The Strength and Elastic Modulus of Pervious Concrete Considering Pore and Fiber during Freeze–Thaw Cycles

Abstract

:1. Introduction

2. Materials and Methods

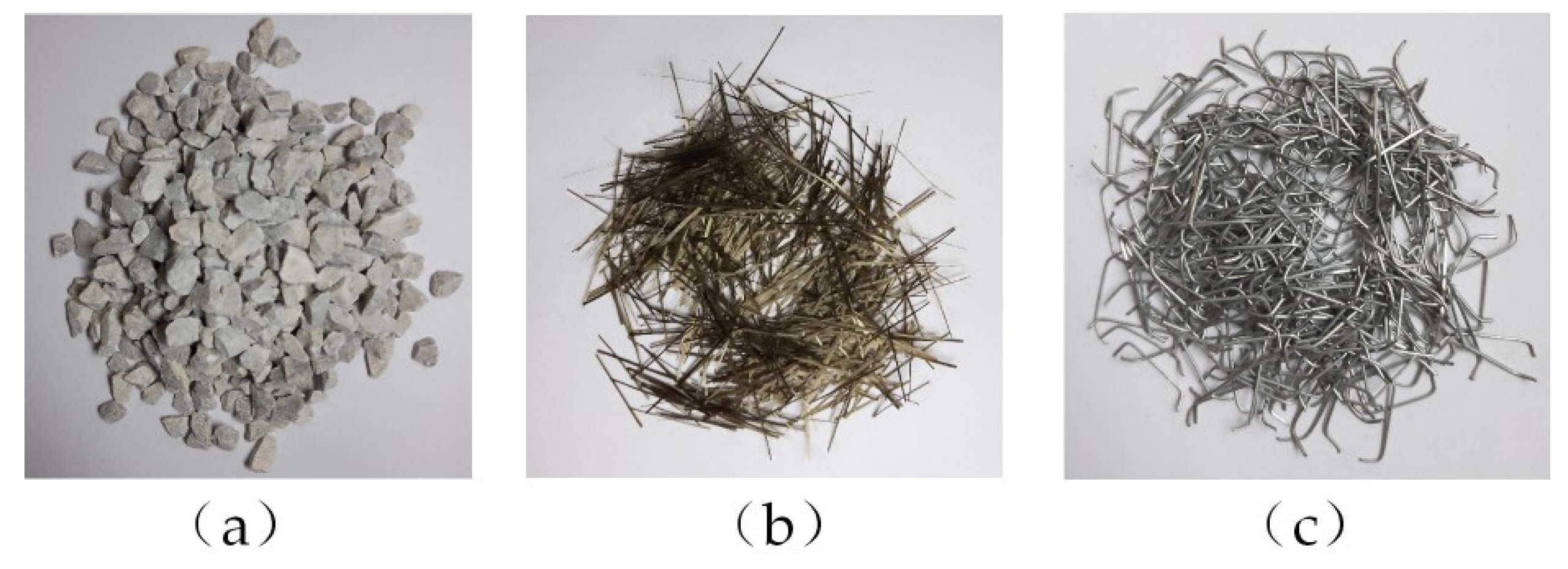

2.1. Materials

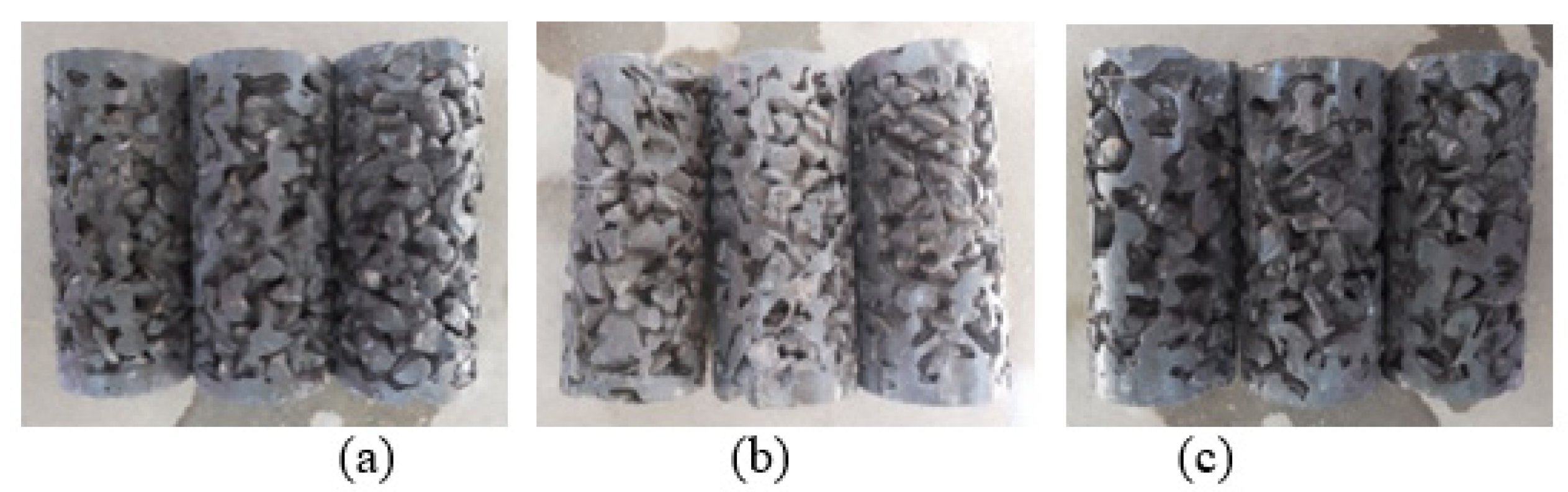

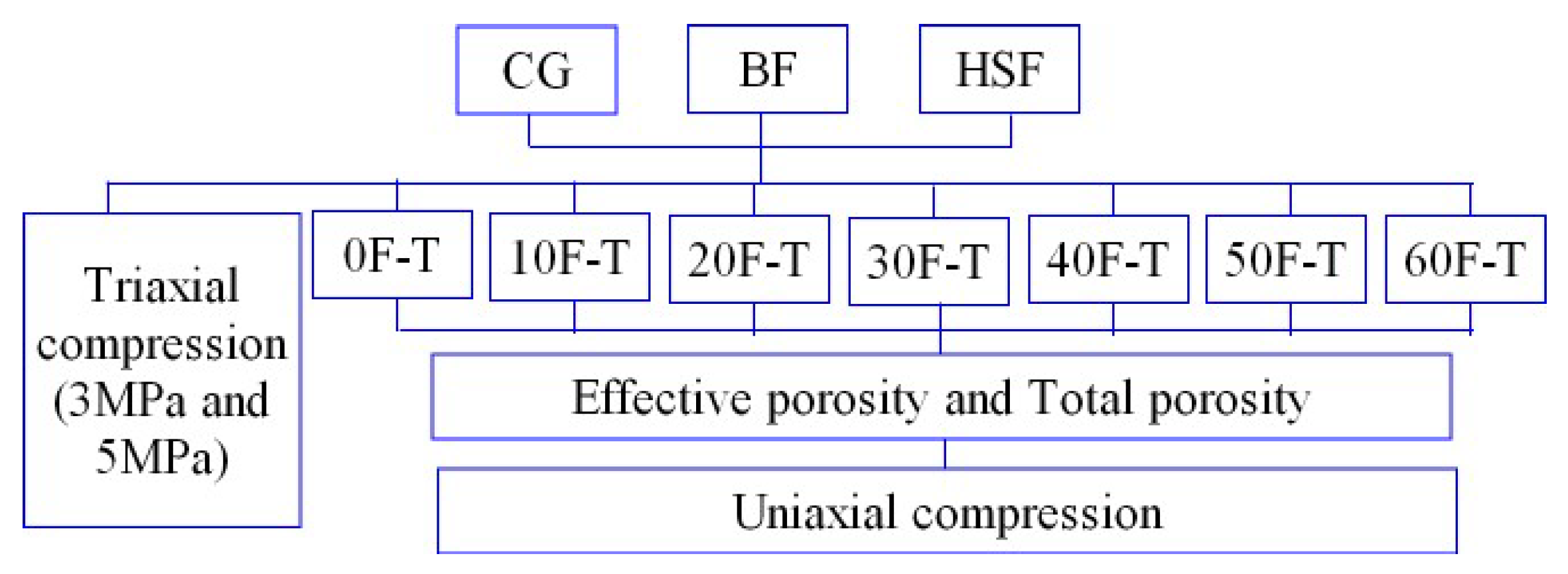

2.2. Mix Design and Specimens Preparation

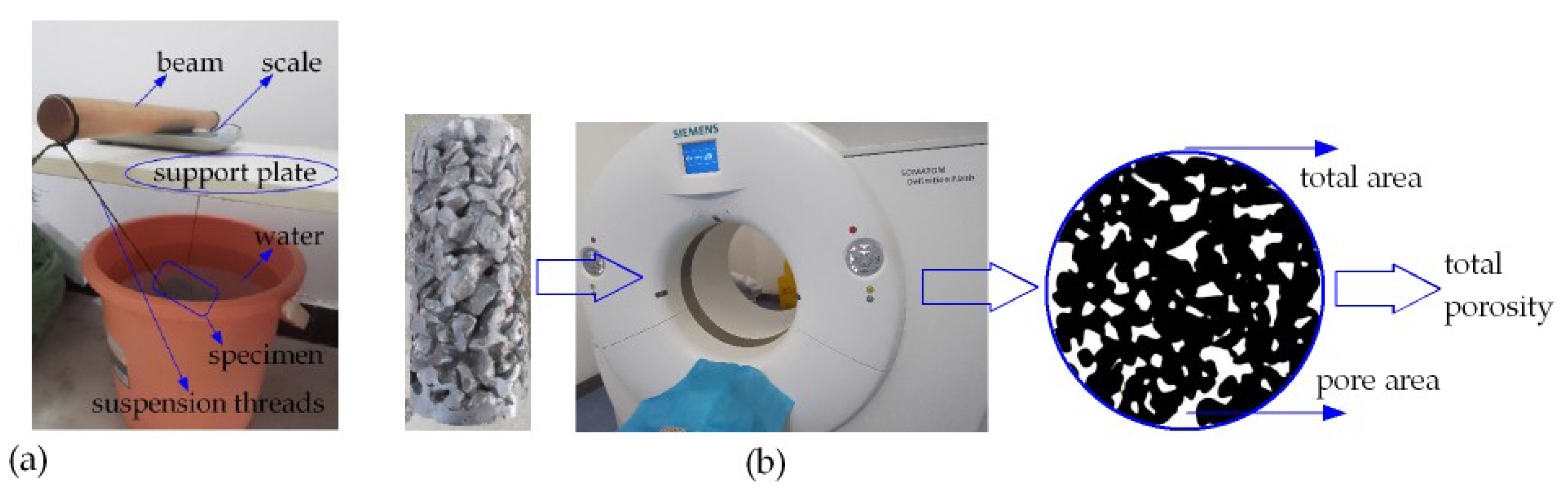

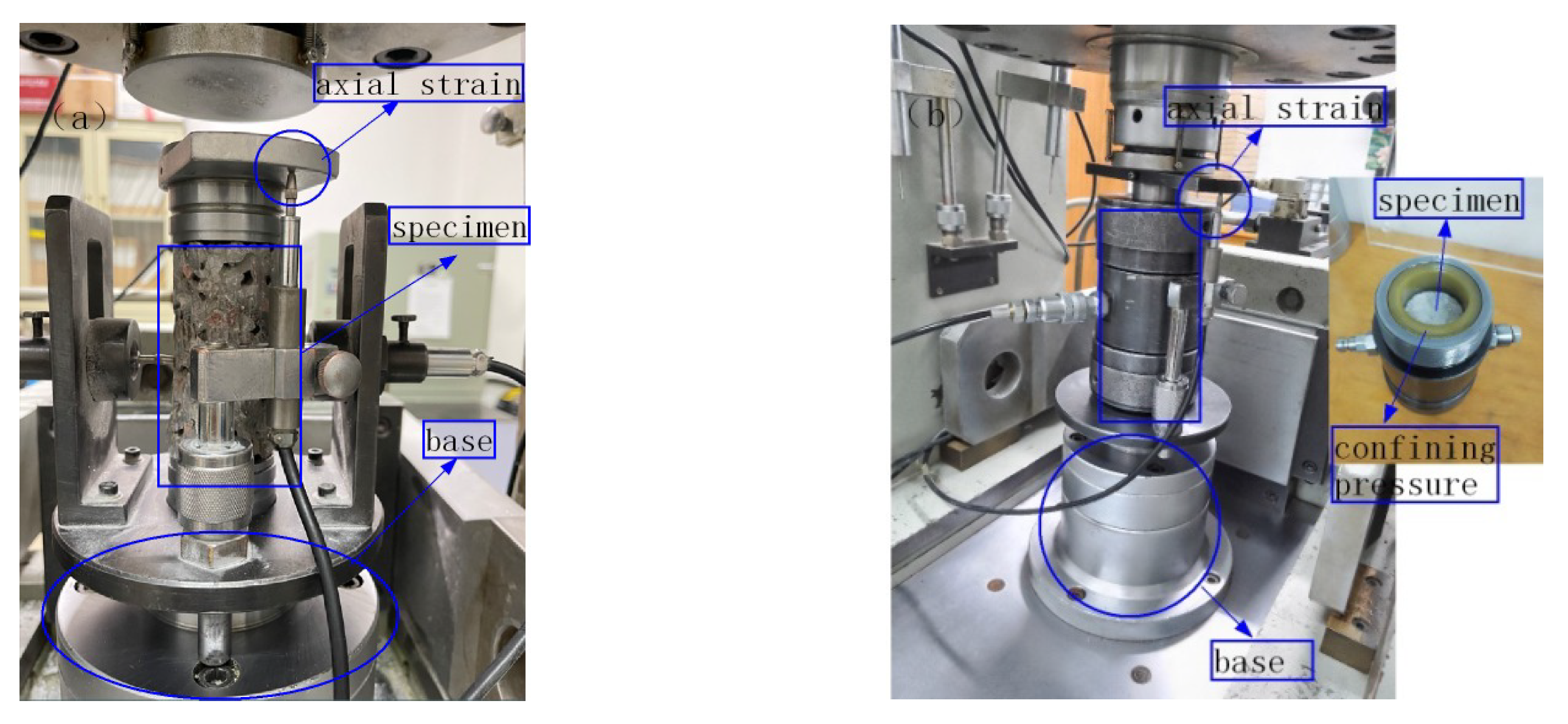

