1. Introduction

Securing food safety is one of the most important research topics for life sustainability and well-being. However, there are various factors that threaten sustainable food safety. Among them, the mixing of foreign substances [

1] is a representative problem that threatens food hygiene, and when consumers ingest these foreign substances, it can cause fatal injury or diseases which effect health. Foreign substances are widely classified as animal, vegetable, mineral, and other abhorrent substances. In particular, because the mixing of insects can cause not only sanitary problems but also a sense of fear, it is crucial to consider the implementation of a monitoring and control system in food manufacturing and distribution spaces. Although foreign substance accidents in food are traditionally prevented by using X-rays [

2], metal detectors [

3], and optical detectors [

4] to monitor the mixing of foreign substances, it is very difficult to detect insects which have penetrated into foods, because insects are usually small in size and have a soft body that is unlike metal. Moreover, it is more difficult to detect insects infiltrating the process of distribution or storage, compared to that of food manufacturing. For example, some packaged foods prevent insects from penetrating through the thick wrapping paper, but some insects (such as

Tribolium castaneum and

Plodia interpunctella, etc.) are still difficult to remove because they have the ability to create holes in the wrapping paper or vinyl [

5]. When these insects have penetrated into foods and warehouses, they contaminate the food by leaving behind various products such as eggs, larvae, and cocoons [

6].

In order to mitigate the penetration of these harmful insects, a method of eradicating insects through periodic fumigation during storage of food is widely used worldwide. The previous studies of fumigation already known so far are as follows.

The most popular method of fumigation worldwide is the use of chemical compounds. This method has been developed since the 1940s [

7,

8,

9,

10], and the recent representative synthetic fumigants are formaldehyde, glutaraldehyde, methyl bromide, ethylene oxide, and chlorine dioxide, etc. However, formaldehyde and glutaraldehyde are commonly used for sterilization of livestock houses, and because they are highly carcinogenic [

11], intensive monitoring and ventilation should be taken during the fumigation procedure. Methyl bromide is another popular fumigant used to control pests in agriculture and shipping. It has also been used as a soil fumigant for killing pathogens, nematodes, and weeds [

12]. Ethylene oxide, a colorless and flammable gas with a faintly sweet odor, is also an effective fumigant. Although ethylene oxide is mainly adopted for medical applications as a powerful oxidizing agent, it also has carcinogenic properties [

13]. Recently, hydrogen phosphide (known as phosphine) [

14] and sulfuryl fluoride [

15] are commonly used for bulk storage of cereal gains as alternatives or replacements for methyl bromide regarding safety. Although these chemical fumigants also have excellent insect repellency effects at the initial stage of use, it is important to note that there is currently no completely safe fumigant and various human hazards have been reported [

16,

17,

18], which limits the handling to only authorized users. In the past few decades, in order to break the trade-off between insect repellency and safety, pesticides using natural extracts, which can increase eco-friendliness and minimize possible harms to the human body, are widely used.

In order to compensate for the shortcomings of the above synthetic pesticide materials, recent research trends are attracting attention as eco-friendly and effective natural material-based fumigants while mitigating the residual toxicity towards humans and animals or the ecosystem. The natural fumigation components from plant extracts are distributed in leaves, seeds, roots, stems, pigments, and plant surfaces, which are secondary metabolites of plants, and they contain various insecticides such as alkaloid, terpenoid, saponin, and phenol compounds. Akkari et al. [

19] used

Ruta chalepensis, which is a kind of medical herb. They obtained extracted oils by vapor dragging and water distillation and then revealed that

Ruta chalepensis has a potential insecticidal and anthelmintic benefit. Liu et al. [

20] use water-distilled essential oil from

Illicium henryi (Illiciaceae) root bark and analyzed it by gas chromatography-mass spectrometry, and found that the oil and its constituent compounds have potential to work as natural insecticides especially for the control of booklice in stored grains. Wang et al. [

21] used the extracted oil of

Dahlia pinnata and determined that it has insecticidal effects against

Sitophilus zeamais and

Sitophilusoryzae (pests of stored cereals). Pyrethroids [

22] are also one of the most representative natural insecticides that have been used in the food and agricultural industry from the 1980s to the present day. However, because pyrethrin has also been recently reported to have many side effects and risks, it is also recommended to not be regularly used [

23].

