Challenges and Strategies for Bio-Based and Biodegradable Plastic Waste Management in Europe

Abstract

:1. Introduction

- -

- New legislation related to single-use plastic;

- -

- Societal pressure;

- -

- Depletion of non-renewable resources.

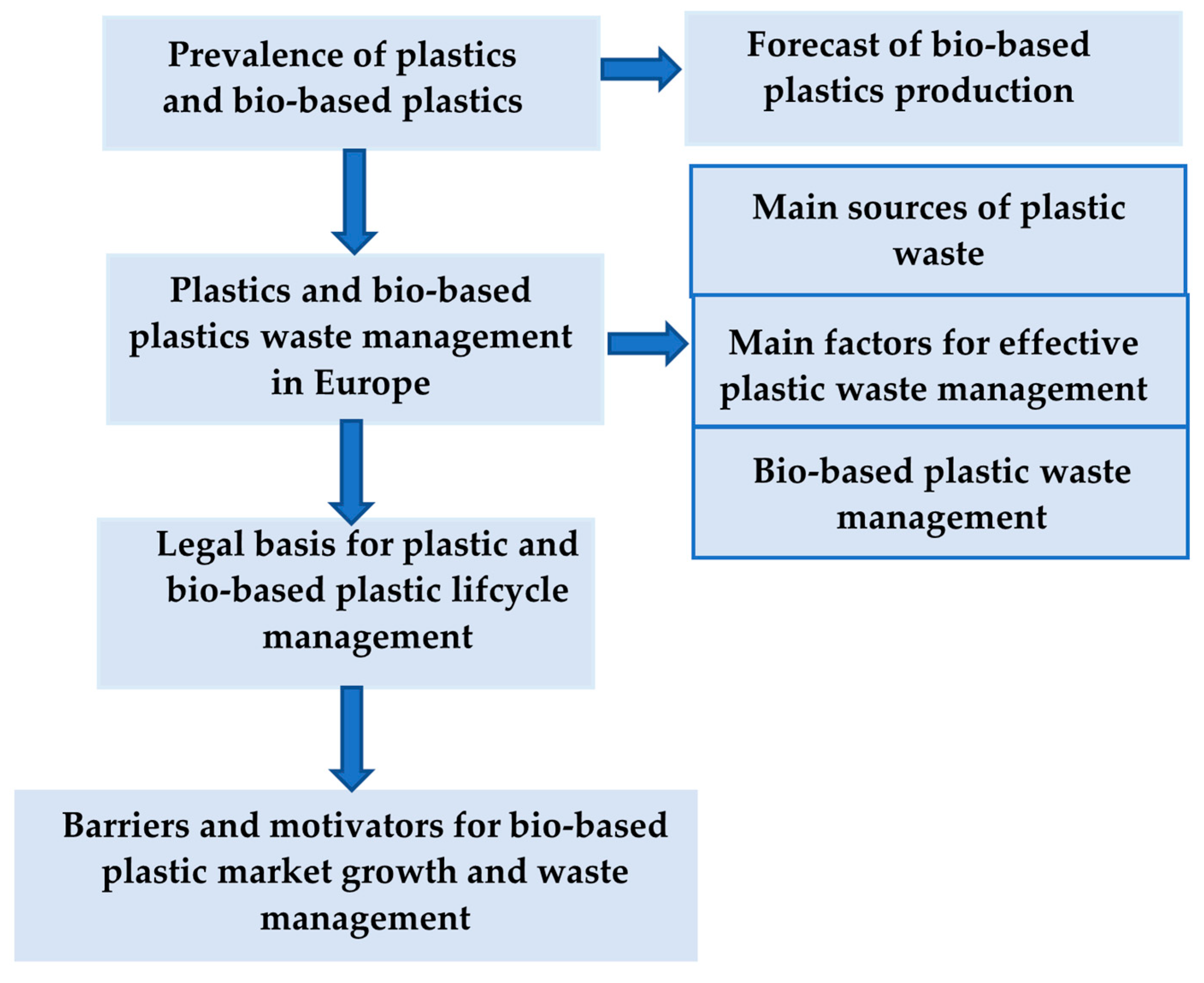

2. Methodological Approach

3. Prevalence of Plastics and Bio-Based Plastics

The Forecast of Bio-Based Plastics Production

4. Waste Management of Fossil-Based and Bio-Based Plastics in Europe

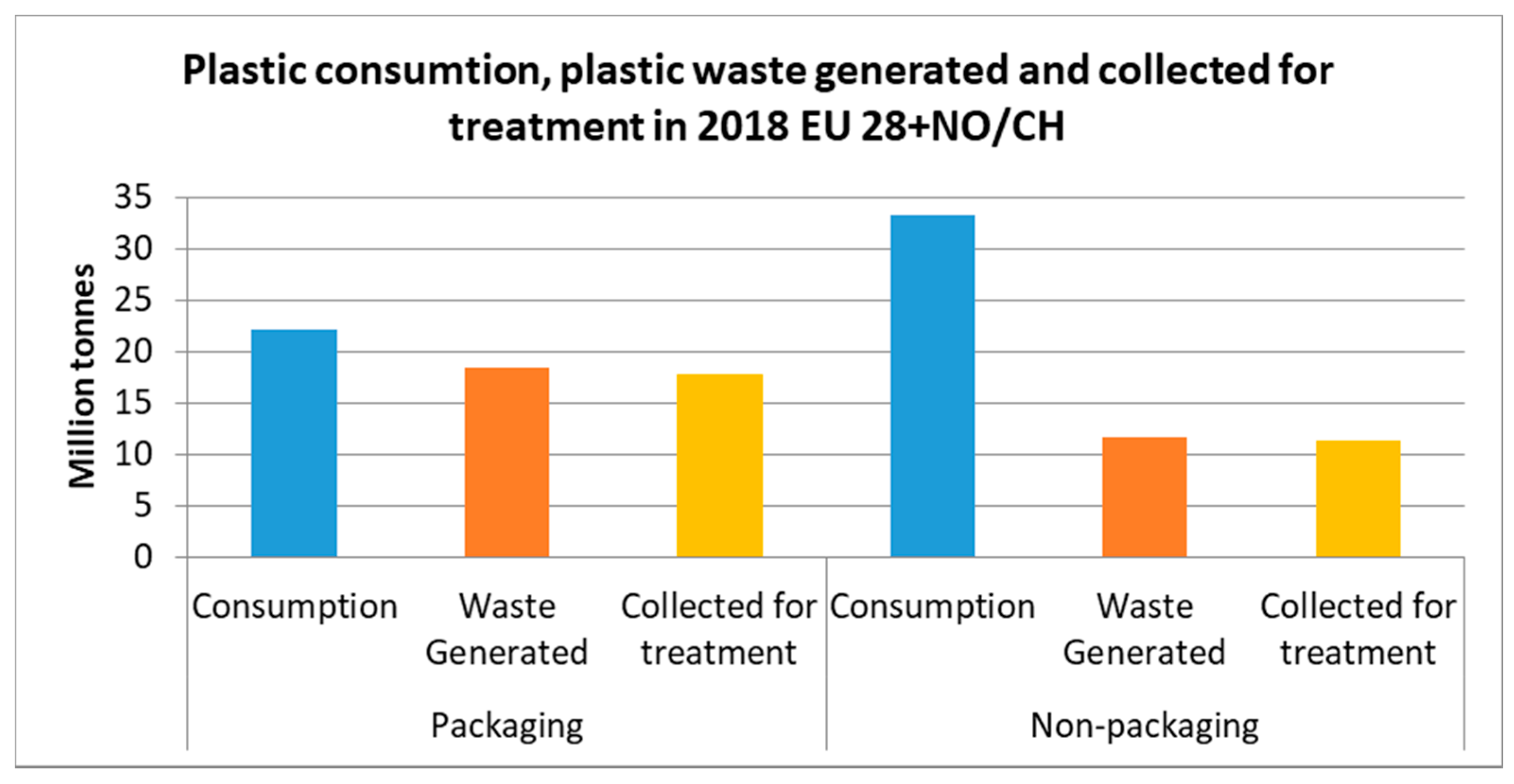

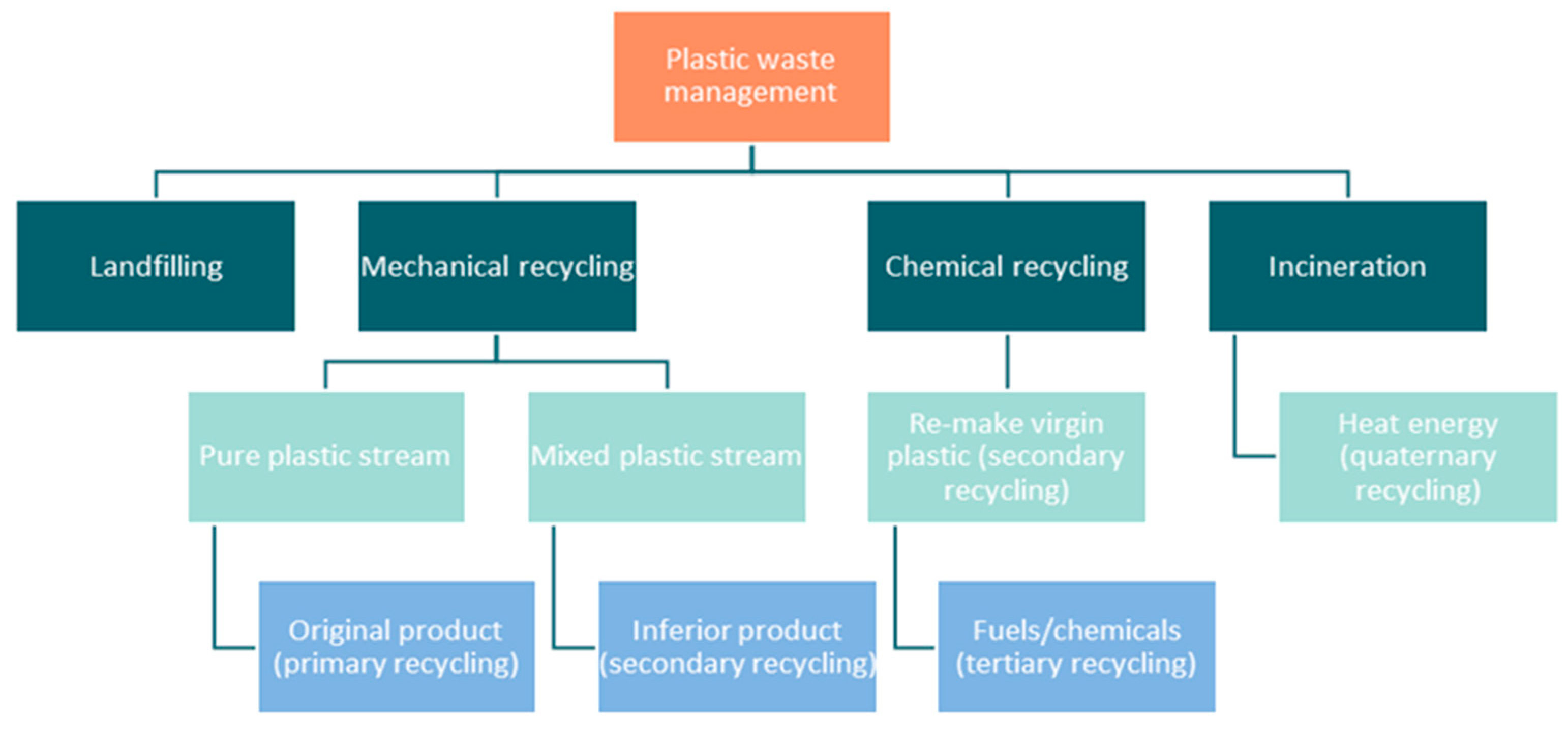

4.1. Plastic Waste Main Sources and Management

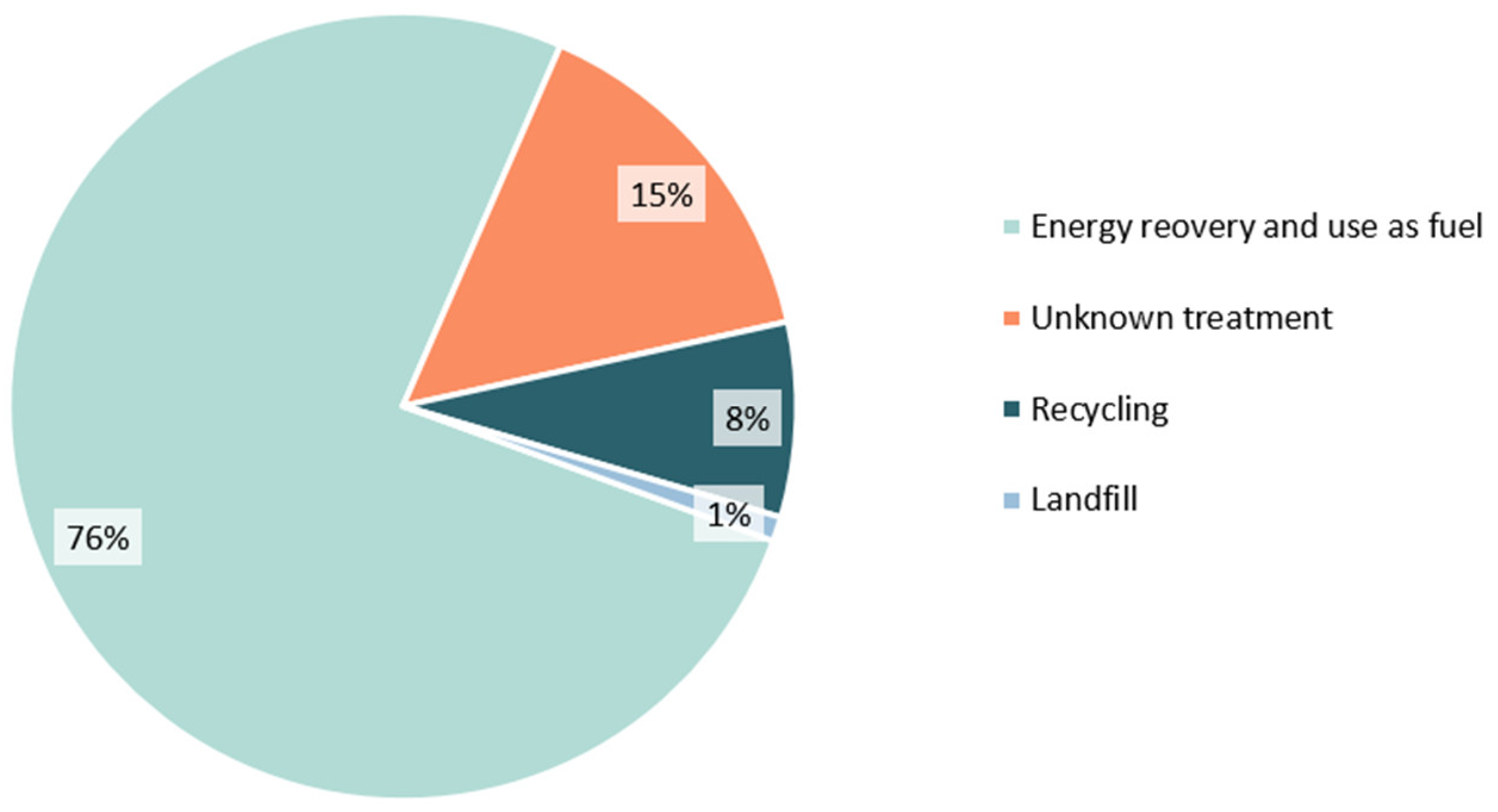

- Case Study: plastic waste treatment rates in Sweden

4.2. The Main Factors Influencing Effective Plastic Waste Management

- Collection and source separation