2.3. Testing Methods

2.4. Effective Modulus Analysis

2.5. Effective Stress Analysis

3. Results and Discussion

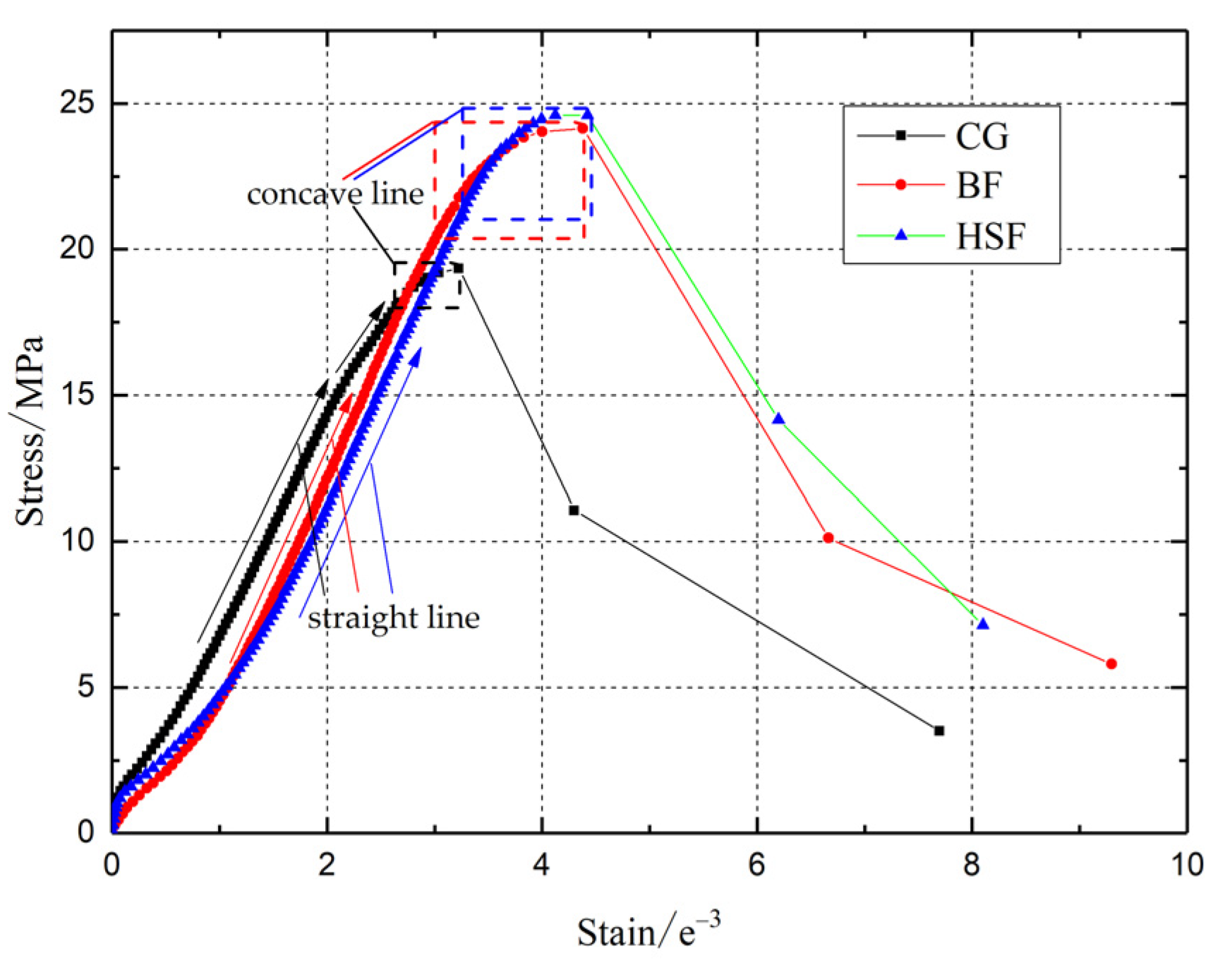

3.1. Uniaxial Compressive Strength

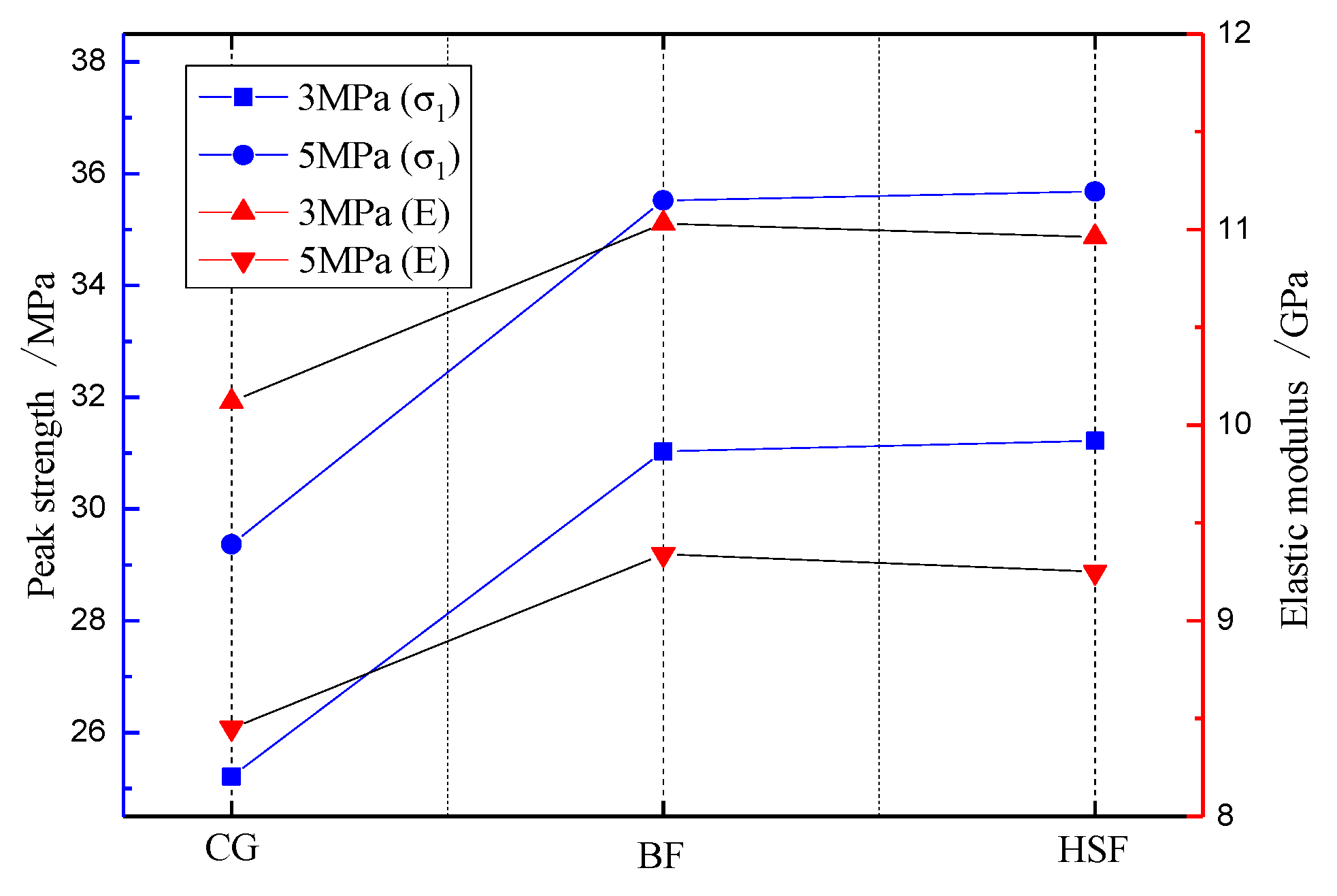

3.2. Triaxle Compressive Strength

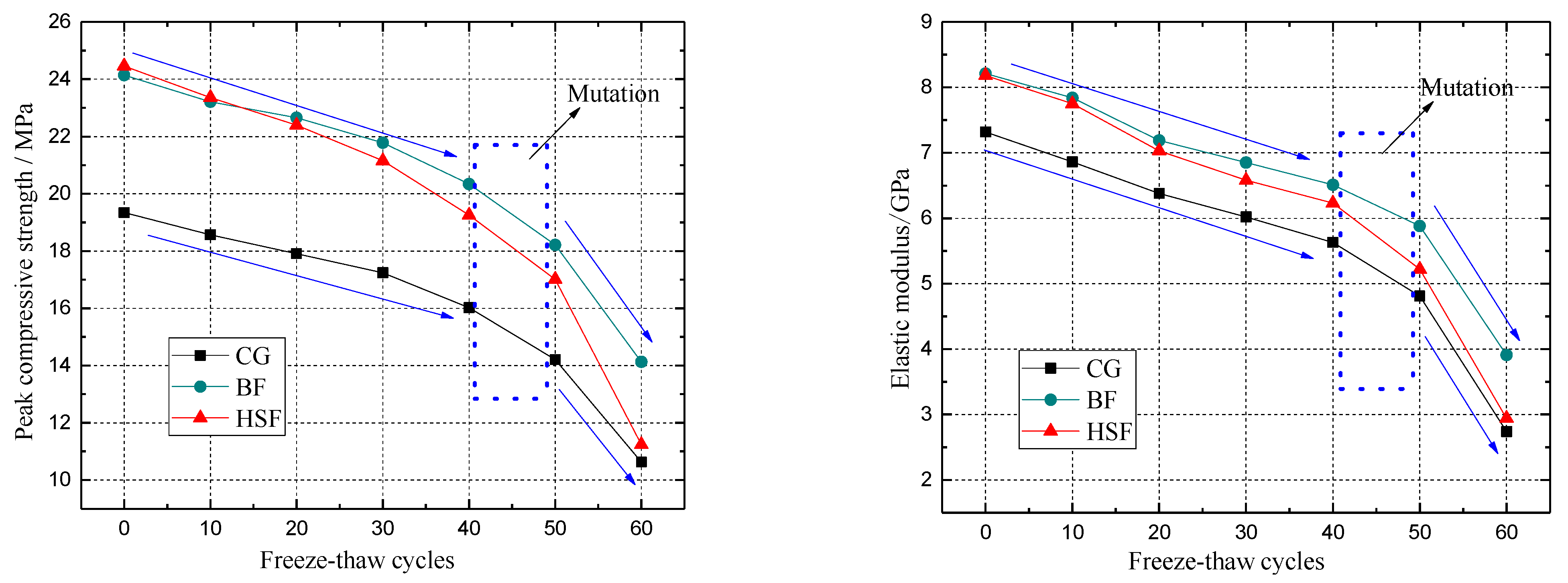

3.3. Effect of Freeze–Thaw Cycles on Strength and Elastic Modulus

4. Conclusions

