Mechanical Properties of Concrete Produced by Light Cement-Based Aggregates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

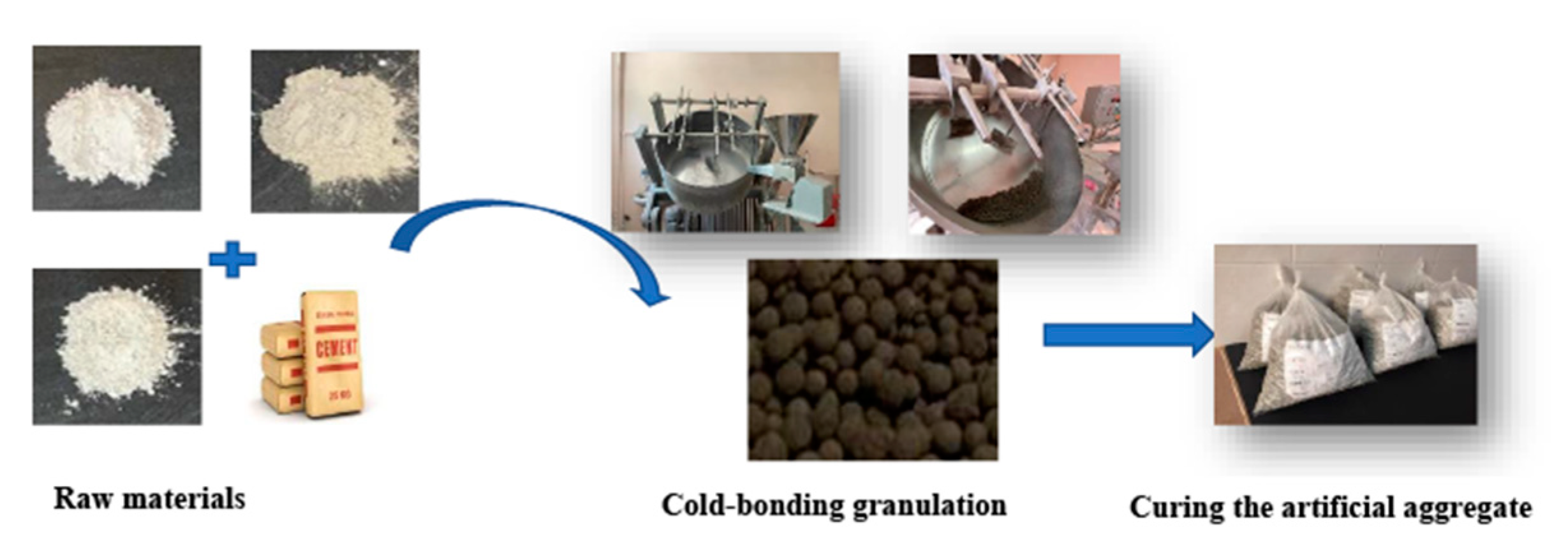

2.2. Production of Artificial LWAs

2.3. Concrete Mix Proportions

2.4. Concrete Casting and Specimen Preparation

2.5. Test Methods

2.5.1. Aggregate Tests

2.5.2. Concrete Tests

3. Results and Discussion

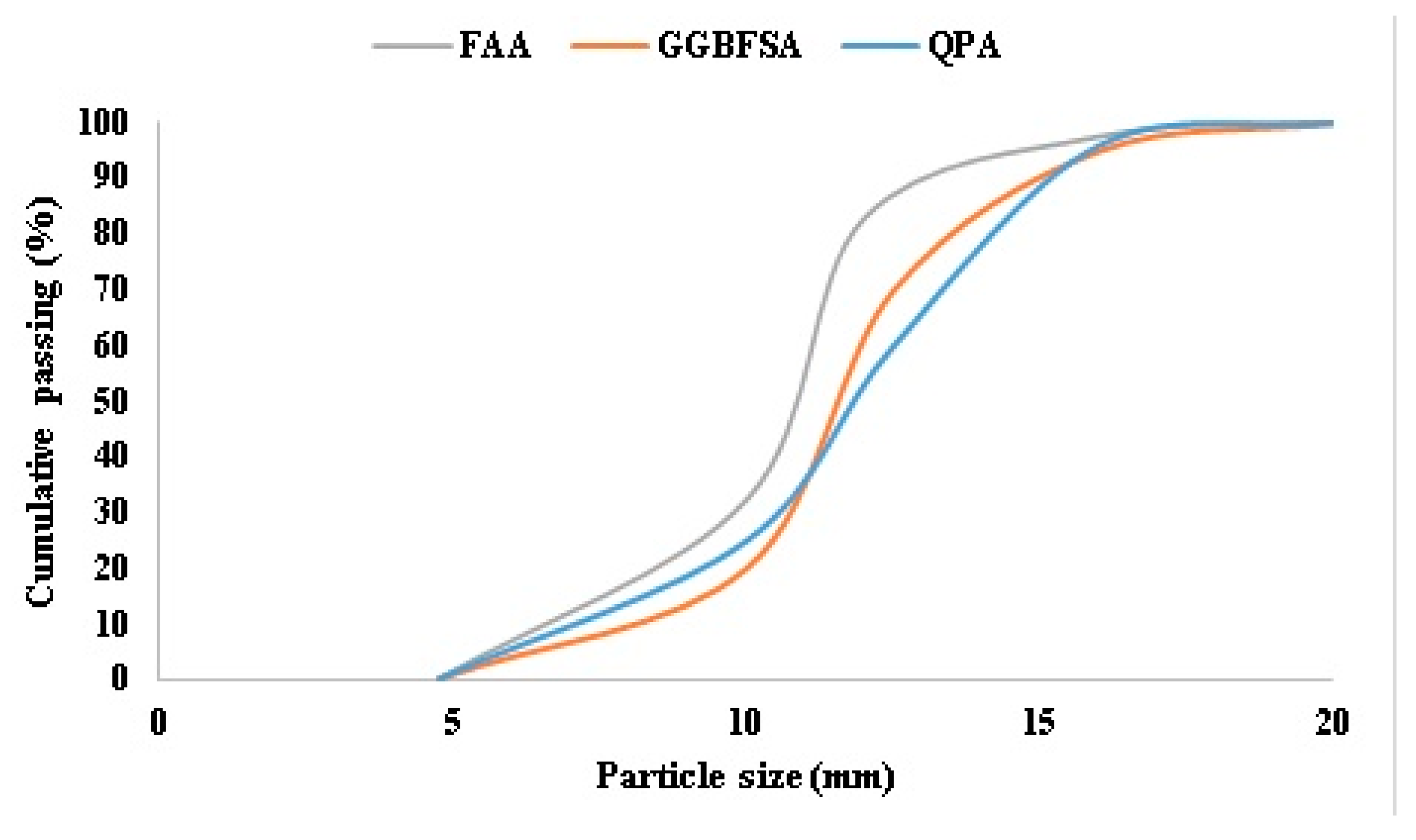

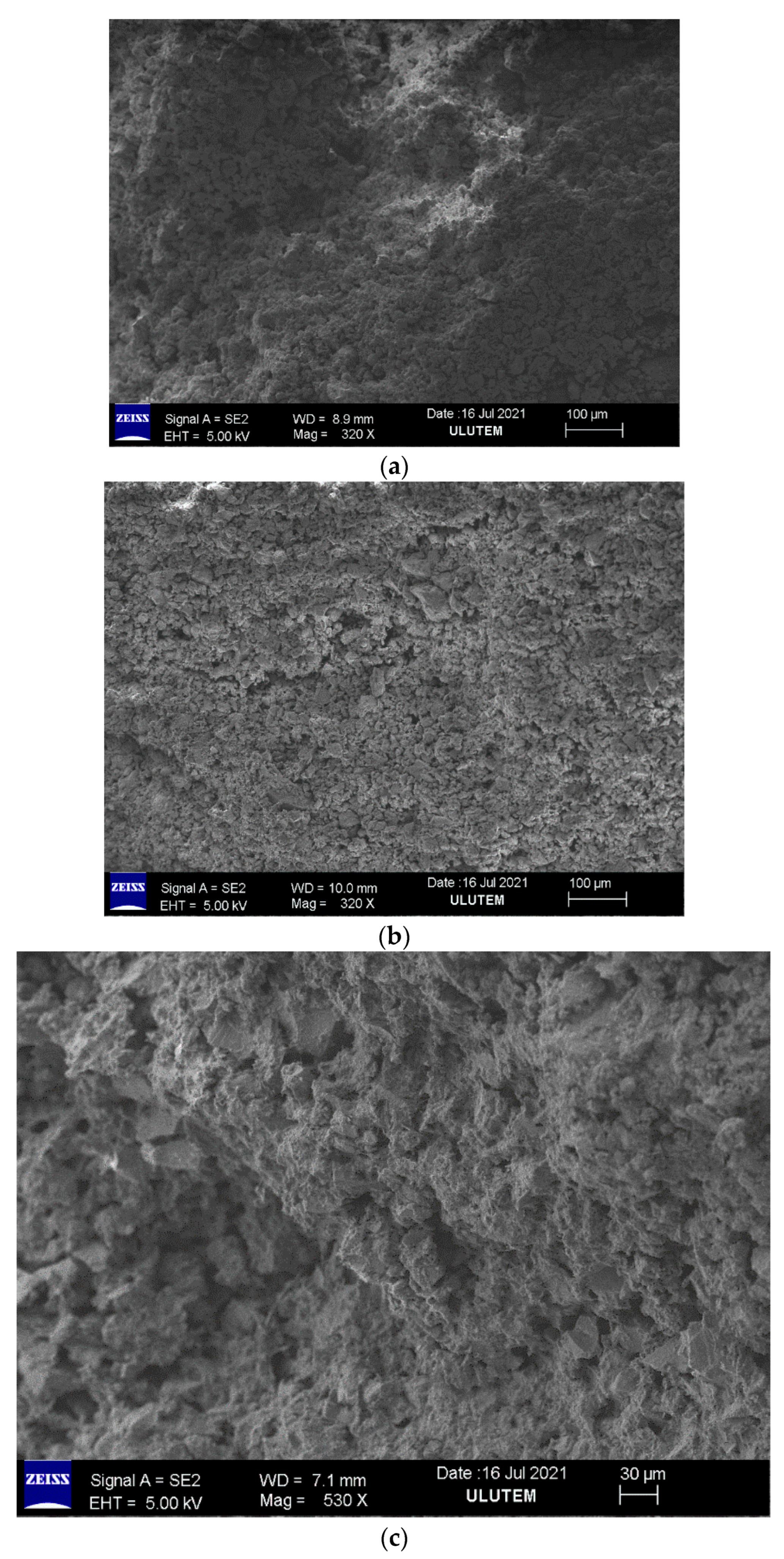

3.1. Results of Aggregate Tests

3.2. Results of Concrete Tests