- Sorting of commingled fractions

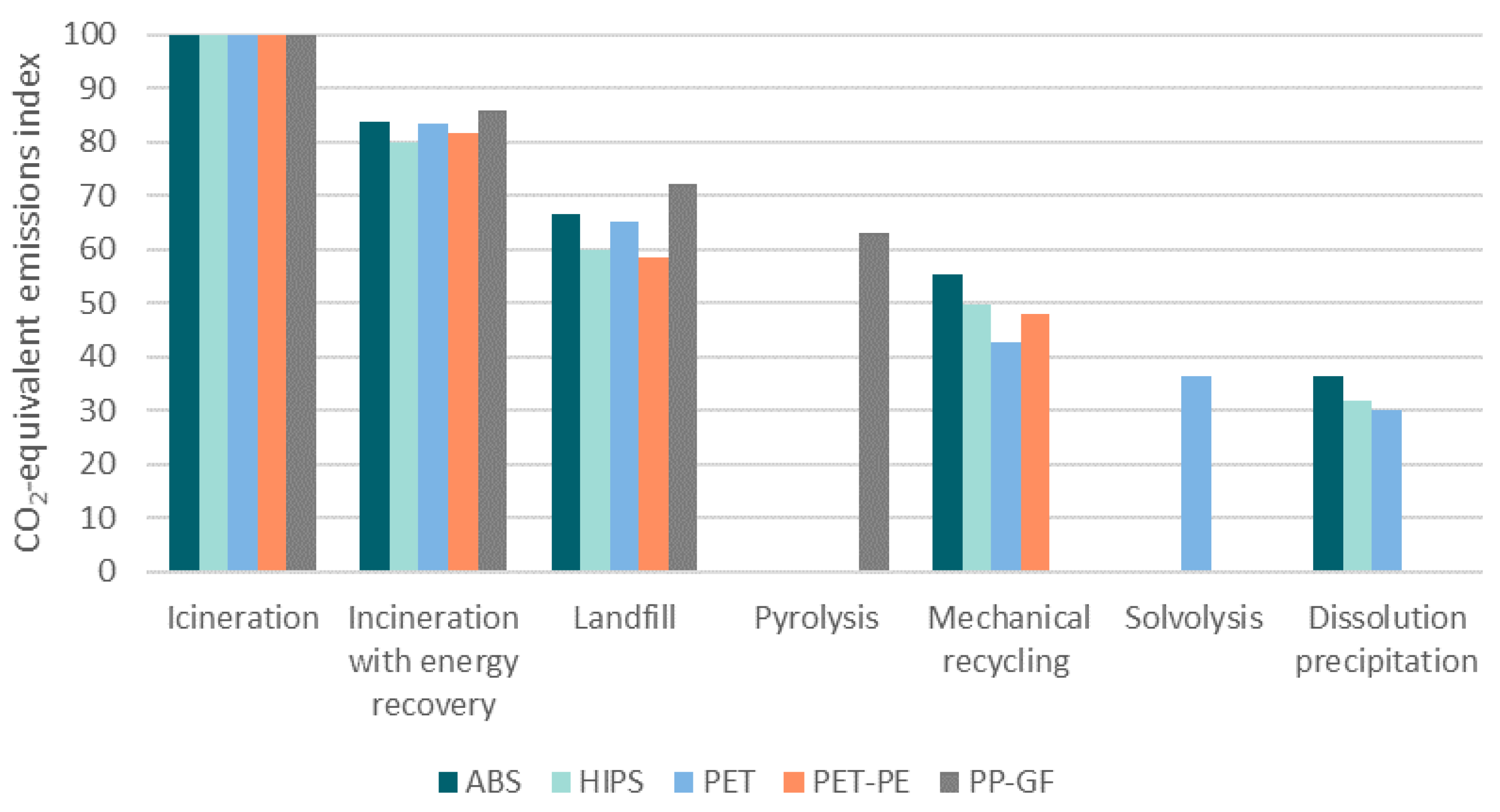

- Effective waste treatment systems

4.3. Bio-Based Plastics Waste Management

5. Policies, Legal Actions, and Regulations

6. Barriers and Motivators for Bio-Based and Biodegradable Plastics Market Growth and Effective Waste Management

- Bio-based and biodegradable plastics are important elements of bio-economy due to their potential to mitigate environmental impacts across the whole value chain, contributing to sustainability aspects through additional development of social and economic values.

- Similarly, the development of the bio-based and biodegradable products can be seen within the logical context of bio-economy strategy, considering the life cycle approach from biomass growth to the end-of life options;

