Sustainable Manufacturing through Systematic Reduction in Cycle Time

Abstract

1. Introduction

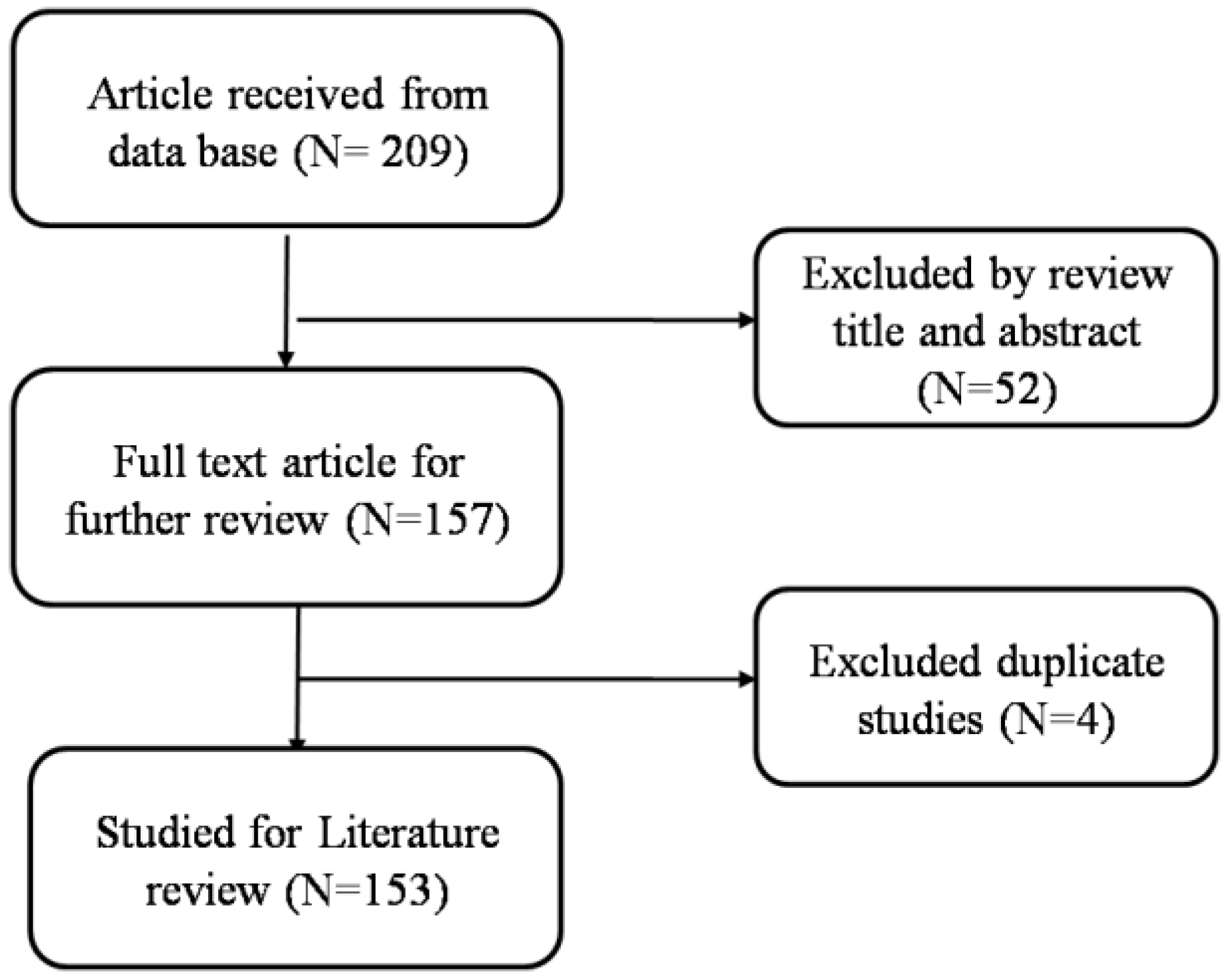

2. Methodology

3. Literature Review

3.1. Sustainable Manufacturing

3.2. Cycle Time Reduction for Sustainable Manufacturing

4. Findings

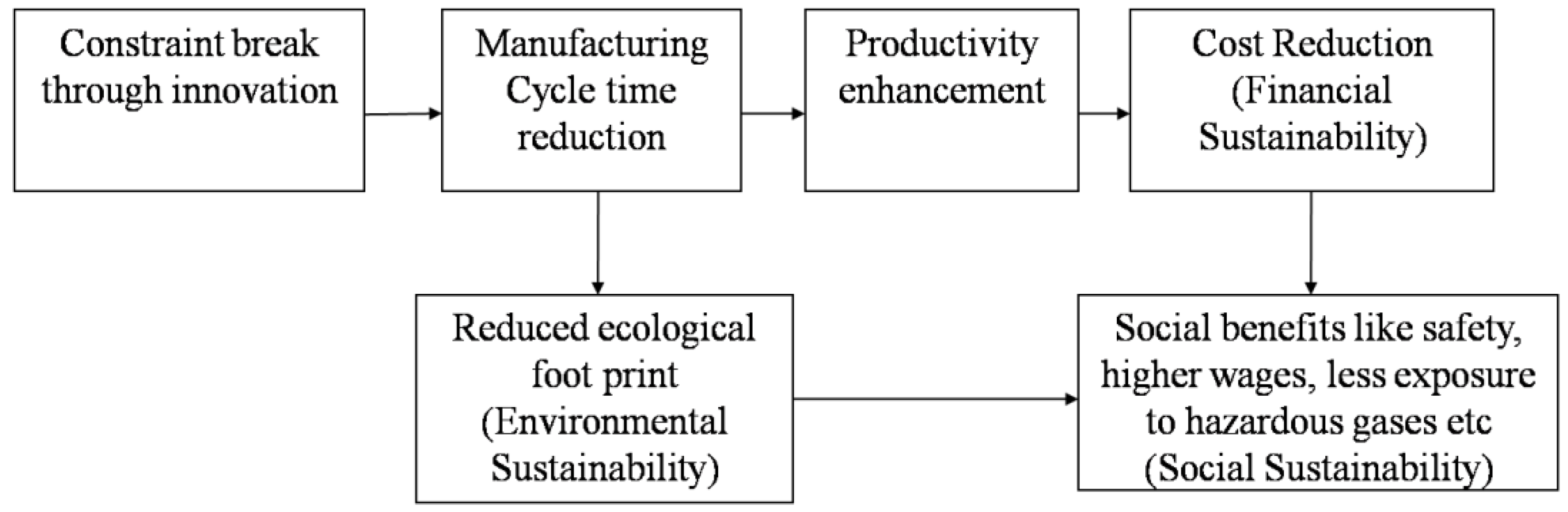

4.1. Systematic Cycle Time Reduction for Sustainability

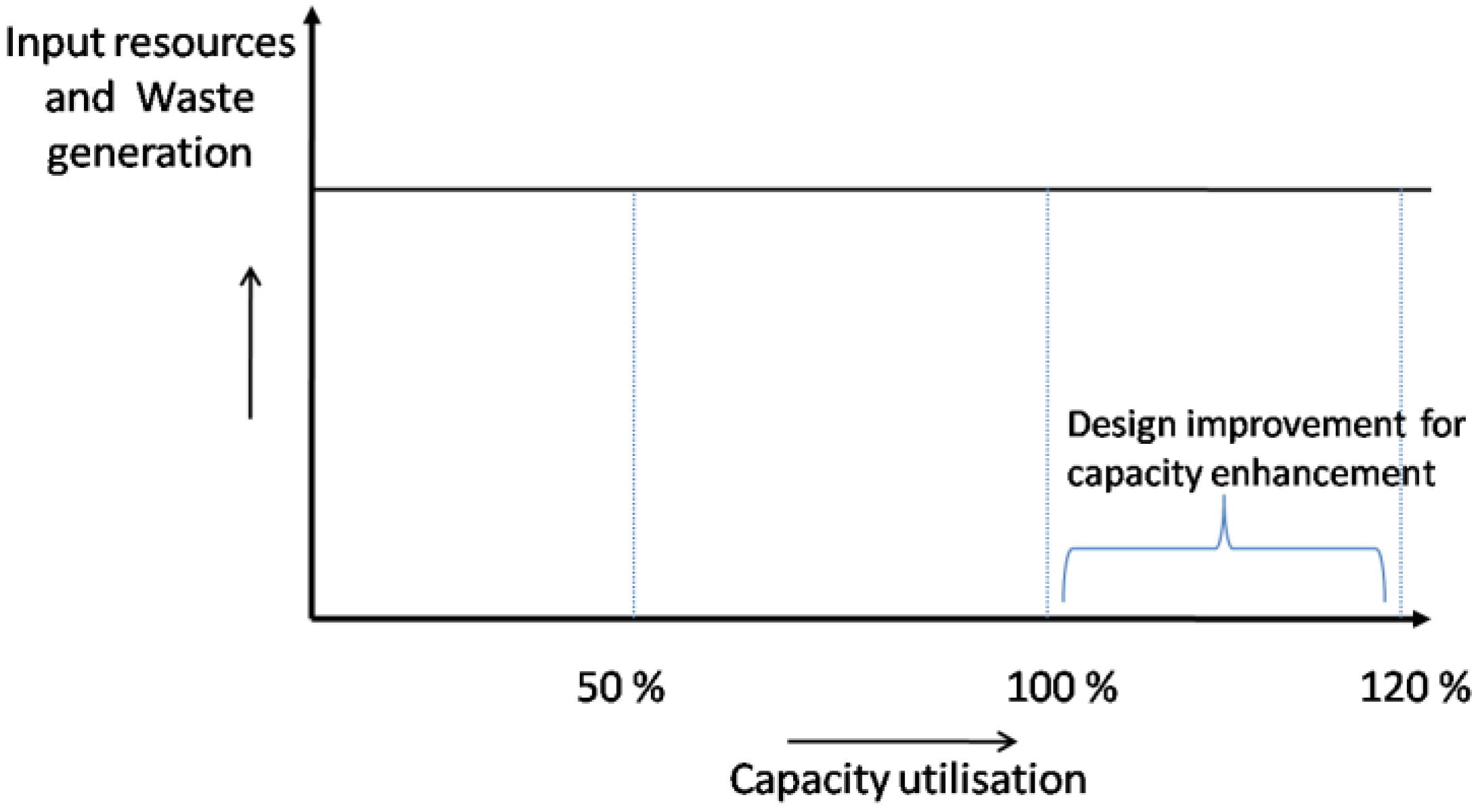

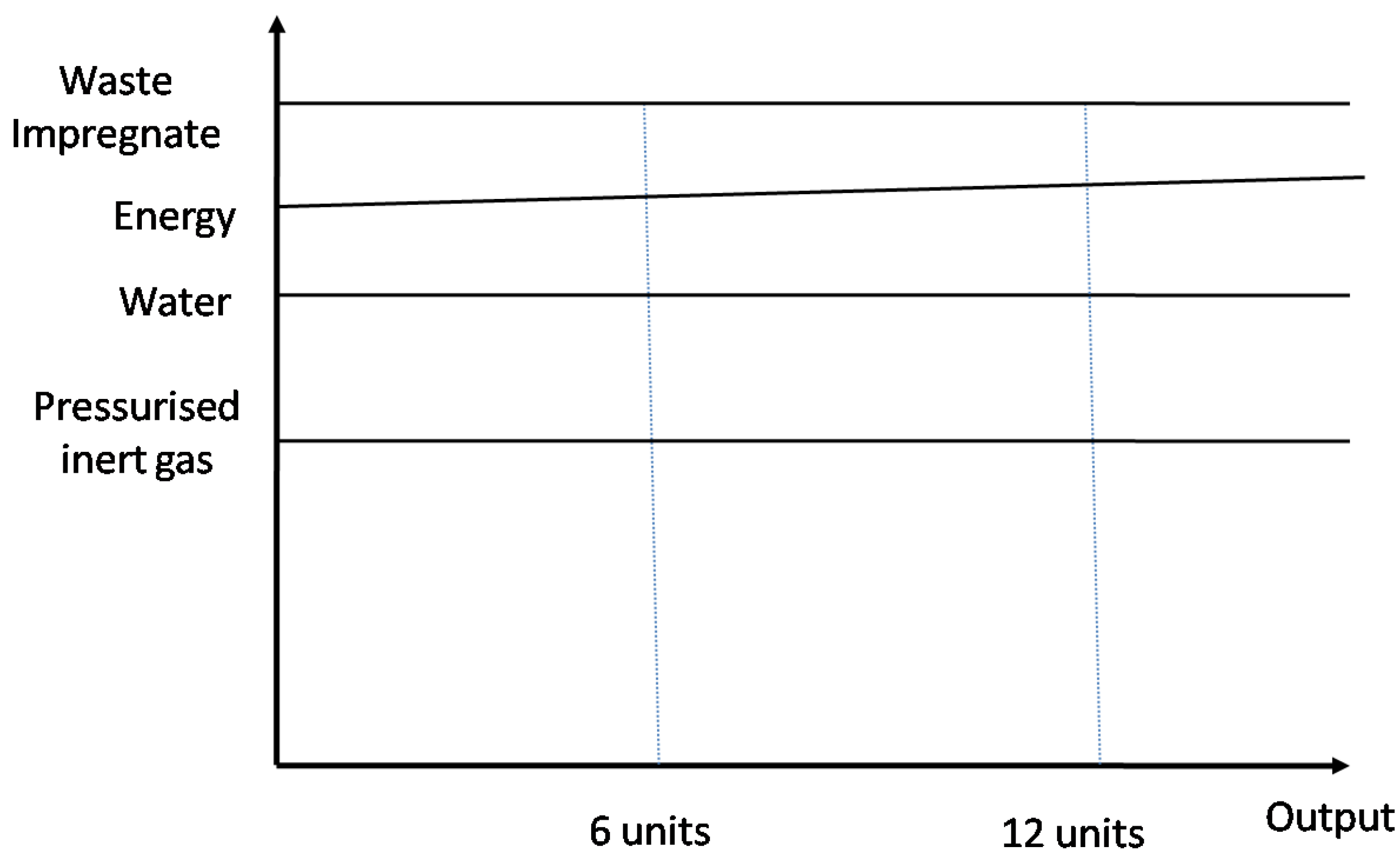

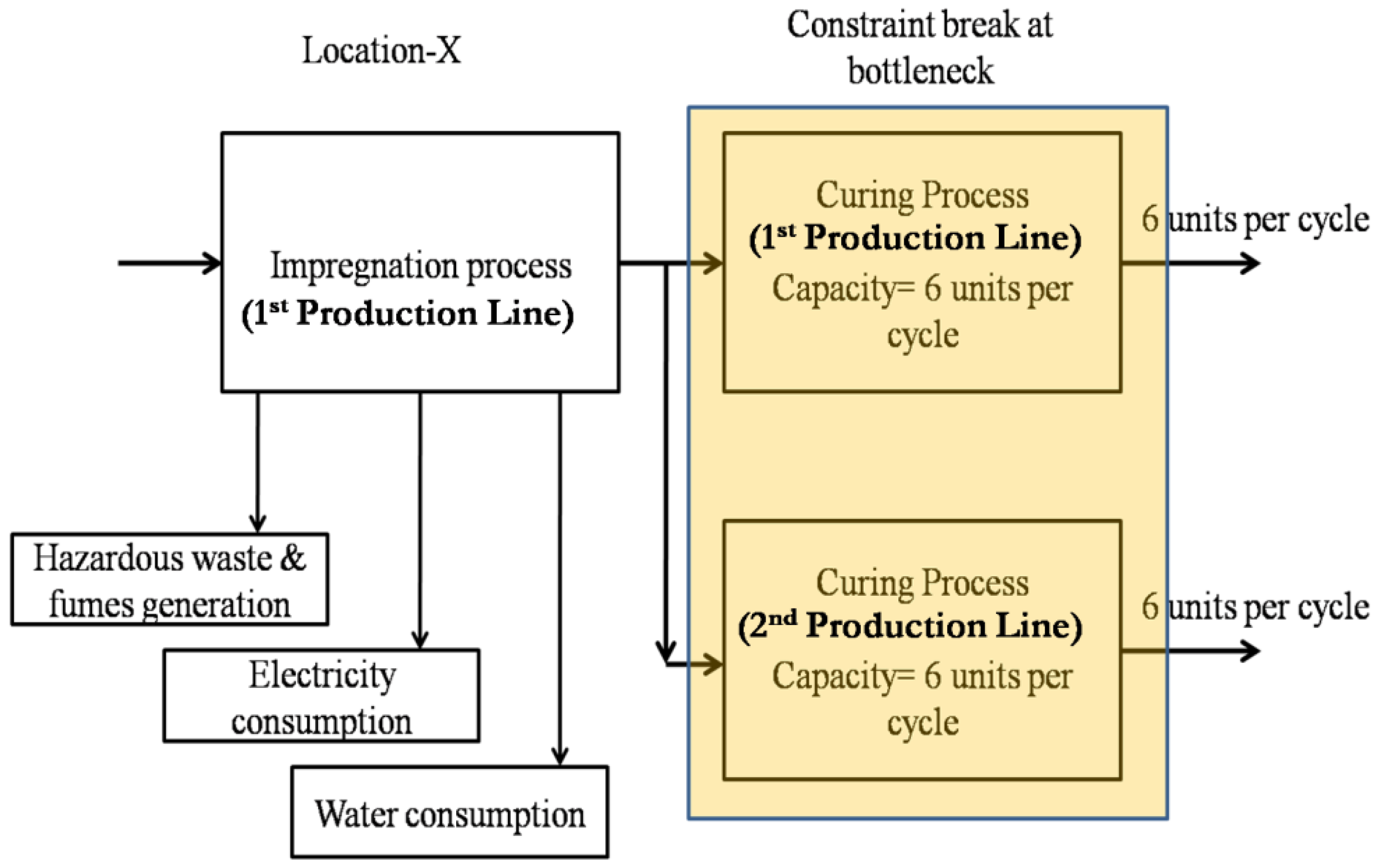

- Identify location ‘X’ (A process that consume a fixed amount of resources, i.e., energy or material, irrespective of its capacity utilisation, as shown in Figure 4).

- Identify and optimise constraints in the production line to utilise location X at a higher or full capacity.

- In case the location X reaches maximum utilisation in the entire manufacturing process, the location ‘X’ can become a new constraint itself.

- Subordinate all the resources of the manufacturing process to the location ‘X’ for further improving the overall sustainability of the manufacturing process.

4.2. Case Study for Step towards Validation of the New Method

5. Discussion

6. Conclusions

6.1. Implications for Theory