3.2.1. Compressive Strength

3.2.2. Splitting Tensile Strength

3.2.3. Net Flexural Strength

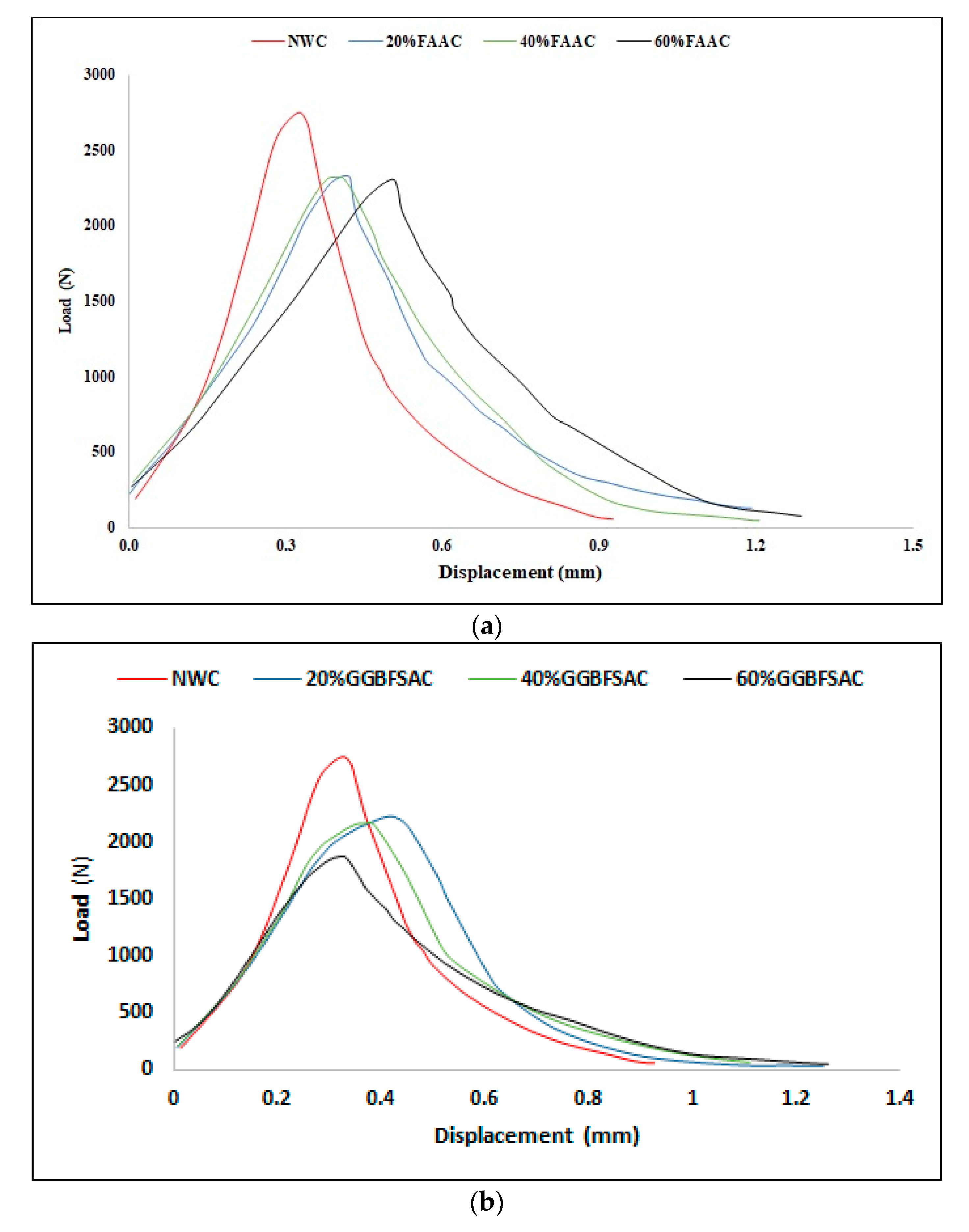

3.2.4. Load–Displacement Curves

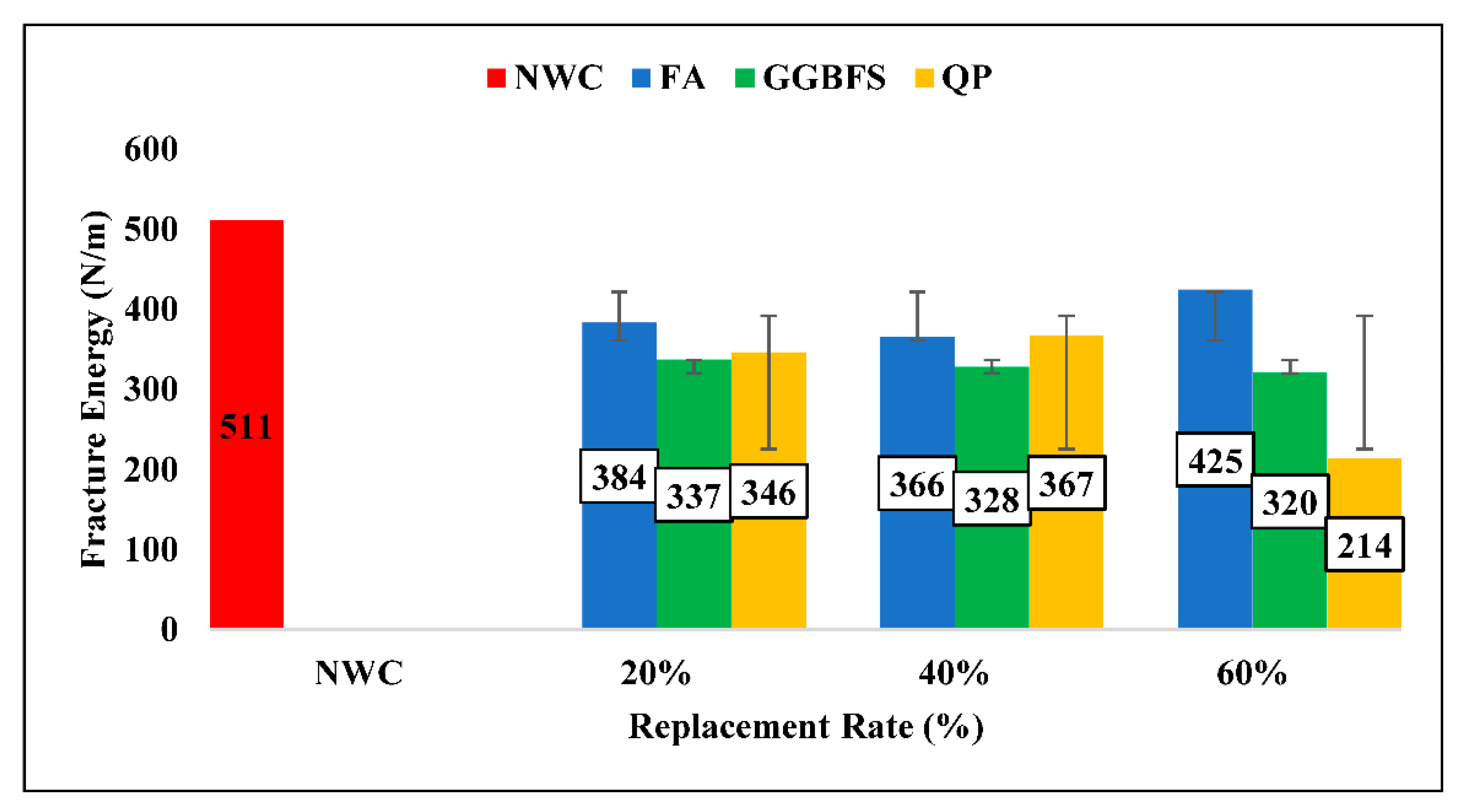

3.2.5. Fracture Energy

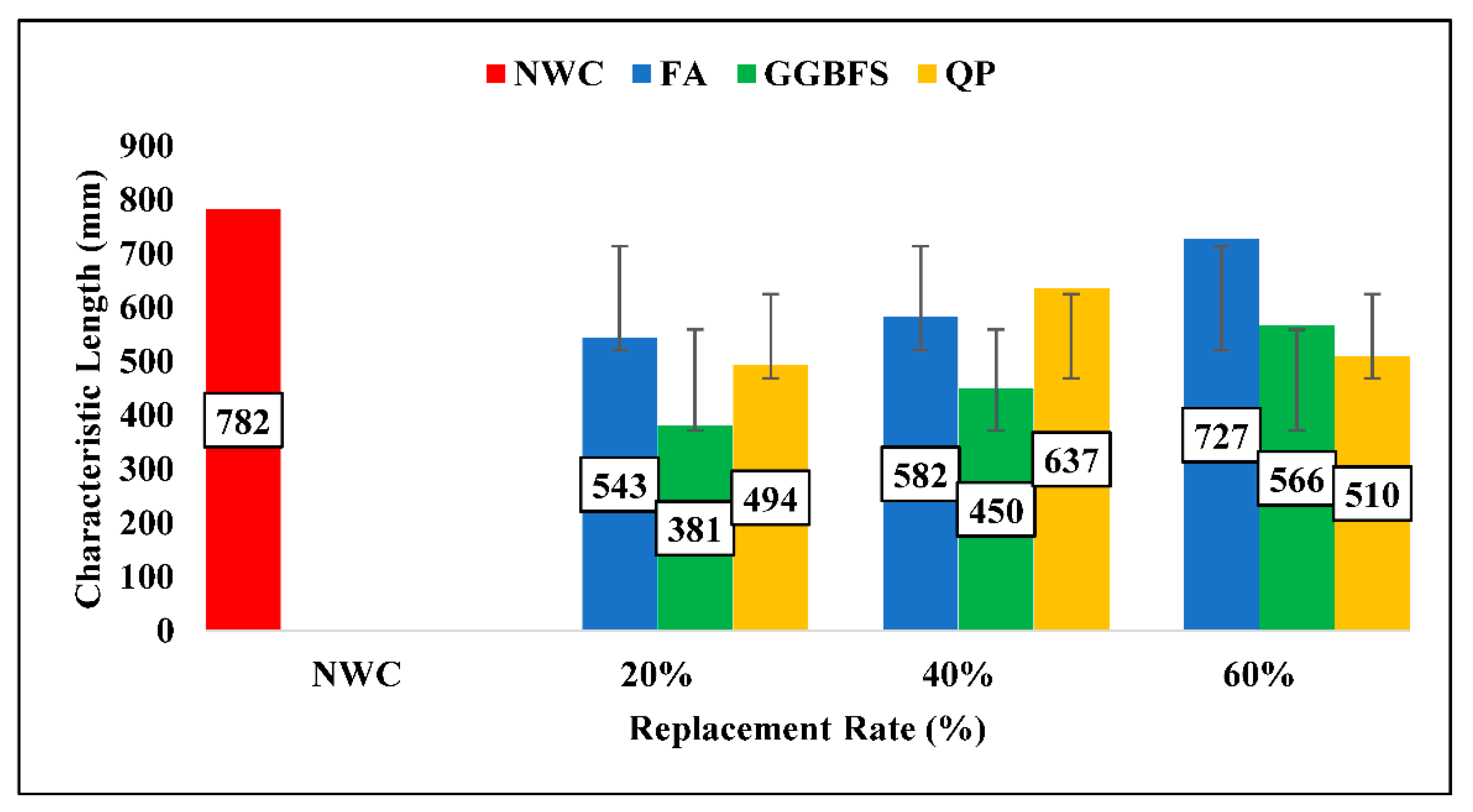

3.2.6. Characteristic Length

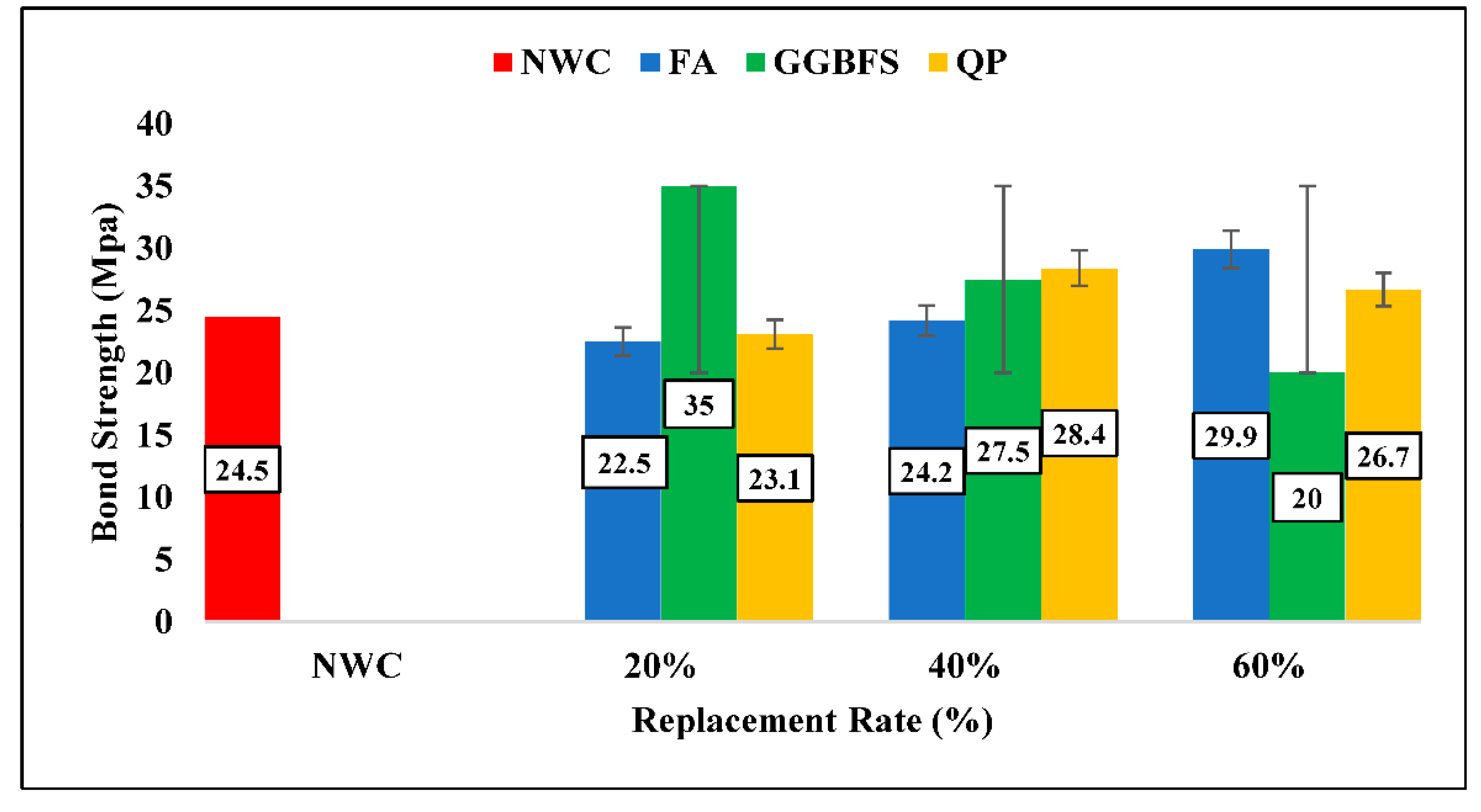

3.2.7. Bond Strength

4. Conclusions

- Artificial LWA was used to build concrete with compressive strengths of 40 MPa and 60 MPa. The maximum compressive strength was achieved for QPLWAC, which recorded 71 MPa at a 40 percent replacement ratio. The artificial LWA may be employed for any desired concrete strength class.

- When used in concrete mixtures, artificial lightweight and ordinary weight particles produced splitting tensile strengths almost identically. Only slightly different changes were discovered. The lower splitting tensile strength values in concrete, including artificial LWA, are related to the lower crushing strength of artificial aggregates and the curing condition of the constructed concrete.

- Artificial LWA concretes resulted in lower net flexural strength results when compared to normal concrete. However, the outcomes were satisfactory for all the concrete mixtures when the correlation between compressive strength and splitting tensile strength was taken into consideration. Regarding the concrete mixes, it was found that the higher ultimate loads occurred in the concrete, including natural, normal-weight aggregate. In contrast, more significant maximum displacement occurred in concrete containing artificial LWA. As a result, it can be concluded that concrete’s tensile strength is reduced by using artificial LWA.

- Because artificial LWA has a lower self-weight, the fracture energy of concrete is lower than that of concrete made with natural, heavier particles. Furthermore, this study’s findings were consistent with previous research on the fracture energy of concrete mixes using artificial LWA. As a result, this shows that lightweight artificial aggregate may be used to make high-fracture-energy concretes.