Meanwhile, in order to help users to perform fumigation, which requires specialization and attention to handling, numerous studies have been carried out on the adaptation of IoT (Internet of Things) technology. The IoT describes physical devices or group of such devices which connect to the Internet or other computer networks by embedding sensors and communication functions, and helps all interconnected devices to share data and remotely perform specific commands and controls. R. Venkatesan et al. [

24] proposed a framework for automatically spraying fumigants of eco-friendly materials using an Android smartphone. The fumigation-related data are also transmitted to the cloud server for further processing. B. Ramalingam et al. [

25] developed an image processing system which recognizes insects caught in traps using IoT and FastRCNN (Region-based Convolutional Neural Networks) [

26] and showed that it is possible to remotely monitor the repellent procedure.

Despite various application attempts to food safety, as described above, most IoT-based pest repellent proposals rely on a specific platform, and must be interworked with heterogeneous devices, including existing traditional fumigators, which are significantly limited. Moreover, when frequency range used for wireless communication or the protocol is different to each other, data exchange and control between them is impossible. In this paper, we propose a remote fumigation control platform which combines Wi-Fi wireless communication, LED light-emitting, and image processing technology as a means to overcome these technical limitations and to solve the trade-off between safety and efficiency of fumigation in food warehouses.

The rest of this paper is organized as follows. Chapter 2 describes the trade-off relationship between fumigation efficiency and its potential human health risks. Chapter 3 describes the proposed approaches for breaking the trade-off. Chapter 4 describes the performance evaluation results for the proposed system. Finally, Chapter 5 concludes this paper with a brief summary.

2. Motivation (Trade-Off between Efficiency and Safety)

In the past, for the control of insects infiltrating food storage, existing studies focused only on the control of them without considering the harmfulness on the human or the food. Accordingly, as an eco-friendly method that can replace chemical synthetic materials, pesticides using natural ingredients have recently received increasing attention. Among them,

Tanacetum cinerariifolium uses pyrethrin, which is a class of organic compound extracted from natural plants. Although pyrethrin acts on the nervous system of insects and cause death, it is known that the risk is generally low for the human body [

27,

28,

29]. In addition, the insect repellent effect is excellent even as a pyrethrin compound itself, and the effect can be enhanced when it is mixed with various natural materials [

30]. However, recent state-of-the-art literature analyzes in detail the trade-off cases in which pyrethrin has negative effects on human health when inhaled continuously or excessively. Wei bao et al. suggested that exposure to pyrethroid insecticides increases the risk of death from cardiovascular disease by approximately three times in their experiments conducted on 2116 adults [

31]. In industrial fields, artificial pesticide materials such as phenothrin, permethrin, and d-phenothrin are widely used by synthesizing natural pyrethrin. Appel et al. [

32] found that soldiers wearing permethrin-treated uniforms developed mild sensory disturbances (e.g., skin irritation and redness). Moreover, it was highlighted that occupational exposure to permethrin is also related to abnormal glucose control in the human body [

