Durability Performance of PVA Fiber Cement-Stabilized Macadam

Abstract

:1. Introduction

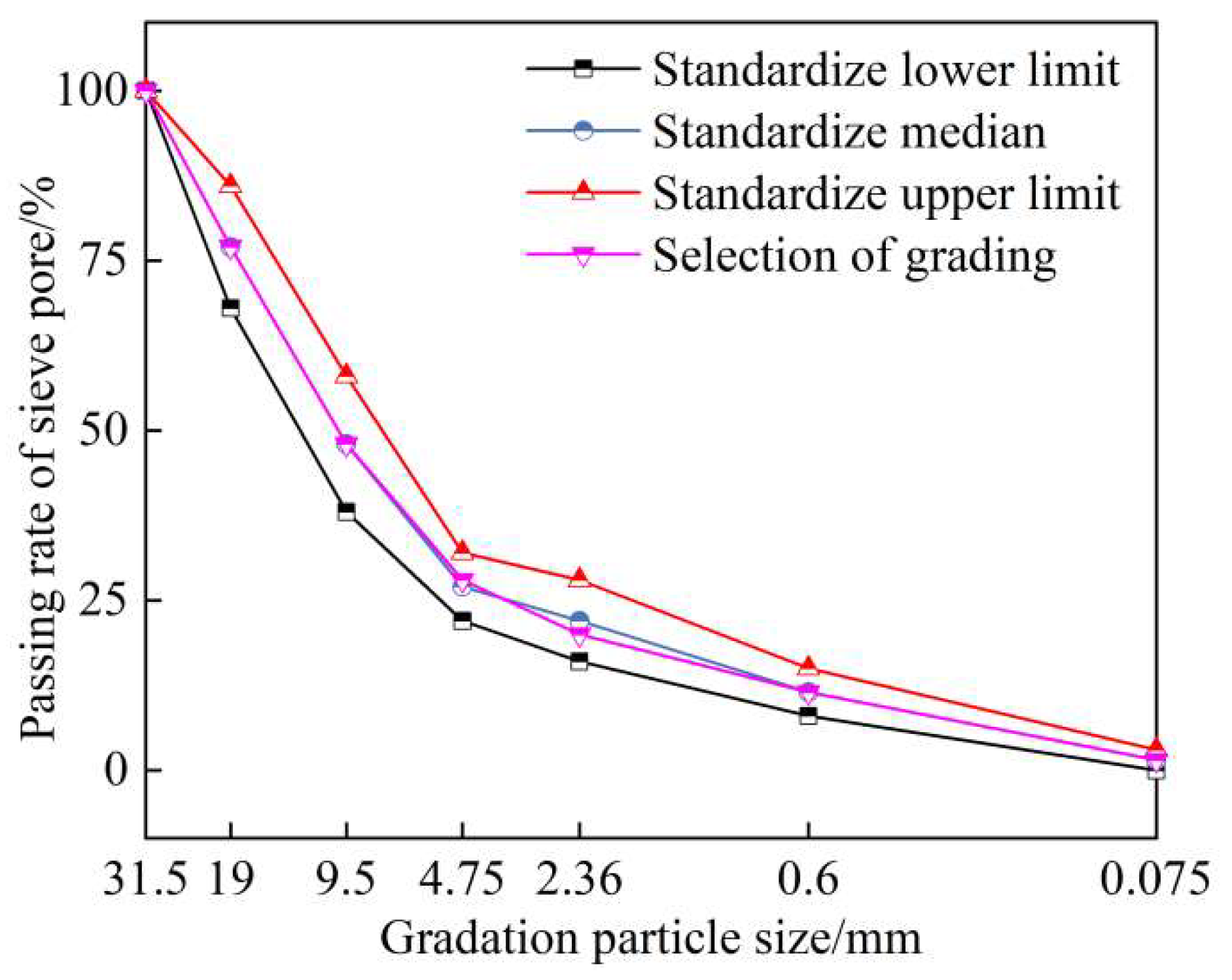

2. Materials and Methods

2.1. Materials

2.2. Fiber Surface Modification

2.3. Testing Methods

- (1)

- Dry shrinkage test

- (2)

- Temperature shrinkage test

- (3)

- Freeze–thaw bending test

- (4)

- Fatigue test

- (5)

