What Prevents Sustainable Last-Mile Delivery in Industry 4.0? An Analysis and Decision Framework

Abstract

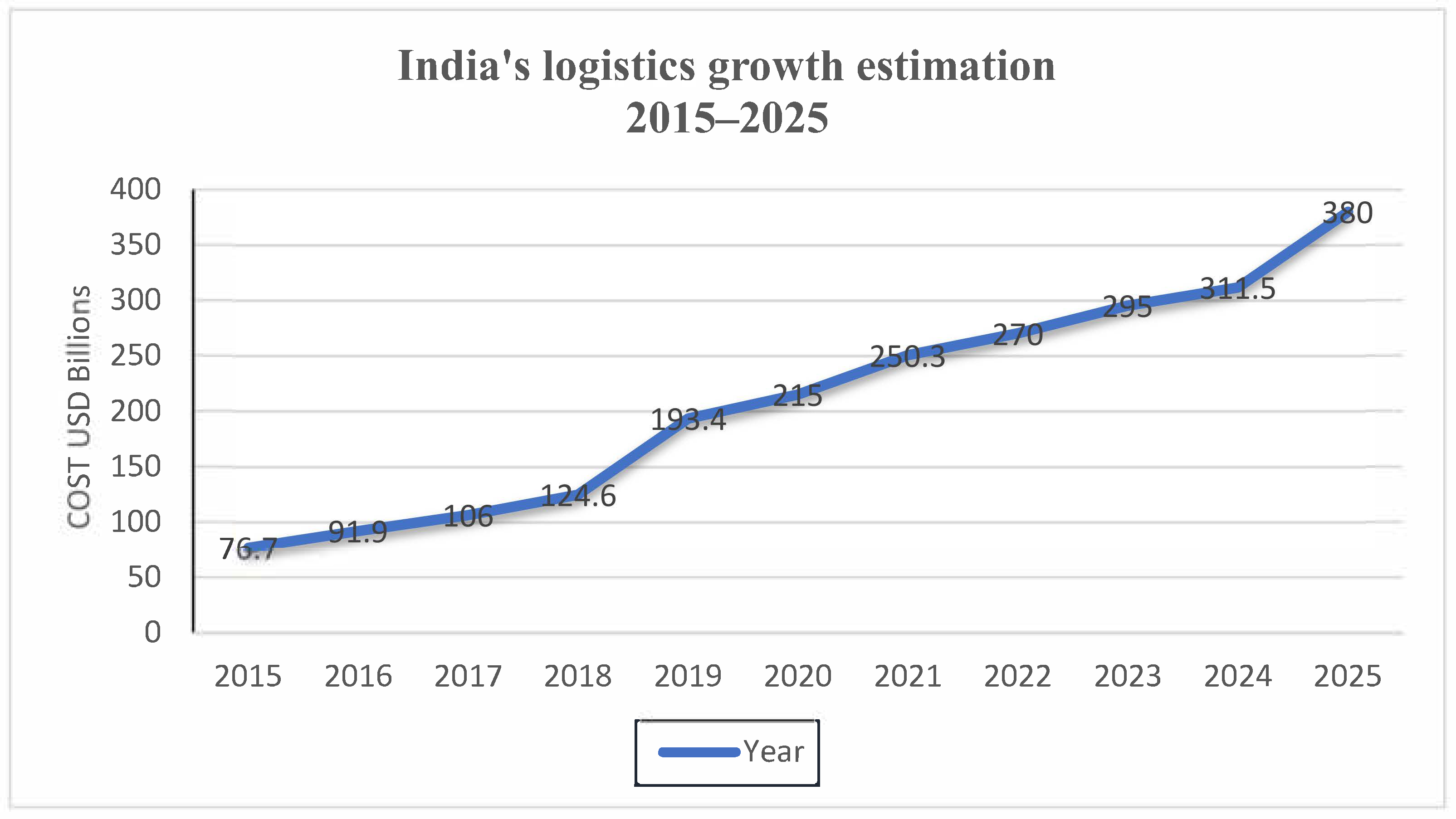

:1. Introduction

2. Literature Review

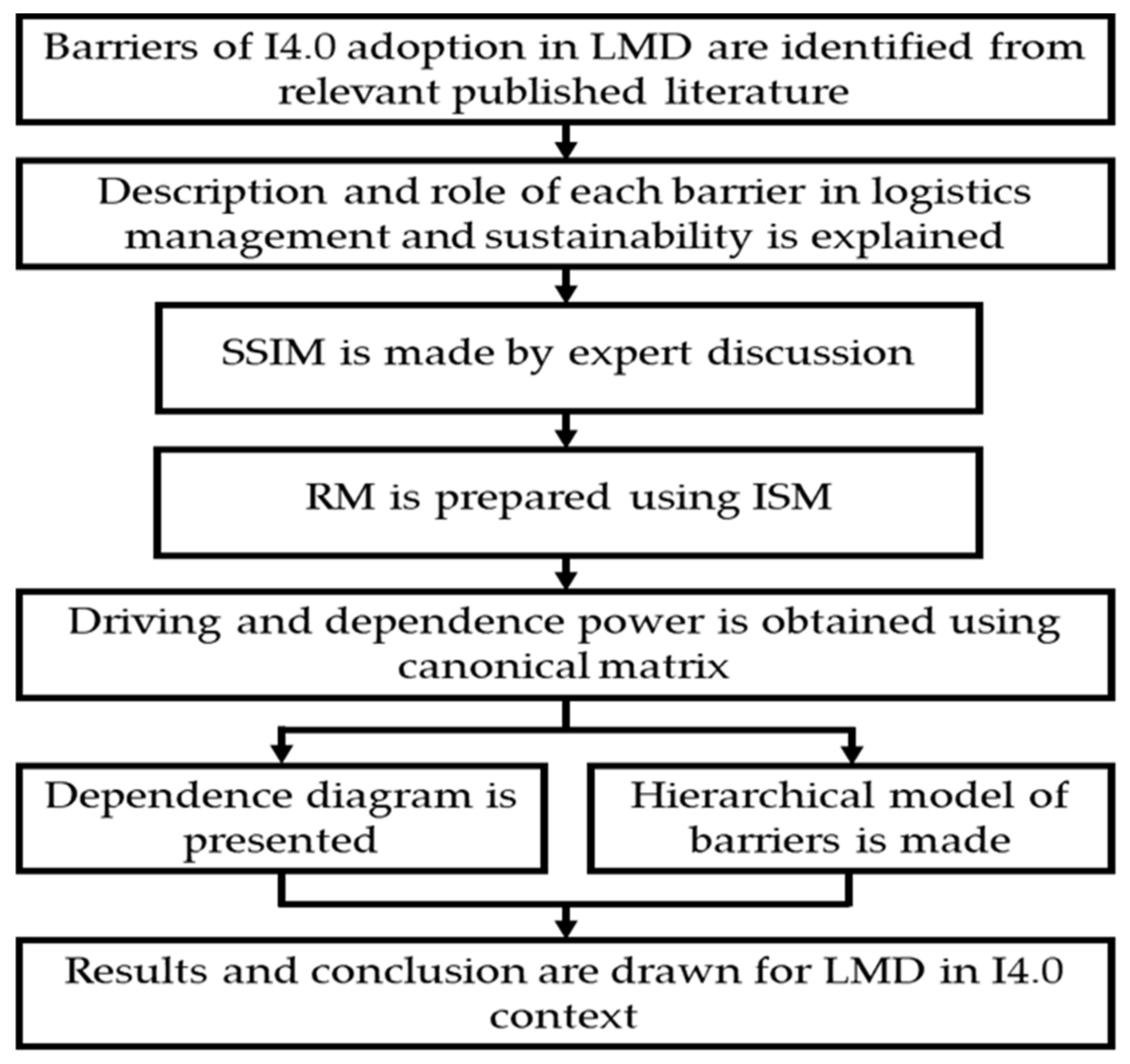

3. Methodology

3.1. Interpretive Structural Methodology (ISM)

3.2. Study of I4.0 Barriers in the Logistics Sector Using ISM

3.3. Structural Self-Interaction Matrix (SSIM)

- V: Factor j is dependent on factor i.

- A: Factor i is dependent on factor j.

- X: Factors i and j function together to accomplish goals.

- O: Factor i and j have no relation.

4. Result and Discussion

4.1. Formulation of RM

- If (i, j) in the SSIM is V, then, (i, j) in the RM becomes 1 and the (j, i) becomes 0.

- If (i, j) in the SSIM is A, then, (i, j) in the RM becomes 0 and the (j, i) becomes 1.

- If (i, j) in the SSIM is X, then, both (i, j) and (j, i) in the RM become 1.

- If (i, j) in the SSIM is O, then, both (i, j) and (j, i) in the RM become 0.

