A Review of Green Supplier Evaluation and Selection Issues Using MCDM, MP and AI Models

Abstract

1. Introduction

2. Research Method

2.1. Research Questions

- RQ1: What are the relevant literature reviews that worked on the DM models to solve the issues of assessment and choice of green supplier between 1990 and 2020?

- RQ2: What are the most often utilized DM models in the literature to address the problems for evaluation and selection the green supplier?

2.2. Research Process of the Systematic Literature Review

2.2.1. First Stage: Database Keyword Search

2.2.2. Second Stage: Title and Abstract Filtering

2.2.3. Third Stage: Full Text Filtering

2.2.4. Fourth Stage: Maintained Papers

3. Background

3.1. Supplier Relationship Management (SRM)

3.1.1. Generality of SRM

3.1.2. The Issues Related to SRM

Supplier Selection and Evaluation

- Determination of the criteria to be used in the evaluation of Suppliers.

- The use of vendor evaluation methodologies in the decision-making process to ensure proper vendor selection.

Other Issues

- Shaping purchasing strategies

- Collaboration

- Supplier management

- Integrated approaches

3.2. Green Supplier Relationship Management (GSRM)

3.3. Generality of DM

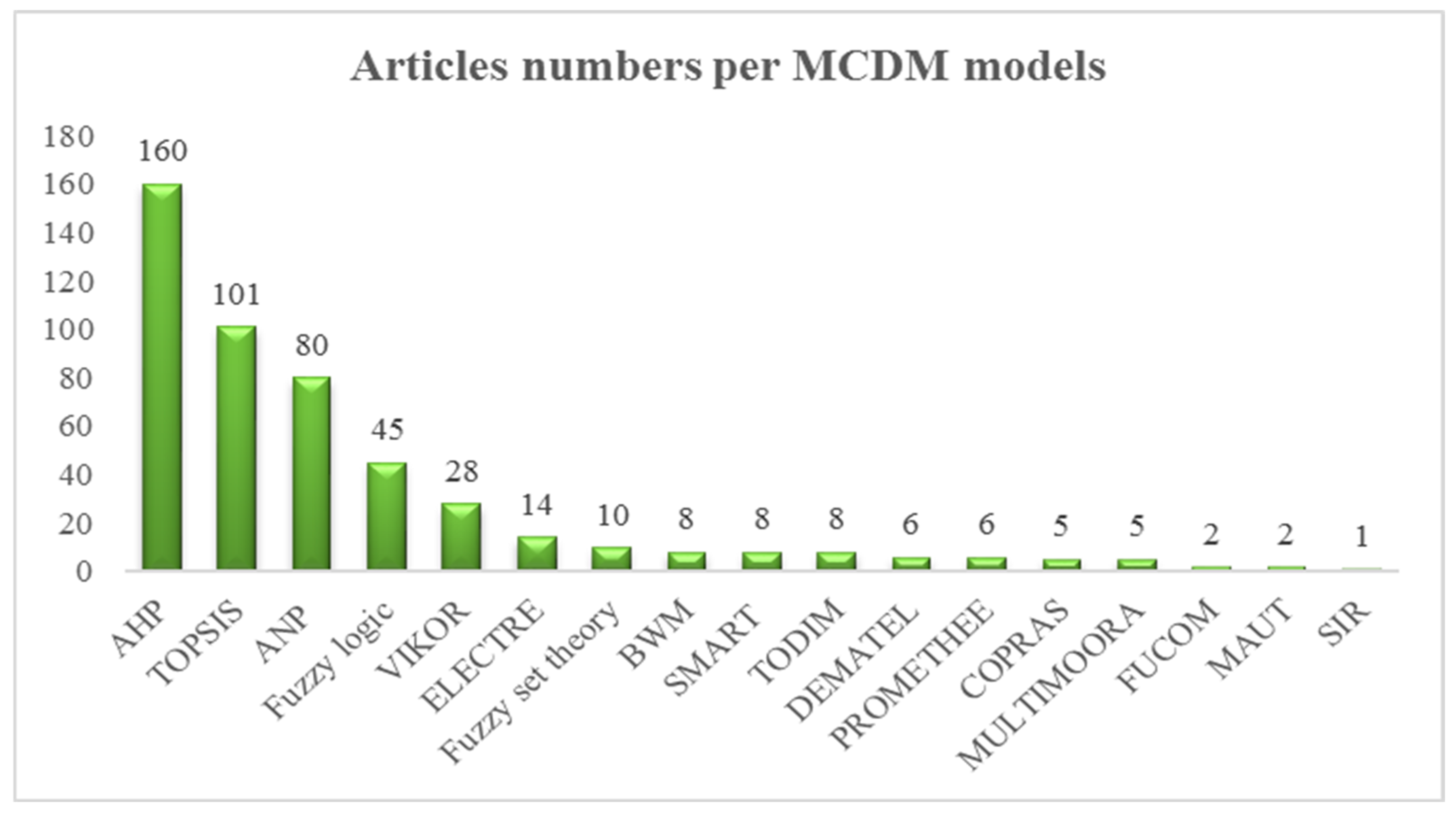

3.3.1. MCDM Models

Analytic Hierarchy Process (AHP)

Technique for Order Performance by Similarity to Ideal Solution (TOPSIS)

Analytic Network Process (ANP)

Fuzzy Logic

Elimination and Choice Expressing Reality (ELECTRE)

Multicriteria Optimization and Compromise Solution (VIKOR)

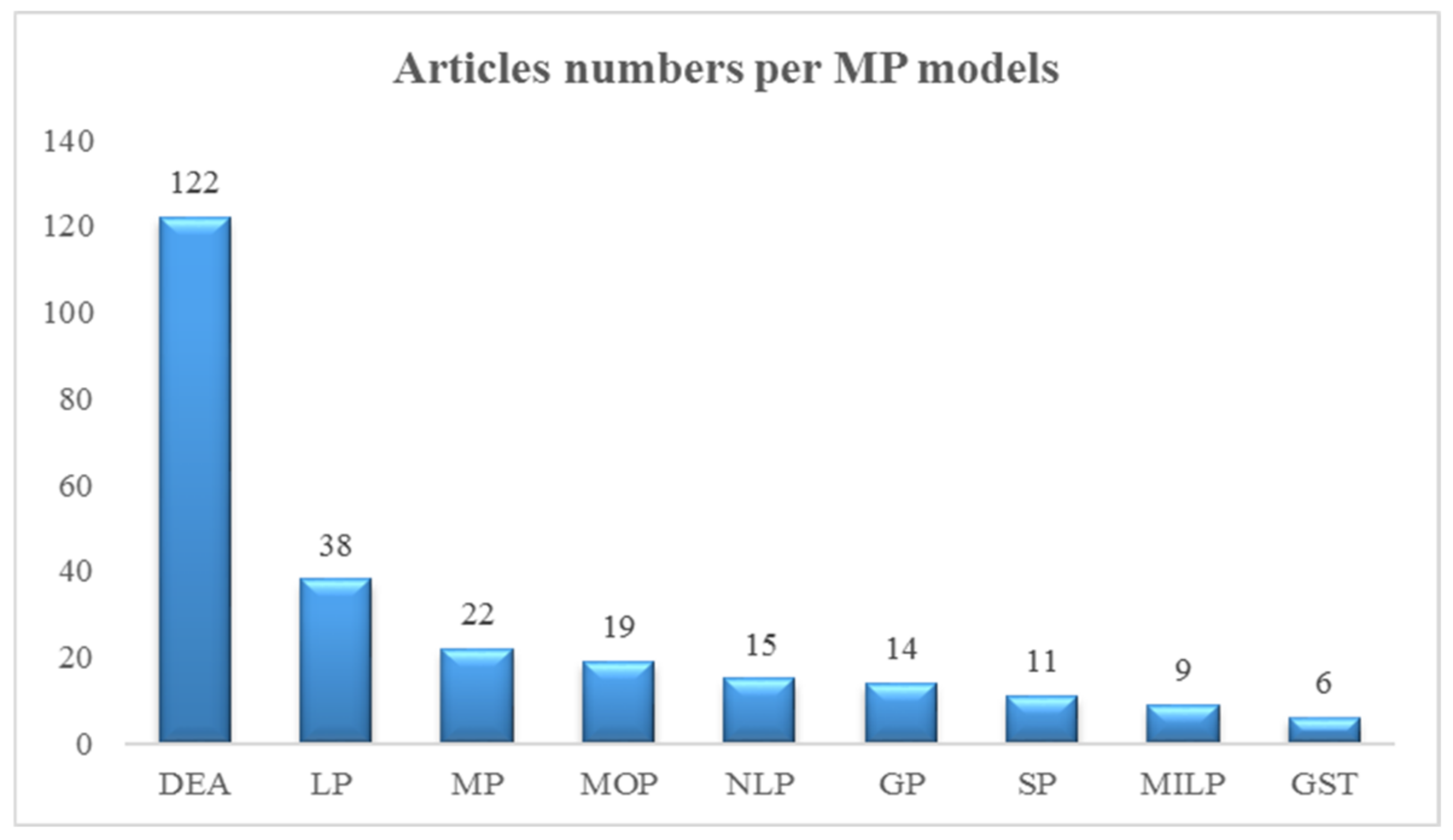

3.3.2. MP Models

Data Envelopment Analysis (DEA)