- Concrete ductility was enhanced as a consequence of using artificial LWA in concrete manufacturing, according to the findings regarding the characteristic length, which is a practical approach to quantify brittleness.

- Artificial LWA used in concrete manufacturing considerably impacts the strength of the connection between the concrete and the reinforcing bar. There is a strong correlation between the reinforcing bar and the artificial LWA. Natural aggregate particles are more rigid than artificial LWA particles. As a result, the lower and comparable concrete resistance to normal concrete is generated after removing the reinforcing bar.

- In conclusion, utilizing artificial LWA in concrete production has a significant impact, not only in terms of preserving the environment, but in the production of concrete with mechanical properties that are comparable with normal concrete and which can be applied in several construction fields.

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Kodur, V.K.R.; Naser, M.Z.; Bhatt, P.P. Energy Engineering; Springer: Berlin/Heidelberg, Germany, 2017; pp. 113–122. [Google Scholar]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical Properties and Mechanical Behaviour of Concrete Made with Recycled Aggregates and Fly Ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Paya, J.; Borrachero, M.V.; Monzo, J.; Peris-Mora, E.; Bonilla, M. Long Term Mechanical Strength Behaviour in Fly Ash/Portland Cement Mortars Prepared Using Processed Ashes. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2002, 77, 336–344. [Google Scholar]

- Sakai, E.; Miyahara, S.; Ohsawa, S.; Lee, S.-H.; Daimon, M. Hydration of Fly Ash Cement. Cem. Concr. Res. 2005, 35, 1135–1140. [Google Scholar] [CrossRef]

- Moon, G.D.; Oh, S.; Choi, Y.C. Effects of the Physicochemical Properties of Fly Ash on the Compressive Strength of High-Volume Fly Ash Mortar. Constr. Build. Mater. 2016, 124, 1072–1080. [Google Scholar] [CrossRef]

- Cheeseman, C.R.; Virdi, G.S. Properties and Microstructure of Lightweight Aggregate Produced from Sintered Sewage Sludge Ash. Resour. Conserv. Recycl. 2005, 45, 18–30. [Google Scholar] [CrossRef]

- Joseph, G.; Ramamurthy, K. Influence of Fly Ash on Strength and Sorption Characteristics of Cold-Bonded Fly Ash Aggregate Concrete. Constr. Build. Mater. 2009, 23, 1862–1870. [Google Scholar] [CrossRef]

- Kayali, O. Fly Ash Lightweight Aggregates in High Performance Concrete. Constr. Build. Mater. 2008, 22, 2393–2399. [Google Scholar] [CrossRef]

- Arslan, H.; Baykal, G. Utilization of Fly Ash as Engineering Pellet Aggregates. Environ. Geol. 2006, 50, 761–770. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Durability of Lightweight Concretes with Lightweight Fly Ash Aggregates. Constr. Build. Mater. 2011, 25, 1430–1438. [Google Scholar] [CrossRef]

- Li, D.; Xu, Z.; Luo, Z.; Pan, Z.; Cheng, L. The Activation and Hydration of Glassy Cementitious Materials. Cem. Concr. Res. 2002, 32, 1145–1152. [Google Scholar] [CrossRef]

- Baykal, G.; Döven, A.G. Utilization of Fly Ash by Pelletization Process; Theory, Application Areas and Research Results. Resour. Conserv. Recycl. 2000, 30, 59–77. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Effects of Lightweight Fly Ash Aggregate Properties on the Behavior of Lightweight Concretes. J. Hazard. Mater. 2010, 179, 954–965. [Google Scholar] [CrossRef]

- Keulen, A.; Van Zomeren, A.; Harpe, P.; Aarnink, W.; Simons, H.A.E.; Brouwers, H.J.H. High Performance of Treated and Washed MSWI Bottom Ash Granulates as Natural Aggregate Replacement within Earth-Moist Concrete. Waste Manag. 2016, 49, 83–95. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Durability Performance of Concrete with Recycled Aggregates from Construction and Demolition Waste Plants. Constr. Build. Mater. 2015, 77, 357–369. [Google Scholar] [CrossRef]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of Recycled Concrete Aggregate in Fly-Ash Concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Lotfy, A.; Al-Fayez, M. Performance Evaluation of Structural Concrete Using Controlled Quality Coarse and Fine Recycled Concrete Aggregate. Cem. Concr. Compos. 2015, 61, 36–43. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Influence of Recycled Aggregate on Slump and Bleeding of Fresh Concrete. Mater. Struct. 2007, 40, 981–988. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Zhang, W.; Jin, H.; Xing, F.; Tang, L. The Impact of Cold-Bonded Artificial Lightweight Aggregates Produced by Municipal Solid Waste Incineration Bottom Ash (MSWIBA) Replace Natural Aggregates on the Mechanical, Microscopic and Environmental Properties, Durability of Sustainable Concrete. J. Clean. Prod. 2022, 337, 130479. [Google Scholar] [CrossRef]

- Kwek, S.Y.; Awang, H. Utilisation of Recycled Silt from Water Treatment and Palm Oil Fuel Ash as Geopolymer Artificial Lightweight Aggregate. Sustainability 2021, 13, 6091. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Atmaca, N. Cold Bonded and Low Temperature Sintered Artificial Aggregate Production by Using Waste Materials. Period. Polytech. Civ. Eng. 2022, 1–11. [Google Scholar] [CrossRef]

- Wei, Y.L.; Cheng, S.H.; Chen, W.J.; Lu, Y.H.; Chen, K.; Wu, P.C. Influence of Various Sodium Salt Species on Formation Mechanism of Lightweight Aggregates Made from Coal Fly Ash-Based Material. Constr. Build. Mater. 2020, 239, 117890. [Google Scholar] [CrossRef]