- According to the circular element model, there is a square relation between effective elastic modulus and porosity of pervious concrete. The effective stress is related to the number and area of cementation points on a section of pervious concrete, and the damage of pervious concrete can be considered as the result of the failure of all cementation points on the section. The improved performance of cement paste between aggregates is suggested to popularize the application of pervious concrete.

- The elastic moduli of pervious concrete of CG, BF and HSF under uniaxial compression were 7.32 GPa, 8.21 GPa and 8.18 GPa, respectively, and an inclined section shear failure of specimens occurred. When the confining pressure was 3 MPa, the elastic moduli of CG, BF and HSF were 8.45 GPa, 9.34 GPa and 9.25 GPa, respectively. When the confining pressure was 5 MPa, the elastic moduli of CG, BF and HSF were 10.12 GPa, 11.03 GPa and 10.96 GPa, respectively.

- With the increase in freeze–thaw cycles, the porosity of pervious concrete increased linearly, and the effective porosity and total porosity were gradually equal, the strength and elastic modulus decreased, and a mutational point appeared between 40 and 50 freeze–thaw cycles. The fiber enhanced the strength of the cementation layer and increased the connection between aggregates, thus improving the strength and integrity of pervious concrete. This can provide a reference for the maintenance and service period of pervious concrete in the northern cities of China.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- AlShareedah, O.; Nassiri, S. Pervious concrete mixture optimization, physical, and mechanical properties and pavement design: A review. J. Clean. Prod. 2020, 288, 125095. [Google Scholar] [CrossRef]