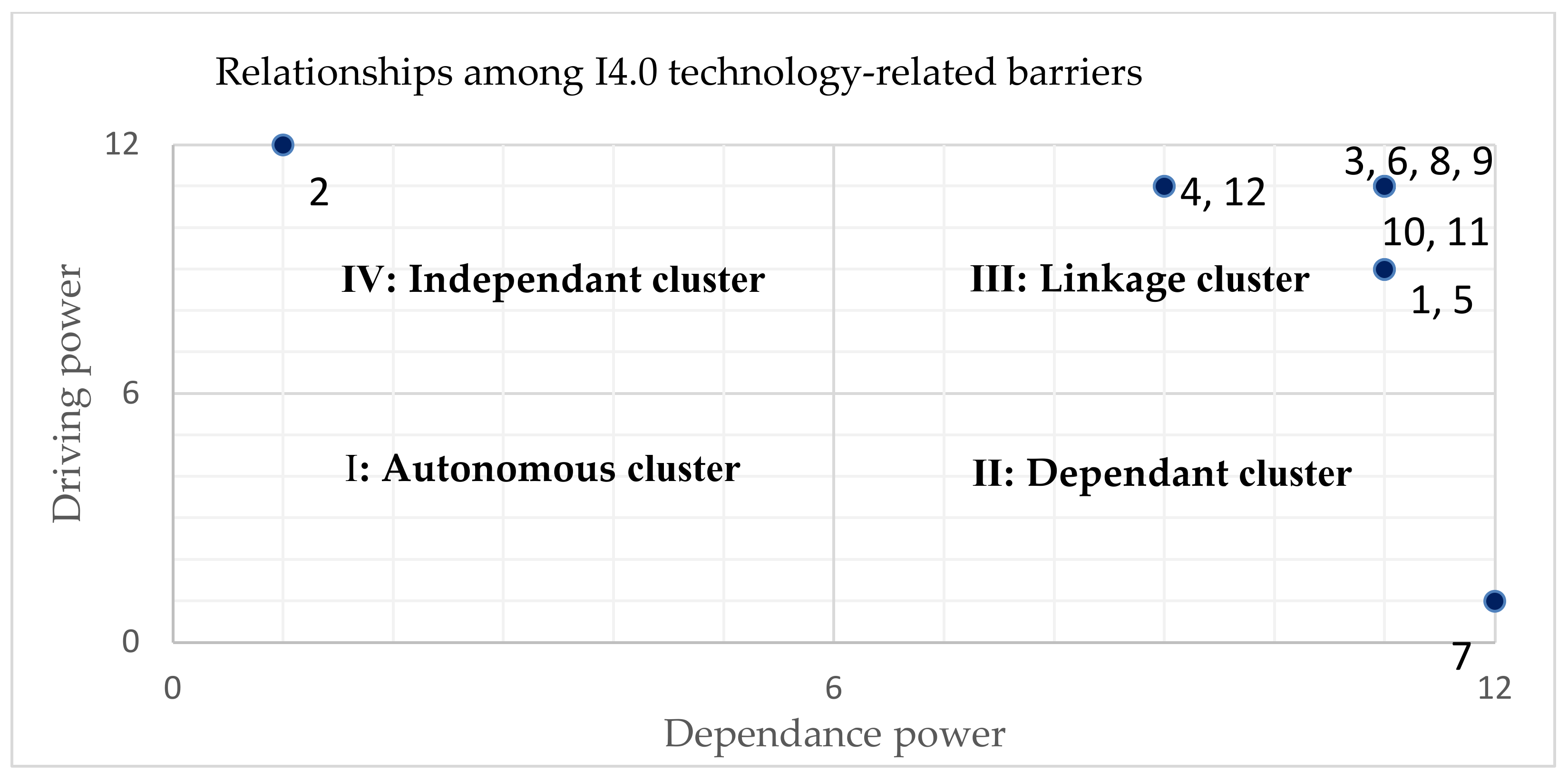

4.2. Canonical Matrix Formulation

4.3. Level Portioning Using RM

4.4. Review of Barriers Obtained

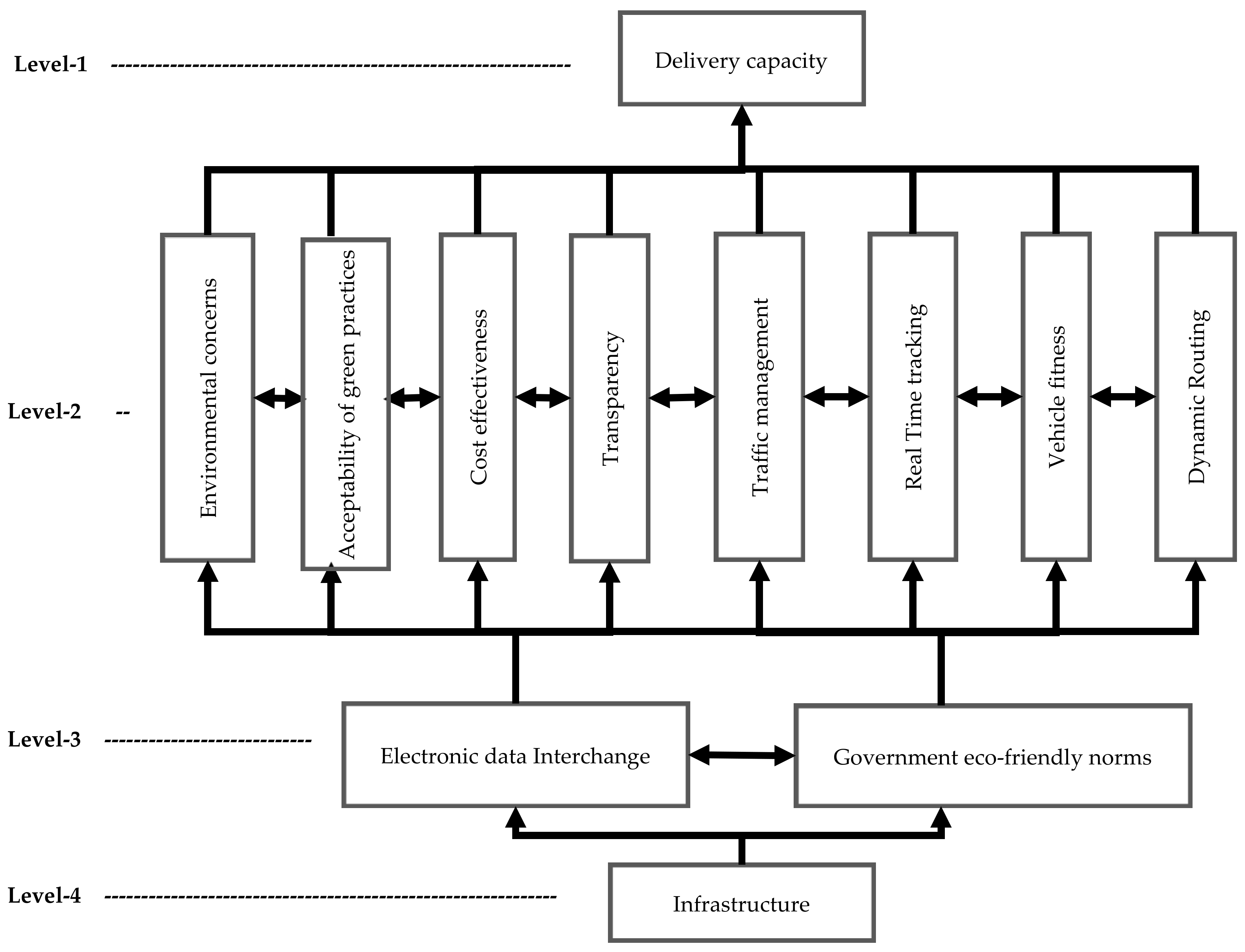

4.5. Levels of Barriers

4.6. MICMAC Analysis

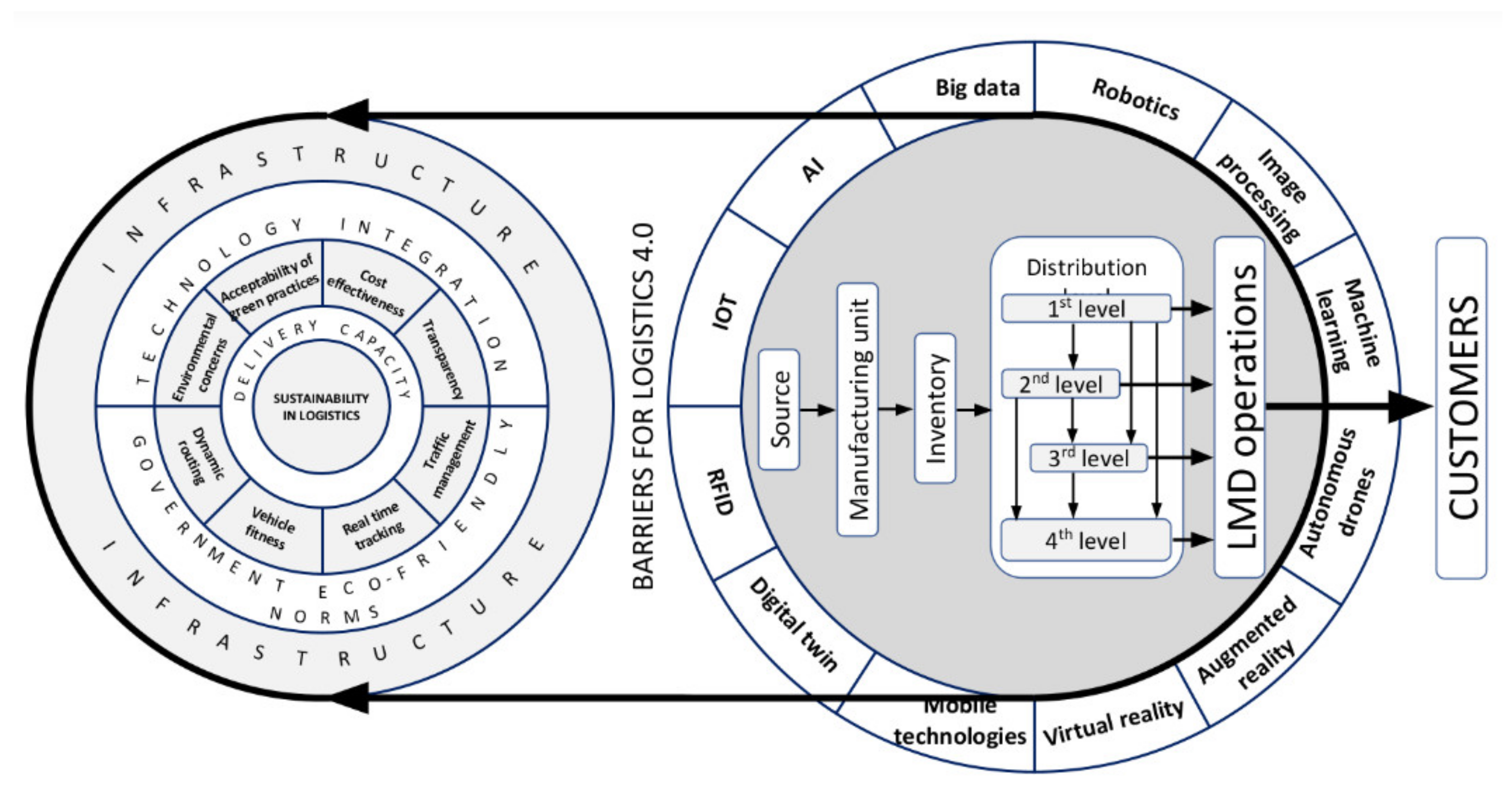

4.7. Proposed Framework

4.8. Discussion

5. Conclusions

6. Future Scope

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wood, L. Global Logistics Market (2022 to 2027)—Industry Trends, Share, Size, Growth, Opportunity and Forecasts; Business Wire: San Francisco, CA, USA, 2022; Available online: https://www.businesswire.com/news/home/20220404005541/en/Global-Logistics-Market-2022-to-2027---Industry-Trends-Share-Size-Growth-Opportunity-and-Forecasts---ResearchAndMarkets.com (accessed on 25 September 2022).

- Matthess, M.; Kunkel, S.; Xue, B.; Beier, G. Supplier Sustainability Assessment in the Age of Industry 4.0—Insights from the Electronics Industry. Clean. Logist. Supply Chain. 2022, 4, 100038. [Google Scholar] [CrossRef]

- Hua, X. China’s Logistics Sector Reports Steady Growth in 2021; Chinadaily: Beijing, China, 2022; Available online: https://www.chinadaily.com.cn/a/202202/14/WS620a0b84a310cdd39bc86849.html (accessed on 20 September 2022).

