Sustainable Supply Chain and Business Performance: The Impact of Strategy, Network Design, Information Systems, and Organizational Structure

Abstract

:1. Introduction

2. Literature Review

2.1. Supply Chain Strategy

2.2. Supply Chain Network Design

2.3. Information Systems

2.4. Organizational Structure

3. Research Methodology

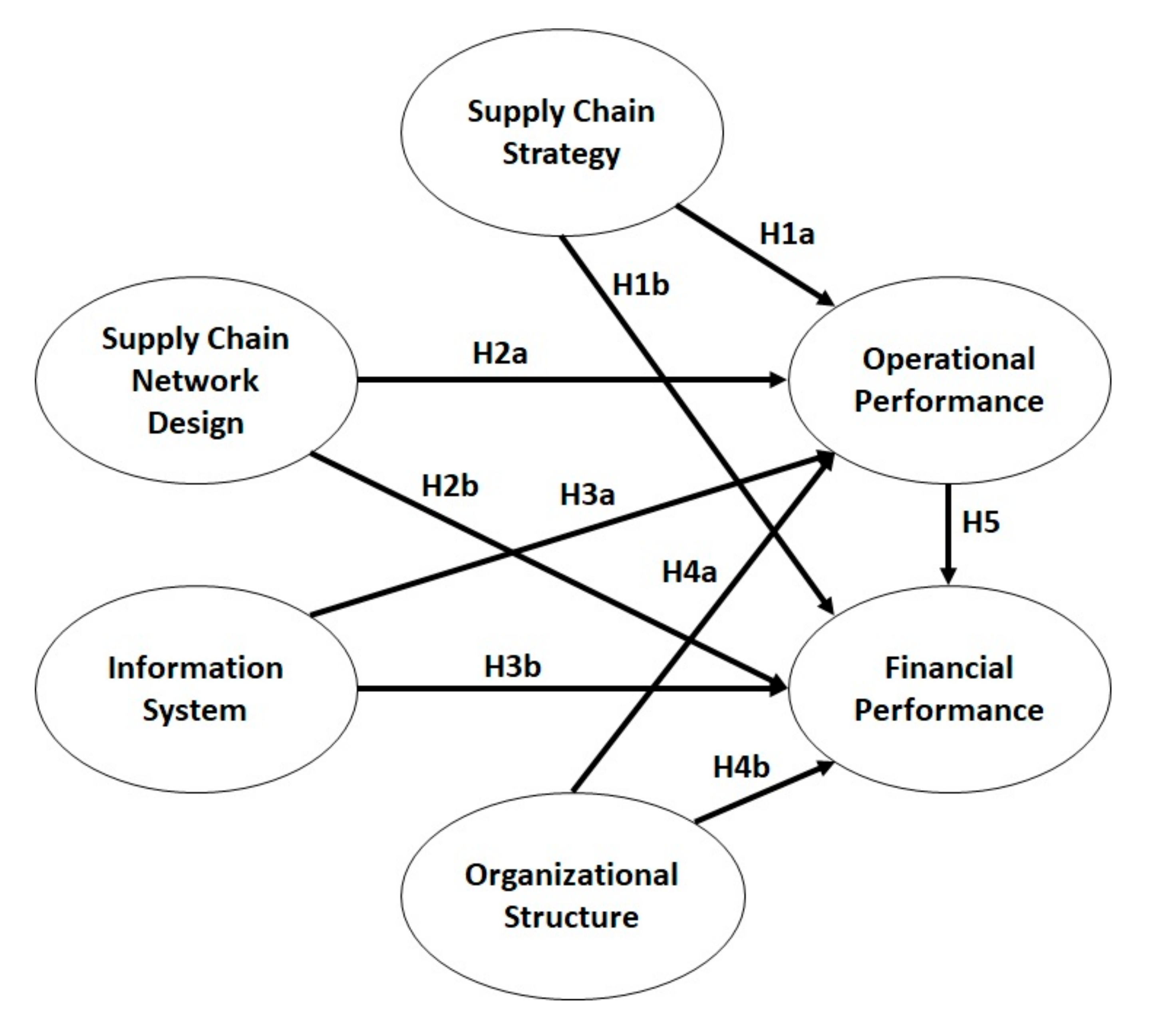

- What is the process of integrating SC with organizational strategy?

- How is organizational performance affected by the supply chain network design?