Linear Programming (LP)

Multiobjective Programming (MOP)

3.3.3. AI Models

Genetic Algorithm (GA)

Grey System Theory (GST)

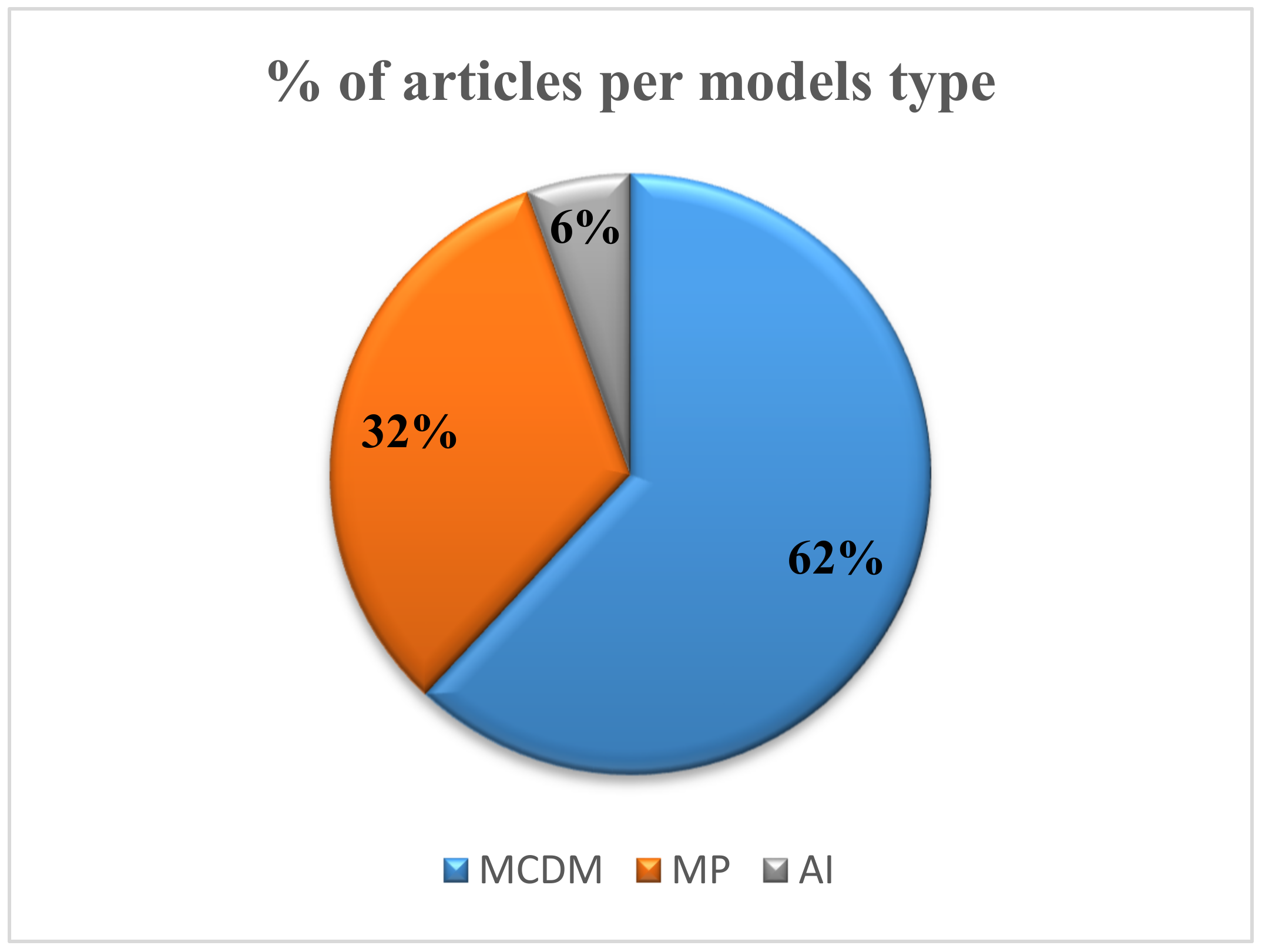

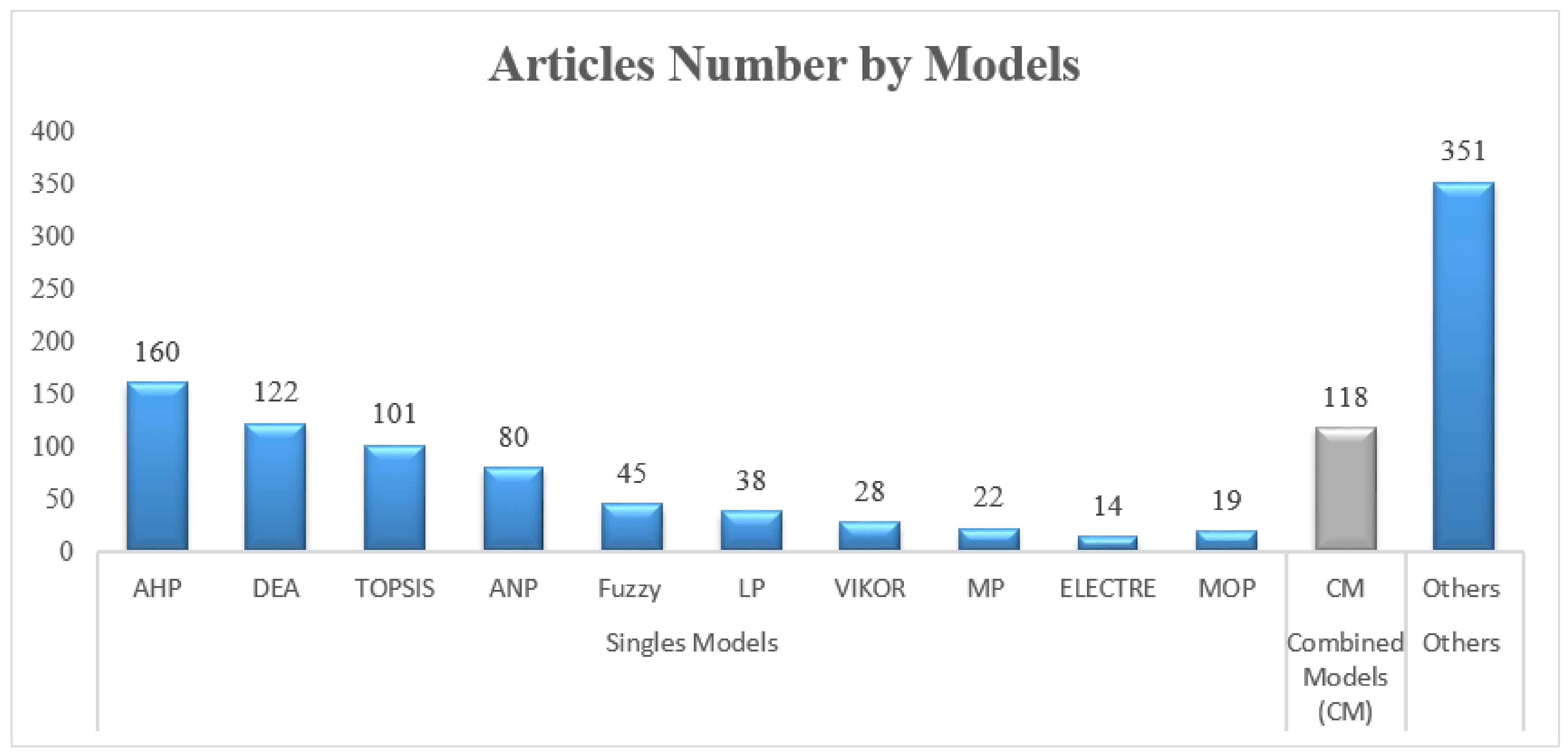

4. Result

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choy, K.; Lee, W.; Lo, V. Design of a case based intelligent supplier relationship management system—The integration of supplier rating system and product coding system. Expert Syst. Appl. 2003, 25, 87–100. [Google Scholar] [CrossRef]

- Agarwal, P.; Sahai, M.; Mishra, V.; Bag, M.; Singh, V. A review of multi-criteria decision making techniques for supplier evaluation and selection. IJIEC 2011, 2, 801–810. [Google Scholar] [CrossRef]

- Imane, I.E.F.; Fouad, J. Synchronous flow in automotive industry: Case study of RENAULT. In Proceedings of the 2017 International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA), Rabat, Morocco, 27–28 April 2017; pp. 199–203. [Google Scholar] [CrossRef]

- Resende, C.H.; Geraldes, C.A.; Lima, F.R. Decision Models for Supplier Selection in Industry 4.0 Era: A Systematic Literature Review. Procedia Manuf. 2021, 55, 492–499. [Google Scholar] [CrossRef]

- Jawab, F.; Bouami, D. La démarche “supply chain management” enjeux et stratégies, cas du commerce électronique et de la grande distribution. Available online: https://hal.archives-ouvertes.fr/hal-01741686 (accessed on 6 December 2022).