- Singh, R.; Goel, S. Pervious concrete—A review on its properties and applications. In Sustainable Engineering; Springer: Singapore, 2019; pp. 157–165. [Google Scholar]

- Chao, X.; Wang, S.S.; Bin, L. Environmental impact analysis of permeable cement concrete pavement in Beijing city based on life cycle. Environ. Eng. 2022, 40, 118–125. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, K.-J.; Liang, D. Mechanical properties of pervious cement concrete. J. Central South Univ. 2012, 19, 3329–3334. [Google Scholar] [CrossRef]

- Liu, R.T.; Liu, H.J.; Sha, F.; Yang, H.L.; Zhang, Q.S.; Shi, S.S.; Zheng, Z. Investigation of the Porosity Distribution, Permeability, and Mechanical Performance of Pervious Concretes. Processes 2018, 6, 78. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Chen, X.; Dong, Q.; Yuan, J.; Hong, Q. Mechanical performance study of pervious concrete using steel slag aggregate through laboratory tests and numerical simulation. J. Clean. Prod. 2020, 262, 121208. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, D. Effects of aggregate species and quality on the properties of pervious concrete: A review. Mater. Rep. 2017, 31, 98–105. [Google Scholar] [CrossRef]

- Hui, L.; Jie, Y.; Fu, K.M. Investigation on the strength and freeze-thaw resistance of pervious concrete based on the properties of cement paste. Mater. Rep. 2022, 36, 13–20. [Google Scholar]

- Chen, S.K.; Peng, L.; Li, B.L. Influence and evaluation analysis of different fibers on the performance of recycled aggregate pervious concrete. J. Basic Sci. Eng. 2022, 30, 208–218. [Google Scholar]

- Liu, R.; Chi, Y.; Jiang, Q.; Meng, X.; Wu, K.; Li, S. Study on physical and mechanical properties of pervious concrete with multi-admixtures. Mag. Concr. Res. 2019, 73, 1–52. [Google Scholar]

- Chindaprasirt, P.; Hatanaka, S.; Mishima, N.; Yuasa, Y.; Chareerat, T. Effects of binder strength and aggregate size on the compressive strength and void ratio of porous concrete. Int. J. Miner. Metall. Mater. 2009, 16, 714–719. [Google Scholar] [CrossRef]

- Tarangini, D.; Kiranmaye, B.R.; Sravana, P.; Naveen. Effect of size of coarse aggregate on properties of pervious concrete. Int. J. Civ. Eng. Technol. 2019, 10, 914–921. [Google Scholar]

- Abdulwahid, M.Y. Influences of different stone powders on pervious concrete strength. Struct. Concr. 2020, 22, E528–E534. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Compression response of normal and high strength pervious concrete. Constr. Build. Mater. 2016, 109, 177–187. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Hu, M.; Wang, J. Study on the pores characteristics and permeability simulation of pervious concrete based on 2D/3D CT images. Constr. Build. Mater. 2019, 200, 687–702. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Linking pore system characteristics to the compressive behavior of pervious concrete. Cem. Concr. Compos. 2016, 70, 130–138. [Google Scholar] [CrossRef]

- Rehder, B.; Banh, K.; Neithalath, N. Fracture behavior of pervious concretes: The effects of pore structure and fibers. Eng. Fract. Mech. 2014, 118, 1–16. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Pore Structure Characterization of Pervious Concrete Using X-Ray Microcomputed Tomography. J. Mater. Civ. Eng. 2018, 30, 04018108. [Google Scholar] [CrossRef]

- Banevičienė, V.; Malaiškienė, J.; Boris, R.; Zach, J. The Effect of Active Additives and Coarse Aggregate Granulometric Composition on the Properties and Durability of Pervious Concrete. Materials 2022, 15, 1035. [Google Scholar] [CrossRef]

- Bo, Y.; Gao, R.D.; Xu, Q.F. Experimental analysis on durability of pervious concrete under complex attack environments. J. Civ. Environ. Eng. 2018, 40, 53–60. [Google Scholar]

- Zhang, J.; Li, L.; Ming, R.R. Freeze-thaw cycle performance of pervious concrete with different admixtures. Bull. Chin. Ceram. Soc. 2017, 36, 1480–1485. [Google Scholar] [CrossRef]

- Xiang, J.Z.; Gui, F.L.; Leng, M.H. Research progress in frost resistance of pervious concrete. Concrete 2021, 5, 51–55. [Google Scholar]

- Liu, R.; Chi, Y.; Chen, S.; Jiang, Q.; Meng, X.; Wu, K.; Li, S. Influence of Pore Structure Characteristics on the Mechanical and Durability Behavior of Pervious Concrete Material Based on Image Analysis. Int. J. Concr. Struct. Mater. 2020, 14, 29. [Google Scholar] [CrossRef]