- Residual toughness evaluation

3. Results and Discussion

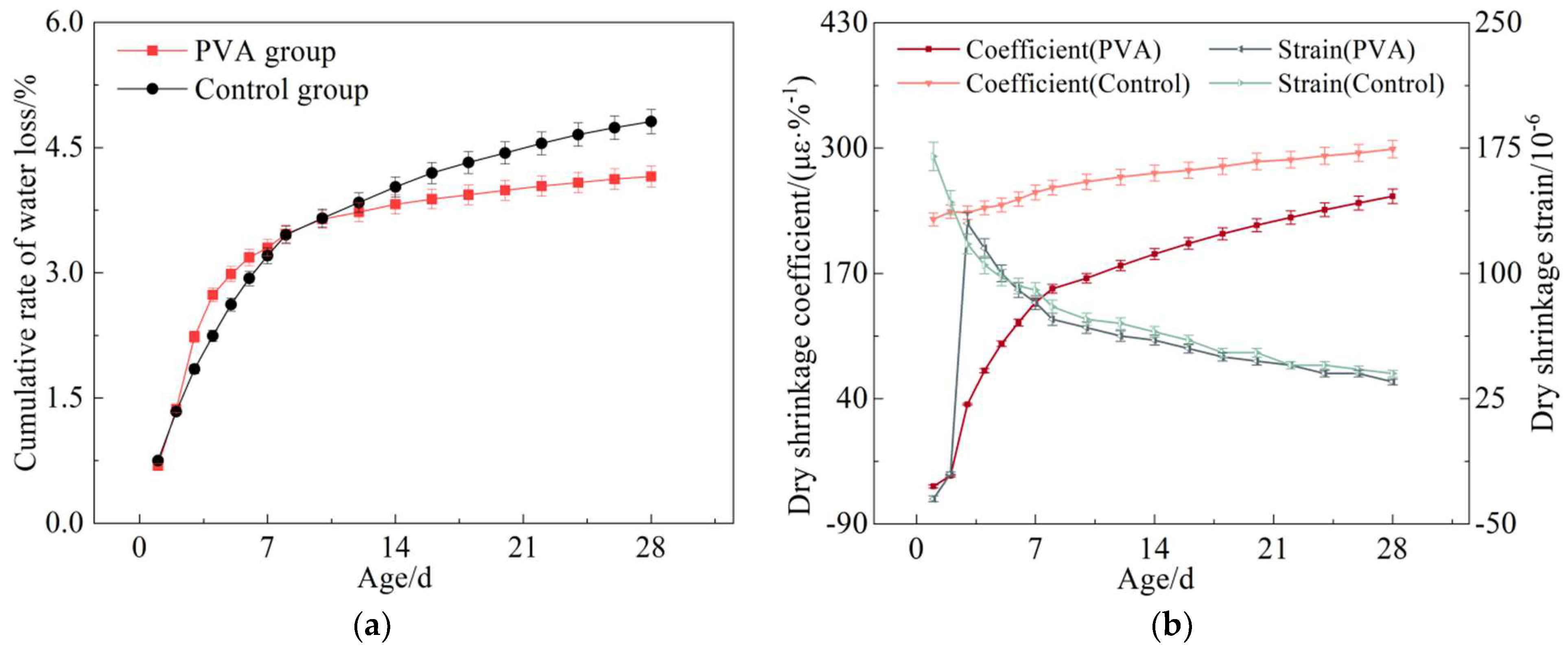

3.1. Shrinkage Characteristics of PVA Fiber Cement-Stabilized Macadam

3.1.1. Dry Shrinkage Performance

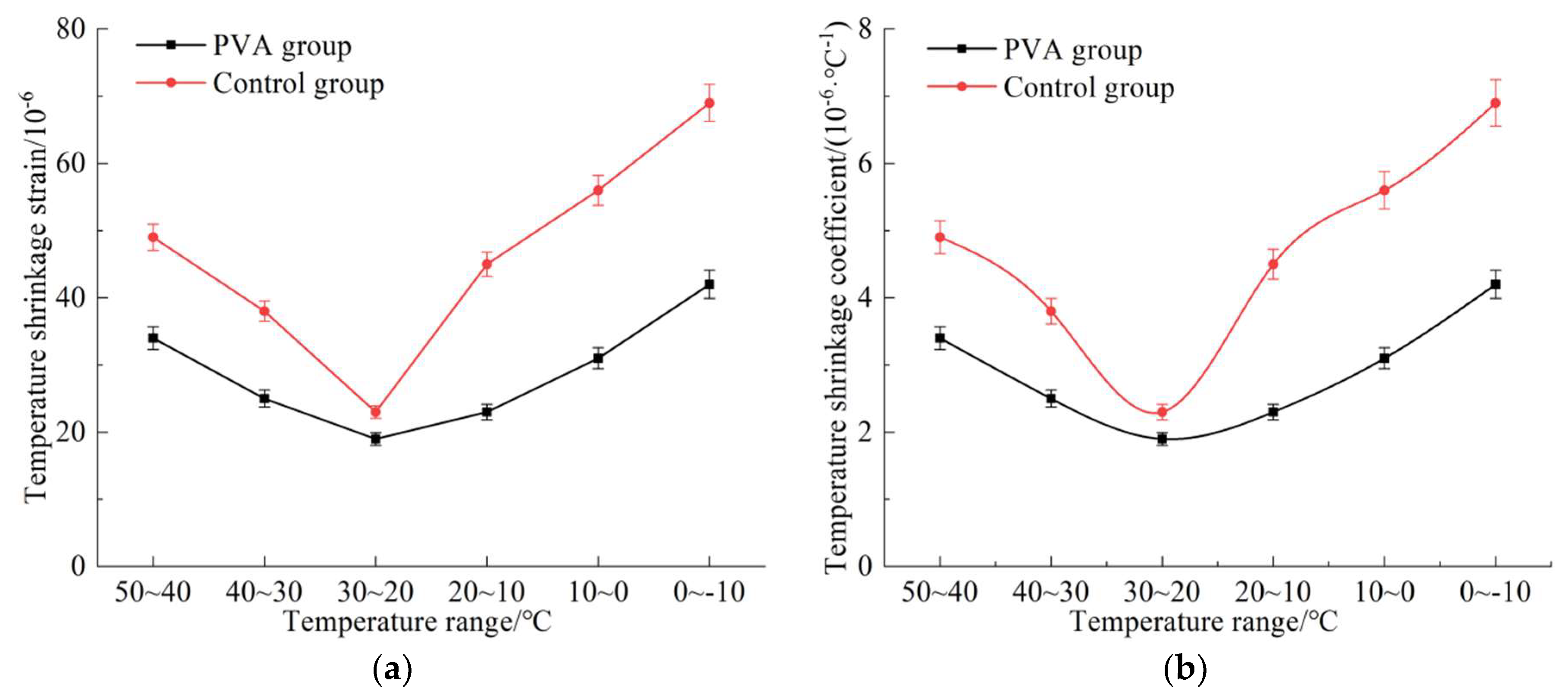

3.1.2. Temperature Shrinkage Performance

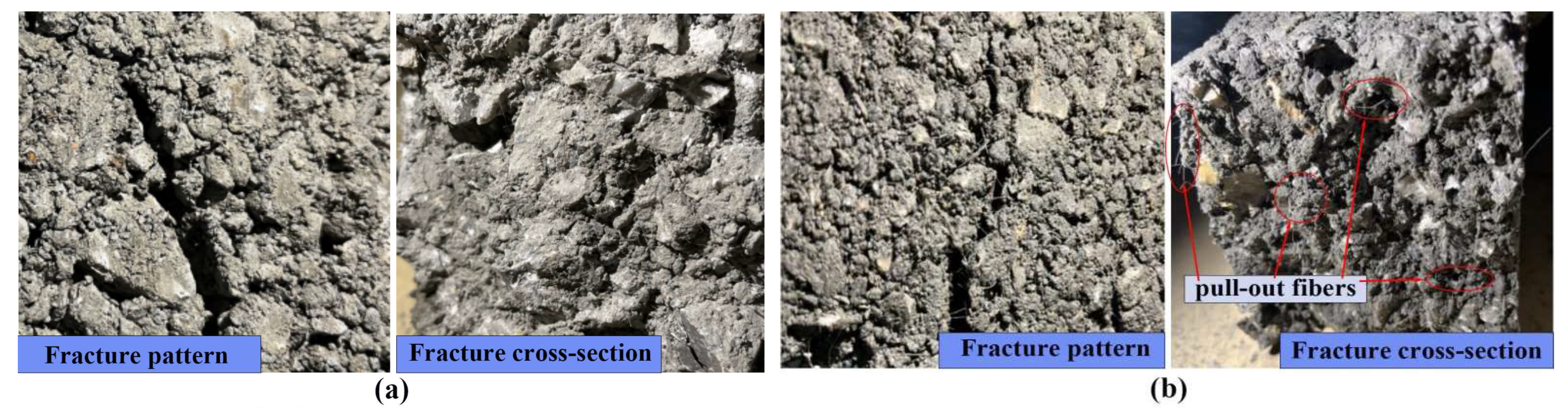

3.2. Low-Temperature Residual Toughness of PVA Fiber Cement-Stabilized Macadam