- Arif, J.; Azzouz, K.; Mouzouna, Y.; Jawab, F. Design on Improvement of Traceability Process in the Outsourcing of Logistics’ Activities Using the Internet of Things (IoT) Applications. Maejo Int. J. Sci. Technol. 2020, 29, 1093–1108. [Google Scholar]

- Frichi, Y.; Jawab, F.; Boutahari, S. The Mixed-Method 5W2D Approach for Health System Stakeholders Analysis in Quality of Care: An Application to the Moroccan Context. IJERPH 2019, 16, 2899. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Liu, R.; Liu, H.-C.; Shi, H. Green Supplier Evaluation and Selections: A State-of-the-Art Literature Review of Models, Methods, and Applications. Math. Probl. Eng. 2020, 2020, 1783421. [Google Scholar] [CrossRef]

- Aouadni, S.; Aouadni, I.; Rebaï, A. A systematic review on supplier selection and order allocation problems. J. Ind. Eng. Int. 2019, 15, 267–289. [Google Scholar] [CrossRef]

- Dutta, P.; Jaikumar, B.; Arora, M.S. Applications of data envelopment analysis in supplier selection between 2000 and 2020: A literature review. Ann. Oper. Res. 2021, 315, 1399–1454. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P.K. Dey, Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Chai, J.; Liu, J.N.; Ngai, E.W. Application of decision-making techniques in supplier selection: A systematic review of literature. Expert Syst. Appl. 2013, 40, 3872–3885. [Google Scholar] [CrossRef]

- Zimmer, K.; Fröhling, M.; Schultmann, F. Schultmann, Sustainable supplier management—A review of models supporting sustainable supplier selection, monitoring and development. Int. J. Prod. Res. 2016, 54, 1412–1442. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Murugesan, Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Chai, J.; Ngai, E.W. Decision-making techniques in supplier selection: Recent accomplishments and what lies ahead. Expert Syst. Appl. 2020, 140, 112903. [Google Scholar] [CrossRef]

- Schramm, V.B.; Cabral, L.P.B.; Schramm, F. Approaches for supporting sustainable supplier selection—A literature review. J. Clean. Prod. 2020, 273, 123089. [Google Scholar] [CrossRef]

- Adesanya, A.; Yang, B.; Bin Iqdara, F.W.; Yang, Y. Improving sustainability performance through supplier relationship management in the tobacco industry. Supply Chain Manag. Int. J. 2020, 25, 413–426. [Google Scholar] [CrossRef]

- Ibn el Farouk, I.; Jawab, F. Improving sustainability in public hospital through Medicines Supply chain management. In Proceedings of the 2020 IEEE 13th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), Fez, Morocco, 2–4 December 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Amoako-Gyampah, K.; Boakye, K.G.; Adaku, E.; Famiyeh, S. Supplier relationship management and firm performance in developing economies: A moderated mediation analysis of flexibility capability and ownership structure. Int. J. Prod. Econ. 2019, 208, 160–170. [Google Scholar] [CrossRef]

- Park, J.; Shin, K.; Chang, T.; Park, J. An integrative framework for supplier relationship management. Ind. Mngmnt Data Syst. 2010, 110, 495–515. [Google Scholar] [CrossRef]

- Lu, M.; Geyao, Y. The Selection of Construction Material Suppliers in Supplier Relationship Management (SRM). In Proceedings of the 2010 International Conference of Information Science and Management Engineering, Sha’anxi, China, 7–8 August 2010; pp. 189–192. [Google Scholar] [CrossRef]

- Hong, G.; Park, S.; Jang, D.; Rho, H. An effective supplier selection method for constructing a competitive supply-relationship. Expert Syst. Appl. 2005, 28, 629–639. [Google Scholar] [CrossRef]

- Ustun, O.; Demirtas, E.A. An integrated multi-objective decision-making process for multi-period lot-sizing with supplier selection. Omega 2008, 36, 509–521. [Google Scholar] [CrossRef]

- Ghodsypour, S.H.; O’Brien, C. A decision support system for supplier selection using an integrated analytic hierarchy process and linear programming. Int. J. Prod. Econ. 1998, 56–57, 199–212. [Google Scholar] [CrossRef]

- Chen, C.-T.; Lin, C.-T.; Huang, S.-F. A fuzzy approach for supplier evaluation and selection in supply chain management. Int. J. Prod. Econ. 2006, 102, 289–301. [Google Scholar] [CrossRef]

- Chandra, C.; Kumar, S. Supply chain management in theory and practice:a passing fad or a fundamental change? Ind. Manag. Data Syst. 2000, 100, 100–114. [Google Scholar] [CrossRef]

- Roodhooft, F.; Konings, J. Vendor selection and evaluation an Activity Based Costing approach. Eur. J. Oper. Res. 1997, 96, 97–102. [Google Scholar] [CrossRef]

- Tronnebati, I.; Jawab, F. The similarities and differences between the green and sustainable supply chain management definitions and factors: A literature review. In Proceedings of the 2020 IEEE 13th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), Fez, Morocco, 2–4 December 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Moufad, I.; Jawab, F. The Determinants of the performance of the urban freight transport-An empirical Analysis. In Proceedings of the 2018 International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA), Tangier, Morocco, 26–27 April 2018; pp. 99–104. [Google Scholar]

- Mokaddem, Y.E.; Jawab, F. Researches and applications of intelligent transportations systems in urban area: Systematic literature review. ARPN J. Eng. Appl. Sci. 2019, 14, 639–652. [Google Scholar]

- Karim, Z.; Fouad, J. Measuring urban public transport performance on route level: A literature review. MATEC Web Conf. 2018, 200, 21. [Google Scholar] [CrossRef][Green Version]

- Jawab, F.; Arif, J. Risk matrix model applied to the outsourcing of logistics’ activities. JIEM 2015, 8, 1179–1194. [Google Scholar] [CrossRef][Green Version]

- Imane, I.E.F.; Talbi, A.; Jawab, F. Chaîne logistique hospitalière: Définition, état de l’art et pistes d’amélioration’. CIGIMS 2012, 2012. [Google Scholar]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Bag, S. Green strategy, supplier relationship building and supply chain performance: Total interpretive structural modelling approach. IJPM 2016, 9, 398. [Google Scholar] [CrossRef]

- Nagel, M.H. Managing the environmental performance of production facilities in the electronics industry: More than application of the concept of cleaner production. J. Clean. Prod. 2003, 11, 11–26. [Google Scholar] [CrossRef]

- Koplin, J.; Seuring, S.; Mesterharm, M. Incorporating sustainability into supply management in the automotive industry—The case of the Volkswagen AG. J. Clean. Prod. 2007, 15, 1053–1062. [Google Scholar] [CrossRef]

- Cousins, P.D.; Lawson, B. The Effect of Socialization Mechanisms and Performance Measurement on Supplier Integration in New Product Development. Br. J. Manag. 2007, 18, 311–326. [Google Scholar] [CrossRef]

- Jemaa, S.; Alayidi, A.; Migdalas, A.; Baourakis, G.; Drakos, P. Green Supplier Evaluation and Selection: An Updated Literature Review. In Operational Research in Agriculture and Tourism; Springer: Cham, Switzerland, 2020; pp. 169–196. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Chan, H.K. An AHP model for selection of suppliers in the fast changing fashion market. Int. J. Adv. Manuf. Technol. 2010, 51, 1195–1207. [Google Scholar] [CrossRef]

- Kumar, J. Transmission Industry to Vendor Selection Decisions. Int. J. Comput. Appl. 2011, 12, 26–30. [Google Scholar]

- Peng, J. Selection of Logistics Outsourcing Service Suppliers Based on AHP. Energy Procedia 2012, 17, 595–601. [Google Scholar] [CrossRef]

- Dweiri, F.; Kumar, S.; Khan, S.A.; Jain, V. Designing an integrated AHP based decision support system for supplier selection in automotive industry. Expert Syst. Appl. 2016, 62, 273–283. [Google Scholar] [CrossRef]

- Dos Santos, B.M.; Godoy, L.P.; Campos, L.M.S. Performance evaluation of green suppliers using entropy-TOPSIS-F. J. Clean. Prod. 2019, 207, 498–509. [Google Scholar] [CrossRef]