- How does the information system in SC impacts their organizational performance?

- How does organizational structure impacts organizational performance?

4. Results

5. Discussion, Implications and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Particulars | Items Loading | Mean |

| Supply Chain Strategy | ||

| The supply chain strategy helps to offer new products and services | 0.827 | 4.26 |

| The strategic decision helps to develop a new product for the marketplace | 0.721 | |

| The supply chain strategy makes the network system of the supply chain more clarify | 0.723 | |

| The supply chain strategy supports the acquisition and implementation of an appropriate information system | 0.801 | |

| The supply chain strategy offers a high level of quality in products or services | 0.838 | |

| The supply chain strategy ensures the internal and external communication between employee, supplier, and customer | 0.701 | |

| Strategic decisions determine the overall direction of corporation supply chain | 0.676 | |

| Corporation strategy help to use effective long-term material planning and implementing low-cost production | 0.803 | |

| Corporation strategy allows sharing their future vision of supply chain with suppliers | 0.651 | |

| Supply Chain Network Design | ||

| The supply chain network design concentrate on improving efficiency | 0.776 | 4.32 |

| The supply chain network design is focused on improving operational standards | 0.675 | |

| The supply chain network design reduces operational hurdles by bridging between the corporation, suppliers, and customers. | 0.851 | |

| The supply chain network design ensures services in a timely manner and at the right place in the market | 0.833 | |

| The supply chain network design focuses on reducing operational expenses and increasing profitability | 0.594 | |

| The supply chain network design provides financial and non-financial support to the corporation by enabling them to deliver orders to customers sooner than competitors | 0.792 | |

| Information Systems | ||

| The corporation keeps full information about issues that affect its business | 0.845 | 4.4 |

| The corporation has the ability to manage inventory of suppliers and the organization optimally to ensure smooth operations | 0.883 | |

| The information system enables the corporation to reduces operational complexities | 0.922 | |

| The corporation uses customers’ feedback to improve the products and services | 0.848 | |

| The information system reduces the time and cost of doing business | 0.92 | |

| The information system enables the corporation to discover new markets | 0.845 | |

| The information system enables the management to make effective decisions | 0.902 | |

| Organizational Structure | ||

| The organizational structure ensures the active participation of the employees in important decisions | 0.855 | 4.06 |

| The organizational structure promotes a sense of vigilance, proactively, and commitments to enhance operational performance | 0.862 | |

| Cross-departmental cooperation is harmonious and collaborative and ensures smooth operations within the organization | 0.855 | |

| The performance appraisal system is well developed and evaluate all employees in fair manners | 0.764 | |

| The organizational structure delegate powers at all level to ensure excellent customer service | 0.846 | |

| Authorities are well divided and administrative procedures are clearly defined. | 0.919 | |

| Job descriptions and standard operating procedures are clearly defined | 0.882 | |

| Operational Performance | ||

| The corporation’s supply chain is more focused on operational aspects rather than financial aspects | 0.859 | 4.02 |

| The corporation respond quickly to market changes to improve their products and services | 0.853 | |

| The supply chain strategy of the organization is well defined, clear and widely understood within your corporation | 0.847 | |

| The supply chain strategy of the organization has the ability to change production capacity quickly based on customer demands | 0.848 | |

| The supply chain strategy of the organization has the ability to reduce operational complexities | 0.857 | |

| Financial Performance | ||

| The management of the company uses supply chain strategy to increase organization operational performance | 0.861 | 4.13 |

| The supply chain strategy of the organization has a significant role in streamlining the operational activities of the organization | 0.883 | |

| The corporation customize products by adding certain models required by customers | 0.871 | |

| The corporation has the capability to control the sales and distribution network which ultimately will impact their financial performance | 0.888 | |

| The supply chain strategy of the organization has the ability to change existing product or design new products to attract a new customer | 0.851 | |

| The supply chain strategy of the organization has a positive impact on organizational financial performance | 0.861 | |

| The management of the company uses supply chain strategy to reduce expenses and increase its profitability | 0.743 | |

References

- Habib, M.; Abbas, J.; Noman, R. Are human capital, intellectual property rights, and research and development expenditures really important for total factor productivity? An empirical analysis. Int. J. Soc. Econ. 2019, 46, 756–774. [Google Scholar] [CrossRef]

