Micro Pumped Hydro Energy Storage: Sketching a Sustainable Hybrid Solution for Colombian Off-Grid Communities

Abstract

:1. Introduction

2. Context of the Research

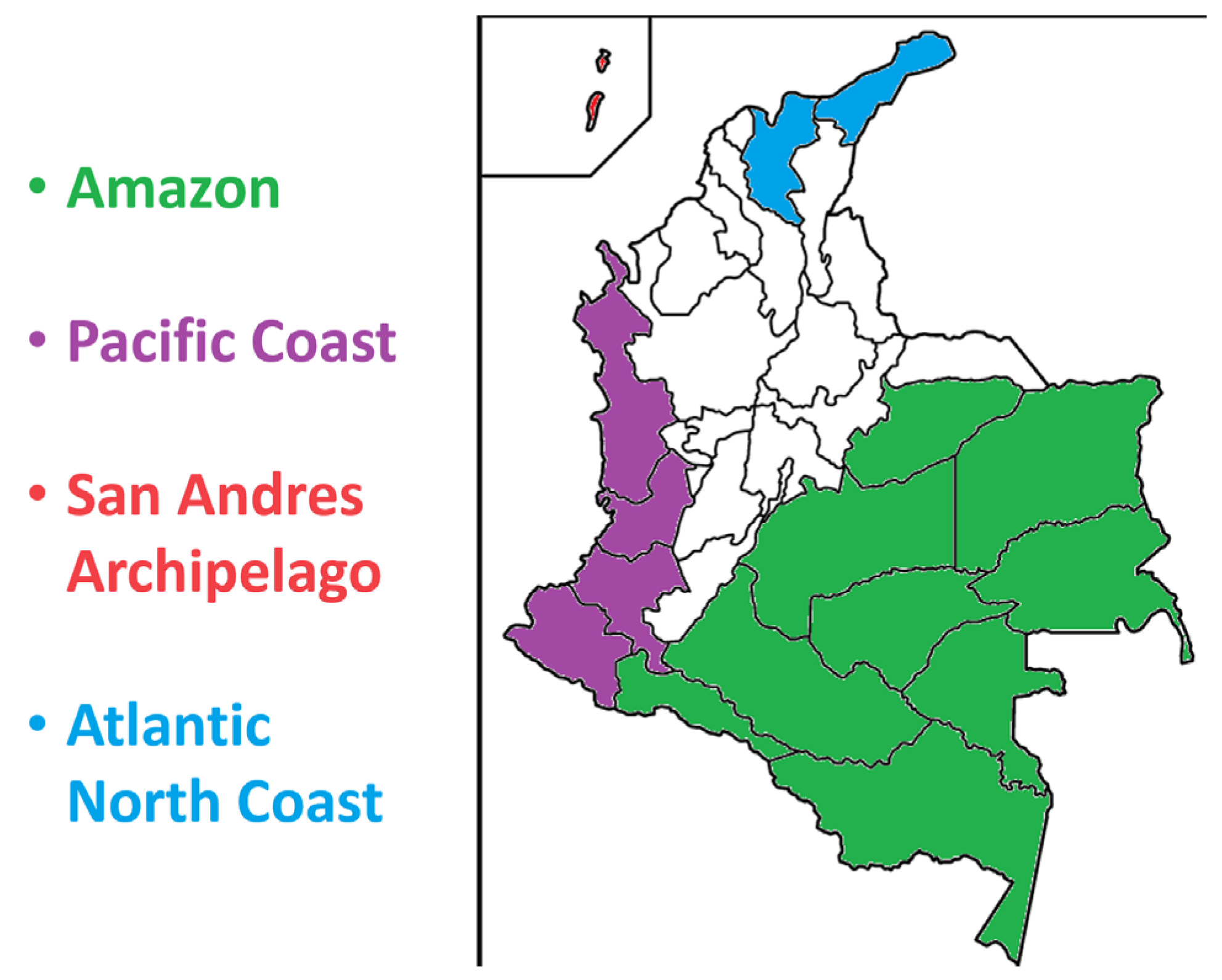

2.1. Geographical Context

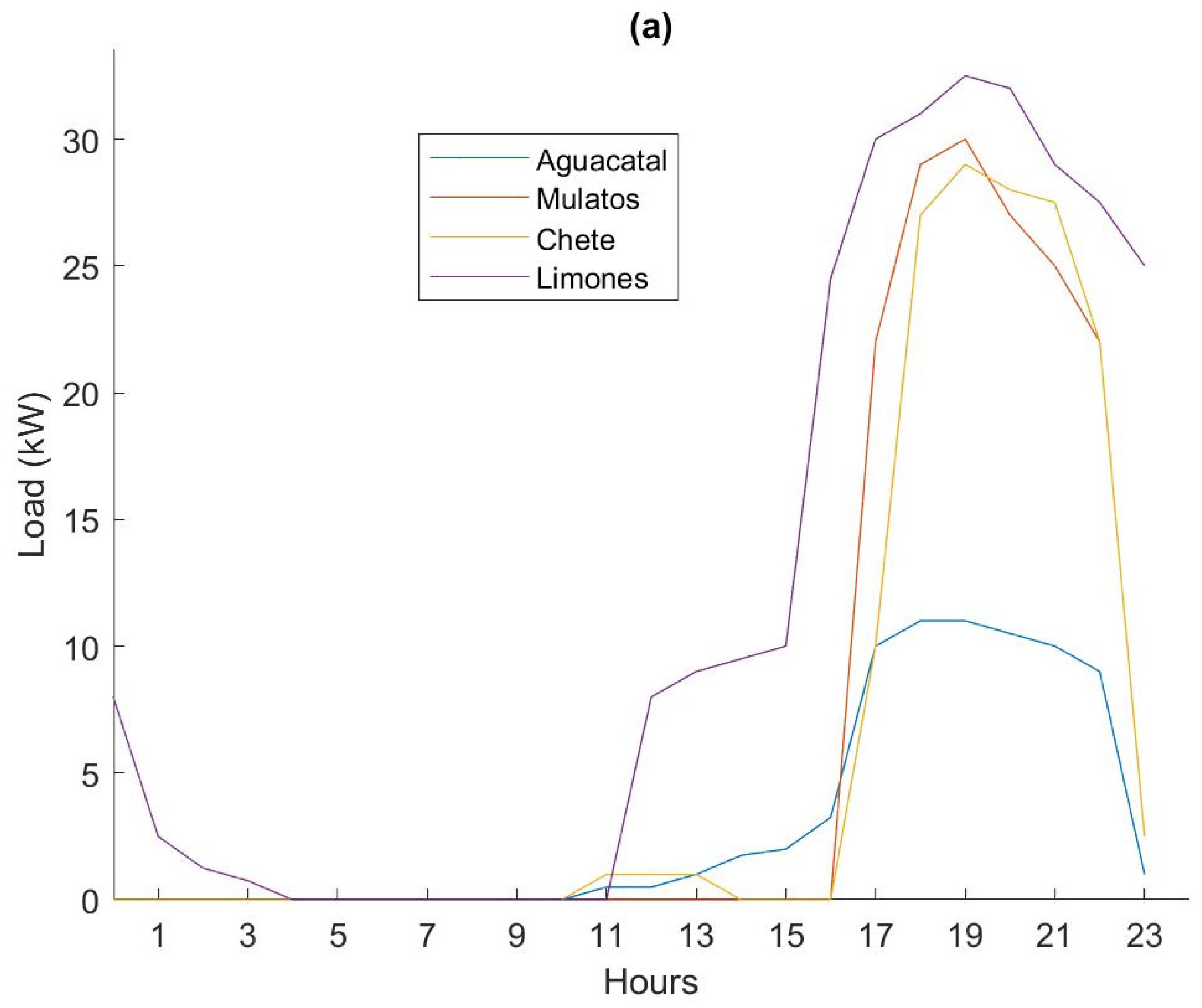

2.2. Energy Mix and Consumption Profiles

2.3. Diesel-Based Generation

2.4. Tolerances in Voltage and Frequency in Isolated Microgrids

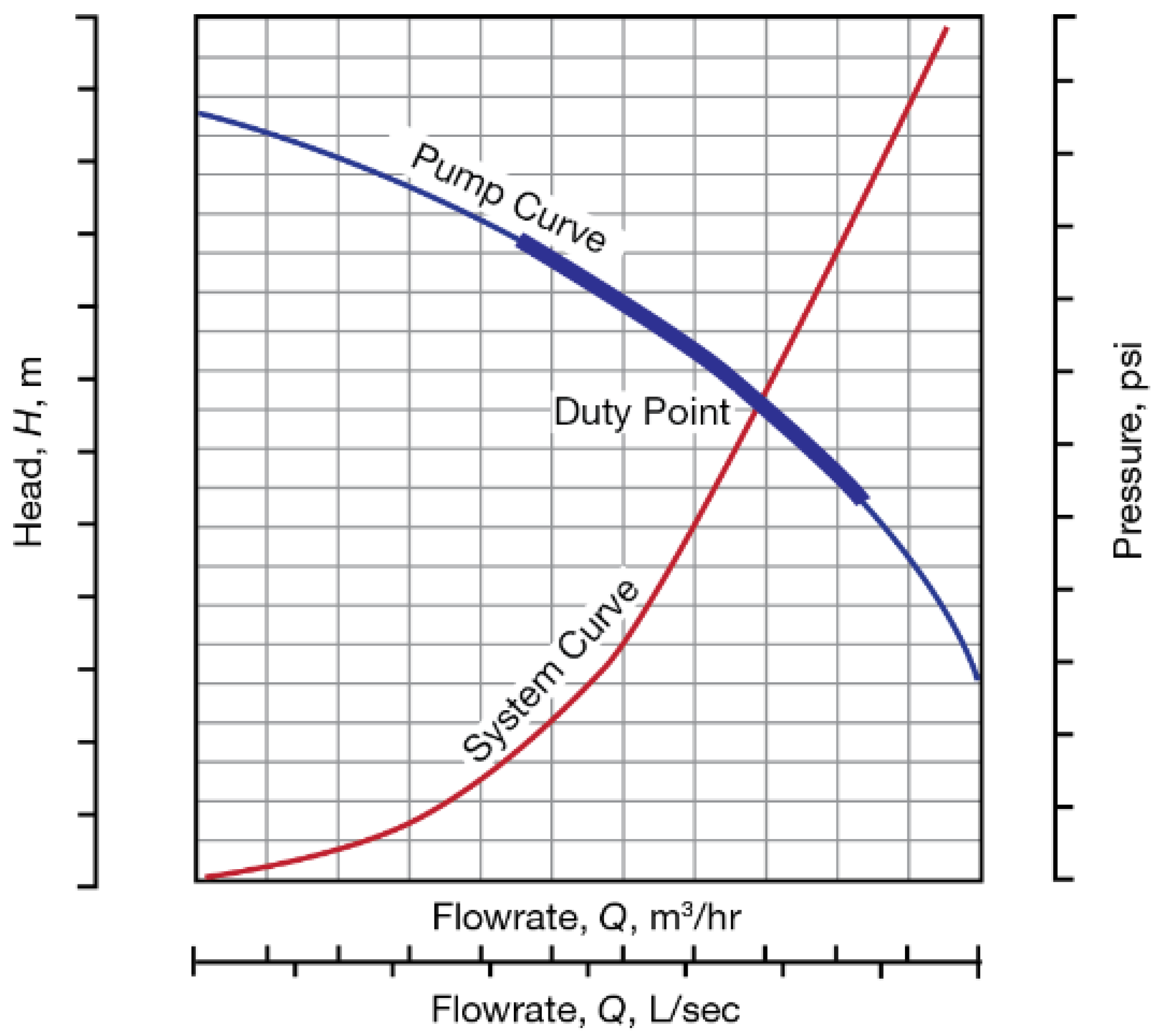

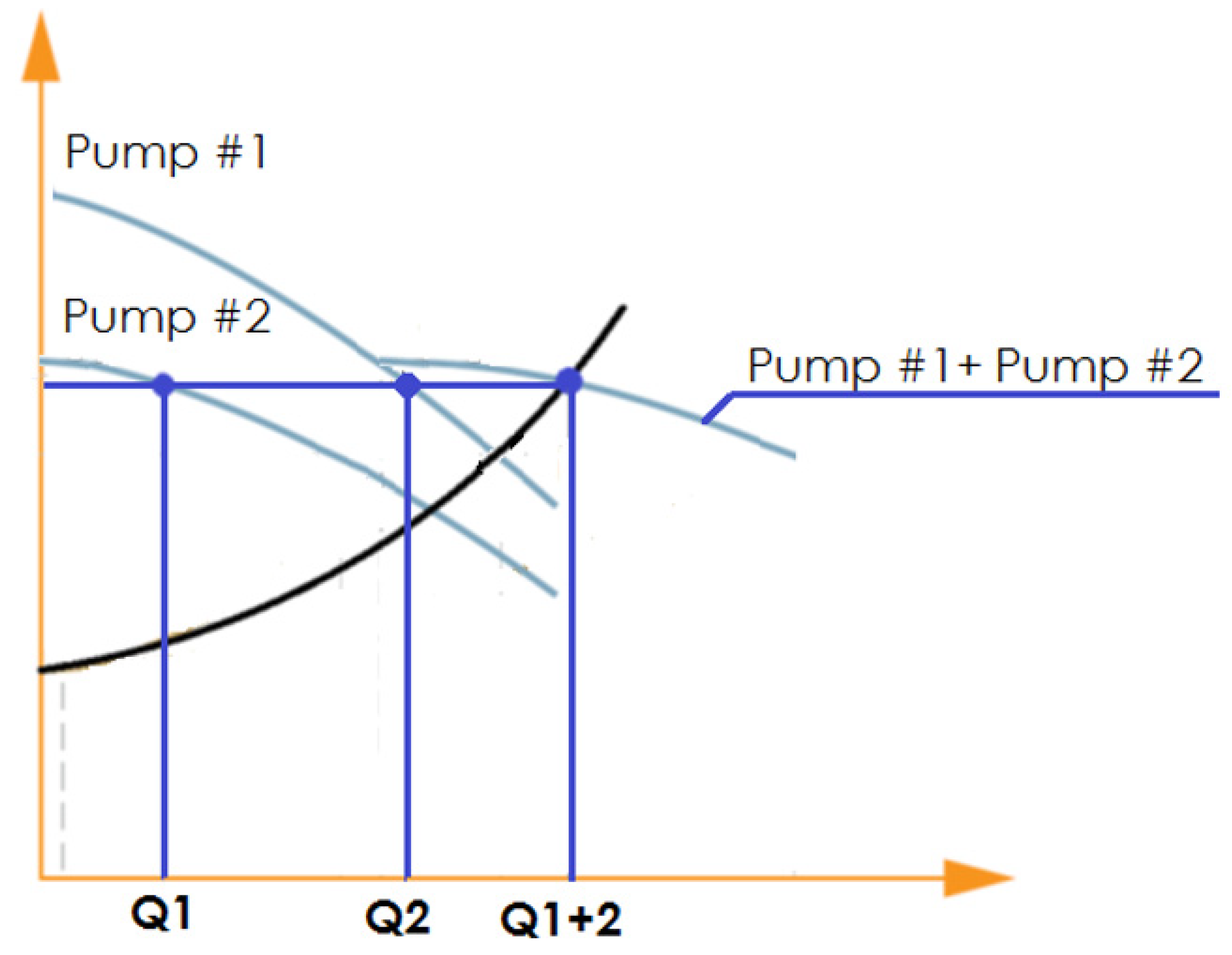

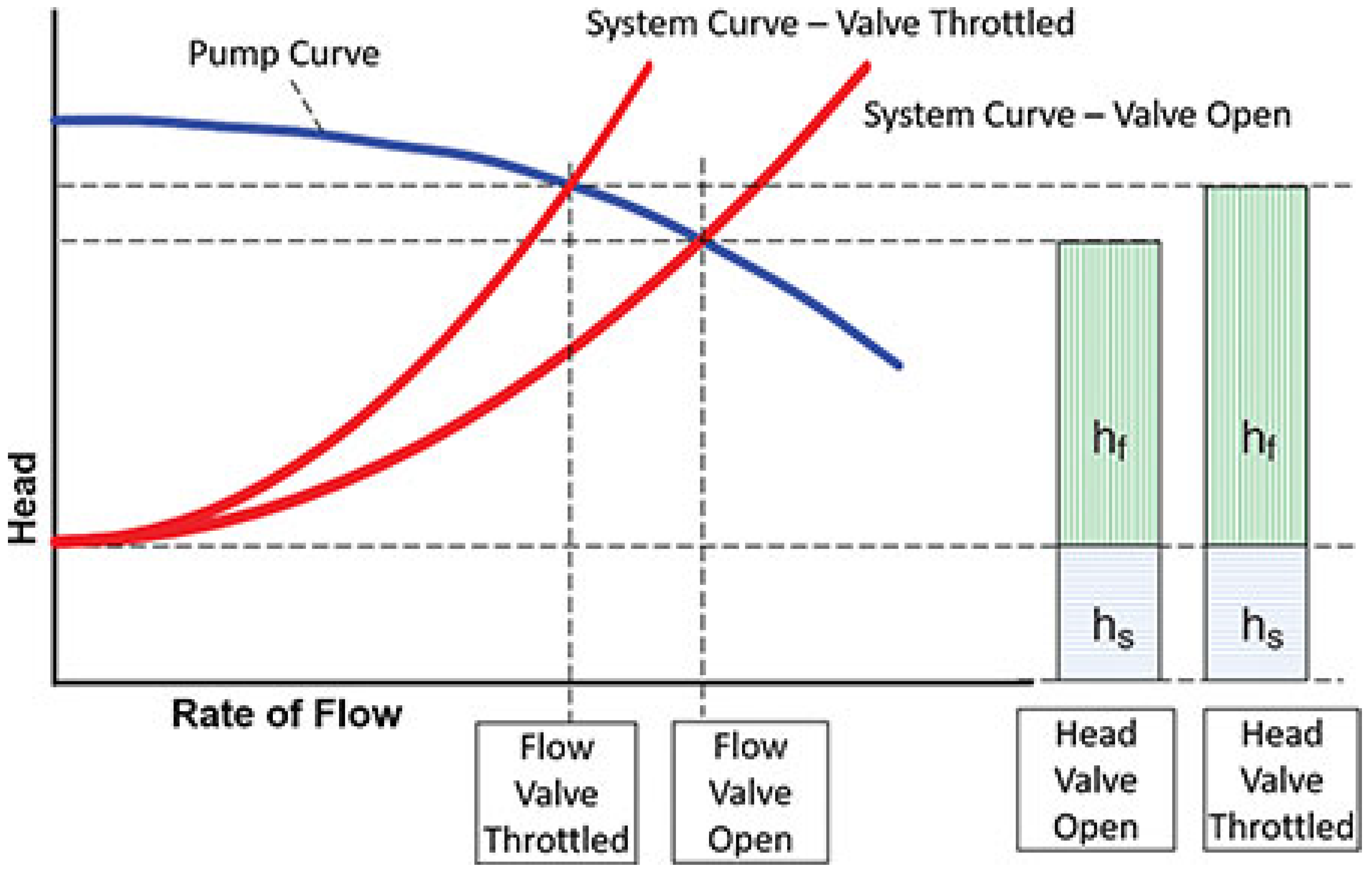

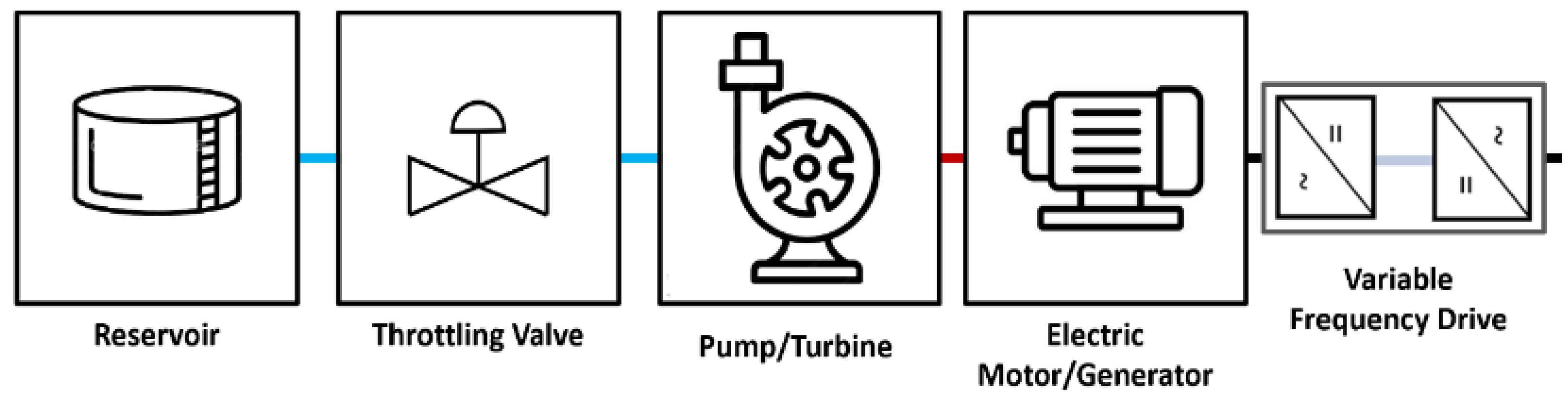