- Shen, L.; Olfat, L.; Govindan, K.; Khodaverdi, R.; Diabat, A. A fuzzy multi criteria approach for evaluating green supplier’s performance in green supply chain with linguistic preferences. Resour. Conserv. Recycl. 2013, 74, 170–179. [Google Scholar] [CrossRef]

- Memari, A.; Dargi, A.; Akbari Jokar, M.R.; Ahmad, R.; Abdul Rahim, A.R. Sustainable supplier selection: A multi-criteria intuitionistic fuzzy TOPSIS method. J. Manuf. Syst. 2019, 50, 9–24. [Google Scholar] [CrossRef]

- Rouyendegh, B.D.; Yildizbasi, A.; Üstünyer, P. Intuitionistic Fuzzy TOPSIS method for green supplier selection problem. Soft Comput. 2020, 24, 2215–2228. [Google Scholar] [CrossRef]

- Gencer, C.; Gürpinar, D. Analytic network process in supplier selection: A case study in an electronic firm. Appl. Math. Model. 2007, 31, 2475–2486. [Google Scholar] [CrossRef]

- Bayazit, O. Use of analytic network process in vendor selection decisions. Benchmarking Int. J. 2006, 13, 566–579 . [Google Scholar] [CrossRef]

- Ghadimi, P.; Dargi, A.; Heavey, C. Making sustainable sourcing decisions: Practical evidence from the automotive industry. Int. J. Logist. Res. Appl. 2017, 20, 297–321. [Google Scholar] [CrossRef]

- Lin, Y.-T.; Lin, C.-L.; Yu, H.-C.; Tzeng, G.-H. A novel hybrid MCDM approach for outsourcing vendor selection: A case study for a semiconductor company in Taiwan. Expert Syst. Appl. 2010, 37, 4796–4804. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Çifçi, G. A novel fuzzy multi-criteria decision framework for sustainable supplier selection with incomplete information. Comput. Ind. 2011, 62, 164–174. [Google Scholar] [CrossRef]

- Humphreys, P.; McCloskey, A.; McIvor, R.; Maguire, L.; Glackin, C. Employing dynamic fuzzy membership functions to assess environmental performance in the supplier selection process. Int. J. Prod. Res. 2006, 44, 2379–2419. [Google Scholar] [CrossRef]

- Florez-Lopez, R. Strategic supplier selection in the added-value perspective: A CI approach. Inf. Sci. 2007, 177, 1169–1179. [Google Scholar] [CrossRef]

- Deng, Y.; Chan, F.T. A new fuzzy dempster MCDM method and its application in supplier selection. Expert Syst. Appl. 2011, 38, 9854–9861. [Google Scholar] [CrossRef]

- De Almeida, A.T. Multicriteria decision model for outsourcing contracts selection based on utility function and ELECTRE method. Comput. Oper. Res. 2007, 34, 3569–3574. [Google Scholar] [CrossRef]

- Tsui, C.-W.; Wen, U.-P. A Hybrid Multiple Criteria Group Decision-Making Approach for Green Supplier Selection in the TFT-LCD Industry. Math. Probl. Eng. 2014, 2014, e709872. [Google Scholar] [CrossRef]

- Lu, H.; Jiang, S.; Song, W.; Ming, X. A Rough Multi-Criteria Decision-Making Approach for Sustainable Supplier Selection under Vague Environment. Sustainability 2018, 10, 2622. [Google Scholar] [CrossRef]

- Bennani, M.; Jawab, F.; Hani, Y.; ElMhamedi, A.; Amegouz, D. A Hybrid MCDM for the Location of Urban Distribution Centers under Uncertainty: A Case Study of Casablanca, Morocco. Sustainability 2022, 14, 9544. [Google Scholar] [CrossRef]

- Meksavang, P.; Shi, H.; Lin, S.-M.; Liu, H.-C. An Extended Picture Fuzzy VIKOR Approach for Sustainable Supplier Management and Its Application in the Beef Industry. Symmetry 2019, 11, 468. [Google Scholar] [CrossRef]

- Wu, Q.; Zhou, L.; Chen, Y.; Chen, H. An integrated approach to green supplier selection based on the interval type-2 fuzzy best-worst and extended VIKOR methods. Inf. Sci. 2019, 502, 394–417. [Google Scholar] [CrossRef]

- Shemshadi, A.; Shirazi, H.; Toreihi, M.; Tarokh, M. A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting. Expert Syst. Appl. 2011, 38, 12160–12167. [Google Scholar] [CrossRef]

- Saen, R.F. A decision model for selecting technology suppliers in the presence of nondiscretionary factors. Appl. Math. Comput. 2006, 181, 1609–1615. [Google Scholar] [CrossRef]

- Kumar, A.; Jain, V. Supplier selection: A green approach with carbon footprint monitoring. In Proceedings of the 2010 8th International Conference on Supply Chain Management and Information, Hong Kong, China, 6–9 October 2010; pp. 1–8. [Google Scholar]

- Songhori, M.J.; Tavana, M.; Azadeh, A.; Khakbaz, M.H. A supplier selection and order allocation model with multiple transportation alternatives. Int. J. Adv. Manuf. Technol. 2011, 52, 365–376. [Google Scholar] [CrossRef]

- Dobos, I.; Vörösmarty, G. Evaluating green suppliers: Improving supplier performance with DEA in the presence of incomplete data. Cent. Eur. J. Oper. Res. 2019, 27, 483–495. [Google Scholar] [CrossRef]

- Talluri, S.; Narasimhan, R. A note on “A methodology for supply base optimization”. IEEE Trans. Eng. Manag. 2005, 52, 130–139. [Google Scholar] [CrossRef]

- Purohit, A.K.; Choudhary, D.; Shankar, R. Inventory lot-sizing with supplier selection under non-stationary stochastic demand. Int. J. Prod. Res. 2016, 54, 2459–2469. [Google Scholar] [CrossRef]

- Wadhwa, V.; Ravindran, A.R. Vendor selection in outsourcing. Comput. Oper. Res. 2007, 34, 3725–3737. [Google Scholar] [CrossRef]

- Ding, H.; Benyoucef, L.; Xie, X. A simulation optimization methodology for supplier selection problem. Int. J. Comput. Integr. Manuf. 2005, 18, 210–224. [Google Scholar] [CrossRef]

- Du, B.; Guo, S.; Huang, X.; Li, Y.; Guo, J. A Pareto supplier selection algorithm for minimum the life cycle cost of complex product system. Expert Syst. Appl. 2015, 42, 4253–4264. [Google Scholar] [CrossRef]

- Okyere, S.; Yang, J.; Adams, C.A. Optimizing the Sustainable Multimodal Freight Transport and Logistics System Based on the Genetic Algorithm. Sustainability 2022, 14, 11577. [Google Scholar] [CrossRef]

- Memon, M.S.; Lee, Y.H.; Mari, S.I. Group multi-criteria supplier selection using combined grey systems theory and uncertainty theory. Expert Syst. Appl. 2015, 42, 7951–7959. [Google Scholar] [CrossRef]

- Castro e Silva, A.D.; Seleme, R.; Silva, W.D.A.; Zattar, I.C.; Nara, E.O.B.; Júnior, O.C.; Benitez, L.B. Evaluation and Choice Criteria of Sustainable Suppliers in the Construction Industry: A Comparative Study in Brazilian Companies. Sustainability 2022, 14, 15711. [Google Scholar] [CrossRef]

- Tronnebati, I.; Jawab, F.; Arif, J. Decision-Making Models for solving Green Supplier Evaluation and Selection problems. In Proceedings of the 2022 14th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), El Jadida, Morocco, 25–27 May 2022; pp. 1–8. [Google Scholar] [CrossRef]