- Song, H.; Yao, J.; Xiang, J. The role of aggregate and cement paste in the deterioration of the transitional interface zone of pervious concrete during freeze-thaw cycles. Case Stud. Constr. Mater. 2022, 16, e01086. [Google Scholar] [CrossRef]

- Liu, H.; Luo, G.; Wang, L.; Gong, Y. Strength time–varying and freeze–thaw durability of sustainable pervious concrete pavement material containing waste fly ash. Sustainability 2019, 11, 176. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.; Zhao, T.; Yang, J. Fracture Behavior of Concrete Exposed to the Freeze-Thaw Environment. J. Mater. Civ. Eng. 2017, 29, 04017071. [Google Scholar] [CrossRef]

- Vancura, M.; MacDonald, K.; Khazanovich, L. Microscopic analysis of paste and aggregate distresses in pervious concrete in a wet, hard freeze climate. Cem. Concr. Compos. 2011, 33, 1080–1085. [Google Scholar] [CrossRef]

- Alam, A.; Haselbach, L. Estimating the Modulus of Elasticity of Pervious Concrete Based on Porosity. Adv. Civ. Eng. Mater. 2014, 3, 256–269. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Wang, J.; Hu, M. Influence of aggregate size on compressive strength of pervious concrete. Constr. Build. Mater. 2019, 209, 463–475. [Google Scholar] [CrossRef]

- Joshaghani, A.; Ramezanianpour, A.A.; Ataei, O.; Golroo, A. Optimizing pervious concrete pavement mixture design by using the Taguchi method. Constr. Build. Mater. 2015, 101, 317–325. [Google Scholar] [CrossRef]

- Zhu, H.; Wen, C.; Wang, Z.; Li, L. Study on the Permeability of Recycled Aggregate Pervious Concrete with Fibers. Materials 2020, 13, 321. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, X.; Liu, J.; Ma, G. Macroscopic effective mechanical properties of porous dry concrete. Cem. Concr. Res. 2013, 44, 87–96. [Google Scholar] [CrossRef]

- Li, C.L.; Zhu, S.Y. Discussion of dual effective stresses in porous media—Analysis on the paper of Re-recognition of dual effective stresses and the comprehensive effect. Pet. Sci. Bull. 2019, 4, 414–429. [Google Scholar]

- Brake, N.A.; Allahdadi, H.; Adam, F. Flexural strength and fracture size effects of pervious concrete. Constr. Build. Mater. 2016, 113, 536–543. [Google Scholar] [CrossRef]

- Wang, H.; Hao, G.; Li, F.; Jiang, M. Analytical solutions to micro-bond model for particles considering width and thickness of bond. Chin. J. Geotech. Eng. 2017, 39, 822–831. [Google Scholar]

| Density (g/cm3) | Specific Surface Area (m2/kg) | Setting Time (min) | 3-Day Strength (MPa) | Ignition Loss (%) | SO2 (%) | MgO (%) | ||

|---|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | Flexural | Compressive | |||||

| 3.10 | 352 | 169 | 234 | 5.53 | 26.9 | 4 | 2.1 | 3 |

|

Confining Pressures (MPa) | Fiber Types | (MPa) |

Peak Strength (MPa) | Elastic Modulus E (GPa) |

|---|---|---|---|---|

| 3 | CG | 22.21 | 25.21 | 8.45 |

| BF | 28.03 | 31.03 | 9.34 | |

| HSF | 28.22 | 31.22 | 9.25 | |

| 5 | CG | 24.37 | 29.37 | 10.12 |

| BF | 30.52 | 35.52 | 11.03 | |

| HSF | 30.68 | 35.68 | 10.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Dai, J.; Shi, B.; Wu, B. The Strength and Elastic Modulus of Pervious Concrete Considering Pore and Fiber during Freeze–Thaw Cycles. Sustainability 2022, 14, 16217. https://doi.org/10.3390/su142316217

Wu Y, Dai J, Shi B, Wu B. The Strength and Elastic Modulus of Pervious Concrete Considering Pore and Fiber during Freeze–Thaw Cycles. Sustainability. 2022; 14(23):16217. https://doi.org/10.3390/su142316217

Chicago/Turabian StyleWu, Yi, Jun Dai, Bailei Shi, and Bingquan Wu. 2022. "The Strength and Elastic Modulus of Pervious Concrete Considering Pore and Fiber during Freeze–Thaw Cycles" Sustainability 14, no. 23: 16217. https://doi.org/10.3390/su142316217