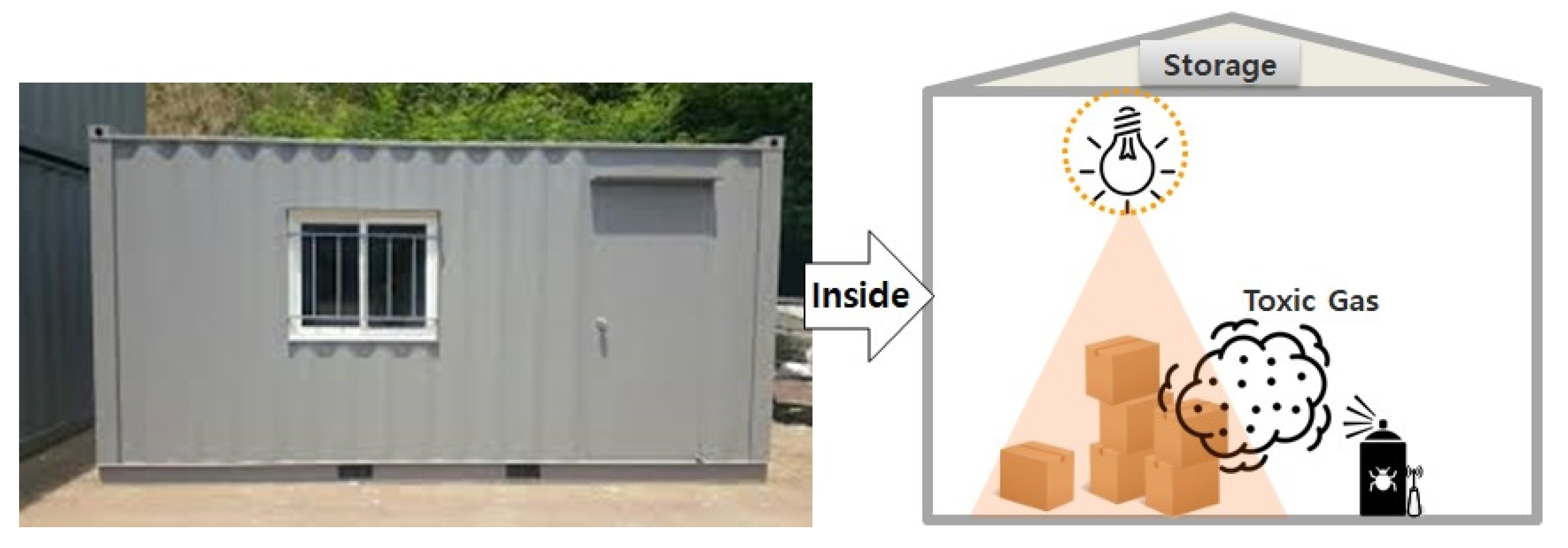

33]. Thus, more careful attention is required when workers handle these fumigants, especially in closed spaces, as shown in

Figure 1. For this, the World Health Organization (WHO) recommends ADI (Acceptable Daily Intake) for

d-phenothrin within 0.07 mg/kg [

34]. In order to minimize these side effects and trade-offs, it is necessary to perform appropriate ventilation and access control for workers during fumigation with pyrethrin-based gas. However, because most of the food storages or retail warehouses have a closed structure in order to prevent deterioration of food, there is a high possibility that toxic gas still remains indoors, even after finishing fumigation. In addition, in the case of a warehouse where a food storage and a market coexist, staff and consumers frequently enter and exit at specific times, which further increases the opportunities for gas contact with the human body. Ultimately, it is still a challenging problem to satisfy both fumigation for the eradication of various pests and safety against harm to the human body. To this end, this study intends to find an alternative which breaks the trade-off from the viewpoint of IoT technologies.

4. Results and Discussion

In accordance with eco-friendly research trends, we have selected and prepared pure pyrethrin oil for fumigation experiments. The oil production method is as follows. First, fresh flowers of pyrethrum are collected and dried in a cool place. Dried flowers lose weight by about 1/4 as the moisture evaporates. After that, 200 mL of 95% ethanol solution and 15 mL of sesame oil are added to 100 g of fresh flowers, and then pulverized using a blender. The main purpose of pulverizing is to increase the amount and concentration of the stock solution. After storage for about 4 days, the pyrethrin oil is extracted by separating the crushed fresh flowers and the stock solution using a sieve. The extracting procedure for

Tanacetum cinerariifolium oil is described in

Figure 12 and summarized as follows.

- (1)

Harvest the pyrethrum and dry it in the shade;

- (2)

Soak in ethanol 95% and sesame oil;

- (3)

Wait about 4 days for the extract to come out;

- (4)

After maturation, filter the pyrethrum flowers using a net;

- (5)

Dilute the filtered oil with water before use.