| Keywords Used in English |

|---|

| Supplier selection and evaluation models |

| DM models to solve GSES problems |

| Green supplier evaluation and selection problems |

| MCDM models for GSES |

| MP method for solving GSES issues |

| GSES and AI thechnique |

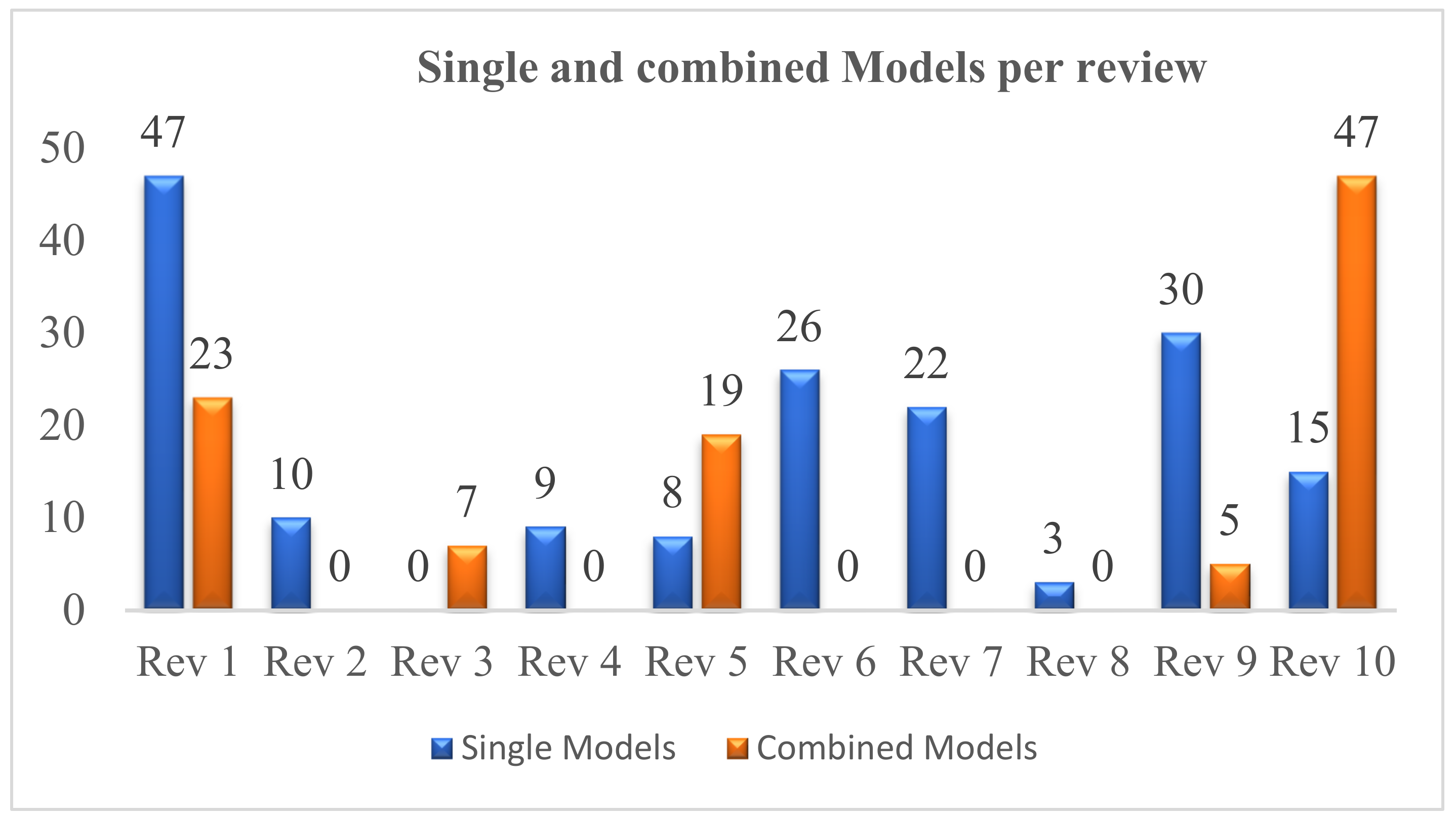

| Sources | Review Number | Time Horizon | Reviewed Studies | Models Number |

|---|---|---|---|---|

| [8] | Rev 1 | 2009 to 2020 | 193 | 47 Single Models and 23 Combined models |

| [9] | Rev 2 | 2000 to 2017 | 122 | 10 Single Models |

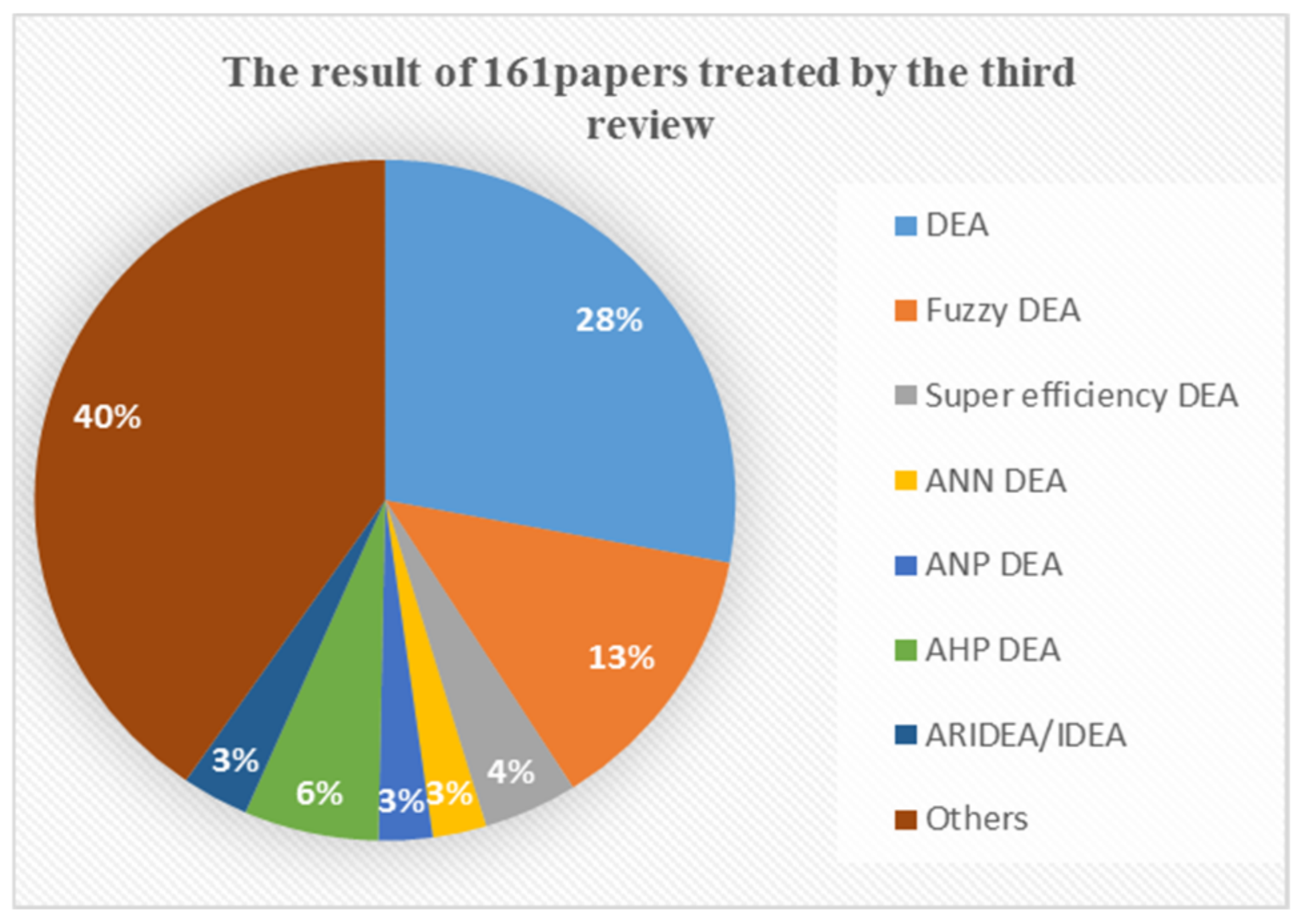

| [10] | Rev 3 | 2000 to 2020 | 161 | 7 Combined Models |

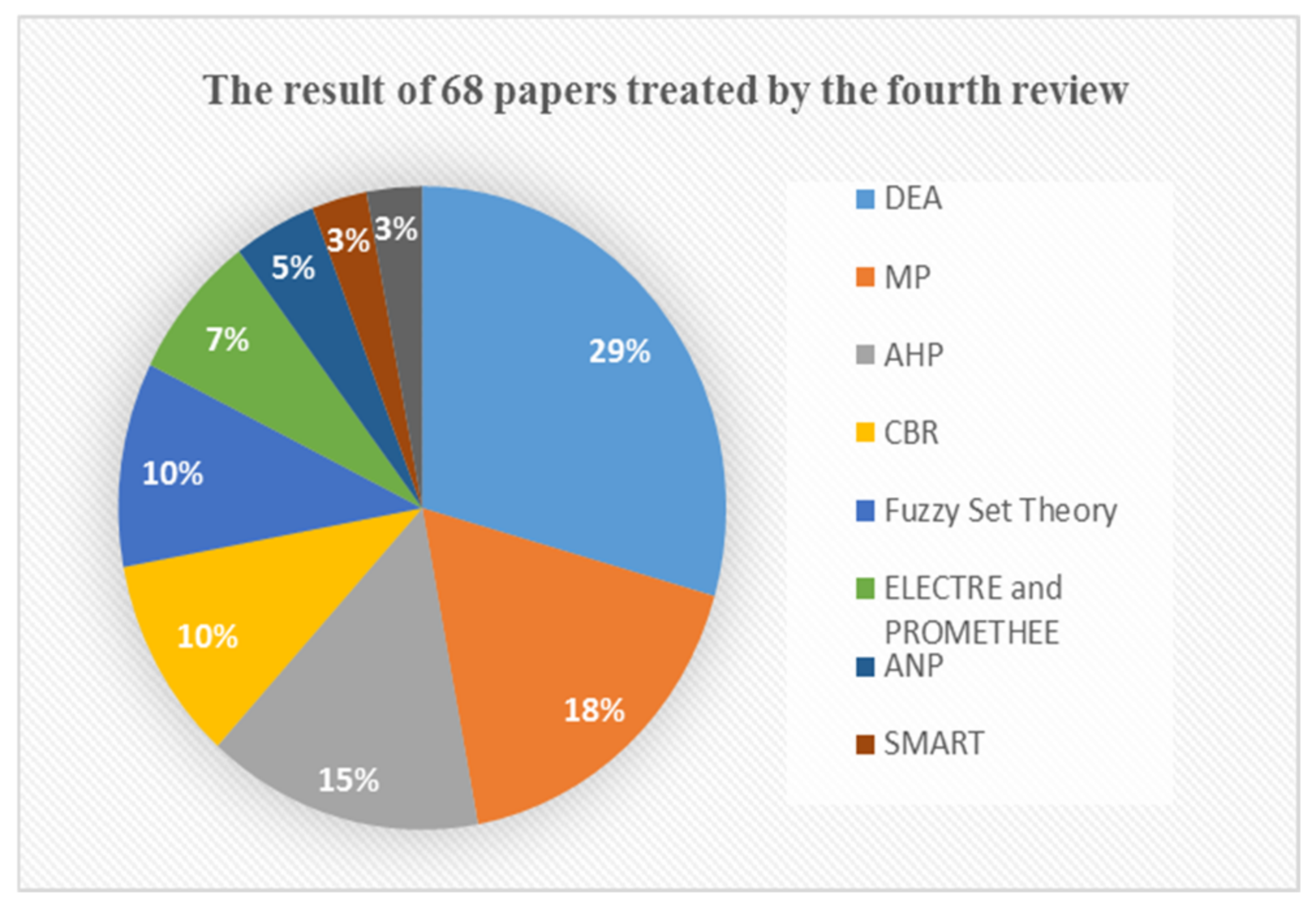

| [2] | Rev 4 | 2000 to 2011 | 68 | 9 single Models |

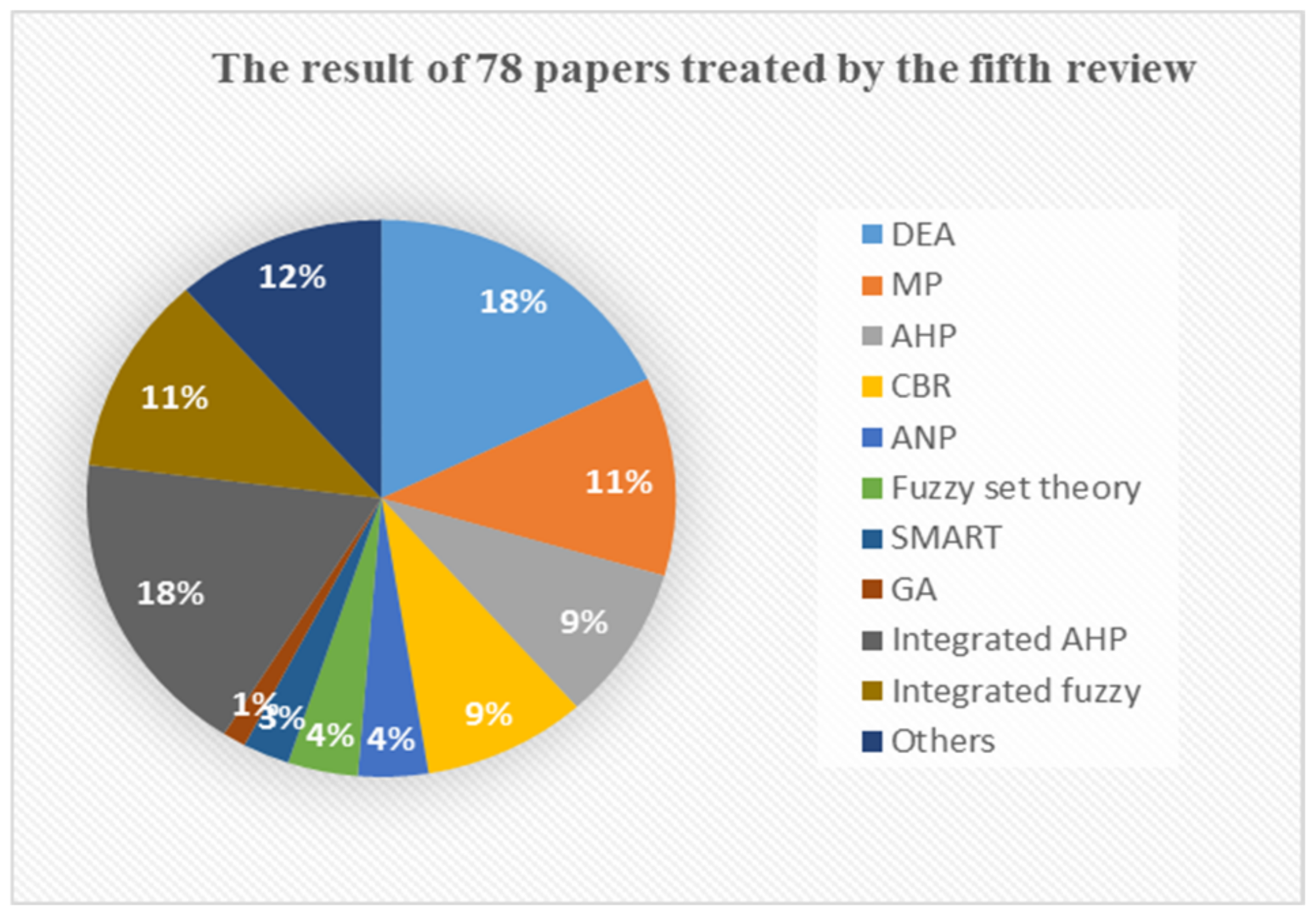

| [11] | Rev 5 | 2000 to 2008 | 78 | 8 single models and 19 Combined Models |

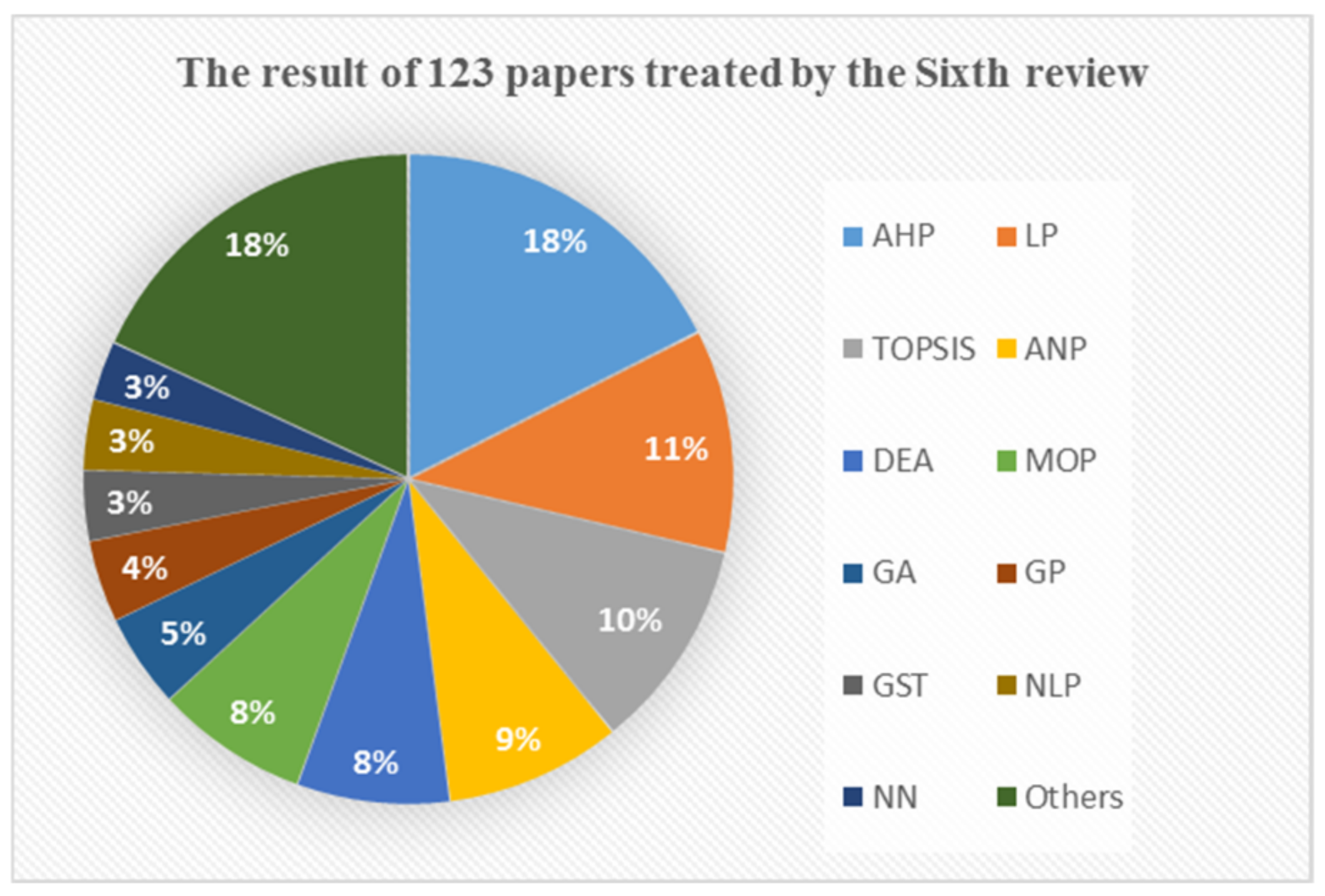

| [12] | Rev 6 | 2008 to 2012 | 123 | 26 single models |

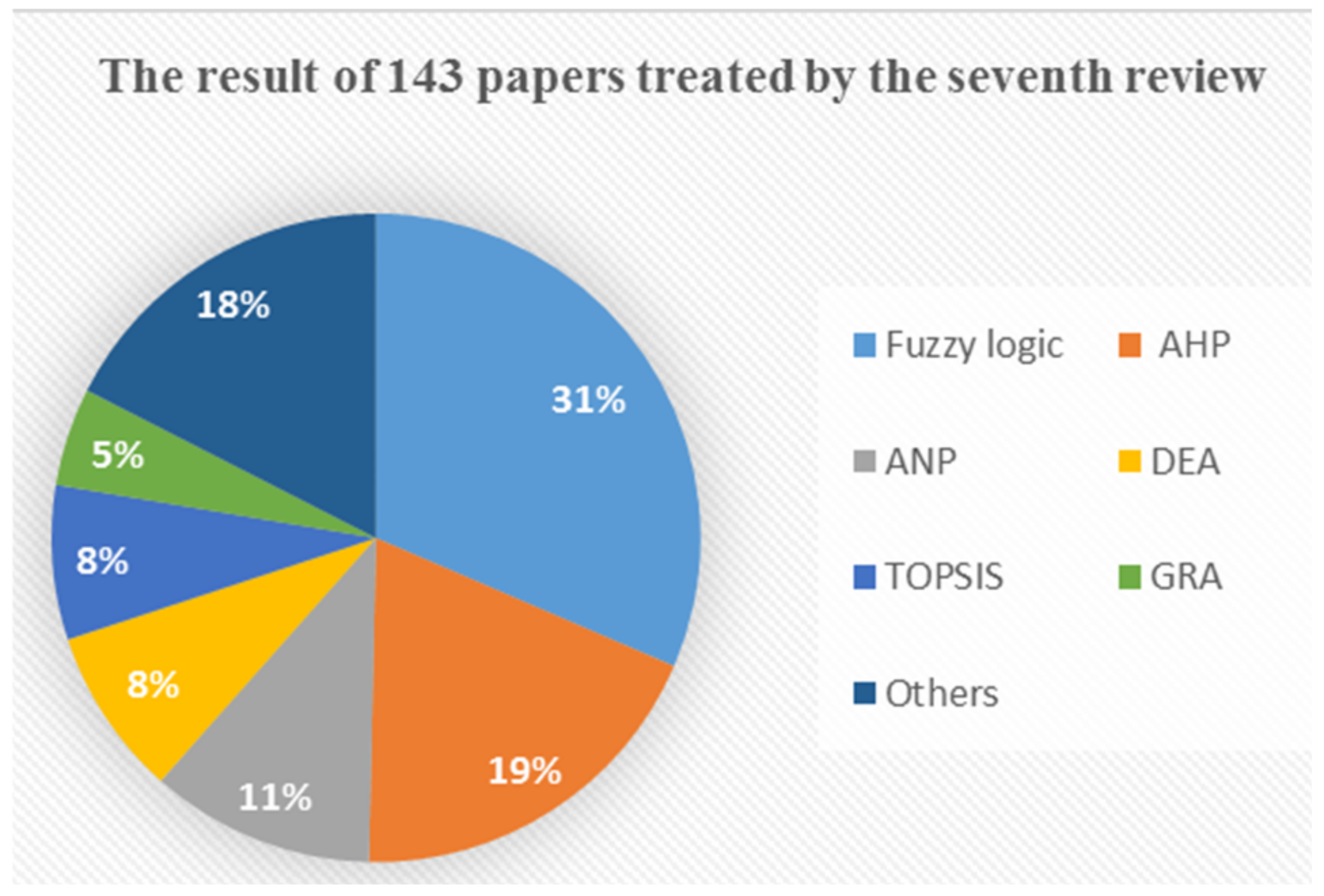

| [13] | Rev 7 | 1997 to 2014 | 143 | 22 single models |

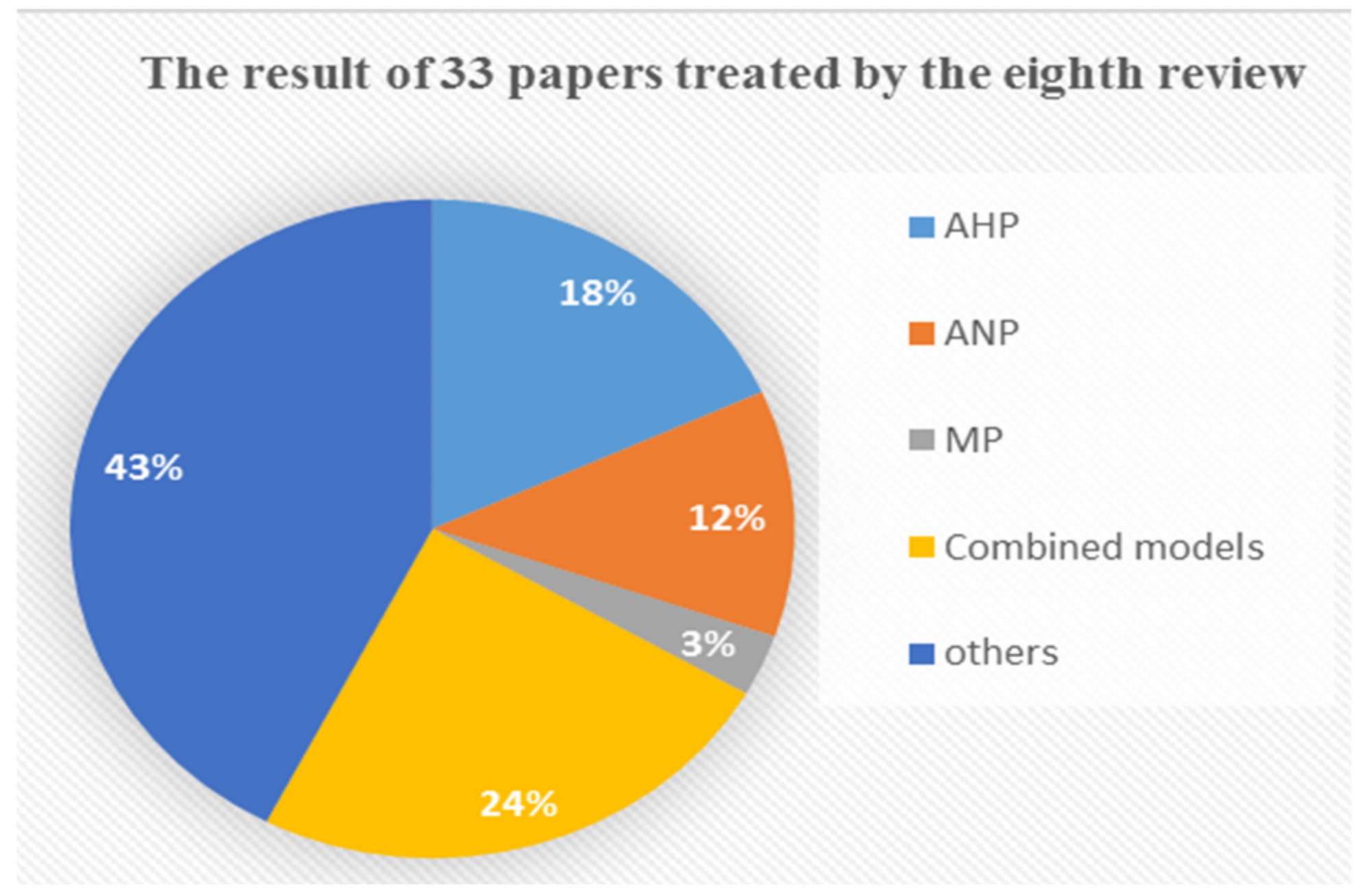