- Xu, M.; Li, J.; Ping, Z.; Zhang, Q.; Liu, T.; Zhang, C.; Aldieri, L.; Xu, M.; Li, J.; Ping, Z.; et al. Can Local Government’s Attention Allocated to Green Innovation Improve the Green Innovation Efficiency? Sustainability 2022, 14, 12059. [Google Scholar] [CrossRef]

- Narayanan, R. Indian Logistics Sector Is Expected to Reach 380 Billion Mark by 2025 Nilesh Ghule Truckbhejo; Express Mobility: Noida, Uttar Pradesh, India, 2022; Available online: https://www.financialexpress.com/express-mobility/indian-logistics-sector-is-expected-to-reach-380-billion-mark-by-2025-nilesh-ghule-truckbhejo/2466424/ (accessed on 25 September 2022).

- Iyer, A. Moving from Industry 2.0 to Industry 4.0: A Case Study from India on Leapfrogging in Smart Manufacturing. Procedia Manuf. 2018, 21, 663–670. [Google Scholar] [CrossRef]

- Priyadarshini, J.; Kr Singh, R.; Mishra, R.; Mustafa Kamal, M. Adoption of Additive Manufacturing for Sustainable Operations in the Era of Circular Economy: Self-Assessment Framework with Case Illustration. Comput. Ind. Eng. 2022, 171, 108514. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an Enabler of Sustainability Diffusion in Supply Chain: An Analysis of Influential Strength of Drivers in an Emerging Economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Sun, S. Size of Logistics Market in India FY 2017–2025; Transportation & Logistics: Hamburg, Germany, 2022; Available online: https://www.statista.com/statistics/1288177/india-size-of-logistics-market/ (accessed on 20 September 2022).