3. Pumped Hydro Generator

4. Designing the PHS with Electrical Machines

4.1. Machine A: Asynchronous Machine (ASM)

4.1.1. Machine A-1: ASM Directly Connected to the Grid

4.1.2. Machine A-2: ASM with a VFD

4.2. Machine B: Synchronous Machine (SM)

4.2.1. Machine B-1: Synchronous Machine with Permanent Magnets (PMSM) Coupled with a VFD

4.2.2. Machine B-2: Self-excited Synchronous Machine (SESM) Coupled with a VFD

4.3. Machine C: Variants (PMSM + SQ and SESM + SQ): Addition of a Squirrel Cage to Synchronous Machines, No VFD

5. Off-Grid Infrastructure for Communities in the Colombian Context

5.1. Configuration 1 (C1): Diesel-Dominated Microgrid

- Only needing a grid-tie inverter. Power flows from the solar array to the AC bus, the genset being the grid master and grid former at all times.

- No need to tame solar production, the more is produced, the less diesel is consumed (up to a limit talked about afterward).

- If the load exceeds the genset’s capacity + solar PV production, the PHS can switch to turbine mode and contribute to feeding the load.

- PV production needs to be curtailed to keep the genset master on the grid, if not it would lead to unacceptable operating conditions for the genset [55].

- There is always a genset running, which means, there is no moment where carbon is not emitted [56]. Additionally, a diesel shortage means no electricity.

- The PHS must be able to absorb the excess power produced by PV and its variations. This demands an accurate sizing of the PHS rotating machines and a strategy to control power intake.

- There is a risk that the PHS runs in pumping mode with the genset, but this can be removed through the general controller algorithms.