| [14] | Rev 8 | 1997 to 2011 | 33 | 3 single models |

| [15] | Rev 9 | 2013 to 2018 | 95 | 30 single models and 5 combined models |

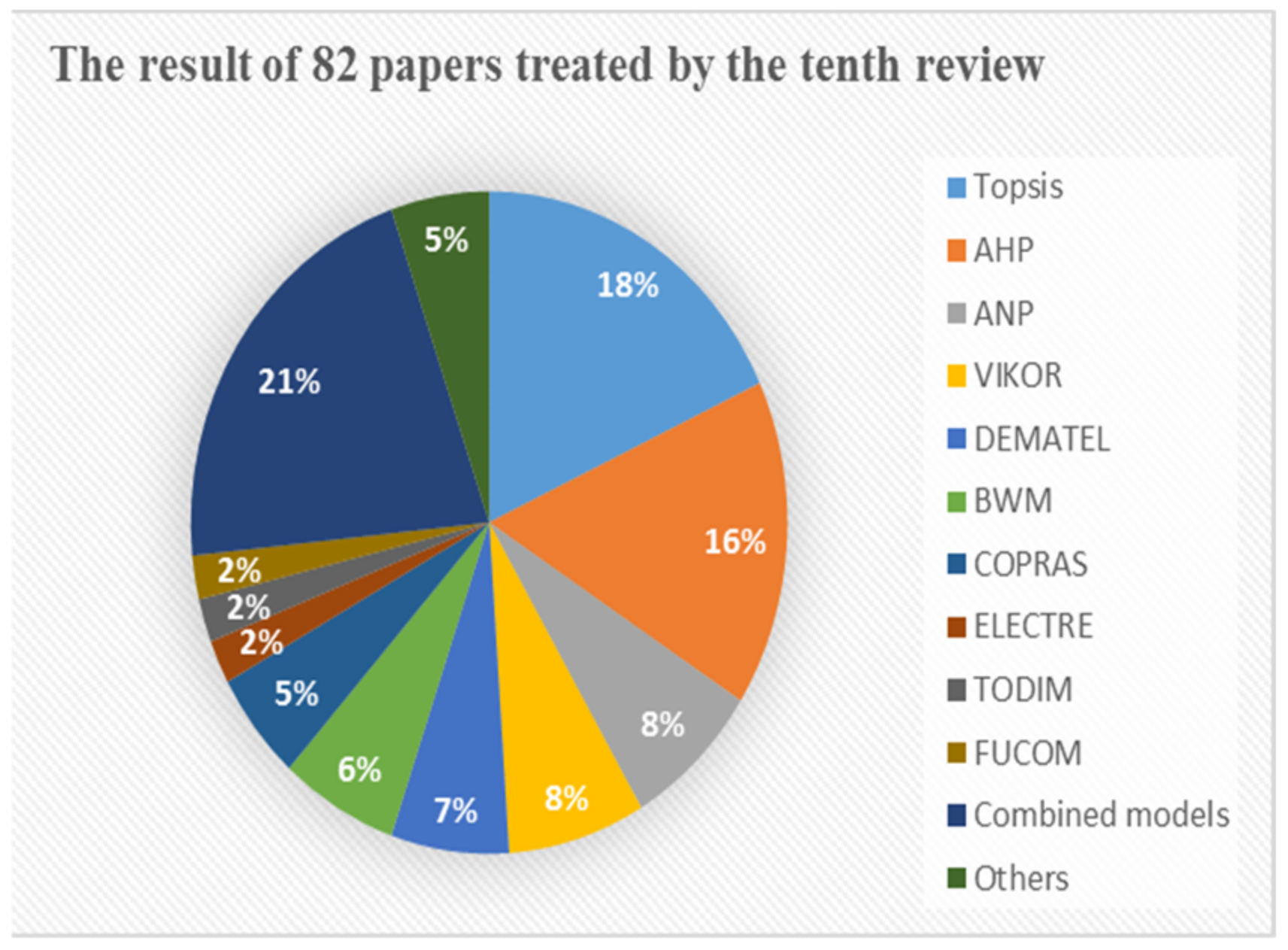

| [16] | Rev 10 | 1990 to 2019 | 82 | 15 single models and 47 Combined models |

| Sources | The Most Prominent Models | Article Quantity |

|---|---|---|

| [8] | DEA | 18 |

| [10] | DEA | 45 |

| [2] | DEA | 20 |

| MP | 12 | |

| [11] | DEA | 14 |

| MP | 9 | |

| [12] | LP | 19 |

| DEA | 13 | |

| MOP | 13 | |

| GP | 7 | |

| GST | 6 | |

| NLP | 6 | |

| [13] | DEA | 12 |

| [14] | MP | 1 |

| [15] | LP | 19 |

| SP | 11 | |

| NLP | 9 | |

| MILP | 9 | |

| GP | 7 | |

| MOP | 6 |

| Sources | The Most Prominent Models | Article Quantity |

|---|---|---|

| [8] | GRA | 6 |

| [2] | CBR | 7 |

| GA | 2 | |

| [11] | CBR | 7 |

| GA | 1 | |

| [12] | GA | 8 |

| NN | 5 | |

| [13] | GRA | 7 |

| Sources | The Most Prominent Models | Article Quantity |

|---|---|---|

| [8] | TOPSIS, MOP | 11 |

| Others Combined models | 28 | |

| Others Single models | 66 | |

| [10] | Fuzzy DEA | 21 |

| Super efficiency DEA | 7 | |

| ANN DEA | 4 | |

| ANP DEA | 4 | |

