Sustainability Investigation in the Building Cement Production System Based on the LCA-Emergy Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Framework

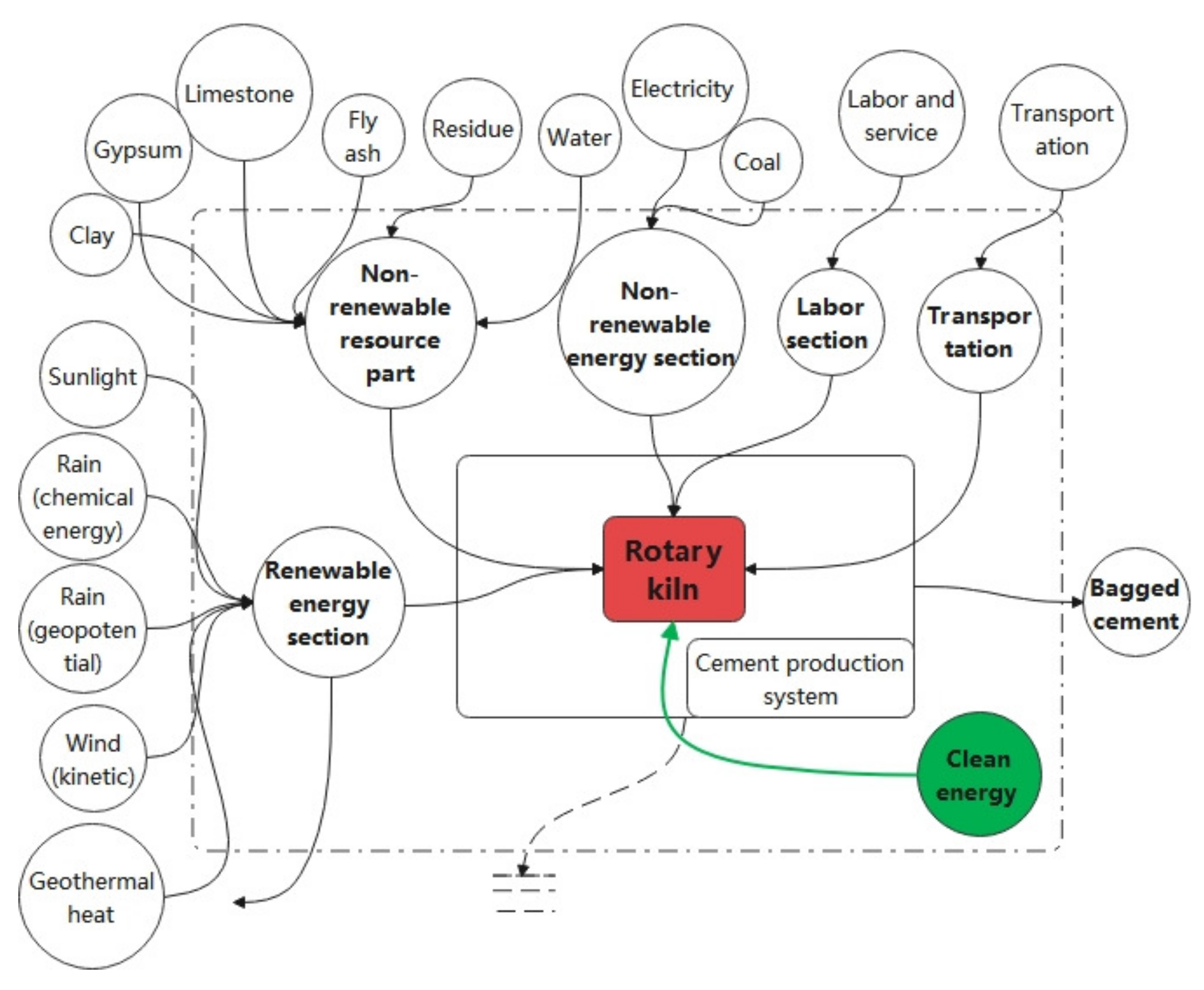

2.2. Cement Production System

- (1)

- Economic loss accounting

- (2)

- Ecological services calculation

- (3)

- Wastewater emergy calculation

- (4)

- Sludge waste emergy calculation

2.3. Emergy Analysis Method

2.3.1. Emergy Introduction

2.3.2. Emergy Diagram

2.3.3. Ecological Indexes

- (1)

- The renewable rate is the ratio between the renewable parts and total emergy values. In general, a higher renewability rate indicates a better ecological input.

- (2)

- The non-renewable rate is the ratio between the renewable inputs and total inputs; this rate is the negative indicator for the system.

- (3)

- The emergy yield ratio can be obtained based on the total emergy and imported emergy input, showing the ability to generate emergy. It uncovers the system structure and emergy distribution.

- (4)

- The environmental loading ratio reveals the ecological stress for the system. When the system has a higher number, it means that the system has a higher pressure.

- (5)

- The emergy sustainability indicator states the final ecological situation for a system from an emergy perspective. A value below 1 indicates that the entire system is unsustainable in the long run.