6.2. Implications for Practice

6.3. Limitations and Direction for Future Research

Author Contributions

Funding

Conflicts of Interest

References

- Abdul-Rashid, S.H.; Sakundarini, N.; Raja Ghazilla, R.A.; Thurasamy, R. The Impact of Sustainable Manufacturing Practices on Sustainability Performance. Int. J. Oper. Prod. Manag. 2017, 37, 182–204. [Google Scholar] [CrossRef]

- Abdul Rashid, S.H.; Evans, S.; Longhurst, P. A Comparison of Four Sustainable Manufacturing Strategies. Int. J. Sustain. Eng. 2008, 1, 214–229. [Google Scholar] [CrossRef]

- Bui, T.-D.; Tseng, J.-W.; Tseng, M.-L.; Lim, M.K. Opportunities and Challenges for Solid Waste Reuse and Recycling in Emerging Economies: A Hybrid Analysis. Resour. Conserv. Recycl. 2022, 177, 105968. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental Impact of Cement Production: Detail of the Different Processes and Cement Plant Variability Evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Jayal, A.D.; Badurdeen, F.; Dillon, O.W.; Jawahir, I.S. Sustainable Manufacturing: Modeling and Optimization Challenges at the Product, Process and System Levels. CIRP J. Manuf. Sci. Technol. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- Pusavec, F.; Krajnik, P.; Kopac, J. Transitioning to Sustainable Production—Part I: Application on Machining Technologies. J. Clean. Prod. 2010, 18, 174–184. [Google Scholar] [CrossRef]

- Bag, S.; Yadav, G.; Wood, L.C.; Dhamija, P.; Joshi, S. Industry 4.0 and the Circular Economy: Resource Melioration in Logistics. Resour. Policy 2020, 68, 101776. [Google Scholar] [CrossRef]

- Johansson, G.; Sundin, E. Lean and Green Product Development: Two Sides of the Same Coin? J. Clean. Prod. 2014, 85, 104–121. [Google Scholar] [CrossRef]

- Despeisse, M. Sustainable Manufacturing Tactics and Improvement Methodology: A Structured and Systematic Approach to Identify Improvement Opportunities. Ph.D. Thesis, Cranfield University, Bedford, UK, 2013. [Google Scholar]

- Pampanelli, A.B.; Found, P.; Bernardes, A.M. A Lean & Green Model for a Production Cell. J. Clean. Prod. 2014, 85, 19–30. [Google Scholar] [CrossRef]

- Choudhary, S.; Nayak, R.; Dora, M.; Mishra, N.; Ghadge, A. An Integrated Lean and Green Approach for Improving Sustainability Performance: A Case Study of a Packaging Manufacturing SME in the U.K. Prod. Plan. Control 2019, 30, 353–368. [Google Scholar] [CrossRef]