3.2.1. Low-Temperature Flexural Toughness

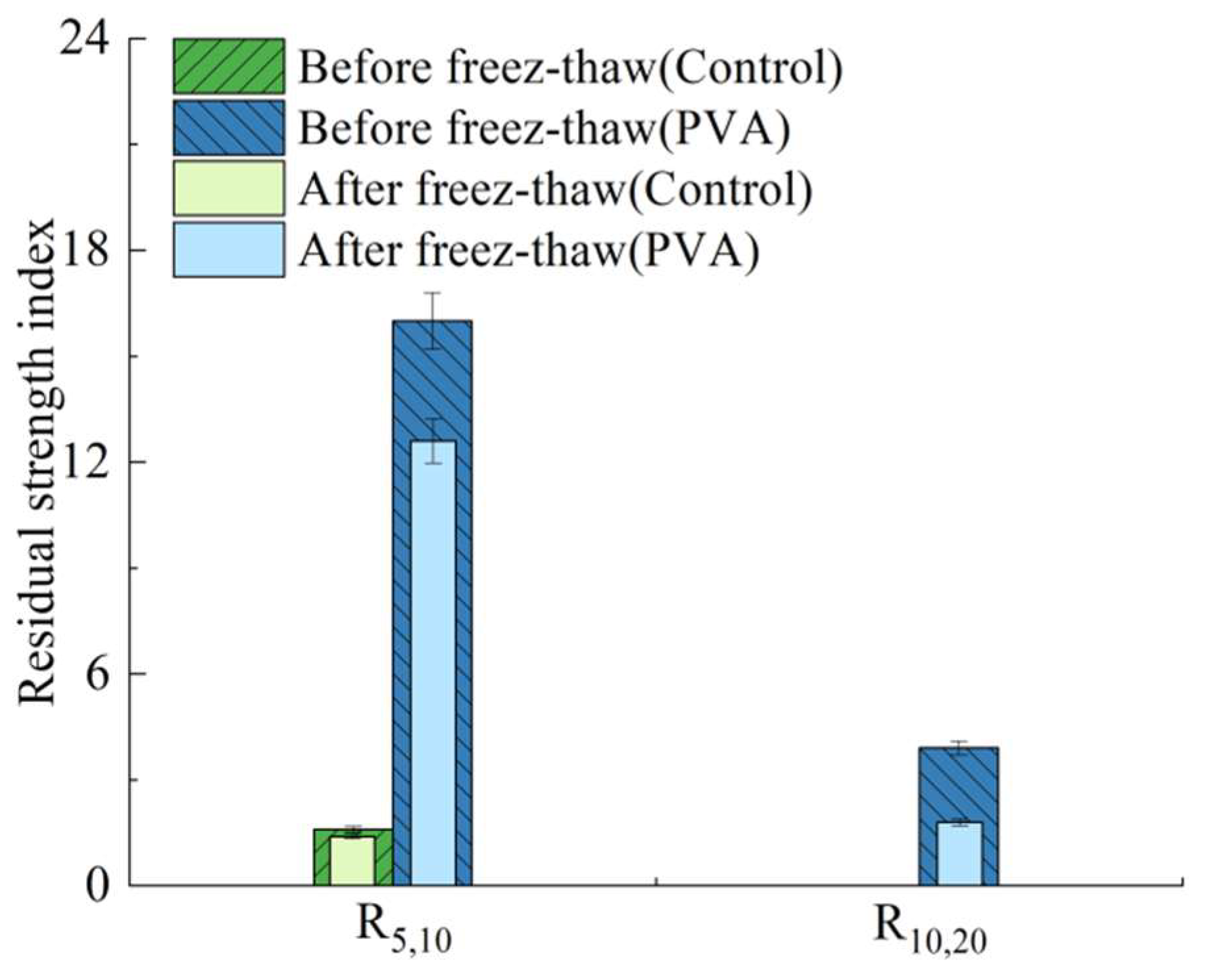

3.2.2. Residual Toughness Evaluation

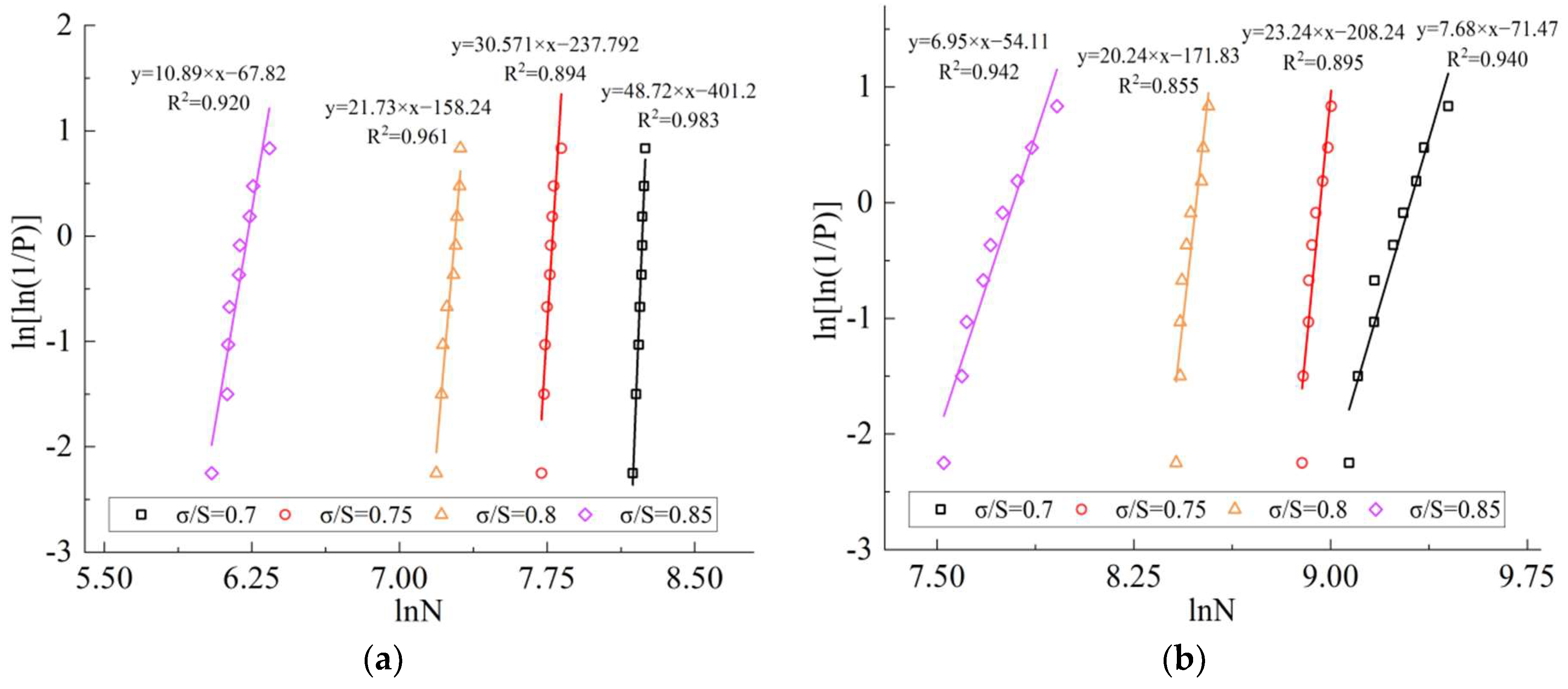

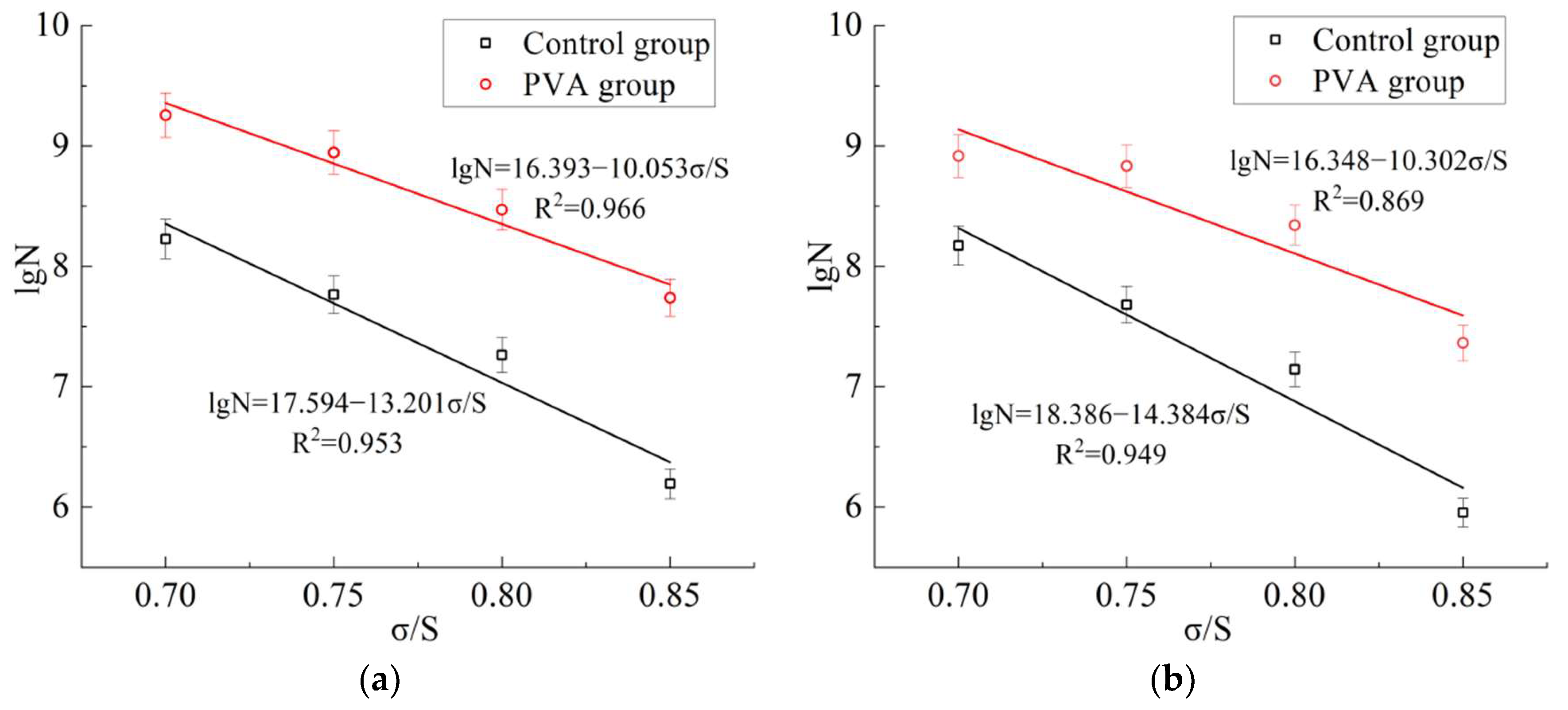

3.3. Fatigue Performance Analysis of PVA Fiber Cement-Stabilized Macadam Based on Weibull Distribution

4. Conclusions and Prospects

- (1)

- PVA fiber effectively improved the deformation characteristics and flexural toughness of cement-stabilized macadam. The cumulative water loss rate and dry shrinkage coefficient of PVA fiber cement-stabilized macadam decreased by 13.7% and 16.4%, respectively, when compared with those without fiber at 28 days of age. The strain and coefficient of temperature shrinkage of PVA fiber cement-stabilized macadam decreased by 17.4~48.9%, compared with those without fiber in the temperature range of −10~50 °C. The residual flexural tensile strength and low-temperature bearing capacity increased by 10.3% and 55.3%, respectively, after fiber incorporation. The deflection after the freeze–thaw cycle decreased by 17.2%, the residual toughness indices increased by 58.6%, 88.1%, and 98.3% and the residual strength index increased by more than 100%.

- (2)

- PVA fiber improved the fatigue performance of cement-stabilized macadam and its fatigue life obeyed the two-parameter Weibull distribution. Its fatigue life under different reliabilities was also higher than the specimens without fiber. The establishment of the prediction equation for the fatigue life of the mix under different reliabilities can reflect the improved effect of PVA fiber on the fatigue performance of cement-stabilized macadam more accurately.