- Abbas, J. Impact of total quality management on corporate green performance through the mediating role of corporate social responsibility. J. Clean. Prod. 2020, 242, 118458. [Google Scholar] [CrossRef]

- Riaz, M.; Pamucar, D.; Farid, H.M.A.; Hashmi, M.R.; Raza, M. q-Rung Orthopair Fuzzy Prioritized Aggregation Operators and Their Application Towards Green Supplier Chain Management. Symmetry 2020, 12, 976. [Google Scholar] [CrossRef]

- Qi, Y.; Huo, B.; Wang, Z.; Yeung, H.Y.J. The impact of operations and supply chain strategies on integration and performance. Int. J. Prod. Econ. 2017, 185, 162–174. [Google Scholar] [CrossRef]

- Mishra, D.; Gunasekaran, A.; Papadopoulos, T.; Dubey, R. Supply chain performance measures and metrics: A bibliometric study. Benchmarking Int. J. 2018, 25, 932–967. [Google Scholar] [CrossRef]

- Stevenson, W.J. Operations Management; McGraw-Hill: London, UK., 2015; ISBN 978-0-07-802410-8. [Google Scholar]

- Perez-Franco, R.; Phadnis, S.; Caplice, C.; Sheffi, Y. Rethinking supply chain strategy as a conceptual system. Int. J. Prod. Econ. 2016, 182, 384–396. [Google Scholar] [CrossRef]

- Arora, A.; Arora, A.S.; Sivakumar, K. Relationships among Supply Chain Strategies, Organizational Performance, and Technological and Market Turbulences. Int. J. Logist. Manag. 2016, 27, 206–232. [Google Scholar] [CrossRef]

- Abbas, J. Impact of total quality management on corporate sustainability through the mediating effect of knowledge management. J. Clean. Prod. 2020, 244, 118806. [Google Scholar] [CrossRef]

- Musyoka, M. Lean Supply Chain Management Practices and Organizational Performance of Large Scale Manufacturing Firms in Kenya; Business University of Nairobi: Nairobi, Kenya, 2015. [Google Scholar]

- Jajja, M.S.S.; Brah, S.A.; Hassan, S.Z. Supply chain strategy and organisational performance: Role of core operational functions. Int. J. Serv. Oper. Manag. 2014, 17, 330. [Google Scholar] [CrossRef]

- Rose, W.; Mann, I.J.S.; Rose, S. A Strategic Perspective and Taxonomy of Supply Chain Strategies. IUP J. Oper. Manag. 2012, 11, 6–42. [Google Scholar]

- Lu, D.; Ding, Y.; Asian, S.; Paul, S.K. From Supply Chain Integration to Operational Performance: The Moderating Effect of Market Uncertainty. Glob. J. Flex. Syst. Manag. 2017, 19, 3–20. [Google Scholar] [CrossRef]

- Adebanjo, D.; Teh, P.-L.; Ahmed, P.K. The impact of supply chain relationships and integration on innovative capabilities and manufacturing performance: The perspective of rapidly developing countries. Int. J. Prod. Res. 2017, 56, 1708–1721. [Google Scholar] [CrossRef]

- Kumar, V.; Chibuzo, E.N.; Garza-Reyes, J.A.; Kumari, A.; Lona, L.R.; Lopez-Torres, G.C. The Impact of Supply Chain Integration on Performance: Evidence from the UK Food Sector. Procedia Manuf. 2017, 11, 814–821. [Google Scholar] [CrossRef] [Green Version]

- Jamshi, J.; Ganeshkumar, C. Causal Linkage among Business Analytics, Supply Chain Performance, Firm Performance and Competitive Advantage. Parik-KIIT J. Manag. 2017, 13, 29. [Google Scholar] [CrossRef]

- Hearnshaw, E.J.; Wilson, M. A complex network approach to supply chain network theory. Int. J. Oper. Prod. Manag. 2013, 33, 442–469. [Google Scholar] [CrossRef]

- Cegielski, C.G.; Jones-Farmer, L.A.; Wu, Y.; Hazen, B.T. Adoption of Cloud Computing Technologies in Supply Chains: An Organizational Information Processing Theory Approach. Int. J. Logist. Manag. 2012, 23, 184–211. [Google Scholar] [CrossRef]

- Rogers, K.W.; Purdy, L.; Safayeni, F.; Duimering, P.R. A supplier development program: Rational process or institutional image construction? J. Oper. Manag. 2006, 25, 556–572. [Google Scholar] [CrossRef]