The extracted oil can be diluted with distilled water at various ratios to make a fumigation solution. The insect repellency experiments on the extracted pyrethrin oil were carried out by dilution at two concentrations of 0.5% and 1%. In general, there are various methods for fumigating the diluted insect repellent oils, which are typically classified into three types: a humidification type (

Figure 13a), a heating type (

Figure 13b), and a spray method (

Figure 13c). The humidification method uses the principle that water molecules diverge to the outside using heating or ultrasonic vibration. In the heating method, when the liquid containing the oil is heated and the boiling point is reached, vaporization occurs, and then the oil spreads to the surroundings. Finally, the spray method performs fumigation by directly spraying the actual liquid through the micro holes of the device.

Figure 13 shows a real example of these devices for fumigation experiments. The proposed fumigation system is designed to be compatible with any legacy devices, which work with 220 V(volt) without being dependent on a specific connecting module by faithfully reflecting the principles of IoT. Thus, all three devices in

Figure 13 are directly connected to the IoT controller (

Figure 4 and

Figure 5) proposed in

Section 3 and can be operated or monitored remotely.

In order to verify the performance of the proposed fumigation system, insecticidal experiments were carried out on

T. castaneum (adult) and

P. interpunctella (larvae) by diluting pyrethrin and water according to three different density ratios (0.5%, 1%, and 2%). The reason for selecting the above two types of insects is that they are representative pests that occur mainly in food storages, and especially because they have a perforating ability. This means that these insects cause a problem of contaminating food by penetrating into packages such as paper and vinyl. The insects were obtained from Prof. Hong’s laboratory of Suncheon National University (Suncheon, Korea) and raised indoors at 27 °C and 70% humidity. These two kinds of insects were placed in a petri dish as shown in

Figure 14. The pyrethrin oil was obtained from Youngbiwon Co.Ltd (Gyeongsan, Korea) and diluted with pure water. For the experimental fumigator, a heating type device which generates steam by heating the liquid to 100 degrees is selected, which can be controlled using 220 V AC power. The model name of this device is DGH-9800G, and the manufacturer is Tienew Co. ltd (Hwaseong, Korea). Its size is 210 mm × 145 mm × 300 mm and the total solution capacity is 1000 mL. For

T. castaneum, the fumigation liquid solution was set to two different ratios (0.5% and 1%), and the actual fumigation was carried out in the sealed breeding box. The breeding box is made of acrylic, and the size is 30 cm × 30 cm × 30 cm. The fumigators and breeders used in the experiment are shown in

Figure 14.

As a result of the first experiment, when 20 adults of

T. castaneum were exposed to 0.5% density ratio of the fumigation solution for one hour, it is observed that 13 insects were killed and seven insects were knocked down, and the others’ movements were significantly dull. After two hours, all insects were killed. For statistical analysis, the experiment is repeated five times with the same conditions and the gathered data were expressed as mean ± SD (Standard Deviation). The fumigation efficiency in terms of knocked down and killed was calculated by using Student’s paired

t-test and one-way analysis of variance with

p-value < 0.05 being considered statistically significant for a confidence interval of 95%. Finally, the overall number of knocked down and killed insects were 7.4 ± 0.894 and 12.6 ± 0.894, respectively. The measured SEMs (Standard Error of the Mean) of killed and knocked down were both 0.4. As a second experiment, the density ratio of the fumigation solution was increased to 1% and fumigation was carried out as above for 20 adults of

T. castaneum. After one hour, three insects were knocked down and 17 insects were killed. However, after 2 h, all 20 animals died. This experiment is also repeated five times for bioassays. The overall number of knocked down and killed insects for 1% density were 2.8 ± 0.836 and 17.2 ± 0.836, respectively. It can be seen that the fumigation effect increases as the density ratio of the fumigation solution increases.