- Mangiaracina, R.; Perego, A.; Seghezzi, A.; Tumino, A. Innovative Solutions to Increase Last-Mile Delivery Efficiency in B2C e-Commerce: A Literature Review. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 901–920. [Google Scholar] [CrossRef] [Green Version]

- Borghetti, F.; Caballini, C.; Carboni, A.; Grossato, G.; Maja, R.; Barabino, B. The Use of Drones for Last-Mile Delivery: A Numerical Case Study in Milan, Italy. Sustainbility 2022, 14, 1766. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A Systematic Review towards a New Logistics System. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Ola, J.; Logan, S.; Vallandingham, R.; Fragapane, G.; Wessel, J.; Aili, S.; Hætta, B.; Nakul, S. Logistics 4.0 and Emerging Sustainable Business Models. Adv. Manuf. 2017, 5, 359–369. [Google Scholar] [CrossRef]

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Caballero Morales, S.O.; Aldrette-Malacara, A. Digital Supply Chain Model in Industry 4.0. J. Manuf. Technol. Manag. 2020, 31, 887–933. [Google Scholar] [CrossRef]

- Salam, M.A. Analyzing Manufacturing Strategies and Industry 4.0 Supplier Performance Relationships from a Resource-Based Perspective. Benchmarking Int. J. 2018, 28, 1697–1716. [Google Scholar] [CrossRef]

