1. Introduction

In 2018, China revised relevant laws [

1], incorporating energy conservation into legal provisions to supply relevant fields and strictly restrict energy use. Industry and buildings consume most of the energy. In particular, buildings consume a large amount of power and emit approximately 30% of greenhouse gas ions [

2]. Through the “China Building Energy Consumption and Carbon Emission Research in 2021”, which was published online by the China Building Energy Efficiency Association and Chongqing University [

3], it is shown that the energy consumption of buildings in the operation stage is 1.03 × 10

9 tons of standard coal equivalent (TCE), and approximately one-fifth of the total energy consumption in China. With the development of building energy conservation, the concepts of energy conservation, green, zero energy consumption, and sustainable buildings have attracted more and more attention. In the evaluation standard for energy-saving buildings, GB/T 50668-2011, energy-saving buildings refer to the buildings designed and constructed in accordance with the local geographical environment and basic methods of energy conservation that meet or are better than the relevant national standards for energy conservation [

4]. However, China’s energy conservation work is mainly concentrated in cities, and the progress of building energy conservation in rural areas is slower [

5]. As time goes by, the performance of buildings’ envelope components declines due to environmental conditions, and it becomes urgent to transform or replace new envelope components to keep the building’s energy consumption within a reasonable range [

6,

7,

8,

9].

As typical public buildings in rural areas, township health centers generally have problems with long operation periods and high building energy consumption. The hospital has to pay excess energy consumption expenses instead of investing in medical treatment. Therefore, energy-saving measures are urgently needed. Building energy-saving measures mainly focus on envelope design, the layout of plane and space, orientation, and types of insulation materials [

10,

11,

12]. Dominguez et al. [

13] evaluated the potential of improving the envelope’s thermal performance to affect the energy demand of residential buildings. Astor et al. [

14] believe that the primary way to reduce building energy consumption is to control and improve the thermal physical characteristics of the building envelope. Feng [

15] studied the influence mode and effect of the heat transfer coefficient and building envelope thermal inertia index on building energy consumption. Yang et al. [

16] found that under the condition of constant heat transfer coefficient, the increase in the heat storage coefficient would reduce the cooling load and increase the heat load of the building. Computer simulation technology, such as EnergyPlus, DOE2, EQuest, TRNSYS, and other energy simulation software and methods, have been developed and can determine the renovation methods and their effects on buildings. Some studies introduced the differences and characteristics of different simulation tools [

17,

18]. EnergyPlus is based on the heat balance method to calculate indoor air temperature and indoor load, where the heat transfer calculation of the envelope adopts the unsteady heat transfer method to calculate the building load more accurately. Hay Hau et al. [

19] conducted a simulation study on the energy use of a single building, and the results showed that the heat transfer between the roof and the exterior wall is a leading cause of building load.

With the development of energy conservation research, the goal is to meet energy conservation standards and pay attention to the cost of energy conservation projects. Since the European Union put forward the concept of “cost optimization” in the building energy efficiency directive issued in 2010, scholars in most EU member states have combined energy-saving projects with the economy [

20]. Chidiak et al. [

21] used the discounted payback period to evaluate the profitability of energy efficiency measures. Kumbaroglu and Madlener [

22] used a new NPV calculation method to assess the highest economic benefits of energy-saving renovation measures. Teng Shao and Wuxing Zheng [

23] used Energy Plus and MOBO optimization engines to explore the influence of various factors on building energy consumption. Xinyi Hu and Hong Zhang [

24] established a framework of active and passive energy-saving technologies to select the best economic transformation strategy for existing rural buildings. Kaynak [

25] proposed to optimize the thickness of the insulation layer of the exterior wall, considering the costs and the payback period of the optimal insulation layer thickness. In reality, it is not easy to rely on a measure or technology to reduce building energy consumption effectively.

In this paper, a health center in the cold area of Linyi, Shandong Province, is taken as the research object. Energy-saving schemes are explored in the following steps: (1) assess the influence of renovation of the envelope structure on building energy consumption; (2) analyze the energy-saving effect of single and multiple renovations of external walls, roofs, and windows; and (3) select the best overall renovation program through economic analysis.