2.3.4. Sensitivity Analysis

3. Results and Discussion

3.1. Main Emergy Contributor

3.2. Emergy Indicator Analysis

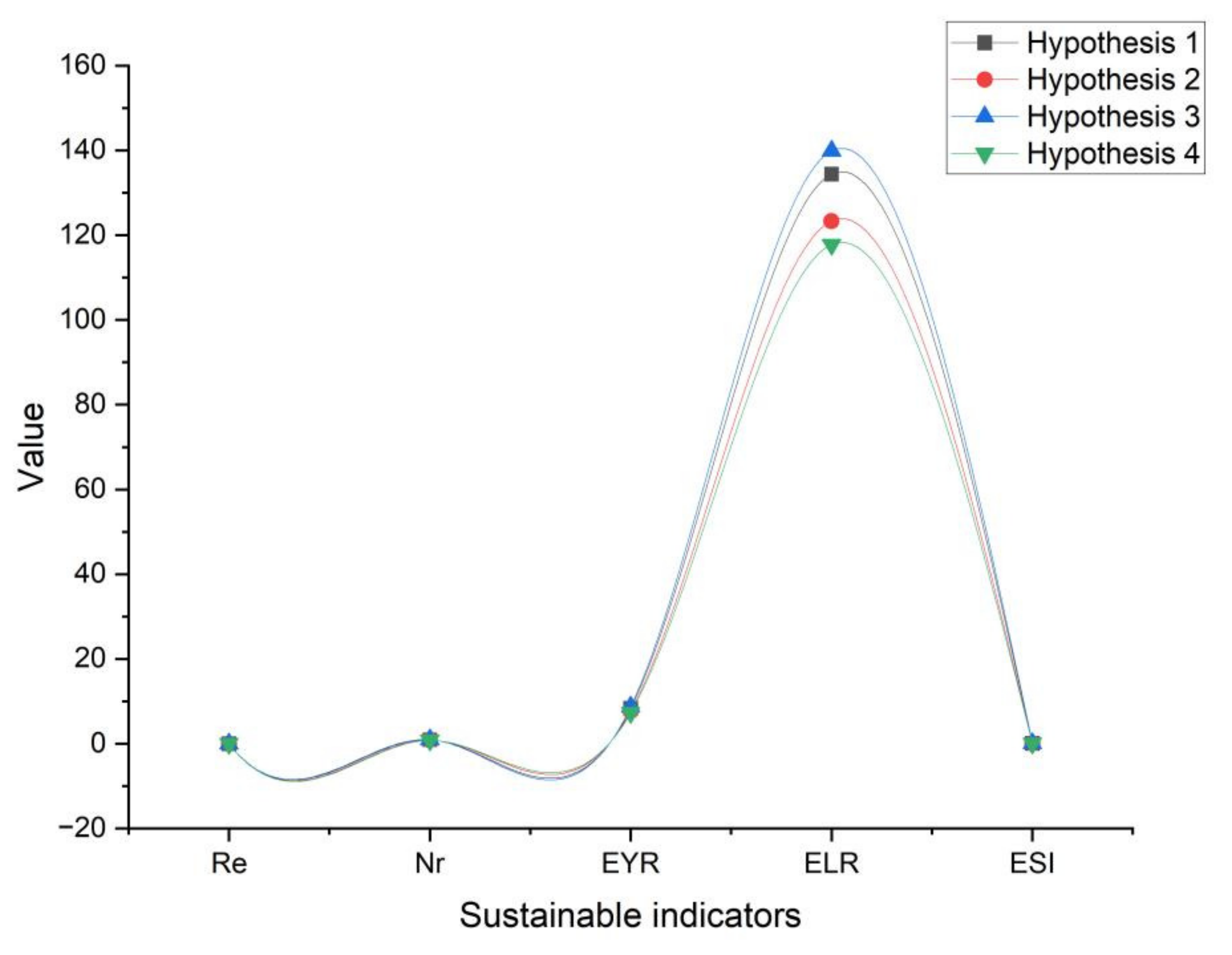

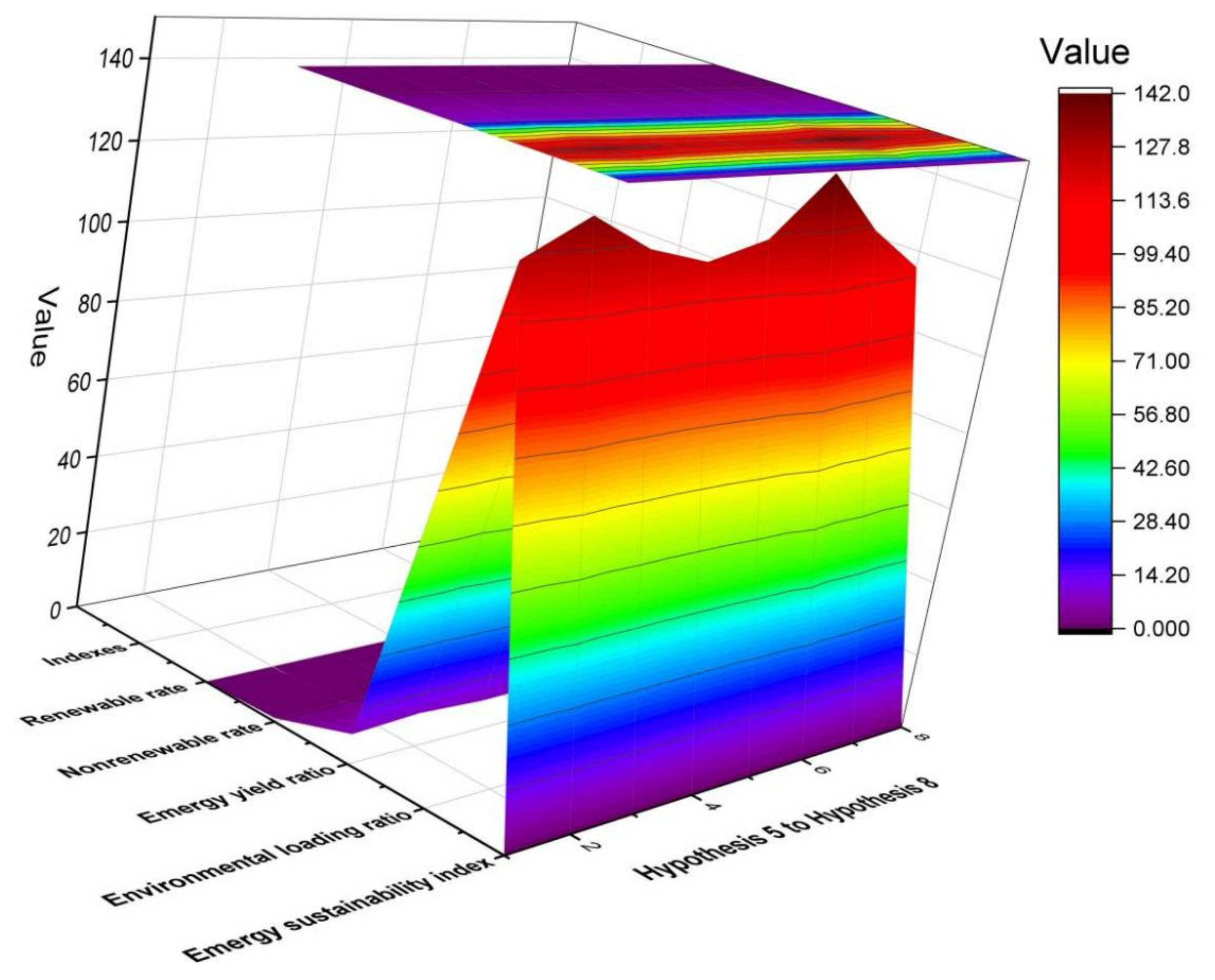

3.3. Sensitivity Result Analysis

3.4. Clean Energy Alternative Analysis

3.4.1. The Specific Process Flow Introduction

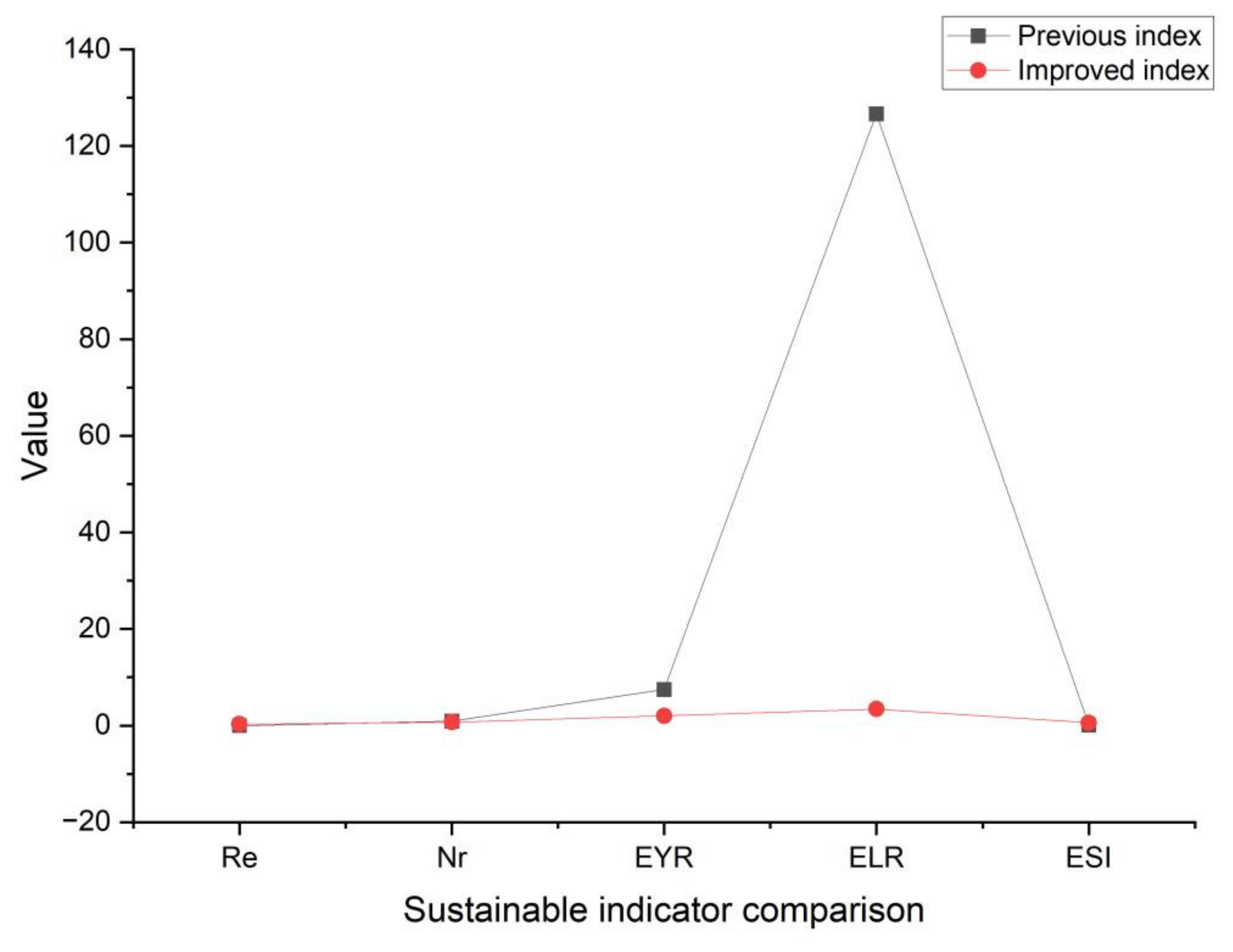

3.4.2. Sustainable Analysis by Integrating the New Energy System

4. Sustainability Improvement Strategies Discussion

4.1. Sustainable Energy Reuse Strategies

4.1.1. Select the Basis of Three Types of Clean Energy

4.1.2. The Effectiveness Validation

4.1.3. Advantages and Barriers to Solar Energy Adoption

4.2. Alternative Resources Reuse Strategies

5. Comparative Analysis and Economic Strategy Research

5.1. Comparative Analysis of Similar Studies

5.2. Economic Impact on Cement Industry

6. Conclusions

- (1)

- Based on the EYR and ELR, the emergy sustainability indicator (ESI) was calculated (far less than one), which indicated that the cement instruction system is unsustainable.

- (2)

- Through the analysis of eight hypotheses, it can be clearly found that the indicators have a very small change in the absolute values, which demonstrates that sensitivity changes were within acceptable limits for the cement production system.

- (3)

- The new type of biological power generation subsystem has effectively improved the ecological sustainability of the whole cement production system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

- (1)

- (2)

- Rain (chemical potential energy) calculation: area of cement production plant = 120,000 m2; rainfall = 0.68 m/yr; water density = 1000 kg/m3; evapotranspiration rate = 60%; Gibbs free energy of water = 4.94 × 103 J/kg; energy = (area) × (rainfall) × (evapotranspiration rate) × (water density) × (Gibbs free energy of water) = 2.42 × 1011 J/yr. UEV = 2.35 × 104 sej/J [62]; emergy of one yr =5.69 × 1015 sej.