- Karpova, N.P. Modern Warehouse Management Systems. Lect. Notes Netw. Syst. 2022, 304, 261–267. [Google Scholar] [CrossRef]

- Bank, R.; Murphy, R. Warehousing Sustainability Standards Development. IFIP Adv. Inf. Commun. Technol. 2013, 414, 294–301. [Google Scholar] [CrossRef] [Green Version]

- Veile, J.W.; Kiel, D.; Müller, J.M. Lessons Learned from Industry 4.0 Implementation in the German Manufacturing Industry Implementation. J. Manuf. Technol. Manag. 2019, 31, 977–997. [Google Scholar] [CrossRef] [Green Version]

- Juliet Orji, I.; Ojadi, F.; Kalu Okwara, U. The Nexus between E-Commerce Adoption in a Health Pandemic and Firm Performance: The Role of Pandemic Response Strategies. J. Bus. Res. 2022, 145, 616–635. [Google Scholar] [CrossRef]

- Pan, S.; Trentesaux, D.; McFarlane, D.; Montreuil, B.; Ballot, E.; Huang, G.Q. Digital Interoperability in Logistics and Supply Chain Management: State-of-the-Art and Research Avenues towards Physical Internet. Comput. Ind. 2021, 128, 103435. [Google Scholar] [CrossRef]

- Gupta, H.; Yadav, A.K.; Kusi-Sarpong, S.; Khan, S.A.; Sharma, S.C. Strategies to overcome barriers to innovative digitalisation technologies for supply chain logistics resilience during pandemic. Technol. Soc. 2022, 69, 101970. [Google Scholar] [CrossRef]

- Zhou, K. Industry 4.0: Towards Future Industrial Opportunities and Challenges. In Proceedings of the 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Attaran, M. Digital Technology Enablers and Their Implications for Supply Chain Management. Supply Chain Forum 2020, 21, 158–172. [Google Scholar] [CrossRef]

- Goswami, M.; Daultani, Y. Make-in-India and Industry 4.0: Technology readiness of select firms, barriers and socio-technical implications. TQM J. 2021, 34, 1485–1505. [Google Scholar] [CrossRef]

- Chhabra, D.; Kr Singh, R. Analyzing barriers to green logistics in context of Circular Economy and Industry 4.0 in the Indian manufacturing industry. Int. J. Logist. Res. Appl. 2022, 1–14. [Google Scholar] [CrossRef]

- Naseem, M.H.; Yang, J.; Xiang, Z. Prioritizing the solutions to reverse logistics barriers for the e-commerce industry in pakistan based on a fuzzy ahp-topsis approach. Sustainability 2021, 13, 12743. [Google Scholar] [CrossRef]

- Mangla, S.K.; Govindan, K.; Luthra, S. Critical Success Factors for Reverse Logistics in Indian Industries: A Structural Model. J. Clean. Prod. 2016, 129, 608–621. [Google Scholar] [CrossRef]

- Kinkel, S.; Baumgartner, M.; Cherubini, E. Prerequisites for the Adoption of AI Technologies in Manufacturing—Evidence from a Worldwide Sample of Manufacturing Companies. Technovation 2022, 110, 102375. [Google Scholar] [CrossRef]

- Sarkar, B.D.; Shankar, R.; Kar, A.K. Severity analysis and risk profiling of port logistics barriers in the Industry 4.0 era. Benchmarking Int. J. 2022; ahead of print. [Google Scholar] [CrossRef]

- Marcon, É.; Soliman, M.; Gerstlberger, W.; Frank, A.G. Sociotechnical factors and Industry 4.0: An integrative perspective for the adoption of smart manufacturing technologies. J. Manuf. Technol. Manag. 2022, 33, 259–286. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R. Evaluating the Circular Supply Chain Implementation Barriers Using Pythagorean Fuzzy AHP-DEMATEL Approach. Clean. Logist. Supply Chain 2021, 2, 100014. [Google Scholar] [CrossRef]

- Subramanian, N.; Gunasekaran, A.; Abdulrahman, M.D.; Qiao, C. Out-in, in-out Buyer Quality Innovation Pathways for New Product Outcome: Empirical Evidence from the Chinese Consumer Goods Industry. Int. J. Prod. Econ. 2019, 207, 183–194. [Google Scholar] [CrossRef]

- Parhi, S.; Joshi, K.; Gunasekaran, A.; Sethuraman, K. Reflecting on an Empirical Study of the Digitalization Initiatives for Sustainability on Logistics: The Concept of Sustainable Logistics 4.0. Clean. Logist. Supply Chain 2022, 4, 100058. [Google Scholar] [CrossRef]

- Merkert, R.; Bliemer, M.C.J.; Fayyaz, M. Consumer Preferences for Innovative and Traditional Last-Mile Parcel Delivery. Int. J. Phys. Distrib. Logist. Manag. 2022, 52, 261–284. [Google Scholar] [CrossRef]

- Senna, P.P.; Ferreira, L.M.D.F.; Barros, A.C.; Bonnín Roca, J.; Magalhães, V. Prioritizing Barriers for the Adoption of Industry 4.0 Technologies. Comput. Ind. Eng. 2022, 171, 108428. [Google Scholar] [CrossRef]

- Montreuil, B. Toward a Physical Internet: Meeting the Global Logistics Sustainability Grand Challenge. Logist. Res. 2011, 3, 71–87. [Google Scholar] [CrossRef]

- Allen, J.; Browne, M.; Woodburn, A.; Leonardi, J. The Role of Urban Consolidation Centres in Sustainable Freight Transport. Transp. Rev. 2012, 32, 473–490. [Google Scholar] [CrossRef]

- Lu, Y. Industrial Integration: A Literature Review. J. Ind. Int. Manag. 2016, 1, 650007. [Google Scholar] [CrossRef]

- Siddiqui, A.A.; Vita, S. Impact of Logistics Performance on Trade with Specific Reference to Garment Sector in Cambodia, Bangladesh and India. Glob. Bus. Rev. 2021, 22, 517–531. [Google Scholar] [CrossRef]

- Kopczewski, M.; Grobelny, Z.; Płucienniczak, M. Telematics–Electronic Data Interchange/EDI/in Port Transport Logistics. J. Decis. Syst. 2020, 29 (Suppl. 1), 301–311. [Google Scholar] [CrossRef]