- Chiarini, A. Sustainable Manufacturing-Greening Processes Using Specific Lean Production Tools: An Empirical Observation from European Motorcycle Component Manufacturers. J. Clean. Prod. 2014, 85, 226–233. [Google Scholar] [CrossRef]

- Piercy, N.; Rich, N. The Relationship between Lean Operations and Sustainable Operations. Int. J. Oper. Prod. Manag. 2015, 35, 282–315. [Google Scholar] [CrossRef]

- Garetti, M.; Taisch, M. Sustainable Manufacturing: Trends and Research Challenges. Prod. Plan. Control 2011, 23, 83–104. [Google Scholar] [CrossRef]

- Niñerola, A.; Ferrer-Rullan, R.; Vidal-Suñé, A. Climate Change Mitigation: Application of Management Production Philosophies for Energy Saving in Industrial Processes. Sustainability 2020, 12, 717. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive Manufacturing of Geopolymer for Sustainable Built Environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Oliveira Neto, G.C.; Leite, R.R.; Shibao, F.Y.; Lucato, W.C. Framework to Overcome Barriers in the Implementation of Cleaner Production in Small and Medium-Sized Enterprises: Multiple Case Studies in Brazil. J. Clean. Prod. 2017, 142, 50–62. [Google Scholar] [CrossRef]