- Sahoo, S.; Selvaraju, A.K.; Suriya Prakash, S. Mechanical Characterization of Structural Lightweight Aggregate Concrete Made with Sintered Fly Ash Aggregates and Synthetic Fibres. Cem. Concr. Compos. 2020, 113, 103712. [Google Scholar] [CrossRef]

- Nadesan, M.S.; Dinakar, P. Structural Concrete Using Sintered Flyash Lightweight Aggregate: A Review. Constr. Build. Mater. 2017, 154, 928–944. [Google Scholar] [CrossRef]

- Balapour, M. Conversion of Waste Coal Combustion Ash to Value-Added Construction Lightweight Aggregates Through a Holistic Thermodynamics-Guided Manufacturing Framework; Drexel University: Philadelphia, PA, USA, 2021. [Google Scholar]

- Senneca, O.; Cortese, L.; Di Martino, R.; Fabbricino, M.; Ferraro, A.; Race, M.; Scopino, A. Mechanisms Affecting the Delayed Efficiency of Cement Based Stabilization/Solidification Processes. J. Clean. Prod. 2020, 261, 121230. [Google Scholar] [CrossRef]

- Ferraro, A.; Colangelo, F.; Farina, I.; Race, M.; Cioffi, R.; Cheeseman, C.; Fabbricino, M. Cold-Bonding Process for Treatment and Reuse of Waste Materials: Technical Designs and Applications of Pelletized Products. Crit. Rev. Environ. Sci. Technol. 2021, 51, 2197–2231. [Google Scholar] [CrossRef]

- Gomathi, P.; Sivakumar, A. Accelerated Curing Effects on the Mechanical Performance of Cold Bonded and Sintered Fly Ash Aggregate Concrete. Constr. Build. Mater. 2015, 77, 276–287. [Google Scholar] [CrossRef]

- Colangelo, F.; Messina, F.; Di Palma, L.; Cioffi, R. Recycling of Non-Metallic Automotive Shredder Residues and Coal Fly-Ash in Cold-Bonded Aggregates for Sustainable Concrete. Compos. Part B Eng. 2017, 116, 46–52. [Google Scholar] [CrossRef]

- Tajra, F.; Elrahman, M.A.; Stephan, D. The Production and Properties of Cold-Bonded Aggregate and Its Applications in Concrete: A Review. Constr. Build. Mater. 2019, 225, 29–43. [Google Scholar] [CrossRef]

- Kang, M.C.; Yoo, D.Y.; Gupta, R. Machine Learning-Based Prediction for Compressive and Flexural Strengths of Steel Fiber-Reinforced Concrete. Constr. Build. Mater. 2021, 266, 121117. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R. Use of Cement Kiln Dust, Blast Furnace Slag and Marble Sludge in the Manufacture of Sustainable Artificial Aggregates by Means of Cold Bonding Pelletization. Materials 2013, 6, 3139–3159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Özkan, H.; Kabay, N.; Miyan, N. Properties of Cold-Bonded and Sintered Aggregate Using Washing Aggregate Sludge and Their Incorporation in Concrete: A Promising Material. Sustainability 2022, 14, 4205. [Google Scholar] [CrossRef]

- Dabhade, A.N.; Chaudari, S.R.; Gajbhaye, A.R. Effect of Fly Ash on Recycle Coarse Aggregate Concrete. Int. J. Civ. Eng. Res. 2014, 2278, 3652. [Google Scholar]

- Faraj, R.H.; Sherwani, A.F.H.; Jafer, L.H.; Ibrahim, D.F. Rheological Behavior and Fresh Properties of Self-Compacting High Strength Concrete Containing Recycled PP Particles with Fly Ash and Silica Fume Blended. J. Build. Eng. 2021, 34, 101667. [Google Scholar] [CrossRef]

- Faraj, R.H.; Hama Ali, H.F.; Sherwani, A.F.H.; Hassan, B.R.; Karim, H. Use of Recycled Plastic in Self-Compacting Concrete: A Comprehensive Review on Fresh and Mechanical Properties. J. Build. Eng. 2020, 30, 101283. [Google Scholar] [CrossRef]

- Faraj, R.H.; Sherwani, A.F.H.; Daraei, A. Mechanical, Fracture and Durability Properties of Self-Compacting High Strength Concrete Containing Recycled Polypropylene Plastic Particles. J. Build. Eng. 2019, 25, 100808. [Google Scholar] [CrossRef]

- Glavind, M.; Munch-Petersen, C. ‘Green’ Concrete in Denmark. Struct. Concr. 2000, 1, 19–25. [Google Scholar] [CrossRef]

- Li, Z.; Ding, Z.; Zhang, Y. Proceedings of the International Workshop on Sustainable Development and Concrete Technology; Center for Transportation Research and Education Iowa State University: Beijing, China, 2004; pp. 55–76. [Google Scholar]

- Danish, A.; Mosaberpanah, M.A. Formation Mechanism and Applications of Cenospheres: A Review. J. Mater. Sci. 2020, 55, 4539–4557. [Google Scholar] [CrossRef]

- Cui, H.Z.; Lo, T.Y.; Memon, S.A.; Xu, W. Effect of Lightweight Aggregates on the Mechanical Properties and Brittleness of Lightweight Aggregate Concrete. Constr. Build. Mater. 2012, 35, 149–158. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A Review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Patel, S.K.; Satpathy, H.P.; Nayak, A.N.; Mohanty, C.R. Utilization of Fly Ash Cenosphere for Production of Sustainable Lightweight Concrete. J. Inst. Eng. Ser. A 2020, 101, 179–194. [Google Scholar] [CrossRef]