- (3)

- In this study, the durability performance of PVA fiber cement-stabilized macadam was analyzed mainly based on indoor tests, and the flexural toughness and fatigue performance were evaluated by combining standard toughness evaluation methods and mathematical statistics, but the durability enhancement mechanism has not yet been investigated. In the future, the durability enhancement mechanism of PVA fiber cement-stabilized macadam must be investigated in depth, and a test road will be needed for long-term performance monitoring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wen, P.H.; Wang, C.H.; Song, L.; Niu, L.; Chen, H. Durability and Sustainability of Cement-Stabilized Materials Based on Utilization of Waste Materials: A Literature Review. Sustainability 2021, 13, 11610. [Google Scholar] [CrossRef]

- Wang, C.; Li, Y.; Wen, P.; Zeng, W.; Wang, X. A comprehensive review on mechanical properties of green controlled low strength materials. Constr. Build. Mater. 2023, 363, 129611. [Google Scholar] [CrossRef]

- Liu, L.Q.; Wang, C.H.; Liang, Q. Preparation of a Heat Insulation Bonding Layer for Roads and its Heat Insulation Effect. J. Clean. Prod. 2022, 365, 132828. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Recycled Hybrid Fiber-Reinforced & Cement-Stabilized Pavement Mixtures: Tensile Properties and Cracking Characterization. Constr. Build. Mater. 2018, 179, 488–499. [Google Scholar]

- Wei, J.; Wang, Y.; Li, X.; Jia, Z.; Qiao, S.; Zhang, Q.; Du, J. Effect of porosity and crack on the thermoelectric properties of expanded graphite/carbon fiber reinforced cement-based composites. Int. J. Energy Res. 2020, 44, 6885–6893. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, C.H.; Li, Y.W.; Feng, L.; Huang, S. Performance Development of Polyurethane Elastomer Composites in Different Construction and Curing Environments. Constr. Build. Mater. 2023, 365, 130047. [Google Scholar] [CrossRef]

- Huang, Y.J. Composition Design and Performance Study of PVA Fibre Cement Stabilized Gravel Base. Master’s Thesis, Chang’an University, Xi’an, China, 2022. [Google Scholar]

- Alam, B.; Yaman, I.O. Fatigue Performance of PVA Fibre Reinforced Cementitious Composite Overlays. Int. J. Pavement Eng. 2019, 22, 822–828. [Google Scholar] [CrossRef]

- Zhang, P.; Yuan, P.; Guan, J.F.; Guo, J. Fracture Behavior of Multi-Scale Nano-SiO2 and Polyvinyl Alcohol Fiber Reinforced Cementitious Composites under the Complex Environments. Theor. Appl. Fract. Mech. 2022, 122, 103584. [Google Scholar] [CrossRef]

- Kim, K.W.; Yu, C.; Han, J.W.; Park, C.G. Strength and Durability of Rapid Set PVA Fiber Reinforced LMC for Pavement Repair. Polym. Polym. Compos. 2019, 27, 179–188. [Google Scholar] [CrossRef]

- Huang, Z.Q.; Xu, G.T.; Liu, X. Fracture Performance of PVA Fiber Cementitious Composites under Freeze-Thaw Cycles. J. Shenyang Univ. Technol. 2018, 40, 352–356. [Google Scholar]

- Zhang, P.; Wang, L.; Zheng, Y.X. Study on Flexural Toughness Properties of PVA Fiber Reinforced Nano-SiO2 Cement Composites. New Build. Mater. 2021, 48, 81–84. [Google Scholar]

- Zhang, P.; Kang, Y.L.; Guo, J.J. Fracture Properties of Nano-SiO2 and PVA Fiber Reinforced Cementitious Composites. J. Build. Mater. 2021, 24, 908–915. [Google Scholar]

- Liu, T.Y.; Zhang, P.; Li, Q.F.; Hu, S.W.; Ling, Y.F. Durability Assessment of PVA Fiber-Reinforced Cementitious Composite Containing Nano-SiO2 Using Adaptive Neuro-Fuzzy Inference System. Crystals 2020, 10, 347. [Google Scholar] [CrossRef]

- Li, Y.J. Study on Crack Resistance and Durability of Cement Stabilized Macadam Mixture with PVA Fiber. Highw. Eng. 2020, 45, 180–188+219. [Google Scholar]

- Yu, J.Y.; Liang, N.X.; Tong, P.; Tang, R.X. Fatigue Life Analysis of Polyvinyl Alcohol Fiber Modified Cement Stability Macadam Base Pavement. Bull. Chin. Ceram. Soc. 2019, 38, 2408–2413+2419. [Google Scholar]

- Zhao, Y.; Yang, X.; Zhang, Q.Y.; Liang, Y.; Xiang, Y.; Qin, M. Crack Resistance and Mechanical Properties of Polyvinyl Alcohol Fiber-Reinforced Cement-Stabilized Macadam Base. Adv. Civ. Eng. 2020, 2020, 6564076. [Google Scholar] [CrossRef]