- (3)

- Rain (geopotential energy) calculation: area of cement production plant =120,000 m2; rainfall = 0.68 m/yr; average elevation = 316 m [63]; water density = 1.00 × 103 kg/m3; runoff rate = 40.00%; energy = (area) × (rainfall) × (runoff rate) × (water density) × (average elevation) × (gravity) = 1.01 × 1011 J/y; UEV = 2.79 × 104 sej/J [39]; emergy of one year = 1.01 × 1011 J/y × 1 y × 2.79 × 104 sej/J = 2.82 × 1015 sej.

- (4)

- Wind energy calculation: area of cement production plant = 120,000 m2; air density = 1.29 kg/m3; velocity of geostrophic wind = 3.25 m/s; drag coefficient = 0.001 [64]; energy = (area) × (air density) × (drag coefficient) × (velocity of geostrophic wind)3 = 5.31 × 103 J/y; UEV = 1.90 × 103 sej/J; emergy of one year = 1.01 × 107 sej.

- (5)

- Geothermal heat calculation: area of cement production plant = 120,000 m2; heat flow (average) = 0.035 J/m2/s; energy = (area) × (heat flow) = 4.2 × 103 J/y; UEV = 3.44 × 104 sej/J; emergy of one year = 1.44 × 108 sej.

References

- Cement Industry Environmental Assessment Report in China. 2021. Available online: https://huanbao.bjx.com.cn/news/20221008/1258794.shtml (accessed on 2 December 2022).

- Tempa, K.; Chettri, N.; Thapa, G.; Phurba; Gyeltshen, C.; Norbu, D.; Gurung, D.; Wangchuk, U. An experimental study and sustainability assessment of plastic waste as a binding material for producing economical cement-less paver blocks. Eng. Sci. Technol. 2022, 26, 101008. [Google Scholar] [CrossRef]

- Xuan, M.-Y.; Bae, S.C.; Kwon, S.-J.; Wang, X.-Y. Sustainability enhancement of calcined clay and limestone powder hybrid ultra-high-performance concrete using belite-rich Portland cement. Constr. Build. Mater. 2022, 351, 128932. [Google Scholar] [CrossRef]

- Yehong, H.; Wen, X.; Feng, Z.; Jialei, Y.; Tian, X.; Ruijun, L.; Xin, W.; Xuefeng, X. Study on Mechanical and Microscopic Properties of Fly Ash Cement-Based Materials in High Geothermal Environment. Adv. Civ. Eng. 2022, 2022, 1768562. [Google Scholar]

- Chen, Y.K.; Sun, Y.; Wang, K.Q.; Kuang, W.Y.; Yan, S.R.; Wang, Z.H.; Lee, H.S. Utilization of bio-waste eggshell powder as a potential filler material for cement: Analyses of zeta potential, hydration and sustainability. Constr. Build. Mater. 2022, 325, 126220. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, Y. Design of Environmentally Friendly Ca-Alginate Beads for Self-Healing Cement-Based Materials. Materials 2022, 15, 5844. [Google Scholar] [CrossRef]

- Zheng, J.; Zeng, G.; Zhou, H.; Cai, G. Experimental Study on Carbonation of Cement-Based Materials in Underground Engineering. Materials 2022, 15, 523. [Google Scholar] [CrossRef]

- Petroche, D.M.; Ramirez, A.D. The Environmental Profifile of Clinker, Cement, and Concrete: A Life Cycle Perspective Study Based on Ecuadorian Data. Buildings 2022, 12, 311. [Google Scholar] [CrossRef]

- Huo, J.; Wang, Z.; Zhang, T.; Ji, X.; Zhang, H.; He, R. The evolution of early-age cracking of cement paste cured in low air pressure environment. J. Build. Eng. 2022, 52, 104489. [Google Scholar] [CrossRef]

- Feng, C. Granger Causality Analysis of Foreign Trade in Cement Products and Ecological Impact in China. Math. Probl. Eng. 2022, 2022, 3467483. [Google Scholar] [CrossRef]

- Zapata, J.F.; Azevedo, A.; Fontes, C.; Monteiro, S.N.; Colorado, H.A. Environmental Impact and Sustainability of Calcium Aluminate Cements. Sustainability 2022, 14, 2751. [Google Scholar] [CrossRef]

- Liu, C.; Liu, G.; Yang, Q.; Luo, T.; He, P.; Franzese, P.P.; Lombardi, G.V. Emergy-based evaluation of world coastal ecosystem services. Water Res. 2021, 204, 117656. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, L. Urban ecological security dynamic analysis based on an innovative emergy ecological footprint method. Environ. Dev. Sustain. 2021, 23, 16163–16191. [Google Scholar] [CrossRef]

- Huang, S.-L.; Hsu, W.-L. Materials flow analysis and emergy evaluation of Taipei’s urban construction. Landsc. Urban Plan. 2003, 63, 61–74. [Google Scholar] [CrossRef]

- Song, T.; Cai, J.; Xu, H.; Deng, Y.; Niu, F.; Yang, Z.; Du, S. Urban Metabolism Based on Emergy and Slack Based Model: A Case Study of Beijing, China. Chin. Geogra. Sci. 2015, 25, 113–123. [Google Scholar] [CrossRef]

- Huang, S.-L.; Chiu, H.-W. Peri-urbanization, land teleconnections, and the equality of ecological exchange: An emergy approach. Landsc. Urban Plan. 2020, 198, 103781. [Google Scholar] [CrossRef]

- Fan, Y.; Meng, J.; Ye, H.; Wang, P.; Wang, Y.; Wang, Y. Sustainability and ecological efficiency of low-carbon power system: A concentrating solar power plant in China. J. Environ. Manag. 2021, 290, 112659. [Google Scholar] [CrossRef]

- Pan, H.; Geng, Y.; Tian, X.; Wilson, J.; Chen, W.; Zhong, S.; Song, S. Emergy-based environmental accounting of one mining system. Environ. Sci. Pollut. Res. 2019, 26, 14598–14615. [Google Scholar] [CrossRef]