2. Research Area

2.1. Field Investigation and Model Selection

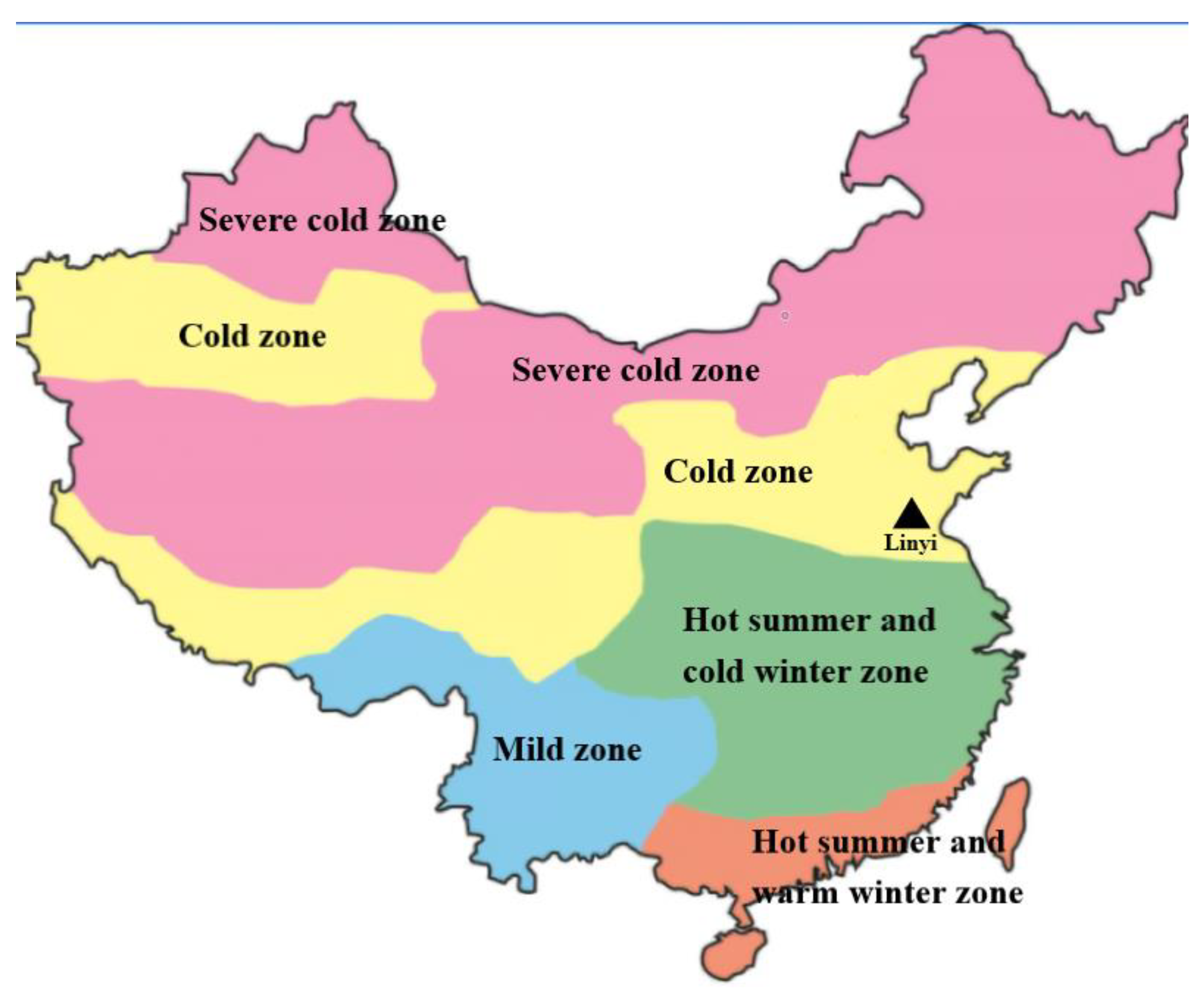

As shown in

Figure 1, this survey is located in Linyi City in the southwest of Shandong Province, which is in a cold climate zone with short spring and autumn seasons and long winter and summer seasons; the average annual temperature is 14 °C, the average daily temperature is 27.1 °C in summer and 3.7 °C in winter, and the average monthly temperature and humidity of Linyi City are shown in

Figure 2.

The field survey of many township hospitals in Linyi city shows that most hospitals were built before this century, with the earliest one being built in the late 1970s. Most buildings are brick and concrete structures with three or four floors. The envelope’s thermal performance is poor, and there are generally no insulation measures for the exterior walls and roofs. After entering the twenty-first century, the vast majority of hospitals only repainted the external walls and replaced parts of the external windows and doors without any substantial energy-saving measures.

2.2. Model Selection

As shown in

Figure 3, the selected building is a three-story brick and concrete structure built in the 1980s. This building is the outpatient building of a hospital.

Figure 4 shows the three-floor plan of the building. The first floor and the second floor are designed to provide medical services, and the third floor is the office area. According to the hospital construction drawings, the external wall of the outpatient building is composed of sintered porous shale brick, while the floor and roof are mainly composed of precast concrete panels; they both do not have insulation measures. The exterior window has an aluminum frame and a single glass exterior window.

Table 1 shows the composition of the building envelope.