- More joint efforts are needed to overcome existing barriers on regulatory, social, and economic level for more rapid growth of bio-based and biodegradable materials.

- Macroeconomic factors, such as crude oil prices, building on GDP, and feedstock costs;

- regulatory factors, such as taxes, subsidies, and bans;

- technological factors, such as scale effect, learning rates, and production costs;

- social factors, such as awareness, customer’s attitude, and switching intention.

7. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ryberg, M.W.; Laurent, A.; Hauschild, M. Mapping of Global Plastics Value Chain and Plastics Losses to the Environment. 2018. Available online: https://wedocs.unep.org/handle/20.500.11822/26745 (accessed on 15 June 2022).

- Plastics—The Facts 2019. An Analysis of European Plastics Production, Demand and Waste Data. 2019. Available online: https://plasticseurope.org/wp-content/uploads/2021/10/2019-Plastics-the-facts.pdf (accessed on 15 June 2022).

- Bianco, A.; Passanant, M. Atmospheric Micro and Nanoplastics: An Enormous Microscopic Problem. Sustainability 2020, 12, 7327. [Google Scholar] [CrossRef]

- European Academies’ Science Advisory Council (EASAC). Policy Report 39, Packaging Plastics in the Circular Economy. 2020. Available online: https://easac.eu/publications/details/packaging-plastics-in-the-circular-economy/ (accessed on 15 June 2022).

- International Energy Agency (IEA). The Future of Petrochemicals—Towards More Sustainable Plastics and Fertilisers. 2018. Available online: https://iea.blob.core.windows.net/assets/bee4ef3a-8876-4566-98cf-7a130c013805/The_Future_of_Petrochemicals.pdf (accessed on 15 June 2022).