- Hudnurkar, M.; Jakhar, S.; Rathod, U. Factors Affecting Collaboration in Supply Chain: A Literature Review. Procedia-Soc. Behav. Sci. 2014, 133, 189–202. [Google Scholar] [CrossRef] [Green Version]

- Parulekar, A.; Verulkar, A. Supply Chain Management And Its Relationship With Organizational Performance: A Literature Review. J. Commer. Manag. Thought 2015, 6, 770. [Google Scholar] [CrossRef]

- Aziziankohan, A.; Jolai, F.; Khalilzadeh, M.; Soltani, R.; Tavakkoli-Moghaddam, R. Green supply chain management using the queuing theory to handle congestion and reduce energy consumption and emissions from supply chain transportation fleet. J. Ind. Eng. Manag. 2017, 10, 213. [Google Scholar] [CrossRef] [Green Version]

- Chopra, S.; Meindl, P. Supply Chain Management: Strategy, Planning, and Operation, 3rd ed.; Prentice Hall Inc.: Upper Saddle River, NJ, USA, 2014; ISBN 9780874216561. [Google Scholar]

- Abbas, J.; Muzaffar, A.; Mahmood, H.K.; Ramzan, M.A.; Rizvi, S.S.u.H. Impact of Technology on Performance of Employees (A Case Study on Allied Bank Ltd, Pakistan). World Appl. Sci. J. 2014, 29, 271–276. [Google Scholar]

- Wang, C.-H. How Organizational Green Culture Influences Green Performance and Competitive Advantage: The Mediating Role of Green Innovation. J. Manuf. Technol. Manag. 2019, 30, 666–683. [Google Scholar] [CrossRef]

- Abbas, J.; Kumari, K. Examining the Relationship between Total Quality Management and Knowledge Management and Their Impact on Organizational Performance. J. Econ. Adm. Sci. 2021. [Google Scholar] [CrossRef]

- Richey, R.G.; Roath, A.S.; Whipple, J.M.; Fawcett, S.E. Exploring a governance theory of supply chain management: Barriers and facilitators to integration. J. Bus. Logist. 2010, 31, 237–256. [Google Scholar] [CrossRef]

- Hamali, S.; Prihandoko, D.; Kurniawan, S.; Ramdhani, R. The effects of supply chain information integration on organizational performance in food small industry. Manag. Sci. Lett. 2020, 10, 695–702. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, R.K.; Modgil, S. Exploring the relationship between ICT, SCM practices and organizational performance in agri-food supply chain. Benchmarking Int. J. 2020, 27, 1003–1041. [Google Scholar] [CrossRef]

- Saragih, J.; Tarigan, A.; Silalahi, E.F.; Wardati, J.; Pratama, I. Supply Chain Operational Capability and Supply Chain Operational Performance: Does the Supply Chain Management and Supply Chain Integration Matters. Int. J. Sup. Chain. Mgt. 2020, 9, 1222. [Google Scholar]

- Shahzad, F.; Du, J.; Khan, I.; Shahbaz, M.; Murad, M.; Khan, M.A.S. Untangling the influence of organizational compatibility on green supply chain management efforts to boost organizational performance through information technology capabilities. J. Clean. Prod. 2020, 266, 122029. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Jenny, M.; Basana, S.R.; Siagian, H. The Effect of Competency Management on Organizational Performance through Supply Chain Integration and Quality. Available online: http://growingscience.com/uscm/Vol9/uscmv9no2.html (accessed on 12 September 2021).

- Imran, M.; Abbas, J. The Role Of Strategic Orientation In Export Performance of China Automobile Industry. In Handbook of Research on Managerial Practices and Disruptive Innovation in Asia; IGI Global: Hershey, PA, USA, 2020; pp. 249–263. [Google Scholar]

- Jin, S.H.; Jeong, S.J.; Kim, K.S. A Linkage Model of Supply Chain Operation and Financial Performance for Economic Sustainability of Firm. Sustainability 2017, 9, 139. [Google Scholar] [CrossRef] [Green Version]

- Eskandarpoura, M.; Dejaxa, P.; Miemczyk, J.; Pétona, O. Sustainable Supply Chain Network Design: An Optimization-Oriented Review. Omega 2015, 54, 11–32. [Google Scholar] [CrossRef]