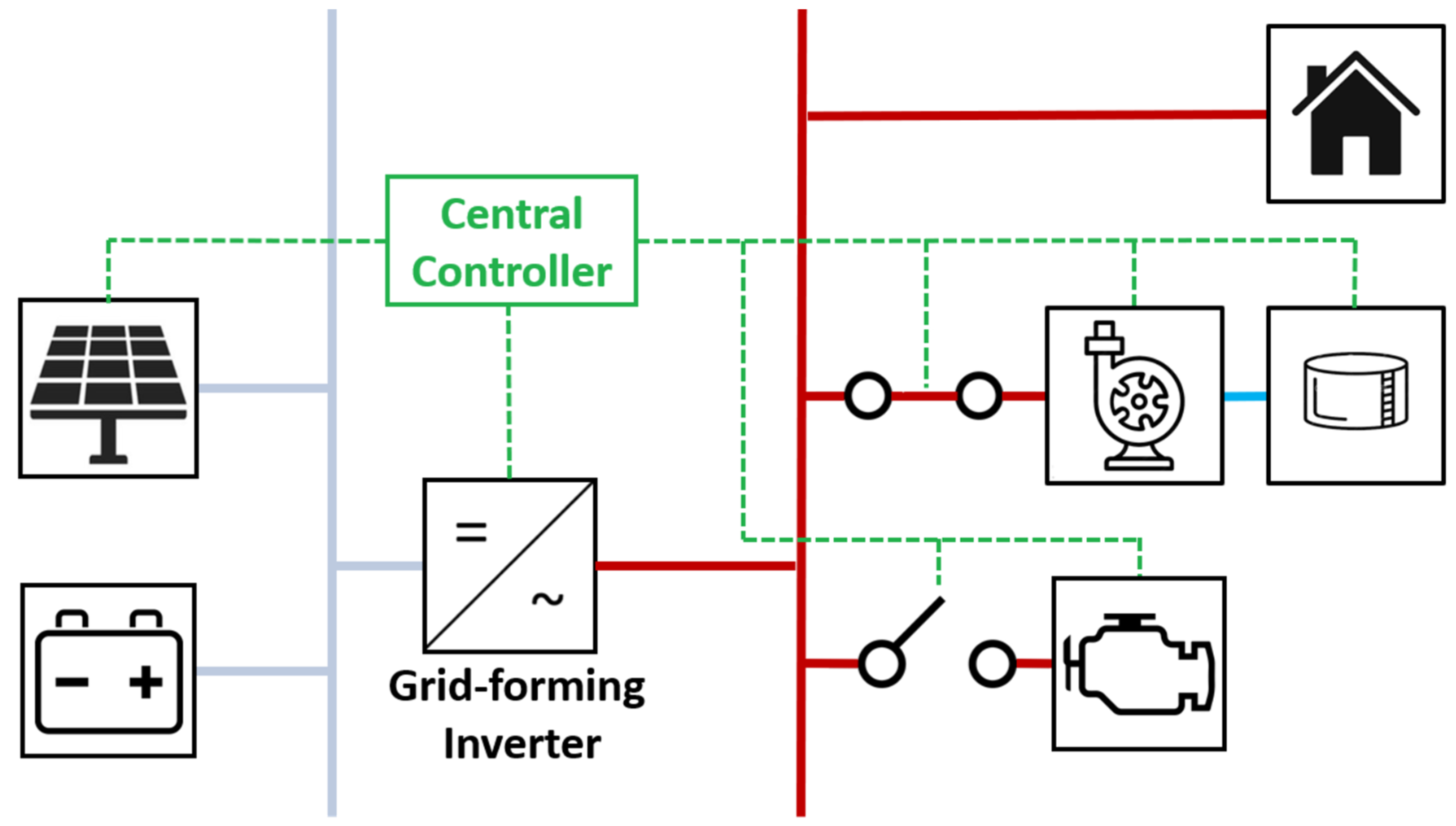

5.2. Configuration 2 (C2): Microgrid with an Automated Switch between All Generators

- A total of 24 h of electricity coverage with PHS and diesel that can take over on the run thanks to the PMS/EMS [55].

- Necessity to have a standalone grid-forming inverter (more expensive than a grid-tie, also needing a small battery bank);

- Necessity to develop a specific set of PMS/EMS which (depending on the number of variables) can be more or less expensive but mainly needs to be dedicated to each site-specific equipment rating.

- Necessity to have a variable pumping system to maximize its use compared to chemical batteries [56];

- The PHS must be able to absorb the excess power produced by PV and its variations.

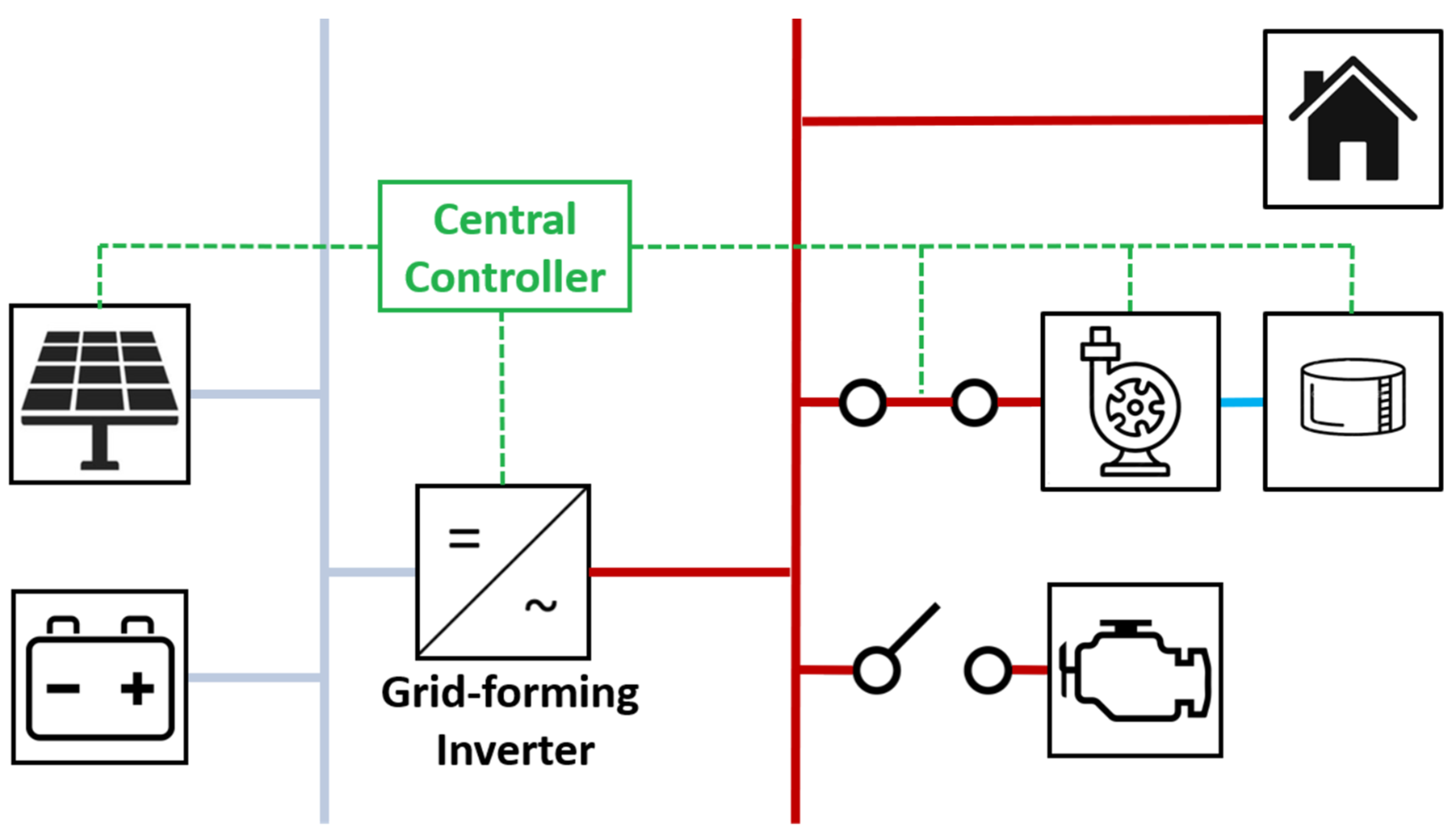

5.3. Configuration 3 (C3): Microgrid with an Automated Switch between All Renewable Means of Production. Diesel Only as a Backup Solution

- Diesel is only used as a backup (for overcast days and long nights);

- Simpler management system and control strategy.

- Necessity to have a standalone grid-forming inverter (more expensive than a grid-tie);

- Necessity to have a variable speed pumping system (to absorb changes in PV production while keeping the load supplied);

- Black-out occurs when the PHS reservoir is empty. In this case, a manual black start can be made with the genset, as most Colombian communities used to do before having storage systems added to their energy mix;

- A full 24 h uninterrupted electricity coverage is not possible by default. It can be a problem if the community has health facilities or other critical loads that cannot afford to be unsupplied.