- Sampaio, P.; Carvalho, A.M.; Domingues, P.; Saraiva, P. Guest Editorial: Quality in the Digital Transformation Era. Int. J. Qual. Reliab. Manag. 2022, 39, 1309–1311. [Google Scholar] [CrossRef]

- Schmidt, C.G.; Wagner, S.M. Blockchain and Supply Chain Relations: A Transaction Cost Theory Perspective. J. Purch. Supply Manag. 2019, 25, 100552. [Google Scholar] [CrossRef]

- Staudt, F.H.; Alpan, G.; Di Mascolo, M.; Rodriguez, C.M.T. Warehouse Performance Measurement: A Literature Review. Int. J. Prod. Res. 2015, 53, 5524–5544. [Google Scholar] [CrossRef]

- Lemardelé, C.; Estrada, M.; Pagès, L.; Bachofner, M. Potentialities of Drones and Ground Autonomous Delivery Devices for Last-Mile Logistics. Transp. Res. Part E Logist. Transp. Rev. 2021, 149, 102325. [Google Scholar] [CrossRef]

- Wong, L.W.; Leong, L.Y.; Hew, J.J.; Tan, G.W.H.; Ooi, K.B. Time to Seize the Digital Evolution: Adoption of Blockchain in Operations and Supply Chain Management among Malaysian SMEs. Int. J. Inf. Manag. 2020, 52, 01997. [Google Scholar] [CrossRef]

- Jena, A.; Patel, S.K. Analysis and Evaluation of Indian Industrial System Requirements and Barriers Affect during Implementation of Industry 4.0 Technologies. Int. J. Adv. Manuf. Technol. 2022, 120, 2109–2133. [Google Scholar] [CrossRef]

- Mothilal, S.; Gunasekaran, A.; Nachiappan, S.P.; Jayaram, J. Key Success Factors and Their Performance Implications in the Indian Third-Party Logistics (3PL) Industry. Int. J. Prod. Res. 2012, 50, 2407–2422. [Google Scholar] [CrossRef]

- Gentili, M.; Mirchandani, P.B.; Agnetis, A.; Ghelichi, Z. Locating Platforms and Scheduling a Fleet of Drones for Emergency Delivery of Perishable Items. Comput. Ind. Eng. 2022, 168, 108057. [Google Scholar] [CrossRef]

- Jennings, D.; Figliozzi, M. Study of Road Autonomous Delivery Robots and Their Potential Effects on Freight Efficiency and Travel. Transp. Res. Rec. 2020, 2674, 1019–1029. [Google Scholar] [CrossRef]

- Ezaki, T.; Imura, N.; Nishinari, K. Towards Understanding Network Topology and Robustness of Logistics Systems. Commun. Transp. Res. 2022, 2, 100064. [Google Scholar] [CrossRef]

- Bachofner, M.; Lemardelé, C.; Estrada, M.; Pagès, L. City Logistics: Challenges and Opportunities for Technology Providers. J. Urban Mobil. 2022, 2, 100020. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Huang, G.Q.; Zhang, Q.Y.D.T. Mining SOTs and Dispatching Rules from RFID-Enabled Real-Time Shopfloor Production Data. J. Int. Manuf. 2012, 25, 825–843. [Google Scholar] [CrossRef]

- Babiceanu, R.F.; Seker, R. Computers in Industry Big Data and Virtualization for Manufacturing Cyber-Physical Systems: A Survey of the Current Status and Future Outlook. Comput. Ind. 2016, 81, 128–137. [Google Scholar] [CrossRef]

- Li, X. RFID-Based Tracking and Monitoring Approach of Real-Time Data in Production Workshop. Assem. Autom. 2018, 39, 648–663. [Google Scholar] [CrossRef]

- Gupta, S.; Borges, R.M. Density-Dependent Fitness Effects Stabilize Parasitic Hitchhiking within a Mutualism. Funct. Ecol. 2019, 33, 2304–2315. [Google Scholar] [CrossRef]

- Chaabane, A.; Montecinos, J.; Ouhimmou, M.; Khabou, A. Vehicle Routing Problem for Reverse Logistics of End-of-Life Vehicles (ELVs). Waste Manag. 2021, 120, 209–220. [Google Scholar] [CrossRef] [PubMed]

- Chandrasiri, C.; Dharmapriya, S.; Jayawardana, J.; Kulatunga, A.K.; Weerasinghe, A.N.; Aluwihare, C.P.; Hettiarachchi, D. Mitigating Environmental Impact of Perishable Food Supply Chain by a Novel Configuration: Simulating Banana Supply Chain in Sri Lanka. Sustainabilty 2022, 14, 12060. [Google Scholar] [CrossRef]

- He, Y.; Wang, X.; Zhou, F.; Lin, Y. Dynamic Vehicle Routing Problem Considering Simultaneous Dual Services in the Last Mile Delivery. Kybernetes 2020, 49, 1267–1284. [Google Scholar] [CrossRef]

- Zhang, M.; Pratap, S.; Zhao, Z.; Prajapati, D.; Huang, G.Q. Forward and Reverse Logistics Vehicle Routing Problems with Time Horizons in B2C E-Commerce Logistics. Int. J. Prod. Res. 2021, 59, 6291–6310. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, M.; Zhang, W.; Zhou, Q.; Zhang, X. What Influences the Effectiveness of Green Logistics Policies? A Grounded Theory Analysis. Sci. Total Environ. 2020, 714, 136731. [Google Scholar] [CrossRef]

- De Koster, M.B.M.; Balk, B.M. Benchmarking and Monitoring International Warehouse Operations in Europe. Prod. Oper. Manag. 2008, 17, 175–183. [Google Scholar] [CrossRef]

- Holeczek, N. Hazardous Materials Truck Transportation Problems: A Classification and State of the Art Literature Review. Transp. Res. Part D Transp. Environ. 2019, 69, 305–328. [Google Scholar] [CrossRef]

- Khan, J.; Ketzel, M.; Kakosimos, K.; Sørensen, M.; Jensen, S.S. Road Traffic Air and Noise Pollution Exposure Assessment—A Review of Tools and Techniques. Sci. Total Environ. 2018, 634, 661–676. [Google Scholar] [CrossRef]