- Tiwari, M.; Mahanty, B.; Sarmah, S.P.; Jenamani, M. Modeling of Responsive Supply Chain; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Ball, P. Dynamic modelling for supply chain management: Dealing with front-end, back-end and integration issues, by Adolfo Crespo Marquez. Prod. Plan. Control. 2011, 24, 141–142. [Google Scholar] [CrossRef]

- Bals, L.; Tate, W.L. Sustainable Supply Chain Design in Social Businesses: Advancing the Theory of Supply Chain. J. Bus. Logist. 2018, 39, 57–79. [Google Scholar] [CrossRef] [Green Version]

- Abbas, J. HEISQUAL: A Modern Approach to Measure Service Quality in Higher Education Institutions. Stud. Educ. Eval. 2020, 67, 100933. [Google Scholar] [CrossRef]

- Lin, C.-C.; Wang, T.-H. Build-to-order supply chain network design under supply and demand uncertainties. Transp. Res. Part B Methodol. 2011, 45, 1162–1176. [Google Scholar] [CrossRef]

- Lashine, S.H.; Fattouh, M.; Issa, A. Location/allocation and routing decisions in supply chain network design. J. Model. Manag. 2006, 1, 173–183. [Google Scholar] [CrossRef]

- Nagurney, A. Optimal supply chain network design and redesign at minimal total cost and with demand satisfaction. Int. J. Prod. Econ. 2010, 128, 200–208. [Google Scholar] [CrossRef]

- Pradabwong, J.; Braziotis, C.; Tannock, J.D.; Pawar, K.S. Business process management and supply chain collaboration: Effects on performance and competitiveness. Supply Chain Manag. Int. J. 2017, 22, 107–121. [Google Scholar] [CrossRef]

- De Vass, T.; Shee, H.; Miah, S.J. The effect of “Internet of Things” on supply chain integration and performance: An organisational capability perspective. Australas. J. Inf. Syst. 2018, 22, 22. [Google Scholar] [CrossRef] [Green Version]

- Abbas, J.; Kumari, K.; Al-Rahmi, W.M. Quality Management System in Higher Education Institutions and Its Impact on Students’ Employability with the Mediating Effect of Industry–Academia Collaboration. JEAS 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Vonderembse, M.A.; Uppal, M.; Huang, S.H.; Dismukes, J.P. Designing supply chains: Towards theory development. Int. J. Prod. Econ. 2006, 100, 223–238. [Google Scholar] [CrossRef]

- Qrunfleh, S.; Tarafdar, M. Supply chain information systems strategy: Impacts on supply chain performance and firm performance. Int. J. Prod. Econ. 2014, 147, 340–350. [Google Scholar] [CrossRef]

- Swafforda, P.M.; Ghoshb, S.; Murthy, N. Achieving Supply Chain Agility Through IT Integration and Flexibility. Int. J. Prod. Econ. 2008, 116, 288–297. [Google Scholar] [CrossRef]

- Bayraktar, E.; Demirbag, M.; Koh, S.L.; Tatoglu, E.; Zaim, H. A causal analysis of the impact of information systems and supply chain management practices on operational performance: Evidence from manufacturing SMEs in Turkey. Int. J. Prod. Econ. 2009, 122, 133–149. [Google Scholar] [CrossRef]

- Dehning, B.; Richardson, V.J.; Zmud, R.W. The financial performance effects of IT-based supply chain management systems in manufacturing firms. J. Oper. Manag. 2006, 25, 806–824. [Google Scholar] [CrossRef]

- Abbas, J.; Sagsan, M. Identification of Key Employability Attributes and Evaluation of University Graduates’ Performance: Instrument Development and Validation. High. Educ. Ski. Work.-Based Learn. 2019, 10, 449–466. [Google Scholar] [CrossRef]

- Liu, Y.; Mezei, J.; Kostakos, V.; Li, H. Applying configurational analysis to IS behavioural research: A methodological alternative for modelling combinatorial complexities. Inf. Syst. J. 2015, 27, 59–89. [Google Scholar] [CrossRef] [Green Version]

- Hou, C.-K. The effects of IT infrastructure integration and flexibility on supply chain capabilities and organizational performance: An empirical study of the electronics industry in Taiwan. Inf. Dev. 2019, 36, 576–602. [Google Scholar] [CrossRef]