5.4. Comparing Configurations

6. Conclusions

7. Perspective of Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. World Energy Outlook 2022; IEA: Paris, France, 2022; p. 524. [Google Scholar]

- Sandia Labs. DOE Global Energy Storage Database. Available online: https://sandia.gov/ess-ssl/gesdb/public/projects.html (accessed on 18 January 2022).

- Nikolaidis, P.; Poullikkas, A. A comparative review of electrical energy storage systems for better sustainability. J. Power Technol. 2017, 97, 27. [Google Scholar]

- Mongird, K.; Viswanathan, V.; Alam, J.; Vartanian, C.; Sprenkle, V.; Baxter, R. 2020 Grid Energy Storage Technology Cost and Performance Assessment; Technical Report; United States Department of Energy: Washington, DC, USA, 2020; p. 20. [Google Scholar]

- Salevid, K. Market Requirements for Pumped Storage Profitability. 2013. Available online: https://uu.diva-portal.org/smash/get/diva2:661286/FULLTEXT01.pdf (accessed on 1 December 2022).

- Lazard. Levelized Cost of Storage—Version 2.0.; Lazard: Hamilton, Bermuda, 2016. [Google Scholar]

- Stocks, M.; Stocks, R.; Lu, B.; Cheng, C.; Blakers, A. Global Atlas of Closed-Loop Pumped Hydro Energy Storage. Joule 2021, 5, 270–284. [Google Scholar] [CrossRef]

- IPSE. Caracterizacion ZNI. Available online: https://asprea.org/pdf/Presentaci%C3%B3n%20de%20Pedro%20Bejarano%20IPSE%20Colombia.pdf (accessed on 1 December 2022).

- IPSE. Oportunidades Actuales En El Campo De Las Energías Renovables En Colombia. 2015. Available online: https://www.mzv.cz/file/1638464/ipse.pdf (accessed on 1 December 2022).

- Hydropower Colombia, Hydropower Potential and Production in Colombia. Available online: https://www.hydropower.org/country-profiles/colombia (accessed on 1 December 2022).

- IPSE. Objetivos Y Funciones Del IPSE. 2022. Available online: https://ipse.gov.co/mapa-del-sito/ipse/direccionamiento-estrategico/objetivos-y-funciones/ (accessed on 1 December 2022).

- Tuckey, A.; Round, S. Round. Grid-Forming Inverters for Grid-Connected Microgrids: Developing “good citizens” to ensure the continued flow of stable, reliable power. IEEE Electrif. Mag. 2022, 10, 39–51. [Google Scholar] [CrossRef]

- Zaleskis, G.; Rankis, I.; Prieditis, M. Self-Excitation System for Synchronous Generator. Electr. Control Commun. Eng. 2013, 4, 32–37. [Google Scholar] [CrossRef] [Green Version]

- Tayab, U.B.; Roslan, M.A.B.; Hwai, L.J.; Kashif, M. A review of droop control techniques for microgrid. Renew. Sustain. Energy Rev. 2017, 76, 717–727. [Google Scholar] [CrossRef]

- Barklund, E.; Pogaku, N.; Prodanovic, M.; Hernandez-Aramburo, C.; Green, T.C. Green, Energy Management in Autonomous Microgrid Using Stability-Constrained Droop Control of Inverters. IEEE Trans. Power Electron. 2008, 23, 2346–2352. [Google Scholar] [CrossRef] [Green Version]

- Notton, G.; Duchaud, J.; Nivet, M.; Voyant, C.; Chalvatzis, K.; Fouilloy, A. The electrical energy situation of French islands and focus on the Corsican situation. Renew. Energy 2019, 135, 1157–1165. [Google Scholar] [CrossRef] [Green Version]

- International Finance Corporation (World Bank). The Dirty Footprint of the Broken Grid; International Finance Corporation: Washington, DC, USA, 2019. [Google Scholar]

- Multon, B.; Moine, G.; Aubry, J.; Haessig, P.; Jaouen, C.; Thiaux, Y.; Ahmed, H.B. Ressources Énergétiques Et Solutions Pour L’alimentation En Électricité Des Populations Isolées; HAL: Belfort, France, 2011; p. 13. [Google Scholar]

- Rockefeller Foundation. Comparing Costs of an Integrated Approach Versus Pure Grid Extension. 2020. Available online: https://www.rockefellerfoundation.org/wp-content/uploads/2020/12/EE-Download-Opportunity-Datasheet-Detailed-Cost-Models-and-Benchmarks.pdf (accessed on 15 November 2022).

- European Union. Sustainable Energy Handbook Module 6.1 Simplified Financial Models; European Union: Maastricht, The Netherlands, 2016. [Google Scholar]

- Jakhrani, A.Q.; Othman, A.-K.; Rigit, A.R.H.; Samo, S.R. Estimation of carbon footprints from diesel generator emissions. In Proceedings of the 2012 International Conference on Green and Ubiquitous Technology, Bandung, Indonesia, 7–8 July 2012; pp. 78–81. [Google Scholar] [CrossRef]

- SSPD. Boletin Tarifario ZNI I. 2022. Available online: https://www.superservicios.gov.co/sites/default/files/inline-files/Boleti%CC%81n_Tarifario_Energi%CC%81a_ZNI_I_Trim_2022.pdf (accessed on 15 November 2022).

- Vides-Prado, A.; Camargo, E.O.; Vides-Prado, C.; Orozco, I.H.; Chenlo, F.; Candelo, J.E.; Sarmiento, A.B. Techno-economic feasibility analysis of photovoltaic systems in remote areas for indigenous communities in the Colombian Guajira. Renew. Sustain. Energy Rev. 2018, 82, 4245–4255. [Google Scholar] [CrossRef]

- Rodríguez-Urrego, D.; Rodríguez-Urrego, L. Photovoltaic energy in Colombia: Current status, inventory, policies and future prospects. Renew. Sustain. Energy Rev. 2018, 92, 160–170. [Google Scholar] [CrossRef]

- CREG. RESOLUCIÓN No. 091 (26 OCT. 2007). 2009. Available online: http://apolo.creg.gov.co/Publicac.nsf/Indice01/Resolucion-2007-Creg091-2007 (accessed on 15 November 2022).

- IRENA. Electricity Storage and Renewables: Costs and Markets to 2030; IRENA: Abu Dhabi, United Arab Emirates, 2017; p. 132. [Google Scholar]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Spitthoff, L.; Shearing, P.; Burheim, O. Temperature, Ageing and Thermal Management of Lithium-Ion Batteries. Energies 2021, 14, 1248. [Google Scholar] [CrossRef]

- Hoppecke. Installation, Commissioning and Operating Instructions for Vented Stationary Lead-Acid Batteries. 2013. Available online: https://www.hoppecke.com/fileadmin/Redakteur/Hoppecke-Main/Products-Import/vl_manual_en.pdf (accessed on 15 November 2022).