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Cabernard, L.; Pfister, S.; Oberschelp, C.; Hellweg, S. Growing environmental footprint of plastics driven by coal combustion. Nat. Sustain. 2021, 5, 139–148. [Google Scholar] [CrossRef]

- Yusuf, A.A.; Ampah, J.D.; Soudagar, M.E.M.; Veza, I.; Kingsley, U.; Afrane, S.; Jin, C.; Liu, H.; Elfasakhany, A.; Buyondo, K.A. Effects of hybrid nanoparticle additives in n-butanol/waste plastic oil/diesel blends on combustion, particulate and gaseous emissions from diesel engine evaluated with entropy-weighted PROMETHEE II and TOPSIS: Environmental and health risks of plastic waste. Energy Convers. Manag. 2022, 264, 1–20. [Google Scholar] [CrossRef]

- Tekman, M.B.; Walther, B.A.; Peter, C.; Gutow, L.; Bergmann, M. Impacts of Plastic Pollution in the Oceans on Marine Species, Biodiversity and Ecosystems; Worldwide Fund for Nature: Gland, Switzerland, 2022. [Google Scholar]

- Jiang, B.; E Kauffman, A.; Li, L.; McFee, W.; Cai, B.; Weinstein, J.; Lead, J.R.; Chatterjee, S.; I Scott, G.; Xiao, S. Health impacts of environmental contamination of micro- and nanoplastics: A review. Environ. Health Prev. Med. 2020, 25, 29. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Andrady, A.; Geyer, R.; Narayan, R.; Perryman, M.; Siegler, T.; Wilcox, C.; Lavender Law, K. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Alessi, E.; Di Carlo, G. Out of the Plastic Trap Saving the Mediterranean from Plastic. Worldwide Fund for Nature Report. 2018. Available online: https://www.wwf.org.uk/sites/default/files/2018-06/WWF_Plastics_MED_WEB.pdf (accessed on 15 June 2022).

- Lindner, C.; Beylage, H. Global Plastics Flow 2018. Converstio Market & Strategy GmbH. 2020. Available online: https://www.carboliq.com/pdf/19_conversio_global_plastics_flow_2018_summary.pdf (accessed on 15 June 2022).

- Kamalakkannan, S.; Abeynayaka, A.; Kulatunga, A.K.; Singh, R.K.; Tatsuno, M.; Gamaralalage, P.J.D. Life Cycle Assessment of Selected Single-Use Plastic Products towards Evidence-Based Policy Recommendations in Sri Lanka. Sustainability 2022, 14, 14170. [Google Scholar] [CrossRef]

- Nova-Institute GmbH. The Global Bio-Based Polymer Market 2019—A Revised View. 2020. Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/20200127-The-global-bio-based-polymer-market-in-2019-A-revised-view.php (accessed on 15 June 2022).

- Zhang, F.; Zhao, Y.; Wang, D.; Yan, M.; Zhang, J.; Zhang, P.; Ding, T.; Chen, L.; Chen, C. Current technologies for plastic waste treatment: A review. J. Clean. Prod. 2021, 282, 124523. [Google Scholar] [CrossRef]

- Alassali, A.; Picuno, C.; Chong, Z.K.; Guo, J.; Maletz, R.; Kuchta, K. Towards Higher Quality of Recycled Plastics: Limitations from the Material’s Perspective. Sustainability 2021, 13, 13266. [Google Scholar] [CrossRef]

- Thiounn, T.; Smith, R.C. Advances and approaches for chemical recycling of plastic waste. J. Polym. Sci. 2020, 58, 1347–1364. [Google Scholar] [CrossRef]

- Lamberti, F.M.; Román-Ramírez, L.A.; Wood, J. Recycling of Bioplastics: Routes and Benefits. J. Polym. Environ. 2020, 28, 2551–2571. [Google Scholar] [CrossRef]

- Filho, W.L.; Barbir, J.; Abubakar, I.R.; Paço, A.; Stasiskiene, Z.; Hornbogen, M.; Fendt, M.T.C.; Voronova, V.; Klõga, M. Consumer attitudes and concerns with bioplastics use: An international study. PLoS ONE 2022, 17, e0266918. [Google Scholar] [CrossRef] [PubMed]

- Popa, C.L.; Dontu, S.I.; Savastru, D.; Carstea, E.M. Role of Citizen Scientists in Environmental Plastic Litter Research—A Systematic Review. Sustainability 2022, 14, 13265. [Google Scholar] [CrossRef]

- Horvat, D.; Wydra, S.; Lerch, C.M. Modelling and Simulating the Dynamics of the European Demand for Bio-Based Plastics. Int. J. Simul. Model. 2018, 17, 419–430. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Tang, J.; Yu, H.; Wang, Y.; Li, H.; Xu, S.; Li, G.; Zhou, Q. Microplastic Pollution in the Soil Environment: Characteristics, Influencing Factors, and Risks. Sustainability 2022, 14, 13405. [Google Scholar] [CrossRef]

- European Bioplastics. Bioplastics Facts and Figures. 2021. Available online: https://docs.european-bioplastics.org/publications/EUBP_Facts_and_figures.pdf (accessed on 15 June 2022).

- European Bioplastics. Available online: https://www.european-bioplastics.org/global-bioplastics-production-will-more-than-triple-within-the-next-five-years/ (accessed on 11 November 2022).

- European Bioplastics. Frequently Asked Questions on Bioplastics. 2022. Available online: https://docs.european-bioplastics.org/publications/EUBP_FAQ_on_bioplastics.pdf (accessed on 15 June 2022).

- Institute for Bioplastics and Biocomposites (IfBB). Biopolymers Facts and Statistics. 2021. Available online: https://www.ifbb-hannover.de/files/IfBB/downloads/faltblaetter_broschueren/f+s/Biopolymers-Facts-Statistics-einseitig-2021.pdf (accessed on 11 November 2022).