- Wang, X.D. JTG/T F20-2015; Technical Guidelines for Construction of Highway Roadbases. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- Han, L.; Cai, H.F.; Chen, X.; Zheng, C.; Guo, W. Study of UHMWPE Fiber Surface Modification and the Properties of UHMWPE/Epoxy Composite. Polymers 2020, 12, 521. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.D.; Li, M.J.; Sha, A.M.; Wang, S.Y.; Zhou, X.Y.; Shen, G.H.; Lu, K.J. JTG E51-2009; Test Methods of Material Stabilized with Inorganic Binders for Highway Engineering. Research Institute of Highway Ministry of Transport: Beijing, China, 2009.

- ASTM C1018-97; Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber Reinforced Concrete (Using Beam with Third-Point Loading). ASTM: Philly, PA, USA, 1997.

- Chen, Q.; Wang, C.H.; Yu, S.X.; Song, Z.; Fu, H.; An, T. Low-Temperature Mechanical Properties of Polyurethane-Modified Waterborne Epoxy Resin for Pavement Coating. Int. J. Pavement Eng. 2022. [Google Scholar] [CrossRef]

- Gu, D.; Liu, H.; Gao, X.; Huang, D.; Zhang, W. Influence of Cyclic Wetting-Drying on the Shear Strength of Limestone with a Soft Interlayer. Rock Mech. Rock Eng. 2021, 54, 4369–4378. [Google Scholar] [CrossRef]

- Wang, L.Q.; Yin, Y.P.; Huang, B.L.; Dai, Z. Damage Evolution and Stability Analysis of the Jianchuandong Dangerous Rock Mass in the Three Gorges Reservoir Area. Eng. Geol. 2019, 265, 105439. [Google Scholar] [CrossRef]

- Wang, S.; Wang, C.H.; Yuan, H.Z.; Ji, X.; Yu, G.; Jia, X. Size Effect of Piezoelectric Energy Harvester for Road with High Efficiency Electrical Properties. Appl. Energy 2023, 330, 120379. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Thomas, B.; Zhang, W.G.; Gu, D. A Novel Random Angular Bend (RAB) Algorithm and DEM Modeling of Thermal Cracking Responses of Sandstone. Geomech. Energy Environ. 2022, 32, 100335. [Google Scholar] [CrossRef]

- Jiang, Y.J.; Yuan, K.J.; Deng, C.Q.; Tian, T. Fatigue Performance of Cement-Stabilized Crushed Gravel Produced Using Vertical Vibration Compaction Method. J. Mater. Civ. Eng. 2020, 32, 04020318. [Google Scholar] [CrossRef]

| Length/mm | Diameter/μm | Aspect Ratio | Density/(g·m−3) | Modulus of Elasticity/GPa | Tensile Strength/MPa | Elongation/% |

|---|---|---|---|---|---|---|

| 12 | 40 ± 5 | 0.3 | 1.30 | ≥35 | ≥1500 | ≤7 |

| Material Type | Reliability/% | Fatigue Life Equation | R2 |

|---|---|---|---|

| Control group | 0.5 | lgN = 17.594 − 13.201σ/S | 0.953 |

| 0.95 | lgN = 18.386 − 14.384σ/S | 0.949 | |

| PVA | 0.5 | lgN = 16.393 − 10.053σ/S | 0.966 |

| 0.95 | lgN = 16.348 − 10.302σ/S | 0.869 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, S.; Wang, C.; Zheng, Q.; Chen, F.; Huang, Y. Durability Performance of PVA Fiber Cement-Stabilized Macadam. Sustainability 2022, 14, 16953. https://doi.org/10.3390/su142416953

Tan S, Wang C, Zheng Q, Chen F, Huang Y. Durability Performance of PVA Fiber Cement-Stabilized Macadam. Sustainability. 2022; 14(24):16953. https://doi.org/10.3390/su142416953

Chicago/Turabian StyleTan, Songyuan, Chaohui Wang, Qi Zheng, Feng Chen, and Yunjie Huang. 2022. "Durability Performance of PVA Fiber Cement-Stabilized Macadam" Sustainability 14, no. 24: 16953. https://doi.org/10.3390/su142416953

APA StyleTan, S., Wang, C., Zheng, Q., Chen, F., & Huang, Y. (2022). Durability Performance of PVA Fiber Cement-Stabilized Macadam. Sustainability, 14(24), 16953. https://doi.org/10.3390/su142416953