- Wamba, S.F.; Dubey, R.; Gunasekaran, A.; Akter, S. The performance effects of big data analytics and supply chain ambidexterity: The moderating effect of environmental dynamism. Int. J. Prod. Econ. 2020, 222, 107498. [Google Scholar] [CrossRef]

- Sutduean, J.; Singsa, A.; Sriyakul, T.; Jermsittiparsert, K. Supply Chain Integration, Enterprise Resource Planning, and Organizational Performance: The Enterprise Resource Planning Implementation Approach. J. Comput. Theor. Nanosci. 2019, 16, 2975–2981. [Google Scholar] [CrossRef]

- Kumari, K.; Abbas, J.; Rashid, S.; Haq, M.A.U. Role of Corporate Social Responsibility in Corporate Reputation via Organizational Trust and Commitment. Rev. Manag. Sci. 2021, 3, 42–63. [Google Scholar]

- Jacobides, M.G. The Inherent Limits of Organizational Structure and the Unfulfilled Role of Hierarchy: Lessons from a Near-War. Organ. Sci. 2007, 18, 455–477. [Google Scholar] [CrossRef] [Green Version]

- Abbas, J.; Sağsan, M. Impact of knowledge management practices on green innovation and corporate sustainable development: A structural analysis. J. Clean. Prod. 2019, 229, 611–620. [Google Scholar] [CrossRef]

- Kumari, K.; Ali, S.B.; Khan, N.U.N.; Abbas, J. Examining the Role of Motivation and Reward in Employees’ Job Performance Through Mediating Effect of Job Satisfaction: An Empirical Evidence. Int. J. Organ. Leadersh. 2021, 10, 401–420. [Google Scholar] [CrossRef]

- Cao, Z.; Huo, B.; Li, Y.; Zhao, X. The impact of organizational culture on supply chain integration: A contingency and configuration approach. Supply Chain Manag. Int. J. 2015, 20, 24–41. [Google Scholar] [CrossRef]

- Van de Ven, A.H.; Leung, R.; Bechara, J.P.; Sun, K. Changing Organizational Designs and Performance Frontiers. Organ. Sci. 2012, 23, 1055–1076. [Google Scholar] [CrossRef] [Green Version]

- Akhavan, R.M.; Beckmann, M. A configuration of sustainable sourcing and supply management strategies. J. Purch. Supply Manag. 2017, 23, 137–151. [Google Scholar] [CrossRef]

- Winnubst, J. Organizational Structure, Social Support, and Burnout. In Professional Burnout: Recent Developments in Theory and Research; CRC Press: Boca Raton, FL, USA, 2018; pp. 151–162. [Google Scholar]

- Min, S.; Zacharia, Z.G.; Smith, C.D. Defining Supply Chain Management: In the Past, Present, and Future. J. Bus. Logist. 2019, 40, 44–55. [Google Scholar] [CrossRef] [Green Version]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Wamba, S.F.; Roubaud, D.; Foropon, C. Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. Int. J. Prod. Res. 2021, 59, 110–128. [Google Scholar] [CrossRef]

- Gorcun, O.F.; Senthil, S.; Küçükönder, H. Evaluation of tanker vehicle selection using a novel hybrid fuzzy MCDM technique. Decis. Making: Appl. Manag. Eng. 2021, 4, 140–162. [Google Scholar] [CrossRef]

- Hair, J.F.; Anderson, R.E.; Tatham, R.L.; Black, W.C. Multivariate Data Analysis, 7th ed.; Pearson: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Bollen, K.A.; Pearl, J. Eight Myths About Causality and Structural Equation Models. In Handbooks of Sociology and Social Research; Springer: Singapore, 2013; pp. 301–328. [Google Scholar]

- Kaiser, H.F.; Rice, J. Little jiffy, mark IV. Educ. Psychol. Meas. 1974, 34, 111–117. [Google Scholar] [CrossRef]

- Kaynak, H. The relationship between total quality management practices and their effects on firm performance. J. Oper. Manag. 2003, 21, 405–435. [Google Scholar] [CrossRef]

- Bagozzi, R.P.; Yi, Y. On the Evaluation of Structural Equation Models. J. Acad. Mark. Sci. 1988, 16, 74–94. [Google Scholar] [CrossRef]

- Bentler, P.M.; Bonett, D.G. Significance Tests and Goodness of Fit in the Analysis of Covariance Structures. Psychol. Bull. 1980, 88, 588–606. [Google Scholar] [CrossRef]