- Manjunatha, M.; Seth, D.; Balaji, K.V.G.D.; Bharath, A. Engineering properties and environmental impact assessment of green concrete prepared with PVC waste powder: A step towards sustainable approach. Case Stud. Constr. Mater. 2022, 17, e01404. [Google Scholar] [CrossRef]

- Carus, M.; Porc, O.; Chinthapalli, R. How Much Biomass Do Bio-Based Plastics Need? Bioplastic Magazine. 2020. Available online: https://renewable-carbon.eu/publications/product/how-much-biomass-do-bio-based-plastics-need-%E2%88%92-article-in-bioplastics-magazine/ (accessed on 15 June 2022).

- Rujnić-Sokele, M.; Pilipović, A. Challenges and Opportunities of Biodegradable Plastics: A Mini Review. Waste Manag. Res. 2017, 35, 132–140. [Google Scholar] [CrossRef]

- Garrido, R.; Cabeza, L.F.; Falguera, V. An Overview of Bioplastic Research on Its Relation to National Policies. Sustainability 2021, 13, 7848. [Google Scholar] [CrossRef]

- Bioplastics Boom: Global Production Will Triple in Five Years as Asia Dominates, Finds EUBP. Available online: https://www.packaginginsights.com/news/bioplastics-boom-global-production-will-triple-in-five-years-as-asia-dominates-finds-eubp.html. (accessed on 21 November 2022).

- Sidek, I.S.; Sarifah, F.S.D.; Siti Rozaimah, S.A.; Nornizar, A. Current Development on Bioplastics and Its Future Prospects: An Introductory Review. Technol. Mag. 2019, 1, 3–8. [Google Scholar] [CrossRef]

- Morales, M.E.; Lhuillery, S.; Ghobakhloo, M. Circularity Effect in the Viability of Bio-Based Industrial Symbiosis: Tackling extraordinary events in value chains. J. Clean. Prod. 2022, 348, 131387. [Google Scholar] [CrossRef]

- Döhler, N.; Wellenreuther, C.; Wolf, A. Market dynamics of biodegradable bio-based plastics: Projections and linkages to European policies. EFB Bioeconomy J. 2022, 2, 100028. [Google Scholar] [CrossRef]

- Horvat, D.; Wydra, S. System Dynamics Modelling of the European Demand for Biobased Plastics. An Analysis Ofects and Framework Conditions on Price Competitiveness and Market Growth. In Proceedings of the XVII International Scientific Conference on Industrial Systems (IS’17), Novi Sad, Serbia, 4–6 October 2017. [Google Scholar]

- Plastics—The Facts 2020. An Analysis of European Plastics Production, Demand and Waste Data. PlasticsEurope. 2020. Available online: https://plasticseurope.org/wp-content/uploads/2021/09/Plastics_the_facts-WEB-2020_versionJun21_final.pdf (accessed on 15 June 2022).

- Leal Filho, W.; Saari, U.; Fedoruk, M.; Iital, A.; Harri, M.; Klöga, M.; Voronova, V. An overview of the problems posed by plastic products and the role of extended producer responsibility in Europe. J. Clean. Prod. 2019, 214, 550–558. [Google Scholar] [CrossRef]

- Monier, V.; Hestin, M.; Cavé, J.; Laureysens, I.; Watkins, E.; Reisinger, H.; Porsch, L. Development of Guidance on Extended Producer Responsibility (EPR). Final Report. 2014. Available online: https://ec.europa.eu/environment/archives/waste/eu_guidance/pdf/Guidance%20on%20EPR%20-%20Final%20Report.pdf (accessed on 15 June 2022).

- Seyring, N.; Dollhofer, M.; Weißenbacher, J.; Herczeg, M.; McKinnon, D.; Bakas, I. Assessment of Separate Collection Schemes in the 28 Capitals of the EU. Final Report. Copenhagen Resource Institute (CRI); BiPRO GmbH. 2015. Available online: https://publications.europa.eu/resource/cellar/2c93de42-a2fa-11e5-b528-01aa75ed71a1.0001.01/DOC_1 (accessed on 15 June 2022).

- Picuno, C.; Alassali, A.; Chong, Z.K.; Kuchta, K. Flows of post-consumer plastic packaging in Germany: An MFA-aided case study. Resour. Conserv. Recycl. 2021, 169, 105515. [Google Scholar] [CrossRef]

- Van Eygen, E.; Laner, D.; Fellner, J. Circular economy of plastic packaging: Current practice and perspectives in Austria. Waste Manag. 2018, 72, 55–64. [Google Scholar] [CrossRef]

- Dahlbo, H.; Poliakova, V.; Mylläri, V.; Sahimaa, O.; Anderson, R. Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag. 2018, 71, 52–61. [Google Scholar] [CrossRef]

- Calabrese, A.; Costa, R.; Levialdi Ghiron, N.; Menichini, T.; Miscoli, V.; Tiburzi, L. Operating modes and cost burdens for the European deposit-refund systems: A systematic approach for their analysis and design. J. Clean. Prod. 2021, 288, 125600. [Google Scholar] [CrossRef]

- Zhou, G.; Gu, Y.; Wu, Y.; Gong, Y.; Mu, X.; Han, H.; Chang, T. A systematic review of the deposit-refund system for beverage packaging: Operating mode, key parameter and development trend. J. Clean. Prod. 2019, 251, 119660. [Google Scholar] [CrossRef]

- Glerean, P. Differences in Sorting and Recycling in Europe. Delara Burkhardt; German Environment Agency. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/421/dokumente/presentation_3._glerean_pre.pdf (accessed on 15 June 2022).