- Pang, M.; Zhang, L.; Wang, C.; Liu, G. Environmental life cycle assessment of a small hydropower plant in China. Int. J. Life Cycle Assess. 2015, 20, 796–806. [Google Scholar] [CrossRef]

- Reza, B.; Sadiq, R.; Hewage, K. A fuzzy-based approach for characterization of uncertainties in emergy synthesis: An example of paved road system. J. Clean. Prod. 2013, 59, 99–110. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, M.; Xiang, Y.; Kong, F.; Li, L. A sustainability comparison between green concretes and traditional concrete using an emergy ternary diagram. J. Clean. Prod. 2020, 256, 120421. [Google Scholar] [CrossRef]

- Zhong, S.; Geng, Y.; Kong, H.; Liu, B.; Tian, X.; Chen, W.; Qian, Y.; Ulgiati, S. Emergy-based sustainability evaluation of Erhai Lake Basin in China. J. Clean. Prod. 2018, 178, 142–153. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, L. Environmental Sustainability Assessment of a New Sewage Treatment Plant in China Based on Infrastructure Construction and Operation Phases Emergy Analysis. Water 2020, 12, 484. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, L.; Yan, Y. A Dynamic Comparison Sustainability Study of Standard Wastewater Treatment System in the Straw Pulp Papermaking Process and Printing & Dyeing Papermaking Process Based on the Hybrid Neural Network and Emergy Framework. Water 2020, 12, 1781. [Google Scholar]

- Brown, M.; Buranakarn, V. Emergy indices and ratios for sustainable material cycles and recycle options. Resour. Conserv. Recycl. 2003, 38, 1–22. [Google Scholar] [CrossRef]

- Akhtar, S.; Reza, B.; Hewage, K.; Shahriar, A.; Zargar, A.; Sadiq, R. Life cycle sustainability assessment (LCSA) for selection of sewer pipe materials. Clean Techn. Environ. Policy 2015, 17, 973–992. [Google Scholar] [CrossRef]

- Zhang, J.; Srinivasan, R.S.; Peng, C. Ecological Assessment of Clay Brick Manufacturing in China Using Emergy Analysis. Buildings 2020, 10, 190. [Google Scholar] [CrossRef]

- Wang, W.; He, Y.; Wu, Y.; Pan, D. Impact of waste slag reuse on the sustainability of the secondary lead industry evaluated from an emergy perspective. Resour. Conserv. Recycl. 2021, 167, 105386. [Google Scholar] [CrossRef]

- Chen, W.; Liu, W.; Geng, Y.; Ohnishi, S.; Sun, L.; Han, W.; Tian, X.; Zhong, S. Life cycle based emergy analysis on China’s cement production. J. Clean. Prod. 2016, 131, 272–279. [Google Scholar] [CrossRef]

- Mikul, H.; Cabezas, H.; Vujanovic, M.; Duic, N. Environmental assessment of different cement manufacturing processes based on Emergy and Ecological Footprint analysis. J. Clean. Prod. 2016, 130, 213–221. [Google Scholar] [CrossRef]

- Song, D.; Lin, L.; Wu, Y. Emergy analysis of a typical New Suspension Preheaters cement plant in China. J. Clean. Prod. 2019, 222, 407–413. [Google Scholar] [CrossRef]

- Zhang, J.; Srinivasan, R.S.; Peng, C. A Systematic Approach to Calculate Unit Emergy Values of Cement Manufacturing in China Using Consumption Quota of Dry and Wet Raw Materials. Buildings 2020, 10, 128. [Google Scholar] [CrossRef]

- Liu, G.; Yang, Z.; Chen, B.; Zhang, J.; Liu, X.; Zhang, Y.; Su, M.; Ulgiati, S. Scenarios for sewage sludge reduction and reuse in clinker production towards regional eco-industrial development: A comparative emergy-based assessment. J. Clean. Prod. 2015, 103, 371–383. [Google Scholar] [CrossRef]

- Wang, Q.; Ma, Z.; Yuan, X.; Wang, J.; Mu, Z.; Zuo, J.; Zhang, J.; Hong, J.; Wang, S. Is cement pavement more sustainable than permeable brick pavement? A case study for Jinan, China. J. Clean. Prod. 2019, 226, 306–315. [Google Scholar] [CrossRef]

- Zhang, X.; Xiang, N.; Pan, H.; Yang, X.; Wu, J.; Zhang, Y.; Luo, H.; Xu, C. Performance comparison of cement production before and after implementing heat recovery power generation based on emergy analysis and economic evaluation: A case from China. J. Clean. Prod. 2021, 290, 125901. [Google Scholar] [CrossRef]

- Songa, D.; Chen, B. Sustainability evaluation of a typical cement production chain in China—An emergy perspective. Energy Procedia 2016, 104, 98–103. [Google Scholar] [CrossRef]

- Odum, H.T. Environmental Accounting: Emergy and Environmental Decision Making; John Wiley and Sons: New York, NY, USA, 1996. [Google Scholar]

- Brown, M.T.; Ulgiati, S. Assessing the global environmental sources driving the geobiosphere: A revised emergy baseline. Ecol. Model 2016, 339, 126–132. [Google Scholar] [CrossRef]

- Brown, M.T.; Bardi, E. Handbook of Emergy Evaluation: A Compendium of Data for Emergy Computation in a Series of Folios, Folio; University of Florida: Gainesville, FL, USA, 2001. [Google Scholar]

- Brown, M.T.; Raugei, M.; Ulgiati, S. On boundaries and ‘investments’in emergy synthesis and LCA: A case study on thermal vs. photovoltaic electricity. Ecol. Indic. 2012, 15, 227–235. [Google Scholar] [CrossRef]

- Lou, B.; Ulgiati, S. Identifying the environmental support and constraints to the Chinese economic growthdan application of the emergy accounting method. Energy Policy 2013, 55, 217–233. [Google Scholar] [CrossRef]

- GB3095-2012; Ambient Air Quality Standards. Ministry of Environmental Protection of PRC: Beijing, China. Available online: https://www.doc88.com/p-3867369563075.html (accessed on 28 October 2022).