- Govindan, K.; Diabat, A.; Madan Shankar, K. Analyzing the Drivers of Green Manufacturing with Fuzzy Approach. J. Clean. Prod. 2015, 96, 182–193. [Google Scholar] [CrossRef]

- Goyal, A.; Agrawal, R.; Kumar Sharma, A. Green Quality Circle: Achieving Sustainable Manufacturing with Low Investment. Resour. Conserv. Recycl. Adv. 2022, 15, 200103. [Google Scholar] [CrossRef]

- Yadav, G.; Mangla, S.K.; Bhattacharya, A.; Luthra, S. Exploring Indicators of Circular Economy Adoption Framework through a Hybrid Decision Support Approach. J. Clean. Prod. 2020, 277, 124186. [Google Scholar] [CrossRef]

- Pansare, R.; Yadav, G.; Nagare, M.R. Reconfigurable Manufacturing System: A Systematic Bibliometric Analysis and Future Research Agenda. J. Manuf. Technol. Manag. 2021, 33, 543–574. [Google Scholar] [CrossRef]

- Rousseau, D.M. Is There Such a Thing as “Evidence-Based Management”? Acad. Manag. Rev. 2006, 31, 256–269. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 3rd ed.; Sage: Thousand Oaks, CA, USA, 2003. [Google Scholar]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM Approach for the Barrier Analysis in Implementing Green Supply Chain Management. J. Clean. Prod. 2013, 47, 283–297. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Dubey, R.; Singh, S.P. Flexible Sustainable Supply Chain Network Design: Current Trends, Opportunities and Future. Glob. J. Flex. Syst. Manag. 2016, 17, 109–112. [Google Scholar] [CrossRef]

- World Commission on Environment and Development. Our Common Future; Oxford University Press: New York, NY, USA, 1987. [Google Scholar]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of the 21st Century; New Society Publishers: Stoney Creek, ON, Canada, 1998. [Google Scholar]

- Moldavska, A.; Welo, T. The Concept of Sustainable Manufacturing and Its Definitions: A Content-Analysis Based Literature Review. J. Clean. Prod. 2017, 166, 744–755. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of Sustainability in Supply Chain Management: A Literature Review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Zhou, B. Lean Principles, Practices, and Impacts: A Study on Small and Medium-Sized Enterprises (SMEs). Ann. Oper. Res. 2012, 241, 457–474. [Google Scholar] [CrossRef]

- Turner, T.J.; Bititci, U.S.; Nudurupati, S.S. Implementation and Impact of Performance Measures in Two SMEs in Central Scotland. Prod. Plan. Control 2005, 16, 135–151. [Google Scholar] [CrossRef]

- Harik, R.; EL Hachem, W.; Medini, K.; Bernard, A. Towards a Holistic Sustainability Index for Measuring Sustainability of Manufacturing Companies. Int. J. Prod. Res. 2015, 53, 4117–4139. [Google Scholar] [CrossRef]

- Amrina, E.; Vilsi, A.L. Key Performance Indicators for Sustainable Manufacturing Evaluation in Cement Industry. Procedia CIRP 2015, 26, 19–23. [Google Scholar] [CrossRef]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of Indicators for Sustainable Manufacturing. Ecol. Indic. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Trumpp, C.; Endrikat, J.; Zopf, C.; Guenther, E. Definition, Conceptualization, and Measurement of Corporate Environmental Performance: A Critical Examination of a Multidimensional Construct. J. Bus. Ethics 2013, 126, 185–204. [Google Scholar] [CrossRef]

- Wu, H.; Lv, K.; Liang, L.; Hu, H. Measuring Performance of Sustainable Manufacturing with Recyclable Wastes: A Case from China’s Iron and Steel Industry. Omega 2017, 66, 38–47. [Google Scholar] [CrossRef]

- Goyal, A.; Agrawal, R. Advanced Manufacturing Management System for Environmental Sustainability: A Review of Select Literature. Int. J. Glob. Bus. Compet. 2017, 12, 1–11. [Google Scholar] [CrossRef]

- Fonda, E.; Meneghetti, A. The Human-Centric SMED. Sustainability 2022, 14, 514. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R.; Garza-Reyes, J.A.; Antony, J. Green Lean Six Sigma Sustainability—Oriented Project Selection and Implementation Framework for Manufacturing Industry. Int. J. Lean Six Sigma, 2022; in press. [Google Scholar] [CrossRef]

- Momaya, K.S. Towards cooperation-based approaches to competitiveness: Exploring the role of EMNEs for sustainability. Int. J. Glob. Bus. Compet. 2015, 10, 3–8. [Google Scholar]

- Garza-Reyes, J.A. Lean and Green—A Systematic Review of the State of the Art Literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef]

- Rodriguez Delgadillo, R.; Medini, K.; Wuest, T. A DMAIC Framework to Improve Quality and Sustainability in Additive Manufacturing—A Case Study. Sustainability 2022, 14, 581. [Google Scholar] [CrossRef]

- Filho, M.G.; Uzsoy, R. The Impact of Simultaneous Continuous Improvement in Setup Time and Repair Time on Manufacturing Cycle Times under Uncertain Conditions. Int. J. Prod. Res. 2013, 51, 447–464. [Google Scholar] [CrossRef]

- Cigolini, R.; Grando, A. Modelling Capacity and Productivity of Multi-Machine Systems. Prod. Plan. Control 2009, 20, 30–39. [Google Scholar] [CrossRef]

- Asadi, N.; Jackson, M.; Fundin, A. Implications of Realizing Mix Flexibility in Assembly Systems for Product Modularity—A Case Study. J. Manuf. Syst. 2019, 52, 13–22. [Google Scholar] [CrossRef]

- Li, L. A Systematic-Theoretic Analysis of Data-Driven Throughput Bottleneck Detection of Production Systems. J. Manuf. Syst. 2018, 47, 43–52. [Google Scholar] [CrossRef]

