/ton) | GHG emission (CO2-eq/tonne fibre) | Water Footprint (m3/kg) | |