Table 1 summarizes these results of the fumigation experiments of

T. castaneum.The fumigation performance experiment was also conducted against

P. interpunctella (larvae) by using the same density ratios of pyrethrum oil and device configuration. Although the fumigation was carried out for 1 to 2 h with the same conditions as

T. castaneum, there was no significant insecticidal effect. So, the exposure time was increased from 24 h to 48 h and each status of insects was observed. In this situation, it is considered that continuous injection of fumigation fog for 24 h causes waste of fumigation oil. Thus, after initial 30 min of fumigation, the box is sealed using a packaging vinyl for 24 h, as shown in

Figure 14b. Then, secondary fumigation for 30 min is performed, and the box is sealed for 24 h again (Total 48 h). This is due to the fact that the space is kept sealed for a certain period of time after fumigation in real field scenarios. As a result of the experiment, when the fumigation was conducted with density ratio of 1% against 20 larvae of

P. interpunctella, it is observed that only one is knocked down and nine insects survived after 24 h. On the other hand, when fumigated at a density ratio of 2%, six larvae were knocked down and 14 larvae survived after 24 h. Finally, after 48 h, it is observed that all larvae were killed. This experiment was also repeated five times for the bioassay, and a total of 100 animals for each concentration were observed, as is shown in

Table 2. These results reveal that although the time it takes to kill each insect is somewhat different, the probability of death increases as the fumigation time is increased. In addition, it is also observed that the insecticidal efficiency is also increased as the density ratio of pyrethrin for fumigation increases. Therefore, in actual field scenarios, it will be possible to achieve the optimal effect by appropriately setting the density ratio and duration time according to the characteristics of the target insect to be controlled. Furthermore, the trade-off relationship between safety and fumigation efficiency can be sufficiently overcome if human access is minimized using the proposed IoT solutions described in the previous section.

To verify the performance for Wi-Fi communication of the proposed system, PDR (Packet Delivery Ratio) and transmission delay were measured by exchanging IMCP (Internet Control Message Protocol) packets between the IoT control unit and the user’s laptop as shown in

Figure 15. PDR denotes the ratio of the number of packets successfully received to the number of data packets transmitted from the laptop. To consider the human behavior, two situations were evaluated as follows: (1) the laptop does not move (stationary), (2) the laptop moves at a speed of 4 km/h (walking). In both cases, the measurement was conducted in a typical warehouse and hallway space. The experiment results for PDR are shown in

Figure 16. In this figure, the PDR performance according to the distance showed lossless wireless communication up to about 80 m, which is similar to the communication distance of a typical Wi-Fi module, which is 50~100 m indoors. However, PDR drops abruptly at a distance exceeding 80 m, and transmission failures are more frequent when the distance is about 140 m. In addition, in the case of the walking scenario, the number of packet losses is slightly higher than the stationary scenario due to irregular mobility. If a user wants to extend the Wi-Fi communication range, there is an option to install an external antenna with a higher dBm or to use multi-hop transmission via ad hoc networking mode [

39].

Meanwhile, the performance evaluation regarding transmission delay is as follows. Transmission delay is defined as the time difference from when the ICMP request is sent to when the response is received. As a result, it was revealed that the maximum delay, the minimum delay, and the average delay for transmission were 68 ms, 3 ms, and 8 ms, respectively. Through this fact, it is expected that there will be no major difficulties in real-time control of fumigation devices. These results indicate that the proposed control system will guarantee real-time wireless communication in indoor environments.

The insect repellency experiment for LED lamps, which is suggested as an alternative to the toxicity of fumigation, was also conducted, and the experimental environment and results are as follows. Because most insects have difficulty recognizing light at a yellow wavelength (590 nm), as explained in

Section 3.2, a yellow lamp was installed indoors and the number of insects that entered the area was observed. A trap was also installed to check the exact number of insects captured, and the types of equipment used are shown in

Figure 17. The experiment was conducted at midnight when insects are most active, and the window was opened about 15 × 85 cm for insect intrusion. However, the conditions of the experiment were conducted differently in four cases as follows.