- Babu, M.; Franciosa, P.; Ceglarek, D. Spatio-Temporal Adaptive Sampling for Effective Coverage Measurement Planning during Quality Inspection of Free Form Surfaces Using Robotic 3D Optical Scanner. J. Manuf. Syst. 2019, 53, 93–108. [Google Scholar] [CrossRef]

- Huang, Z.; Kim, J.; Sadri, A.; Dowey, S.; Dargusch, M.S. Industry 4.0: Development of a Multi-Agent System for Dynamic Value Stream Mapping in SMEs. J. Manuf. Syst. 2019, 52, 1–12. [Google Scholar] [CrossRef]

- Liker, J. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Womack, J.; Jones, D.; Roos, D. The Machine that Changed the World; Rawson Associates: New York, NY, USA, 1990. [Google Scholar]

- Bellisario, A.; Pavlov, A. Performance Management Practices in Lean Manufacturing Organizations: A Systematic Review of Research Evidence. Prod. Plan. Control 2018, 29, 367–385. [Google Scholar] [CrossRef]

- Johnson, M.S. The Application of Microwave Preheating in Resin Transfer Moulding. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 1995. [Google Scholar]

- Rother, M.; Shook, J. Learning to See: Value Steam Mapping to add and Eliminate Muda; The Lean Enterprise Institute: Boston, MA, USA, 1999. [Google Scholar]

- Yildirim, M.B.; Mouzon, G. Single-Machine Sustainable Production Planning to Minimize Total Energy Consumption and Total Completion Time Using a Multiple Objective Genetic Algorithm. IEEE Trans. Eng. Manag. 2012, 59, 585–597. [Google Scholar] [CrossRef]

- Yuan, C.; Zhai, Q.; Dornfeld, D. A Three Dimensional System Approach for Environmentally Sustainable Manufacturing. CIRP Ann. 2012, 61, 39–42. [Google Scholar] [CrossRef]

- Li, K.; Zhang, X.; Leung, J.Y.-T.; Yang, S.-L. Parallel Machine Scheduling Problems in Green Manufacturing Industry. J. Manuf. Syst. 2016, 38, 98–106. [Google Scholar] [CrossRef]

- Allwood, J.M.; Childs, T.H.C.; Clare, A.T.; De Silva, A.K.M.; Dhokia, V.; Hutchings, I.M.; Leach, R.K.; Leal-Ayala, D.R.; Lowth, S.; Majewski, C.E.; et al. Manufacturing at Double the Speed. J. Mater. Processing Technol. 2016, 229, 729–757. [Google Scholar] [CrossRef]

- Deif, A.M. A System Model for Green Manufacturing. J. Clean. Prod. 2011, 19, 1553–1559. [Google Scholar] [CrossRef]

- Koukoulaki, T. The Impact of Lean Production on Musculoskeletal and Psychosocial Risks: An Examination of Sociotechnical Trends over 20 Years. Appl. Ergon. 2014, 45, 198–212. [Google Scholar] [CrossRef] [PubMed]

- Bouville, G.; Alis, D. The Effects of Lean Organizational Practices on Employees’ Attitudes and Workers’ Health: Evidence from France. Int. J. Hum. Resour. Manag. 2014, 25, 3016–3037. [Google Scholar] [CrossRef]

- Parker, S.K. Longitudinal Effects of Lean Production on Employee Outcomes and the Mediating Role of Work Characteristics. J. Appl. Psychol. 2003, 88, 620–634. [Google Scholar] [CrossRef] [PubMed]

- Conti, R.; Angelis, J.; Cooper, C.; Faragher, B.; Gill, C. The Effects of Lean Production on Worker Job Stress. Int. J. Oper. Prod. Manag. 2006, 26, 1013–1038. [Google Scholar] [CrossRef]

- Thun, J.-H.; Lehr, C.B.; Bierwirth, M. Feel Free to Feel Comfortable—an Empirical Analysis of Ergonomics in the German Automotive Industry. Int. J. Prod. Econ. 2011, 133, 551–561. [Google Scholar] [CrossRef]

- Rathi, R.; Kaswan, M.S.; Garza-Reyes, J.A.; Antony, J.; Cross, J. Green Lean Six Sigma for Improving Manufacturing Sustainability: Framework Development and Validation. J. Clean. Prod. 2022, 345, 131130. [Google Scholar] [CrossRef]

- Davies, J.; Mabin, V.J.; Balderstone, S.J. The Theory of Constraints: A Methodology Apart?—A Comparison with Selected OR/MS Methodologies. Omega 2005, 33, 506–524. [Google Scholar] [CrossRef]

- Goldratt, E.M. Theory of Constraints; North River Press Inc.: Croton-on-Hudson, NY, USA, 1990. [Google Scholar]

- Despeisse, M.; Ball, P.D.; Evans, S.; Levers, A. Industrial Ecology at Factory Level—A Conceptual Model. J. Clean. Prod. 2012, 31, 30–39. [Google Scholar] [CrossRef]

- ElMaraghy, H.A.; Youssef, A.M.A.; Marzouk, A.M.; ElMaraghy, W.H. Energy Use Analysis and Local Benchmarking of Manufacturing Lines. J. Clean. Prod. 2017, 163, 36–48. [Google Scholar] [CrossRef]

- Rybski, C.; Jochem, R.; Homma, L. Empirical Study on Status of Preparation for ISO 9001:2015. Total Qual. Manag. Bus. Excell. 2017, 28, 1076–1089. [Google Scholar] [CrossRef]

- Goyal, A.; Agrawal, R.; Chokhani, R.K.; Saha, C. Waste Reduction through Kaizen Approach: A Case Study of a Company in India. Waste Manag. Res. 2018, 37, 102–107. [Google Scholar] [CrossRef] [PubMed]