| AHP DEA | 10 | |

| ARIDEA/IDEA | 5 | |

| Others Combined models | 65 | |

| [11] | Others Single models | 9 |

| [12] | Others Single models | 31 |

| [13] | Others Single models | 25 |

| [14] | Others Combined models | 8 |

| Others Single models | 14 | |

| [15] | Others Single models | 7 |

| Sources | The Most Prominent Models | Article Quantity |

|---|---|---|

| [8] | TOPSIS | 21 |

| VIKOR | 14 | |

| ELECTRE | 6 | |

| TODIM | 6 | |

| MULTIMOORA | 5 | |

| AHP | 5 | |

| ANP | 5 | |

| [9] | AHP | 47 |

| TOPSIS | 26 | |

| ANP | 21 | |

| VIKOR | 7 | |

| ELECTRE | 6 | |

| PROMETHEE | 6 | |

| SMART | 4 | |

| MAUT | 2 | |

| BWM | 2 | |

| SIR | 1 | |

| [2] | AHP | 10 |

| Fuzzy Set Theory | 7 | |

| ELECTRE and PROMETHEE | 5 | |

| ANP | 3 | |

| SMART | 2 | |

| [11] | AHP | 7 |

| ANP | 3 | |

| Fuzzy set theory | 3 | |

| SMART | 2 | |

| Integrated AHP | 14 | |

| Integrated fuzzy | 9 | |

| [12] | AHP | 30 |

| TOPSIS | 18 | |

| ANP | 15 | |

| [13] | Fuzzy logic | 45 |

| AHP | 27 | |

| ANP | 16 | |

| TOPSIS | 11 | |

| [14] | AHP | 6 |

| ANP | 4 | |

| [15] | AHP | 13 |

| TOPSIS | 8 | |