(Condition 1) Trap only: Condition without any insect repellent equipment.

(Condition 2) Trap and LED lamp: Evaluation of insect repellent effect with LED lamp alone.

(Condition 3) Trap and fumigator: Evaluation of insect repellent effect with fumigator alone.

(Condition 4) Trap, LED, and fumigator: Evaluation of insect repelling effect with both devices simultaneously.

These experimental conditions are shown in

Figure 18. For all conditions, after opening the window for about 10 min, the number of random insects which entered was counted. When the fumigator was operated, the ventilation was also performed by operating the fan for the next experiment. These experiments were also performed at least five times and all data were expressed as mean ± SD and SEM. The results for each condition are summarized in

Table 3, where Student’s paired

t-test was also adopted with

P < 0.05. In case of using LED insect repellent lamp (condition 2), it is observed that only 10 insects are captured, which is considerably less insect invasion compared to the condition without any equipment (condition 1). In addition, it was confirmed that the effect was superior to that when fumigation was carried out (condition 3) because the insect firstly recognizes LED light and intrudes before smelling the fumigation fog outside the building. If both devices are used simultaneously (condition 4), the number of insects was five, which is the lowest result among all conditions. As a result, it is important to note that when the proposed system is properly used with various equipment simultaneously employed, the effect of insect repellency is maximized and safety also can be guaranteed.

Finally, an experiment for detection accuracy was conducted on the proposed image processing algorithm, which recognizes a person entering a room via use of a camera. For this, when a person entered the building 200 times at an arbitrary time, the number of successful detections was counted. As a result of the experiment, a total of 192 detections were confirmed, which is about 96% accuracy. The main cause of the detection failure was when the shape of the object was temporarily invisible due to the backlight of the sun during a specific time period. This can be overcome by changing the installation angle of the camera or performing dynamic adjustment of the iris, which remains a possibility for future work.

5. Conclusions

Insect penetration in food presents a risk of not only contamination of food itself, but also of spreading various harmful substances to people who consume it. To tackle this, pest control is an open research problem which is still ongoing worldwide. Currently, fumigation is widely used as the most popular insecticidal method, and fumigation materials are developed in various forms from artificial synthetic materials to natural materials. In addition, recent research trends of fumigants focus on the development of eco-friendly materials, considering harmfulness to the human body rather than mere insecticidal performance. Nevertheless, it is still common that most fumigation smoke is dangerous to human health, and there is a trade-off relationship between the effectiveness of insect repellents and securing safety for humans. In this paper, to overcome this trade-off, a system that combines IoT technology with existing fumigation technology is proposed. First, it was confirmed that the existing toxic substances can be replaced with eco-friendly substances using pyrethrum, and a wireless framework that can control fumigators without human access was designed for more active safety.

In this paper, to overcome this trade-off, a novel system which combines IoT technology with organic fumigation is proposed. First, it was confirmed that the existing toxic substances can be replaced through eco-friendly substances using pyrethrum, and a wireless framework that can control fumigators without human access was designed for more active safety. It was confirmed that the existing synthetic toxic material can be substituted through eco-friendly pyrethrin oils from Tanacetum cinerariifolium. A wireless IoT framework that can control fumigators without human access was designed for more active safety. In particular, by providing various convenience and automation functions, such as a timer and density setting, unnecessary waste and misuse of fumigation solutions can be prevented. This function is expected to be more useful at night when workers are difficult to access, and insects are active. Beside this insecticidal fumigation using an IoT platform, an LED lamp control system is also proposed to maximize the repelling effect by using the specific wavelength of the light. In particular, when the fumigation and the LED lamp are used together, effectiveness and safety can be further strengthened. As a complementary function, we developed a camera-based human recognition system and a history tracking database, which temporarily stops or postpones fumigation in case of inevitable human access. This proposed technology will serve as an opportunity to apply various IoT technologies to food industry and is expected to be a solution to overcome the trade-off between safety and efficiency of fumigation.