- Choi, S.H.; Park, K.B.; Roh, D.H.; Lee, J.Y.; Mohammed, M.; Ghasemi, Y.; Jeong, H. An Integrated Mixed Reality System for Safety-Aware Human-Robot Collaboration Using Deep Learning and Digital Twin Generation. Robot. Comput. Integr. Manuf. 2022, 73, 102258. [Google Scholar] [CrossRef]

- Pang, J.; Ong, S.K.; Nee, A.Y.C. Image and Model Sequences Matching for On-Site Assembly Stage Identification. Robot. Comput. Integr. Manuf. 2021, 72, 102185. [Google Scholar] [CrossRef]

- Wang, K. Logistics 4.0 Solution-New Challenges and Opportunities. In Proceedings of the 6th International Workshop of Advanced Manufacturing and Automation, Manchester, UK, 10–11 November 2016; Atlantis Press: Paris, France, 2016; pp. 68–74. [Google Scholar] [CrossRef] [Green Version]

- Strozzi, F.; Colicchia, C.; Creazza, A.; Noè, C.; Strozzi, F.; Colicchia, C.; Creazza, A.; Noè, C. Literature Review on the ‘Smart Factory’ Concept Using Bibliometric Tools. Int. J. Prod. Res. 2017, 7543, 1–20. [Google Scholar] [CrossRef]

- Ali, S.S.; Kaur, R. Effectiveness of Corporate Social Responsibility (CSR) in Implementation of Social Sustainability in Warehousing of Developing Countries: A Hybrid Approach. J. Clean. Prod. 2021, 324, 129154. [Google Scholar] [CrossRef]

- Giusti, R.; Manerba, D.; Bruno, G.; Tadei, R. Synchromodal Logistics: An Overview of Critical Success Factors, Enabling Technologies, and Open Research Issues. Transp. Res. Part E Logist. Transp. Rev. 2019, 129, 92–110. [Google Scholar] [CrossRef]

- Jain, V.; Ajmera, P. Modelling the Enablers of Industry 4.0 in the Indian Manufacturing Industry. Int. J. Prod. Perform. Manag. 2019, 70, 1233–1262. [Google Scholar] [CrossRef]

- Inkinen, T.; Hämäläinen, E. Reviewing Truck Logistics: Solutions for Achieving Low Emission Road Freight Transport. Sustainbility 2020, 12, 6714. [Google Scholar] [CrossRef]

- Villa, R.; Monzón, A. A Metro-Based System as Sustainable Alternative for Urban Logistics in the Era of e-Commerce. Sustainbilty 2021, 13, 4479. [Google Scholar] [CrossRef]

- Mirzaei, M.; Zaerpour, N.; de Koster, R. The Impact of Integrated Cluster-Based Storage Allocation on Parts-to-Picker Warehouse Performance. Transp. Res. Part E Logist. Transp. Rev. 2021, 146, 102207. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Narwane, V.S.; Narkhede, B.E.; Muduli, K. Implementation Barriers of Smart Technology in Indian Sustainable Warehouse by Using a Delphi-ISM-ANP Approach. Int. J. Product. Perform. Manag. 2022, 71, 696–721. [Google Scholar] [CrossRef]

- Warfield, J.N. Crossing Theory and Hierarchy Mapping. IEEE Trans. Syst. Man. Cybern. 1977, 7, 505–523. [Google Scholar] [CrossRef]

- Bakhtari, A.R.; Waris, M.M.; Sanin, C.; Szczerbicki, E. Evaluating Industry 4.0 Implementation Challenges Using Interpretive Structural Modeling and Fuzzy Analytic Hierarchy Process. Cybern. Syst. 2021, 52, 350–378. [Google Scholar] [CrossRef]

- Anderson, T.; Liam, R.; Garrison, D.R.; Archer, W. Assessing teaching presence in a computer conferencing context. J. Asynchronous Learn. Netw. 2001, 5, 1–17. Available online: http://hdl.handle.net/2149/725 (accessed on 25 September 2022). [CrossRef]

- Kapse, C.P.; Kumar, A.; Dash, M.K.; Zavadskas, E.K.; Luthra, S. Developing textile entrepreneurial inclination model by integrating experts mining and ISM-MICMAC. Int. J. Prod. Res. 2018, 56, 4709–4728. [Google Scholar] [CrossRef]

- Qureshi, M.R.N.M. A Bibliometric Analysis of Third-Party Logistics Services Providers (3PLSP) Selection for Supply Chain Strategic Advantage. Sustainability 2022, 14, 11836. [Google Scholar] [CrossRef]

- Cheng, Y.; Chen, K.; Sun, H.; Zhang, Y.; Tao, F. Data and Knowledge Mining with Big Data towards Smart Production. J. Ind. Inf. Integr. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Bag, S.; Yadav, G.; Dhamija, P.; Kataria, K.K. Key Resources for Industry 4.0 Adoption and Its Effect on Sustainable Production and Circular Economy: An Empirical Study. J. Clean. Prod. 2021, 281, 125233. [Google Scholar] [CrossRef]

| Synod | Barriers and Sources | Description | Role in Sustainability and Utility in LMD |

|---|---|---|---|

| 1 | Environmental Concerns [27,31,32] | Environmental concerns consider pollution or the consequences of vehicle emissions into the air on the road or in the water, which act as a pollutant during logistics operations. |

|

| 2 | Infrastructure [33,34,35] | A need for numerous hardware installations and software updates creates infrastructure challenges to I4.0. A high-tech (Information and Technology) IT-based infrastructure is required to implement I4.0 technologies in last-mile delivery to create communication. |

|

| 3 | Acceptability of Green practices [36,37,38] | Green practices in logistics management are described as green purchasing, green production, green materials management, green distribution, and reverse logistics. Green logistics refers to new developments in the purchase and delivery of products at the doorstep with the help of green technology innovations (GTIs). |

|

| 4 | Electronic Data Interchange (EDI) [39,40,41] | EDI is the process of sending business documents between companies in a standardized format. A common electronic format that substitutes paper-based documents such as purchase orders or invoices is the most basic definition of EDI. |

|

| 5 | Cost effectiveness [42,43,44] | I4.0 is primarily associated with investments in fixed assets; both tangible and intangible, these investments are substantial in the logistics sector, as well involving a huge cost initially and cost saving in the long run. |