- Hamdoun, M.; Chiappetta Jabbour, C.J.; Ben Othman, H. Knowledge Transfer and Organizational Innovation: Impacts of Quality and Environmental Management. J. Clean. Prod. 2018, 193, 759–770. [Google Scholar] [CrossRef]

- Yadav, G.; Kumar, A.; Luthra, S.; Garza-Reyes, J.A.; Kumar, V.; Batista, L. A Framework to Achieve Sustainability in Manufacturing Organisations of Developing Economies Using Industry 4.0 Technologies’ Enablers. Comput. Ind. 2020, 122, 103280. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Behdad, S.; Wang, B. The Evolution and Future of Manufacturing: A Review. J. Manuf. Syst. 2016, 39, 79–100. [Google Scholar] [CrossRef]

- Madan Shankar, K.; Kannan, D.; Udhaya Kumar, P. Analyzing Sustainable Manufacturing Practices—A Case Study in Indian Context. J. Clean. Prod. 2017, 164, 1332–1343. [Google Scholar] [CrossRef]

- Zhao, X.; Hou, J. Applying the Theory of Constraints Principles to Tourism Supply Chain Management. J. Hosp. Tour. Res. 2021, 46, 400–411. [Google Scholar] [CrossRef]

- Ekleş, E.; Ay Türkmen, M. Integrating the Theory of Constraints and Six Sigma: Process Improvement Implementation. Istanb. Bus. Res. 2022, 51, 123–147. [Google Scholar] [CrossRef]

- Suddaby, R. Editor’s Comments: Why Theory? Acad. Manag. Rev. 2014, 39, 407–411. [Google Scholar] [CrossRef]

- Rynes, S.L.; Bartunek, J.M.; Daft, R.L. Across the Great Divide: Knowledge Creation and Transfer between Practitioners and Academics. Acad. Manag. J. 2001, 44, 340–355. [Google Scholar] [CrossRef]

- Mackelprang, A.W.; Habermann, M.; Swink, M. How Firm Innovativeness and Unexpected Product Reliability Failures Affect Profitability. J. Oper. Manag. 2015, 38, 71–86. [Google Scholar] [CrossRef]

- Goyal, A.; Agrawal, R.; Saha, C.R. Quality Management for Sustainable Manufacturing: Moving from Number to Impact of Defects. J. Clean. Prod. 2019, 241, 118348. [Google Scholar] [CrossRef]

- Su, H.-C.; Linderman, K.; Schroeder, R.G.; Van de Ven, A.H. A Comparative Case Study of Sustaining Quality as a Competitive Advantage. J. Oper. Manag. 2014, 32, 429–445. [Google Scholar] [CrossRef]

- Bag, S.; Yadav, G.; Dhamija, P.; Kataria, K.K. Key Resources for Industry 4.0 Adoption and Its Effect on Sustainable Production and Circular Economy: An Empirical Study. J. Clean. Prod. 2021, 281, 125233. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R.; Reyes, J.A.G.; Antony, J. Exploration and Investigation of Green Lean Six Sigma Adoption Barriers for Manufacturing Sustainability. IEEE Trans. Eng. Manag. 2021, 1–15. [Google Scholar] [CrossRef]

- Alayón, C.; Säfsten, K.; Johansson, G. Conceptual Sustainable Production Principles in Practice: Do They Reflect What Companies Do? J. Clean. Prod. 2017, 141, 693–701. [Google Scholar] [CrossRef]

- Walmsley, T.G.; Ong, B.H.Y.; Klemeš, J.J.; Tan, R.R.; Varbanov, P.S. Circular Integration of Processes, Industries, and Economies. Renew. Sustain. Energy Rev. 2019, 107, 507–515. [Google Scholar] [CrossRef]

- Easton, G.S.; Rosenzweig, E.D. The Role of Experience in Six Sigma Project Success: An Empirical Analysis of Improvement Projects. J. Oper. Manag. 2012, 30, 481–493. [Google Scholar] [CrossRef]

- Mackelprang, A.W.; Nair, A. Relationship between Just-In-Time Manufacturing Practices and Performance: A Meta-Analytic Investigation. J. Oper. Manag. 2009, 28, 283–302. [Google Scholar] [CrossRef]

- Fullerton, R.R.; Kennedy, F.A.; Widener, S.K. Lean Manufacturing and Firm Performance: The Incremental Contribution of Lean Management Accounting Practices. J. Oper. Manag. 2014, 32, 414–428. [Google Scholar] [CrossRef]

- Fullerton, R.R.; McWatters, C.S. The Production Performance Benefits from JIT Implementation. J. Oper. Manag. 2000, 19, 81–96. [Google Scholar] [CrossRef]

- Alemam, A.; Li, S. Eco-Design Improvement for the Diaphragm Forming Process. Int. J. Sustain. Eng. 2016, 9, 401–410. [Google Scholar] [CrossRef]

- Dobrzykowski, D.D.; McFadden, K.L.; Vonderembse, M.A. Examining Pathways to Safety and Financial Performance in Hospitals: A Study of Lean in Professional Service Operations. J. Oper. Manag. 2016, 42–43, 39–51. [Google Scholar] [CrossRef]