- Zhang, H.; Asutosh, A.T.; Zhang, J. A quantitative sustainable comparative study of two biogas systems based on energy, emergy and entropy methods in China. Environ. Dev. Sustain. 2022, 24, 13583–13609. [Google Scholar] [CrossRef]

- Report on In-Depth Research and Investment Prospects of China’s Photovoltaic Industry in 2022–2026. Available online: http://www.ocn.com.cn/reports/2326guangfuchanye.shtml (accessed on 2 December 2022).

- China Clean Energy Development Report in 2022. Available online: http://ep.baidajob.com/article-6625460.html (accessed on 2 December 2022).

- Solar Thermal Utilization Industry Health Report in China of 2021. Available online: https://wenku.baidu.com/view/49b87135c6da50e2524de518964bcf84b8d52d48.html (accessed on 2 December 2022).

- The Implementation Plan for Promoting the High-Quality Development of New Energy in the New Era, National Energy Administration of China. Available online: http://www.nea.gov.cn/2022-05/30/c_1310608545.htm (accessed on 2 December 2022).

- Zhu, R.; Wang, Y.; Xiang, Y.; Sun, C.; Chang, R.; Hu, G.; Gao, Z. Study on climate characteristics and development potential of wind energy resources in China. Acta Energ. Sol. Sin. 2021, 42, 409–418. [Google Scholar]

- Huang, Q.; Guo, Y.; Jiang, J.; Ming, B. Development pathway of China’s clean electricity under carbon peaking and carbon neutrality goals. J. Shanghai Jiaotong Univ. 2021, 55, 1499–1509. [Google Scholar]

- Jurasz, J.; Mikulik, J.; Dabek, P.; Guezgouz, M.; Ka’zmierczak, B. Complementarity and ‘Resource Droughts’ of Solar and Wind Energy in Poland: An ERA5-Based Analysis. Energies 2021, 14, 1118. [Google Scholar] [CrossRef]

- Lv, A.; Li, T.; Zhang, W.; Liu, Y. Spatiotemporal Distribution and Complementarity of Wind and Solar Energy in China. Energies 2022, 15, 7365. [Google Scholar] [CrossRef]

- Wang, Z.; Li, B.; Liang, X. Utilization of river sediment, sewage sludge and wheat straw as the primary raw material in sintered-shale bricks. J. Mater. Cycles Waste Manag. 2022, 24, 2401–2415. [Google Scholar] [CrossRef]

- Chu, D.C.; Kleib, J. Mouhamadou Amar, Mahfoud Benzerzour, Nor-Edine Abriak. Recycling of dredged sediment as a raw material for the manufacture of Portland cement—Numerical modeling of the hydration of synthesized cement using the CEMHYD3D code. J. Build. Eng. 2022, 48, 103871. [Google Scholar] [CrossRef]

- Kim, H.-J.; Khalid, H.R. The Effects of Calcium Aluminate Cement Substitution on Physicochemical Properties of Geopolymer–Zeolite Composites. Arab. J. Sci. Eng. 2022, 47, 5073–5078. [Google Scholar] [CrossRef]

- Vásquez-Torres, O.O.; Cabrera-Poloche, F.D.; Tobón, J.I. Performance of Low-Grade Calcined Clays as Supplementary Cementitious Material in Relation to their Geological Characteristics. Clays Clay Miner. 2022, 70, 233–251. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, J.; Wang, Y.; Qi, Y.; Liao, W.; Shui, W.; Li, L.; Qi, H.; Yu, X. An environmental sustainability assessment of China’s cement industry based on emergy. Ecol. Indic. 2017, 72, 452–458. [Google Scholar] [CrossRef]

- Cormos, C.-C. Decarbonization options for cement production process: A techno-economic and environmental evaluation. Fuel 2022, 320, 123907. [Google Scholar] [CrossRef]

- Mancini, V.; Verdone, N.; Trinca, A.; Vilardi, G. Economic, environmental and exergy analysis of the decarbonisation of cement production cycle. Energy Convers. Manag. 2022, 260, 115577. [Google Scholar] [CrossRef]

- Zheng, R.; Wang, Y.; Liu, Z.; Zhou, J.; Yue, Y.; Qian, G. Environmental and economic performances of municipal solid waste incineration fly ash low-temperature utilization: An integrated hybrid life cycle assessment. J. Clean. Prod. 2022, 340, 130680. [Google Scholar] [CrossRef]

- Wojtacha-Rychter, K.; Smoliński, A. Multi-Case Study on Environmental and Economic Benefits through Co-Burning Refuse-Derived Fuels and Sewage Sludge in Cement Industry. Materials 2022, 15, 4176. [Google Scholar] [CrossRef]

- Lu, Y.M.; Yue, T.X.; Chen, C.F.; Fan, Z.M.; Wang, Q.M. Solar radiation modeling based on stepwise regression analysis in China. J. Remote Sens. 2010, 14, 852–864. [Google Scholar]

- Wu, M.Q.; Zhang, A.D.; Kan, Z.Q.; Sun, X.B.; Lin, X. Land surface temperature retrieved using MODIS data in Shandong Province. In Proceedings of the 2013 21st International Conference on Geoinformatics, San Francisco, CA, USA, 20–22 June 2013. [Google Scholar]

- Lee, J.M.; William, B.W. Building emergy analysis of Manhattan: Density parameters forhigh-density and high-rise developments. Ecol. Model. 2017, 363, 157–171. [Google Scholar] [CrossRef]