- McBride, S.P.; Shukla, A.; Bose, A. Processing and Characterization of a Lightweight Concrete Using Cenospheres. J. Mater. Sci. 2002, 37, 4217–4225. [Google Scholar] [CrossRef]

- Nadesan, M.S.; Dinakar, P. Influence of Type of Binder on High-Performance Sintered Fly Ash Lightweight Aggregate Concrete. Constr. Build. Mater. 2018, 176, 665–675. [Google Scholar] [CrossRef]

- RILEM, D.R. Draft Recommendation: “Determination of the Fracture Energy of Mortar and Concrete by Means of Three-Point Bend Tests on Notched Beams”. Mater. Struct. 1985, 18, 484. [Google Scholar]

- Balendran, R.V.; Zhou, F.P.; Nadeem, A.; Leung, A.Y.T. Influence of Steel Fibres on Strength and Ductility of Normal and Lightweight High Strength Concrete. Build. Environ. 2002, 37, 1361–1367. [Google Scholar] [CrossRef]

- Hillerborg, A. The Theoretical Basis of a Method to Determine the Fracture EnergyG F of Concrete. Mater. Struct. 1985, 18, 291–296. [Google Scholar] [CrossRef]

- RILEM, R.C. Recommendations for the Testing and Use of Constructions Materials Bond Test for Reinforcement Steel. Pull-Out Test 1996, 3. [Google Scholar] [CrossRef]

- İpek, S.; Ayodele, O.A.; Mermerdaş, K. Influence of Artificial Aggregate on Mechanical Properties, Fracture Parameters and Bond Strength of Concretes. Constr. Build. Mater. 2020, 238, 117756. [Google Scholar] [CrossRef]

| Chemical Composition (%) | Portland Cement | FA | QQBFS | QP |

|---|---|---|---|---|

| CaO | 62.58 | 4.24 | 34.12 | 0.28 |

| SiO2 | 20.25 | 56.20 | 36.41 | 89.05 |

| Al2O3 | 5.31 | 20.17 | 10.39 | 5.03 |

| Fe2O3 | 4.04 | 6.69 | 0.69 | 3.62 |

| MgO | 2.82 | 1.92 | 10.26 | – |

| SO3 | 2.73 | 0.49 | – | – |

| K2O | 0.92 | 1.89 | 0.97 | 0.28 |

| Na2O | 0.22 | 0.58 | 0.35 | – |

| Loss on ignition | 3.02 | 1.78 | 1.64 | – |

| Specific gravity | 3.15 | 2.25 | 2.79 | 2.65 |

| Blaine fineness (m2/kg) | 326.00 | 287.00 | 418.00 | – |

| Mix ID | Replacement Rate (%) | Cement (kg/m3) | Water (kg/m3) | River Sand (kg/m3) | Natural Aggregate (kg/m3) | Manufactured Aggregate (kg/m3) | SP (kg/m3) |

|---|---|---|---|---|---|---|---|

| 20 | 360 | 158 | 733.3 | 589.4 | 80 | 4.45 | |

| FAAC | 40 | 360 | 158 | 733.3 | 442 | 157.7 | 4.45 |

| 60 | 360 | 158 | 733.3 | 294.7 | 236.7 | 4.45 | |

| 20 | 360 | 158 | 733.3 | 589.3 | 93.7 | 4.45 | |

| GGBFSAC | 40 | 360 | 158 | 733.3 | 442 | 187.7 | 4.45 |

| 60 | 360 | 158 | 733.3 | 294.7 | 281.3 | 4.45 | |

| QPAC | 20 | 360 | 158 | 733.3 | 589.4 | 82.5 | 4.45 |

| 40 | 360 | 158 | 733.3 | 442.1 | 165 | 4.45 | |

| 60 | 360 | 158 | 733.3 | 294.7 | 247.5 | 4.45 |

| Mix ID | Maximum Aggregate Size (mm) | Fineness Modulus | Specific Gravity | Apparent Specific Gravity | Density (kg/m3) | Water Absorption (%) | Crushing Strength (N) |

|---|---|---|---|---|---|---|---|

| FAA | 16 | 1.78 | 1.43 | 2.43 | 937.59 | 28.52 | 722.96 |

| GGBFSA | 12.5 | 2.67 | 1.74 | 2.43 | 1114.42 | 16.27 | 1038.98 |

| QA | 12.5 | 1.53 | 1.61 | 2.70 | 928.00 | 18.00 | 675.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, M.A.; Atmaca, N.; Abdullah, A.A.; Atmaca, A. Mechanical Properties of Concrete Produced by Light Cement-Based Aggregates. Sustainability 2022, 14, 15991. https://doi.org/10.3390/su142315991

Ibrahim MA, Atmaca N, Abdullah AA, Atmaca A. Mechanical Properties of Concrete Produced by Light Cement-Based Aggregates. Sustainability. 2022; 14(23):15991. https://doi.org/10.3390/su142315991

Chicago/Turabian StyleIbrahim, Mais Abdulrazzaq, Nihat Atmaca, Ahmed Assim Abdullah, and Adem Atmaca. 2022. "Mechanical Properties of Concrete Produced by Light Cement-Based Aggregates" Sustainability 14, no. 23: 15991. https://doi.org/10.3390/su142315991

APA StyleIbrahim, M. A., Atmaca, N., Abdullah, A. A., & Atmaca, A. (2022). Mechanical Properties of Concrete Produced by Light Cement-Based Aggregates. Sustainability, 14(23), 15991. https://doi.org/10.3390/su142315991