According to the environmental protection policy requirements, the hospital is not allowed to use coal-fired boilers for winter heating any more, and has therefore adopted split air conditioning for cooling in summer and heating in winter. According to the questionnaire given to hospital staff, a few rooms on the first floor are round-the-clock shops, while the rest are closed on national holidays.

Table 2 shows the working hours and baseline temperatures of most rooms in the hospital on weekdays. Except for the energy consumption caused by heating and refrigeration, other energy consumption, such as lighting and medical equipment energy consumption, are not within the scope of this study.

2.3. Model Establishment and Validation

As shown in

Figure 5, SketchUp is used to establish a model of the outpatient building of a township hospital. Field survey data provide the parameters for the model. Thermal properties are assigned through Open Studio, and thermal performance parameters are entered in EnergyPlus based on the actual practice of the building envelope.

To verify the accuracy of the model and minimize the thermal disturbance of personnel, lighting, and equipment, the unused room on the third floor was selected for the thermal environment test (the room marked in red in

Figure 4 is the test room, and

Figure 6 is the actual photo of the test room), while the influence of indoor thermal disturbance was not considered in the simulation. The test was divided into outdoor and indoor parts, and the test parameters are indoor and outdoor air-dry bulb temperatures and relative humidity. The test was conducted from 13 February to 27 February 2022, with a frequency of one hour. The test instrument was the temperature and humidity recorder.

Table 3 shows the information on the test instrument.

During the simulation, the outdoor meteorological data, such as dry bulb temperature and relative humidity, replaced the corresponding data in the original meteorological files. Based on the multiple influences of air temperature on buildings, the simulated indoor temperature from 20 February to 27 February was selected to compare with the measured indoor temperature in the same period.

Figure 7 shows a comparison between the simulated and the measured indoor air temperatures. The simulated indoor air temperature in the room is consistent with the measured value, which is higher than the simulated value. The difference between the measured and the simulated temperatures is significant in the daytime. Since the selected test room was located in the office area, it was impossible to avoid the thermal disturbance of other rooms and personnel actions in the test room.

The method to verify the accuracy of the model refers to the two evaluation indexes in the ASHRAE Guideline 14-2014 25: the standard mean deviation (NMBE) and the coefficient of variation of root mean square error (CVRMSE). NMBE is less than 10% and CVRMSE is less than 15%, indicating that the established model is consistent with the actual construction.

The calculation formula is as follows:

where

represent the actual temperature, the simulation temperature, and the average actual temperature, respectively.

By putting the obtained temperature data into the formula, the calculated results of NMBE and CVRMSE were 9.9% and 11.1%, respectively, which were within the range required by the ASHRAE14-2014 specification; so it can be shown that the established model is consistent with the actual building.

5. Conclusions

Currently, public buildings in rural areas in China have long construction times, serious aging of envelope structures, and high building energy consumption, which curb the development of rural areas and environmental protection. The effective way to solve the problem is to formulate the appropriate building energy-saving scheme through building energy consumption simulations. Taking a village health center in Linyi city as an example, this paper carried out the optimization simulation of single and multiple parts of the envelope structure and determined the energy-saving renovation scheme. According to the research results, the following conclusions can be drawn:

1. For the transformation of the nontransparent envelope structure, the better the thermal performance of the insulation material, the more significant the energy-saving effect; the building energy consumption decreases with the increase in the thickness of the insulation material, but the reduction trend of the building energy consumption will be smaller and smaller. In terms of the influence of a nontransparent envelope on building energy consumption, using materials with the same type and thickness, the energy-saving benefit of a single roof renovation is better than that of a single renovation of the exterior wall. The energy-saving efficiency of the north wall is better than that of the side wall, and the energy-saving efficiency of the south wall is the worst.

2. For the transformation of the transparent envelope, the influence of the nontransparent envelope on building energy consumption is shown in two aspects: First, the heat transfer coefficient of the outer window, where the smaller the heat transfer coefficient, the better the energy-saving effect. The second is the solar heat gain coefficient of the outer window, where the solar heat gain will increase the cooling load in the summer and reduce the heating load in the winter. In the case of poor thermal performance of nontransparent envelopes, using the exterior window of the thermal reflection class will increase the energy consumption of the building.

3. For the renovation of each orientation envelope structure, in the case of single orientation renovation with the same measures, the energy-saving effect of the renovation of the north orientation envelope structure is better than that of the south orientation envelope structure; the south-facing envelope is suitable for the use of low light transmittance type of external windows.

4. The overall building envelope transformation can effectively reduce the building’s energy consumption, and the energy consumption of the renovated buildings is between 3.48 and 17.75, and the initial investment in the case is between 50,000 and 375,000. To select the plan for the more worthwhile investment, the case with a recovery period of between 2.04 and 5.5 years is calculated and determined: the initial investment recovery period of Plan 2 is the shortest; Plan 5 has the highest energy efficiency (91.11%).