- Jansen, M.; van Thoden Velzen, U.; Pretz, T. Handbook for Sorting of Plastic Packaging Waste Concentrates. Wageningen UR Food & Biobased Research. 2015. Available online: https://research.wur.nl/en/publications/handbook-for-sorting-of-plastic-packaging-waste-concentrates-sepa (accessed on 15 June 2022).

- Institute Cyclos-HTP. Verification and Examination of Recyclability. Requirements and Assessment Catalogue of the Institute Cyclos-HTP for EU-Wide Certification. Institute Cyclos-HTP. 2021. Available online: https://www.cyclos-htp.de/publications/r-a-catalogue/#:~:text=Recycling%20is%20an%20important%20element,instrument%20of%20applied%20product%20responsibility (accessed on 15 June 2022).

- Picuno, C.; van Eygen, E.; Brouwer, M.T.; Kuchta, K.; van Thoden Velzen, E.U. Factors Shaping the Recycling Systems for Plastic Packaging Waste—A Comparison between Austria, Germany and The Netherlands. Sustainability 2021, 13, 6772. [Google Scholar] [CrossRef]

- Vollmer, I.; Jenks, M.J.F.; Roelands, M.C.P.; White, R.J.; Harmelen, T.; Wild, P.; Laan, G.P.; Meirer, F.; Keurentjes, J.T.F.; Weckhuysen, B.M. Beyond Mechanical Recycling: Giving New Life to Plastic Waste. Angew. Chem. Int. Ed. 2020, 59, 15402–15423. [Google Scholar] [CrossRef] [Green Version]

- Dilkes-Hoffman, L.S.; Pratt, S.; Lant, P.A.; Laycock, B. 19—The Role of Biodegradable Plastic in Solving Plastic Solid Waste Accumulation. In Plastics to Energy; William Andrew Publishing: Norwich, NY, USA, 2019. [Google Scholar] [CrossRef]

- Lange, J.-P. Managing Plastic Waste—Sorting, Recycling, Disposal, and Product Redesign. ACS Sustain. Chem. Eng. 2021, 9, 15722–15738. [Google Scholar] [CrossRef]

- Ljungkvist Nordin, H.; Westöö, A.-K.; Boberg, N.; Fråne, A.; Guban, P.; Sörme, L.; Ahlm, M. Mapping of Plastic Flows in Sweden (Kartläggning av Plastflöden i Sverige). SMED-Rapport nr 1. 2019. Available online: https://www.naturvardsverket.se/globalassets/media/publikationer-pdf/8800/978-91-620-8854-5.pdf. (accessed on 15 June 2022).

- Woodard, R.; Harder, M.K.; Bench, M. Participation in curbside recycling schemes and its variation with material types. Waste Manag. 2006, 26, 914–919. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martinho, G.; Gomes, A.; Santos, P.; Ramos, M.; Cardoso, J.; Silveira, A.; Pires, A. A case study of packaging waste collection systems in Portugal—Part I: Performance and operation analysis. Waste Manag. 2017, 61, 108–116. [Google Scholar] [CrossRef] [PubMed]

- Niaounakis, M. Recycling of biopolymers—The patent perspective. Eur. Polym. J. 2019, 114, 464–475. [Google Scholar] [CrossRef]

- Spierling, S.; Röttger, C.; Venkatachalam, V.; Mudersbach, M.; Herrmann, C.; Endres, H.-J. Bio-based Plastics—A Building Block for the Circular Economy? Procedia CIRP 2018, 69, 573–578. [Google Scholar] [CrossRef]

- Van den Oever, M.; Molenveld, K.; Van der Zee, M.; Bos, H. Bio-Based and Biodegradable Plastics—Facts and Figures. Focus on Food Packaging in The Netherlands. Wageningen Food & Biobased Research. 2017. Available online: https://www.wur.nl/upload_mm/1/e/7/01452551-06c5-4dc3-b278-173da53356bb_170421%20Report%20Bio-based%20Plastic%20Facts.pdf (accessed on 15 June 2022).

- Consorzio Italiano Compostatori. Paper and Bioplastics: Monitoring of Compost Friendly Materials. Carta e Bioplastiche: Il Monitoraggio dei Materiali Amici del Compost. Available online: http://www.compostabile.com/carta-e-bioplastiche-il-monitoraggio-dei-materiali-amici-del-compost/ (accessed on 15 June 2022).

- Italian Composting and Biogas Association. Annual Report on Biowaste Recycling. Italian Composting and Biogas Association. 2017. Available online: https://www.compost.it/wp-content/uploads/2019/08/Rapporto-CIC-2017-Eng-v-2.6-web-version.pdf (accessed on 15 June 2022).

- Umweltbundesamt. Bio-Based and Biodegradable Plastics. 2020. Available online: https://www.umweltbundesamt.de/biobasierte-biologisch-abbaubare-kunststoffe#haufig-gestellte-fragen-faq (accessed on 15 June 2022).

- UNEP. Plastics: Single-Use Plastics: A Roadmap for Sustainability. 2018. Available online: https://www.unep.org/resources/report/single-use-plastics-roadmap-sustainability (accessed on 15 June 2022).

- UNEP. Basel Convention on the Control of Transboundary Movement of Hazardous Wastes. 2011. Available online: https://wedocs.unep.org/20.500.11822/8385 (accessed on 15 June 2022).

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sustainabledevelopment.un.org/post2015/transformingourworld/publication (accessed on 15 June 2022).

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy. 2015. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52015DC0614 (accessed on 15 June 2022).