- Hu, L.; Bentler, P.M. Fit Indices in Covariance Structure Modeling: Sensitivity to Underparameterized Model Misspecification. Psychol. Methods 1998, 3, 424–453. [Google Scholar] [CrossRef]

- Browne, M.W.; Cudeck, R. Alternative Ways of Assessing Model Fit. Sociol. Methods Res. 1992, 21, 230–258. [Google Scholar] [CrossRef]

- Hinkin, T.R. A Brief Tutorial on the Development of Measures for Use in Survey Questionnaires. Organ. Res. Methods 1998, 1, 104–121. [Google Scholar] [CrossRef]

- Peterson, R.A. Meta-Analysis of Alpha Cronbach’ s Coefficient. J. Consum. Res. 1994, 21, 381–391. [Google Scholar] [CrossRef]

| Description | Frequency | Percent | |

|---|---|---|---|

| Gender | Male | 186 | 92.1% |

| Female | 16 | 7.9% | |

| Age | Upto 30 | 49 | 29.02% |

| From 31 to 40 | 118 | 58.42% | |

| More than 40 | 25 | 12.38% | |

| Educational level | Undergraduate | 166 | 82.18% |

| Postgraduate or above | 36 | 17.82% | |

| Year of experience | Less than 2 years | 6 | 2.97% |

| From 2 to 6 years | 42 | 20.79% | |

| From 7 to 11 years | 123 | 60.89% | |

| More than 11 years | 31 | 15.35% | |

| Position | CEO/MD | 4 | 1.98% |

| Senior manager | 37 | 23.27% | |

| Junior manager | 125 | 61.88% | |

| Senior employee | 26 | 12.87% | |

| Total | 202 | ||

| Items | of items | Loading Ranges | Composite Reliability | Variance Explained |

|---|---|---|---|---|

| * SCS | 9 | 0.651–0.838 | 0.89 | 59.45% |

| SCND | 6 | 0.594–0.851 | 0.85 | 66.37% |

| IS | 7 | 0.645–0.922 | 0.78 | 77.65% |

| OS | 7 | 0.564–0.919 | 0.84 | 73.25% |

| OP | 5 | 0.647–0.859 | 0.79 | 72.67% |

| FP | 7 | 0.593–0.888 | 0.76 | 73.23% |

| Pearson Correlation | Operational Performance | Financial Performance | SC Strategy | SC Network Design | Information System | Organizational Structure |

|---|---|---|---|---|---|---|

| Operational Performance | 0.729 | - | - | - | - | - |

| Financial Performance | 0.556 | 0.777 | - | - | - | - |

| Supply Chain Strategy | 0.645 | 0.765 | 0.771 | - | - | - |

| SC Network Design | 0.648 | 0.705 | 0.733 | 0.707 | - | - |

| Information System | 0.634 | 0.66 | 0.703 | 0.697 | 0.747 | - |

| Organizational Structure | 0.518 | 0.674 | 0.756 | 0.645 | 0.671 | 0.707 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Q.; Abdul Rahman, A.A.; Jiang, H.; Abbas, J.; Comite, U. Sustainable Supply Chain and Business Performance: The Impact of Strategy, Network Design, Information Systems, and Organizational Structure. Sustainability 2022, 14, 1080. https://doi.org/10.3390/su14031080

Fu Q, Abdul Rahman AA, Jiang H, Abbas J, Comite U. Sustainable Supply Chain and Business Performance: The Impact of Strategy, Network Design, Information Systems, and Organizational Structure. Sustainability. 2022; 14(3):1080. https://doi.org/10.3390/su14031080

Chicago/Turabian StyleFu, Qinghua, Abdul Aziz Abdul Rahman, Hui Jiang, Jawad Abbas, and Ubaldo Comite. 2022. "Sustainable Supply Chain and Business Performance: The Impact of Strategy, Network Design, Information Systems, and Organizational Structure" Sustainability 14, no. 3: 1080. https://doi.org/10.3390/su14031080

APA StyleFu, Q., Abdul Rahman, A. A., Jiang, H., Abbas, J., & Comite, U. (2022). Sustainable Supply Chain and Business Performance: The Impact of Strategy, Network Design, Information Systems, and Organizational Structure. Sustainability, 14(3), 1080. https://doi.org/10.3390/su14031080