- Miller, B.I. A study of the fifilling of hurricane Donna over land (2000). Mon. Weather Rev. 1964, 92, 389–406. [Google Scholar] [CrossRef]

| Item | Human Health Damage | DALY (a/kg) |

|---|---|---|

| Dust | Respiratory disease | 5.46 × 10−5 |

| SO2 | Respiratory disease | 8.87 × 10−5 |

| NOx | Respiratory disease | 3.75 × 10−5 |

| Section | Item | Data | Ref. For Data | UEVs (sej/Unit) | Emergy (sej/Yr) | UEVs Ref. | % |

|---|---|---|---|---|---|---|---|

| Renewable energy section | Sunlight | 4.2 × 1014 J | Calculated | 1 | 4.2 × 1014 | [39] | 0.00 |

| Rain (chemical energy) | 2.42 × 1011 J | Calculated | 2.35 × 104 | 5.69 × 1015 | [39] | 0.00 | |

| Rain(geopotential) | 1.01 × 1011 J | Calculated | 2.79 × 104 | 2.82 × 1015 | [39] | 0.00 | |

| Wind(kinetic) | 5.31 × 103 J | Calculated | 1.9 × 103 | 1.01 × 107 | [39] | 0.00 | |

| Geothermal heat | 4.2 × 103 J | Calculated | 3.44 × 104 | 1.44 × 108 | [39] | 0.00 | |

| Non-renewable resource part | Clay | 2.4 × 1010 kg | Collected | 2.0 × 1012 | 4.8 × 1022 | [25] | 4.21 |

| Gypsum | 6.73 × 1010 kg | Collected | 1.27 × 1012 | 8.55 × 1022 | [25] | 7.50 | |

| Limestone | 6.84 × 1011 kg | Collected | 1.27 × 1012 | 8.69 × 1023 | [25] | 76.2 | |

| Fly ash | 5.6 × 108 kg | Collected | 1.4 × 1013 | 7.84 × 1021 | [40] | 0.69 | |

| Residue | 9.4 × 107 kg | Collected | 1.42 × 1012 | 1.33 × 1020 | [32] | 0.01 | |

| Water | 2.5 × 1010 kg | Collected | 1.29 × 106 | 3.23 × 1016 | [40] | 0.00 | |

| Non-renewable energy section | Electricity | 2.81 × 1017 J | Collected | 4.5 × 105 | 1.26 × 1023 | [40] | 11.09 |

| Coal | 5.2 × 1015 J | Collected | 8.77 × 104 | 4.56 × 1020 | [32] | 0.04 | |

| Labor section | Labor and service | 6.8 × 108 | Collected | 7.42 × 1011 | 5.05 × 1020 | [41] | 0.04 |

| Transportation | Transportation | 72 t·km | Collected | 7.61 × 1011 | 5.48 × 1016 | [25] | 0.00 |

| Air pollutants section | Dust | 80 mg/m3 | Calculated | ~ | 1.34 × 1012 | [42] | 0.00 |

| SO2 | 20 mg/m3 | Calculated | ~ | 2.89 × 1011 | [42] | 0.00 | |

| NOX | 50 mg/m3 | Calculated | ~ | 7.13 × 1011 | [42] | 0.00 | |

| Total | 100 | ||||||

| No. | Indexes | Value |

|---|---|---|

| 1 | Renewable rate (Re) | 0.0% |

| 2 | Non-renewable rate (Nr) | 88.6% |

| 3 | Emergy yield ratio (EYR) | 7.45 |

| 4 | Environmental loading ratio (ELR) | 126.6 |

| 5 | Emergy sustainability indicator (ESI) | 0.058 |

| Indexes | 5% Change | −5% Change | 10% Change | −10% Change | ||||

|---|---|---|---|---|---|---|---|---|

| Former | Latter | Former | Latter | Former | Latter | Former | Latter | |

| Re | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% |

| Nr | 88.6% | 89.38% | 88.6% | 88.4% | 88.6% | 89.82% | 88.6% | 87.79% |

| EYR | 7.45 | 8.42 | 7.45 | 7.62 | 7.45 | 8.82 | 7.45 | 7.22 |

| ELR | 126.6 | 135.3 | 126.6 | 122.4 | 126.6 | 141.8 | 126.6 | 115.9 |

| ESI | 0.058 | 0.06223 | 0.058 | 0.06225 | 0.058 | 0.0622 | 0.058 | 0.06229 |

| Indexes | 5% Change | −5% Change | 10% Change | −10% Change | ||||

|---|---|---|---|---|---|---|---|---|

| Former | Latter | Former | Latter | Former | Latter | Former | Latter | |

| Re | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% | 0.0% |

| Nr | 88.6% | 92.7% | 88.6% | 85.1% | 88.6% | 96.5% | 88.6% | 81.2% |

| EYR | 7.45 | 8.36 | 7.45 | 7.67 | 7.45 | 8.71 | 7.45 | 7.33 |

| ELR | 126.6 | 134.4 | 126.6 | 123.3 | 126.6 | 139.9 | 126.6 | 117.8 |

| ESI | 0.058 | 0.062 | 0.058 | 0.0622 | 0.058 | 0.0623 | 0.058 | 0.062 |

| Input | Data | Ref. For Data | UEVs (sej/Unit) | UEVs Ref. | Emergy (sej) |

|---|---|---|---|---|---|

| Sunlight | 3.24 × 1011 J | Collected | 1 | [39] | 3.24 × 1011 |

| Rain (chemical energy) | 5.1 × 108 J | Collected | 2.35 × 104 | [39] | 1.2 × 1013 |

| Rain (geopotential) | 8.2 × 108 J | Collected | 2.79 × 104 | [39] | 2.29 × 1013 |