- LaGanga, L.R. Lean Service Operations: Reflections and New Directions for Capacity Expansion in Outpatient Clinics. J. Oper. Manag. 2010, 29, 422–433. [Google Scholar] [CrossRef]

| S. No. | Goals |

|---|---|

| 1 | Reduction in raw material consumption |

| 2 | Use of non-hazardous material |

| 3 | Replacement of hazardous material with non-hazardous materials |

| 4 | Increased use of recycled materials |

| 5 | Reduction in waste generation |

| 6 | Increased recycling/treatment of waste |

| 7 | Reduction in hazardous waste |

| 8 | Reduction in energy consumption |

| 9 | Reduction in energy used per unit product |

| 10 | Increased use of renewable (solar, water power, and wind) energy |

| 11 | Reduction in greenhouse gas emissions |

| 12 | Less transportation of vehicles |

| 13 | Less emission of pollutants |

| 14 | Reduced water consumption |

| 15 | Increased use of recycled water |

| 16 | Reduction in discharge of waste water |

| 17 | Reduced numbers of environmental accidents and spills and resultant monetary fines |

| 18 | Reduced use of land |

| 19 | Use of green buildings |

| 20 | Rise in quality |

| 21 | Reduction in air emission |

| 22 | Reduced cost |

| 23 | Reduction in fuel consumption |

| 24 | Reduction in noise pollution |

| 25 | Conservation of natural habitat |

| S. No. | Authors | Description |

|---|---|---|

| 1 | Johnson M. S. [53] | Applied microwave preheating in resin transfer moulding to reduce the prolonged cycle time and achieved moderate cost in production without degrading the component quality. |

| 2 | Rother and Shook [54] Womack et al. [51] | Presented the concept of cycle time reduction as a tool for competitiveness. |

| 3 | Yildirim M. B. and Mouzon G. [55] | Developed a method by which total completion time is reduced along with minimising total energy consumption in production by a single machine. |

| 4 | Yuan C. et al. [56] | In a three-dimensional system approach for environmental sustainable manufacturing in Atomic Layer Deposition (ALD) technology, energy consumption is minimised through cycle time and process temperature. |

| 5 | Li K. et al. [57] | Scheduled the parallel machines to minimise total completion time subject to the constraints that total machine cost is not more than a given threshold under green manufacturing environment based on reducing consumption of energy and producing pollutants, hence reducing total cost. |

| 6 | Allwood J. M. et al. [58] | Explored the hypothetical question of doubling the speed of the manufacturing process. In exploration, constraints in material processing, system operation and co-ordination were discussed. |

| Instrument | Description |

|---|---|

| Organisation | Indian manufacturing company pioneered continuous improvement techniques in India. |

| Approval | Approval of management for improvement activity and, thereafter, its publication. |

| Objective | To improve the manufacturing process for reducing consumption of resources and yielding higher productivity with reduction in cycle time. |

| Unit of analysis | Economic, environmental, and social gains. |

| Time limit | Twelve months. |

| Sources of data and analysis | Existing information and results of trial. |

| Construct validity | Available recorded data and data from trials. |

| Internal validity | Solution development through ‘brainstorming’ method. |

| External validity | Robust testing and approval from field experts. |

| Key questions | What are the gains on the three dimensions of sustainability through cycle time reduction? |

| Activities at Location X | Resource | Ecological Footprint | |

|---|---|---|---|

| Consumption | Variation with Output | ||

| Heating of components | Electricity | Slight variation | Increase of carbon footprint |

| Use of vacuum pumps | Electricity and oil | Fixed | Increase of carbon footprint |

| Heating of impregnate | Water in cooling process | Fixed | Consumption of water |

| Electricity | Fixed | Increase of carbon footprint | |

| Deterioration of impregnate (aging effect) | Fixed | Hazardous waste generation | |

| Pressure through gas | Pressurised inert gas | Fixed | Emission of fumes in atmosphere |

| Generation of waste | Material | Fixed | Hazardous waste generation |

| S. No. | Metrics of Sustainable Manufacturing | Achieved in Outcome from Case Study |

|---|---|---|

| 1 | Reduction in raw material consumption | Yes |

| 2 | Reduction in waste generation | Yes |

| 3 | Reduction in hazardous waste | Yes |

| 4 | Reduction in energy consumption | Yes |

| 5 | Reduction in energy used per unit product | Yes |

| 6 | Reduction in greenhouse gas emissions | Yes |

| 7 | Less transportation of vehicles | Yes |

| 8 | Less emission of pollutants | Yes |

| 9 | Reduced water consumption | Yes |

| 10 | Reduction in discharge of waste water | Yes |

| 11 | Reduction in air emission | Yes |

| 12 | Reduced cost | Yes |

| 13 | Reduction in fuel consumption | Yes |

| 14 | Reduction in noise pollution | Yes |

| S. No. | Resource Savings | Economic Benefit | Impact on Environment | Social Impact |

|---|---|---|---|---|

| 1 | Energy | Yes | Reduced carbon footprint by 50% | ------- |

| 2 | Human resources in operation | Yes | ------ | More training and fatigue reduction |

| 3 | Material | Yes | Reduced hazardous waste | Reduces exposure of employees to the hazardous material |

| 4 | Pressurised inert gas | Yes | Reduced emission in air by 50% | Improves air quality |

| 5 | Water consumption | ------ | Reduced water footprint by 50% | Saves ground water for nearby community |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goyal, A.; Vaish, D.C.; Agrawal, R.; Choudhary, S.; Nayak, R. Sustainable Manufacturing through Systematic Reduction in Cycle Time. Sustainability 2022, 14, 16473. https://doi.org/10.3390/su142416473

Goyal A, Vaish DC, Agrawal R, Choudhary S, Nayak R. Sustainable Manufacturing through Systematic Reduction in Cycle Time. Sustainability. 2022; 14(24):16473. https://doi.org/10.3390/su142416473

Chicago/Turabian StyleGoyal, Ankur, Dinesh Chandra Vaish, Rajat Agrawal, Sonal Choudhary, and Rakesh Nayak. 2022. "Sustainable Manufacturing through Systematic Reduction in Cycle Time" Sustainability 14, no. 24: 16473. https://doi.org/10.3390/su142416473

APA StyleGoyal, A., Vaish, D. C., Agrawal, R., Choudhary, S., & Nayak, R. (2022). Sustainable Manufacturing through Systematic Reduction in Cycle Time. Sustainability, 14(24), 16473. https://doi.org/10.3390/su142416473