- Dufo-López, R.; Cortés-Arcos, T.; Artal-Sevil, J.; Bernal-Agustín, J. Comparison of Lead-Acid and Li-Ion Batteries Lifetime Prediction Models in Stand-Alone Photovoltaic Systems. Appl. Sci. 2021, 11, 1099. [Google Scholar] [CrossRef]

- McManus, M. Environmental consequences of the use of batteries in low carbon systems: The impact of battery production. Appl. Energy 2012, 93, 288–295. [Google Scholar] [CrossRef] [Green Version]

- Santillán-Saldivar, J.; Gaugler, T.; Helbig, C.; Rathgeber, A.; Sonnemann, G.; Thorenz, A.; Tuma, A. Design of an end Point Indicator for Mineral Resource Supply Risks in Life Cycle Sustainability Assessment. J. Ind. Ecol. 2020, 25, 1051–1062. Available online: https://onlinelibrary.wiley.com/doi/epdf/10.1111/jiec.13094 (accessed on 15 November 2022). [CrossRef]

- STEPSOL: An Innovative Hydraulic Storage Solution. 2018. Available online: https://www.youtube.com/watch?v=sIuzsryMkMQ&t=1s (accessed on 15 November 2022).

- Savin, O.; Badina, C.; Drommi, J.-L.; Baroth, J.; Charbonnier, S.; Bérenguer, C. Influence of Starts and Stops on the Aging of Hydroelectric Generator Stators by Thermal Cycling: Empirical Study and Accelerated Lifetime Model. In Proceedings of the 31st European Safety and Reliability Conference (ESREL 2021), Angers, France, 19–23 September 2021; pp. 3214–3221. [Google Scholar] [CrossRef]

- KSB. Multitec/Multitec-RO Pompe Multicellulaire Haute Pression Notice De Service/Montage. Available online: https://live-commerce-proxy-e2e-sales.ksb.com/rest/v2/ksb/users/anonymous/odata/disfile?application=PDF&documentType=YTO&documentNumber=1777.8&documentPart=FR&documentVersion=17&checksum=fb82bfe25a0f33f103f23bcbcb461fe42204aa6280bb9da9979b7116589ac846&salesOrg=1010&extension=PDF&mimetype=application%2Fpdf (accessed on 15 November 2022).

- Waide, P.; Brunner, C.U. Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems; IEA Energy Papers; OECD Publishing: Paris, France, 2011. [Google Scholar] [CrossRef]

- Shirinda, K.; Kusakana, K.; Koko, S.P. Techno-economic analysis of a standalone solar PV with groundwater pumped-hydro-storage system. In Proceedings of the 2019 International Conference on the Domestic Use of Energy (DUE), Wellington, South Africa, 25–27 March 2019; p. 6. [Google Scholar]

- Javed, M.S.; Ma, T.; Jurasz, J.; Canales, F.A.; Lin, S.; Ahmed, S.; Zhang, Y. Economic analysis and optimization of a renewable energy based power supply system with different energy storages for a remote island. Renew. Energy 2020, 164, 1376–1394. [Google Scholar] [CrossRef]

- Javed, M.S.; Ma, T.; Jurasz, J.; Mikulik, J. A hybrid method for scenario-based techno-economic-environmental analysis of off-grid renewable energy systems. Renew. Sustain. Energy Rev. 2021, 139, 110725. [Google Scholar] [CrossRef]

- Greacen, C.; Engel, R.; Quetchenbach, T. A Guidebook on Grid Interconnection and Islanded Operation of Mini-Grid Power Systems Up to 200 Kw. p. 80. Available online: https://www.osti.gov/servlets/purl/1171616 (accessed on 1 December 2022).

- Ekanayake, J. Induction generators for small hydro schemes. Power Eng. 2002, 16, 61–67. [Google Scholar] [CrossRef]

- Chilipi, R.; Sumaiti, A.A.; Singh, B. Control of Self-Excited Induction Generator-based Micro-Hydro Power Generation System Feeding Single-Phase and Three-Phase Loads. In Proceedings of the 2020 IEEE Industry Applications Society Annual Meeting, Detroit, MI, USA, 10–16 October 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Evans, P. Star Delta Starters Explained. Available online: https://theengineeringmindset.com/star-delta-startes/ (accessed on 1 December 2022).

- Laughton, M.A.; Warne, D.J. Motors and Actuators. In Electrical Engineer’s Reference Book; Elsevier: Amsterdam, The Netherlands, 2003; pp. 20-1–20-44. [Google Scholar] [CrossRef]

- Sellers, D. Variable Frequency Drive System Efficiency—Part 1. Available online: https://av8rdas.wordpress.com/2010/12/18/variable-frequence-drive-system-efficiency/ (accessed on 1 December 2022).

- Le Mao, T. Intégration De Micro-STEP Solaire Dans Un Contexte Insulaire. Ph.D. Thesis, Université Grenoble Alpes, Grenoble, France, 2020. [Google Scholar]

- Capelo, B.; Pérez-Sánchez, M.; Fernandes, J.F.; Ramos, H.M.; López-Jiménez, P.A.; Branco, P.C. Electrical behaviour of the pump working as turbine in off grid operation. Appl. Energy 2017, 208, 302–311. [Google Scholar] [CrossRef]

- Nag, S.; Lee, K.Y. DFIM-Based Variable Speed Operation of Pump-Turbines for Efficiency Improvement. IFAC-PapersOnLine 2018, 51, 708–713. [Google Scholar] [CrossRef]

- Belhadji, L. Optimisation Du Contrôle Commande D’un Système Hydraulique Réversible À Vitesse Variable. Ph.D. Thesis, Université Grenoble Alpes, Grenoble, France, 2013; p. 198. [Google Scholar]

- Reljić, D.; Čorba, Z.; Dumnić, B. Application of permanent magnet synchronous generators within small-scale hydropower systems. J. Process. Energy Agric. 2010, 14, 4. [Google Scholar]

- Maroufian, S. Generator Applications of Synchronous Reluctance Machines (SynRM). Available online: https://users.encs.concordia.ca/~peer/ppts/Sarah.pdf (accessed on 1 December 2022).