| ANP | 6 | |

| [16] | Topsis | 17 |

| AHP | 15 | |

| ANP | 7 | |

| VIKOR | 7 | |

| DEMATEL | 6 | |

| BWM | 6 | |

| COPRAS | 5 | |

| ELECTRE | 2 | |

| TODIM | 2 | |

| FUCOM | 2 | |

| Combined models | 20 | |

| Others | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tronnebati, I.; El Yadari, M.; Jawab, F. A Review of Green Supplier Evaluation and Selection Issues Using MCDM, MP and AI Models. Sustainability 2022, 14, 16714. https://doi.org/10.3390/su142416714

Tronnebati I, El Yadari M, Jawab F. A Review of Green Supplier Evaluation and Selection Issues Using MCDM, MP and AI Models. Sustainability. 2022; 14(24):16714. https://doi.org/10.3390/su142416714

Chicago/Turabian StyleTronnebati, Imane, Manal El Yadari, and Fouad Jawab. 2022. "A Review of Green Supplier Evaluation and Selection Issues Using MCDM, MP and AI Models" Sustainability 14, no. 24: 16714. https://doi.org/10.3390/su142416714

APA StyleTronnebati, I., El Yadari, M., & Jawab, F. (2022). A Review of Green Supplier Evaluation and Selection Issues Using MCDM, MP and AI Models. Sustainability, 14(24), 16714. https://doi.org/10.3390/su142416714