|

| 6 | Transparency [8,45,46] | The logistics industry, powered by cutting-edge technology, may boost visibility and transparency as a result of digitization throughout the supply chain management. Building a smart system helps increase visibility for enterprises and creates fear of data privacy. |

|

| 7 | Delivery capacity [47,48,49] | By precisely projecting delivery timings for each stage of the flow, from preparation and staging through time on site and time back to the delivery pickup point. It can also affect the managment of bulk orders where preferential business is made. |

|

| 8 | Traffic management [37,50,51] | Traffic management is a necessary problem with unexpected vehicles on delivery routes causing delays in LMD. Traffic jams create a lot of noise and air pollution leading to environmental problems. |

|

| 9 | Real-Time tracking system (RTLS) [52,53,54] | Any system that precisely pinpoints the position of a person or an object is referred to as an RTLS. An RTLS is a goal that may be achieved with several asset management and location systems, not a particular system or technology. |

|

| 10 | Vehicle fitness [37,55,56] | It covers the vehicle concerns of availability and health for the last-mile delivery services. A combination of physical and computerized test equipment should be used throughout the examination of vehicle conditions. |

|

| 11 | Dynamic Routing [57,58,59] | Dynamic routing is a networking technique that provides the optimal data routing plan for logistics services. Unlike static routing, dynamic routing allows routers to make decisions based on rapid changes in the logical network topology. |

|

| 12 | Government Eco-Friendly norms [4,33,60] | The government is making eco-friendly policies for freight carriers to lower emissions and support “cleaner” transportation. It also provides certain subsidies for implementing green practices in smart supply chains. |

|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | X | A | O | A | V | A | O | A | A | A | A | A |

| 2 | X | V | V | V | V | V | V | V | O | V | O | |

| 3 | X | V | V | X | V | V | V | V | V | X | ||

| 4 | X | V | V | V | V | V | V | V | A | |||

| 5 | X | V | V | A | A | A | A | O | ||||

| 6 | X | V | V | V | V | V | A | |||||

| 7 | X | A | A | A | A | O | ||||||

| 8 | X | A | A | V | A | |||||||

| 9 | X | A | V | A | ||||||||

| 10 | X | V | A | |||||||||

| 11 | X | O | ||||||||||

| 12 | X | |||||||||||

|

| |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 3 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 4 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 5 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| 6 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| 8 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 9 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 10 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 11 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 12 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | DRP | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 9 |

| 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 12 |

| 3 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| 4 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| 5 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 9 |

| 6 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| 7 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 |

| 8 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| 9 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| 10 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| 11 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| 12 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| DEP | 11 | 1 | 11 | 9 | 11 | 11 | 12 | 11 | 11 | 11 | 11 | 9 |

| Barrier | Reachability | Antecedent | Intersection | Level |

|---|---|---|---|---|

| 1 | 1, 3, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 5, 6, 8, 9, 10, 11 | |

| 2 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 2 | 2 | |

| 3 | 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | |

| 4 | 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 2, 3, 4, 6, 8, 9, 10, 11, 12 | 3, 4, 6, 8, 9, 10, 11, 12 | |

| 5 | 1, 3, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 5, 6, 8, 9, 10, 11 | |

| 6 | 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | |

| 7 | 7 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 7 | 1 |

| 8 | 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | |

| 9 | 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | |

| 10 | 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | |

| 11 | 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | |

| 12 | 1, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 2, 3, 4, 6, 8, 9, 10, 11, 12 | 3, 4, 6, 8, 9, 10, 11, 12 |

| Barriers | Reachability | Antecedent | Intersection | Level |

|---|---|---|---|---|

| 1 | 1, 3, 5, 6, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 5, 6, 8, 9, 10, 11 | 2 |

| 2 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 2 | 2 | |

| 3 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 2 |

| 4 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 2, 3, 4, 6, 8, 9, 10, 11, 12 | 3, 4, 6, 8, 9, 10, 11, 12 | |

| 5 | 1, 3, 5, 6, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 5, 6, 8, 9, 10, 11 | 2 |

| 6 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 2 |

| 8 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 2 |

| 9 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 2 |

| 10 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 2 |

| 11 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 2 |

| 12 | 1, 3, 4, 5, 6, 8, 9, 10, 11, 12 | 2, 3, 4, 6, 8, 9, 10, 11, 12 | 3, 4, 6, 8, 9, 10, 11, 12 |

| Barriers | Reachability | Antecedent | Intersection | Level |

|---|---|---|---|---|

| 2 | 2, 4, 12, | 2, | 2, | |

| 4 | 4, 12, | 2, 3, 4, 6, 8, 9, 10, 11, 12, | 4, 12, | 3 |

| 12 | 4, 12, | 2, 3, 4, 6, 8, 9, 10, 11, 12, | 4, 12, | 3 |

| Barrier | Reachability | Antecedent | Intersection | Level |

|---|---|---|---|---|

| 2 | 2 | 2 | 2 | 4 |

| Variables | Level |

|---|---|

| 7 | 1 |

| 1, 3, 5, 6, 8, 9, 10 | 2 |

| 4, 12 | 3 |

| 2 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, V.P.; Prakash, S.; Singh, R. What Prevents Sustainable Last-Mile Delivery in Industry 4.0? An Analysis and Decision Framework. Sustainability 2022, 14, 16423. https://doi.org/10.3390/su142416423

Sharma VP, Prakash S, Singh R. What Prevents Sustainable Last-Mile Delivery in Industry 4.0? An Analysis and Decision Framework. Sustainability. 2022; 14(24):16423. https://doi.org/10.3390/su142416423

Chicago/Turabian StyleSharma, Vijay Prakash, Surya Prakash, and Ranbir Singh. 2022. "What Prevents Sustainable Last-Mile Delivery in Industry 4.0? An Analysis and Decision Framework" Sustainability 14, no. 24: 16423. https://doi.org/10.3390/su142416423

APA StyleSharma, V. P., Prakash, S., & Singh, R. (2022). What Prevents Sustainable Last-Mile Delivery in Industry 4.0? An Analysis and Decision Framework. Sustainability, 14(24), 16423. https://doi.org/10.3390/su142416423