| Wind (kinetic) | 6.72 × 102 J | Collected | 1.9 × 103 | [39] | 1.28 × 106 |

| Geothermal heat | 8.1 × 102 J | Collected | 3.44 × 104 | [39] | 2.79 × 107 |

| Water | 3.3 × 1014 kg | Collected | 1.29 × 106 | [39] | 4.26 × 1020 |

| Manure | 2.49 × 1016 kg | Collected | 1.68 × 106 | [43] | 4.18 × 1023 |

| Total | 4.18 × 1023 | ||||

| Sustainable Indexes | Previous Index | Improved Index |

|---|---|---|

| Renewable rate (Re) | 0.0% | 29.3% |

| Non-renewable rate (Nr) | 88.6% | 70.7% |

| Emergy yield ratio (EYR) | 7.45 | 2.02 |

| Environmental loading ratio (ELR) | 126.6 | 3.42 |

| Emergy sustainability indicator (ESI) | 0.058 | 0.591 |

| Sustainable Indexes | Previous Index | Improved Index |

|---|---|---|

| Renewable rate (Re) | 0.0% | 11.1% |

| Non-renewable rate (Nr) | 88.6% | 88.9% |

| Emergy yield ratio (EYR) | 7.45 | 1.12 |

| Environmental loading ratio (ELR) | 126.6 | 9.01 |

| Emergy sustainability indicator (ESI) | 0.058 | 0.125 |

| Sustainable Indexes | Previous Index | Improved Index |

|---|---|---|

| Renewable rate (Re) | 0.0% | 4.22% |

| Non-renewable rate (Nr) | 88.6% | 95.8% |

| Emergy yield ratio (EYR) | 7.45 | 6.53 |

| Environmental loading ratio (ELR) | 126.6 | 23.69 |

| Emergy sustainability indicator (ESI) | 0.058 | 0.276 |

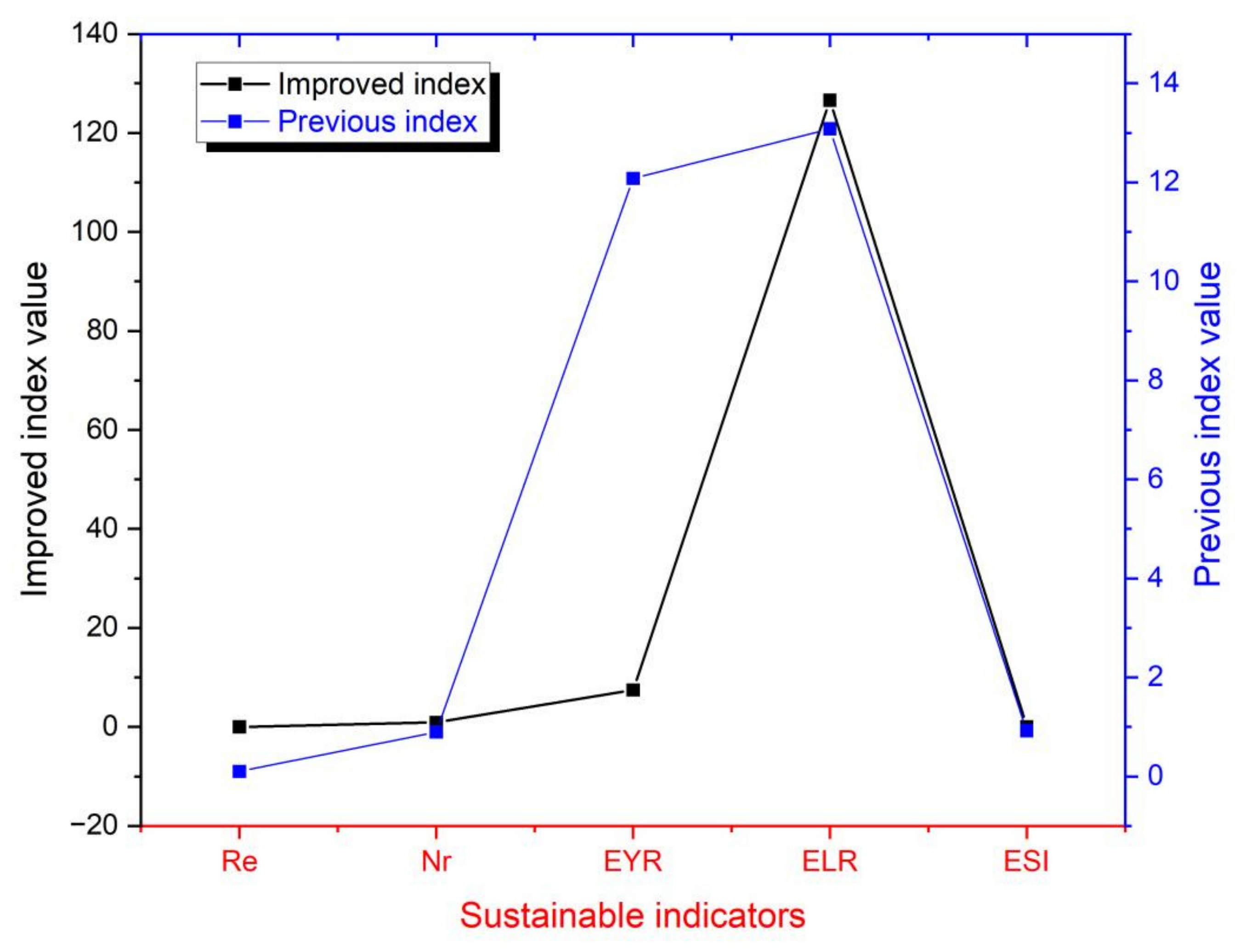

| Sustainable Indexes | Previous Index | Improved Index |

|---|---|---|

| Renewable rate (Re) | 0.0% | 10% |

| Non-renewable rate (Nr) | 88.6% | 90% |

| Emergy yield ratio (EYR) | 7.45 | 12.08 |

| Environmental loading ratio (ELR) | 126.6 | 13.08 |

| Emergy sustainability indicator (ESI) | 0.058 | 0.924 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Liu, Y.; Zhang, J.; Zhang, H.; Huang, L.; Xu, D.; Zhang, C. Sustainability Investigation in the Building Cement Production System Based on the LCA-Emergy Method. Sustainability 2022, 14, 16380. https://doi.org/10.3390/su142416380

Wang H, Liu Y, Zhang J, Zhang H, Huang L, Xu D, Zhang C. Sustainability Investigation in the Building Cement Production System Based on the LCA-Emergy Method. Sustainability. 2022; 14(24):16380. https://doi.org/10.3390/su142416380

Chicago/Turabian StyleWang, Hairuo, Yexin Liu, Junxue Zhang, He Zhang, Li Huang, Dan Xu, and Chunxia Zhang. 2022. "Sustainability Investigation in the Building Cement Production System Based on the LCA-Emergy Method" Sustainability 14, no. 24: 16380. https://doi.org/10.3390/su142416380

APA StyleWang, H., Liu, Y., Zhang, J., Zhang, H., Huang, L., Xu, D., & Zhang, C. (2022). Sustainability Investigation in the Building Cement Production System Based on the LCA-Emergy Method. Sustainability, 14(24), 16380. https://doi.org/10.3390/su142416380