- ABB. IE5 Synchronous Reluctance Motors, News. Available online: https://new.abb.com/news/detail/80775/ie5-synchronous-reluctance-motors (accessed on 9 February 2022).

- Bidgoli, M.A.; Yang, W.; Ahmadian, A. DFIM versus synchronous machine for variable speed pumped storage hydropower plants: A comparative evaluation of technical performance. Renew. Energy 2020, 159, 72–86. [Google Scholar] [CrossRef]

- Krishna., V.B.M.; Sandeep, V.; Murthy, S.S. Experimental Study on Three Phase Permanent Magnet Synchronous Generator for Pico Hydro Isolated Systems. In Proceedings of the 2021 International Conference on Sustainable Energy and Future Electric Transportation (SEFET), Hyderabad, India, 21–23 January 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Salas, V.; Suponthana, W.; Salas, R. Overview of the off-grid photovoltaic diesel batteries systems with AC loads. Appl. Energy 2015, 157, 195–216. [Google Scholar] [CrossRef]

- Shezan, S.; Julai, S.; Kibria, M.; Ullah, K.; Saidur, R.; Chong, W.; Akikur, R. Performance analysis of an off-grid wind-PV (photovoltaic)-diesel-battery hybrid energy system feasible for remote areas. J. Clean. Prod. 2016, 125, 121–132. [Google Scholar] [CrossRef]

- Habib, M.; Ladjici, A.A.; Khoucha, F. Frequency Control in Off-Grid Hybrid Diesel/PV/Battery Power System. In Proceedings of the 4th International Conference on Electrical Engineering and Control Technologies (CEECT 2022), Shanghai, China, 16–18 December 2022; p. 7. [Google Scholar]

| Hours of Electricity Coverage | |||||||

| 0 h | 1–6 h | 7–12 h | 13–18 h | 19–23 h | 24 h | No Info | |

| Number of Communities | 71 | 1278 | 215 | 4 | 0 | 75 | 129 * |

| Number of Diesel Gensets | |||

| 1 | 2 | 3+ | |

| Number of Communities | 1708 | 32 | 20 |

| Community | Aguacatal | Mulatos | Chete | Limones |

|---|---|---|---|---|

| Installed Power (kW) | 25 | 40 | 98 | 118 |

| Number of Households | 150 | 112 | 167 | 350 |

| Percentage of Nominal Power Pn (%) | 100 | 80 | 60 | 40 | 20 |

| Efficiency (%) | 38 | 37 | 36 | 30 | 22 |

| Fuel Consumption (g/kWh_electric) | 230 | 235 | 240 | 280 | 400 |

| Electrical Machine | M-A-1 ASM | M-A-2 ASM + VFD | M-B-1 PMSM + VFD | M-B-2 SESM + VFD | M-C-1 PMSM + SQ | M-C-2 SESM + SQ |

|---|---|---|---|---|---|---|

| Comments | No power electronics Overheating at low speeds | Overheating at low speeds | Rare earth concern (magnets) | Redundancy of power electronics with AVR and VFD | No power electronics Rare earth concern (magnets) | Small AC/DC converter for excitation system |

| Market availability | Mass production | Mass production | Mass production | A rare combination of common machines | Rarer product than ASM | Custom motor build |

| Price range [50,51,52,53] | Motor: 90–120 USD/kW | Motor: 90–120 USD/kW VFD: 50–70 USD/kW | Motor: 150–200 USD/kW VFD: 50–70 USD/kW | Motor: 150–200 USD/kW VFD: 50–70 USD/kW | Motor: 150–200 USD/kW | Motor: >150–200 USD/kW (since custom build) |

| Frequency regulation | Throttling valve (constant power output) | VFD | VFD | VFD | Throttling valve (constant power output) | Throttling valve |

| Reactive power source | No (unless capacity bank present) | Only with 4Q VFD | Yes | Yes | Yes | Yes |

| Self-start mechanism | Inherent (high start-up current) | Inherent + VFD allows lower start-up currents | Obligatory VFD | Obligatory VFD | Inherent (high start-up current) | Inherent (high start-up current) |

| Efficiency range [47,48,49] | IE1-IE4 70–90% | IE1-IE4 70–90% | IE3-IE5 85–95% | IE3-IE5 85–95% | IE3-IE5 85–95% | IE3-IE5 85–95% |

| Power regulation mechanism; Power range (% of nominal power in each mode) | Pumping: throttling valve; 25–100% Turbining: throttling valve; 100% | Pumping: VFD; 0–100% Turbining: VFD 25–100% | Pumping: VFD; 0–100% Turbining: VFD; 20–100% | Pumping: VFD; 0–100% Turbining: VFD or AVR + valve; 20–100% | Pumping: throttling valve; 25–100% Turbining: throttling valve; 100% | Pumping: throttling valve; 25–100% Turbining: throttling valve + AVR; 20–100% |

| C1 | C2 | C3 | |

|---|---|---|---|

| ASM | Yes | No | No |

| ASM + VFD | Yes | Only with 4Q VFD | Only with 4Q VFD |

| PMSM + VFD | Yes | Yes | Yes |

| SESM + VFD | Yes | Yes | Yes |

| PMSM + SQ | Yes (constant load) | Yes (constant load) | Yes (constant load) |

| SESM + SQ | Yes | Yes | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guignard, N.; Cristofari, C.; Debusschere, V.; Garbuio, L.; Le Mao, T. Micro Pumped Hydro Energy Storage: Sketching a Sustainable Hybrid Solution for Colombian Off-Grid Communities. Sustainability 2022, 14, 16734. https://doi.org/10.3390/su142416734

Guignard N, Cristofari C, Debusschere V, Garbuio L, Le Mao T. Micro Pumped Hydro Energy Storage: Sketching a Sustainable Hybrid Solution for Colombian Off-Grid Communities. Sustainability. 2022; 14(24):16734. https://doi.org/10.3390/su142416734

Chicago/Turabian StyleGuignard, Nathan, Christian Cristofari, Vincent Debusschere, Lauric Garbuio, and Tina Le Mao. 2022. "Micro Pumped Hydro Energy Storage: Sketching a Sustainable Hybrid Solution for Colombian Off-Grid Communities" Sustainability 14, no. 24: 16734. https://doi.org/10.3390/su142416734

APA StyleGuignard, N., Cristofari, C., Debusschere, V., Garbuio, L., & Le Mao, T. (2022). Micro Pumped Hydro Energy Storage: Sketching a Sustainable Hybrid Solution for Colombian Off-Grid Communities. Sustainability, 14(24), 16734. https://doi.org/10.3390/su142416734