- European Commission. A New Circular Economy Action Plan. For a Cleaner and More Competitive Europe. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0098 (accessed on 15 June 2022).

- European Commission. Communication from the Commission. The European Green Deal. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640 (accessed on 15 June 2022).

- European Commission. Directive (EU) 2019/904 of the European Parliament and of the Council. On the Reduction of the Impact of Certain Plastic Products on the Environment. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1590979695787&uri=CELEX:32019L0904 (accessed on 15 June 2022).

- European Commission. Single-Use Plastics. 2021. Available online: https://environment.ec.europa.eu/topics/plastics/single-use-plastics_en (accessed on 28 November 2022).

- The EU in 2021. General Report on the Activities of the European Union. 2022. Available online: https://op.europa.eu/webpub/com/general-report-2021/en/ (accessed on 28 November 2022).

- European Commission. Policy Framework on Biobased, Biodegradable and Compostable Plastics. 2021. Available online: https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/13138-Policy-framework-on-biobased-biodegradable-and-compostable-plastics_en (accessed on 28 November 2022).

- OECD. Policies for Bioplastics in the Context of a Bioeconomy; OECD Science, Technology and Industry Policy Papers, No. 10; OECD Publishing: Paris, France, 2013; Available online: https://www.oecd-ilibrary.org/science-and-technology/policies-for-bioplastics-in-the-context-of-a-bioeconomy_5k3xpf9rrw6d-en (accessed on 28 November 2022).

- European Commission. Regulation (EC) No 66/2010 of the European Parliament and of the Council on the EU Ecolabel. 2009. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02010R0066-20171114&qid=1590991576604&from=EN (accessed on 15 June 2022).

- ISO 14024; Environmental Labels and Declarations—Type I Environmental Labelling—Principles and Procedures. European Union: Brussels, Belgium, 2018. Available online: https://www.iso.org/standard/72458.html (accessed on 15 June 2022).

- Senthilkumaran, A.; Babaei-Ghazvini, A.; Nickerson, M.T.; Acharya, B. Comparison of Protein Content, Availability, and Different Properties of Plant Protein Sources with Their Application in Packaging. Polymers 2022, 14, 1065. [Google Scholar] [CrossRef]

- Mülhaupt, R. Green Polymer Chemistry and Bio-based Plastics: Dreams and Reality. Macromol. Chem. Phys. 2013, 214, 159–174. [Google Scholar] [CrossRef]

- Cucina, M.; de Nisi, P.; Tambone, F.; Adani, G. The role of waste management in reducing bioplastics’ leakage into the environment: A review. Bioresour. Technol. 2021, 337, 125459. [Google Scholar] [CrossRef] [PubMed]

- Taufik, D.; Reinders, M.J.; Molenveld, K.; Onwezen, M.C. The paradox between the environmental appeal of bio-based plastic packaging for consumers and their disposal behavior. Sci. Total Environ. 2019, 705, 135820. [Google Scholar] [CrossRef]

- Magnier, L.; Crié, D. Communicating packaging eco-friendliness: An exploration of consumers’ perceptions of eco-designed packaging. Int. J. Retail. Distrib. Manag. 2015, 43, 350–366. [Google Scholar] [CrossRef]

- Sijtsema, S.J.; Onwezen, M.C.; Reinders, M.J.; Dagevos, H.; Partanen, A.; Meeusen, M. Consumer perception of bio-based products—An exploratory study in 5 European countries. NJAS -Wagening. J. Life Sci. 2016, 77, 61–69. [Google Scholar] [CrossRef]

- Fredi, G.; Dorigato, A. A Recycling of bioplastic waste: A review. Adv. Ind. Eng. Polym. Res. 2021, 4, 159–177. [Google Scholar] [CrossRef]

- Piemonte, V.; Sabatini, S.; Gironi, F. Chemical recycling of PLA: A great opportunity towards the sustainable development? J. Polym. Environ. 2013, 21, 640–647. [Google Scholar] [CrossRef]

- Rivas, L.F.; Casarin, S.A.; Nepomuceno, N.C.; Alencar, M.I.; Agnelli, J.A.M.; De Medeiros, E.S.; Neto, A.D.O.W.; Oliveira, M.; De Medeiros, A.M.; E Santos, A.S.F. Reprocessability of PHB in extrusion: ATR-FTIR, tensile tests and thermal studies. Polímeros 2017, 27, 122–128. [Google Scholar] [CrossRef]

| Factor | Barriers | Motivators |

|---|---|---|

| Economic |

|

|

| Regulatory |

|

|

| Technological |

|

|

| Social |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stasiškienė, Ž.; Barbir, J.; Draudvilienė, L.; Chong, Z.K.; Kuchta, K.; Voronova, V.; Leal Filho, W. Challenges and Strategies for Bio-Based and Biodegradable Plastic Waste Management in Europe. Sustainability 2022, 14, 16476. https://doi.org/10.3390/su142416476

Stasiškienė Ž, Barbir J, Draudvilienė L, Chong ZK, Kuchta K, Voronova V, Leal Filho W. Challenges and Strategies for Bio-Based and Biodegradable Plastic Waste Management in Europe. Sustainability. 2022; 14(24):16476. https://doi.org/10.3390/su142416476

Chicago/Turabian StyleStasiškienė, Žaneta, Jelena Barbir, Lina Draudvilienė, Zhi Kai Chong, Kerstin Kuchta, Viktoria Voronova, and Walter Leal Filho. 2022. "Challenges and Strategies for Bio-Based and Biodegradable Plastic Waste Management in Europe" Sustainability 14, no. 24: 16476. https://doi.org/10.3390/su142416476